Radiating type thin-film flip-chip packaging construction

A thin-film chip-on-chip packaging and heat-dissipating technology, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of inconvenience, general products without structure, etc., and achieve the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

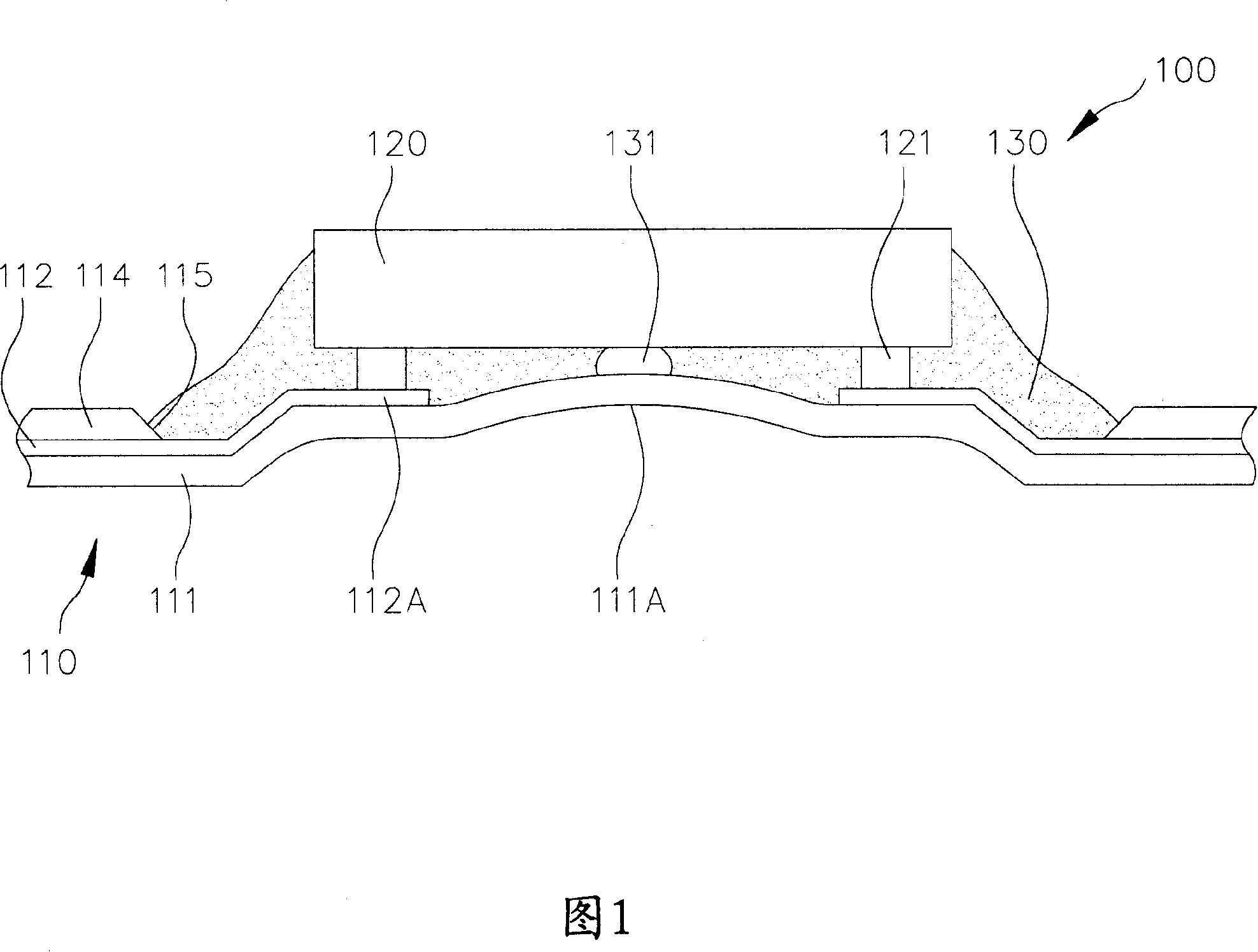

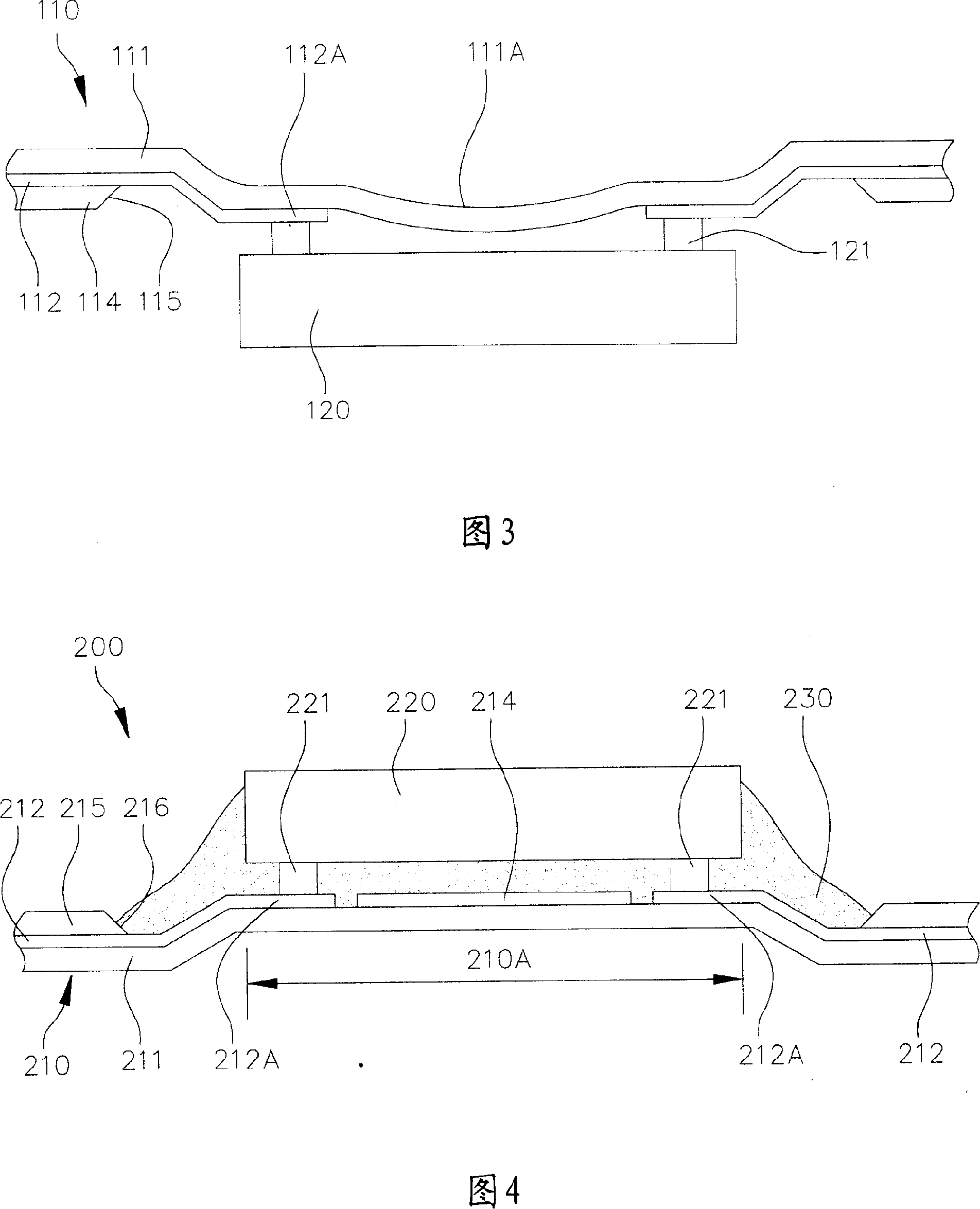

[0059] Please refer to FIG. 4 , which is a schematic cross-sectional view of a chip-on-film packaging structure according to the first preferred embodiment of the present invention. According to the first embodiment of the present invention, a chip-on-film package structure is disclosed. The chip-on-film package structure 200 mainly includes a circuit film 210 , a chip 220 and a dot-coated glue 230 . The chip 220 is bonded to the circuit film 210, and the circuit film 210 defines a flip-chip bonding area 210A corresponding to the chip 220 and having a roughly rectangular shape (as shown in FIG. 5 ).

