A conductive and heat-insulating fabric based on silver fibers

A silver fiber and fabric technology, applied in fiber processing, fiber chemical characteristics, cellulose/protein conjugated rayon, etc., can solve the problems of reduced binder content, reduced aerosol content, and reduced thermal insulation capacity of fabrics , to achieve the effect of preventing dispersion, improving strength, and high heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The specific preparation process of heat insulating acetate fiber is as follows:

[0038] Step 1, take by weighing 68g cellulose diacetate and 42g chitosan and be dissolved in the 1.5L acetic acid solution of certain concentration, then add 13g sodium-based bentonite wherein, obtain composite stock solution after mixing;

[0039] Step 2. Add 50 g of ethyl orthosilicate into 500 mL of ethanol solution, stir and dissolve evenly to obtain ethyl orthosilicate solution;

[0040] Step 3. Dissolve 50g of aluminum chloride hexahydrate in 450mL of water, then add the ethyl orthosilicate solution prepared in step 2, stir and mix for 50-70min, so that the ethyl orthosilicate and aluminum chloride hexahydrate are fully Hydrolyze, then drop dilute hydrochloric acid therein to adjust the pH of the solution to 3, and add 6 g of sodium silicate to it at the same time, stir and react for 2 hours, adjust the pH of the solution to 7 by dilute ammonia water, and then stand at room temperat...

Embodiment 2

[0044] The preparation process of siloxane-linked polyimide fiber is as follows:

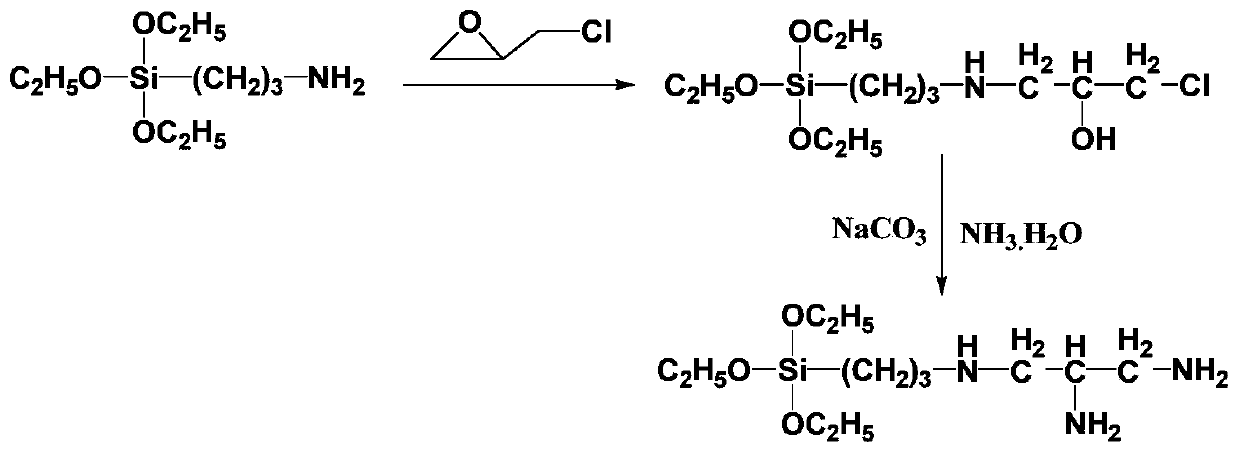

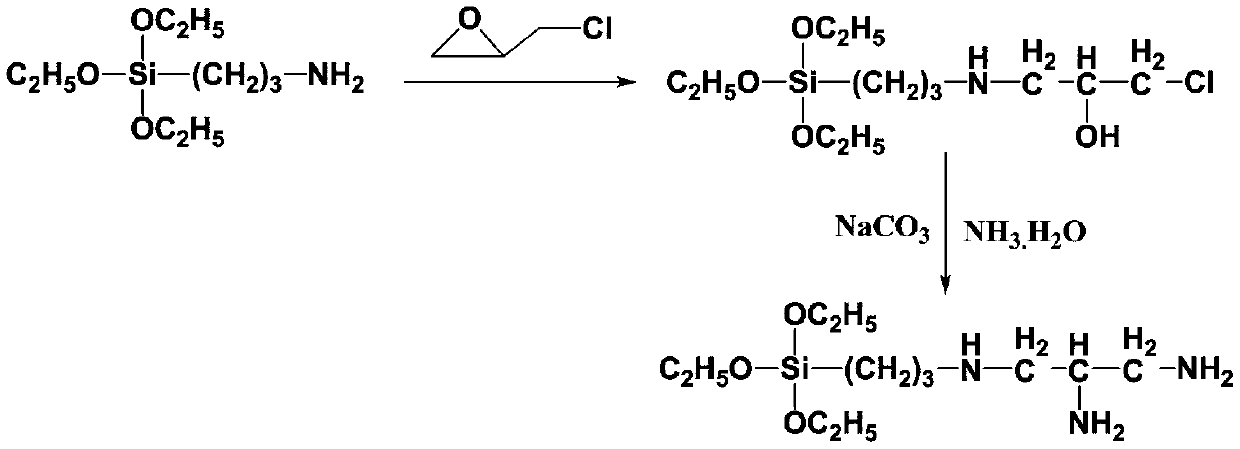

[0045] ①Add 50g of 3-aminopropyltriethoxysilane to 500mL of toluene, and at the same time add 19g of epichlorohydrin, raise the temperature to 50°C and stir for 5-6 hours, then raise the temperature to 90°C, add 15.5g of carbonic acid Sodium is used as a catalyst, and 60 mL of concentrated ammonia water is added at the same time, and the reaction is stirred for 10-12 hours to obtain diaminosiloxane;

