Patents

Literature

44results about How to "Improves application uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

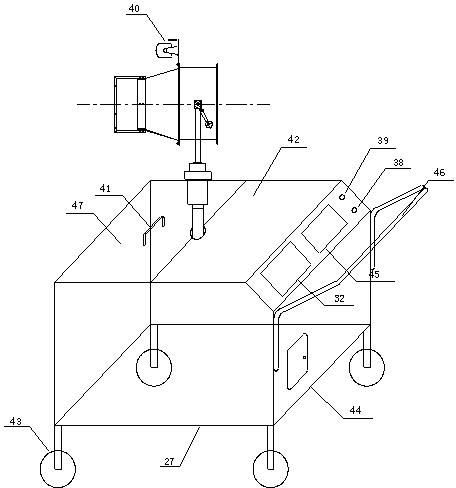

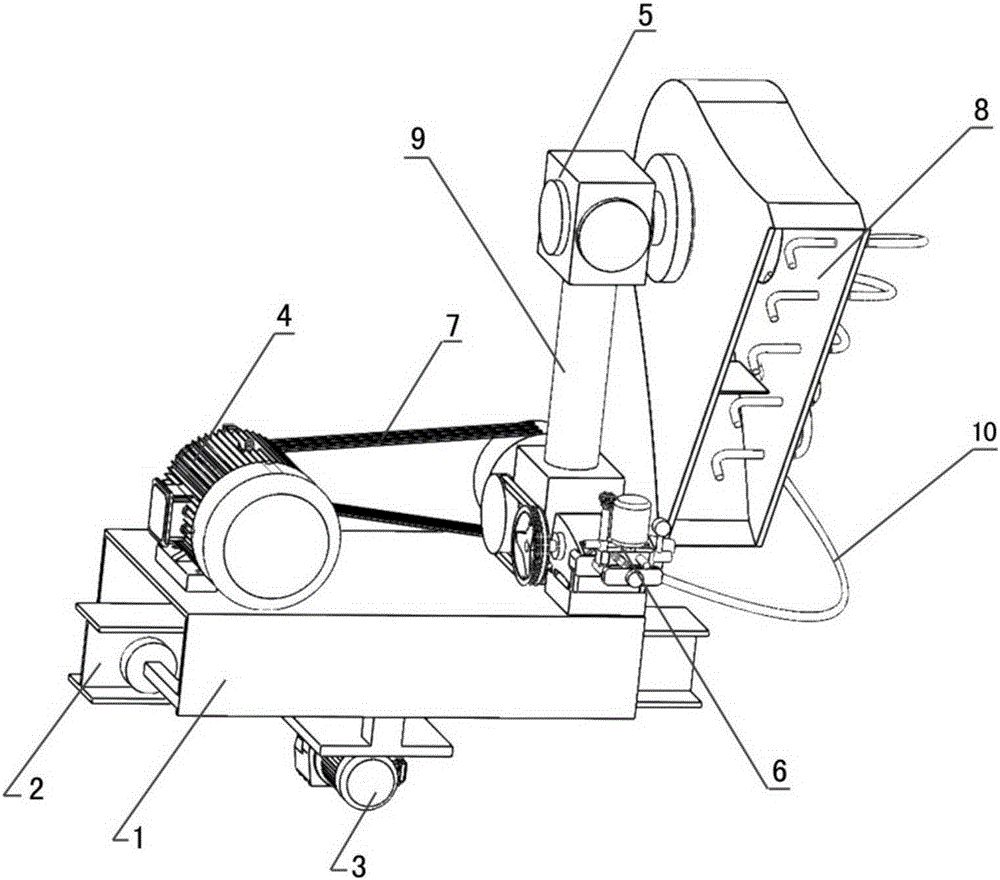

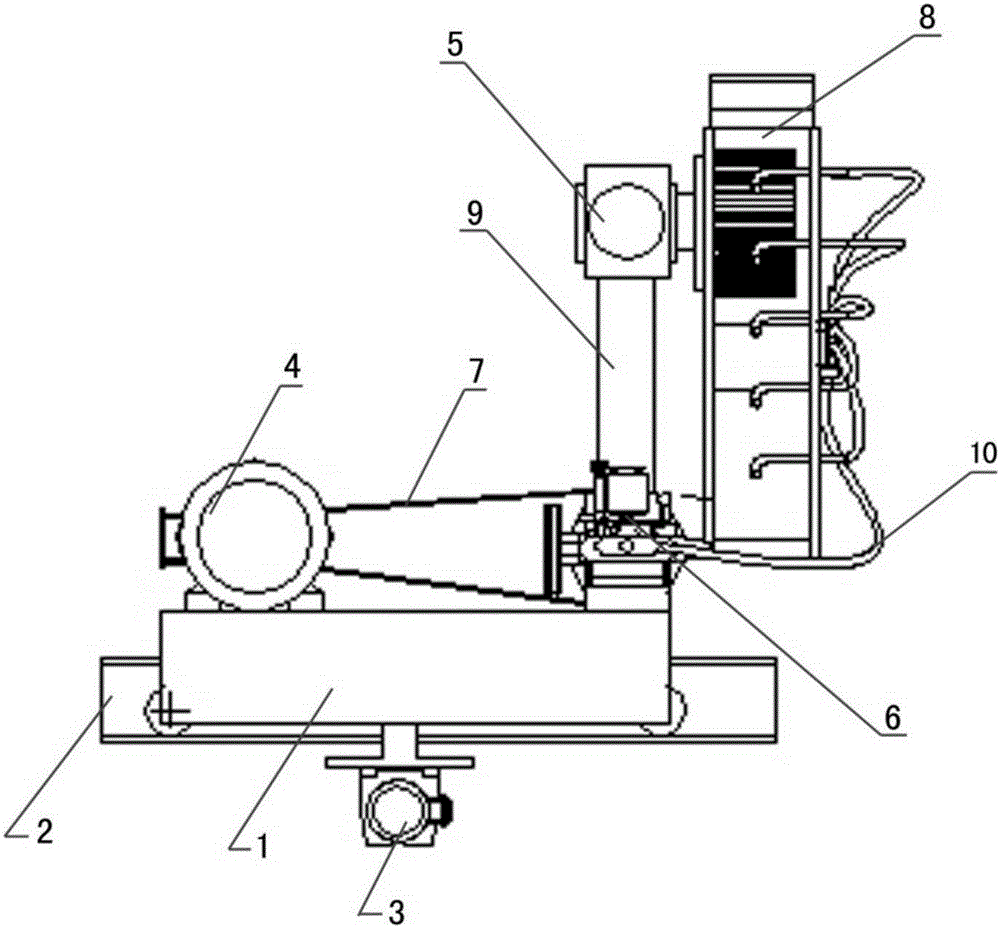

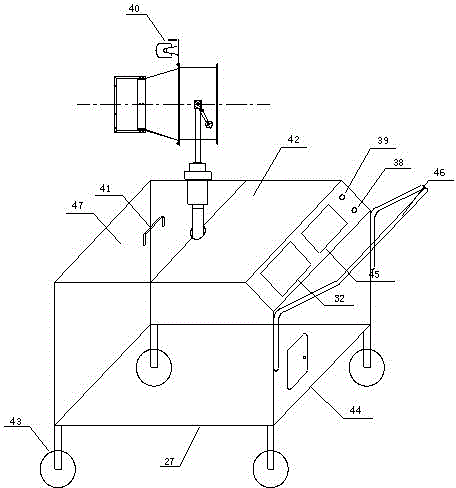

