Thermoplastic polyurethane (TPU) thin film used for automobile surface protection, and preparation method of self-repair coating of TPU thin film

A self-repairing technology for the surface of automobiles, which is applied in the direction of surface coating liquid devices, coatings, special surfaces, etc., which can solve the problems of inability to protect the surface of the automobile, no anti-static function, high cost of thermotropic liquid crystal epoxy resin, etc. Problems, to achieve the effect of widely popularizing and applying, maintaining clean and beautiful appearance, and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

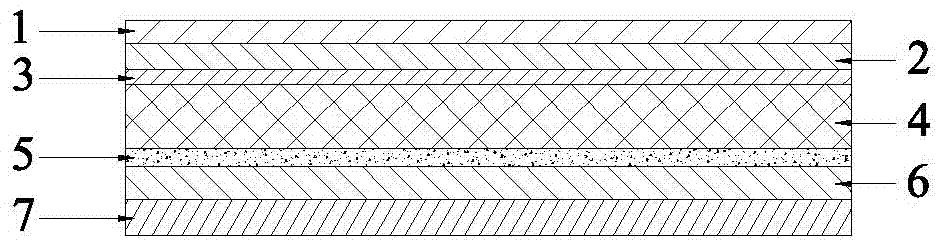

[0042] Example 1: see figure 1 , the embodiment of the present invention provides a TPU film for automobile surface protection, which includes a PE protective layer 1, a self-repairing coating 2, an antifouling layer 3, an elastic TPU layer 4, an adhesive layer 5, a release layer 6 and a PET Layer 7, the PE protective layer 1, self-healing coating 2, antifouling layer 3, elastic TPU layer 4, adhesive layer 5, release layer 6 and PET layer 7 are laminated sequentially from top to bottom.

[0043]Specifically, the self-healing coating includes the following raw materials in parts by weight: 1000 parts of isocyanate substances, 1100 parts of polyols containing conjugated structures, 18 parts of catalysts, 130 parts of chain extenders, 1300 parts of solvents, and 80 parts of dispersants Parts, 60 parts of defoamer.

[0044] Wherein, the isocyanate substance is a mixture of conjugated butadiene isocyanate and modified epoxy isocyanate in a ratio of 1:3; the polyol containing a con...

Embodiment 2

[0053] Embodiment 2: a kind of TPU film and its self-repairing coating preparation method for automobile surface protection provided by the present embodiment, it is basically consistent with implementation 1, and difference is in the following differences:

[0054] The self-healing coating includes the following raw materials in parts by weight: 1100 parts of isocyanate substances, 1200 parts of polyols containing conjugated structures, 16 parts of catalysts, 150 parts of chain extenders, 1100 parts of solvents, 70 parts of dispersants, Foam agent 45 parts.

[0055] Among them, the PE protective layer is preferably a PE medium-adhesive film with a thickness of 18 μm, its peel strength is 20g / cm, and the elongation rate is 420%, which can resist the corrosion of the self-repairing layer by the external environment; preferably, the self-repairing coating is coated The thickness of the cloth film is 6µm, which meets the function of self-repairing of automobiles; the self-repairi...

Embodiment 3

[0063] Embodiment 3: a kind of TPU film and its self-repairing coating preparation method for automobile surface protection provided by the present embodiment, it is basically consistent with implementation 1, and difference is in the following differences:

[0064] The self-healing coating includes the following raw materials in parts by weight: 900 parts of isocyanate substances, 1000 parts of polyols containing conjugated structures, 12 parts of catalysts, 100 parts of chain extenders, 500 parts of solvents, 60 parts of dispersants, Foam agent 40 parts.

[0065] Wherein, the isocyanate substance is selected from modified epoxy isocyanate; the polyol containing conjugated structure is selected from 1,3 conjugated butadienyl propyl acrylate pentanediol and phenyl butadienyl Butanediol is composed of a mixture of 1::1; preferably, the chain extender is ethylenediamine; wherein, the solvent is white electric oil and isopropanol, methyl ethyl ketone and tetrahydrofuran in the or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com