Patents

Literature

142results about How to "Improve the sticking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

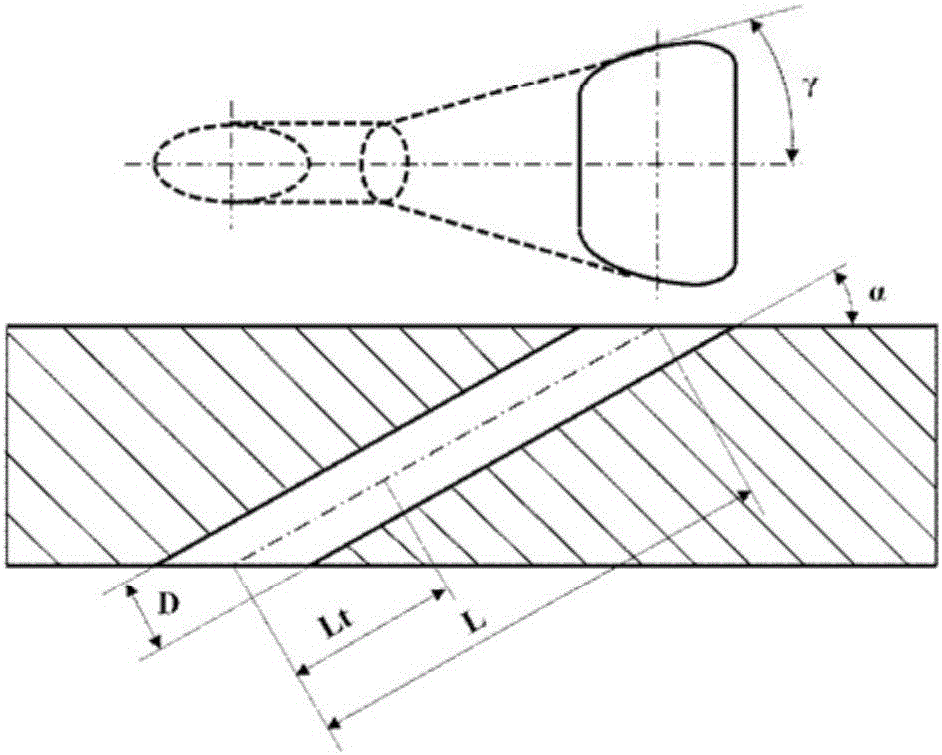

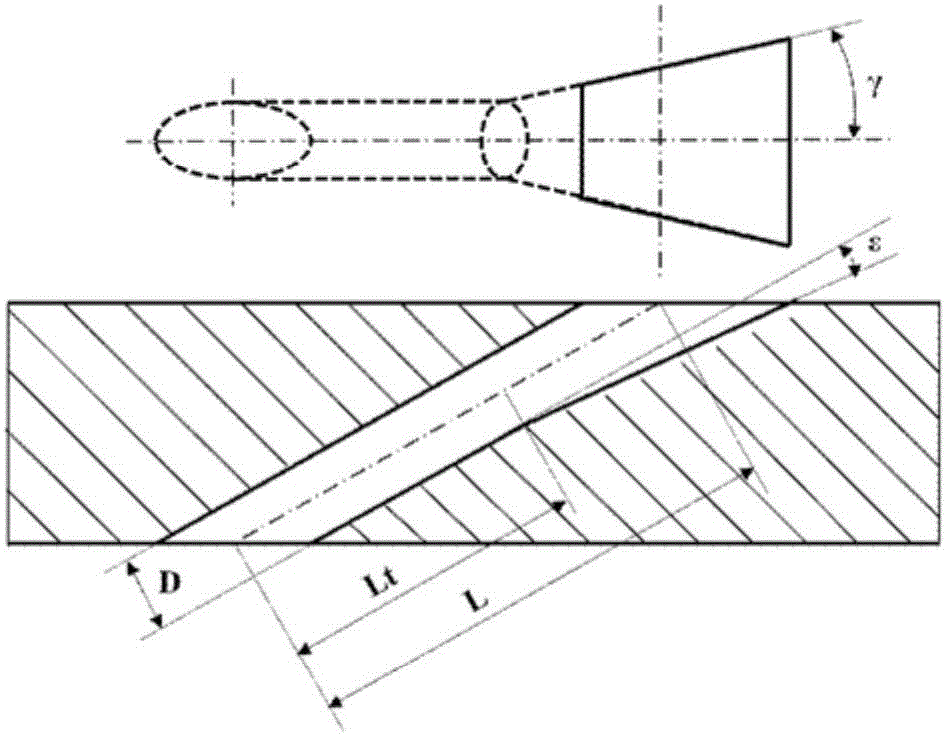

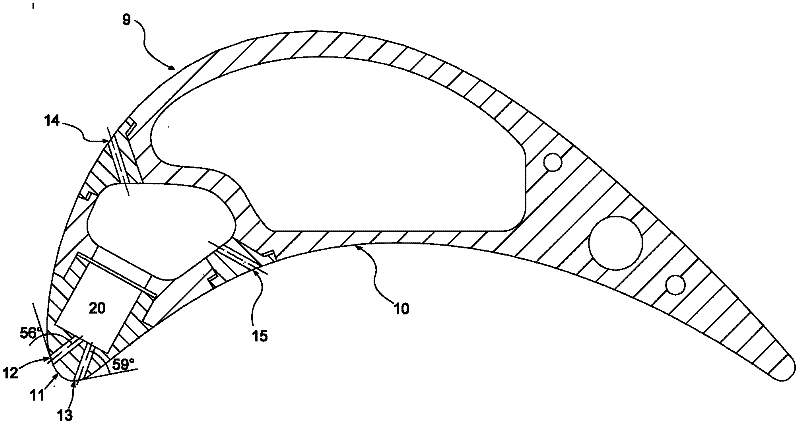

Discrete air film cooling hole shape

ActiveCN103244196AImprove cooling efficiencyReduce export momentumBlade accessoriesMachines/enginesTurbine bladeCooling effect

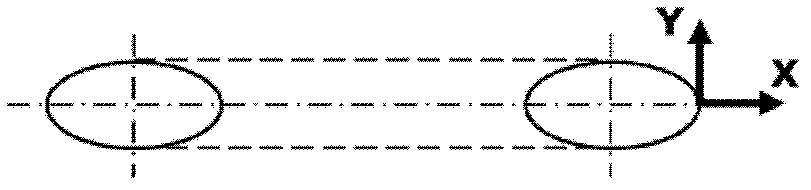

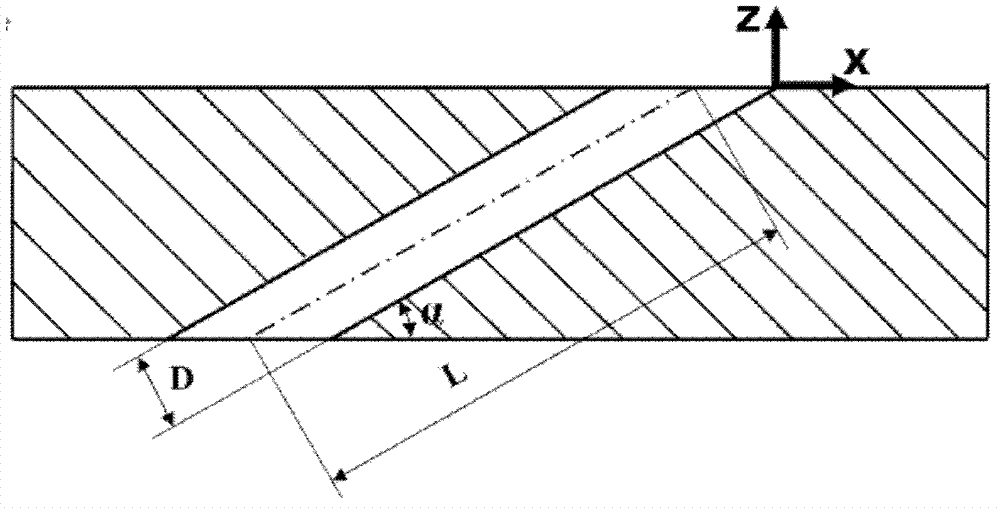

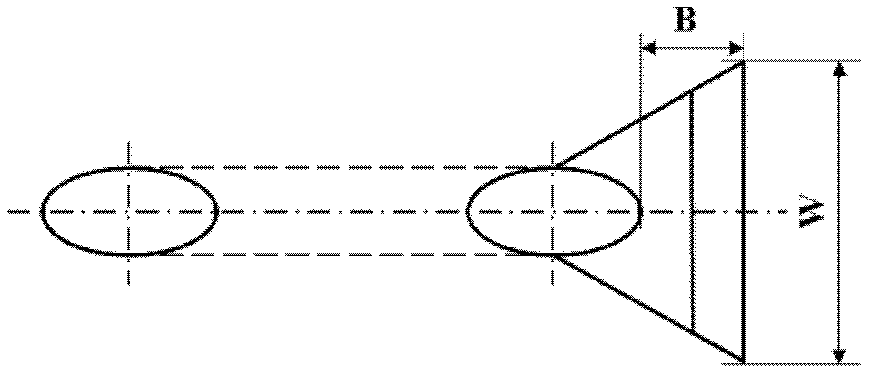

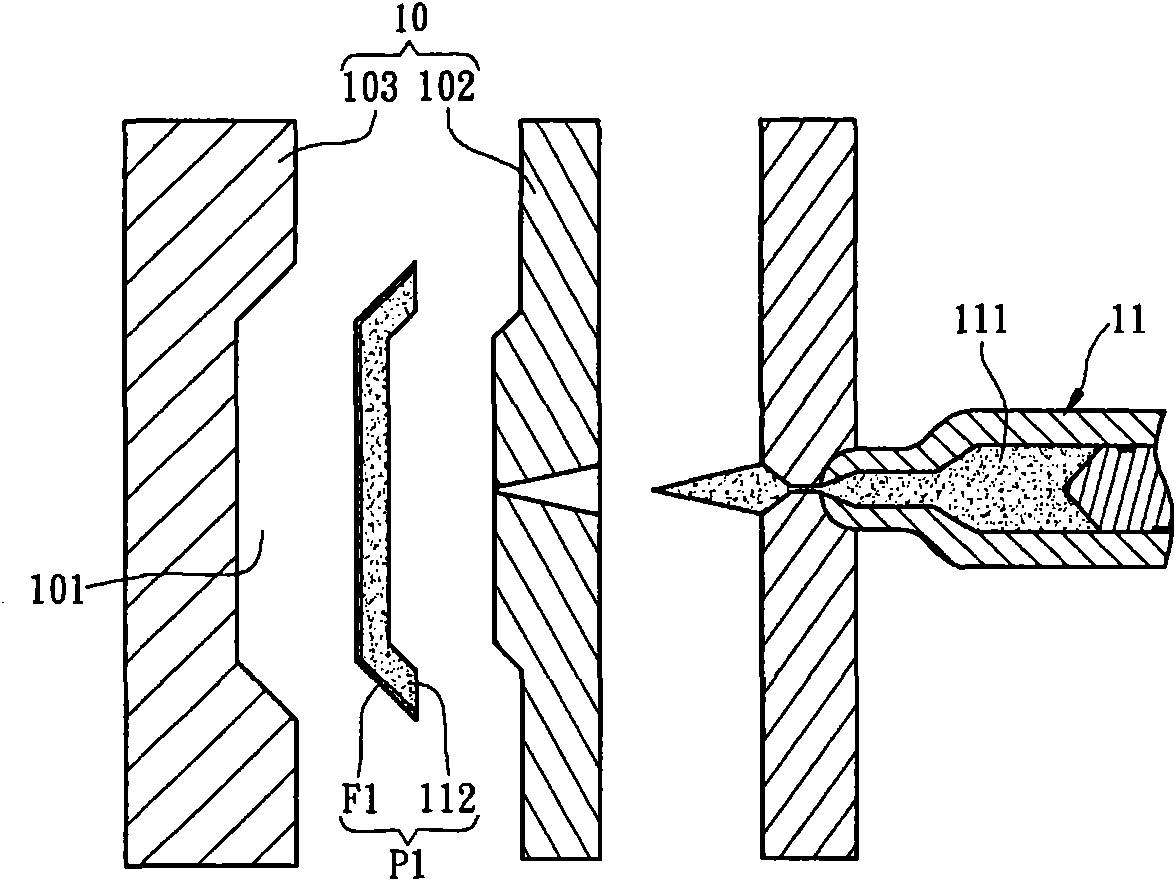

The invention discloses a discrete air film cooling hole shape and relates to the technology of gas turbines. In the discrete air film cooling hole shape, a cylindrical hole outlet sinks for a depth from a cooled surface and is provided with an expanding structure starting at the center of the cylindrical hole outlet, the expanding structure is in bilateral symmetry with a cylindrical hole central line as the symmetrical axis, the sink depth H is 0.2-0.5 times of the diameter of a cylindrical hole, the expanding width W is 3-4 times of the diameter of the cylindrical hole, and the expanding length B is 1.0-2.0 times of the diameter of the cylindrical hole. The hole shape comprises: 1) a fundamental form; and 2) an expanded boss arranged in the space between the lower stream of an air outlet edge of the cylindrical hole and an air outlet edge of the expanding structure on the basis of the fundamental form. The discrete air film cooling hole shape has the advantages of being high in crosswise average air film cooling efficiency, good in cooling effect in high blowing ratio, less in pneumatic loss and easy to achieve. The discrete air film cooling hole shape is used in air film cooling of the gas turbines and is suitable for pressure surface, suction surface and end wall discrete hole air film cooling of turbine blades.

Owner:中科合肥中型燃气轮机研究院有限公司

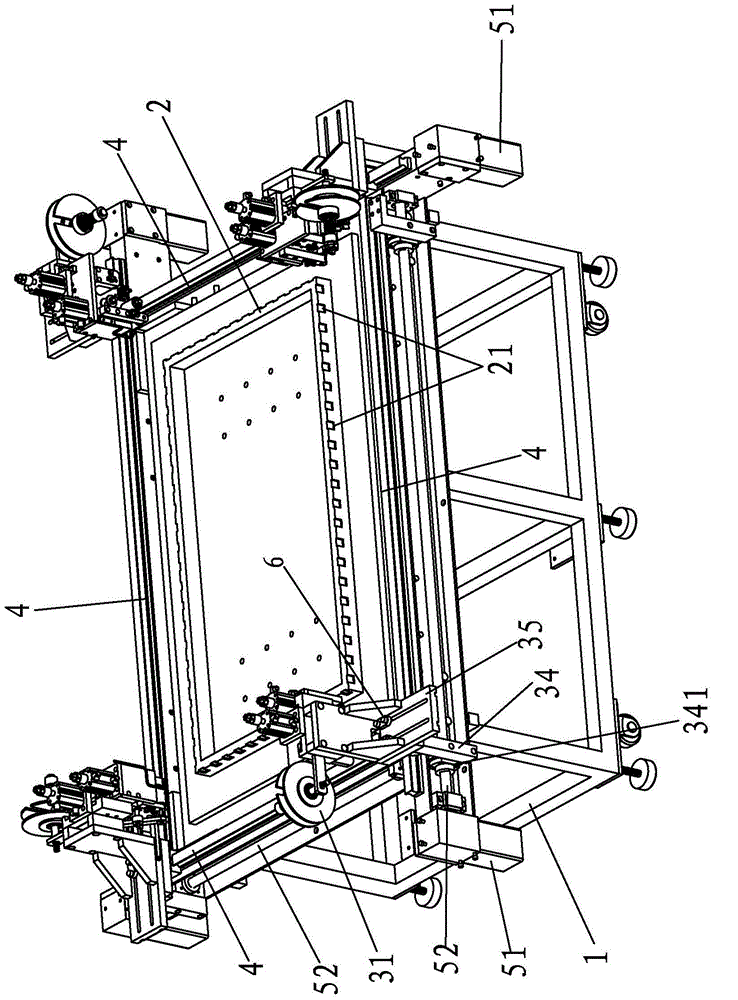

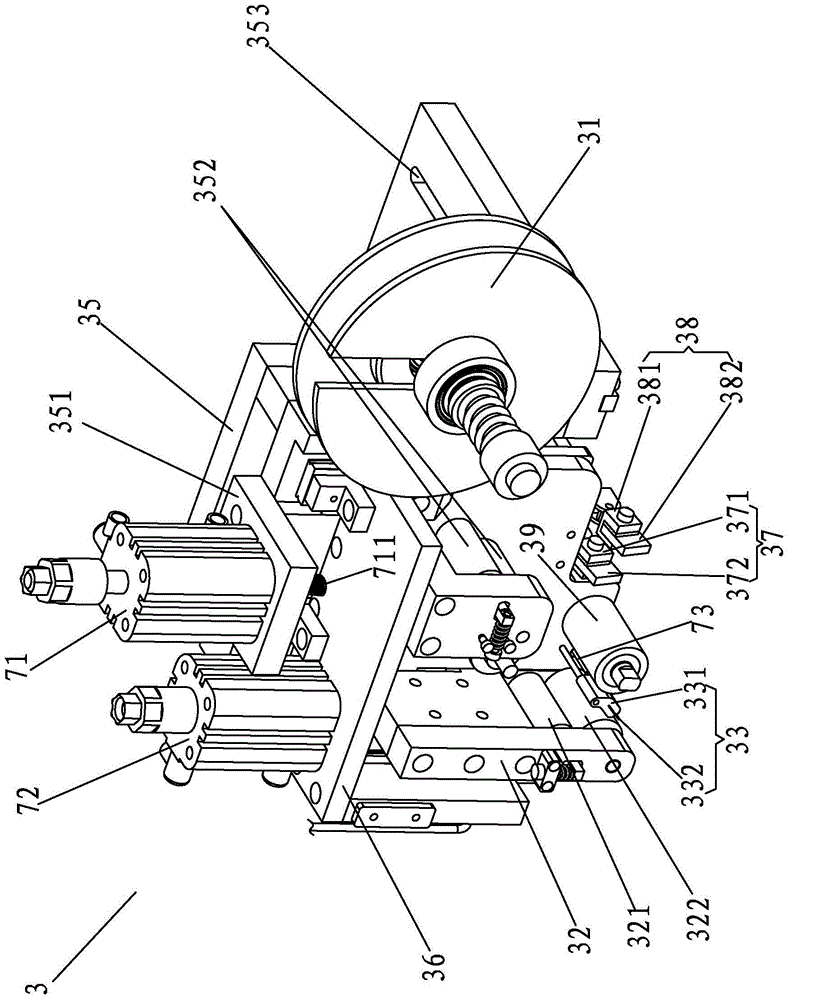

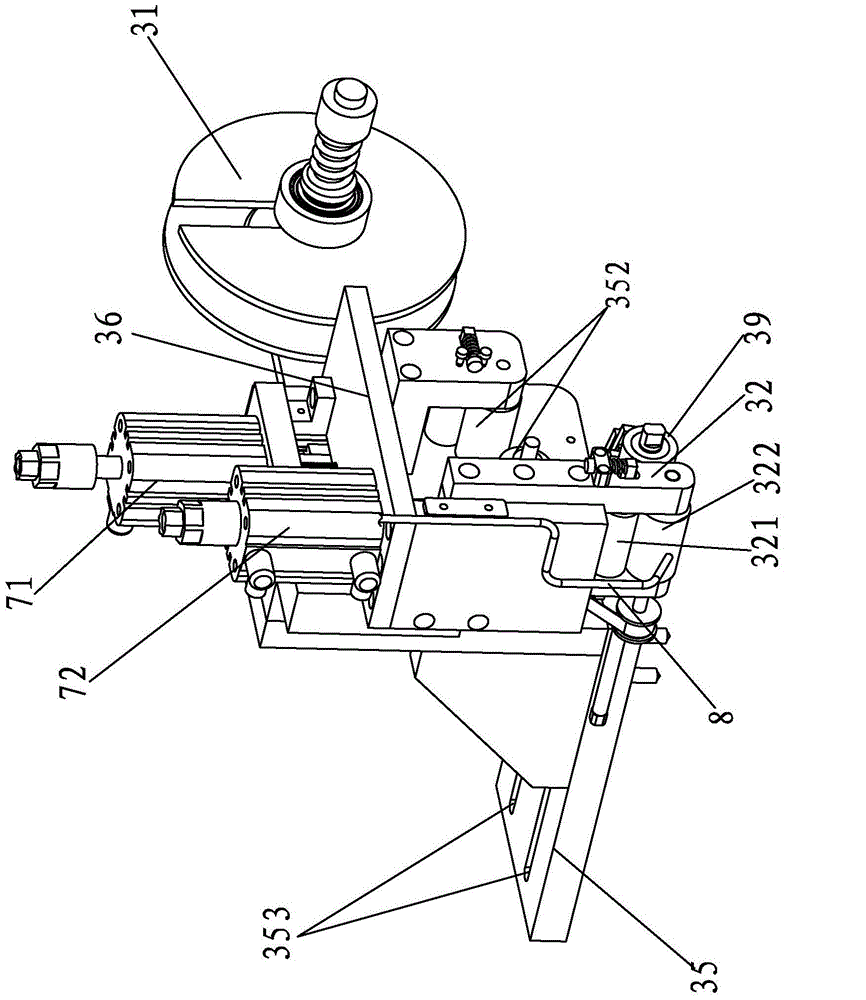

Automatic laminator

ActiveCN103978759AThe operation steps are the sameImprove efficiencyLamination ancillary operationsLaminationMechanical engineeringEngineering

The invention discloses an automatic laminator. A frame is included, and the frame is provided with a fixed table and a laminator; the laminator comprises a laminator head and a movement driving mechanism; the laminator head comprises a mounting seat and a take-up reel, a front pressure head for sticking an easy tear film on the right side of a front frame, a film cutting tool bit for cutting the easy tear film, a rectangular pressure head for folding the easy tear film extending out of the right side of the front frame downwards, and a side pressure head for pressing the easy tear film folded to the side face of the front frame on the side face of the front frame, wherein the tape reel, the front pressure head, the film cutting tool bit, the rectangular pressure head and the side pressure head are arranged on the mounting seat and at the same side; and the film cutting tool bit is behind the front pressure head, and the rectangular pressure head is between the side pressure head and the film cutting tool bit. Compared with the prior art, the automatic laminator of the invention realizes mechanical automatic lamination operation to substitute traditional manual operation, and has the advantages of high efficiency, time and labor saving, no bubble or wrinkle, and good lamination effect.