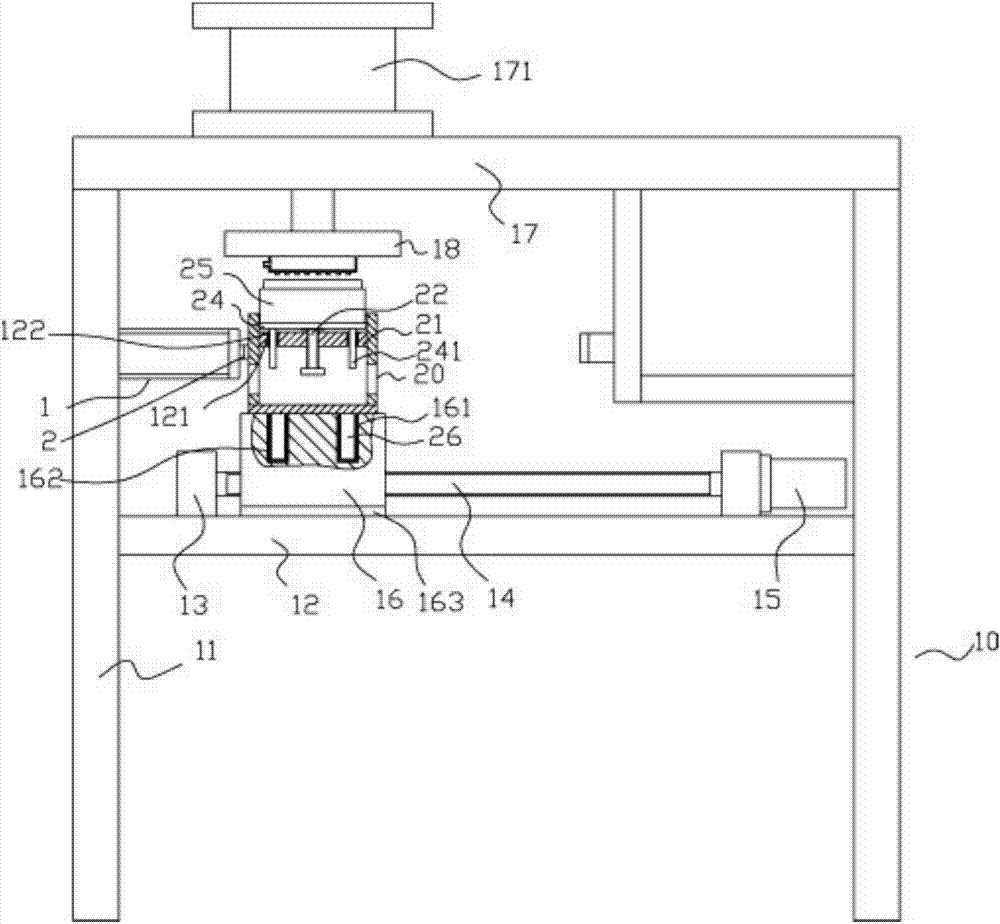

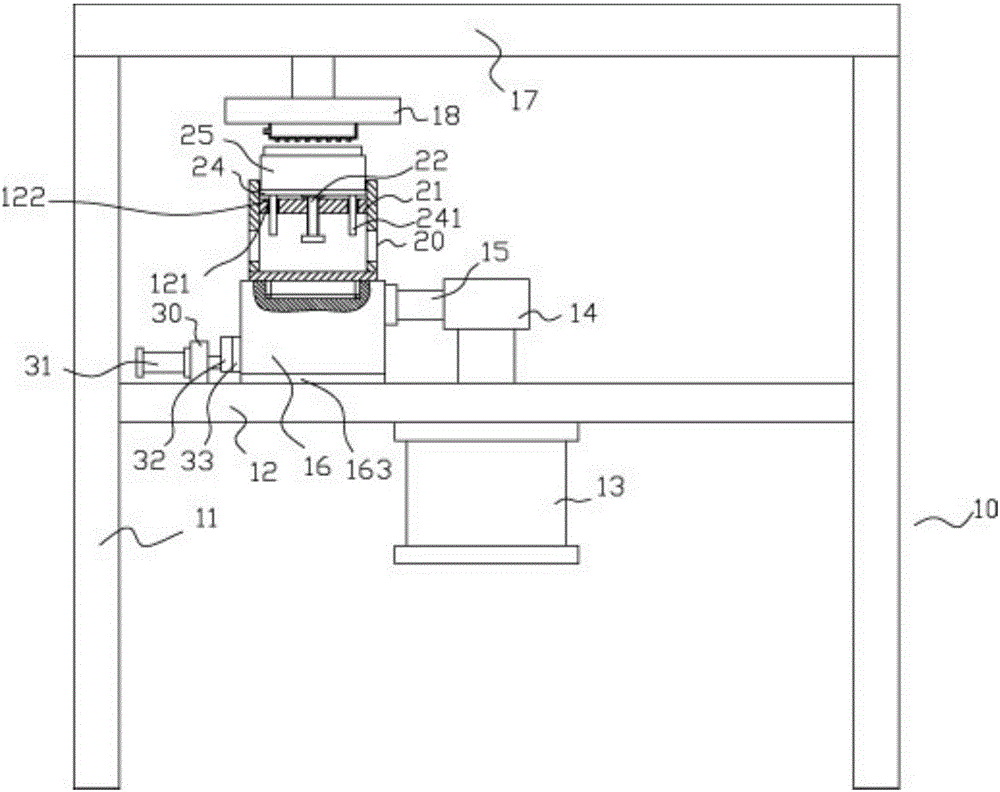

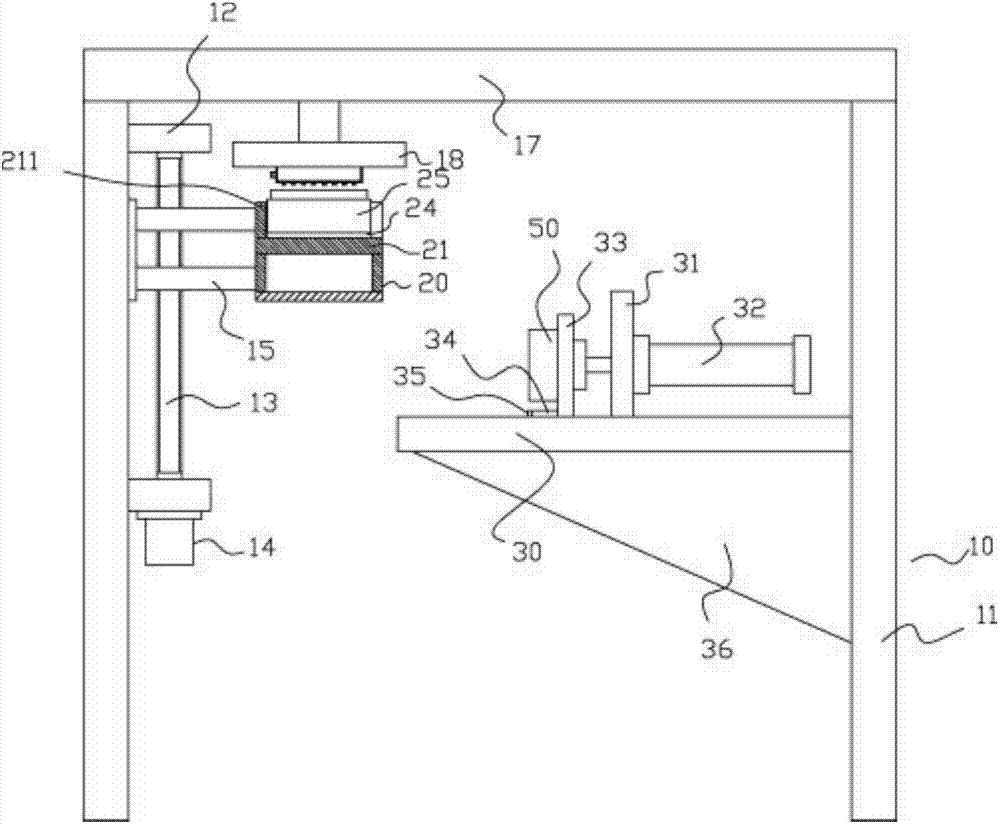

