Patents

Literature

139results about How to "Thermally conductive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyamide composite material as well as preparation method and use thereof

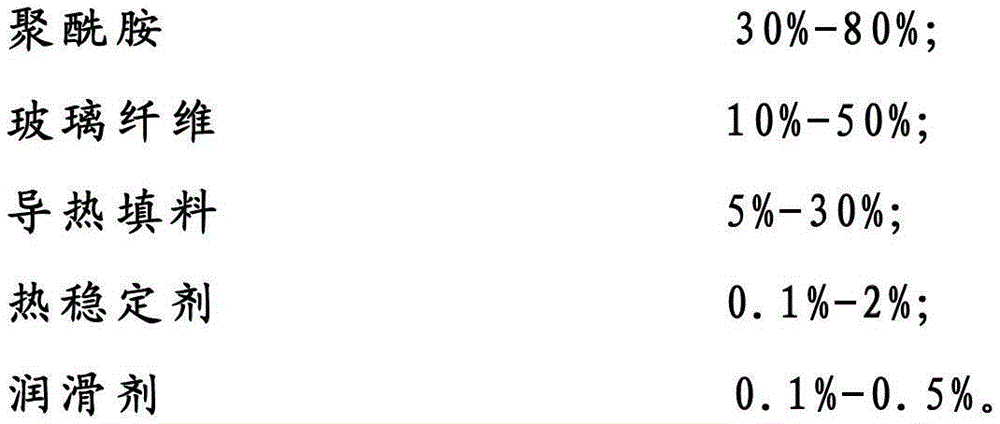

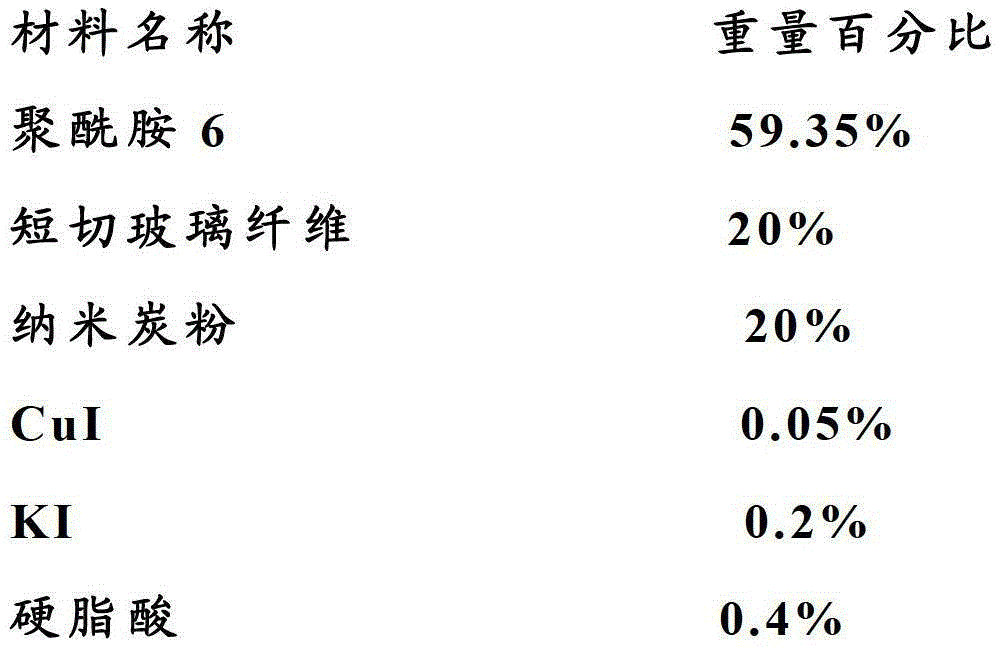

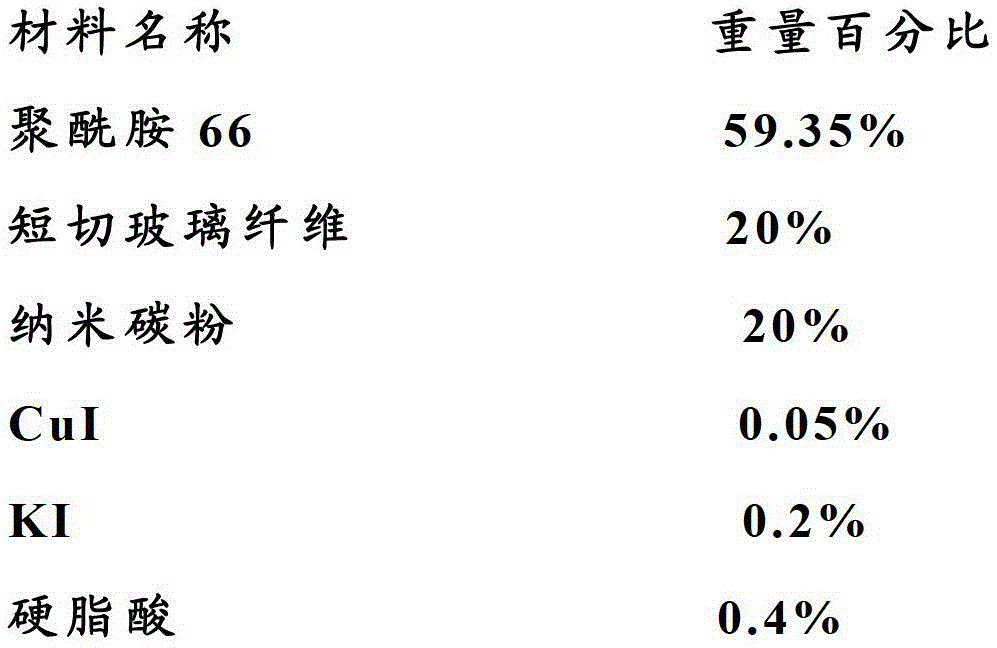

The invention discloses a polyamide composite material. The polyamide composite material comprises the following components in percentage by weight: 30%-80% of polyamide, 10%-50% of glass fiber, 5%-30% of heat-conducting filler, 0.1%-2% of a heat stabilizer and 0.1%-0.5% of a lubricant. A special screw assembly design on a twin-screw extruder is adopted, so that the powder can be well dispersed without adding a coupling agent, and the comprehensive performances are still better. In the composite material, the nanometer heat conducting filler is added, so that the heat conducting performance of the composite material is improved under the condition that the mechanical performance is not reduced, the using temperature of the composite material is increased to 180 DEG C and the service life of the composite material is prolonged.

Owner:大河宝利材料科技(苏州)有限公司

LED (light-emitting diode) lamp glass lamp shell heat-conducting and explosion-proof coating material and preparation method thereof

The invention discloses an LED (light-emitting diode) lamp glass lamp shell heat-conducting and explosion-proof coating material and a preparation method thereof. The coating material is prepared from a component A and a component B, wherein the component A is prepared from modified graphene, vinyl base silicone oil and a catalyst; the component B is prepared from vinyl base silicone oil, vinyl base silicone resin, hydrogen-containing silicone oil, an inhibitor and a tackifier. The heat-conducting and explosion-proof coating material provided by the invention can be used for coating the surface of an LED lamp glass lamp shell, a layer of protection film is formed after curing, and cracking after the glass lamp shell falls off is prevented, so that the phenomenon that a non-insulated electrified part or an internal connecting wire can be contacted, or mechanical insulation of internal parts of equipment is damaged is avoided.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

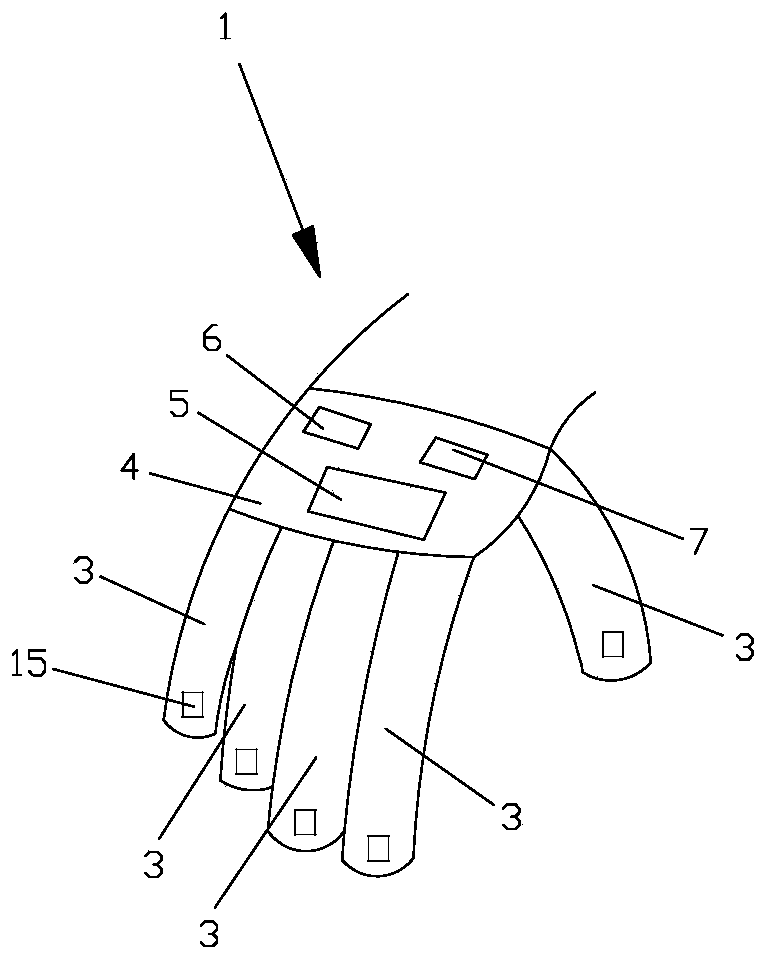

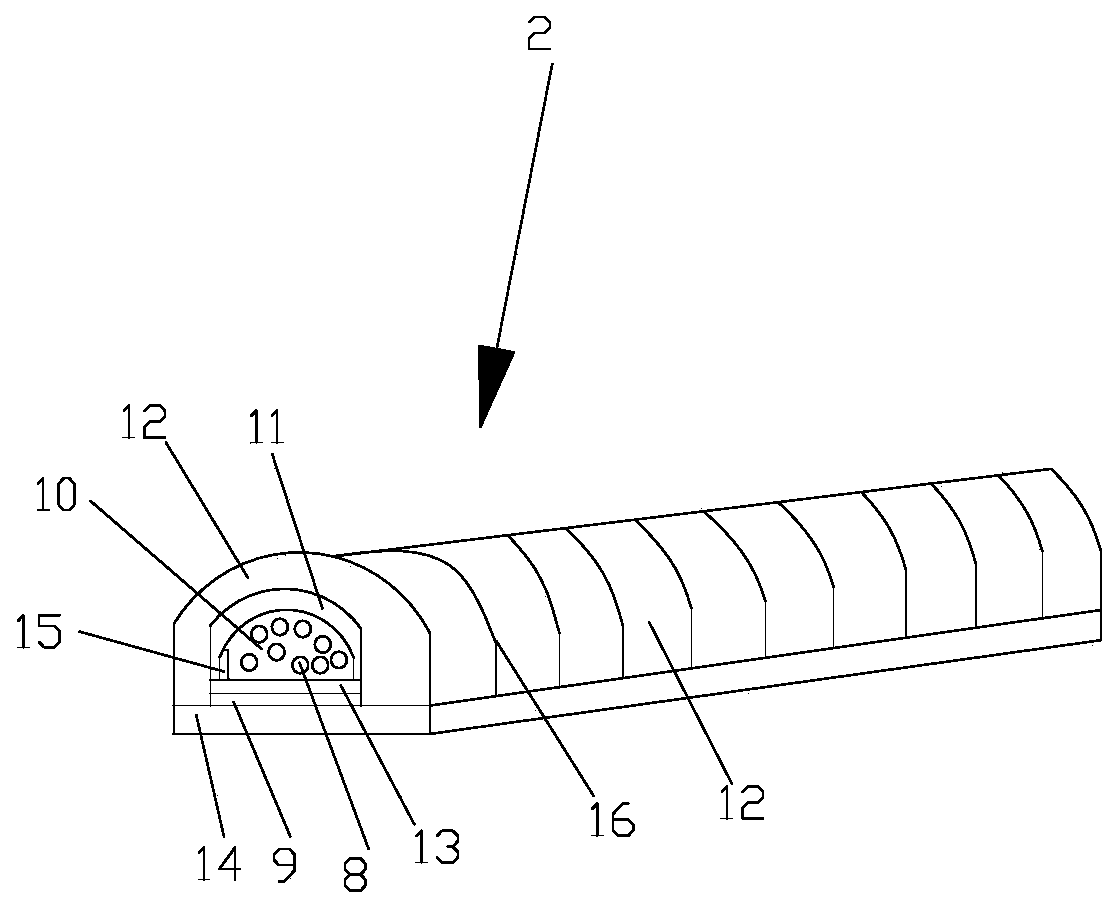

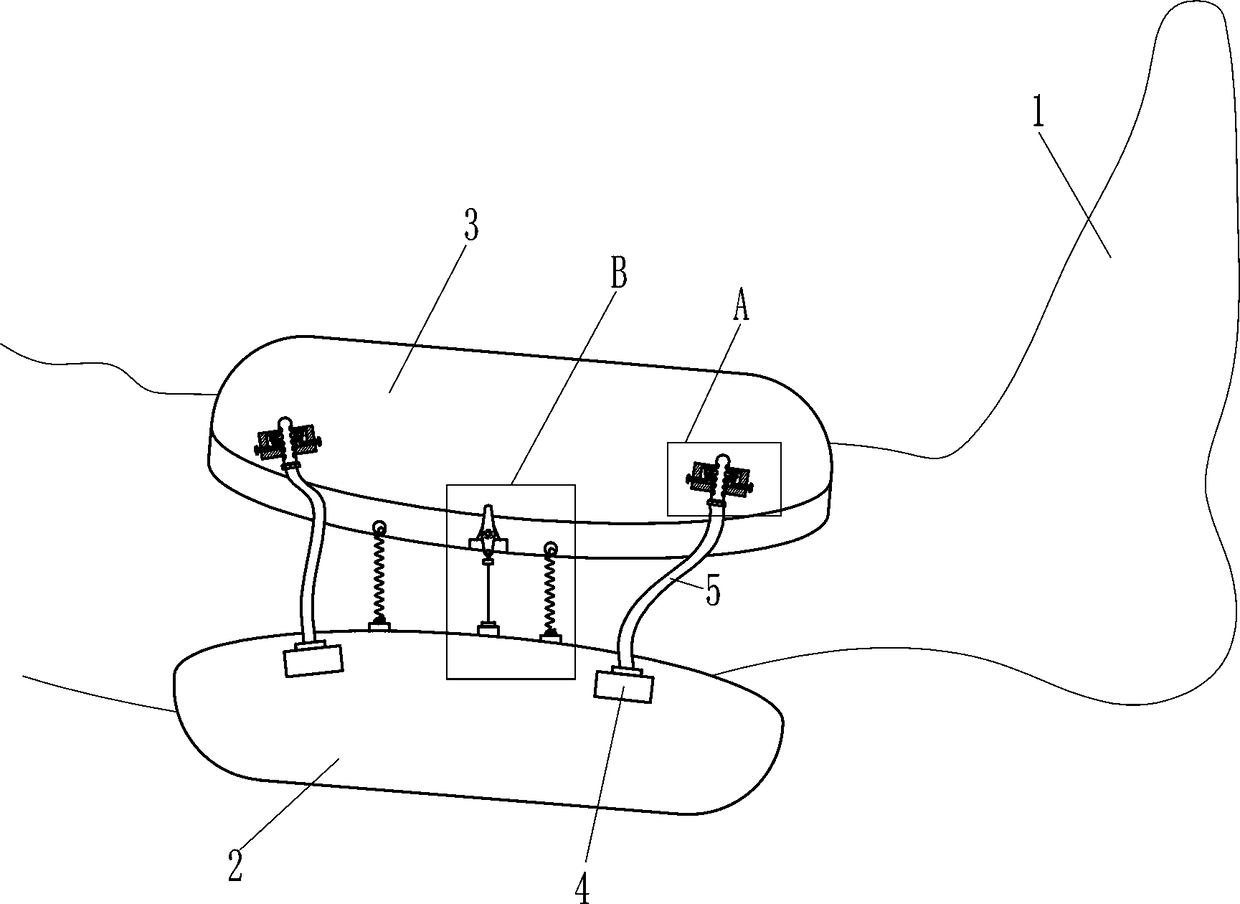

Thermal expansion fluid composite non-special-shaped cavity driven type robot soft hand

The invention discloses a plurality of different types of thermal expansion fluid composite non-special-shaped cavity driven type robot soft hands. All the robot soft hands comprise a plurality of thermal expansion fluid composite non-special-shaped cavity driven type robot soft fingers and thermal expansion fluid composite non-special-shaped cavity driven type robot palms, wherein the thermal expansion fluid composite non-special cavity driving type robot soft fingers adopt a thermal expansion fluid and shape memory alloy composite non-special-shaped cavity single-side driver, a thermal expansion fluid and an electric control heating material composite non-special-shaped cavity single-side driver, a thermal expansion fluid and shape memory alloy composite non-special-shaped cavity double-side driver, a thermal expansion fluid and electric control heating material composite non-special-shaped cavity double-side driver. According to the thermal expansion fluid composite non-special cavity driven type robot soft hands, the thermal expansion fluid composite non-special-shaped cavity is adopted, a thermal expansion fluid control valve to regulate the one-way flow of partial substancesin the thermal expansion fluid is combined, and the rigidity of the gripped article of the finger of the soft body can be improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