Owner:FUJIAN RICHES ELECTRONICS SCI & TECH

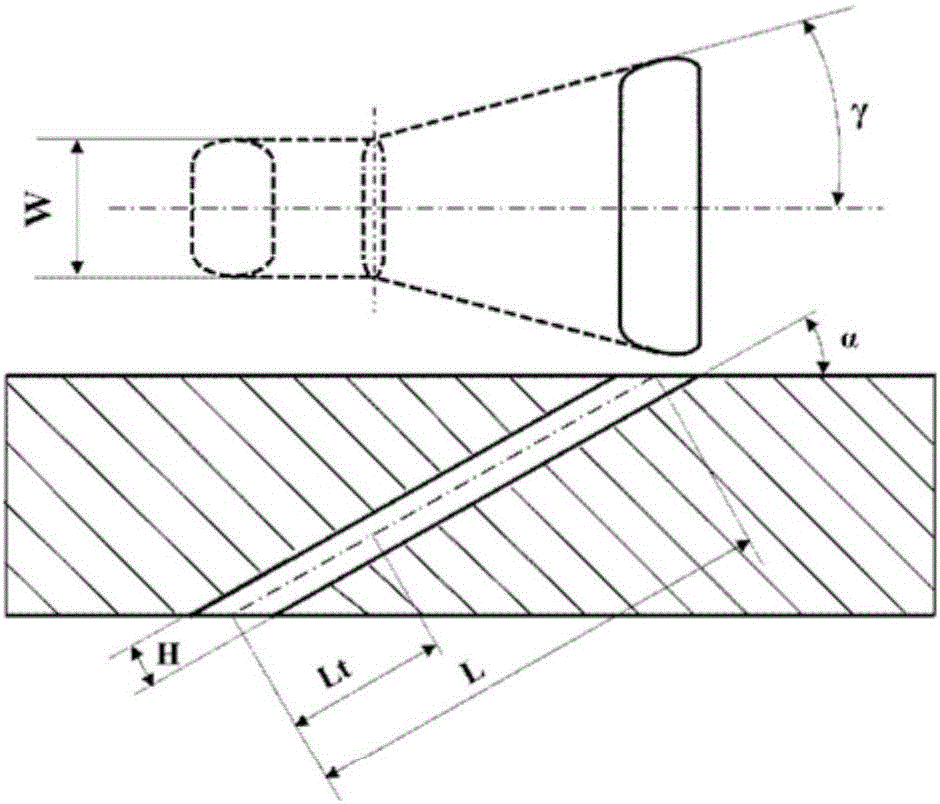

Disperse air film cooling hole structure

InactiveCN106401654AExpand the outlet widthEvenly distributedEngine fuctionsBlade accessoriesCold airTurbine blade

The invention discloses a disperse air film cooling hole structure which is used for air film cooling of bodies or upper edge plates and lower edge plates of turbine blades of a gas turbine. A cooling hole is overall of the expansion structure and is divided into a straight section and an expansion section in the cold air flow direction; the straight section is located on the cold air side; and the expansion section is located on the gas side. The cross section profile of the straight section is a flat rectangle, and each of short edges at the two sides of the flat rectangle has an inwards-contracting structure. The disperse air film cooling hole has the advantages that an air film is large in transverse width and uniform in covering, and the air film cooling effect is good; a stable reverse-kidney-shaped vortex pair is formed at the downstream position, and the air film is not prone to being separated from the wall face under a high blowing ratio; the cold air outlet velocity is high, and the pneumatic mixing loss is small; and the disperse air film cooling hole is simple in structure and can be easily achieved in actual turbine cooling blades.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

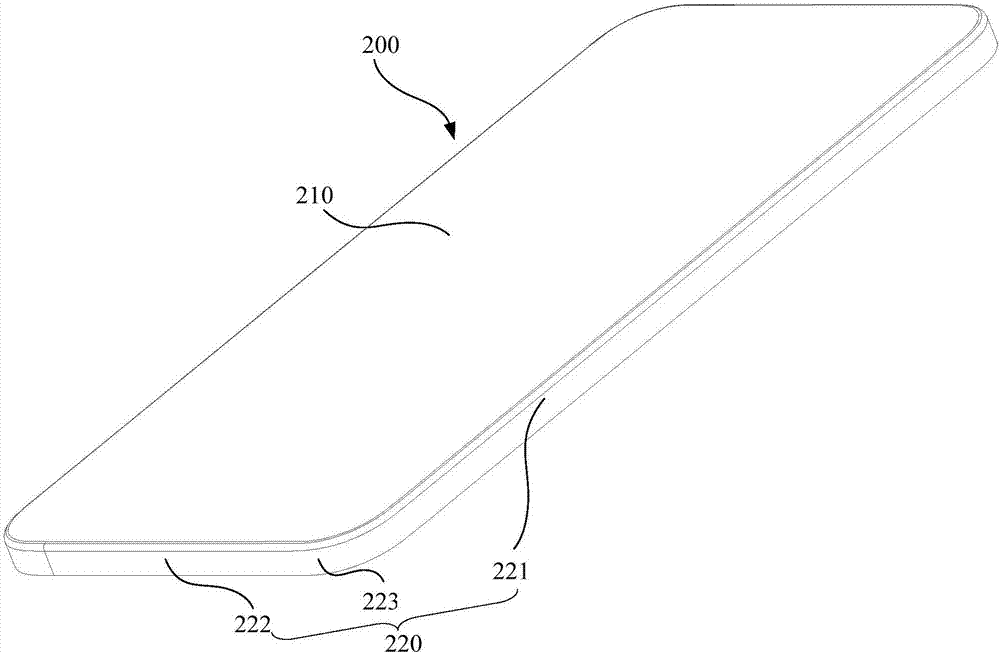

Electronic device shell, electronic device and electronic device shell processing method

ActiveCN107241882AEnsure integrityEnsure consistencyCasings/cabinets/drawers detailsCoatingsEngineeringFrame work

The invention relates to an electronic device shell, an electronic device and an electronic device shell processing method. The electronic device shell comprises a decoration sheet and a shell body, wherein the decoration sheet comprises an ink layer, the shell body is integrated formed with the decoration sheet by a mode of injection molding, the shell body comprises a cover plate part and a frame part, the frame work is arranged at an edge of the cover plate part in an encircling way, the decoration sheet is attached onto an outer surface of the cover plate part, and the ink layer covers the cover plate part. The electronic device processing method comprises the following steps of providing the decoration sheet, wherein the decoration sheet comprises the ink layer and a binding layer, and the binding layer and the ink layer are arranged in a lamination way; placing the decoration sheet in a profile cavity of an injection die, and closing the die; injecting a molten injection liquid into the profile cavity of the injection die, and forming the shell body connected with the decoration sheet after the injection liquid is cooled; and opening the die and taking out of the shell body provided with the decoration sheet. By attaching the decoration sheet onto a part of the shell body, and the appearance effect can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

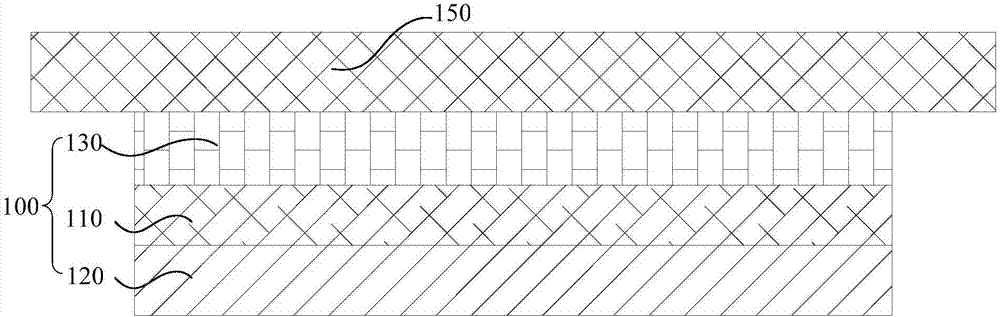

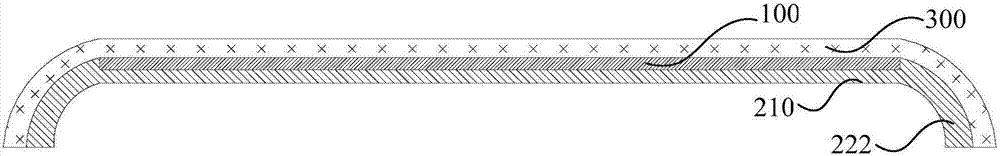

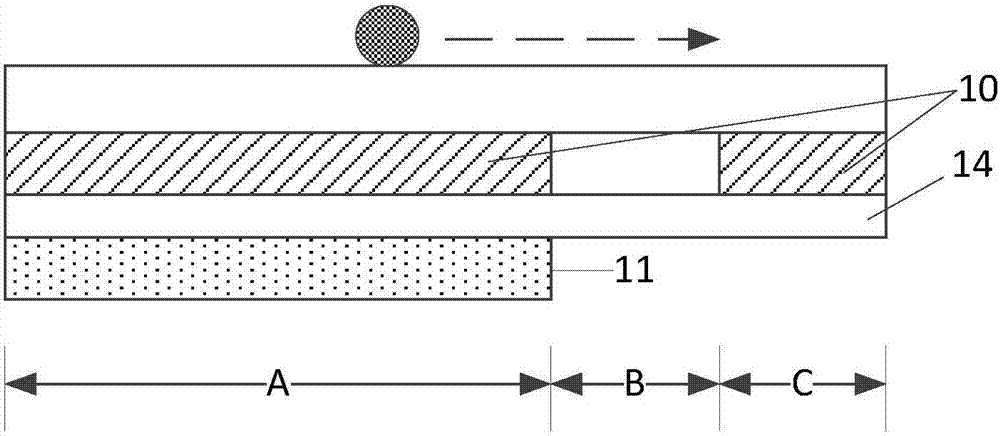

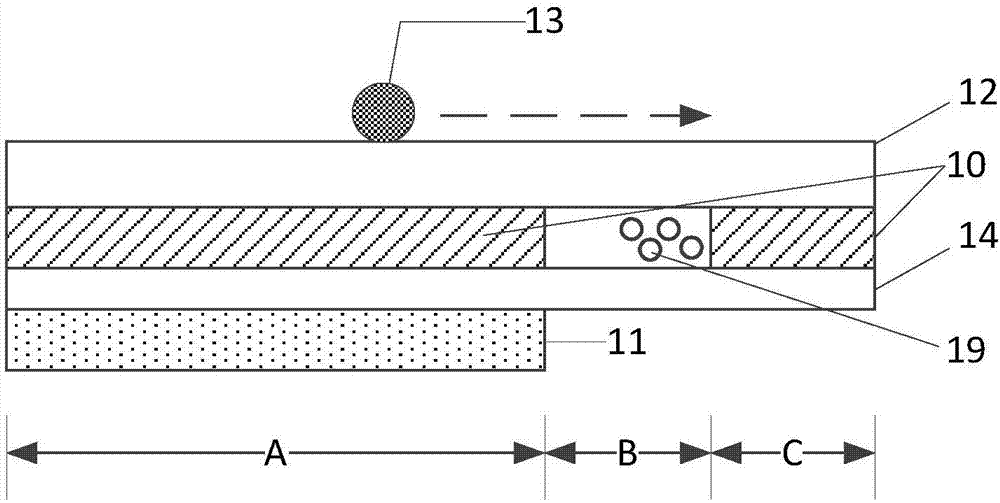

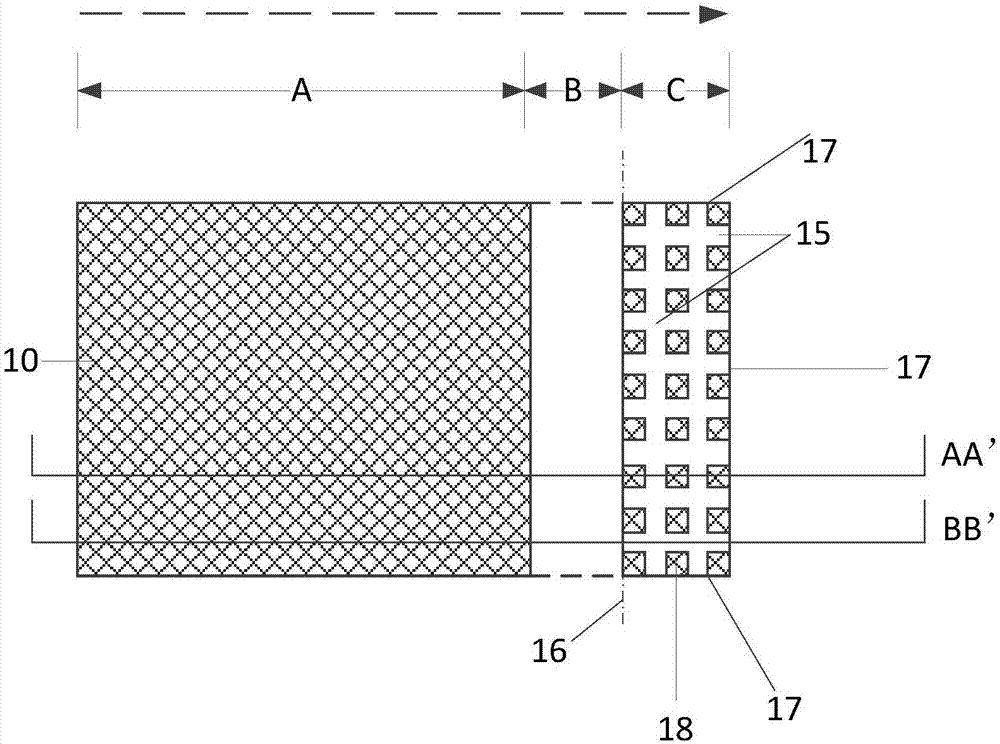

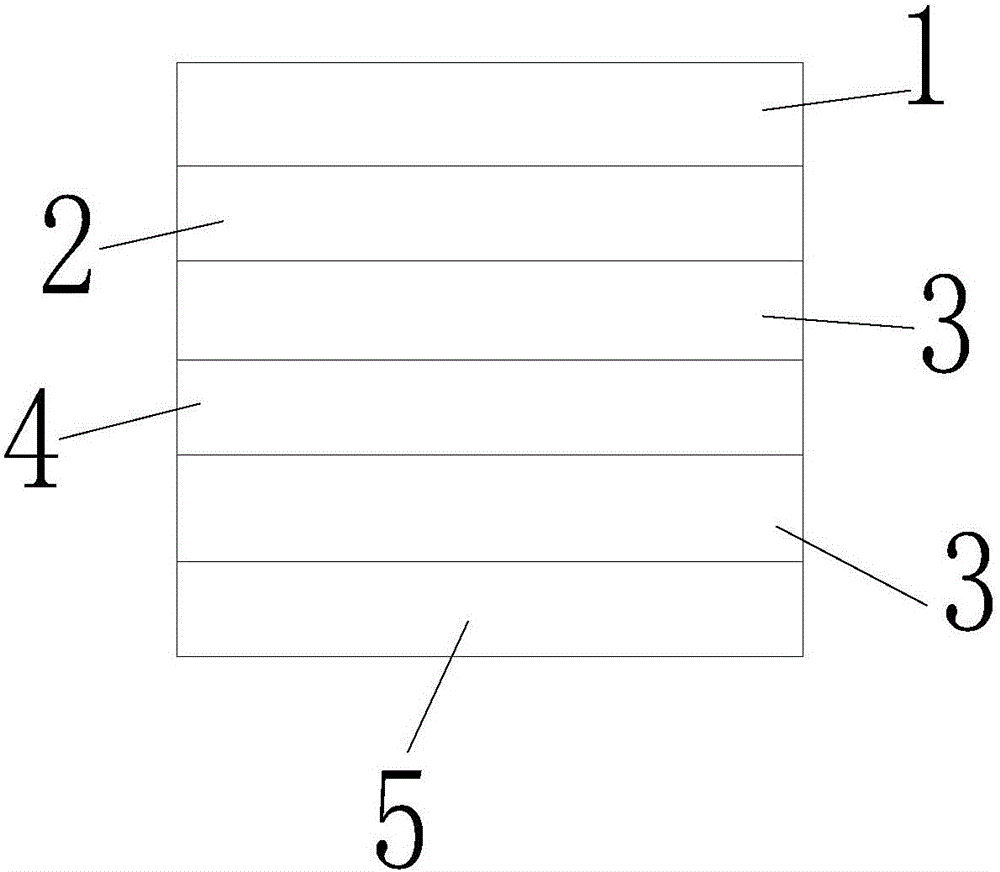

Flexible display panel and display device

ActiveCN107579169AImprove the sticking effectAvoid gatheringSolid-state devicesSemiconductor/solid-state device manufacturingTectorial membraneDisplay device

An embodiment of the invention provides a flexible display panel and a display device. The flexible display panel comprises: a first area, a second area and a third area, the second area included in aplane of the flexible display panel, with the second area arranged between the first area and the third area; a flexible substrate having a first surface and a second surface facing each other, wherein the flexible substrate covers the first area, the second area and the third area; and a first protective film positioned on a first side of the flexible substrate, wherein the first protective filmcovers not the second area but the first area and the third area, one side, far away from the flexible substrate, of the first protective film covering the third area has a groove structure, the groove structure extends from a junction of the second and third areas to a first edge of the third area except for the junction, and the first edge coincides with the edge of the first protective film. The flexible display panel and the display device according to the technical scheme allow bubbles in the second area to be discharged, and attaching effect of the protective film is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Adhesive tape used as shielding cover and application of adhesive tape

InactiveCN106010338AReduce surface resistancePlay a cooling effectMagnetic/electric field screeningFilm/foil adhesivesConductive coatingOxidation resistant

The invention discloses adhesive tape used as a shielding cover and application of the adhesive tape. When used as the shielding cover, the adhesive tape is excellent in shielding effect, thin and light. The adhesive tape comprises a release layer, a conductive adhesive layer, a fiber layer, a conductive adhesive layer, a conductive base body layer and an anti-oxidization conductive coating which are sequentially connected. The thickness of the adhesive tape is 0.03-0.3 mm. The conductive base body layer is a copper foil layer, an aluminum foil layer, a conductive fabric layer or a stainless steel layer. The thickness of the conductive base body layer is 0.005-0.25 mm. The adhesive tape can achieve electricity conductivity, shielding, grounding, anti-oxidization, heat conductivity and the like at the same time.

Owner:昆山汉品电子有限公司

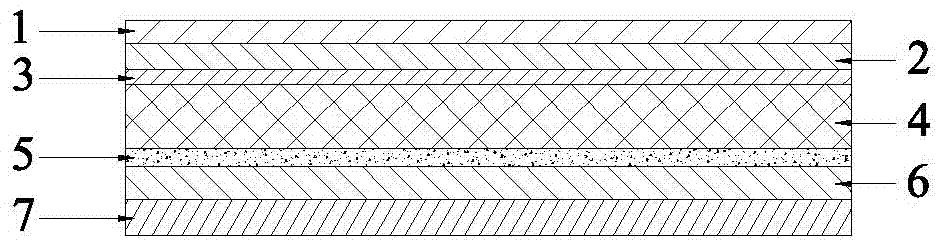

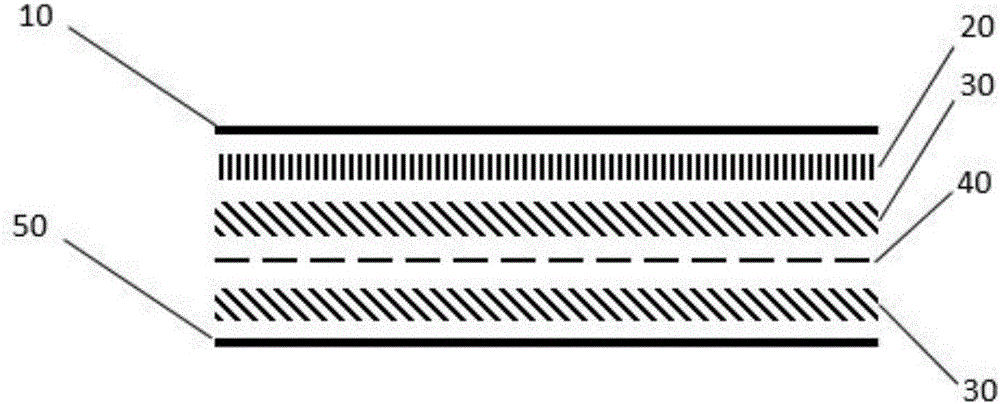

Thermoplastic polyurethane (TPU) thin film used for automobile surface protection, and preparation method of self-repair coating of TPU thin film

InactiveCN107323055AAvoid scratchesAvoid adsorptionSynthetic resin layered productsPolyurea/polyurethane coatingsPolyethylene terephthalateThermoplastic polyurethane

The invention discloses a thermoplastic polyurethane (TPU) thin film used for automobile surface protection. The TPU thin film comprises a polyethylene (PE) protective layer, a self-repair coating, an antifouling layer, an elastic TPU layer, an adhesive layer, a release layer and a polyethylene terephthalate (PET) layer which are sequentially stuck from top to bottom; the invention also discloses a preparation method of the self-repair coating. The TPU thin film used for automobile surface protection is ingenious and reasonable in structural design; in a process of production and processing and before use, the PE protective layer can effectively protect the self-repair coating; the self-repair coating can prevent the situation that traces are left on the surface of an automobile since the surface of the automobile is scratched, thus enabling the whole attractiveness of the automobile not to be influenced; the self-repair coating can realize self repair in temperature changes, thus achieving the effect of effectively protecting the surface of the automobile; the antifouling layer can prevent dust absorption so as to maintain the surface of the automobile to be clean and attractive; the elastic TPU layer is used as a carrier of the antifouling layer and the self-repair coating, is aging-resistant, not yellowed, mould-proof and damp-proof, and has a function of protecting a paint layer of the surface of the automobile. The TPU thin film used for automobile surface protection is good in comprehensive performance, excellent in protection effect and beneficial to extensive promotion and application.

Owner:DONGGUAN DINGLI FILM TECH

Termination adhesive tape and manufacture method thereof

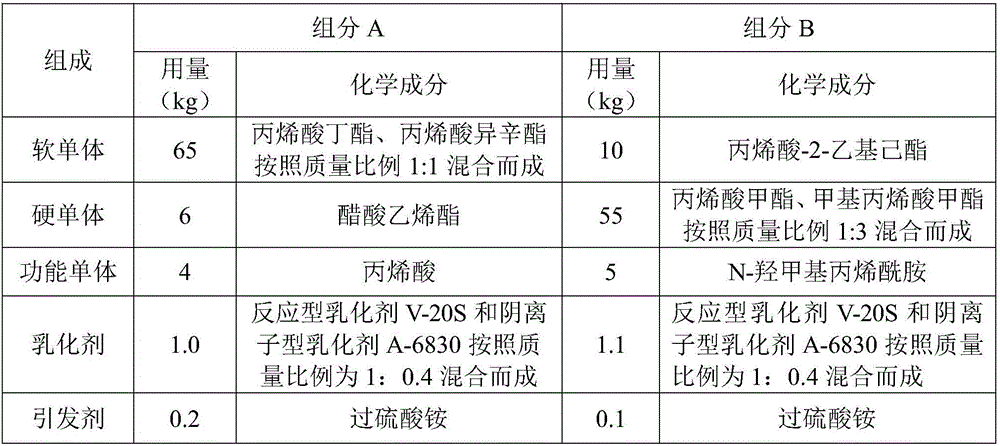

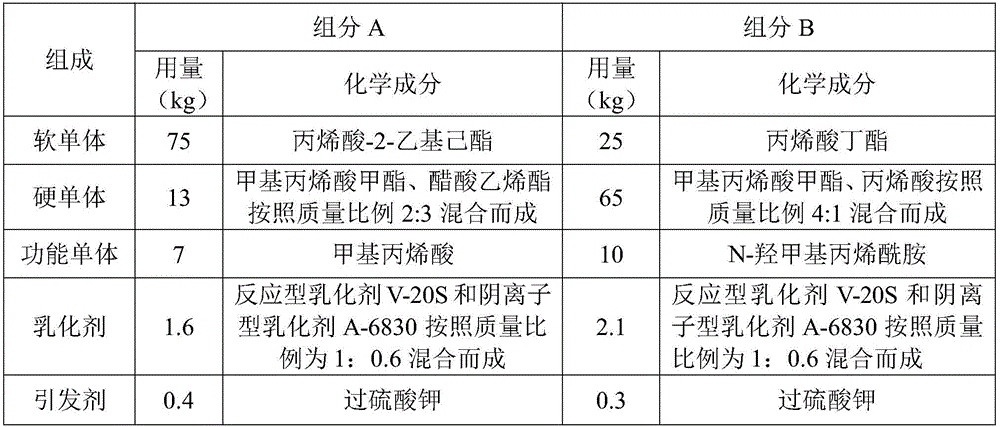

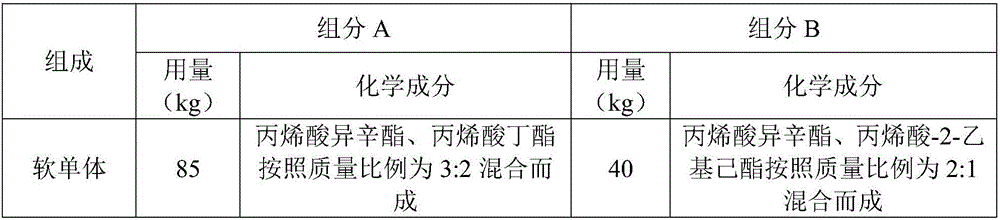

InactiveCN102250562AMeet application needsLow costFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateBenzoyl peroxide

The invention relates to the technical field of adhesive tapes, and particularly relates to a termination adhesive tape and a manufacture method thereof. The termination adhesive tape comprises a base tape and a glue layer located on the base tape, wherein the glue layer is an acrylic glue layer, which is composed of the following raw materials in parts by weight: 1-5 parts of butyl acrylate, 5-12 parts of vinyl acetate, 40-60 parts of ethyl acetate, 20-35 parts of iso-octyl acrylate, 0.5-2 parts of hydroxyethyl methacrylate, 1-3 parts of acrylic acid, 2-4 parts of toluene and 0.1-0.4 part of benzoyl peroxide. The manufacture method sequentially comprises the following steps: A. preparing the acrylic glue: titrating toluene-dissolved benzoyl peroxide used as an initiator to a mixed solution of butyl acrylate, vinyl acetate, ethyl acetate, iso-octyl acrylate, hydroxyethyl methacrylate and acrylic acid at the temperature of 80 DEG C, and ensuring the titration time of 2 hours and self-reaction time of 2.5 hours; and B. applying the acrylic glue on the base tape, sequentially drying, cooling and coiling. The termination adhesive tape provided by the invention has the advantages of low cost, beautiful appearance, simple manufacture process and good electrolyte resistance.