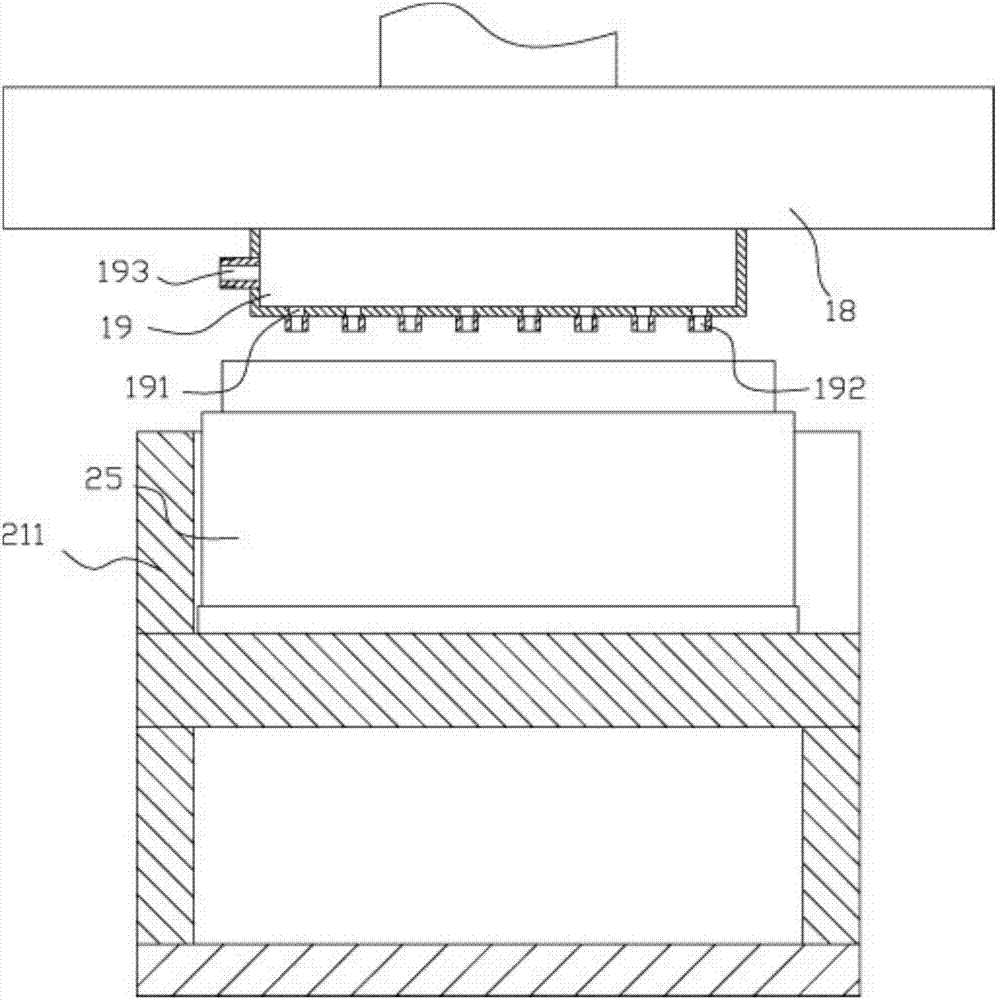

Self-controlled efficient and electrostatic-spraying pesticide application machine for greenhouses

InactiveCN102166548AIncrease profitGuaranteed control effectLiquid spraying apparatusSpray discharge apparatusHuman–machine interfaceEngineering