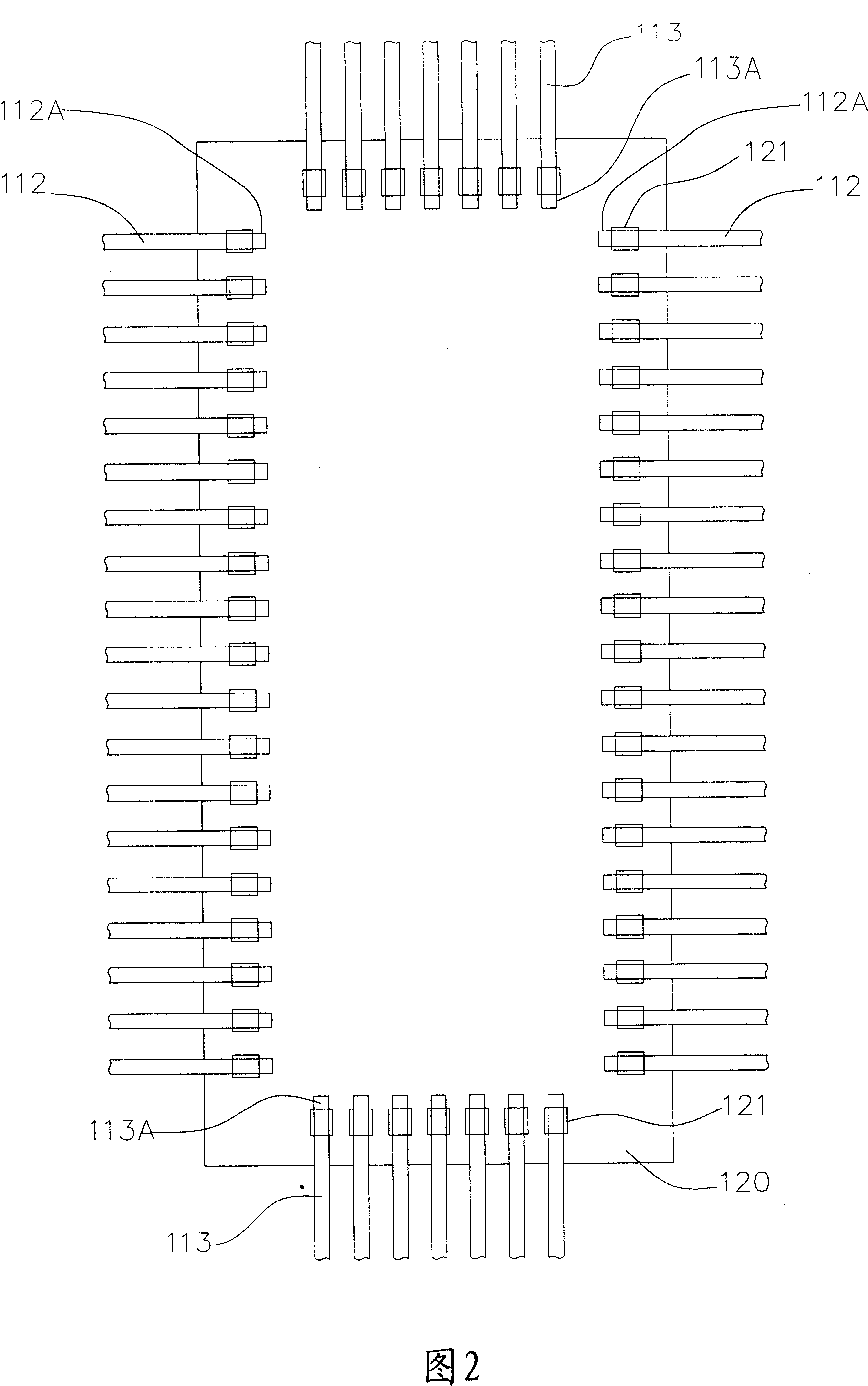

[0060] Please refer to FIG. 4 and FIG. 5 . FIG. 5 is a bottom perspective view of a chip-on-film packaging structure according to a first preferred embodiment of the present invention. The above-mentioned circuit film 210 has a soft dielectric layer 211 , a plurality of long side leads 212 , a plurality of short side leads 213 and a supporting copper pad 214 . Usually, the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com