Owner:东莞市苏粤电子包装材料有限公司

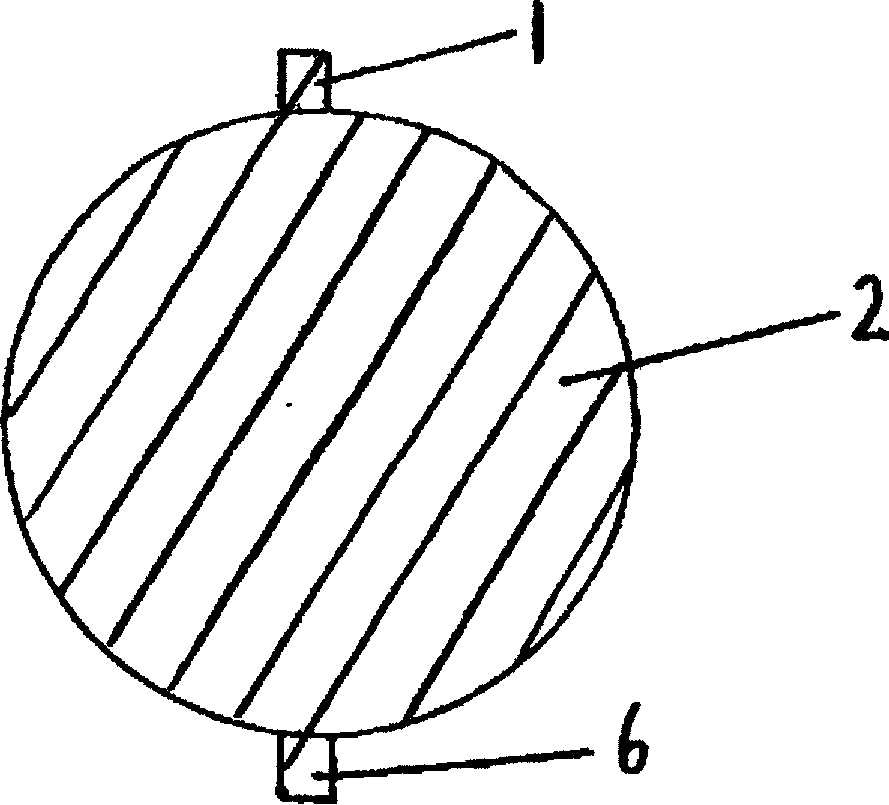

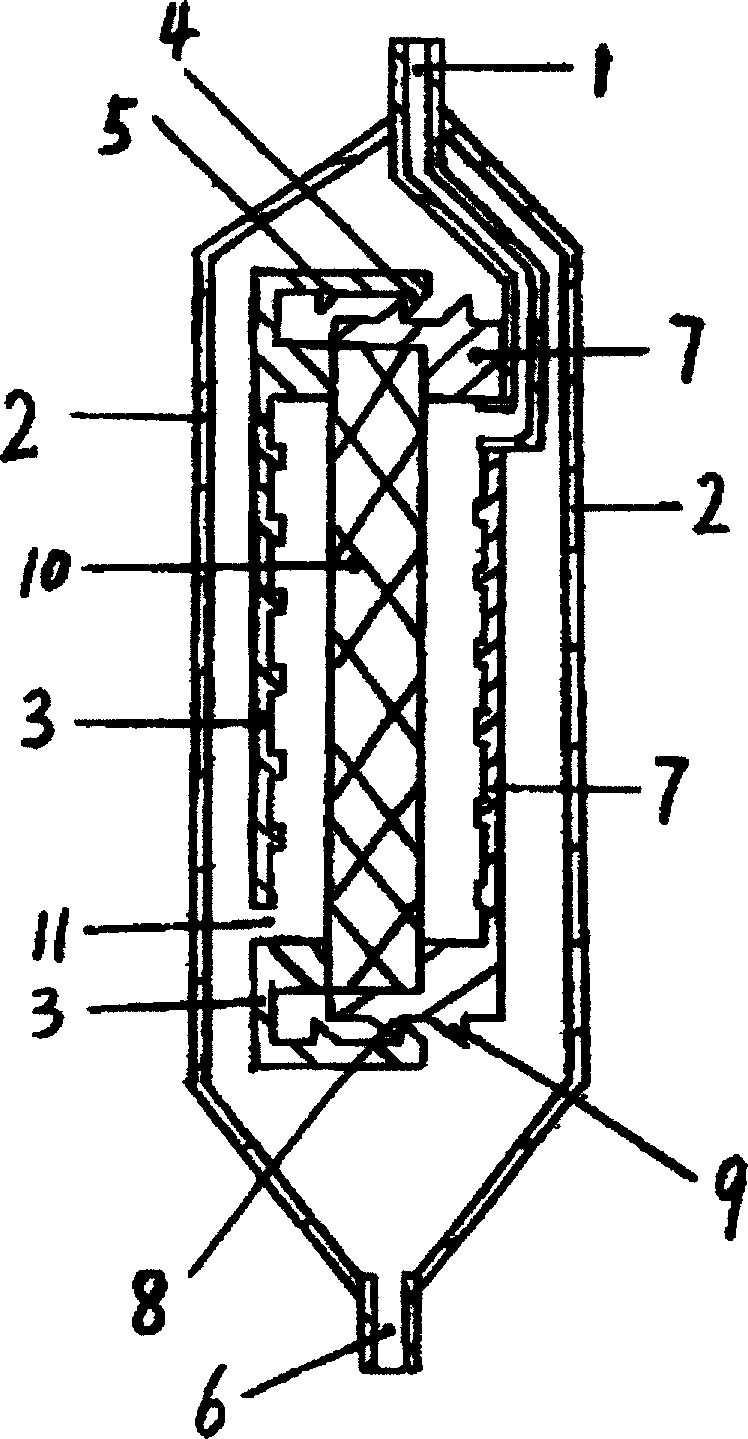

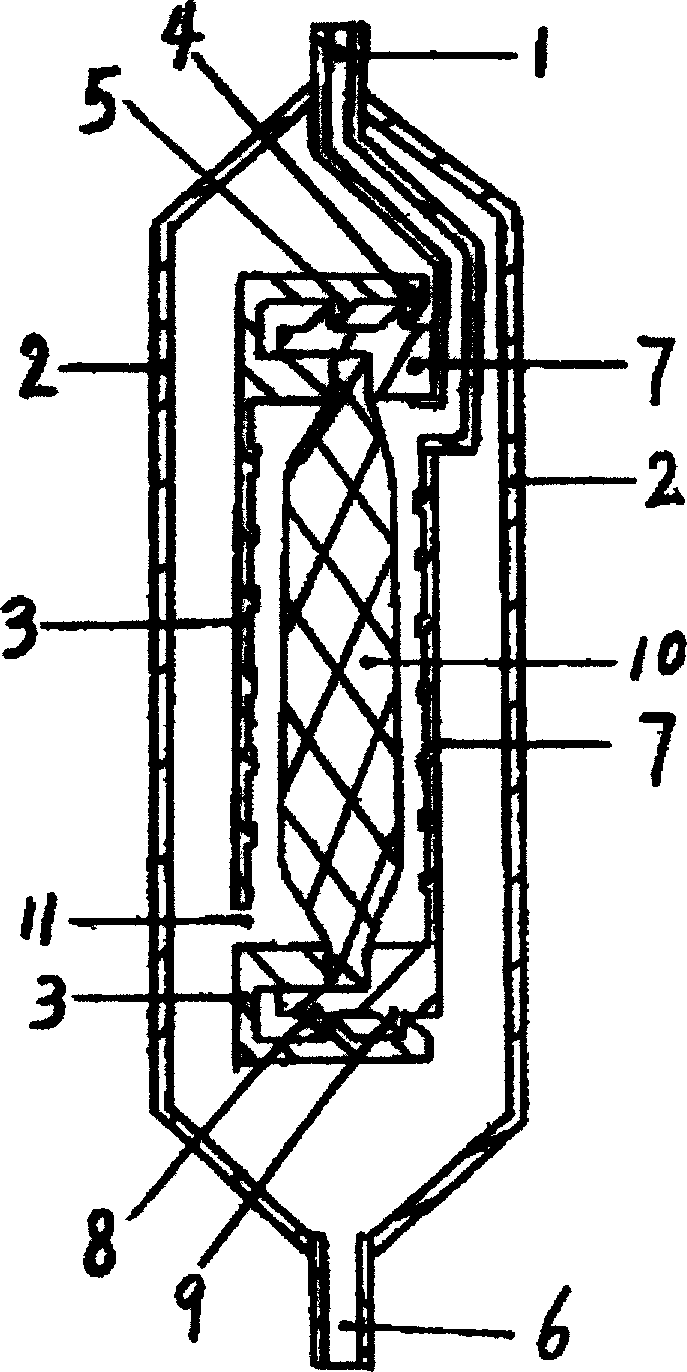

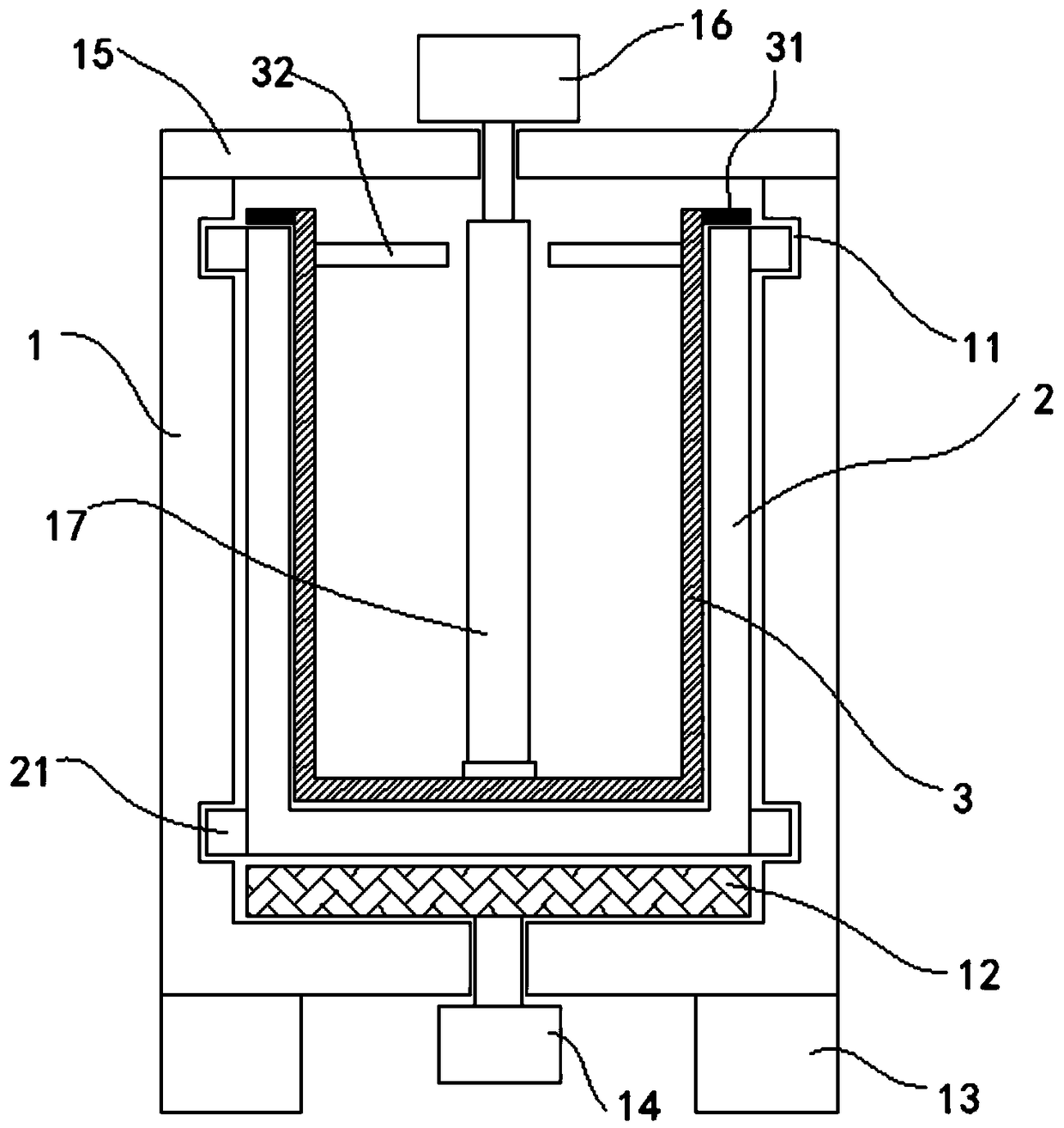

Leucocyte filter

InactiveCN1634615AImprove fermentation rateReduce adverse reactionsHaemofiltrationSoft bodyWhite blood cell number

The invention concerns a leucocyte filter, which belongs to medical transfusion apparatus for removing leucocyte in blood. It consists of upper duct 1, elastic soft body 2, upper fastening body 3, down duct 6, down fastening body 7, microporous membrane 10 and characterizes in that a body case is assembled by elastic soft body 2, upper fastening body 3, down fastening body 7 and only upper duct 1 and down duct 6 inside the body case communicates to the outside, the rest of which is closed.

