Preparation method of composite board assembly capable of ensuring smooth biting of roll and rolling method

A composite plate and rolling technology, which is applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problem that the roll-rolled composite plate cannot be bitten smoothly, so as to improve equipment safety and production efficiency, reduce Difficulty in production and the effect of reducing difficulty in biting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Raw material cutting

[0027] Composite material 3 is 304 stainless steel: length 10700mm, width 1850mm, thickness 15mm, smelting composition of composite material 3 stainless steel

[0028] See Table 1;

[0029] Base material 1 is Q235B steel: length 11000mm, width 1850mm, thickness 230mm.

[0030] Table 1304 stainless steel melting composition (%)

[0031] C Si mn P S als Ni Cr 0.08 0.30 0.40 0.014 0.003 0.027 7.6 17.7

[0032] (2) Composite plate blank welding composite

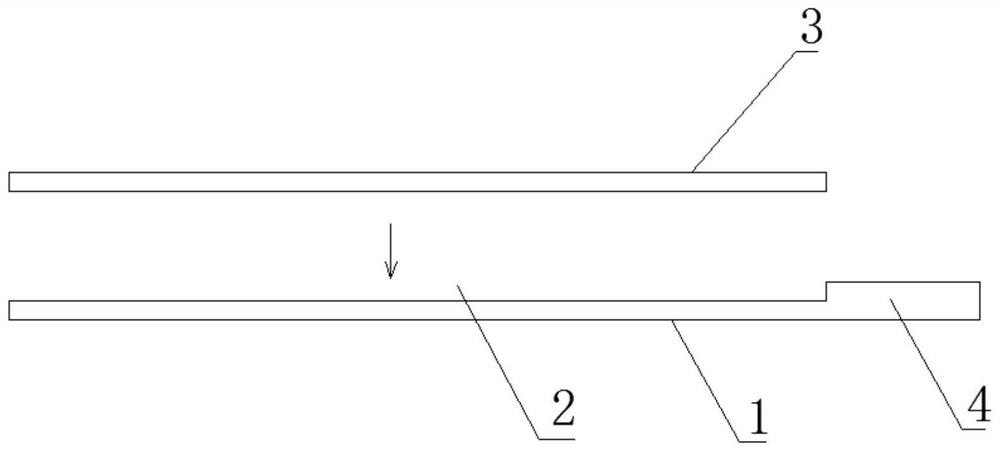

[0033] Such as figure 1 , milling is carried out on one end plane of the base material 1 and the composite material 3 having the same length, a sunken plane 2 with a milling depth of 15 mm and a length of 10700 mm, and the other end forms the base material end 4; the processing surface of the composite material 3 is milled flat, clean The processed surfaces of the composite material 3 and the base material 1 are free from oil, dust, debris, and moisture, s...

Embodiment 2

[0047] (1) Raw material cutting

[0048] Composite material 3 is 2205 duplex stainless steel: length 10500mm, width 1800mm, thickness 18mm, the melting composition of composite material 3 stainless steel is shown in Table 2;

[0049] Base material 1 is Q235B steel: length 10900mm, width 1800mm, thickness 230mm.

[0050] Table 2 Melting composition of duplex stainless steel (%)

[0051] C Si mn P S als Ni Cr Mo N 0.03 1.00 2.00 0.008 0.003 0.027 5.8 22.4 3.3 0.14

[0052] (2) Composite plate blank welding composite

[0053] Carry out deep milling on one end plane of the base material 1 and composite material 3 having the same length, milling a sunken plane 2 with a depth of 18 mm and a length of 10500 mm, and form the end of the base material 4 at the other end; perform flat milling on the processing surface of the composite material 3, Clean the processed surface of composite material 3 and base material 1 to make it free from oil, du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com