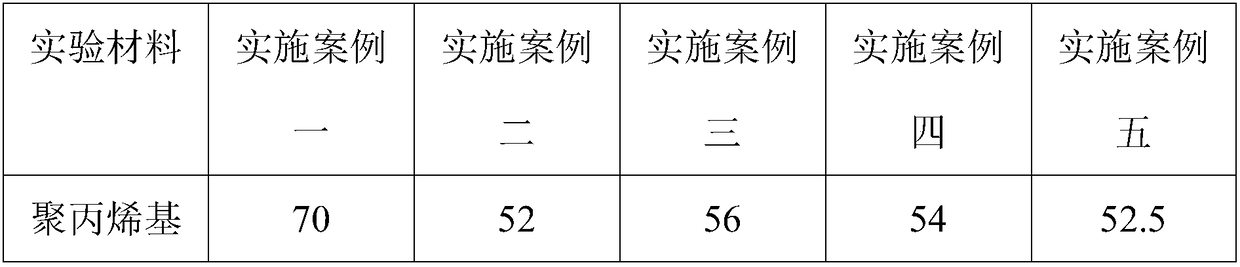

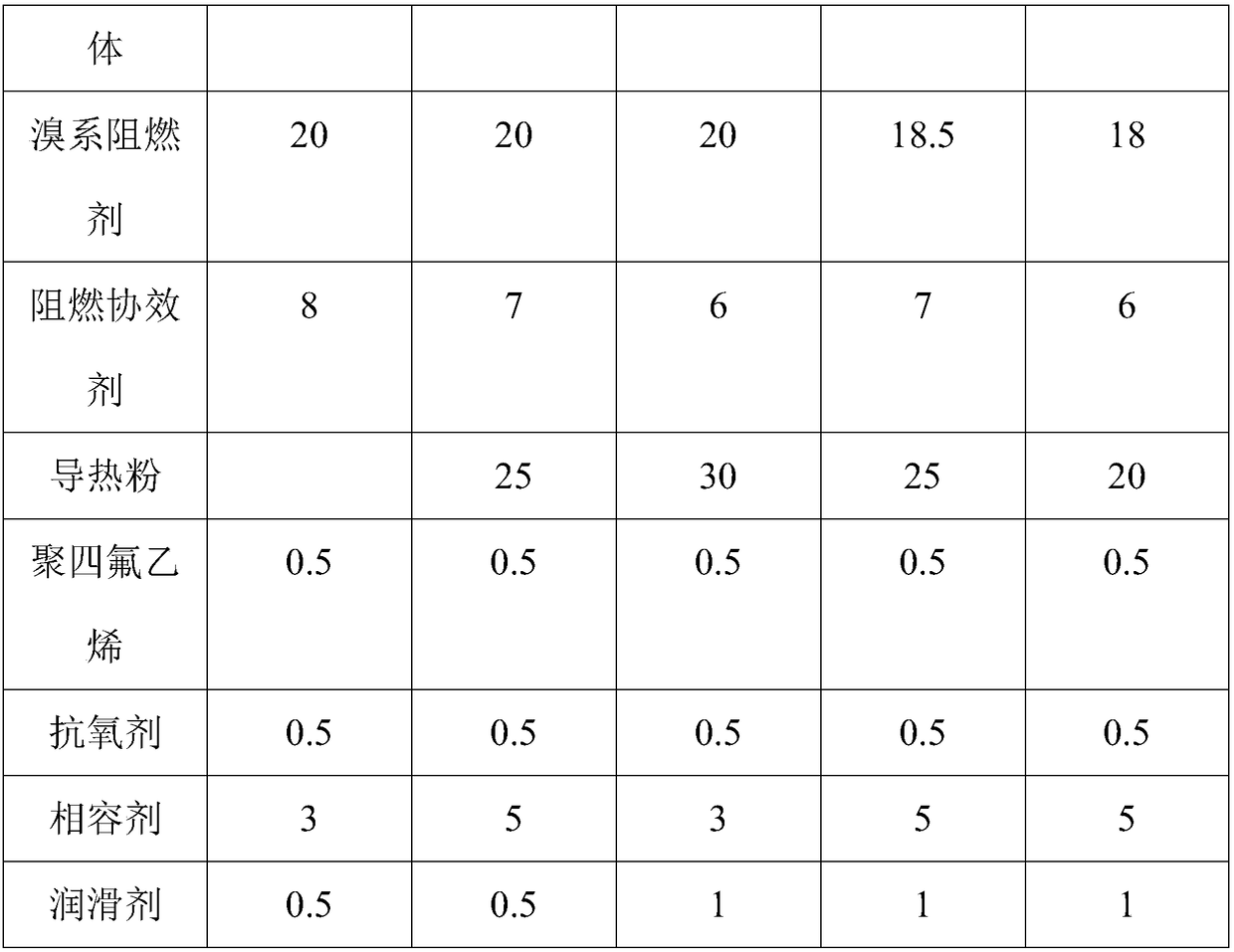

Heat-conducting and flame-retardant V0 polypropylene material for storage battery of new-energy vehicle and preparation method

The invention discloses a heat-conducting and flame-retardant V0 polypropylene material for a storage battery of a new-energy vehicle and a preparation method. The heat-conducting and flame-retardantV0 polypropylene material is prepared from the following raw materials in parts by mass: 30-50 parts of polypropylene matrix, 15-25 parts of brominated flame-retardant agent, 5-8 parts of flame-retardant agent synergist, 15-30 parts of heat-conducting powder, 0.5-1 part of polytetrafluoroethylene, 0.5-1 part of antioxidant, 3-5 parts of compatibilizer and 0.5-1 part of lubricant. The heat-conducting and flame-retardant V0 polypropylene material and the preparation method disclosed by the invention have the beneficial effects that the raw materials are added into a high-speed mixing machine foruniform mixing according to the proportion, and are melted and extruded by a dual-screw extruder; the whole operation and processing are simple, the mixing is uniform and the direct granulation can be achieved; all the used materials can not cause influence on the environment, so that the environment-friendly effect is achieved and the cost of the material is reduced; the heat-conducting and flame-retardant V0 polypropylene material has heat conductivity and low shrinkage and realizes V0-grade flame retardance.

Owner:广东亨嘉橡塑科技有限公司

Heat conducting polyamide composite material and preparation method thereof

ActiveCN102850780AImprove machinabilitySmall mechanical propertiesHeat-exchange elementsPolymer scienceHeat conducting

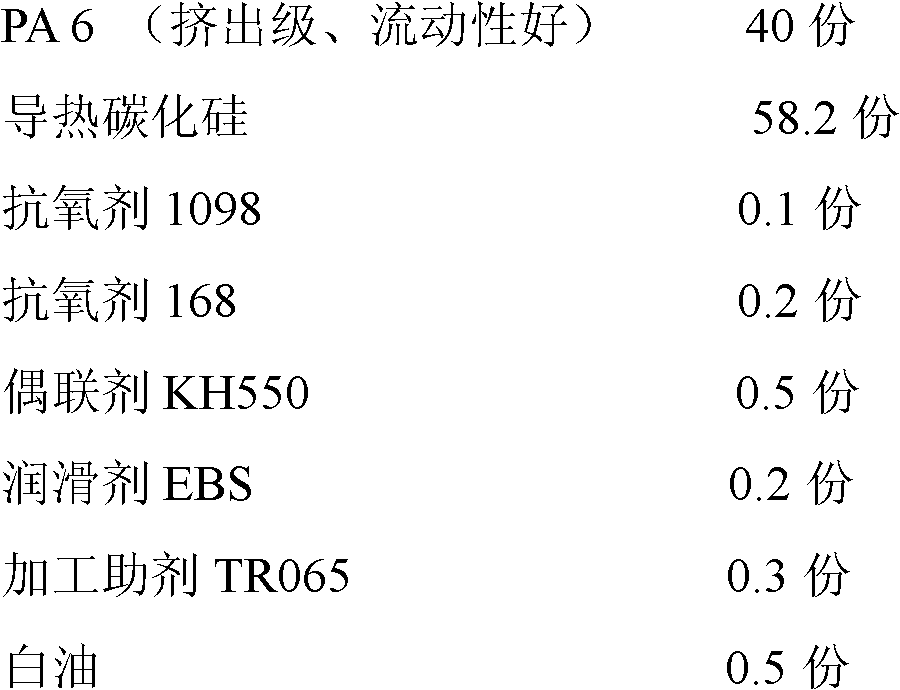

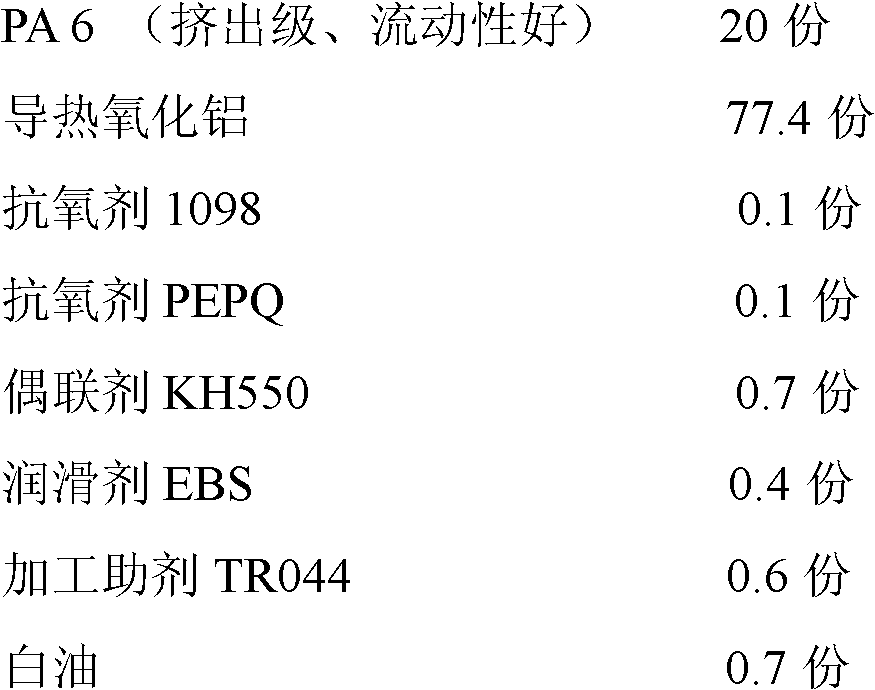

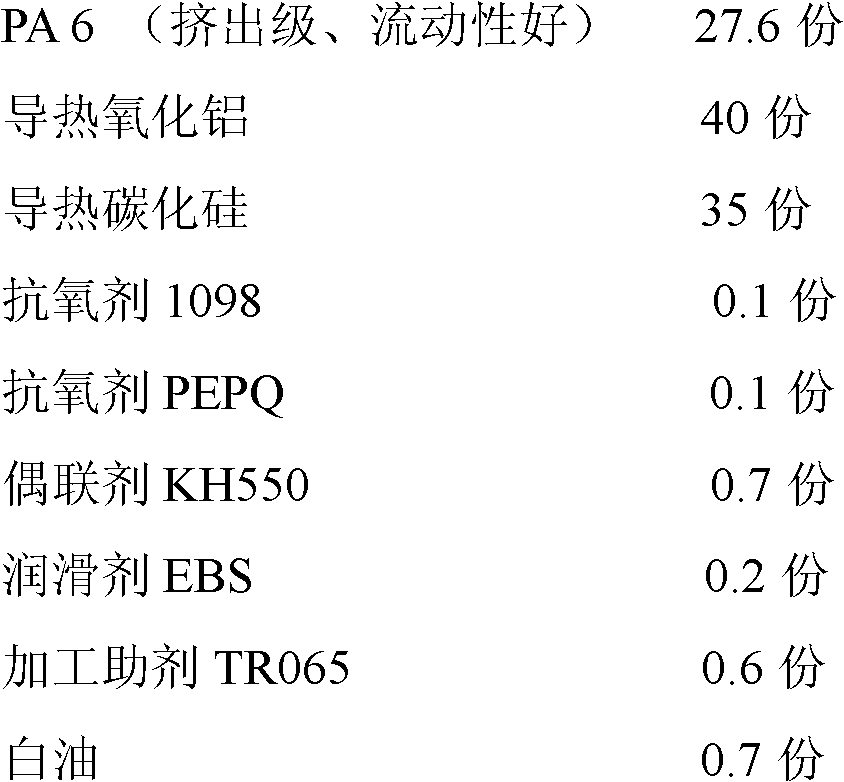

The invention discloses heat conducting polyamide composite material and preparation method thereof, falling into the technical field of high polymer composite material. The heat conducting polyamide composite material is composed of PA resin 20-40, heat conducting filling 58.2-77.4, antioxidant 0.2-0.3, coupling agent 0.5-0.7, liquid assistant 0.5-0.7, lubricant 0.2-0.4, and processing assistant 0.3-0.6 parts by weight. The method includes mixing the coupling agent 0.5-0.7 parts and liquid assistant 0.5-0.7 parts, adding into dry heat conducting filling 58.2-77.4 parts, stirring for 30 min via a high-speed mixing machine, and drying for 3 h at 100 DEG C. for use; placing PA resin 20-40 parts, antioxidant 0.2-0.3 parts, lubricant 0.2-0.4 parts, processing assistant 0.3-0.6 parts and the mixture obtained from the first step into a high-speed mixing machine, stirring for 15 min, and performing extrusion and granulation via an extruding machine. The composite material has heat conducting property, low density, good processability, and low cost.

Owner:HEFEI GENIUS NEW MATERIALS

Low-dielectric-constant organic silicon pouring sealant and preparation method thereof

ActiveCN111423842AThermally conductiveLow dielectric constantNon-macromolecular adhesive additivesMacromolecular adhesive additivesDielectricPtru catalyst

The invention provides an organic silicon pouring sealant with a low dielectric constant. The invention belongs to the technical field of organosilicon pouring sealants. The organic silicon pouring sealant comprises a component A and a component B. The component A comprises, by weight, 10-40 parts of vinyl silicone oil, 1-10 parts of a diluent, 0-20 parts of a heat conduction filler, 10-60 parts of a low dielectric material, and 0.1-2.0 parts of a catalyst. The component B comprises, in parts by weight: 10 to 40 parts of vinyl silicone oil, 5 to 30 parts of a cross-linking agent, 0 to 20 partsof a heat conduction filler, 10 to 60 parts of a low dielectric material and 0.1 to 1.0 part of an inhibitor; the preparation method comprises the following steps: carrying out organic treatment on alow-dielectric material, stirring in a reaction kettle, cooling, stirring again, cooling again to obtain the finished product A and the finished product B, and uniformly mixing the prepared finishedproduct A and the finished product B according to the mass ratio of 1: 1 for later use. The phase change pouring sealant can solve the problem that a porous material containing air is unstable in an organic silicon system, the organic silicon pouring sealant is stable in storage, the dielectric constant is lower than 3.0 (1MHz), and heat conduction and viscosity are moderate.

Owner:GUANGZHOU HUITIAN FINE CHEM

Multilayer printed circuit board structure

InactiveCN104066265AThermally conductiveHygroscopicCircuit susbtrate materialsFiberConductive materials

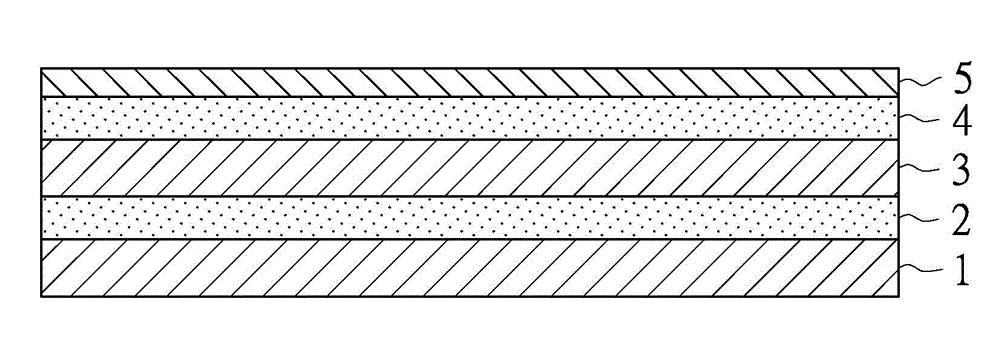

The invention discloses a multilayer printed circuit board structure which is obtained through successively stacking the components of: an aluminum foil base layer, a first prepreg, an aluminum foil middle layer, a second prepreg and a copper foil surface layer, wherein the first prepreg and the second prepreg are respectively prepared through dipping fiber cloth into a heat-conductive material, so that the heat-conductive material can be filled in the gaps of the fiber cloth, wherein the heat-conductive material is prepared through mixing a resin and a filler at least. According to the multilayer printed circuit board structure, through stacking and combining the aluminum foil base layer, the first prepreg, the aluminum foil middle layer, the second prepreg and the copper foil surface layer, and through the resin component contained in the first prepreg and the second prepreg, the multilayer printed circuit board structure can possess the advantages of: high heat conductivity, low moisture absorption property, high heat resistance, high melting point, low dielectric constant, low dielectric loss coefficient, no easy board delamination, etc.