Owner:杨星

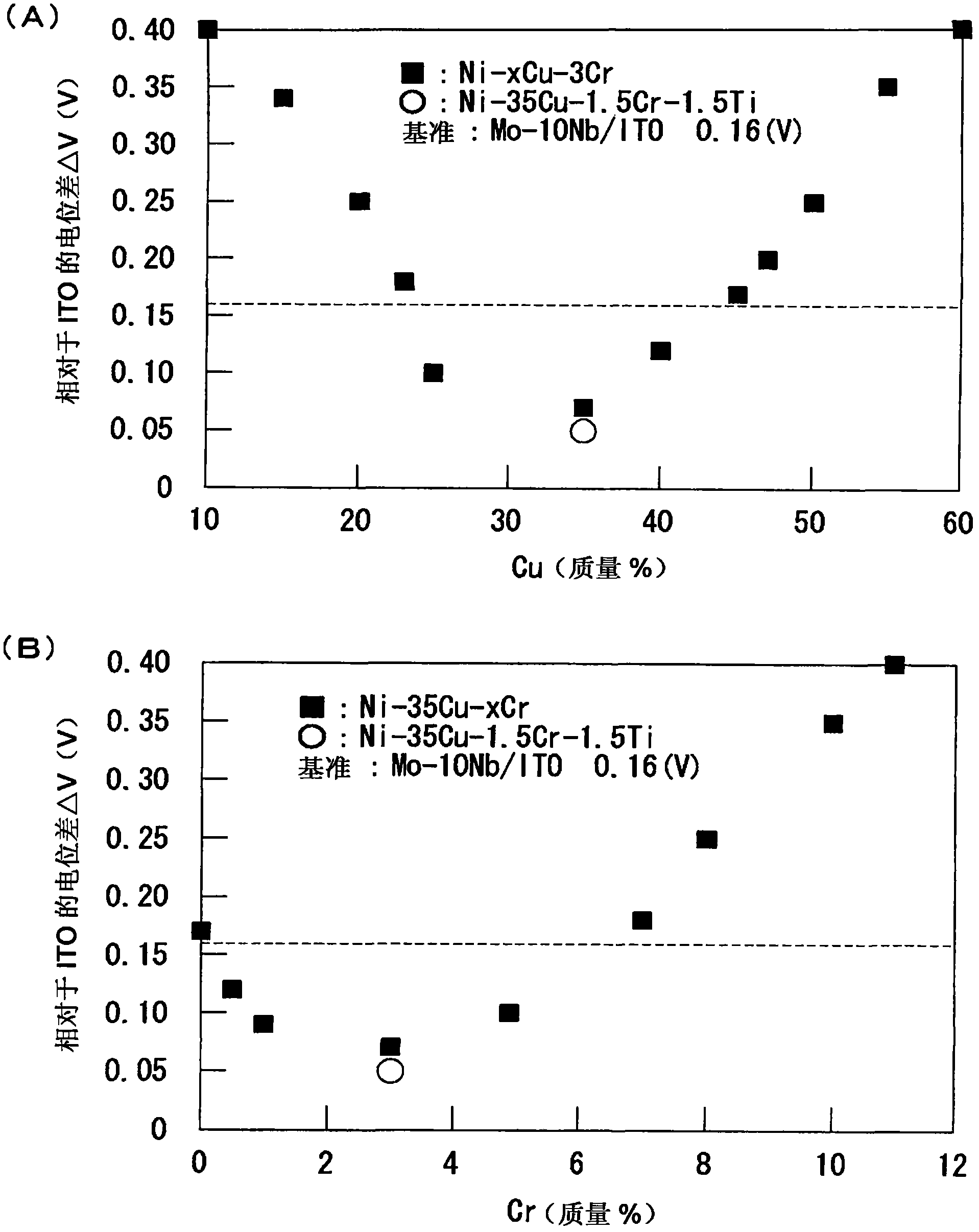

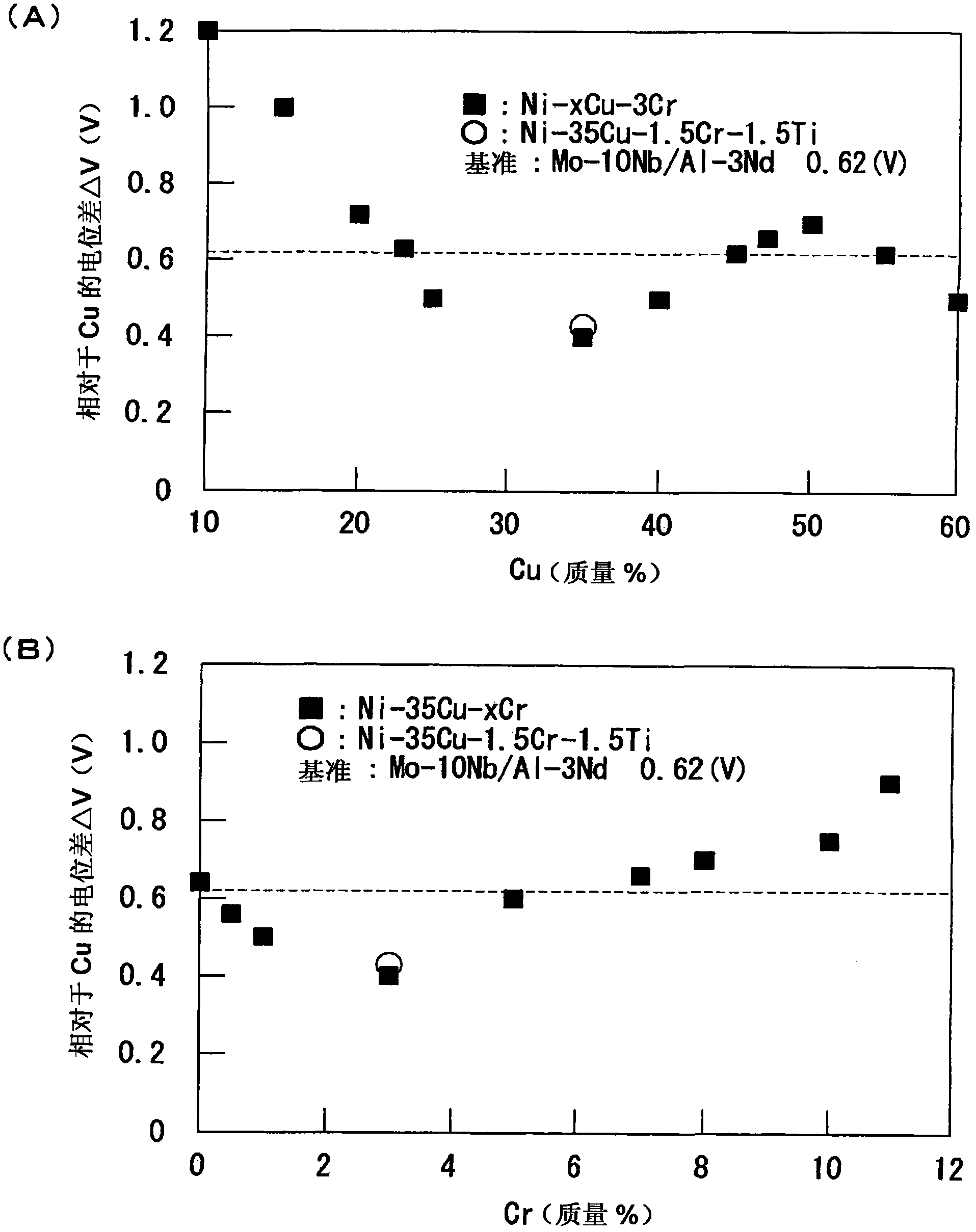

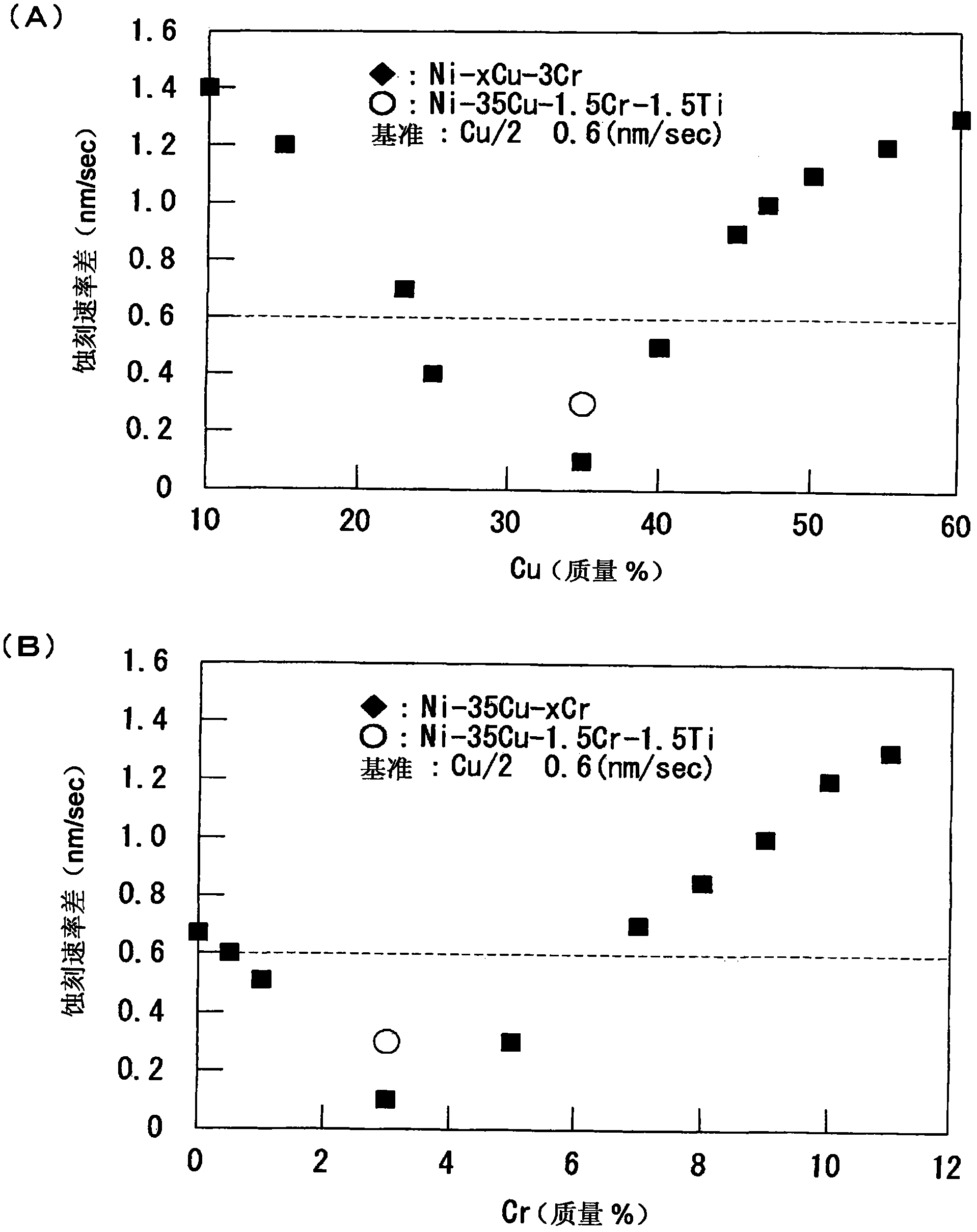

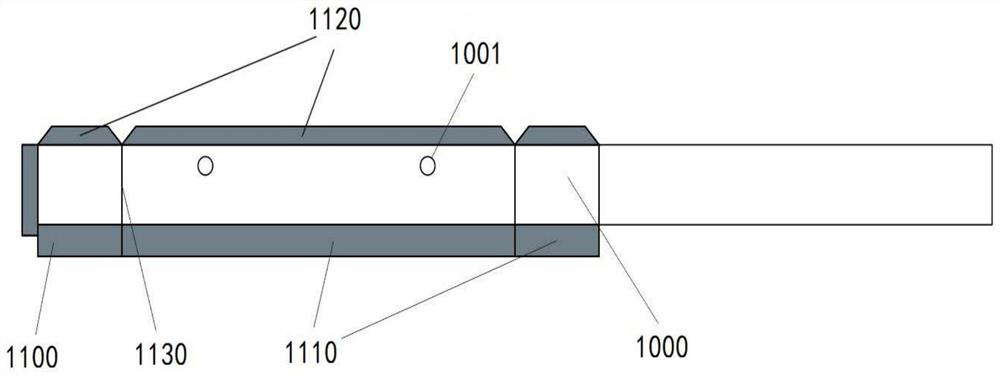

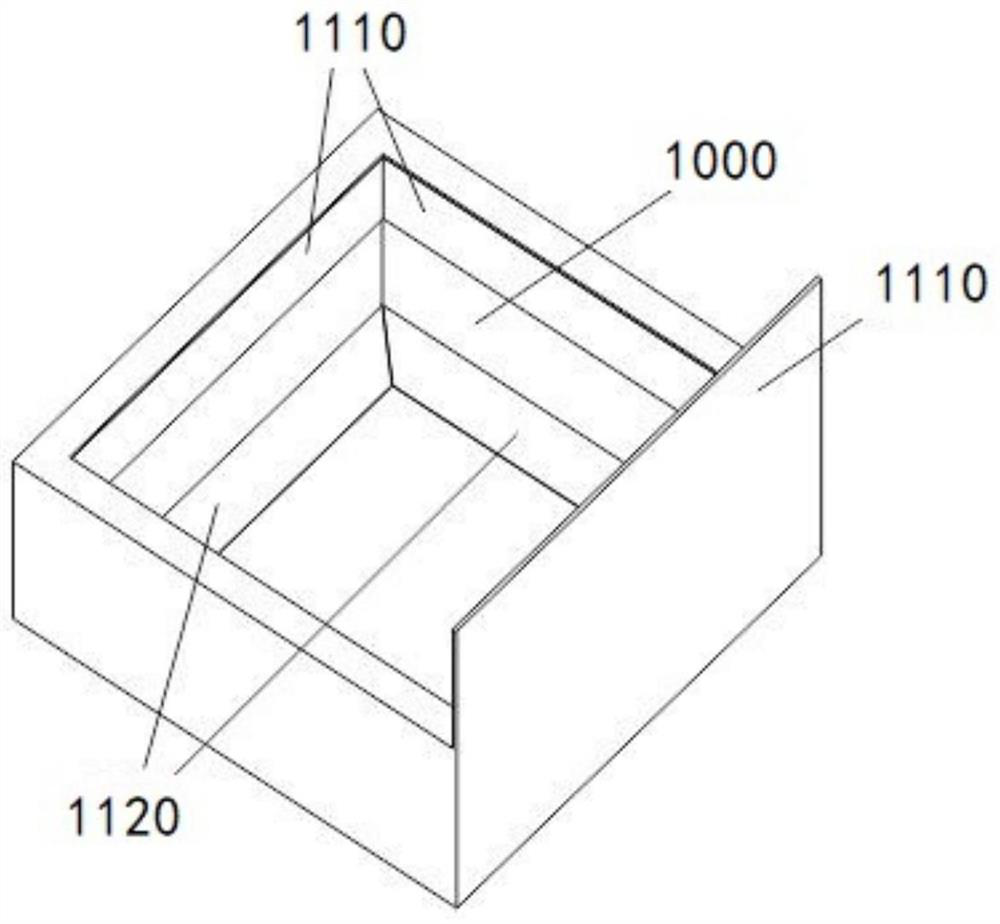

Ni-cu alloy target material used in cu electrode protection film and laminated film

ActiveCN102321832ASuppresses deterioration of electrical characteristicsImprove adhesionVacuum evaporation coatingSputtering coatingEtchingAtomic diffusion

The invention aims to provide a Ni-Cu alloy target material used in a Cu electrode protection film and a laminated film manufactured by using the target material, wherein, the target material can be used as a protection film of the Cu electrode, can restrain an electrical characteristic degradation caused by the electrolytic corrosion or atomic diffusion of the Cu electrode, can form patterns in a higher precision via a wet etching method, can form a protection film having good attachment performance on a transparent electrode and can carry out sputtering effectively. The invention relates to the Ni-Cu alloy target material used in the Cu electrode protection film and the laminated film manufactured by using the target material, the target material comprises, by mass, 15%<=Cu<=55%, and 0.5%<=Cr, Ti<=10.0%, with the balance being Ni and unavoidable impurities.

Owner:DAIDO STEEL CO LTD

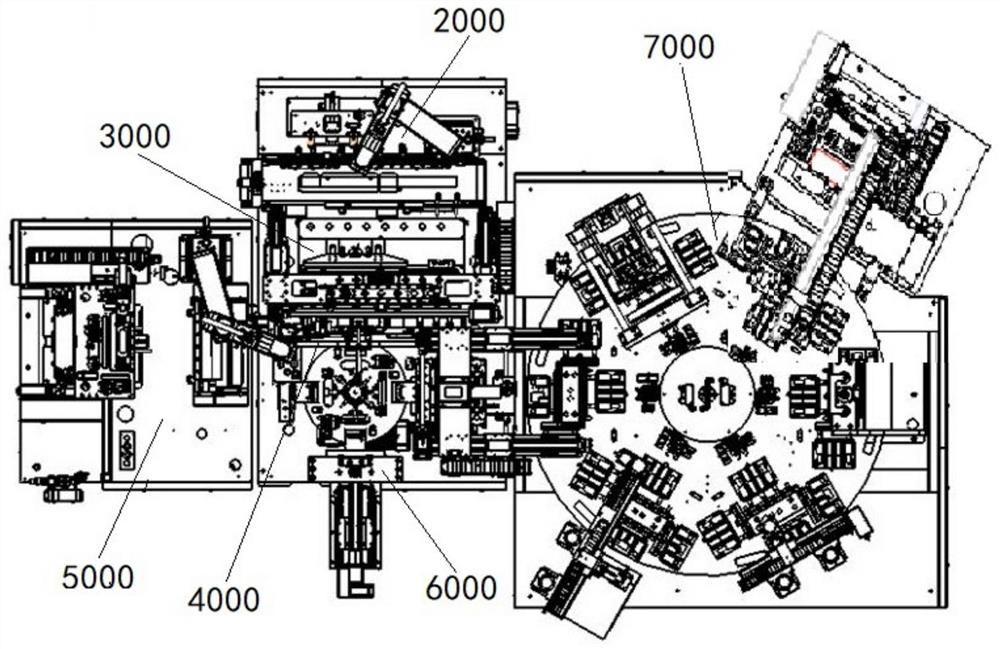

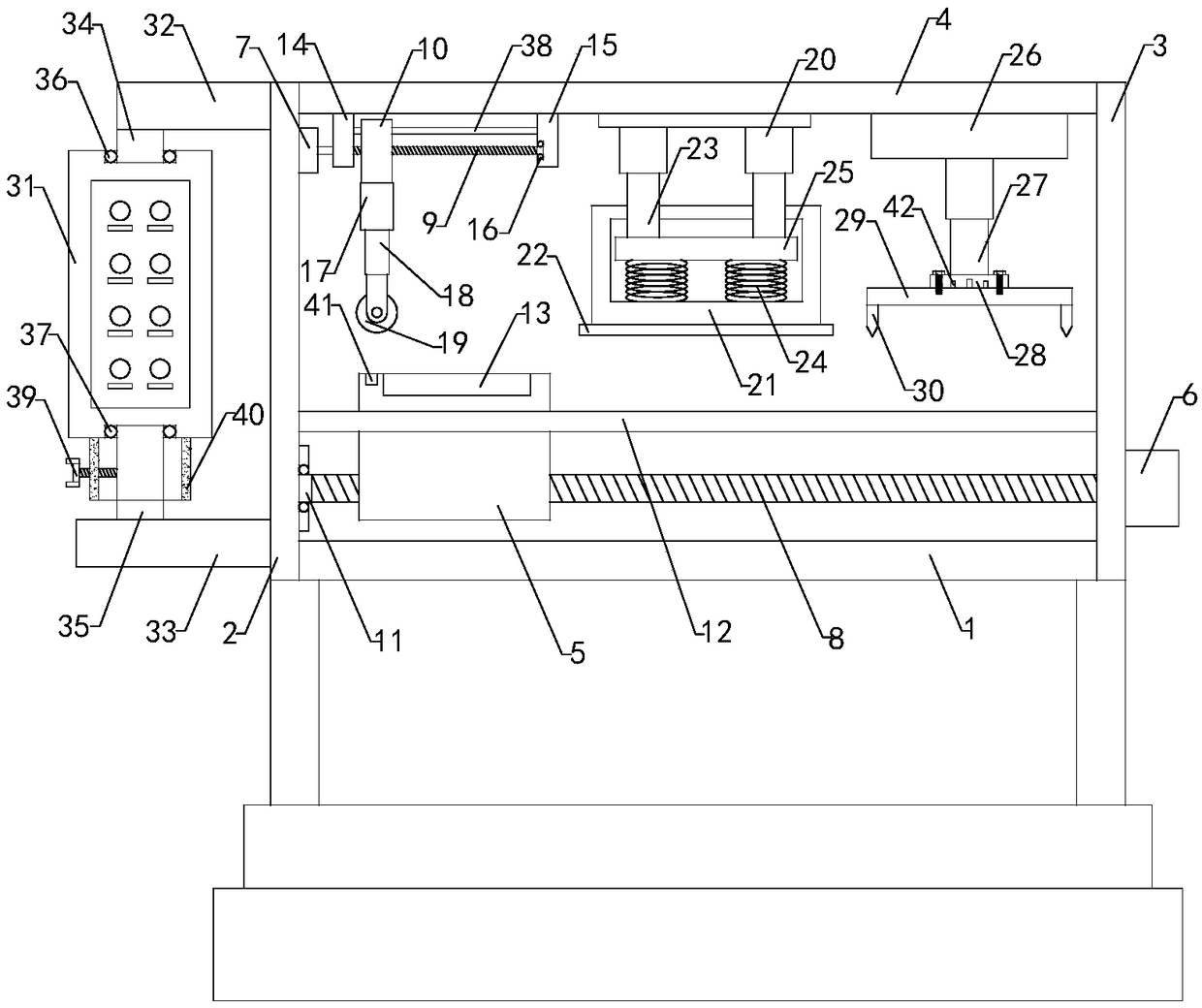

Packaging carton forming equipment

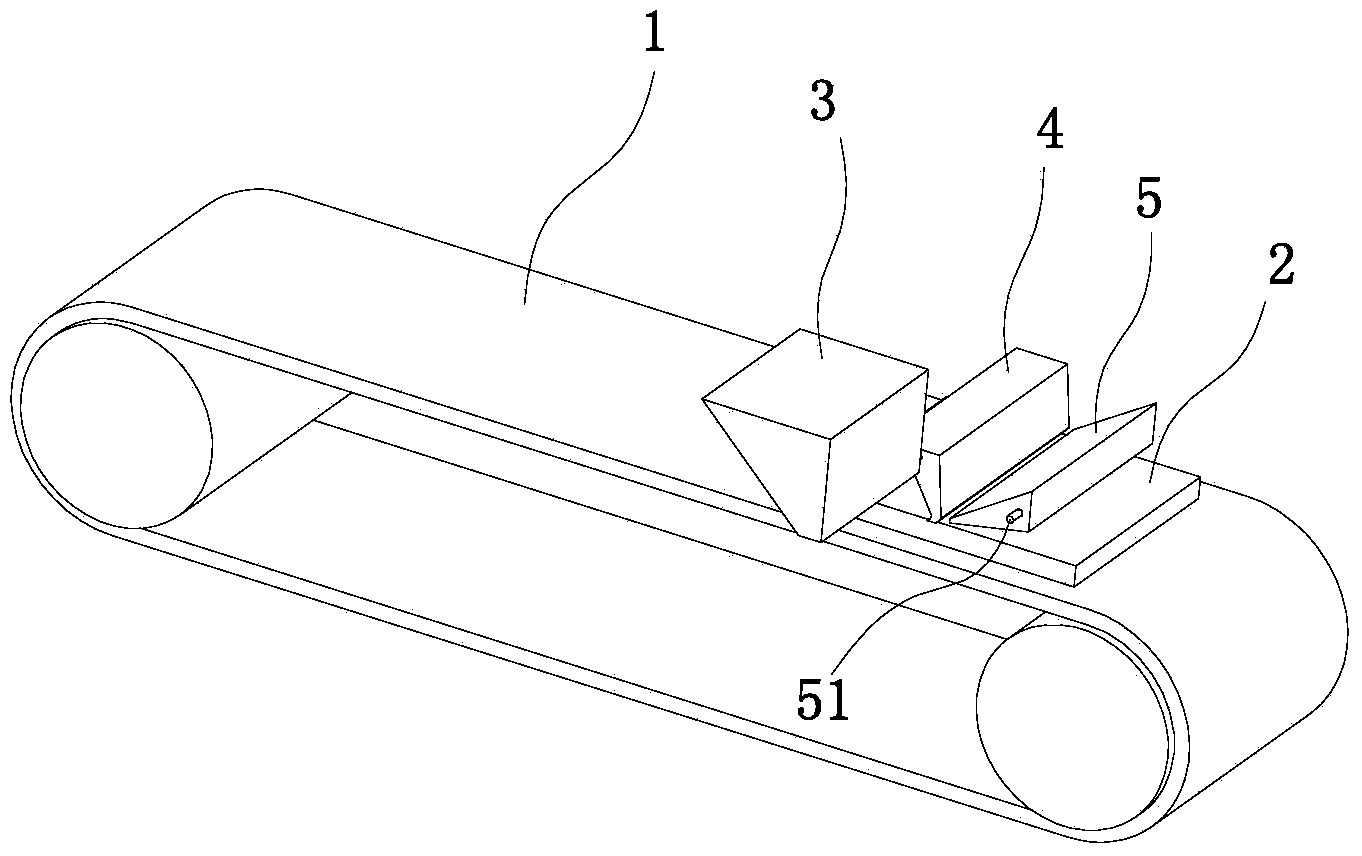

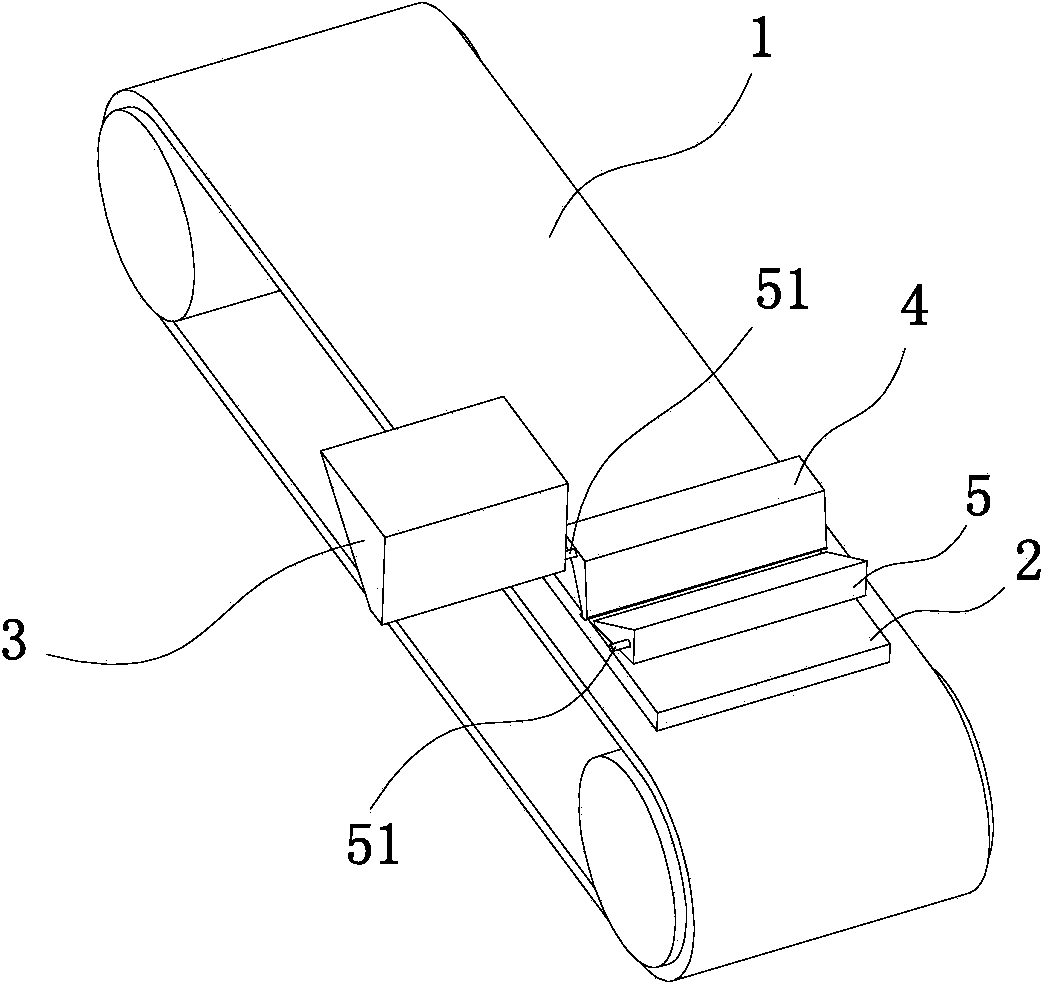

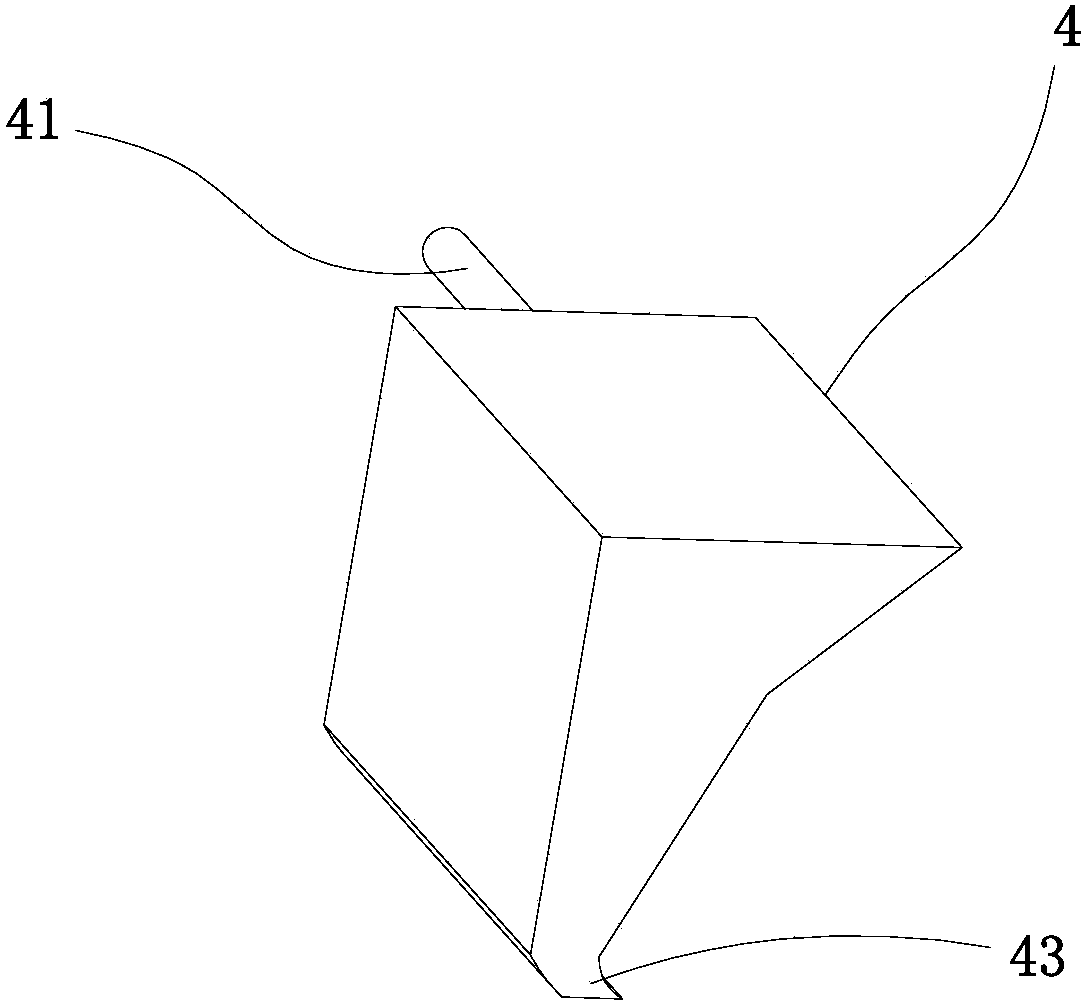

PendingCN112339335AImprove hem adhesionImprove the sticking effectBox making operationsPaper-makingCartonPaperboard

The invention relates to the technical field of automatic packaging machines, in particular to packaging carton forming equipment. The packaging carton forming equipment comprises an edge folding, edge covering and edge pressing device, an enclosure frame forming device, a sticker gluing and grabbing device, a short edge folding and edge scraping device and a multi-station rotary disc. The edge folding, edge covering and edge pressing device is used for conducting edge folding, edge covering and edge pressing on surface paper attached to the surface of a paperboard. The enclosure frame formingdevice is used for folding the paperboard to form an enclosure frame. The sticker gluing and grabbing device is used for attaching top surface paper to the top face of the paperboard after the enclosure frame is formed. The short edge folding and edge scraping device is used for conducting edge folding and edge scraping on the top surface paper. The multi-station rotary disc is used for conducting edge covering, bottom card gluing and bubble removing on the paperboard after the enclosure frame is formed. According to the packaging carton forming equipment, multiple procedures of edge folding,edge covering, edge pressing, enclosure frame forming, bottom card gluing, bubble removing and the like are integrated on the same equipment, the whole full-automatic process is achieved, manual operation is not needed, the labor cost is saved, and the production efficiency of packaging boxes is greatly improved.

Owner:XUCHANG YUTO PRINTING & PACKING

Grafted protein hydrogel biological material and its preparing process

The invention relates to an aquagel material used to recover hurt nerve center. Wherein, it uses nerve center cross method to graft the layer adhesive protein (Laninin) with nerve grow activity to the molecule skeleton of transparent acid aquagel, to rpare the aquagel frame, which can accelerate the regeneration of nerve axon.

Owner:首都医科大学北京神经科学研究所

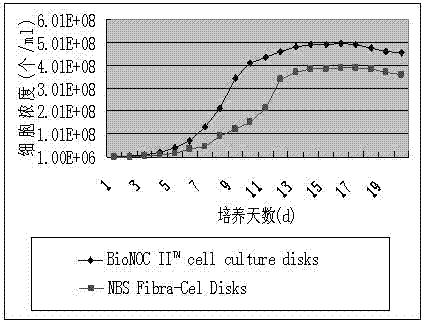

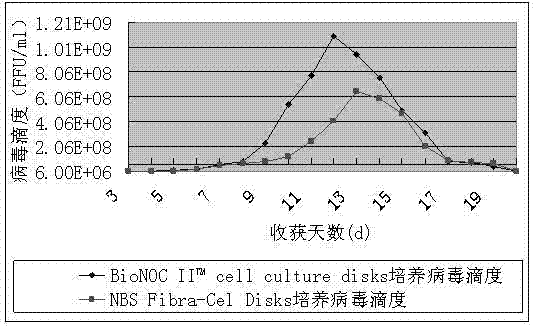

Method for producing rabies vaccine by applying bioreactor and sheet carrier

InactiveCN102240400AHigh densityHigh viral titeMicroorganism based processesAntiviralsFixed bedVolumetric Mass Density

The invention relates to a method for producing rabies vaccines by applying a bioreactor and a sheet carrier, belonging to the technical field of biological products. The method comprises the following steps of: culturing cells by taking BioNOC IITM cell culture disks of the Taiwan SaiYu cell technology Co., Ltd as carriers in a Celligen 310 type 14 L bioreactor with a fixed bed basket-type stirring system; preparing rabies viruses with high titer through specific jar cell density, added viruses and the set parameters of the Celligen 310 type 14 L bioreactor; and producing the rabies vaccines. The method disclosed by the invention has the advantages of high density of cultured cells, high titer of the rabies viruses, high yield and low production cost; the Celligen 310 type 14 L bioreactor is enlarged in surface area used for cell adherence growth by adding the BioNOC IITM cell culture disks and then achieves the cell culture density at 5*108 / ml by creating good culture conditions; according to the method disclosed by the invention, the titer of the rabies viruses is correspondingly, greatly logarithmically enhanced and can maximally reach 1*109 FFU / ml, and therefore production cost is greatly reduced; in addition, the method disclosed by the invention is suitable for the large-scale production of rabies vaccines.

