Graphene-based composite filter material applied to filter stick for cigarette

A graphene-based, graphene-based technology, applied in applications, e-liquid filters, tobacco, etc., can solve problems such as the negative impact of smoking quality, reduce the moisture and taste of smoke, and compress the overall structure of the filter rod, so as to improve the temperature of smoke. Too high, the effect of improving the collapse of the filter rod structure and avoiding the increase of cigarette smoking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

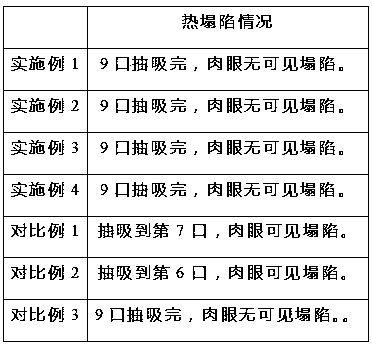

Embodiment 1

[0033] A graphene-based composite filter material applied to cigarette filter rods is made by bonding the developed graphene-based membrane material to the surface of the filter rod paper-based material in the form of upper and lower layers. Wherein, the preparation of the graphene-based film material for cigarettes comprises the following steps:

[0034] Step (1), select the specific surface area as 600 m 2 / g, graphene oxide with a sheet diameter of 5-10 μm and an average number of layers of 5-7 layers;

[0035] Step (2), reducing the graphene oxide selected in step (1) with 5% natural reducing agent vitamin C solution to obtain reduced graphene oxide with a C / O of 5.5-6;

[0036] Step (3), mix lemongrass, palmarosa and Moringa raw materials together according to the mass ratio of 1:5:3, extract twice with 80% ethanol solution that is 3 times the mass of plant raw materials, filter and combine the extracts, and separate Obtain plant extract and fiber solid slag; beat the p...

Embodiment 2

[0044] A graphene-based composite filter material applied to cigarette filter rods. The developed graphene-based membrane material is used to bond the inner surface of the uncoated tobacco flavor to the surface of the polylactic acid film in the form of upper and lower layers. Wherein, the preparation of the graphene-based film material for cigarettes comprises the following steps:

[0045] Step (1), select the specific surface area as 500 m 2 / g, graphene oxide with a sheet diameter of 7-10 μm and an average number of layers of 5-7 layers;

[0046] In step (2), the graphene oxide selected in step (1) is reduced with a 7.5% natural reducing agent chitosan and vitamin C complex (m / m=1:1) solution to obtain a C / O of 5.5 ~6 reduced graphene oxide;

[0047] Step (3), mix lemongrass, palmarosa and Moringa raw materials together according to the mass ratio of 1:6:4, then extract 3 times with 80% ethanol solution twice the mass of plant raw materials, filter and combine the extracts,...

Embodiment 3

[0054] A graphene-based composite filter material applied to cigarette filter rods. The developed graphene-based membrane material is bonded to the surface of the filter rod paper-based material in the form of upper and lower layers. Wherein, the preparation of the graphene-based film material for cigarettes comprises the following steps:

[0055] Step (1), select the specific surface area as 700 m 2 / g, graphene oxide with a sheet diameter of 5-7 μm and an average number of layers of 5-7 layers;

[0056] In step (2), the graphene oxide selected in step (1) is reduced with a 6% solution of a compound (m / m=1:5) of natural reducing agent vitamin C and gallic acid to obtain a C / O of 5.5~ 6 reduced graphene oxide;

[0057] Step (3), mix lemongrass, palmarosa and Moringa raw materials together according to the mass ratio of 1:8:7, and then extract 4 times with 80% ethanol solution with 5 times the mass of plant raw materials, filter and combine the extracts, respectively Obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com