Carbon fiber electric heating plate

An electric heating plate, carbon fiber heating technology, applied in the direction of ohmic resistance heating, electric heating devices, electrical components, etc., can solve the problems of occupying usable area, large energy consumption, limited heating area of electric heaters, etc., to achieve high electrothermal conversion efficiency, saving The effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

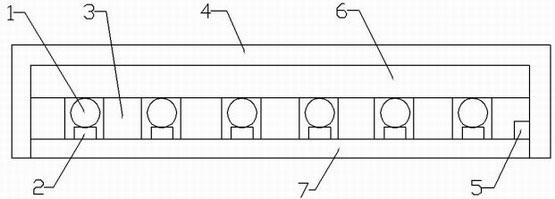

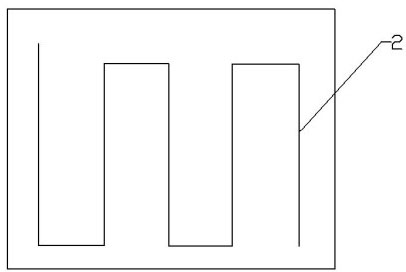

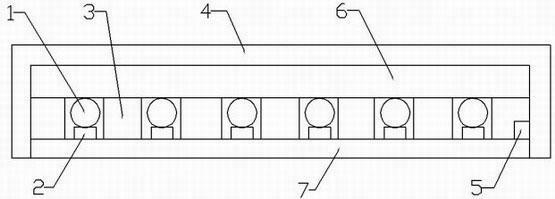

[0011] exist figure 1 , figure 2 In the schematic diagram of the carbon fiber electric heating plate shown, its main structure includes: a carbon fiber heating cable 1 is arranged in the installation groove 2, the carbon fiber heating cable 1 adopts a curved design, and a heat conducting layer 3 is arranged in the bending gap. The outer protective layer is an aluminum-magnesium alloy frame 4, the carbon fiber heating cable 1 is connected to the power supply through the electrical contact 5, and the upper and lower sides of the carbon fiber heating cable 1 are respectively laid with an insulating layer 6 and a cooling plate 7.

[0012] The working principle of the present invention: after the power is turned on, the carbon fiber heating cable starts to generate heat, the heat preservation layer prevents heat loss, the heat conduction layer prevents the occurrence of damage caused by uneven heating inside the present invention, and the heat dissipation plate efficiently and eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com