Owner:长春生物制品研究所有限责任公司

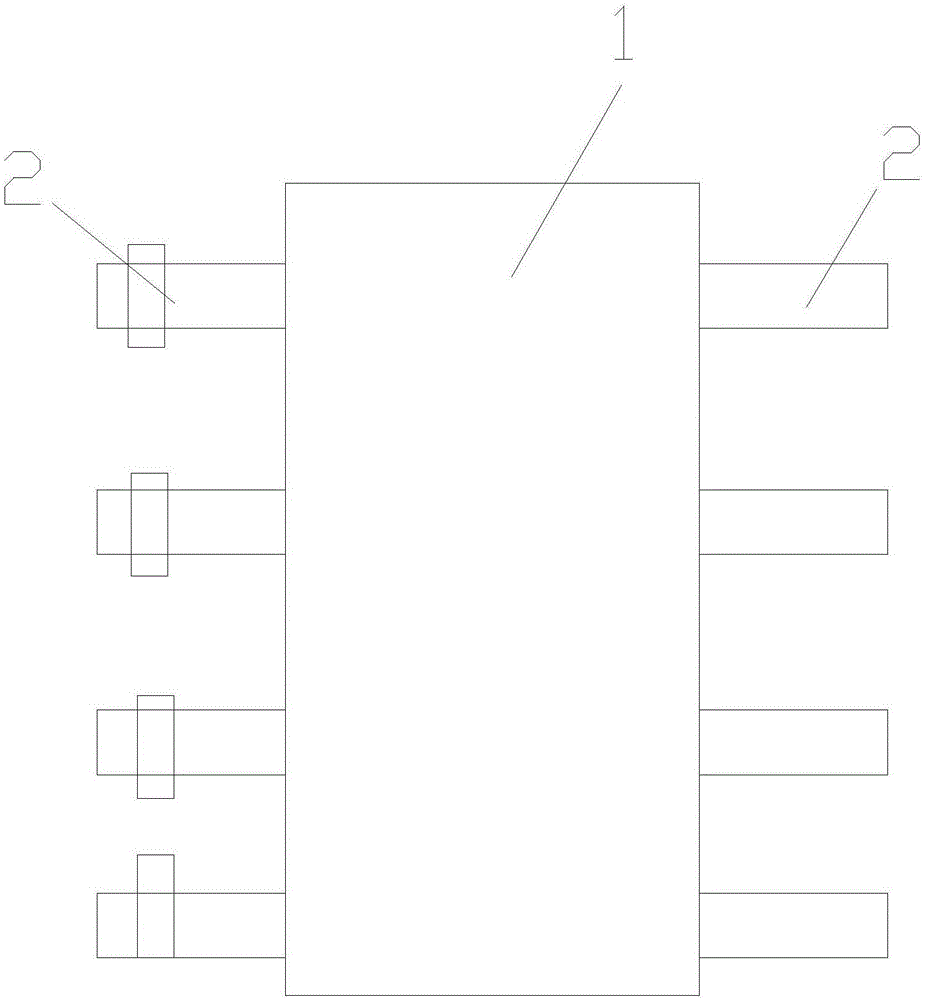

A covering film attaching device for the production of flexible circuit boards

InactiveCN109152236AAvoid damageImprove the sticking effectNon-metallic protective coating applicationBall bearingFlexible circuits

The invention relates to the technical field of a circuit board processing accessory device, in particular to a covering film attaching device used for the production of a flexible circuit board, which has high automation degree, does not need to attach the film manually, and improves the working efficiency. And the adhered film can be compacted to improve the adhesion effect of the film; At the same time, the attached film can be cut to reduce the burden of subsequent processing and improve the reliability of use; Including console, Left support plate, right support plate, top plate, First motor, Second motor, The first lead screw, the second lead screw, the slider, the first ball bearing, the front stop lever, the rear gear lever, the left fixing plate, the right fixing plate, the secondball bearing, the electro-hydraulic cylinder, the hydraulic lever and the pressure roller are provided with a fixing groove at the top end of the mounting table, and further comprising a first cylinder, a compaction box, a pressing plate, a first piston rod, a spring, a limiting plate, a second cylinder, a second piston, a mounting plate, a knife plate and a cutter.

Owner:YANCHENG HUAXU OPTOELECTRONICS TECH CO LTD

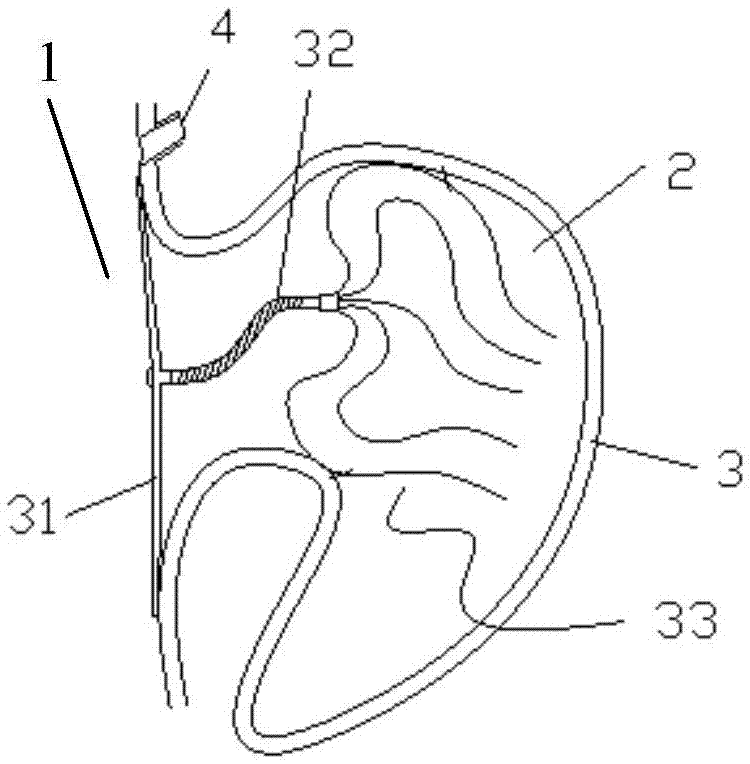

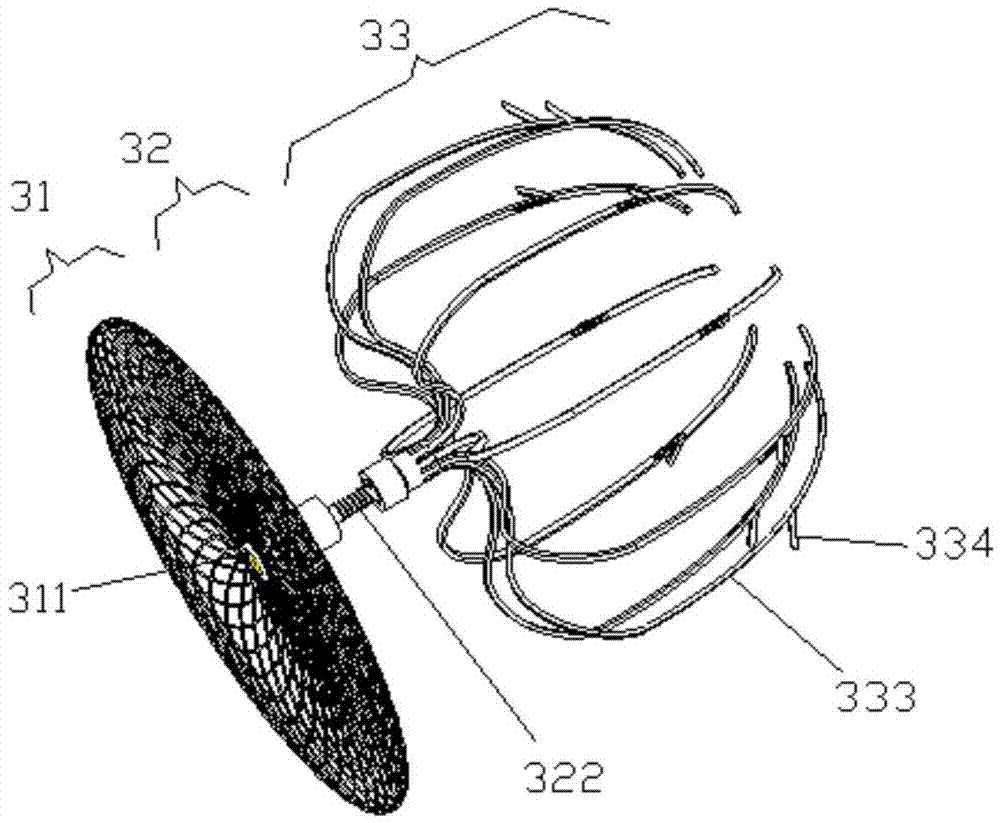

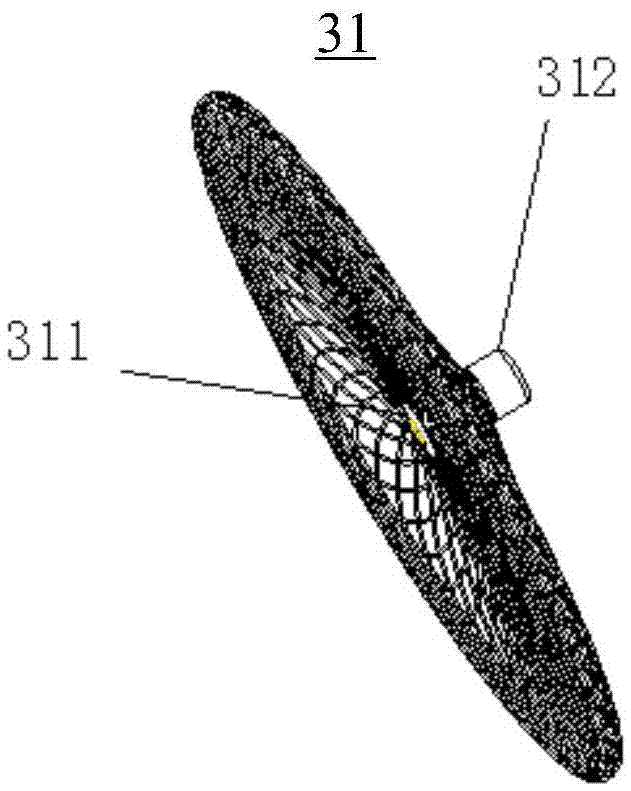

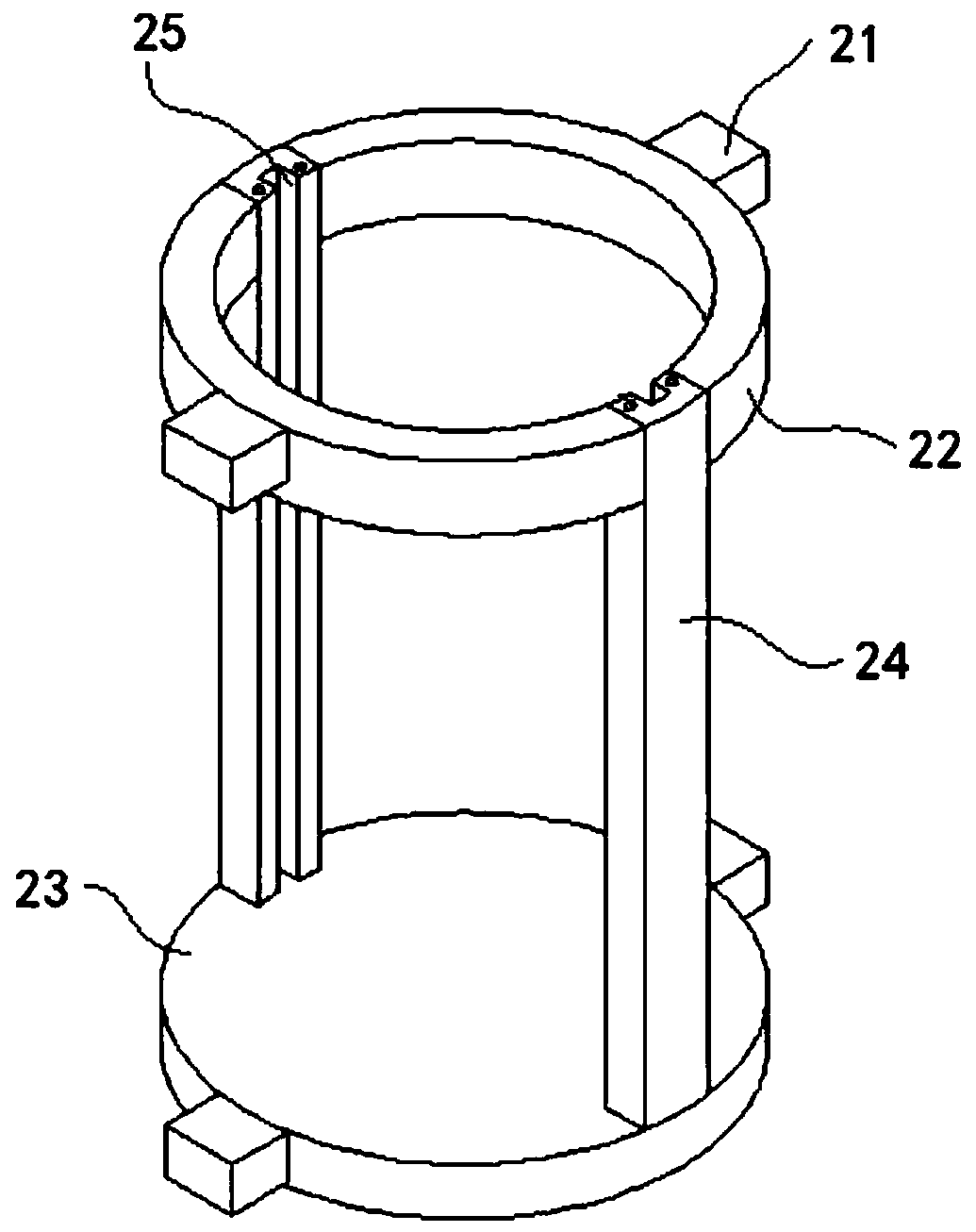

Left auricle occluder

The invention relates to a left auricle occluder. The left auricle occluder comprises a sealing disc and a fixing rack located on one side of a far end of the sealing disc. The left auricle occluder further comprises a connecting part connecting the sealing disc with the fixing rack. The fixing rack comprises a framework structure. The framework structure comprises a near-end side surface and a support peripheral surface which is connected to the near-end side surface and extends towards the far end. The connecting part is connected with the near-end side surface. The left auricle occluder has the following beneficial effects: the fixing rack is configured to be in the structure with one enclosed end and an opened end composed of at least two support rods; therefore, enough support force for the fixing rack is ensured while each support rod is independent of each other; support rods can maintain good pasting and covering performance of a cavity wall of a left auricle; stability and fixation performance of the fixing rack in the left auricle are enhanced; and the fixing rack can be fixed in the left auricle without needing to set an anchor thorn so that damage to the cavity wall of the left auricle is avoided.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

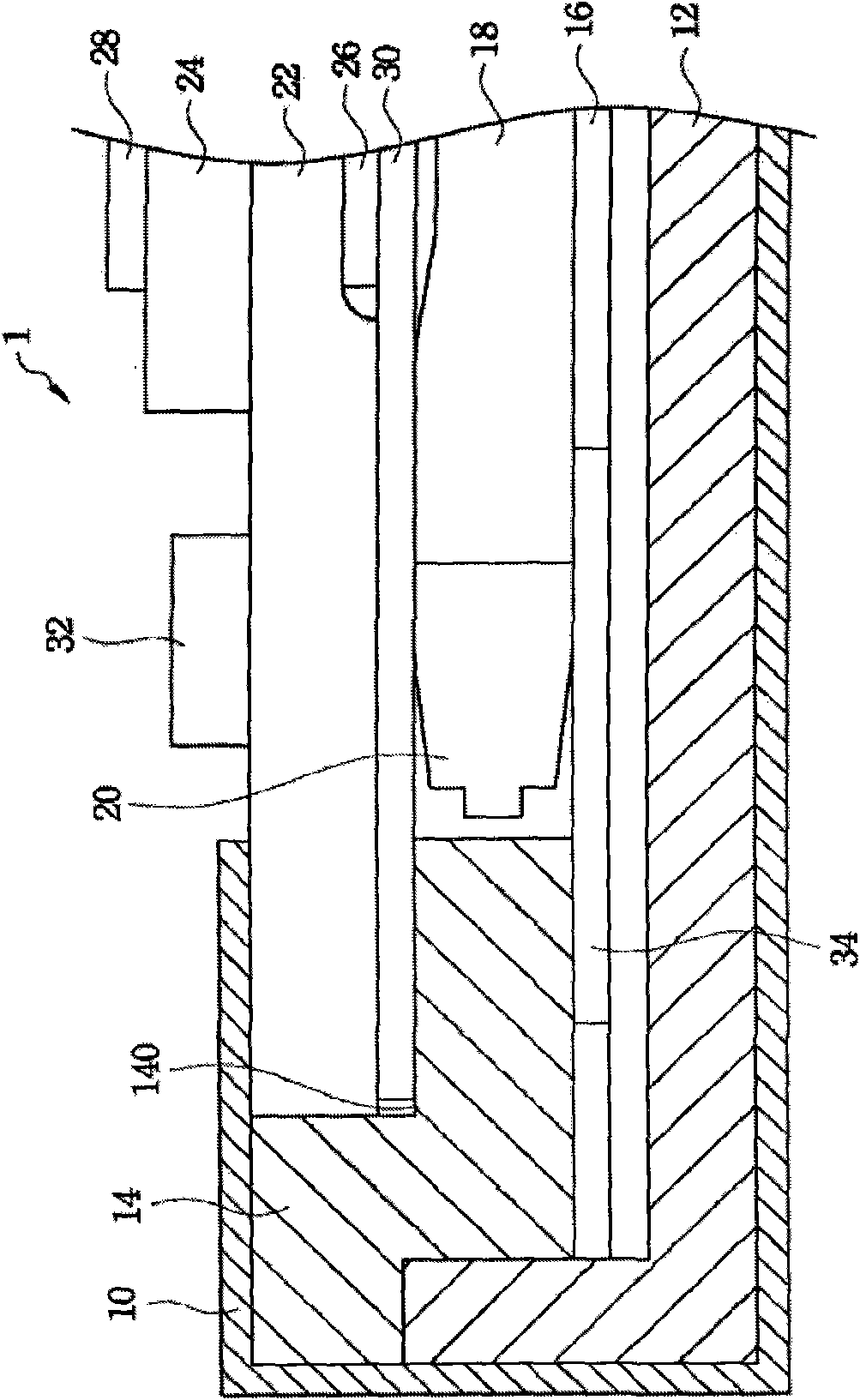

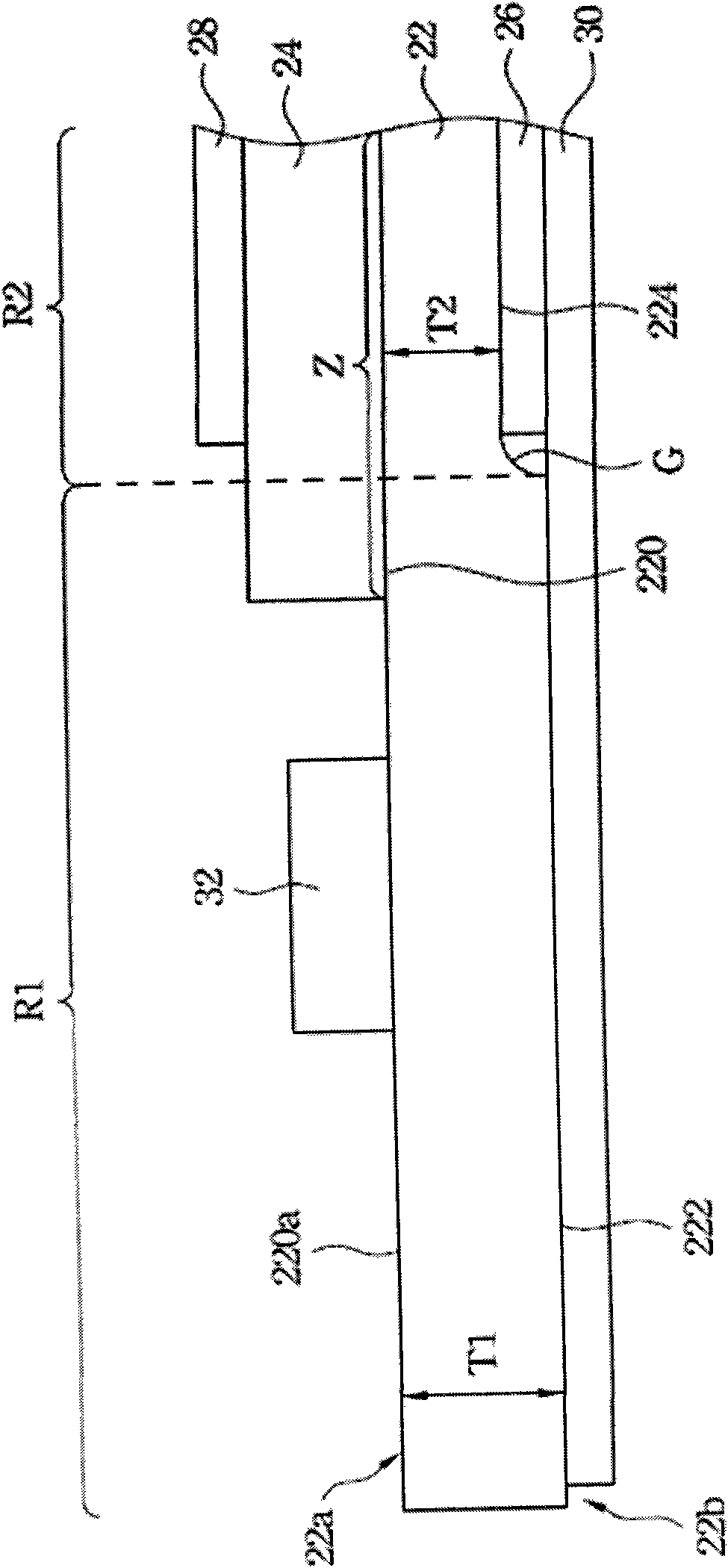

Display device and manufacturing method thereof

InactiveCN102305974AIncreasing the thicknessImprove the sticking effectNon-linear opticsFlexible circuitsColor gel

The invention provides a display device, which comprises a first base plate and a second base plate. The first base plate is provided with a first fixed area and a second fixed area. The second base plate is adhered to the first base plate to ensure that a joint surface in the first fixed area is exposed. The second fixed area is positioned in an adhesion area of the first base plate and the second base plate. The first fixed area has a first thickness. The second fixed area has a second thickness. The first thickness is greater than the second thickness to ensure that the first base plate forms a section difference between the first fixed area and the second fixed area. For the display device provided by the invention, the main point is that the thickness of a thin-film transistor glass base plate in an outer pin joint area of the thin-film transistor glass base plate is increased on the basis of not increasing the thicknesses of a colored filter glass base plate and the thin-film transistor glass base plate in the adhesion area of the colored filter glass base plate and the thin-film transistor glass base plate. By increasing the thickness of the thin-film transistor glass base plate in the outer pin joint area of the thin-film transistor glass base plate, a flexible circuit board and an electronic component can be effectively prevented from damaging the thin-film transistor glass base plate when jointed to the outer pin joint area.