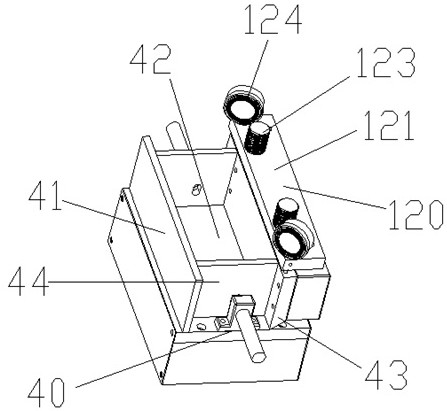

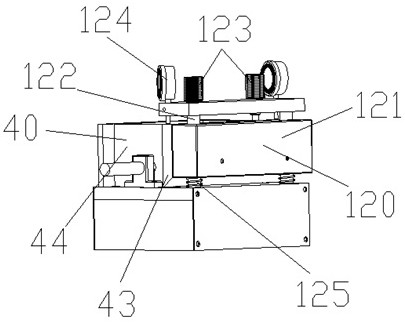

The invention relates to a self-controlled efficient and electrostatic-spraying pesticide application machine for greenhouses, and the machine provided by the invention comprises a spraying dolly, a pesticide supply system, a pressure fluctuation elimination system, an HMI-PLC (human-machine interface-programmable logic controller) human-machine interactive automatic logic control system, a rotating electrostatic spray system, a high-definition mistform vedio monitoring system, a machine frame and a power supply system, wherein the pesticide supply system, the pressure fluctuation elimination system, the HMI-PLC man-machine interactive automatic logic control system, the rotating electrostatic spray system and the power supply system are arranged in a spraying dolly shell (42); the high-definition mistform vedio monitoring system is arranged at the top of the spraying dolly; and the HMI-PLC man-machine interactive automatic logic control system is connected between the pesticide supply system and the rotating electrostatic spray system by virtue of a pipeline. By using the machine provided by the invention, on the premise of ensuring the pest control effect, the utilization rate of pesticides is improved, the pest control cost is reduced, the environmental pollution is reduced, the production efficiency and the social efficiency are improved simultaneously, and the labor intensity is reduced.