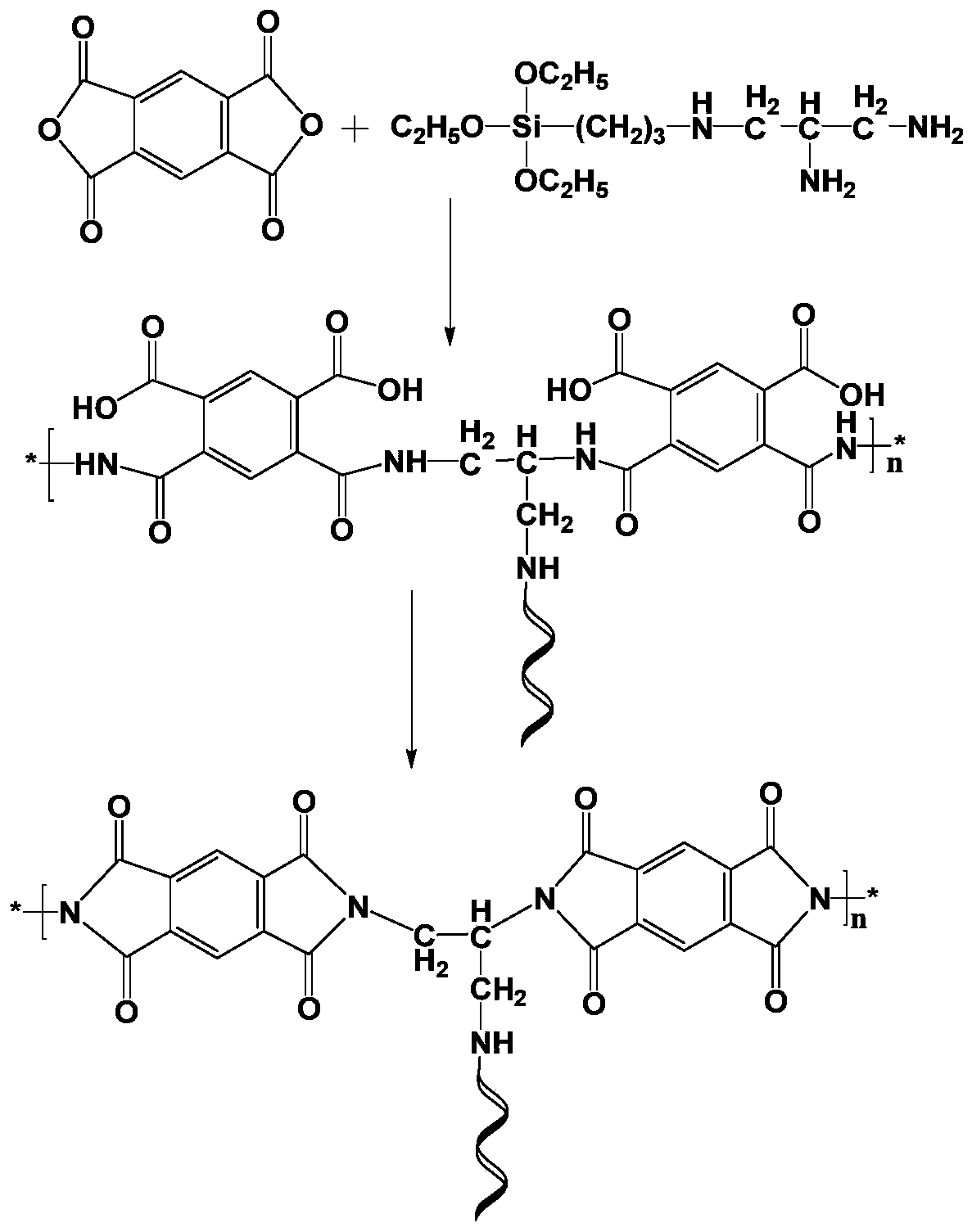

[0046] ② Weigh 40g of pyromellitic dianhydride and add it into 480mL of acetone and stir to dissolve, then add 76.8g of diaminosiloxane into it, stir and react at room temperature for 2h, then add 10g of acetic anhydride dehydrating agent and 4.8g of pyridine into it, heat up React at 50°C for 2 hours to obtain siloxane-linked polyimide;

[0047] ③Add 40g of siloxane-linked polyimide into the mixed solution of 160mL ethanol and 200mL water, then add dilute hydrochloric acid to it to adjust the pH=...

Embodiment 3

[0050] A specific preparation process of a conductive and heat-insulating fabric based on silver fibers is as follows:

[0051] In the first step, the thermal insulation acetate fiber prepared in Example 1 and the siloxane-linked polyimide fiber and silver fiber prepared in Example 2 are woven to form a composite yarn;

[0052] In the second step, 380g of hydroquinone was added into water and stirred to dissolve, then 1kg of composite yarn was added to it, ultrasonically oscillated for 5 minutes, and 3.2L of formaldehyde solution was added dropwise to it after the temperature was raised to 70°C. After the addition is complete, constant temperature and ultrasonic reaction for 3 hours, then add 100g of starch solution to it, and ultrasonic reaction for 30 minutes, and consume the incompletely reacted formaldehyde solution through the starch solution;

[0053] The third step is to pull out the yarn and soak it in ethanol solution for 1 hour, then dry it;

[0054] In the fourth s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com