Owner:AU OPTRONICS (XIAMEN) CORP +1

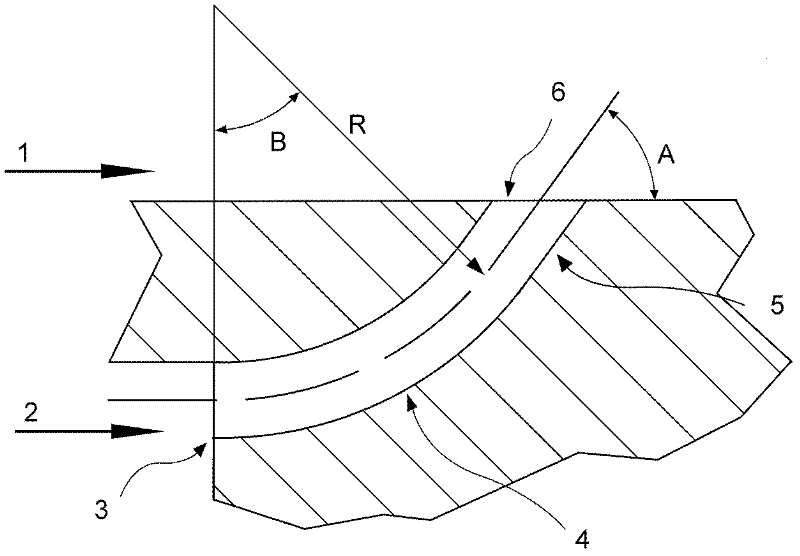

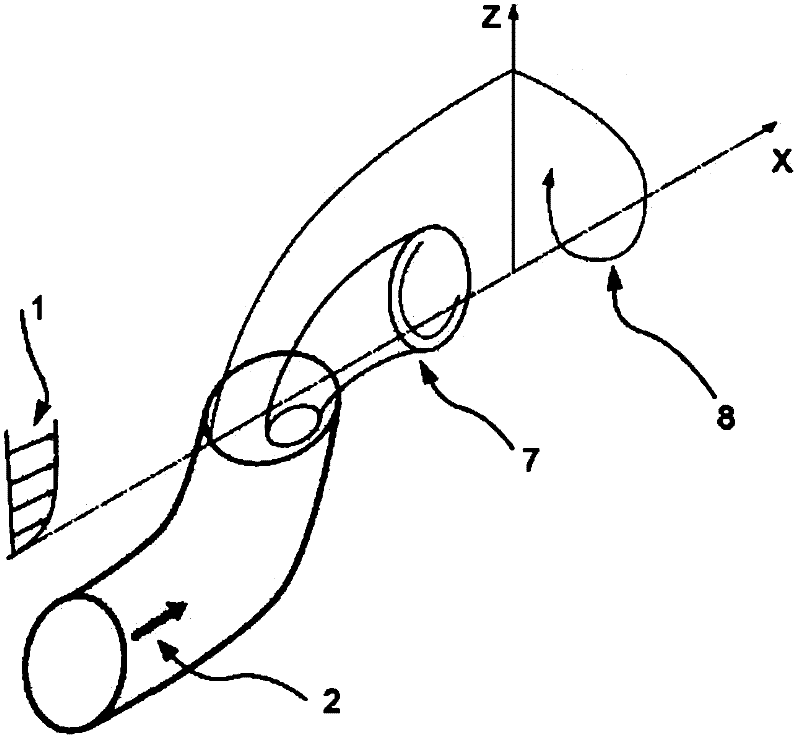

Air film hole based on secondary flows of bent passage

InactiveCN102312683AReduce the number of rowsAvoid liftingTurbine/propulsion engine coolingBlade accessoriesEngineeringTurbine

The invention belongs to the technical field of high-temperature component cooling of an air turbine, in particular to an air film hole based on secondary flows of a bent passage, which comprises two parts: a bent passage section and a straight passage section, wherein the bent passage section is a circular arc and is formed by bending an air film hole inlet in the air flow incoming direction. Because of the bent passage of the air film hole, on one hand, cooling air flows generate secondary flowing by an air film, formed passage vortexes are bent through the transverse pushing of high-temperature air flows after leaving the air film hole, the rotation direction opposite to kidney-shaped vortexes is realized, the development of the kidney-shaped vortexes can be inhibited after the interaction, the strength of the kidney-shaped vortexes is weakened, the attaching capability of the air film to the wall surface is improved, and the air film cooling efficiency is improved. On the other hand, because of the existence of the passage vortexes, the cooling air flows have higher expansion speed at the outlet part of the air film hole, and the coverage width of the air film can be increased.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Wrist accessory-free blood oxygen measurement equipment capable of being attached to skin automatically and manufacturing method of wrist accessory-free blood oxygen measurement equipment

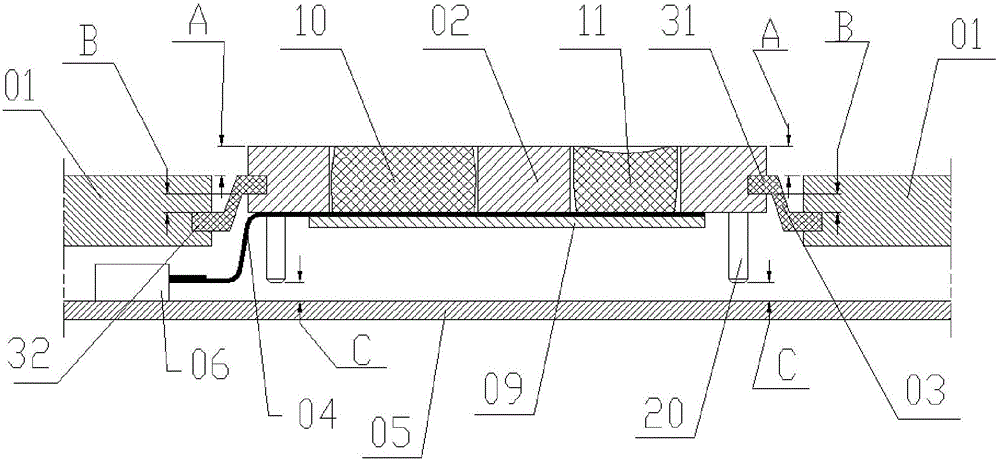

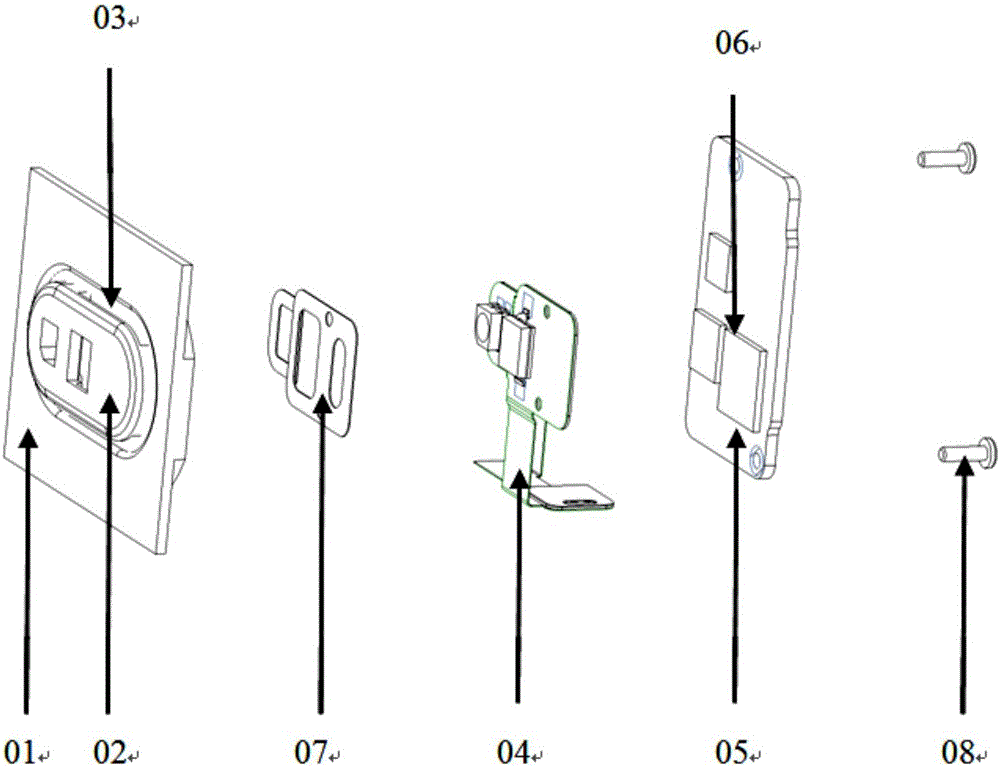

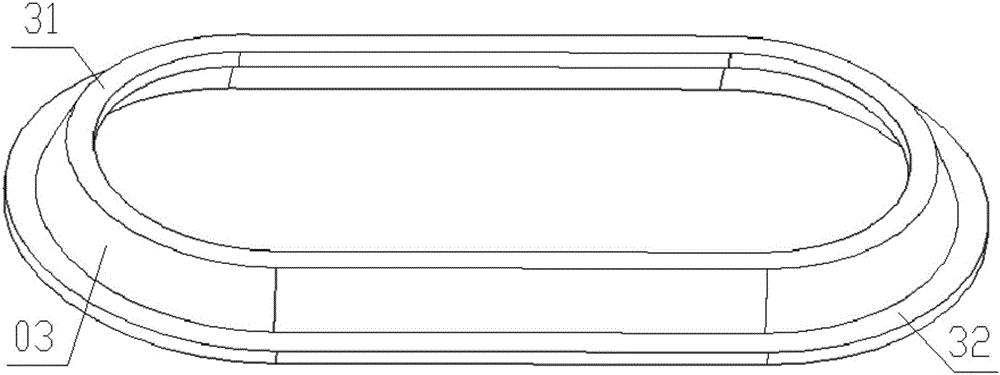

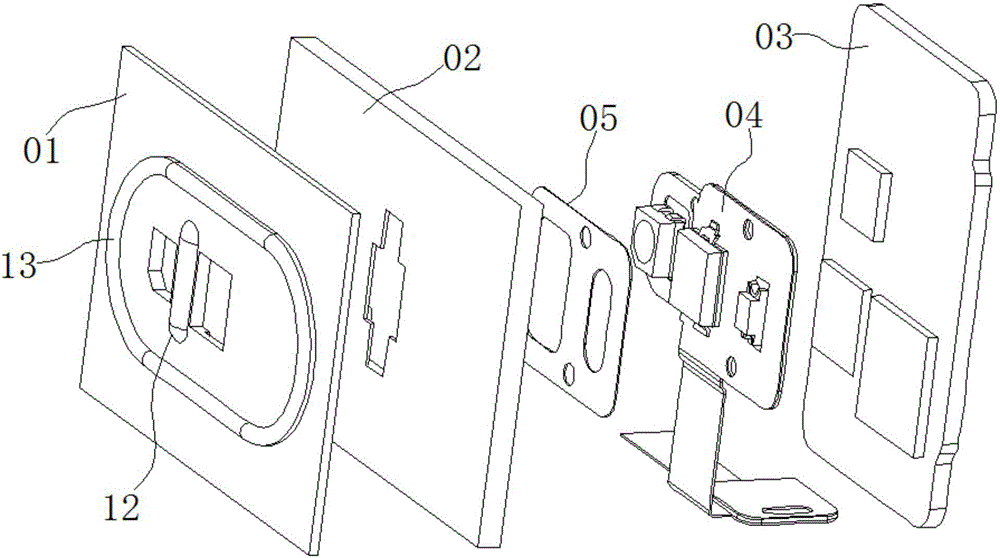

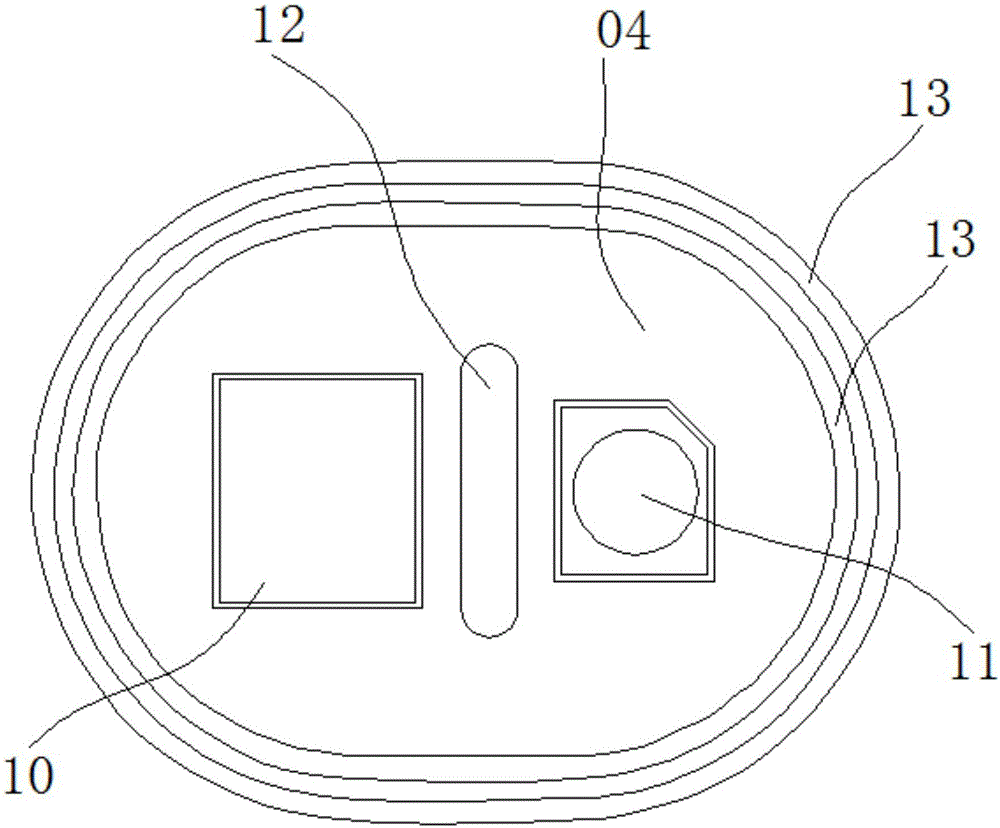

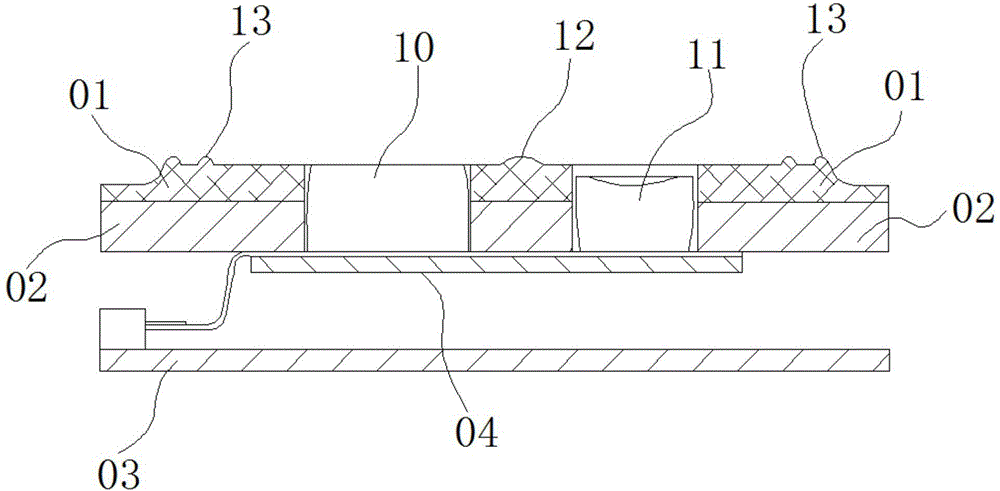

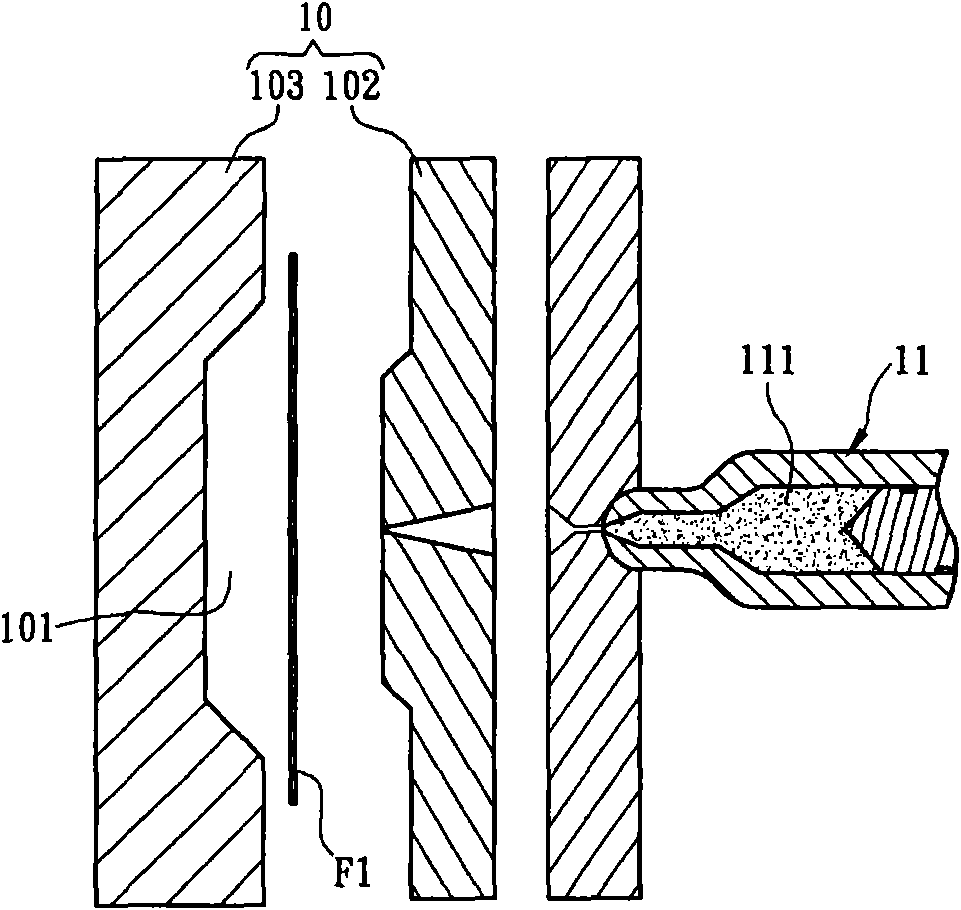

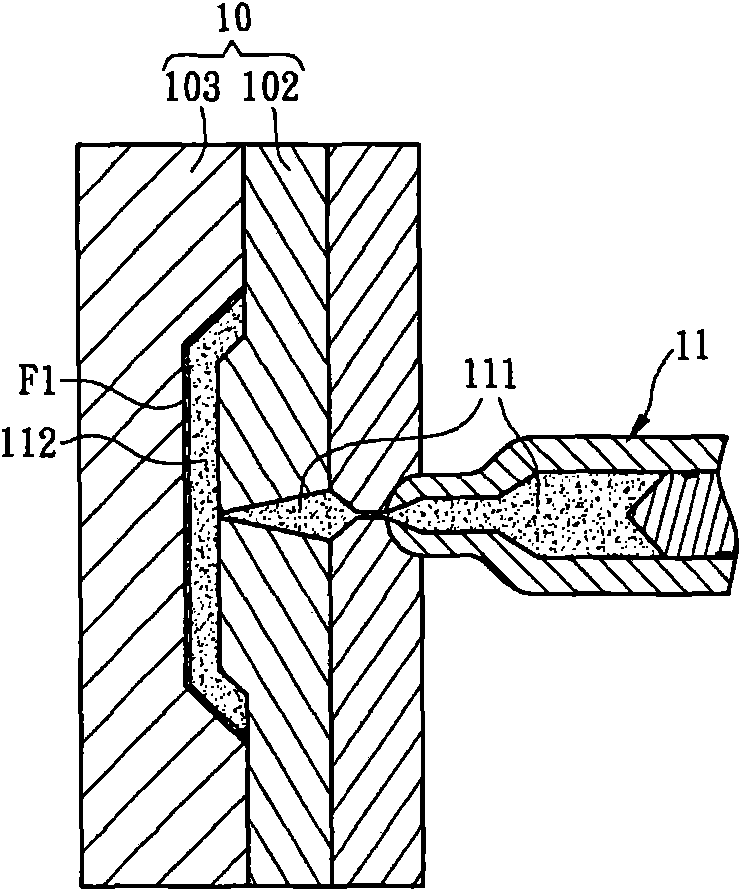

ActiveCN105919602ASimple structureImprove performanceDiagnostic recording/measuringSensorsContact forceLight-emitting diode

The invention discloses wrist accessory-free blood oxygen measurement equipment capable of being attached to skin automatically. The wrist accessory-free blood oxygen measurement equipment comprises a casing (01), a PCBA (printed circuit board assembly) circuit mainboard (05) and an FPC (flexible printed circuit) (04) arranged on the PCBA circuit mainboard (05), wherein a photosensitive sensor (10) and a red / infrared dual-light-source light emitting diode (11) are arranged on the FPC (04); an FPC bearing part (02) is further arranged on the FPC (04); the casing (01) and the FPC bearing part (02) are connected into a whole through an elastic arm (03); the elastic arm (03) adopts a hollow ring ladder shape and is big-end-down. The contact force of a signal collecting part and the skin can be automatically regulated by the elastic arm (03) and can automatically adapt to the wrist diameter, and the attachment degree of signal collection is guaranteed, so that the comfort level of wearing and the accuracy of blood oxygen measurement are remarkably improved.

Owner:CHENGDU ICARETECH

Wrist accessory-free blood oxygen measurement equipment and manufacturing method thereof

InactiveCN105997103ASimple structureImprove performanceDiagnostic recording/measuringSensorsSkin surfaceEngineering

The invention discloses a wrist-type blood oxygen measuring device without accessories and a manufacturing method thereof. The device comprises a PCBA circuit main board and an FPC flexible circuit board arranged on the PCBA circuit main board. The left and right sides of the FPC flexible circuit board are respectively A photosensitive sensor and a red / infrared dual light source light-emitting diode are fixed, an FPC bearing part is arranged on the FPC flexible circuit board, a housing measurement contact part is fixed on the FPC bearing part, and a spacer is integrally formed on the housing measurement contact part. Light wall and light-blocking wall; add a light-blocking wall between the photosensitive sensor and the red / infrared dual light source light-emitting diode, which can better block the light emitted by the light-emitting diode from being directly reflected by the surface of the skin under test to the photosensitive sensor that receives the signal; A light-blocking wall is added around the soft rubber to better isolate the signal interference of ambient light on the signal receiver, thus significantly improving the measurement accuracy.

Owner:成都菲斯普科技有限公司

Injection moulding method of membrane inside mould

The invention relates to an injection moulding method of a membrane inside a mould, comprising the following steps: correspondingly adjusting the shape of the membrane according to the shape of a mold cavity inside the mould; then correspondingly placing the membrane into the mold cavity; and finally ejecting a plastic to be moulded in the mould so that the membrane is closely jointed with the plastic.

Owner:ASUSTEK COMPUTER INC

Metal section bar protection film and production method thereof

InactiveCN106047211AImprove the sticking effectExcellent peelabilityEster polymer adhesivesPressure sensitive film/foil adhesivesTectorial membraneEmulsion

The invention provides a metal section bar protection film and a production method thereof. An emulsion pressure-sensitive adhesive has the characteristics of large cohesion, small content of micro-molecules, certain initial viscosity, good persistent viscosity, stable mechanical performances and stable thermal performance, the use performances are not affected after the emulsion pressure-sensitive adhesive is stored at normal temperature for 6 months, the coating film formation performance is good, and hole shrinkage and crack phenomena does not exist in the coating process; the protection film produced by using the pressure-sensitive adhesive has the advantages of good coating performance and peelability, good adhesive surface film formation uniformity, no hole shrinkage or cracking, high cohesion, and suitableness for high-surface energy surface coating; and the protection film can be applied to coating of micro-porous anodized aluminum and stainless steel plate surfaces without residual adhesive or mottles.

