Aluminum-yttrium-phosphorus interalloy and preparation method thereof

A phosphorus master alloy and a technology for master alloy, applied in the field of aluminum-yttrium-phosphorus master alloy and its preparation, can solve the problems of reduced refinement effect, reduced P content and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

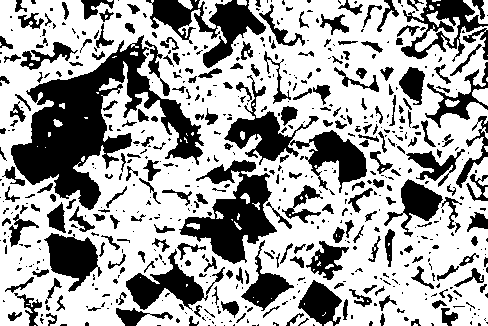

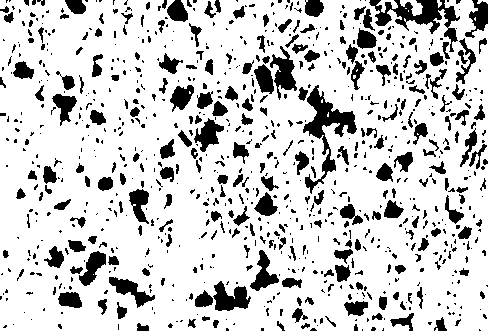

Image

Examples

Embodiment 1

[0023] (1) The raw materials are weighed according to the mass percentage of industrial pure aluminum 21.5%, aluminum-phosphorus master alloy 64.0%, and industrial pure yttrium 14.5%, wherein the mass percentage of aluminum in the aluminum-phosphorus master alloy is 92.5%, and the mass percentage of phosphorus is 7.5%;

[0024] (2) Melt industrial pure aluminum in a melting furnace, raise the temperature of the melting furnace to 1000°C-1100°C, first add aluminum-phosphorus intermediate alloy, stir for 5-10 minutes and mix well, then add industrial pure yttrium, and heat up to 1300°C ℃–1400℃, keep warm for 10-20 minutes;

[0025] (3) After stirring evenly, it can be directly poured into shape, which can be cast into ingots, prepared into wire rods or other shapes.

[0026] According to the above ratio and process, an aluminum-yttrium-phosphorus master alloy with the best composition can be obtained. The mass percentage of its chemical composition is: phosphorus 4.7-4.9%, yttr...

Embodiment 2

[0028] (1) The raw materials are weighed according to the mass percentage of industrial pure aluminum 8.0%, aluminum-phosphorus master alloy 70.0%, and aluminum-yttrium alloy 22.0%, wherein the mass percentage of aluminum in the aluminum-phosphorus master alloy is 95.0%, and the mass percentage of phosphorus 5.0%, the mass percentage of aluminum in the aluminum-yttrium alloy is 50%, and the mass percentage of yttrium is 50%;

[0029] (2) Melt industrial pure aluminum to 900°C-1050°C in a melting furnace, first add aluminum-phosphorus intermediate alloy, stir for 5-10 minutes, then add aluminum-yttrium alloy, heat up to 1200°C-1300°C, keep warm 10-15 minutes;

[0030] (3) After stirring evenly, it can be directly poured into shape, which can be cast into ingots, prepared into wire rods or other shapes.

[0031] The aluminum-yttrium-phosphorus master alloy prepared according to the above ratio and process has a chemical composition of 3.3-3.6% phosphorus, 10.8-11.2% yttrium, an...

Embodiment 3

[0033] (1) The raw materials are weighed according to the mass percentage of 22.9% of industrial pure aluminum, 57.1% of aluminum-phosphorus master alloy, and 20.0% of aluminum-yttrium alloy. Wherein the mass percentage of aluminum in the aluminum-phosphorus master alloy is 96.5%, the mass percentage of phosphorus is 3.5%, the mass percentage of aluminum in the aluminum-yttrium alloy is 70.0%, and the mass percentage of yttrium is 30.0%;

[0034] (2) Melt industrial pure aluminum to 850°C-1000°C in the melting furnace, first add aluminum-phosphorus intermediate alloy, after stirring for 5-10 minutes, then add aluminum-yttrium alloy, heat up to 1200°C-1250°C, Keep warm for 5-10 minutes;

[0035] (3) After stirring evenly, it can be directly poured into shape, which can be cast into ingots, prepared into wire rods or other shapes.

[0036] The aluminum-yttrium-phosphorus master alloy prepared according to the above-mentioned ratio and process has a chemical composition of 1.9-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com