Owner:叶云照

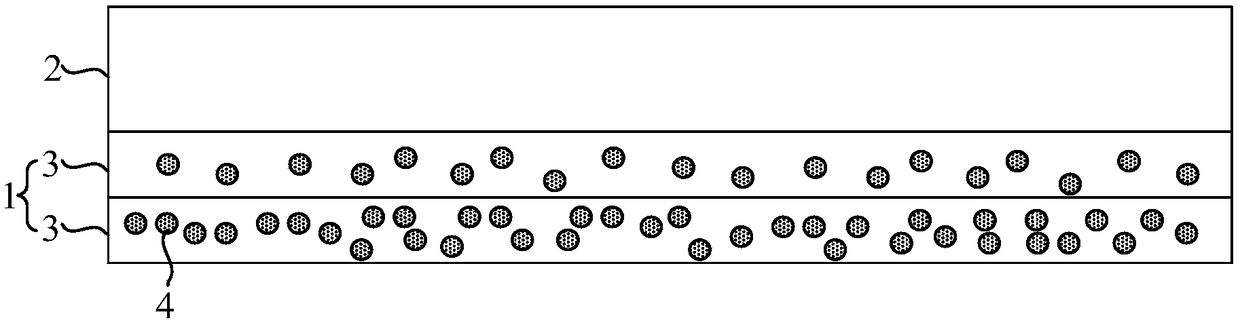

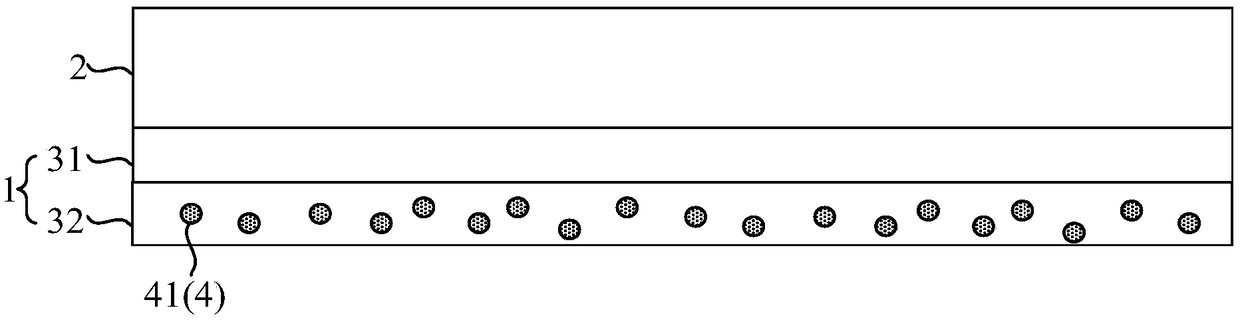

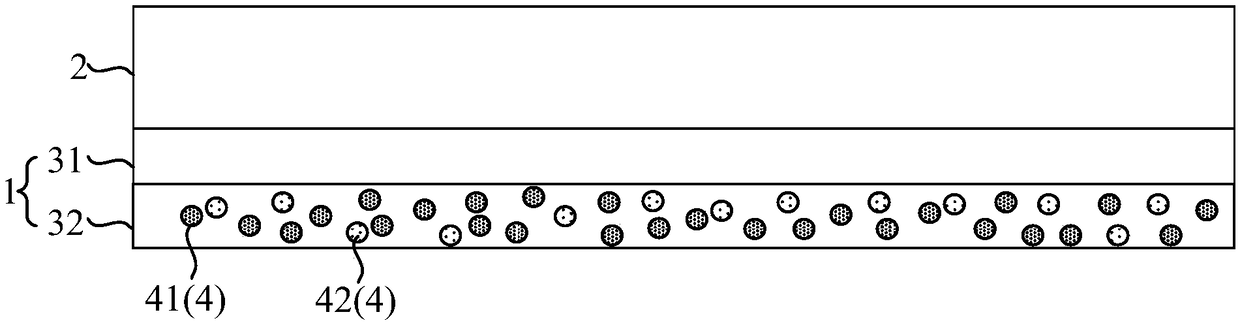

Flexible display panel, manufacturing method thereof and flexible display device

The embodiment of the invention provides a flexible display panel, a manufacturing method thereof and a flexible display device, and relates to the technical field of displaying. On the premise that good bending performance and display performance of the flexible display panel are guaranteed, the cooling performance of the flexible display panel is improved. The flexible display panel comprises aflexible substrate body and a display layer arranged on the flexible substrate body; the flexible substrate body comprises at least two flexible substrates, and at least one flexible substrate is doped with a particulate material with heat-conducting performance; moreover, in the direction away from the display layer, the concentration of the particulate material doped in the flexible substrates is gradually increased. The flexible display panel is used for achieving image display.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

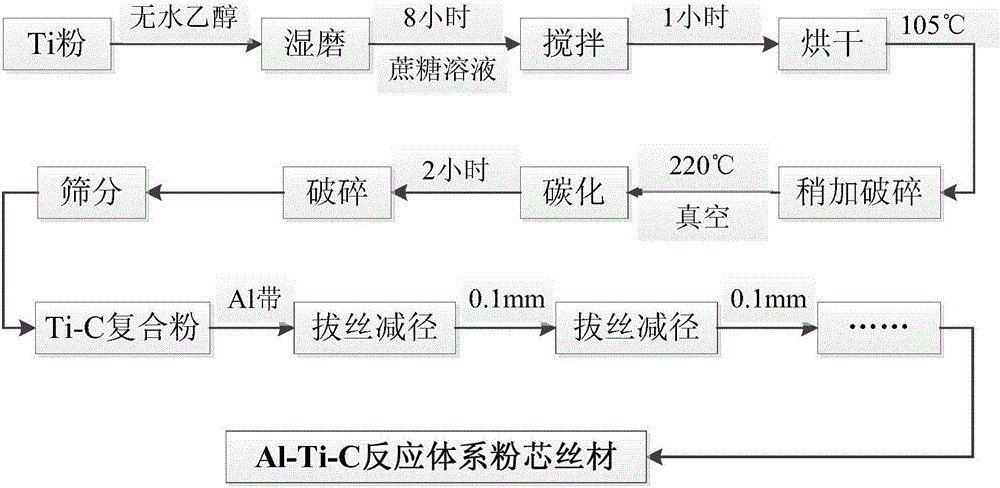

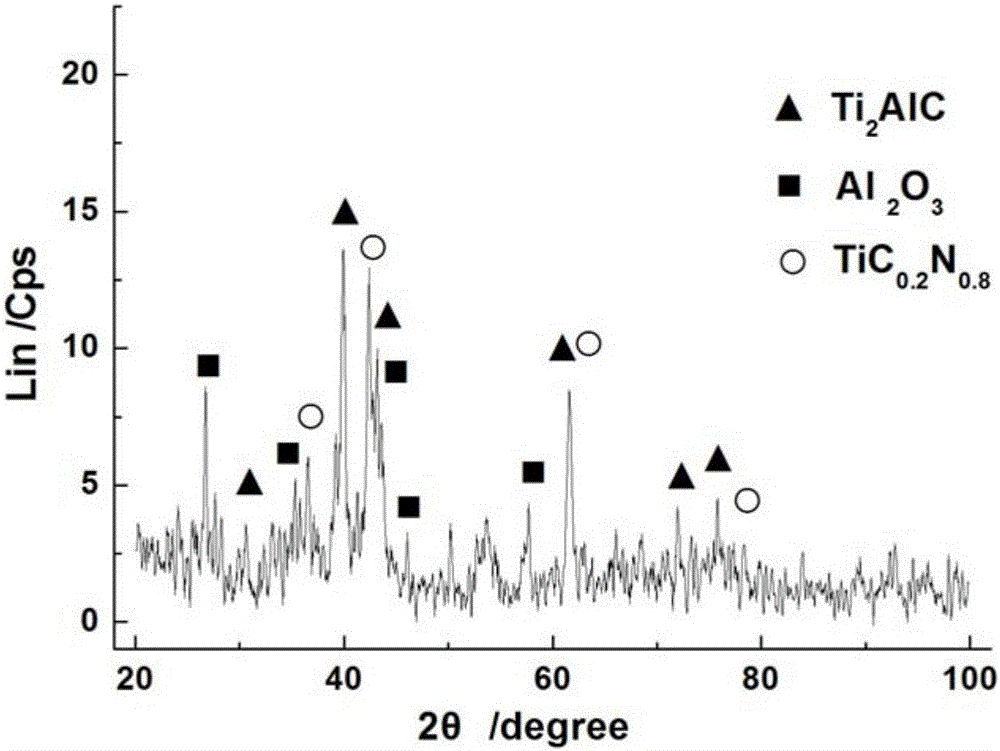

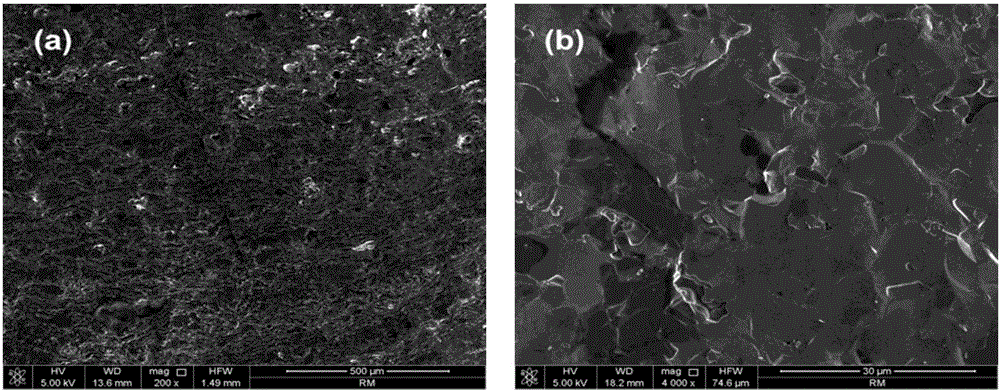

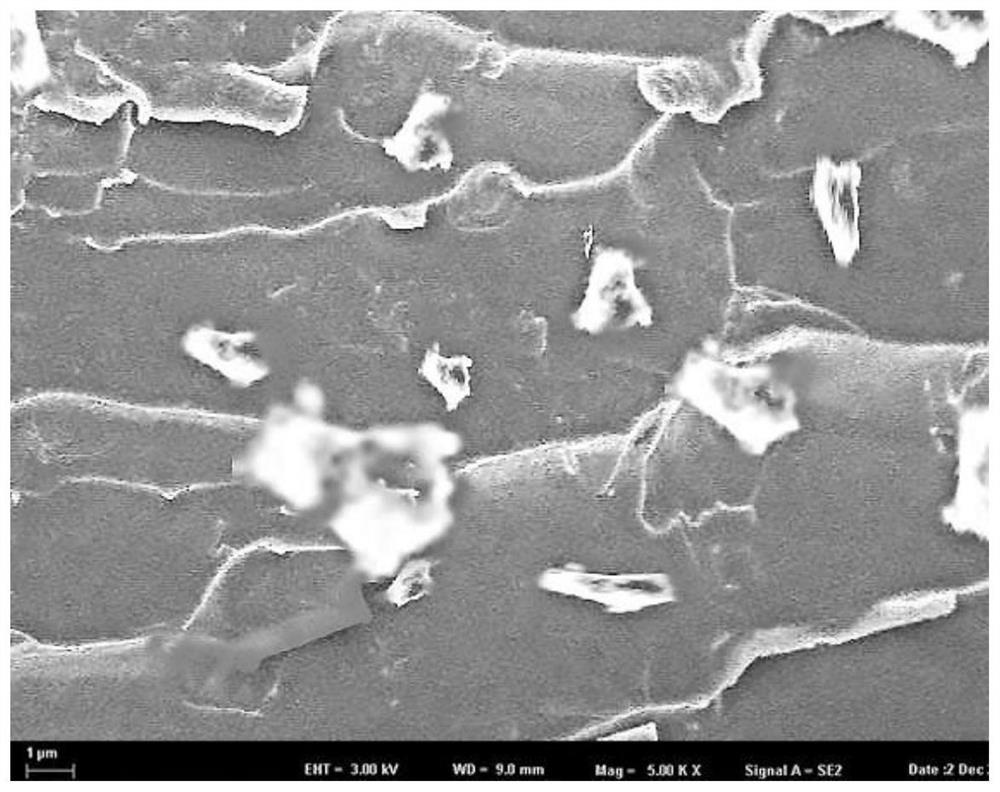

Preparation method for Al-Ti-C system reaction cored wire

InactiveCN104988448AImprove performanceEnhanced mass transferMolten spray coatingSelf-propagating high-temperature synthesisCeramic coating

The invention relates to the technical field of ceramic matrix composite preparation, and in particular to a preparation method for an Al-Ti-C system reaction cored wire. The method includes the steps that firstly, titanium powder is wetly ground in an organic solvent medium (absolute ethyl alcohol or acetone), a sucrose solution is added, and therefore a mixed material is generated; secondly, the mixed material is evenly stirred and then dried and placed in a vacuum heat treatment furnace so as to be heated, sucrose is carbonized, and a Ti-C mixed system is formed; thirdly, the carbonized mixed material is crushed, Ti-C composite powder with the proper grain diameter is obtained through screening and serves as a cored material; fourthly, an aluminum belt serves as a skin material, the Ti-C composite powder serves as the cored material, and a multi-stage continuous wire-drawing diameter-reducing method is adopted for preparing the Al-Ti-C cored wire. The method is characterized in that the skin material and the cored wire are both components of the reaction system, the Al-Ti-C reaction system is formed and generates a self-propagating high-temperature synthesis (SHS) reaction in the spraying process, a Ti2AlC-base ceramic coating is synthesized in situ, low-cost raw materials can be used, and a composite ceramic coating with the high performance can be acquired through the SHS reaction.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

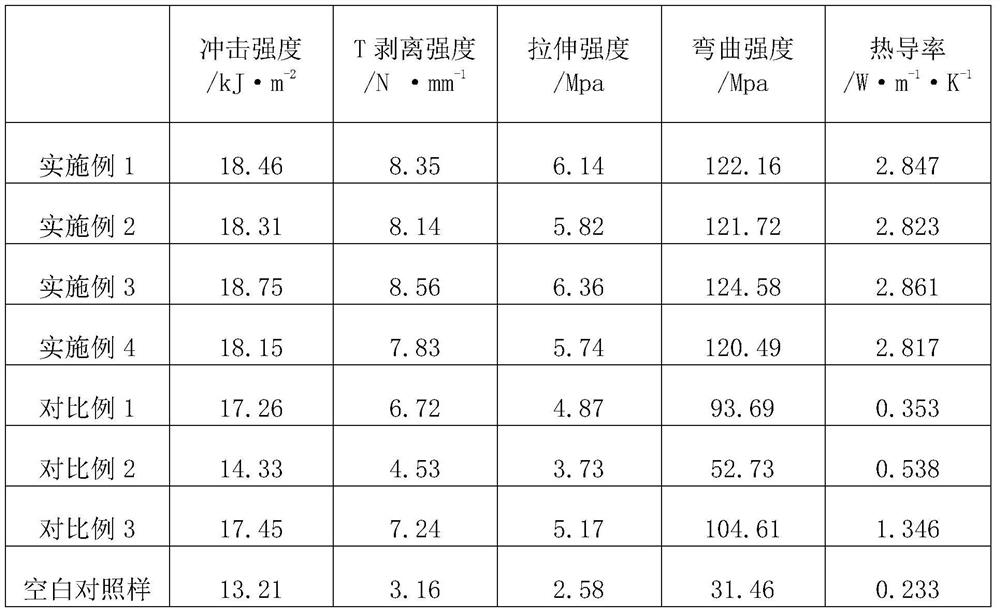

Graphite-based high-strength heat-conducting epoxy resin adhesive and preparation method thereof

InactiveCN111621253AImprove adhesionImprove insulation performanceNon-macromolecular adhesive additivesEpoxy resin adhesivesHexadecanePolymer science

The invention relates to the technical field of adhesives, and discloses a graphite-based high-strength heat-conducting epoxy resin adhesive and a preparation method thereof. The adhesive comprises the following components in parts by weight: bisphenol A type epoxy resin, calcium carbonate, modified graphite, composite glass fibers, 1, 4-butanediol diglycidyl ether, a curing agent polydiphenyl substituted cetane dicarboxylic anhydride, a curing accelerator pyridine and absolute ethyl alcohol. The preparation method comprises the following steps: performing ultrasonic oscillation dispersion onmodified graphite to obtain a graphite suspension; adding bisphenol A epoxy resin, calcium carbonate, composite glass fibers and 1, 4-butanediol diglycidyl ether into the graphite suspension, and uniformly mixing to obtain a premix; and adding polydiphenyl substituted hexadecane dicarboxylic anhydride and pyridine into the premix, pouring into a metal mold, and standing while keeping the temperature, thereby obtaining the graphite-based high-strength heat-conducting epoxy resin adhesive. The adhesive prepared by the method has high mechanical strength and excellent heat-conducting property, and the application range of the epoxy resin adhesive is expanded.

Owner:李磊

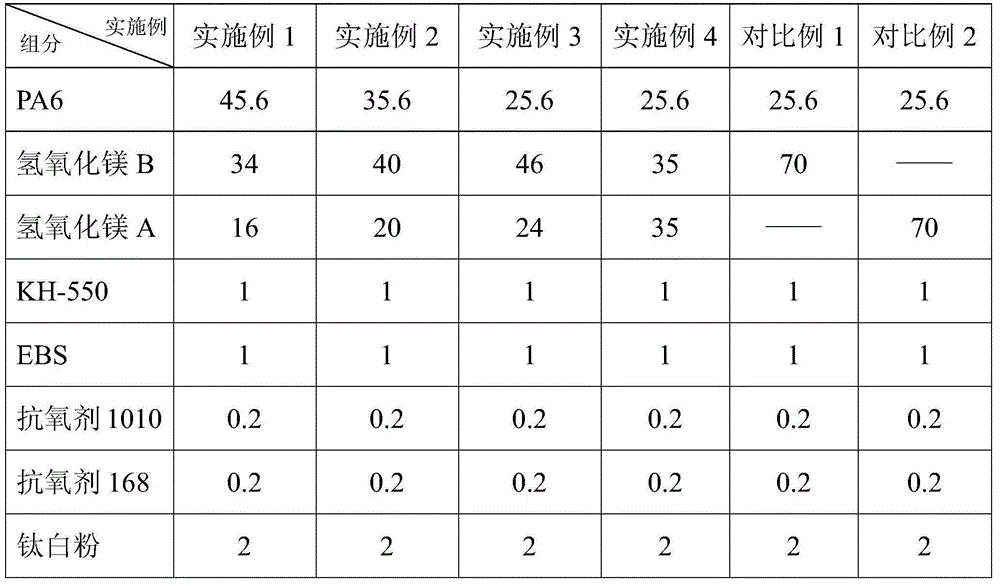

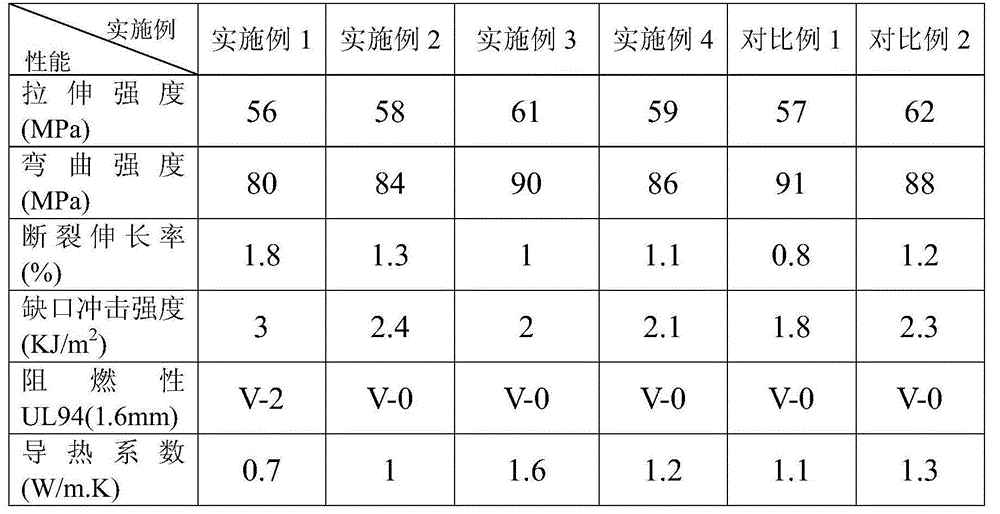

Heat conducting nylon composite material and preparation method thereof

The invention relates to a heat conducting nylon composite material and a preparation method thereof. The heat conducting nylon composite material comprises nylon and heat conducting fillers, wherein the heat conducting fillers include magnesium hydroxide A and magnesium hydroxide B; the grain size of magnesium hydroxide A is 200-1500 meshes; and the grain size of magnesium hydroxide B is 5000-12000 meshes. The heat conducting nylon composite material and the preparation method have the advantages that as two kinds of magnesium hydroxide with different grain sizes are compounded and adopted as the heat conducting fillers of the heat conducting nylon composite material, large-size magnesium hydroxide grains form a heat conducting network while small-size magnesium hydroxide grains fill the space among large-size magnesium hydroxide, thus finely filling the heat conducting network and being beneficial to improving the heat conductivity of plastics; besides, magnesium hydroxide belongs to a halogen-free flame retardant, so that nylon is endowed with certain flame retardance while the heat conductivity of nylon is improved after magnesium hydroxide is added to nylon.