Owner:XIANGYANG SUNVALOR AEROSPACE FILMS CO LTD

Display assembly

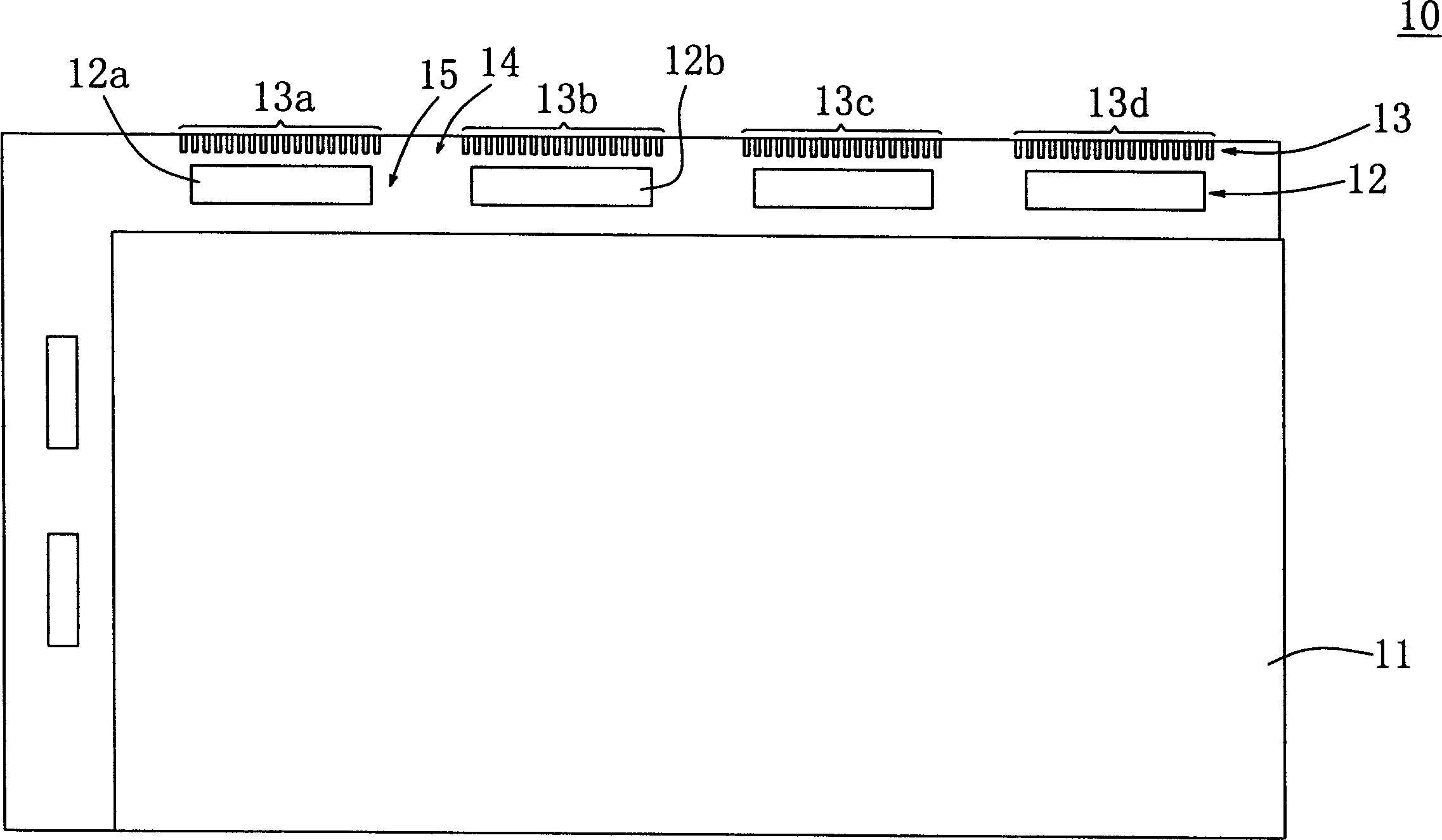

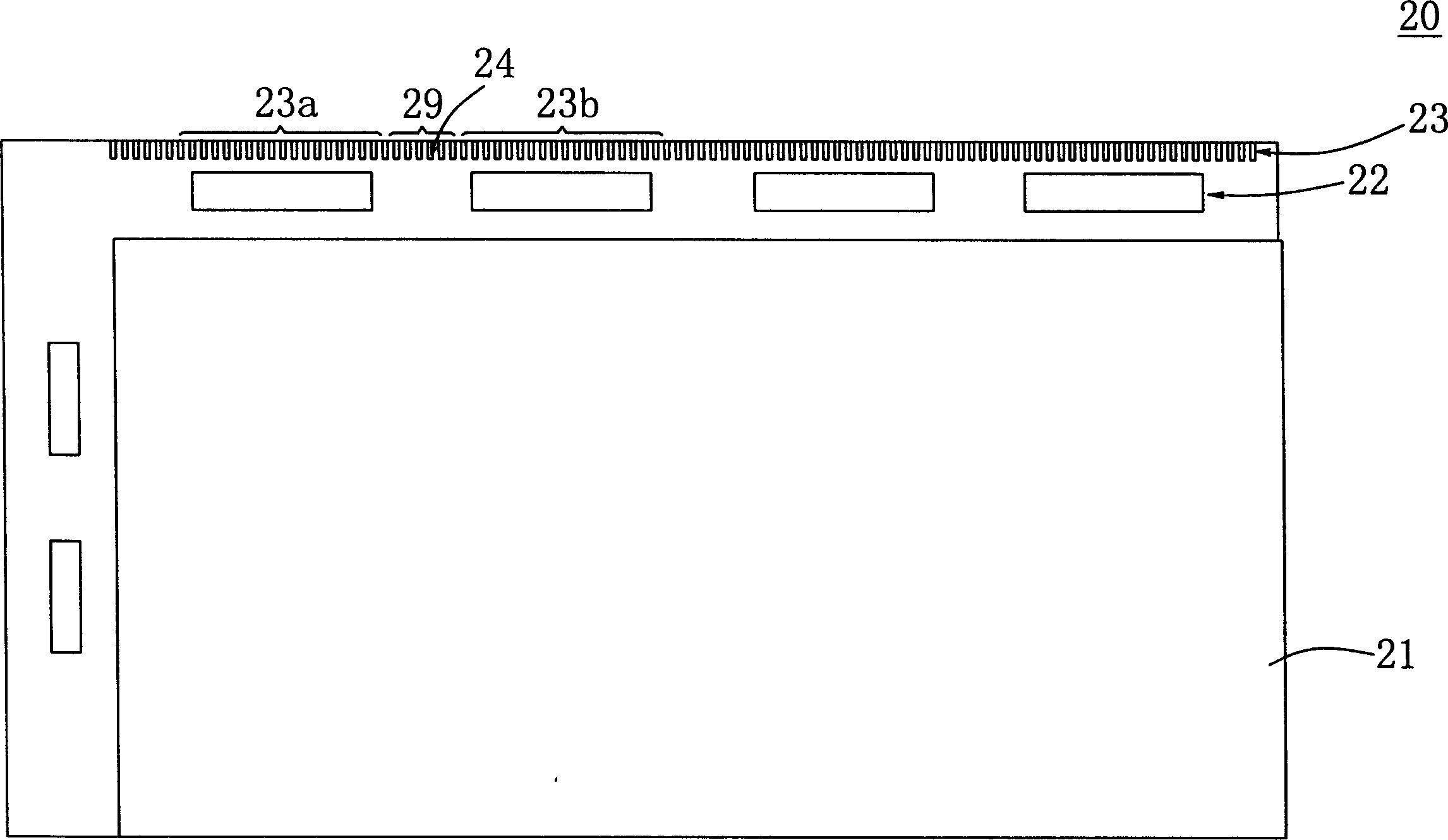

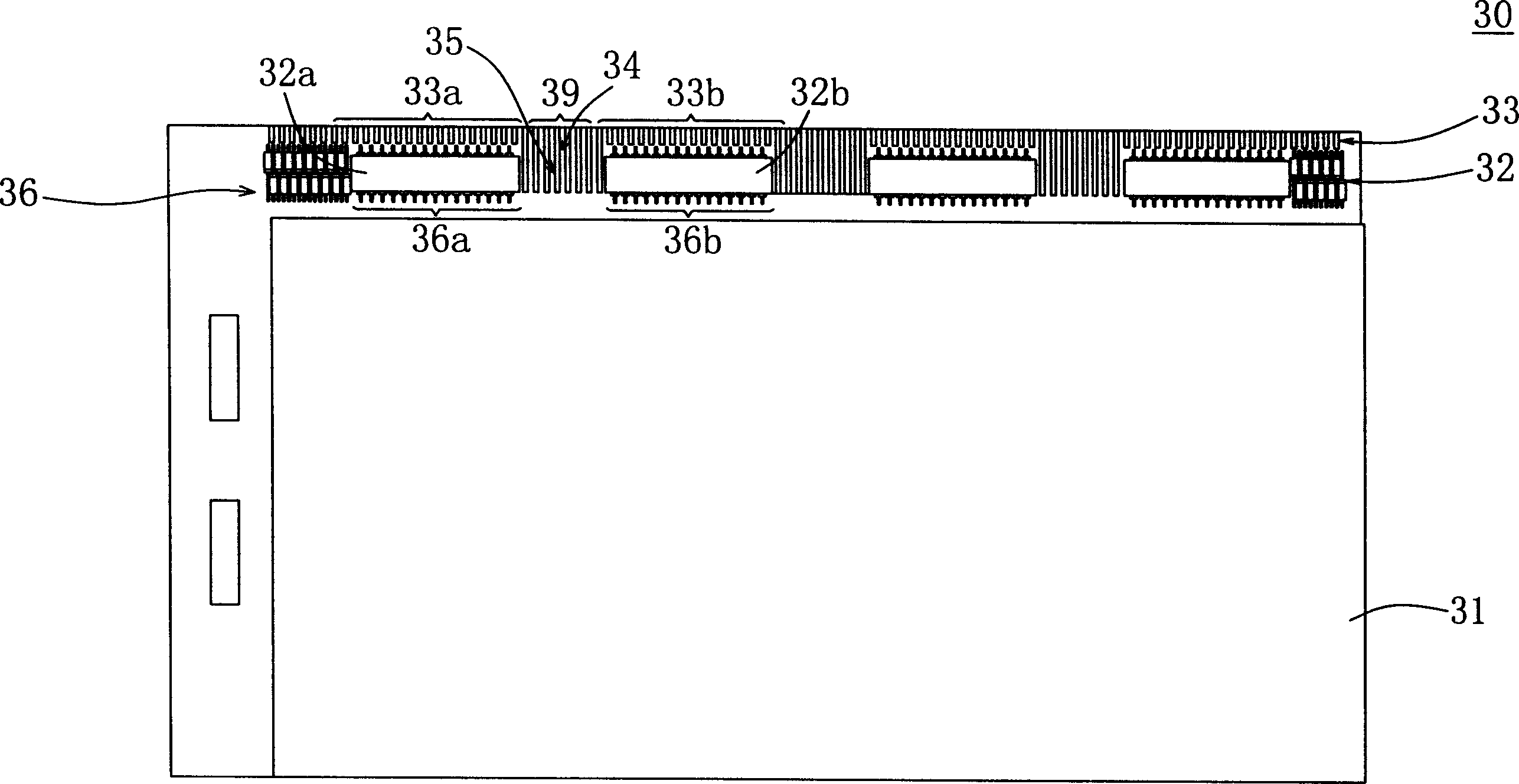

ActiveCN1542506AImprove the sticking effectAvoid bad fitStatic indicating devicesNon-linear opticsEngineeringDisplay device

The display assembly includes one glass substrate, one first set of pins, one second set of pins and several dummy pins. The first set of pins and the second set of pins are configured in the edges of the glass substrate. One flexible printed circuit is configured on the first set of pins and the second set of pins via the first anisotropic conductive film. The dummy pins are set between the first set of pins and the second set of pins on the glass substrate. When the first anisotropic conductive film is adhered on the set of pins and the second set of pins, it is also adhered onto the dummy pins to increase the adhesion between the glass substrate and the first anisotropic conductive film. The design with increased wires of the present invention can raise the adhesion of the anisotropic conductive film, and this avoid forming residual adhesive and poor stitching.

Owner:AU OPTRONICS CORP

Environment-friendly flame-retardant building coating and preparation method thereof

ActiveCN109280462AImprove scalabilityImprove water absorptionFireproof paintsAnti-corrosive paintsWater basedMetallurgy

The invention discloses an environment-friendly flame-retardant building coating and a preparation method thereof. The environment-friendly flame-retardant building coating comprises a base coating and a surface coating; the base coating directly coats a wall surface to form a pre-coating layer, and the thickness of the pre-coating layer is 0.4-1.2 mm; and the surface coating coats the pre-coatinglayer to form a surface coating layer. The preparation method of the building coating comprises a preparation method of the base coating and a preparation method of the surface coating. According tothe invention, double-layer coating is adopted, uneven parts on a coated wall surface are perfectly filled, attractiveness of the coated wall surface is improved, and overall cost is reduced. A good adhesion effect is achieved between the pre-coating layer and the surface coating layer, and meanwhile, the oily pre-coating layer can have a better coating effect with the wall surface. The water-based surface coating layer can reduce the volatilization speed of harmful gas of the pre-coating layer, so that the effects of ensuring environment protection and health can be ensured while coating quality is ensured.

Owner:CHINA STATE CONSTR HAILONG TECH CO LTD +2

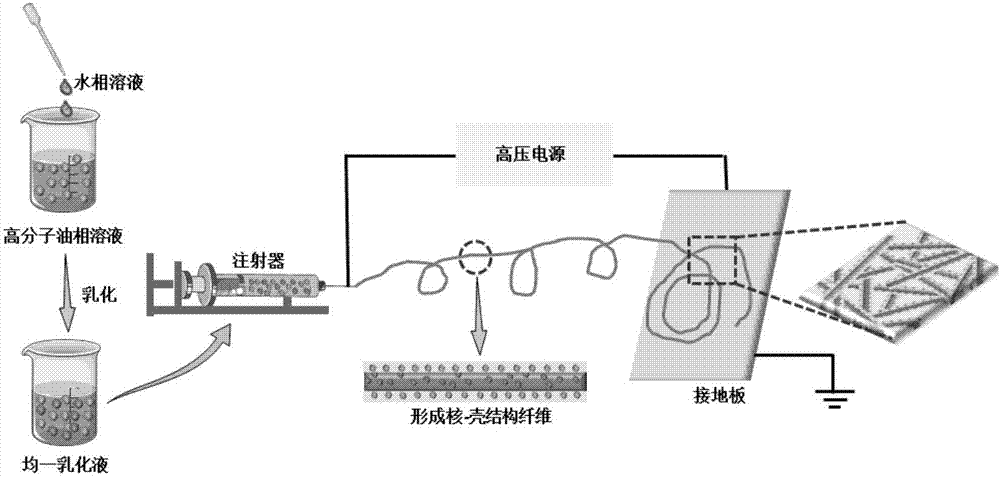

Postoperative adhesion-resisting polymer thin film and preparation method thereof

The invention provides a preparation method of a postoperative adhesion-resisting polymer thin film. The preparation method comprises the following steps: (A) mixing a biodegradable polymer material, an emulsifying agent and an organic solvent to obtain a polymer solution; mixing glucosan with water to obtain an aqueous phase solution; (B) adding the aqueous phase solution into the polymer solution, and mixing and emulsifying to obtain homogeneous emulsion; (C) carrying out electrostatic spinning on the homogeneous emulsion to obtain an electrostatic spinning fibrous membrane; (D) drying the electrostatic spinning fibrous membrane and then carrying out ultraviolet ozone treatment to obtain the postoperative adhesion-resisting polymer thin film. The postoperative adhesion-resisting polymer thin film provided by the application is excellent in overall property and free of biotoxicity, can be well attached to tissues, and has a better inhibiting effect on fibroblasts and inflammatory factors, thereby effectively isolating the tissues to realize an adhesion-resisting effect.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Detachable insulating sleeve for steam pipelines and equipment

InactiveCN106838546AReduce the impactImprove the sticking effectThermal insulationPipe protection by thermal insulationInorganic saltsGlass fiber

The invention discloses a detachable steam pipeline and equipment insulation cover, including insulation clothing; multiple sets of buckles are arranged on both sides of the insulation clothing; at the splicing place of the two insulation clothing, a constriction is arranged at one port, and The inner wall of the necking is provided with a waterproof rib or groove, and the port on the other side spliced with it forms a flare matching the necking, and a corresponding waterproof groove or rib is arranged on the flare; The thermal insulation clothing is provided with an outer layer, an inner layer and an intermediate layer; a detachable steam pipe and equipment thermal insulation cover of the present invention is composed of a plurality of thermal insulation clothing, which is detachable and reduces the possibility of large-scale replacement of the thermal insulation cover. The impact on the pipeline is reduced; the composite thermal insulation blanket composed of inorganic salt fiber layer, aluminum foil glass fiber cloth and aluminum foil airbag reflective layer has excellent thermal insulation performance; the soft thermal insulation cover can meet good covering performance and good sealing performance; Each subsection itself has good sealing and waterproof performance and long service life.

Owner:SUZHOU JUNYUE NEW MATERIAL TECH

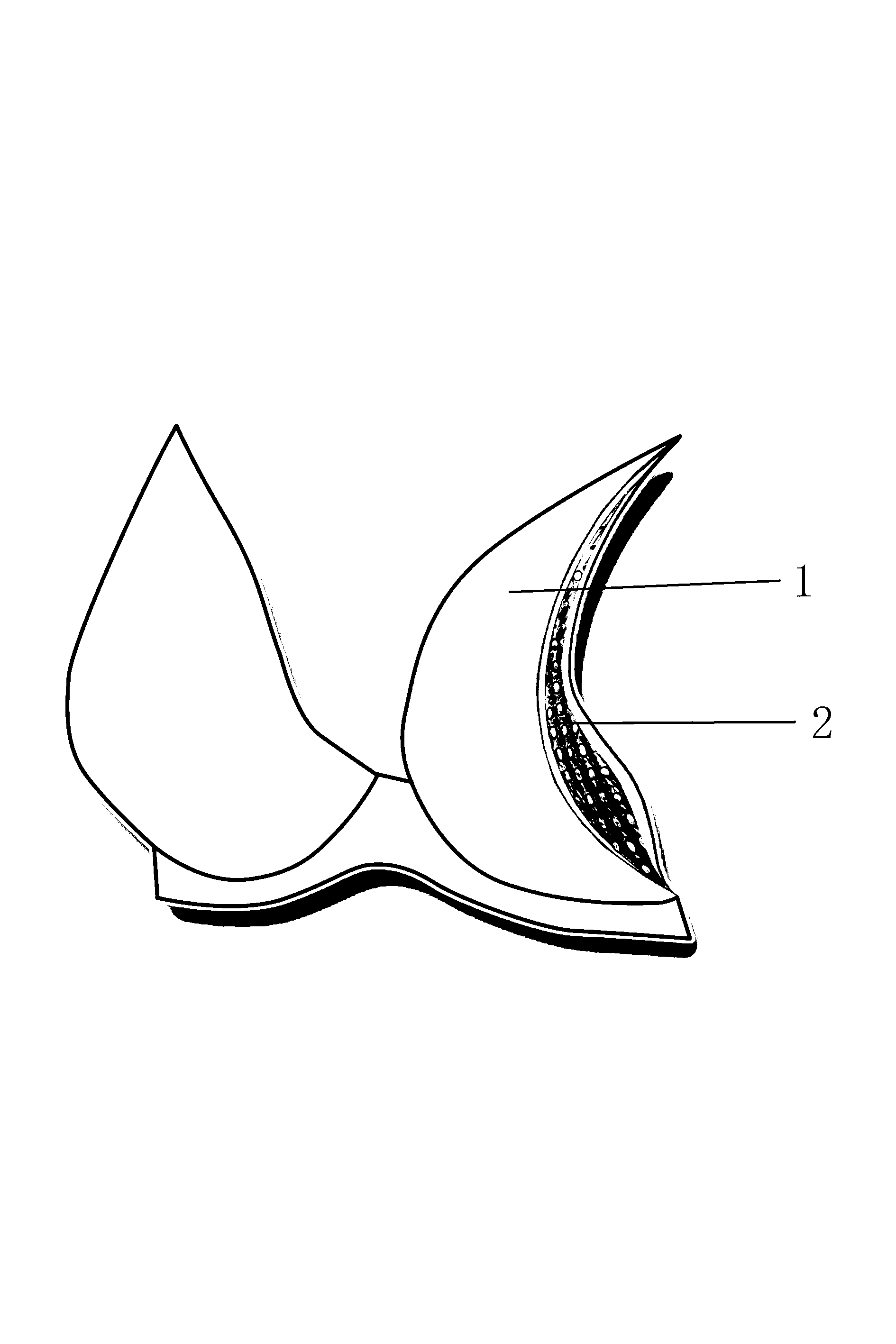

Bra with silica gel linings with massage function

InactiveCN103126088AImprove breathabilityImprove the sticking effectBrassieresRoller massageMedicineMassage

The invention relates to a bra with linings with a massage function. Compared with the prior art, the bra with the linings with the massage function is characterized in that the silica gel massage linings are arranged inside the bra, pure natural silica gel materials are adopted, and the silica gel massage linings are good in attaching effect and applicable to any types of chests. Ventilating holes on the silica gel massage linings ensure that the bra is good in air permeability. Massage particles on the surfaces of the silica gel massage linings can massage chests, keep the chests fit, promote blood circulation, and accelerate metabolism. The product is reasonable in integral design, ingenious in conception and good in practicability.

