Adhesive tape used as shielding cover and application of adhesive tape

A technology of shielding cover and tape, applied in the fields of magnetic field/electric field shielding, adhesive, film/flake adhesive, etc., can solve the problems of cost, heavy weight, complicated processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

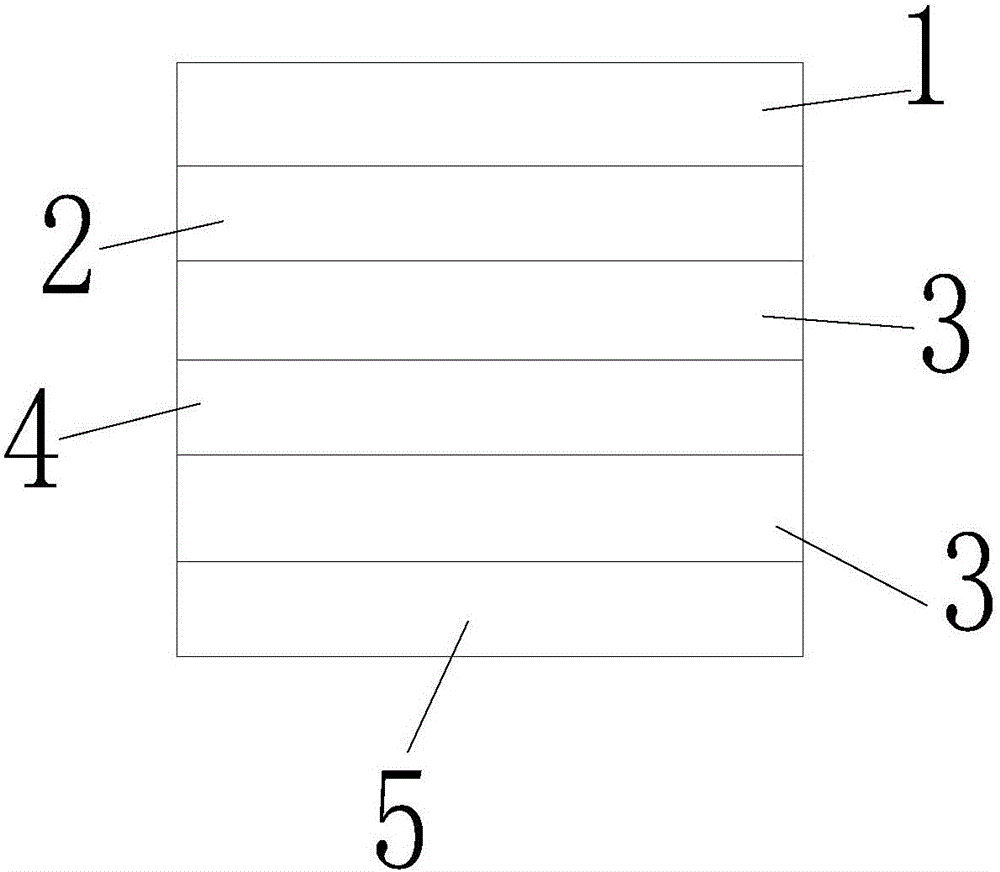

[0031] The adhesive tape used as a shielding cover of the present invention comprises a release layer 5, a conductive adhesive layer 3, a conductive fiber layer 4, a conductive adhesive layer 3, a conductive matrix layer 2 and an oxidation-resistant conductive coating 1 which are connected in sequence. The thickness of the adhesive tape is 0.03mm. The conductive base layer is a copper foil layer, and the thickness of the conductive base layer is 0.005mm. The conductive adhesive layer includes in parts by mass: 60 parts of acrylic resin, 0.5 parts of curing agent, and 4 parts of conductive particles. The conductive particles are copper powder. The conductive fiber layer is conductive cloth.

Embodiment 2

[0033] The adhesive tape used as a shielding cover of the present invention comprises a release layer 5, a conductive adhesive layer 3, a conductive fiber layer 4, a conductive adhesive layer 3, a conductive matrix layer 2 and an oxidation-resistant conductive coating 1 which are connected in sequence. The thickness of the adhesive tape is 0.1 mm. The conductive base layer is an aluminum foil layer, and the thickness of the conductive base layer is 0.05mm. The conductive adhesive layer includes in parts by mass: 95 parts of acrylic resin, 5 parts of curing agent, and 25 parts of conductive particles. The conductive particles are silver powder. The conductive fiber layer is conductive non-woven fabric.

Embodiment 3

[0035] The adhesive tape used as a shielding cover of the present invention comprises a release layer 5, a conductive adhesive layer 3, a conductive fiber layer 4, a conductive adhesive layer 3, a conductive matrix layer 2 and an oxidation-resistant conductive coating 1 which are connected in sequence. The thickness of the adhesive tape is 0.3 mm. The conductive base layer is a conductive cloth layer, and the thickness of the conductive base layer is 0.25mm. The conductive adhesive layer includes in parts by mass: 80 parts of acrylic resin, 4 parts of curing agent, and 30 parts of conductive particles. The conductive particles are nickel powder. The conductive fiber layer is conductive gauze.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com