Owner:东莞市宝临塑胶有限公司

Silicone elastomer with microwave activity

The invention relates to silicone elastomers filled with magnetite or containing magnetite, their production and the use of compositions according to the invention after crosslinking for the production of extrudates and moldings and are microwave active or magnetic or both microwave active and magnetic.

Owner:WACKER CHEM GMBH

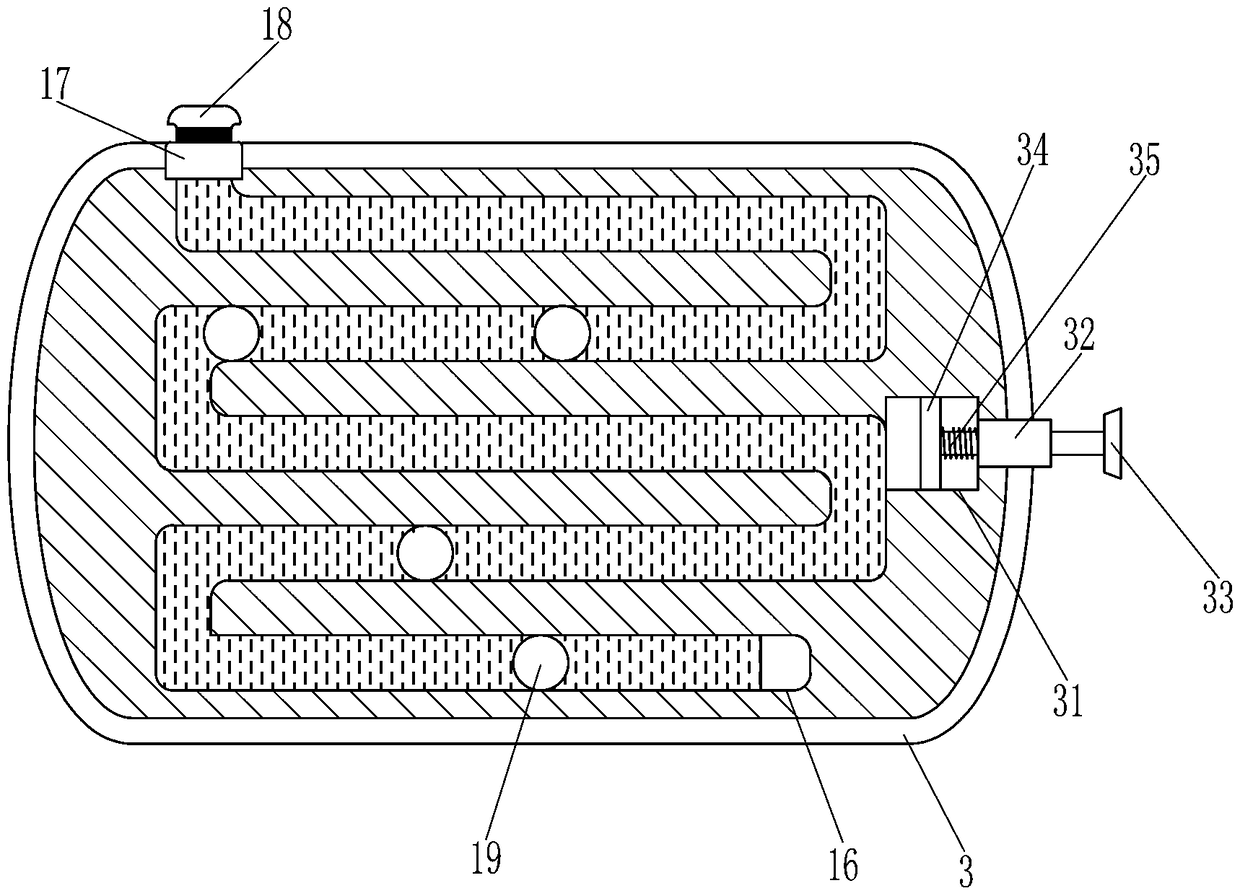

Shank hot compress plate for orthopedic patients

InactiveCN109223294AEasy to pressReduce the temperatureTherapeutic coolingSuction-kneading massageLeg typePhysical medicine and rehabilitation

The invention relates to a shank hot compress plate for patients, and especially relates to a shank hot compress plate for orthopedic patients. The technical problem to be solved is to provide an orthopedic patient calf hot compress board which is simple in operation, can be massaged and hot compressed by the patient himself, and saves labor. The technical scheme of the invention is as follows: the orthopedic patient calf hot compress plate comprises a leg guard plate, a hot compress plate, a first connecting block, a fixing belt, an opening round rod, a fixing block, a first guide sleeve, a first guide rod and the like; A leg guard plate is arrange at that bottom of the leg mold, a hot compress plate is arranged at the top of the leg mold, a first connecting block is arranged on the leftand right sides of the front and back sides of the leg guard plate, and a fixing belt is arranged on the top of the first connecting block. The shank hot compress plate can adjust the device accordingto the difference of the individual leg type and fix the device on the patient's leg through the cooperation of the open round bar and the first guide bar. By injecting hot water into the water injection chamber, the calf region of the patient can be hot compressed; With a rotary handle, the patient can press the calf repeatedly.

Owner:王帅华

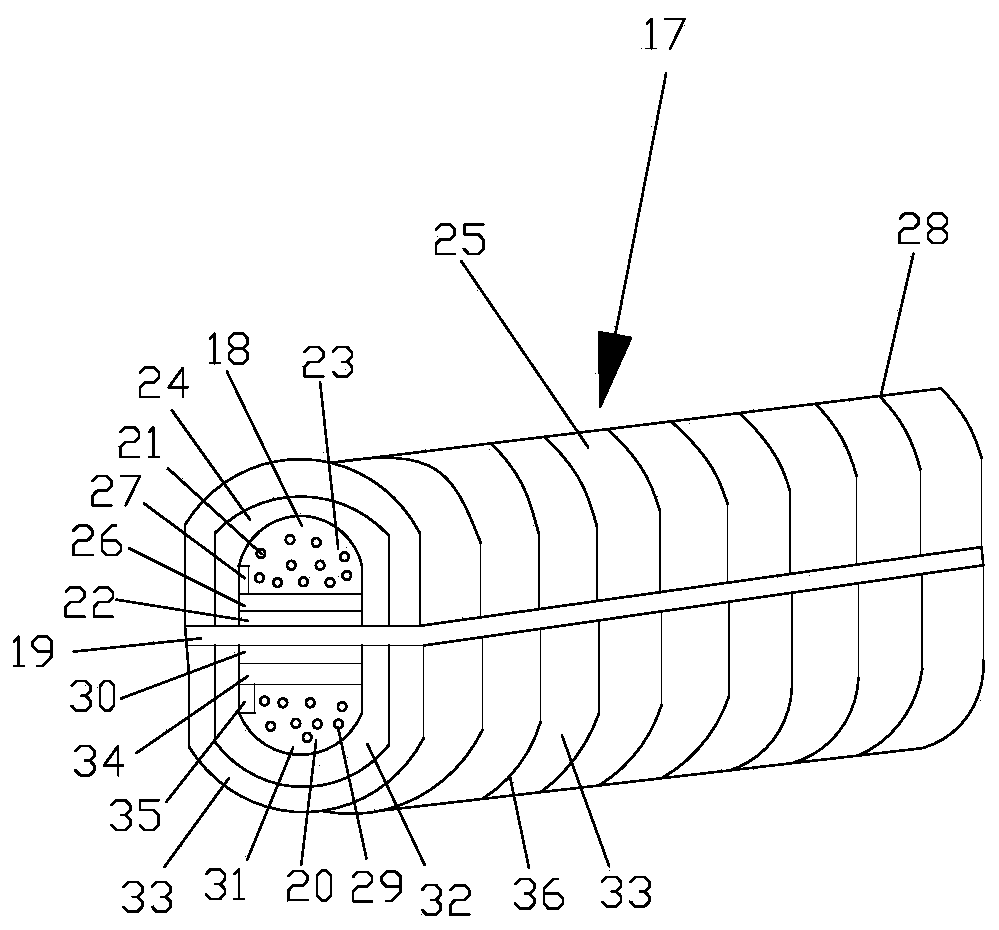

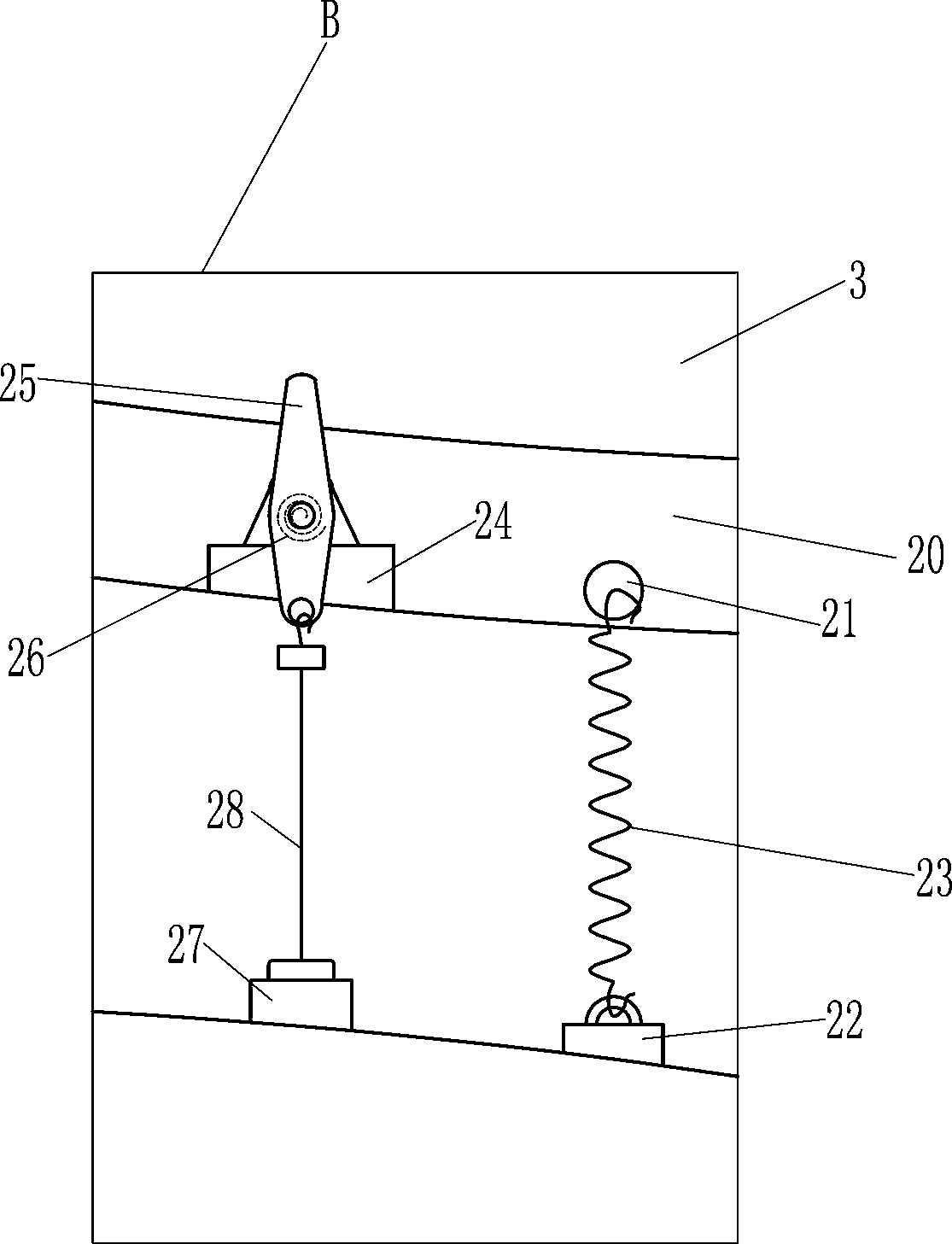

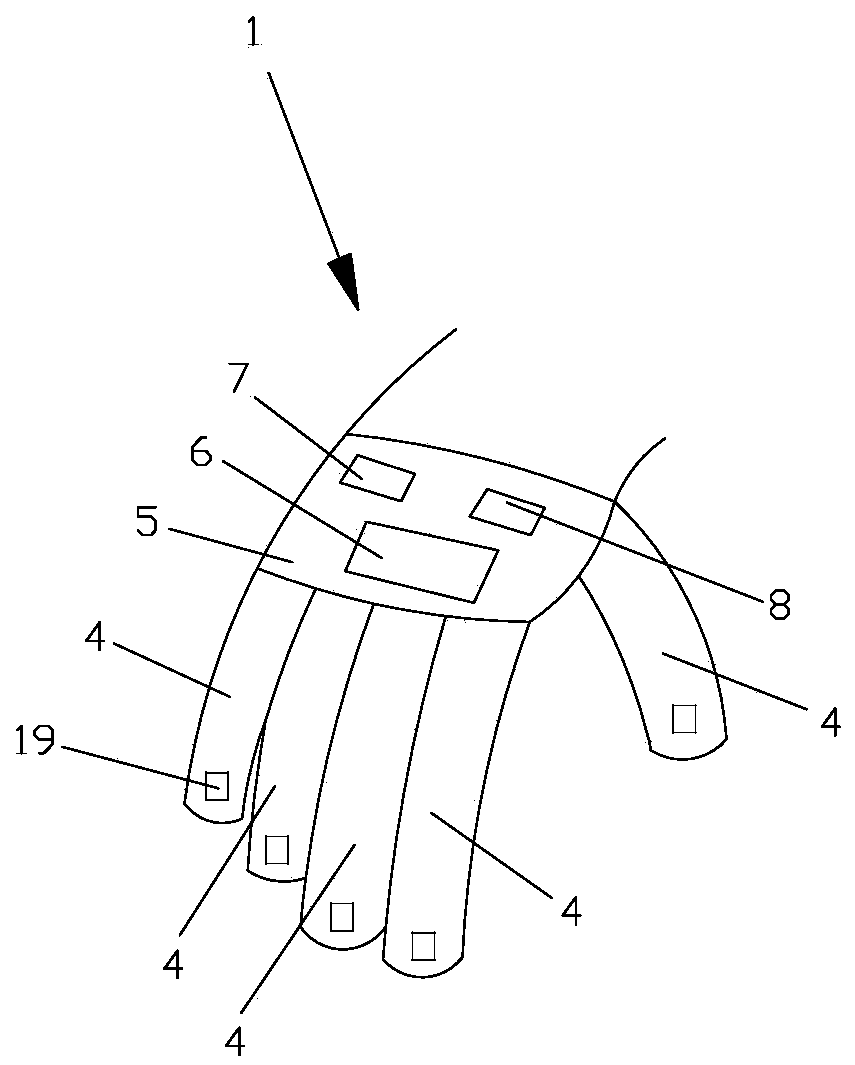

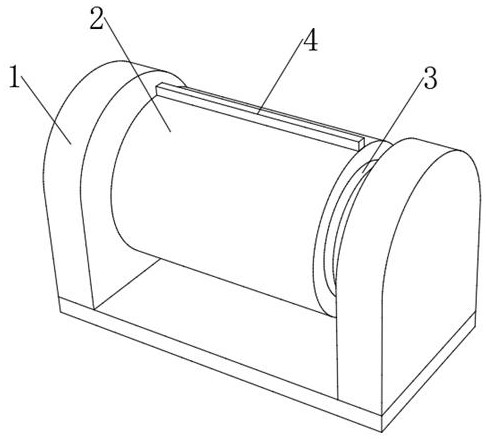

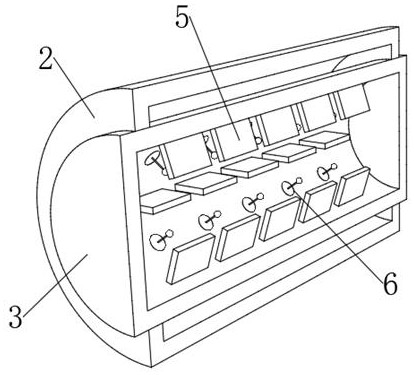

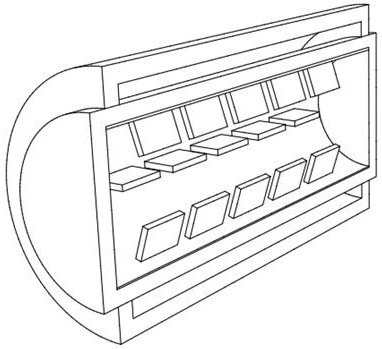

Thermal expansion fluid composite spherically-shaped cavity drive type robot soft hand

PendingCN109955275AThermally conductiveLiquidProgramme-controlled manipulatorGripping headsEngineeringShape-memory alloy

The invention discloses several different thermal expansion fluid composite spherically-shaped cavity drive type robot soft hands. Each thermal expansion fluid composite spherically-shaped cavity drive type robot soft hand comprises a plurality of thermal expansion fluid composite spherically-shaped cavity drive type robot soft fingers and a thermal expansion fluid composite spherically-shaped cavity drive type robot soft palm, wherein the thermal expansion fluid composite spherically-shaped cavity drive type robot soft fingers adopts a thermal expansion fluid and shape memory alloy compositespecially-shaped cavity single-side driver, a thermal expansion fluid and electric-control heating material composite specially-shaped cavity single-side driver, a thermal expansion fluid and shape memory alloy composite specially-shaped cavity dual-side driver, and a thermal expansion fluid and electric-control material composite specially-shaped cavity dual-side driver. Thermal expansion deformation drive of the thermal expansion fluid composite specially-shaped cavity and deformation drive of the shape memory alloy are combined, so that the thermal expansion fluid composite spherically-shaped cavity drive type robot soft hand has the strengthening effect of cooperative superposing and dual-driving.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