Owner:镇江和盛环境科技有限公司 +2

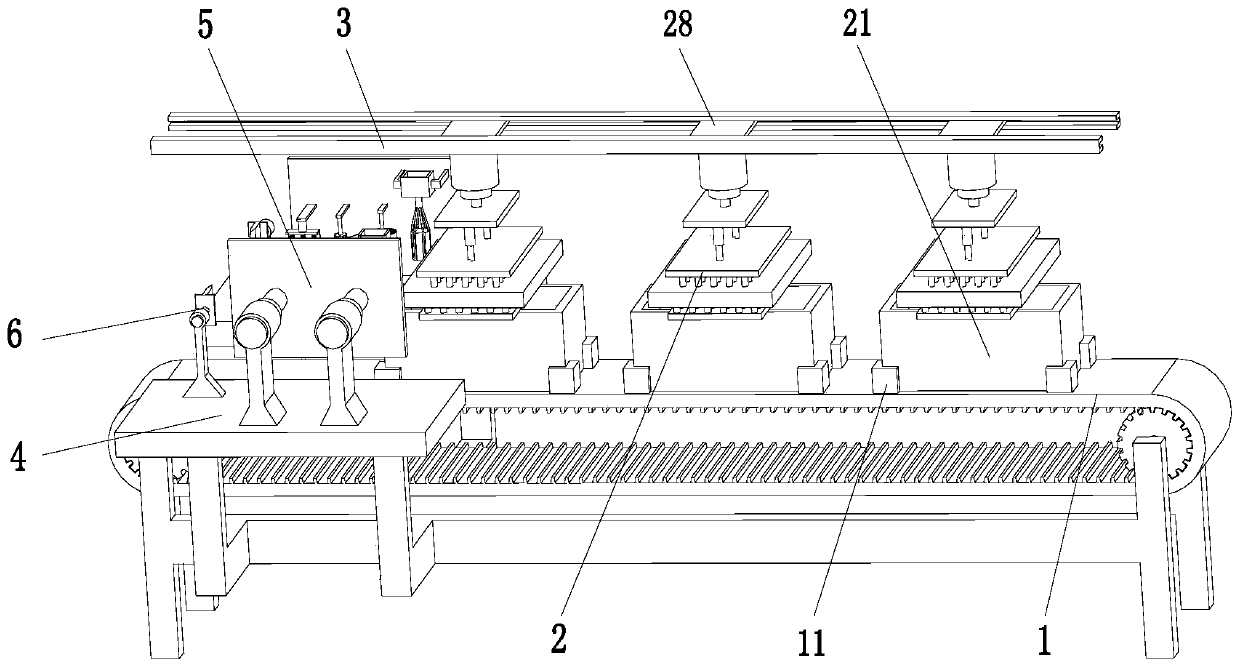