Owner:天津欧迪芬服装销售有限公司

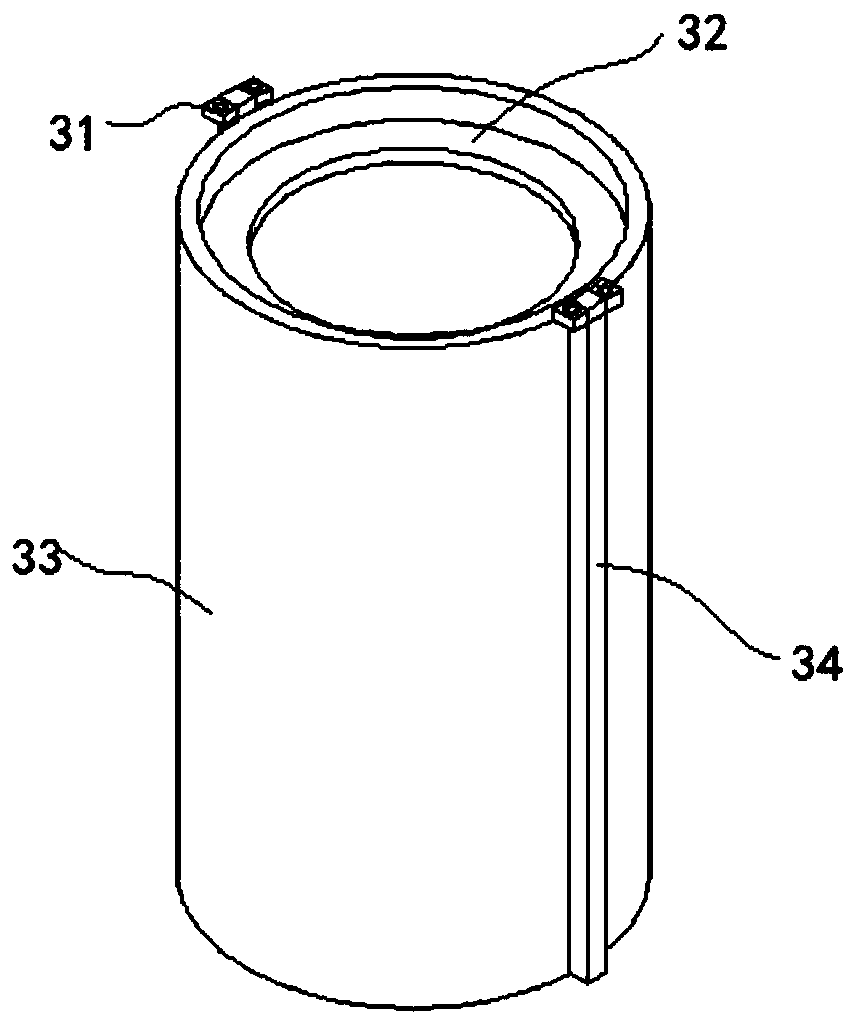

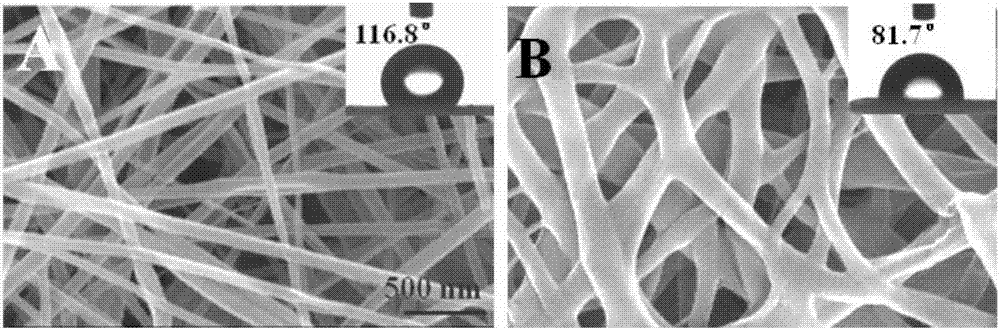

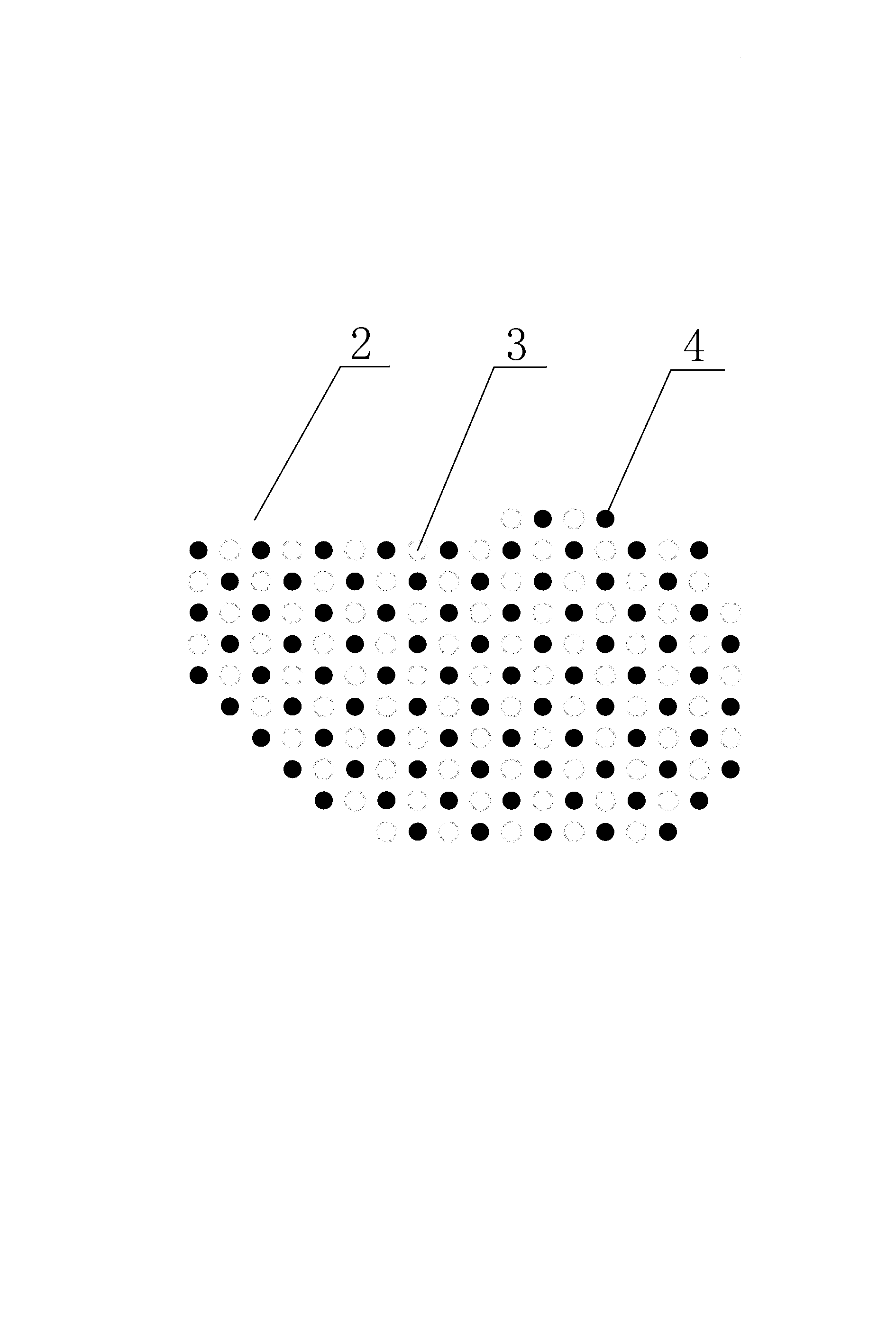

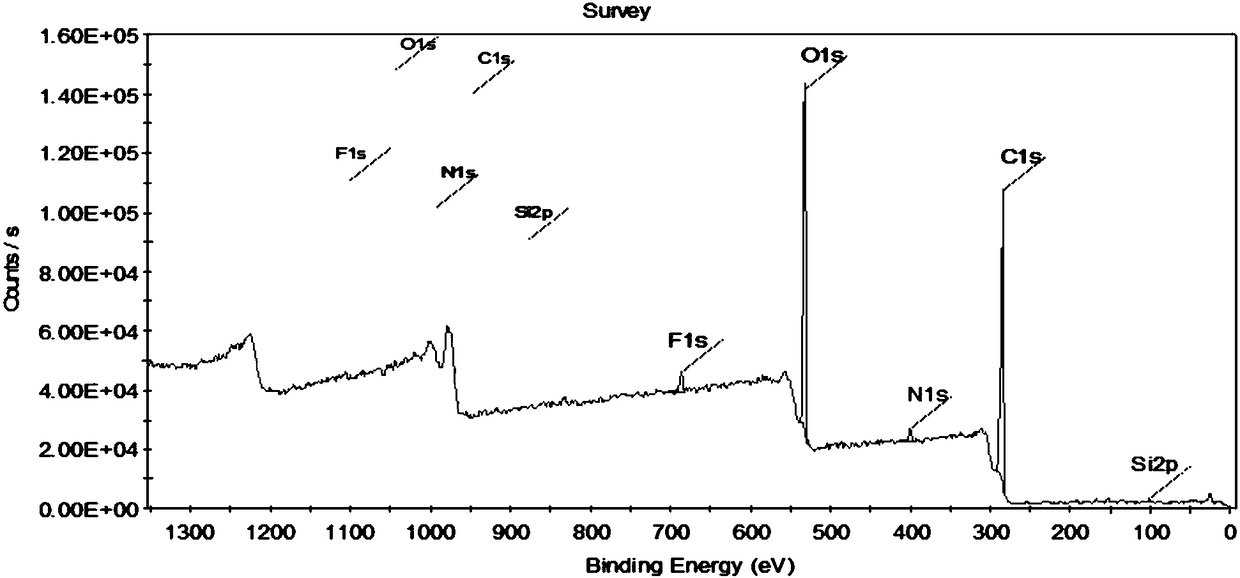

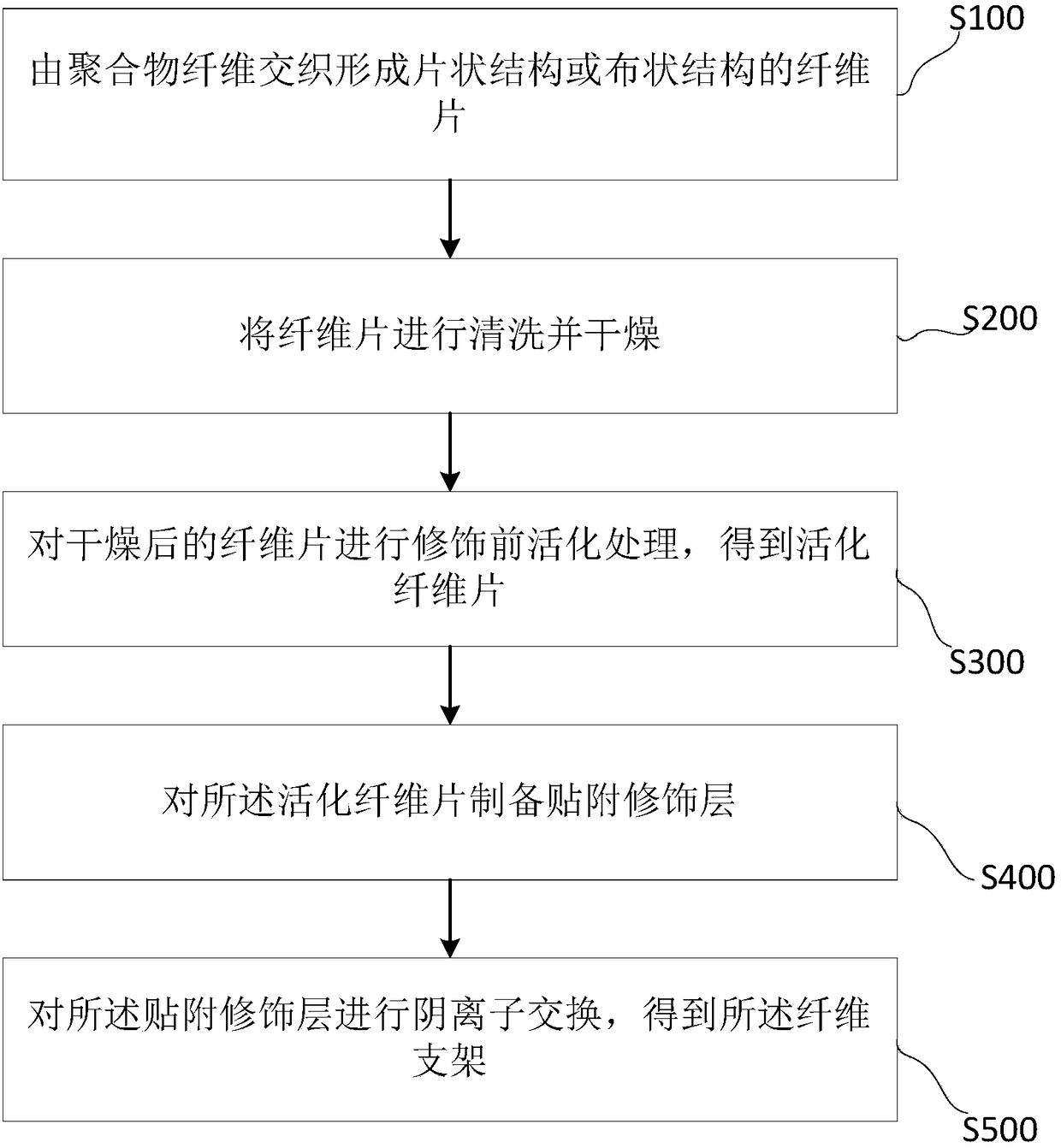

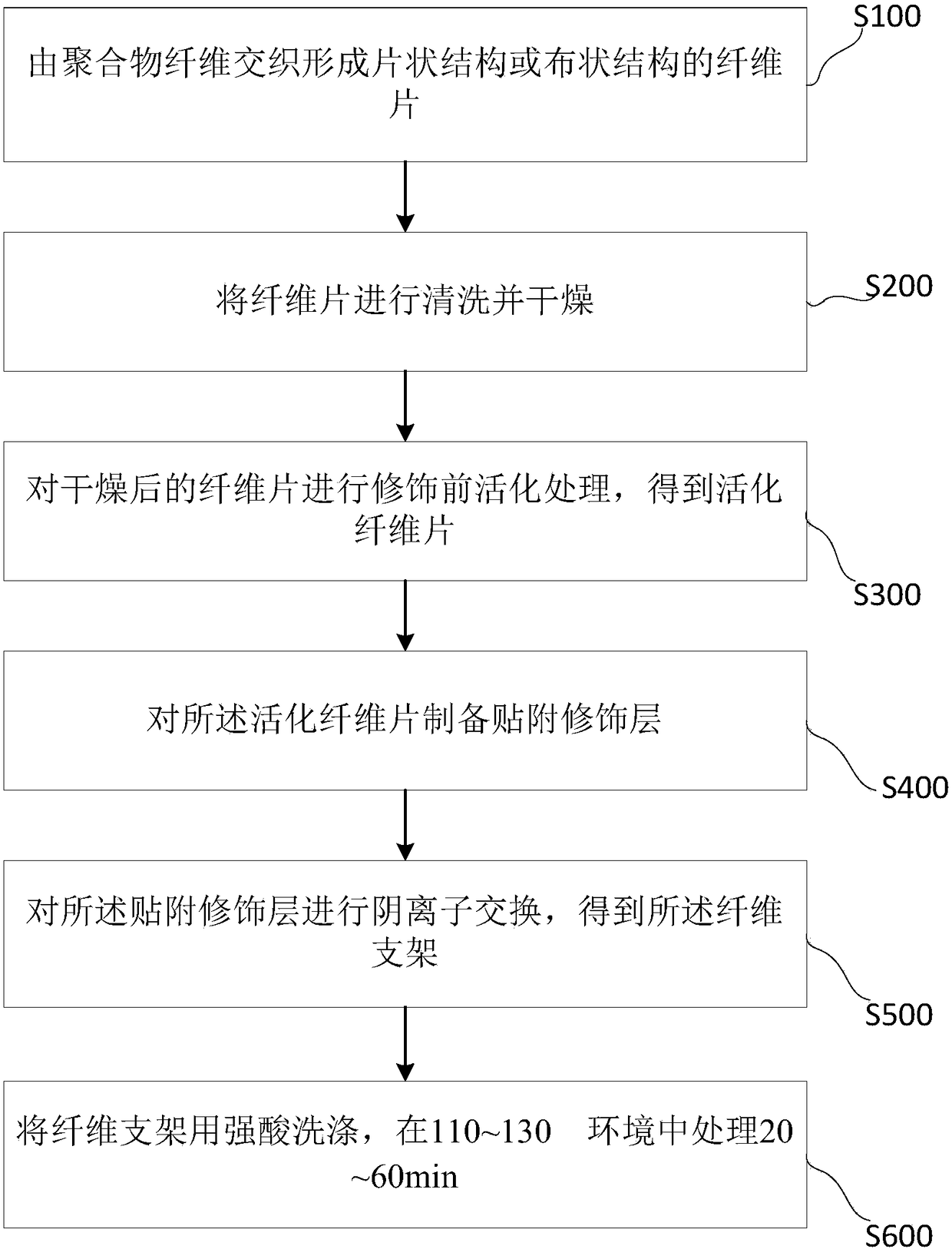

Fibrous scaffold, and preparation method and application thereof

ActiveCN108118023ABig gapIncrease cell attachment abilityAnimal cellsFibre typesFiberCultured Cell Line

The invention provides a fibrous scaffold, a preparation method for the fibrous scaffold and application of the fibrous scaffold to animal cell culture. The fibrous scaffold comprises polymeric fibersand a positive-charge modification layer covering the surfaces of the polymeric fibers, wherein the diameters of the polymeric fibers are in a range of 10 to 60 [mu]m, and surface positive charge concentration is 0.2 to 0.3 mmol / g. The fibrous scaffold provided by the invention has greater gaps, higher mechanical strength, stable performance and complete hydrophilicity, can be cyclically utilized, and is beneficial for culture and growth of cells. The preparation method for the fibrous scaffold is simple in steps and suitable for production of various scales.

Owner:GUANGDONG UNISUN BIOTECHNOLOGY CO LTD

Traditional Chinese medicine plaster for treating chronic pyelonephritis

InactiveCN101953982ATo cure diseaseRegain healthHeavy metal active ingredientsHydroxy compound active ingredientsDiseaseChronic pyonephrosis

The invention discloses a traditional Chinese medicine plaster for treating chronic pyelonephritis, which relates to three formulae A, B and C, wherein the formula A comprises 20 medicines in weight: 50g of radix scrophulariae, 50g of radix rehmanniae, 30g of goldthread root, 30g of baikal skullcap root, 30g of cape jasmine, 40g of amur corktree bark, 40g of rhizoma anemarrhenae, 40g of tortoise plastron,40g of carapax trionycis, 30g of angelica, 40g of red peony root, 30g of rhizoma alismatis, 30g of fiveleaf akebia, 30g of toosendan fruit, 30g of umbellate pore furgus, 30g of pangolin, 30g of radix achyranthis bidentatae, 30g of liquorice, 10g of hair and 30g of plantain seed; the formula B comprises 10 medicines which are ground into fine powder for later use: 100g of talcum, 20g of agilawood, 20g of costus root, 10g of cloven, 15g of cattail pollen, 15g of japanese fern spore, 15g of amber, 15g of borneol, 30g of rhubarb and 10g of cinnamon; and the formula C comprises 4 medicines which are respectively prepared in weight for later use: 1500ml of sesame oil, 550g of yellow lead powder, 30ml of azone and 1g of musk. The traditional Chinese medicine plaster of the invention treats the chronic pyelonephritis disease in a plaster form, and can achieve the effects of curing disease and restoring health under the condition that the daily production and life of patients are unaffected.

Owner:杨鲲

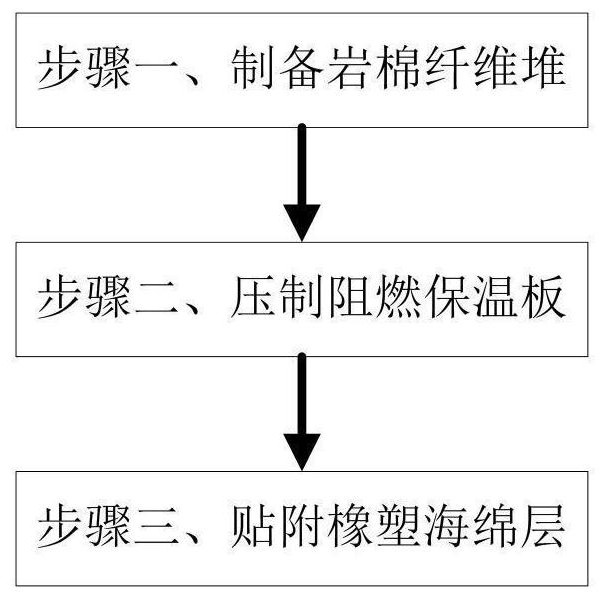

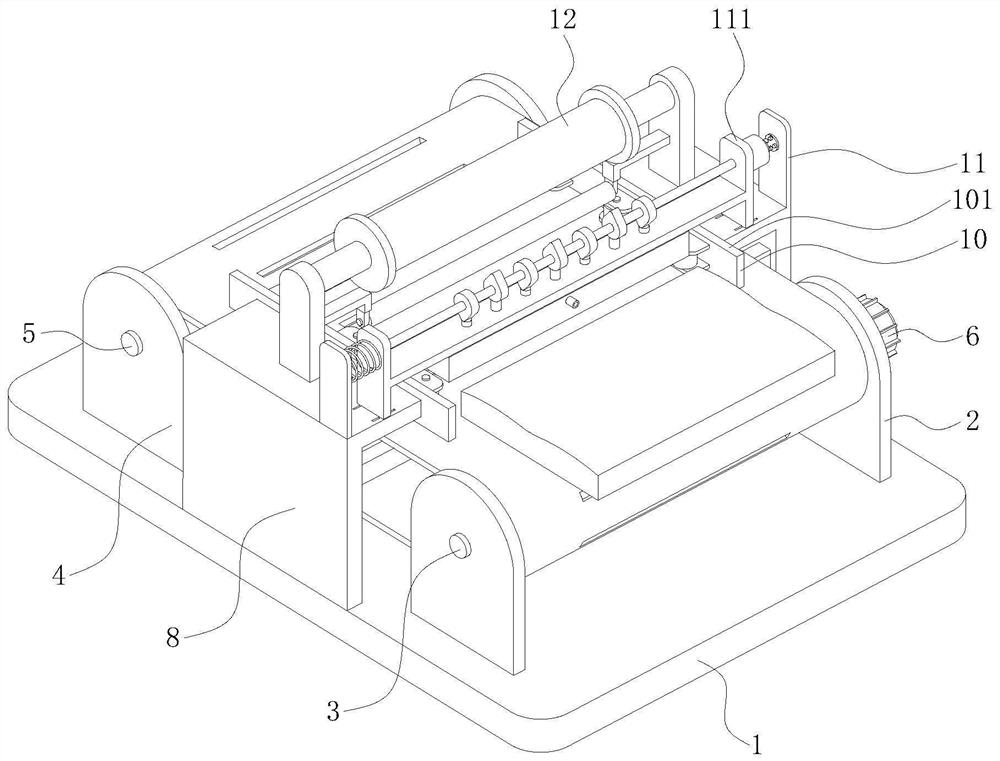

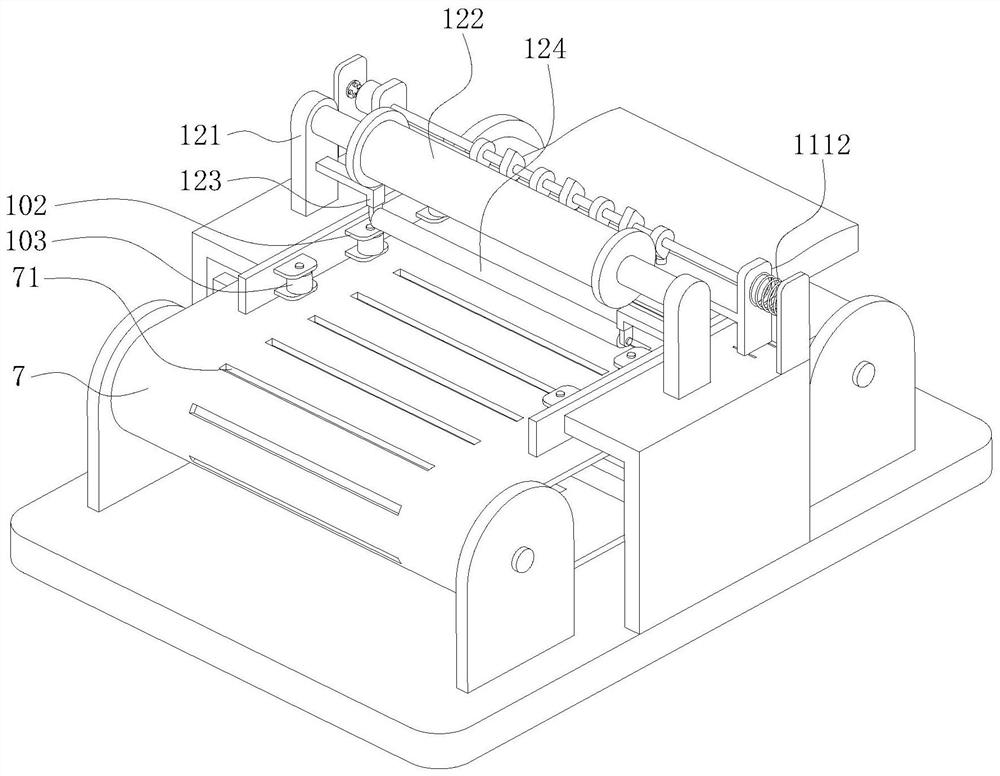

Manufacturing process of flame-retardant rubber-plastic sponge insulation board

InactiveCN112092420AUniform glue outputGuaranteed uniformity of adhesionFlat articlesAdhesive glueCotton fibre

The invention belongs to the technical field of insulation boards, and particularly relates to a manufacturing process of a flame-retardant rubber-plastic sponge insulation board. The manufacturing process comprises the following steps of 1, preparing a rock wool fiber pile: carrying out high-temperature melting on basalt ore to form a liquid, forming rock wool fibers through blowing of a centrifuge, and stacking on a conveying belt of a settling chamber to form the rock wool fiber pile; step 2, pressing the flame-retardant insulation board: pressurizing the stacked rock wool fiber piles through a pressurizing roller, feeding the rock wool fiber piles into a curing oven, mixing the rock wool fiber piles with a binder, a dust-proof agent and a water repellent to generate the flame-retardantinsulation board, and then cooling and curing the flame-retardant insulation board; and step 3, attaching a rubber-plastic sponge layer: attaching the rubber-plastic sponge layer to the surface of the flame-retardant insulation board prepared in the step 2, wherein the step 3 is completed by cooperation with a manufacturing device for the flame-retardant rubber-plastic sponge insulation board. Rubber-plastic sponge can be tightly attached to the surface of a rock wool board, glue is evenly distributed on the surface of the rock wool board, and the attaching effect of the rubber-plastic spongeis improved.

Owner:储超超

Material strip lubricating device

InactiveCN104174773AImproves application uniformityImprove the sticking effectShaping toolsLiquid surface applicatorsFuel tankEngineering

The invention relates to a material strip lubricating device. The material strip lubricating device comprises a conveyor belt; a material strip is placed on the conveyor belt; a dripping nozzle is arranged above the material belt and communicated with an oil tank; the dripping nozzle is of a casing structure with the large upper end and the small lower end; the outer side of the upper end of the dripping nozzle is provided with an oil pipe which is communicated with the oil tank; the inner wall of the dripping nozzle is fixedly connected with an oil guide plate in an inclined mode; the high end of the oil guide plate is provided with an arc-shaped oil guide area and located below an oil inlet of the oil pipe; a plurality of oil leakage holes are uniformly formed in the oil guide plate; the lower end of the dripping nozzle is provided with an oil guide portion with an oil falling groove, wherein the oil guide portion is bent towards the conveying direction of the conveyor belt; the material strip lubricating device also comprises a blow head which is arranged above the material belt and located on the front side of the dripping nozzle; an air nozzle of the blow head is towards the oil falling groove of the dripping nozzle. According to the material strip lubricating device, the oil flow is uniformly guided to drip to the oil guide portion through the oil guide plate, oil droplets are uniformly daubed on the material belt through the oil falling groove due to the oil guide portion, and accordingly the daub uniformity is high and an auxiliary oil layer is attached to the upper surface of the material belt due to the blowing effect of the blow head which is arranged on the front side and accordingly the attachment capability is improved.

Owner:寇兴国 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com