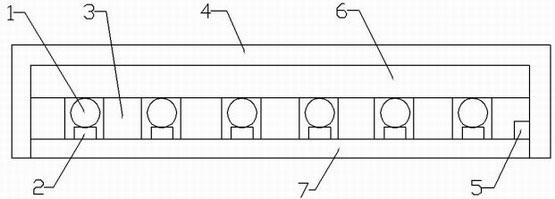

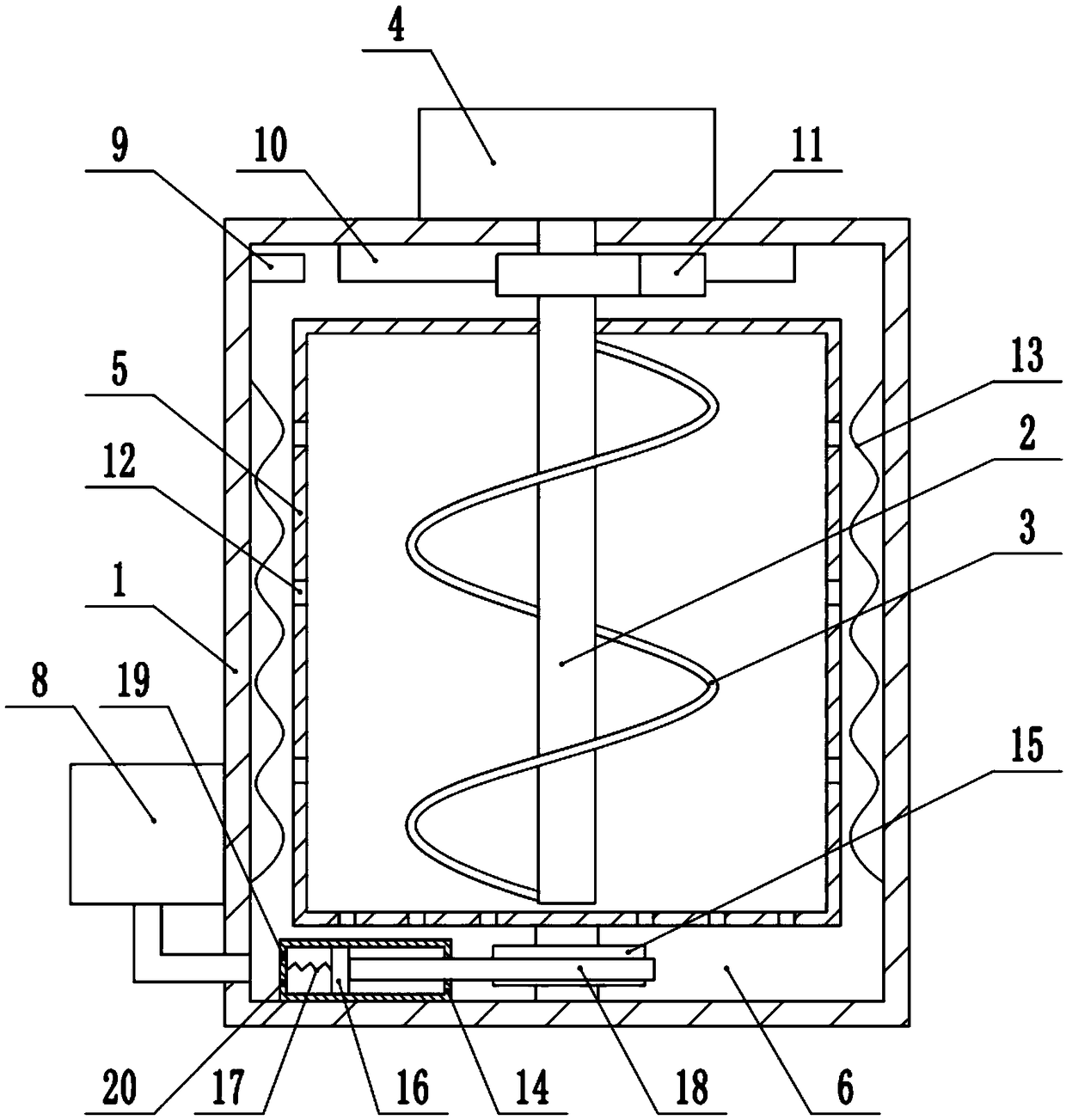

Up-and-down type roller drying equipment for biomass fuel

ActiveCN113532056AReduce stickinessHeated withDrying chambers/containersDrying solid materialsProcess engineeringMechanical engineering

The invention discloses up-and-down type roller drying equipment for biomass fuel, and belongs to the technical field of material drying. According to the up-and-down type roller drying equipment, the biomass fuel can be driven by a shoveling plate to dynamically roll in a rolling mode of an inner roller, a control box on an outer heating cylinder provides heat and applies a magnetic field, so that the inner roller is always heated uniformly, and a high-temperature area is not prone to occurring; an up-and-down layer is arranged on the inner roller, when the up-and-down layer rotates to the upper side, the up-and-down layer is interfered by the magnetic field of the control box to generate a repulsion phenomenon, the up-and-down layer can actively arch towards the inner side, and synchronously pulls an up-and-down strip to be unfolded, so that the biomass fuel adhering to a wall is stripped; the shape is restored after the up-and-down layer rolls away from the magnetic field range of the control box, so that the contact heat conduction effect of the biomass fuel and the metal wall of the inner roller cannot be influenced; and compared with an existing roller dryer, the up-and-down type roller drying equipment has the advantages that the wall adhering phenomenon of the biomass fuel can be reduced by utilizing the up-and-down action of the up-and-down layer, and the drying efficiency is improved.

Owner:南通汉森农业科技有限公司

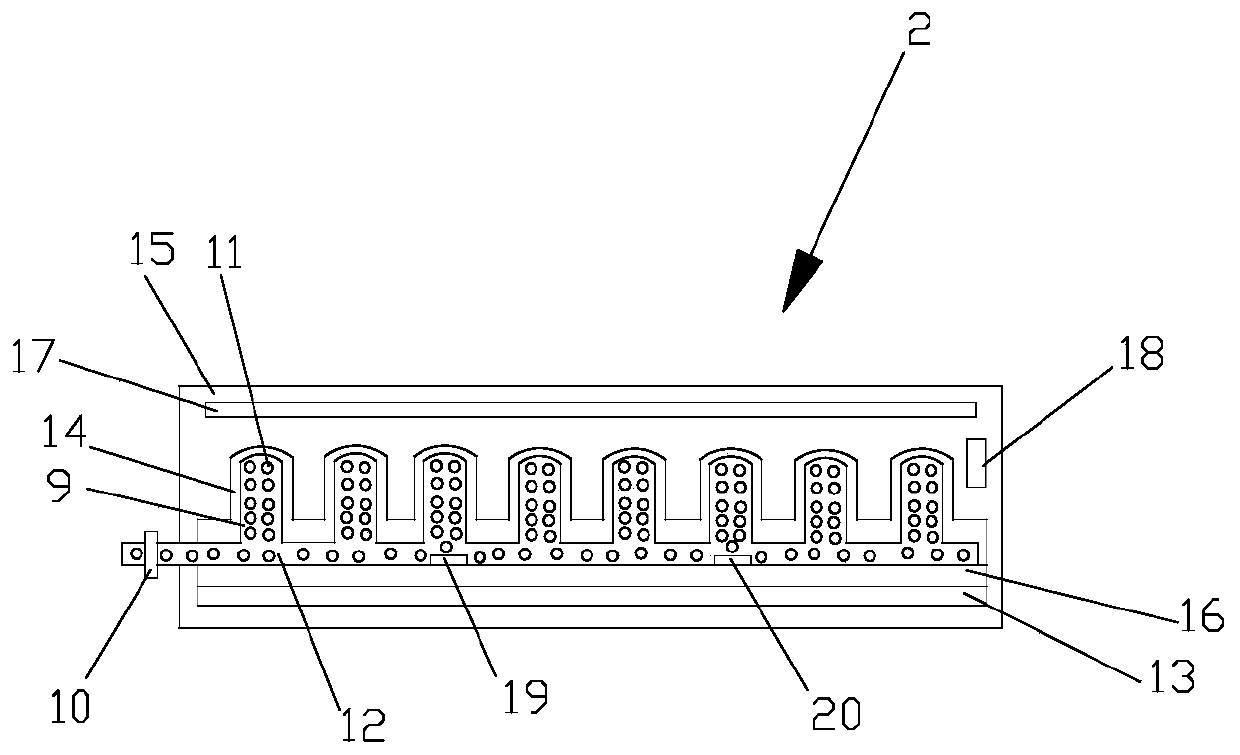

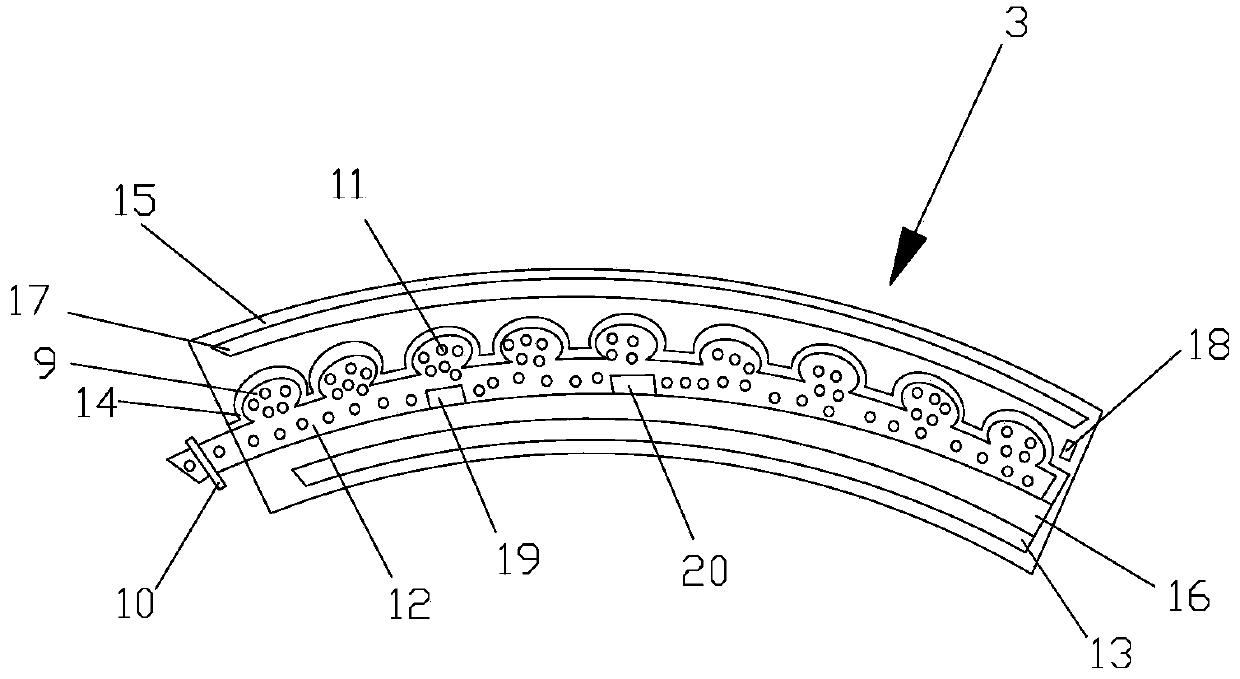

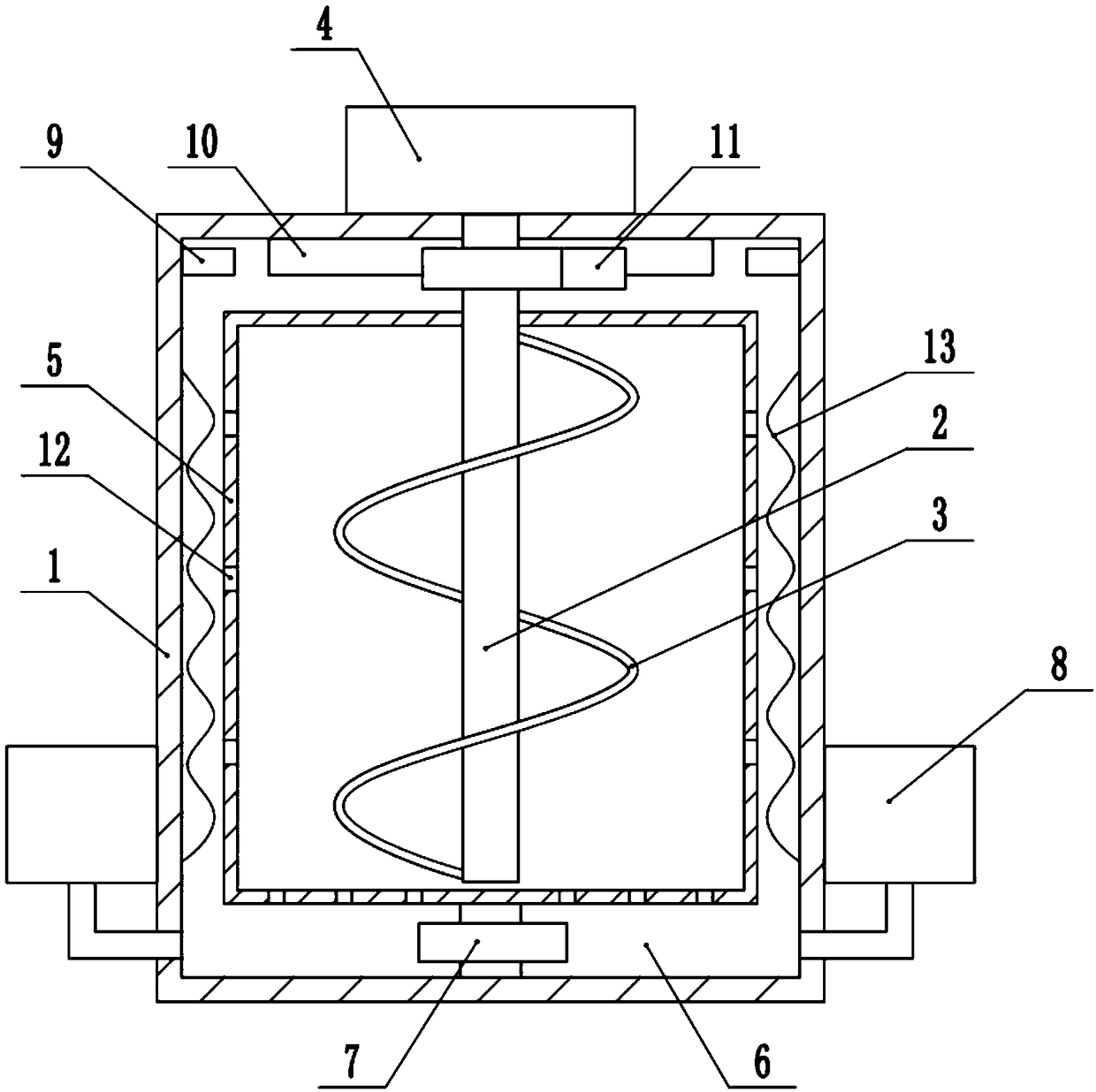

Carbon fiber electric heating plate

InactiveCN102595666AThermally conductiveHigh electrothermal conversion efficiencyOhmic-resistance heatingElectricityFiber

The invention relates to a carbon fiber electric heating plate which is characterized in that a carbon fiber heating cable is arranged in a mounting groove; the carbon fiber heating cable adopts the bending design; a heat conduction layer is arranged in a bent gap; an outer protection layer of the carbon fiber electric heating plate is an aluminium magnesium alloy frame body; the carbon fiber heating cable is connected with a power supply by an electric contact; and an insulating layer and a heat dissipating plate are respectively laid at the upper and lower parts of the carbon fiber heating cable. The carbon fiber electric heating plate has the beneficial effects that the carbon fiber heating cable is used as a heating source; the carbon fiber heating cable has double heat conduction effects of heat conduction and thermal radiation; the carbon fiber electric heating plate has high electrothermal conversion efficiency; electric energy is saved; and the outer protection layer is the aluminium magnesium alloy frame body, so that the carbon fiber electric heating plate is firm and durable.

Owner:BORUISI TECH DALIAN

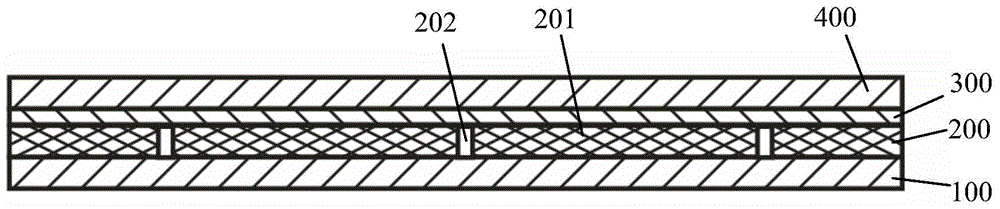

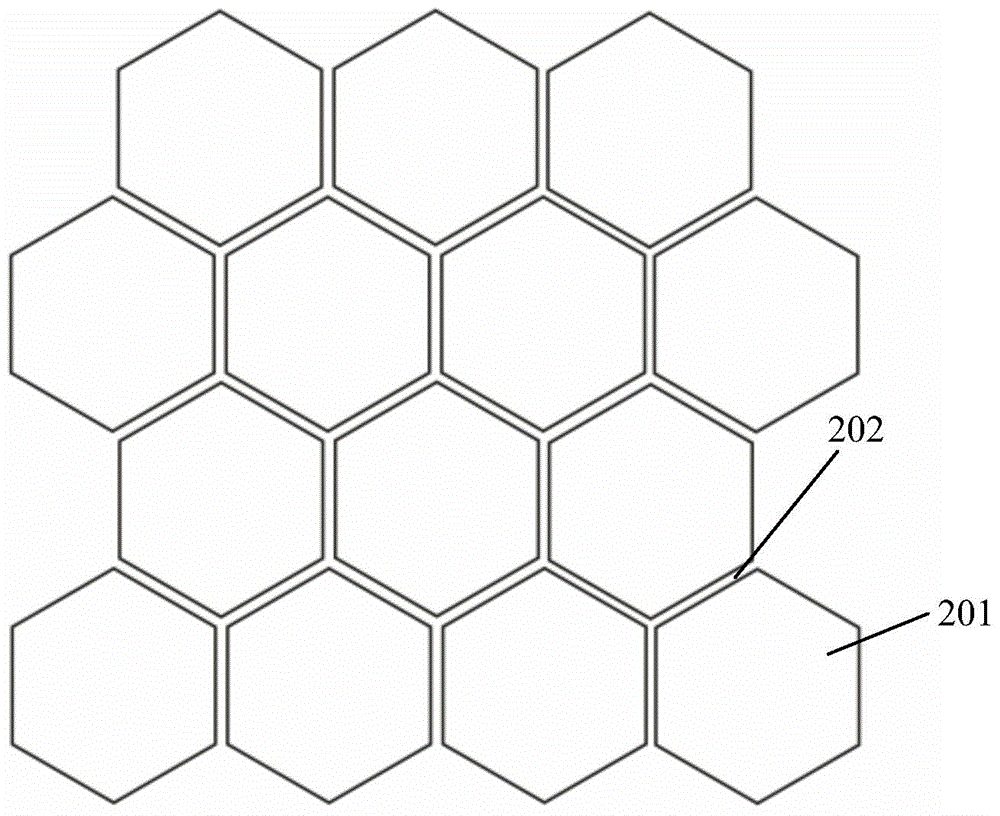

Heat conduction film and manufacturing method thereof

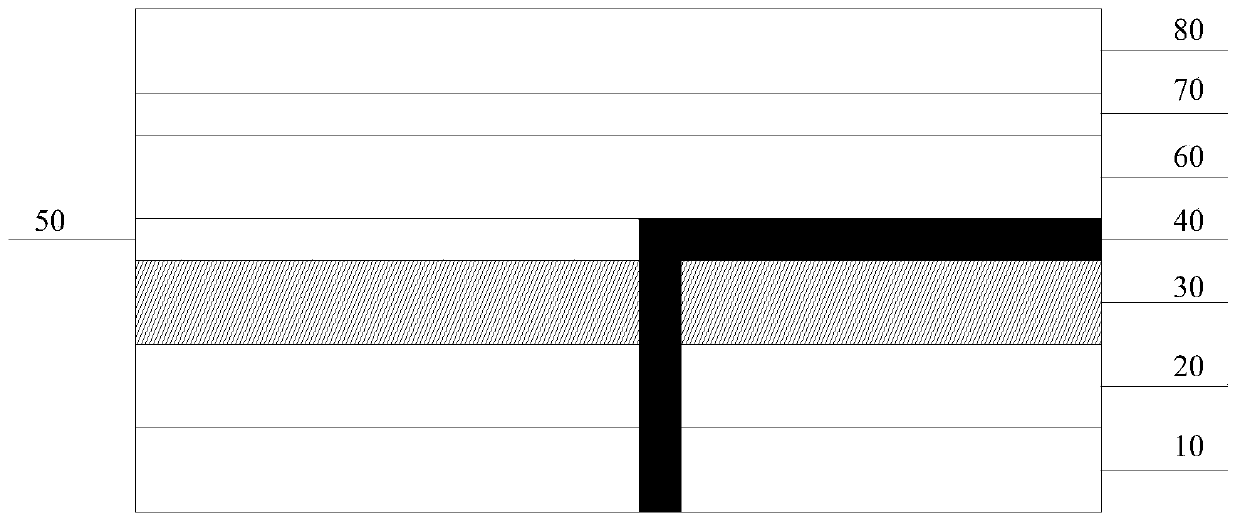

ActiveCN105990274AFacilitated DiffusionWith electrical insulationSemiconductor/solid-state device detailsSynthetic resin layered productsSurface layerEngineering

