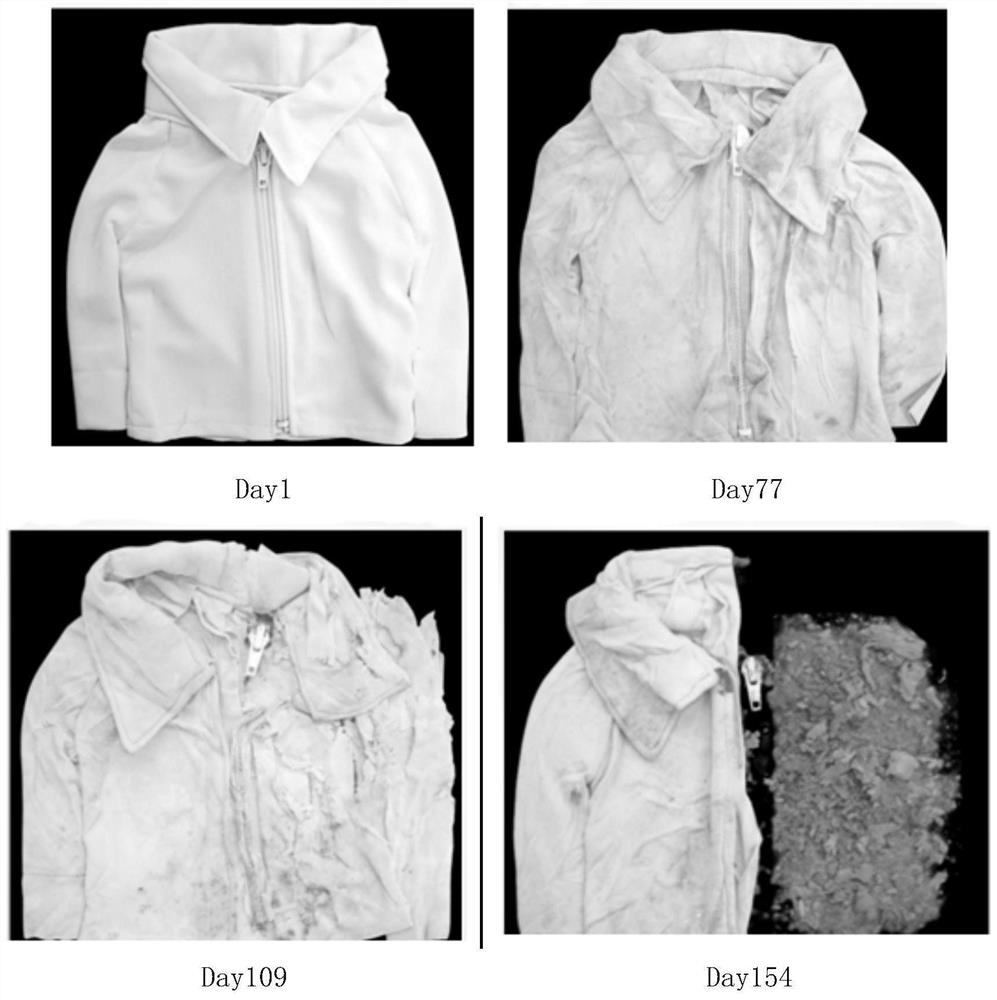

A kind of composite polyester and preparation method thereof

A technology of polyester and microcapsules, applied in the field of polyester, can solve the problems of polyester endangering the ecological environment and other problems, and achieve the effect of stable and reliable effect, good use effect and strong ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

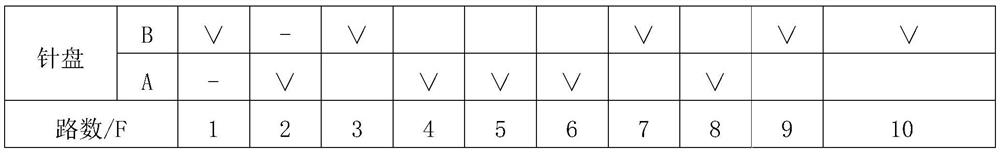

[0043] Example of the preparation method of composite polyester

[0044] The embodiment of the present invention provides a preparation method of composite polyester, which is used for preparing the above-mentioned composite polyester, which specifically includes the following steps:

[0045] Preparation of microcapsule wall material hydrosol: the edible natural polymer material is stirred and dissolved in hot water, cooled to room temperature and then filtered to remove insoluble matter to obtain the microcapsule wall material hydrosol. Specifically, the edible natural polymer material is stirred and dissolved in hot water at 70-100° C. The stirring is usually carried out in a mixer, and the stirring speed is 150-200 r / min. After that, the original stirring speed is used, and the temperature is At a specific temperature of 50-75°C, constant temperature stirring for 1-12h, cooling to room temperature and filtering out insoluble matter to obtain a hydrosol of the microcapsule w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com