Fixing cutter group with positioning device

A technology for fixing cutters and positioning devices, which is applied in the direction of cutters, shearing devices, and metal processing equipment used in shearing machines, and can solve the problems of inconvenient tool setting, tool change, assembly and disassembly, low size consistency of parts, and Poor processing accuracy and other problems, to achieve the effect of simple structure, high processing accuracy, and ensure the sharpness of the blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

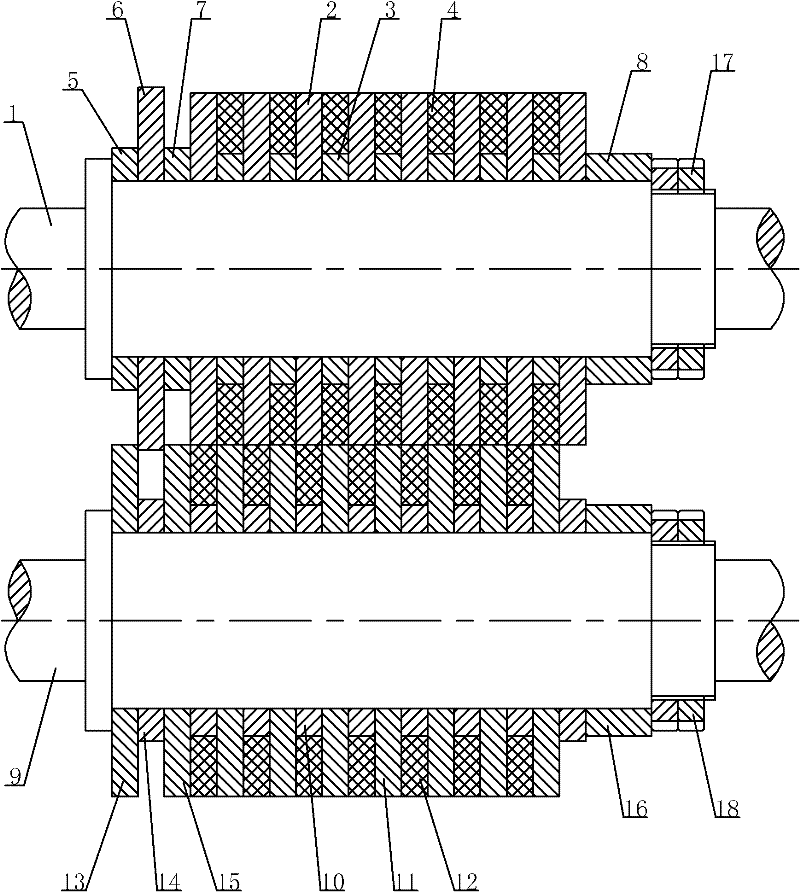

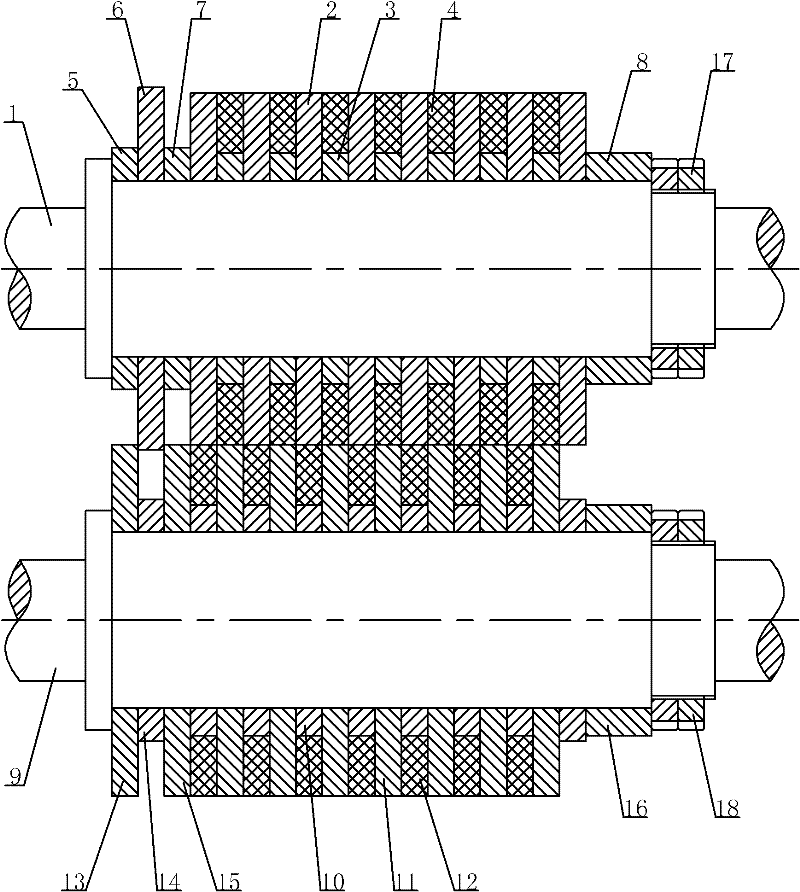

[0024] Such as figure 1 The shown fixed cutter group with a positioning device includes an upper knife part and a lower knife part, and the upper knife part includes an upper knife shaft 1 and disc knives 1 and 2 arranged in the middle of the upper knife shaft 1 at even intervals. Knife shim one 3, rubber ring one 4 is arranged on the outside of said knife shim one 3, said lower knife part includes lower knife shaft 9 and knife shim two 10 and disc knife two 11 installed in the middle of lower knife shaft 9 at even intervals, A rubber ring 2 12 is arranged on the outside of the knife shim 10, and a guide knife shim 1 5, a guide knife 6 and a positioning knife shim 7 are installed on the left part of the upper knife shaft 1, and the guide knife shim 1 5 is located on the guide knife On the left side of one 6, the positioning knife pad 7 is located on the right side of the guide knife one 6 and on the left side of the disc knife one 2, the disc knife one 2, the knife pad one 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com