The invention discloses a heat conduction film and a manufacturing method thereof. The heat conduction film successively comprises, from bottom to top, a bottom layer of a flexible base material, a structural layer and a surface layer of the flexible base material. The structural layer is formed by geometric blocks which are distributed on a bottom layer surface in a protruded mode. Connected grooves are formed between the adjacent geometric blocks. A thickness of the structural layer is 30-50 microns. A width of each groove is the 0.5-3 microns. A pressure working medium is filled in each groove and each groove is full of the pressure working medium. Groove ports around the heat conduction film are plugged. Pressure of the pressure working medium in each groove is 0.5-2MPa. The heat conduction film of the invention has a series of advantages that heat conductivity and an insulating property are possessed; a suitable field is wide, manufacturing cost is low and so on.

Owner:SHANGHAI LIANGZI HUIJING ELECTRONICS CO LTD

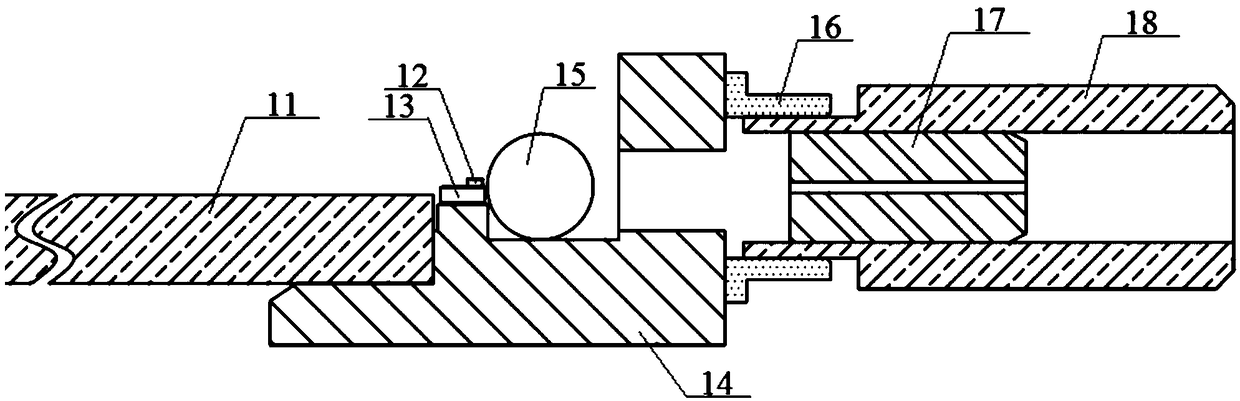

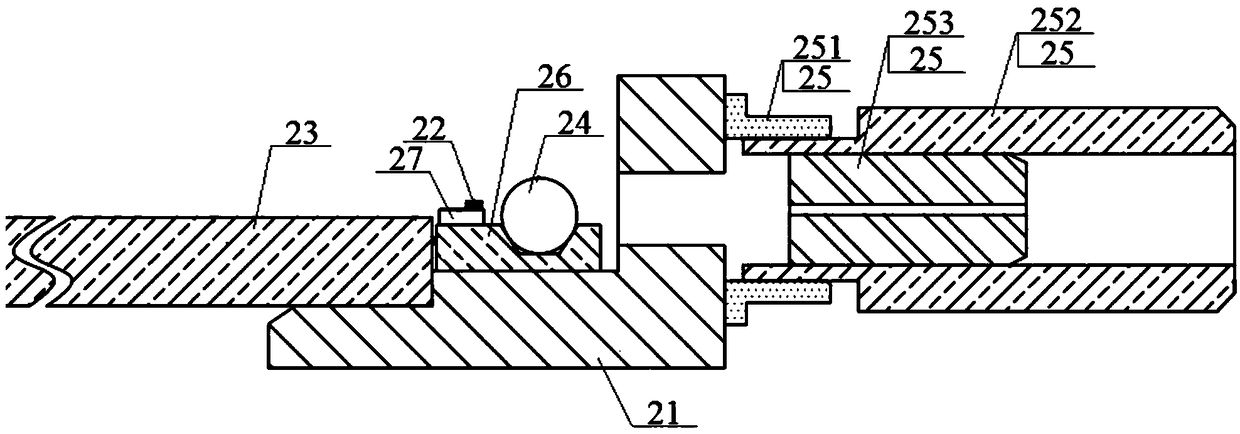

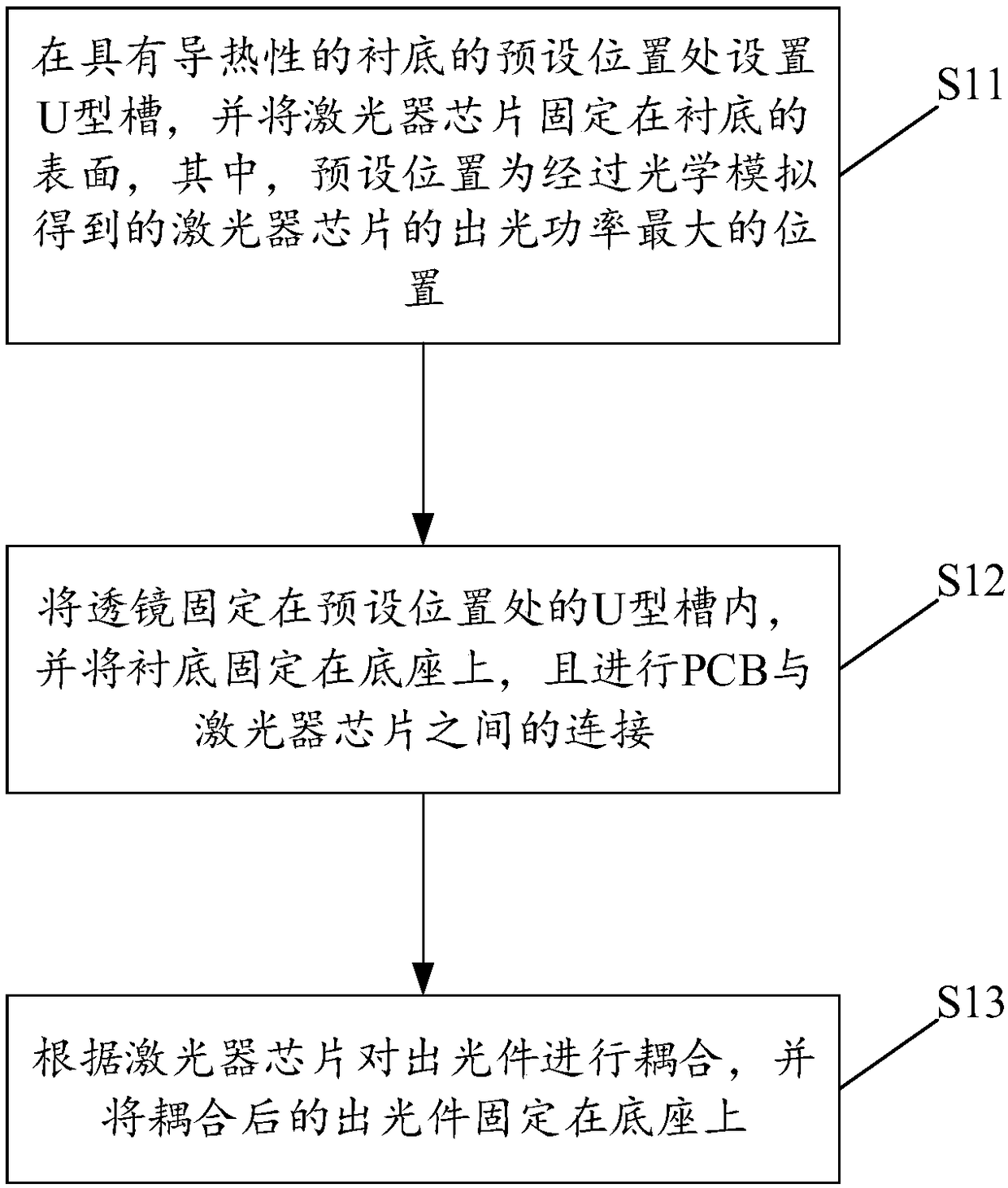

Optical module, optical module emitting optical device and preparation method thereof

PendingCN109358398AIncrease light output powerThermally conductiveCoupling light guidesOptical ModuleCoupling

The invention discloses an optical module, an optical module emitting optical device and a preparation method thereof. The optical module emitting optical device comprises a base, a laser chip, a PCBconnected to the laser chip, a lens, and a light-emitting member connected to the laser chip and fixed on the base. The invention further comprises a substrate fixed on the base and provided with a U-shaped groove at a preset position. The substrate has thermal conductivity. The laser chip is fixed on the surface of the substrate. The lens is fixed in a U-shaped groove at a preset position. The preset position is a position where the optical power of the laser chip obtained by optical simulation is the largest. The above technical solution disclosed in the present application can directly fixthe lens in the U-shaped groove of the substrate without coupling and fixing the lens by the automatic lens coupling machine and the laser welding machine. Therefore, the coupling complexity of the optical module emitting optical device can be reduced, the preparation efficiency of the optical module emitting optical device can be improved, and the manufacturing cost of the optical module emittingoptical device can be reduced.

Owner:DONGGUAN MENTECH OPTICAL & MAGNETIC CO LTD

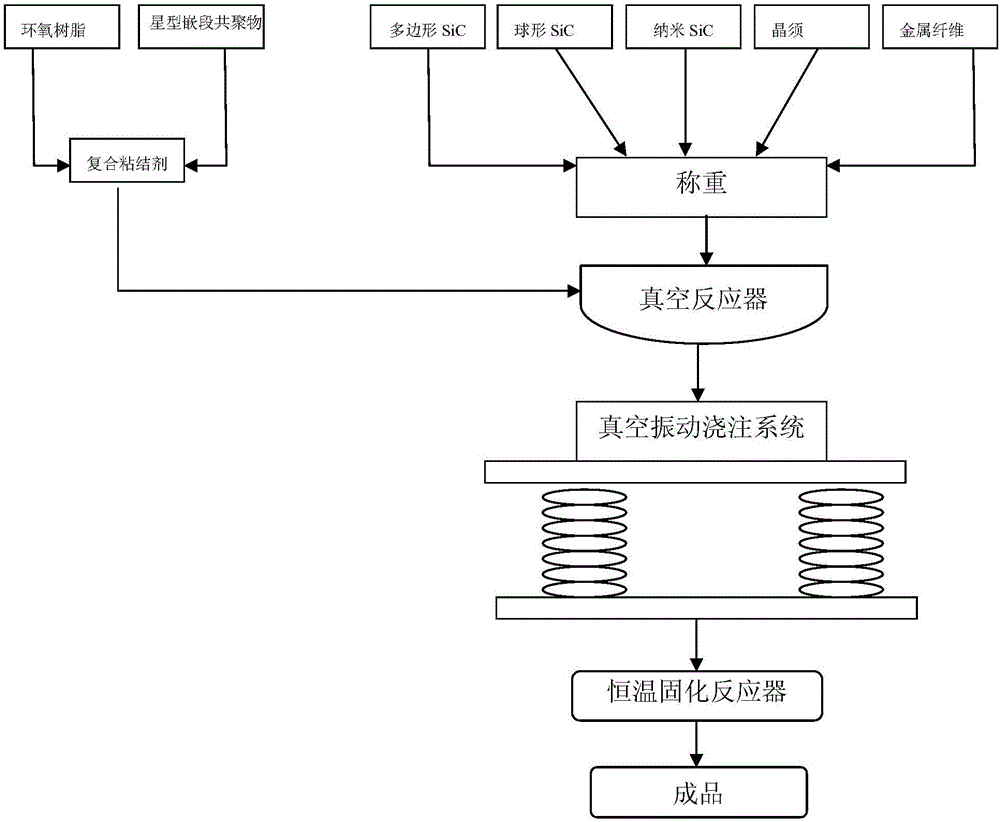

Dispersion strengthened ceramic composite material and preparation method thereof

The invention discloses a dispersion strengthened ceramic composite material and a preparation method thereof and belongs to the field of composite materials and engineering ceramic materials. The composite material is formed by compounding silicon carbide of different forms, calcium sulfate whiskers, metal fibers and a composite adhesive, wherein the silicon carbide of different forms, the calcium sulfate whiskers, the metal fibers and the composite adhesive are interweaved and distributed. The preparation method comprises the following steps: 1) uniformly mixing the silicon carbide, the calcium sulfate whiskers, the metal fibers and the composite adhesive under vacuum conditions so as to prepare slurry; 2) vibrating and casting the slurry in a mold under vacuum; and 3) curing the mold and cast slurry, thereby obtaining the dispersion strengthened ceramic composite material. According to the method disclosed by the invention, the problems of wear and corrosion of highly corrosive solid-liquid media on pump materials during transport are effectively solved, and the prepared composite material has the characteristics of high metal matrix adhesion force, high hardness, wear resistance, corrosion resistance, oxidation resistance, thermal shock resistance and the like and is applied to the fields of chemical industry, pharmacy, papermaking and the like.

Owner:NORTHEASTERN UNIV +1

Piston ring

InactiveCN102748468AHigh temperature resistantFriction-resistantPiston ringsFiberTemperature resistance

The invention discloses a piston ring, which comprises the following compositions in percentage by mass: 4-6% of carbon fiber powder, 13-17% of glass fiber, 9-11% of copper powder, 2-3% of molybdenum disulfide, and the balance of polytetrafluoroethylene powder. The piston ring disclosed by the invention has the advantages that: as the carbon fiber is adopted for replacing traditional graphite, as a special fiber consisting of carbon elements, the carbon fiber, besides having the properties of high temperature resistance, friction resistance, electric conduction, heat conduction and corrosion resistance and the like of common carbon materials, also has significant anisotropy, and shows a high strength and a small specific gravity along the axial direction of the fiber, therefore, the carbon fiber has a high specific strength, and plays a significant role in increasing the strength of the piston ring, the strength is more than 150 kg / cm2, and the resisted high temperature can reach more than 300 DEG C.

Owner:江苏新氟隆塑胶有限公司

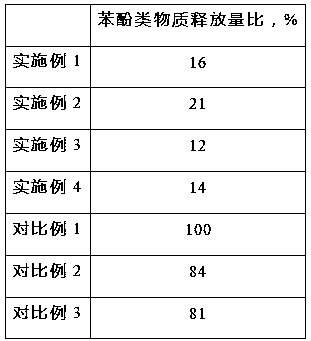

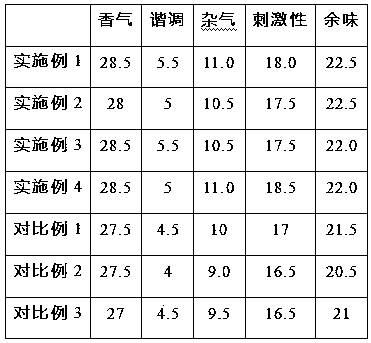

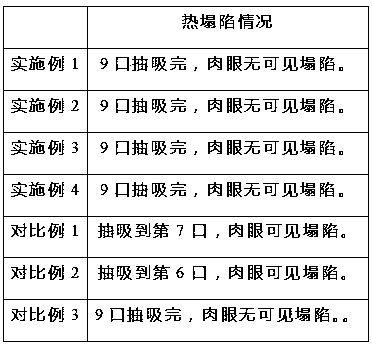

Graphene-based composite filter material applied to filter stick for cigarette

ActiveCN109875112AEnhance sensory experienceImprove suction qualityTobacco smoke filtersFiberPaper based

The invention relates to a graphene-based composite filter material applied to a filter stick for a cigarette and belongs to the technical field of novel filter sticks for cigarettes. According to thegraphene-based composite filter material, firstly graphene oxide is subjected to partial reduction, and the graphene oxide and a spice plant fiber is subjected to crosslinking treatment and casting into a graphene-based thin film; the graphene-based thin film is subjected to hydrophobic modification, a compound system with a plane extraction extract and spice for the cigarette is used for conducting perfuming coating on the graphene-based thin film, the graphene-based thin film is bonded and compounded with a filter stick paper base material for the cigarette or a polylactic acid thin film, and the graphene-based composite filter material applied to the filter stick for the cigarette is prepared. The prepared graphene-based composite filter material has good adsorption slow-release performance, heat conduction performance and hydrophobic performance in the cigarette smoking process, the sensory quality of the main stream smoke can be improved, the problem of thermal collapse of the filter stick for the cigarette is solved, the phenol compound in the main stream smoke can also be obviously lowered, and the quality of the cigarette product is comprehensively improved.

Owner:CHINA TOBACCO YUNNAN IND

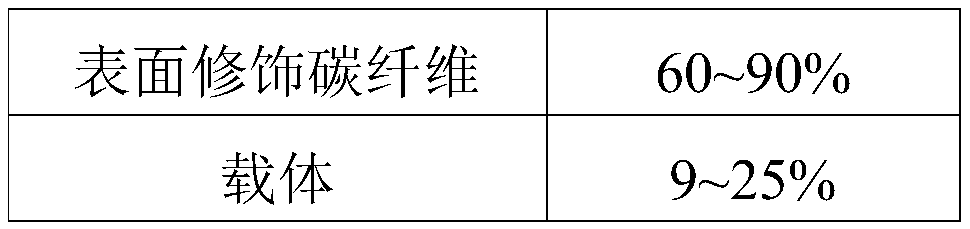

High-filling surface finish carbon fiber master batches for plastic reinforcement and preparation method thereof

The invention discloses a preparation method for high-filling surface finish carbon fiber master batches for plastic reinforcement. The preparation method comprises the steps of (1) raw materials areprepared; (2) a carrier and an additive in the step (1) are thrown in a high-speed mixer for 5-7 min, and a mixture A is obtained; (3) the mixture A in the step (2) is added into a double-threaded rodextruder through a main feeding port, surface finish carbon fiber in the step (1) is added into the double-threaded rod extruder through a lateral feeding port, and the double-threaded rod extruder extrudes the surface finish carbon fiber out in a melting mode; (4) through stretching, cooling, master batch cutting and drying treatment, the high-filling surface finish carbon fiber master batch products are obtained. The invention provides the high-filling surface finish carbon fiber master batches for plastic reinforcement. The problems that in the preparation process of the high-filling surface finish carbon fiber master batches, the interface bonding force between the master batches and the carrier is poor, and the dispersion of the master batches is uneven are solved, and a material hasconductive and heat-conducting properties.

Owner:SHANGHAI UNIV

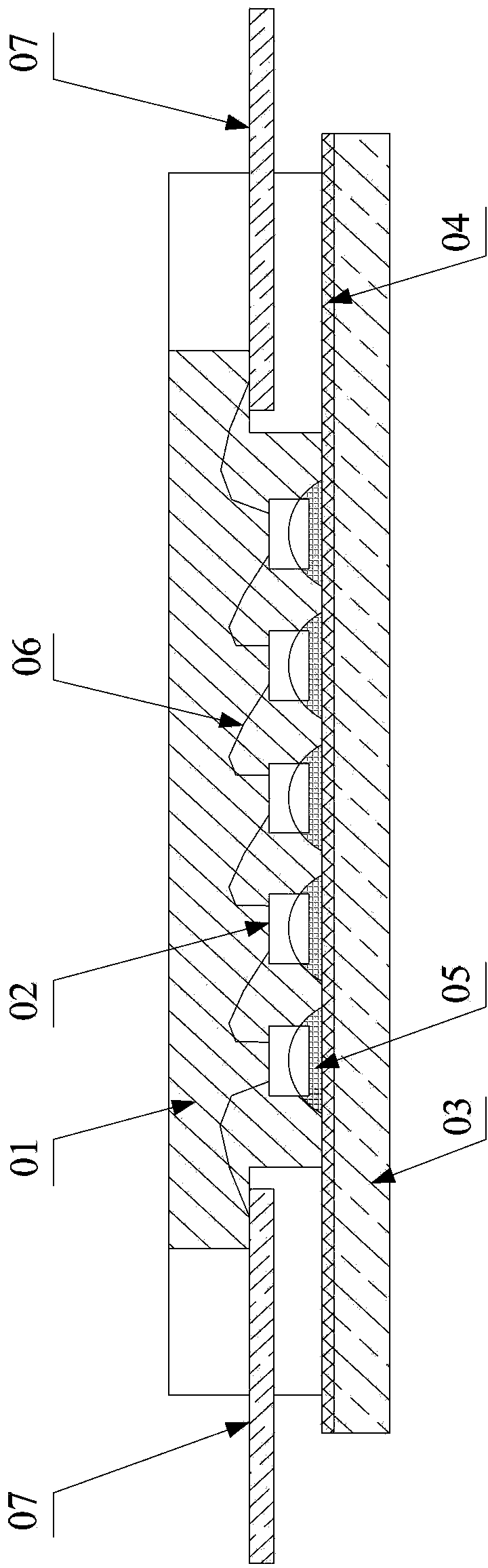

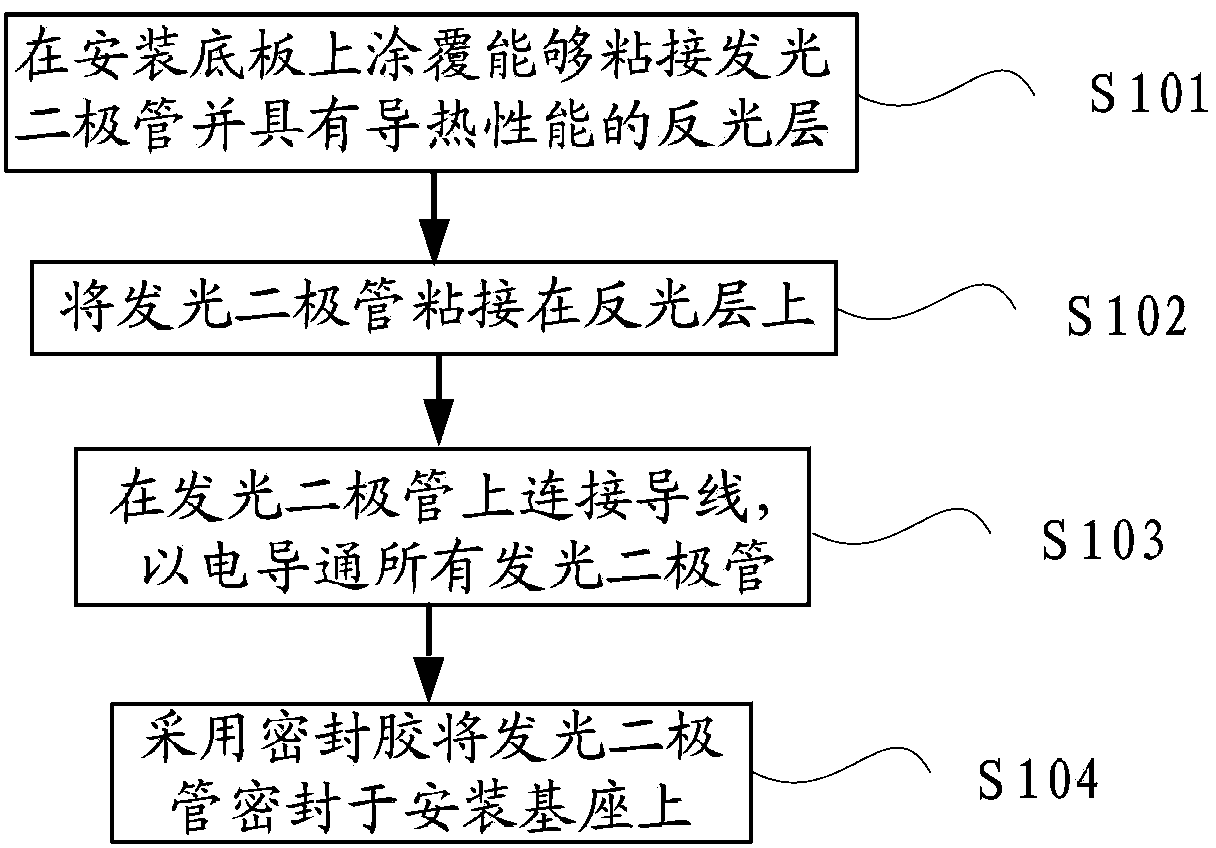

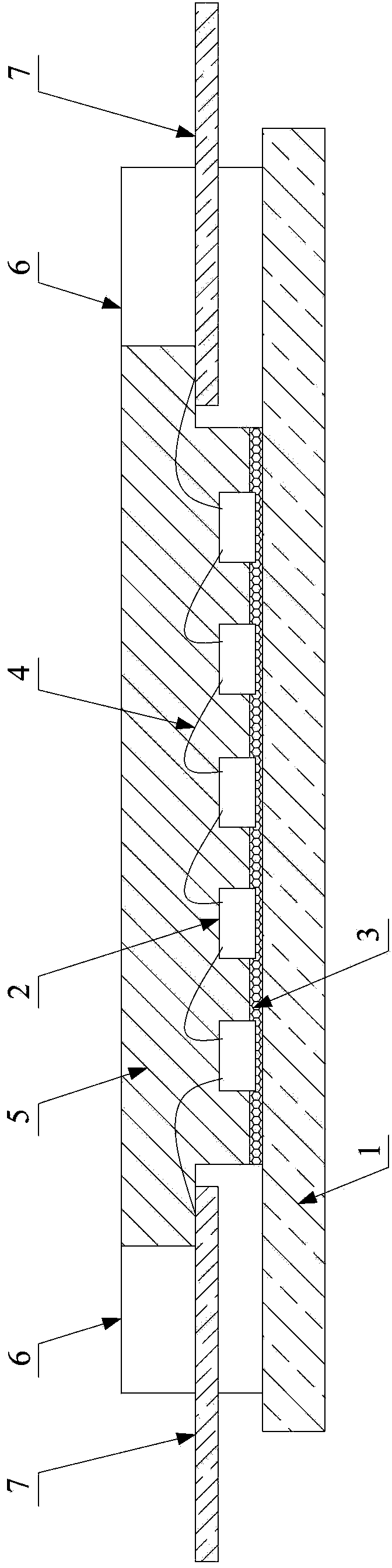

Light-emitting diode packaging process

InactiveCN104347605AGuaranteed uniform conductionConsistent heat dissipationSolid-state devicesSemiconductor devicesAdhesiveMultiple point

The invention provides a light-emitting diode packaging process. The method comprises the following steps that a light-reflecting layer which can be stuck to a light-emitting diode and has heat conductivity is coated on a mounting bottom plate; the light-emitting diode is stuck to the light-reflecting layer; a lead is connected to the light-emitting diode, so that the light-emitting diode is electrified; the light-emitting diode is sealed on the mounting bottom plate by a sealing adhesive. According to the light-emitting diode provided by the invention, an electroplated layer and a crystal solidifying adhesive are substituted by the light-reflecting layer; due to the fact that the top surface and the bottom surface of the light-reflecting layer are planes and are coating layers which are in an integral form, and the coating thickness and the uniformity of the top surface and the bottom surface are more precisely controlled than the crystal solidifying adhesive which are arranged at multiple points and are stacked, the radiating effect of a plurality of light-emitting diodes stuck to different positions and having the same thickness on the light-reflecting layer are consistent by precisely controlling the thickness of the light-reflecting layer, the quality difference of different lamp beads is reduced even avoided, and the quality consistency of different lamp beads is further improved.

Owner:惠州市华阳光电技术有限公司

Insulated heat conduction film for lithium ion battery

InactiveCN107799675AImprove securityInsulationSecondary cellsJackets/cases materialsDiethylene glycol monobutyl etherDibutyl sebacate

The invention discloses an insulated heat conduction film for a lithium ion battery. The insulated heat conduction film is used for covering the surface of a battery body. The insulated heat conduction film is prepared from the following ingredients including alkylolamide polyethylene oxide ester, inositol hexaphosphate, diethylene glycol monobutyl ether, dilauryl thiodipropionate, sodium secondary alkyl sulfonate, sodium hexametaphosphate, dibutyl sebacate, polytetrafluoroethylene, styrene and dibutyl phthalate. The insulation heat conduction film has dual attributes of insulation and heat conduction, and covers the surface of the battery body; the safety performance of the battery can be effectively improved.

Owner:SUZHOU GREEN POWER TECH CO LTD

Formula and process of environment-friendly epoxy resin glue

InactiveCN111849363AWill not polluteWith low temperature resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyPotassium persulfate

The invention relates to the technical field of glue, particularly to a formula and a process of environment-friendly epoxy resin glue. The epoxy resin glue is prepared from the following raw materials in parts by weight: 55-80 parts of epoxy resin, 8-15 parts of sodium dodecyl benzene sulfonate, 6-12 parts of potassium persulfate, 2-3 parts of a preservative, 2-5 parts of dibutyl phthalate, 2-5 parts of nanometer silicon dioxide, 4-6 parts of glass fibers, 3-6 parts of a low-temperature-resistant anti-freezing agent, 4-10 parts of a modifier, 2-4 parts of a quick drying agent, 5-8 parts of anodor masking agent, 2-4 parts of scented water and 220-280 parts of deionized water. By arranging the low-temperature-resistant anti-freezing agent, the modifier, the quick-drying agent, the odor masking agent, the scented water and the glass fibers, the epoxy resin glue has a quick solidification function, corrosion resistance, high-temperature resistance, low-temperature resistance and the like, and is environmentally friendly.

Owner:今程粘胶(惠州)有限公司

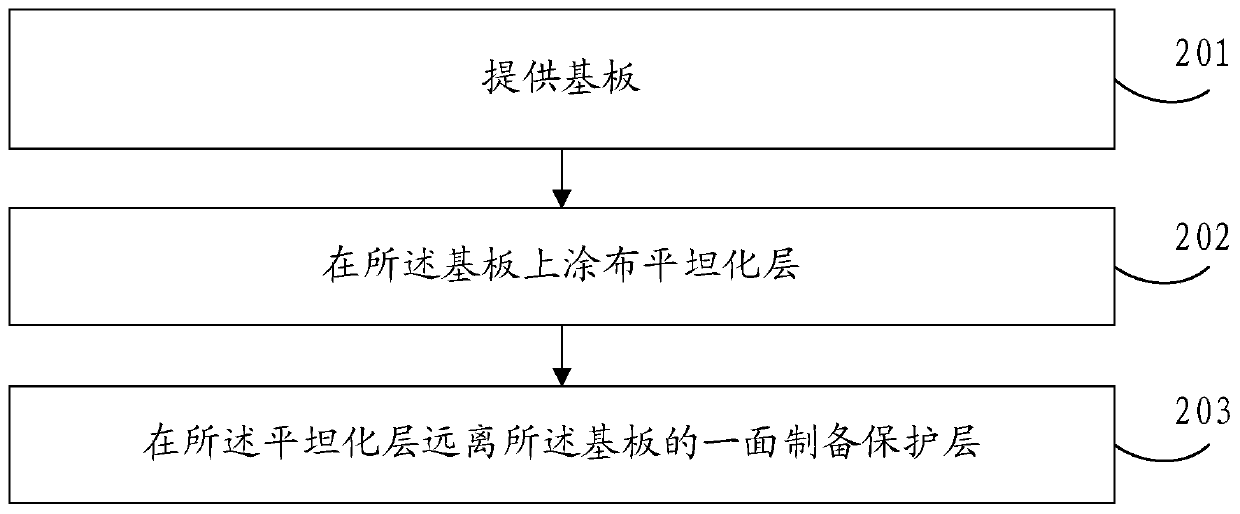

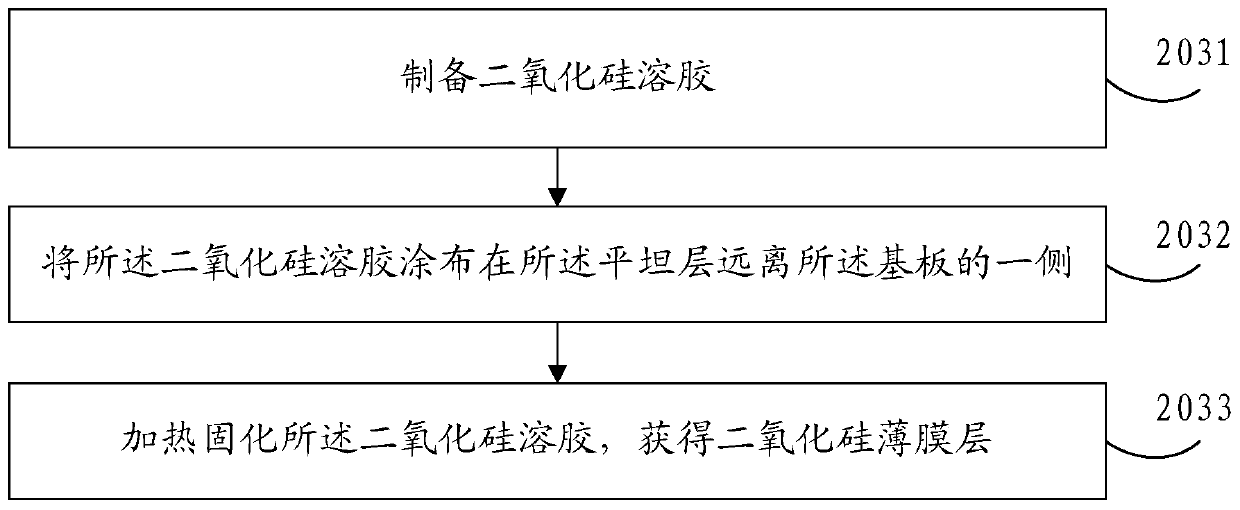

Display device and preparation method thereof

PendingCN110208977AImprove glow qualityEffective protectionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceWhite light

The embodiment of the invention provides a display device. The display device comprises a substrate, a planarized layer covering the substrate and a protective layer covering one side, deviating fromthe substrate, of the planarized layer; and the protective layer has thermal conductivity, transparency and insulativity. According to the embodiment of the invention, the protective layer with the thermal conductivity, transparency and insulativity covers the planarized layer, the planarized layer can be effectively protected, the planarized layer is prevented from deforming in a follow-up preparation process, loss of blue light in white light of the planarized layer is reduced, color temperature is increased, the white light is improved, and light emitting quality of the display device is improved.

Owner:BOE TECH GRP CO LTD +1

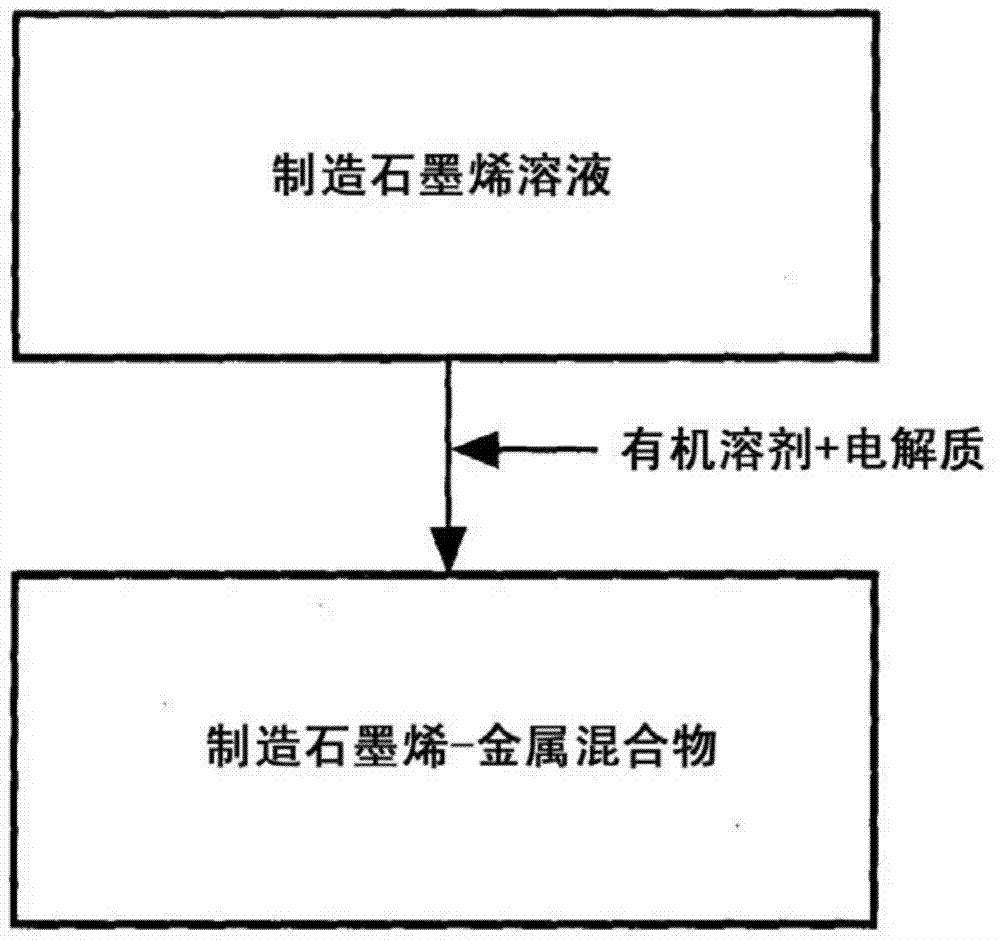

Method for preparing of composition for surface treatment of metal, surface-treated steel sheet using same and method for manufacturing same

InactiveCN104755656AConductiveCorrosion resistanceElectrophoretic coatingsMetallic material coating processesSheet steelElectrophoresis

The present invention relates to a method for preparing a composition for the surface treatment of metal, a surface-treated steel sheet which is surface-treated with the composition and to a method for manufacturing the surface-treated steel sheet. To accomplish the objective, the method of the present invention may involve the preparing of a composition for the surface treatment of metal using graphene having superior characteristics such as corrosion resistance, electrical conductivity and thermal conductivity. The composition may be effectively coated onto the metal surface by means of electrophoresis, and thus a highly functional surface-treated steel sheet can be obtained.

Owner:POHANG IRON & STEEL CO LTD

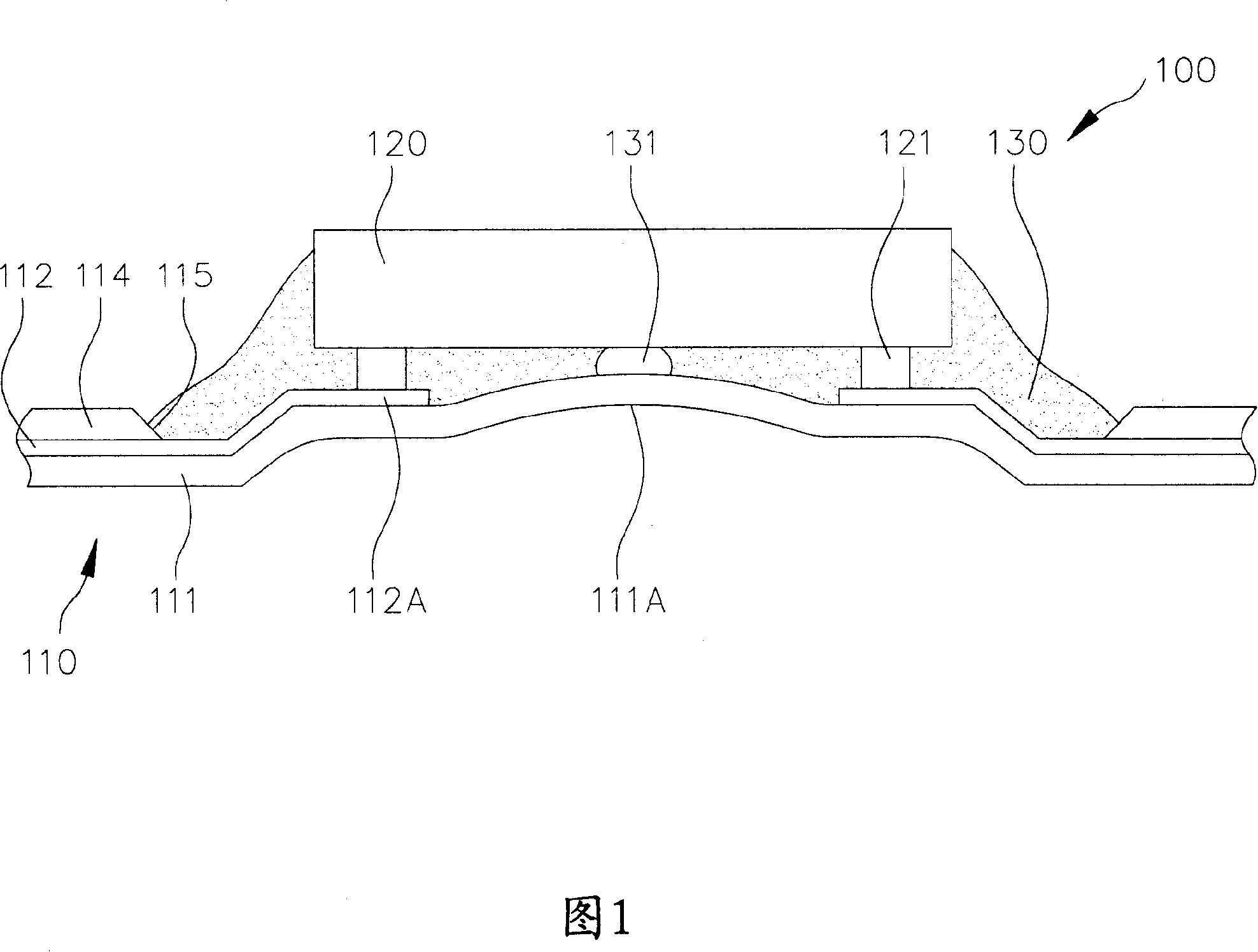

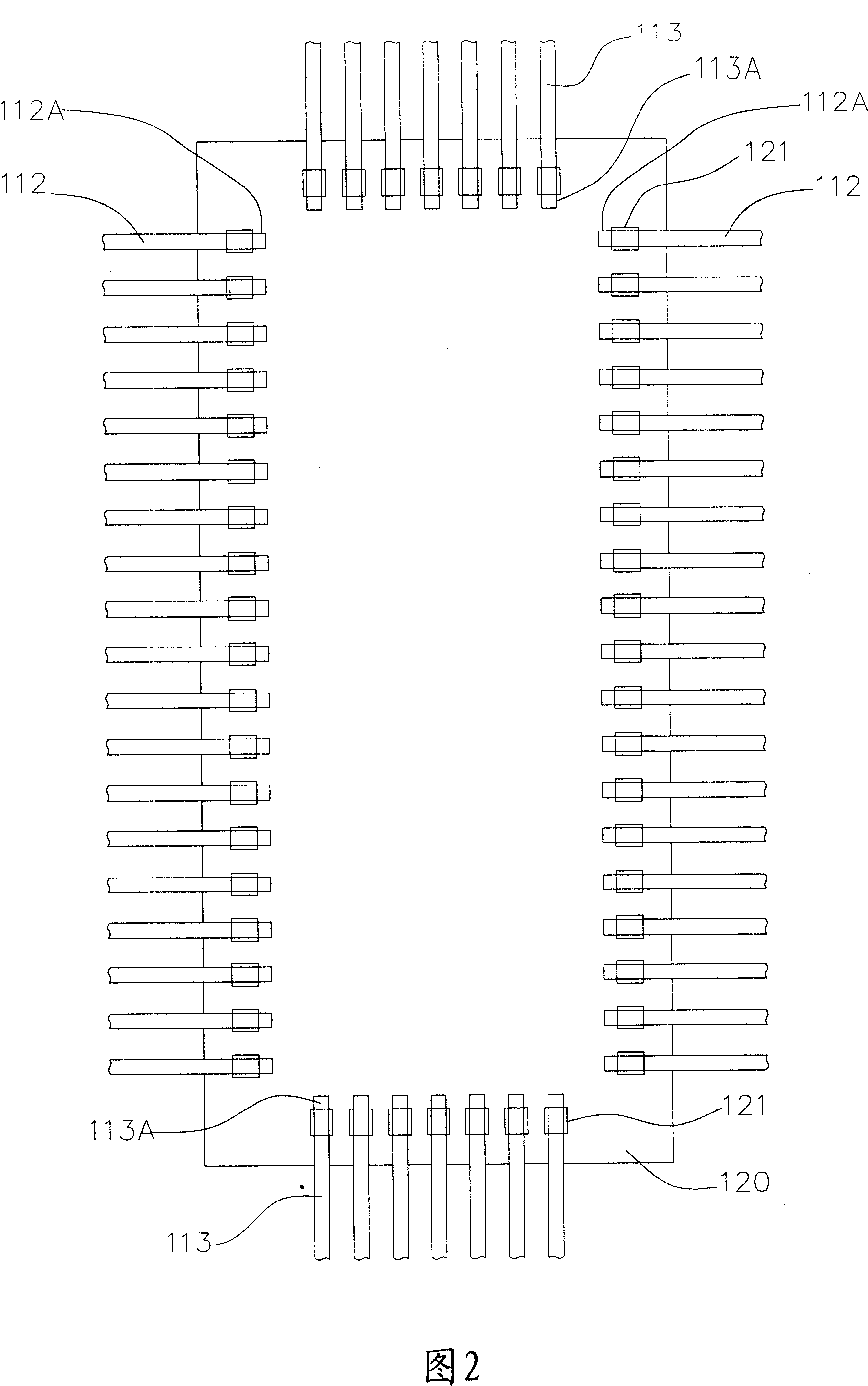

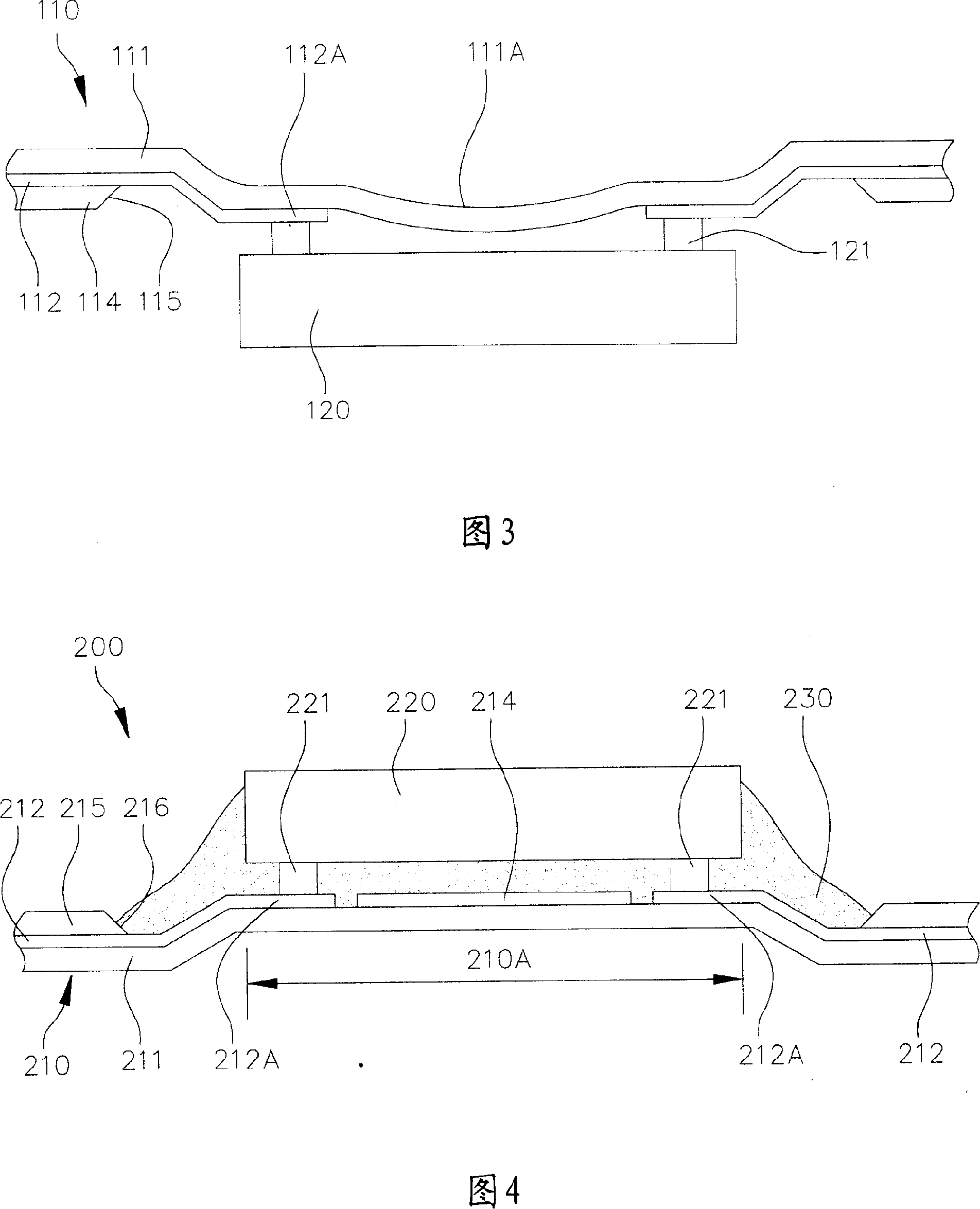

Radiating type thin-film flip-chip packaging construction

InactiveCN101131988APrevent collapseThermally conductiveSemiconductor/solid-state device detailsSolid-state devicesChip on filmColloid

The present invention relates to a heat-dissipated-and-Chip-On-Film package, and mainly includes a circuit film, a protruded wafer and a point-coated colloid. The circuit film is defined with a pair of joint regions of wafer which correspond to the wafer, and has a soft dielectric layer, even numbers of pins and a supporting copper pad. Even numbers of inner joints of the pins are arranged around the joint regions of wafer, and the supporting copper pad is formed in central of the joint regions of wafer, thus collapse of the soft dielectric layer during combination of the protrusions of the wafer and the inner joints of the pins can be avoided. Therefore, the point-coated colloid can be successfully filled between the circuit film and the wafer, and no bubble will occur.

Owner:CHIPMOS TECH INC

Stirring device for PE blown film raw material particle machining

The invention relates to the technical field of PE blown films, and discloses a stirring device for PE blown film raw material particle machining. The device comprises an outer box body; the outer boxbody is internally and rotationally connected with a stirring shaft, and the stirring shaft is fixedly connected with a stirring blade; the outer box body is internally and rotationally connected with an inner box body used for loading raw material particles, a cavity is arranged between the inner box body and the outer box body, a driving mechanism used for driving the inner box body to rotate is arranged in the cavity, and a ventilation hole communicating with the cavity is formed in the inner box body; and an air supplying box communicating with the cavity is arranged on the outer box body, a switch for opening and closing the air supplyng box is arranged on the inner wall of the outer box body, a first rack which can abut against the switch is slidably connected to the inner wall of the outer box body, and the stirring shaft is coaxially connected with a sector gear which is meshed with the first rack. According to the device, the problem of non-uniform stirring of the raw material particles in the prior art can be solved.

Owner:CHONGQING RUITING PLASTIC

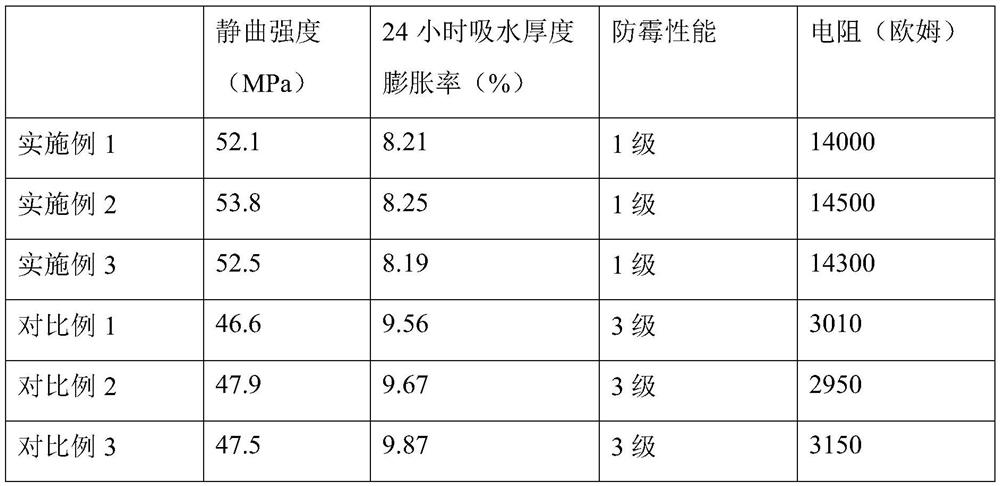

Production technology of graphene fiber board

PendingCN114074369ASimple production processImprove efficiencyFlat articlesDomestic articlesAdhesiveViscose

The invention provides a production technology of a graphene fiber board. The production technology comprises the steps: peeling and slicing raw wood; cleaning the wood chips; performing cooking; performing hot grinding to obtain wood chip fibers; putting the dried wood chip fibers into a glue applying device, and applying glue, wherein the glue comprises a graphene-based additive; drying the glued wood chip fibers; pre-pressing to obtain a formed fiber board blank; feeding the formed fiber board blank into a hot press for hot press molding; coating the upper surface and the lower surface of the fiber board blank with graphene anti-corrosion layers; enabling a flame-retardant fiber layer to be attached to the graphene anti-corrosion layer and located on the upper surface of the fiber board blank, and forming the flame-retardant fiber layer by compounding wood fibers, a flame retardant and an adhesive; attaching a nano graphene layer to the flame-retardant fiber layer, wherein the nano graphene layer is a single-layer nano graphene layer; performing cutting; and stacking and curing. The fiber board is simple in production process and high in efficiency, and has anti-corrosion and waterproof functions.

Owner:辽宁德尔新材料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com