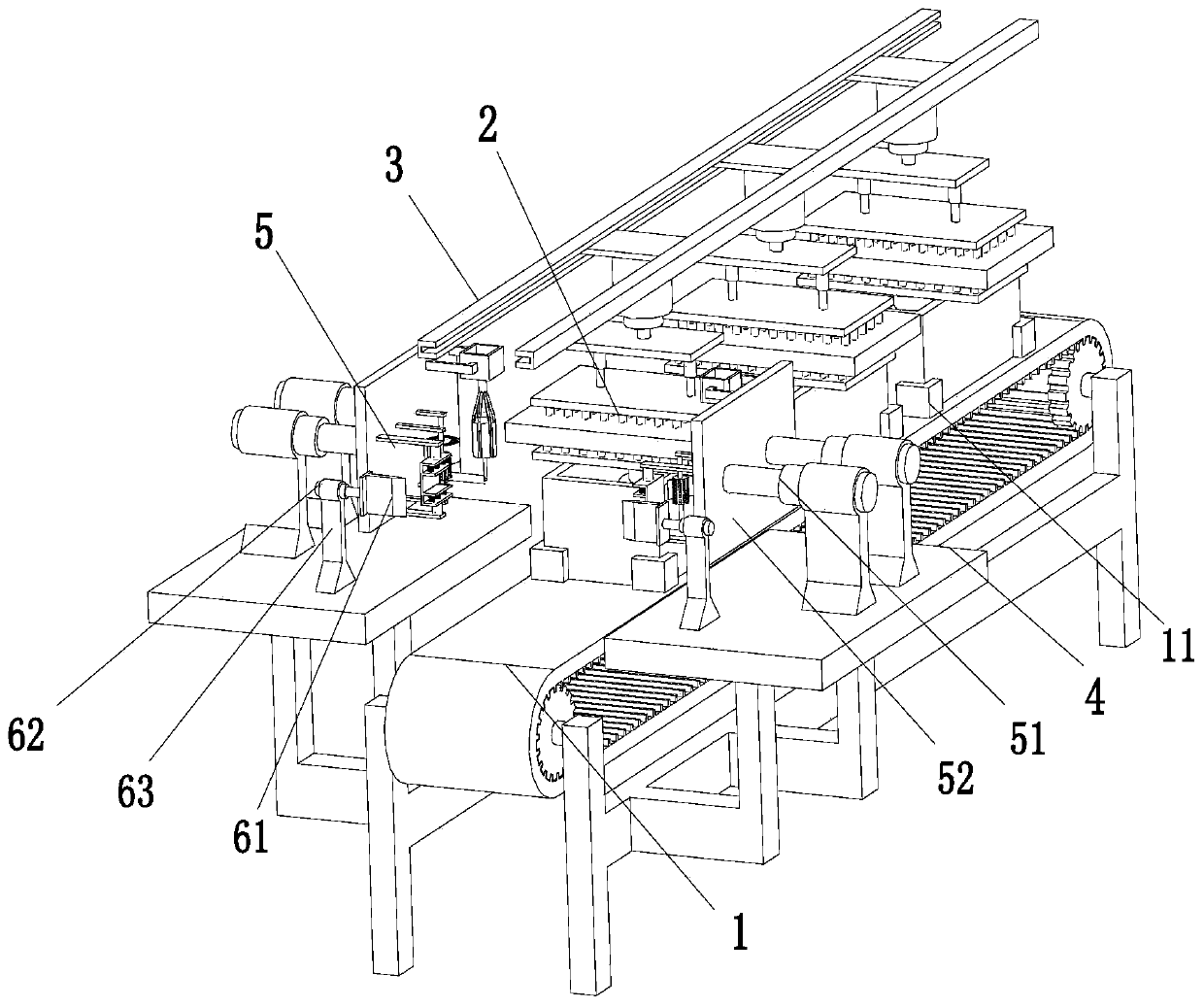

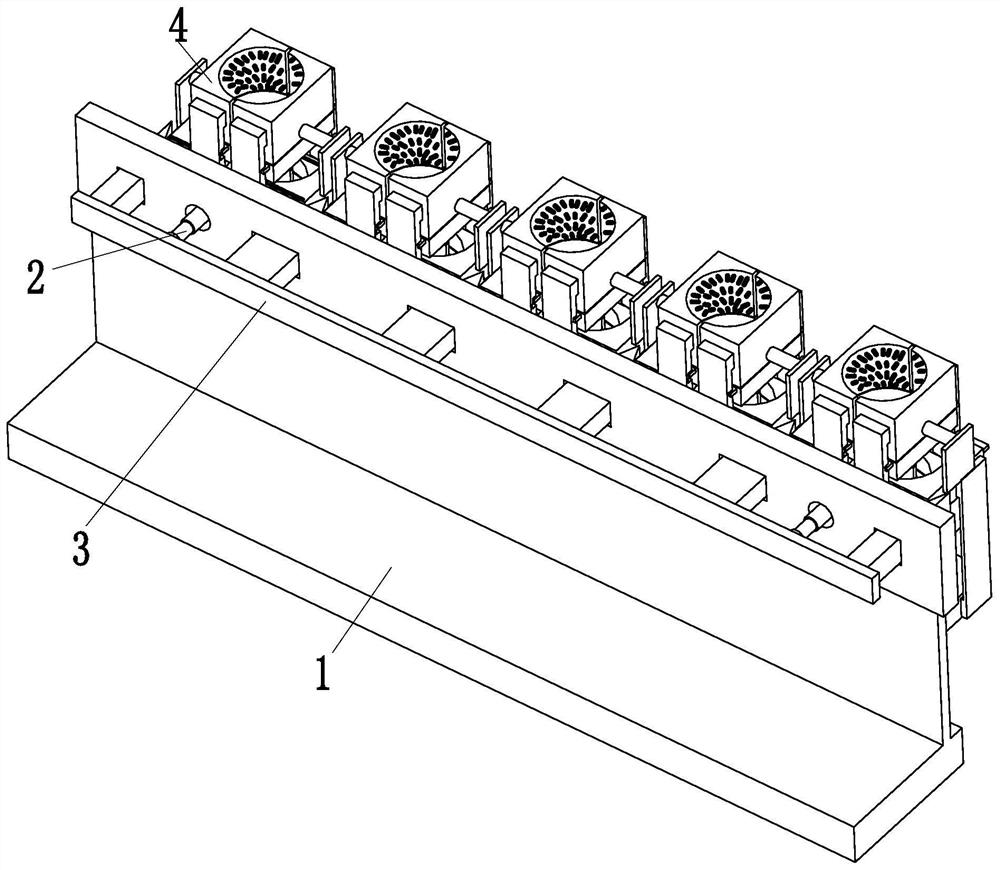

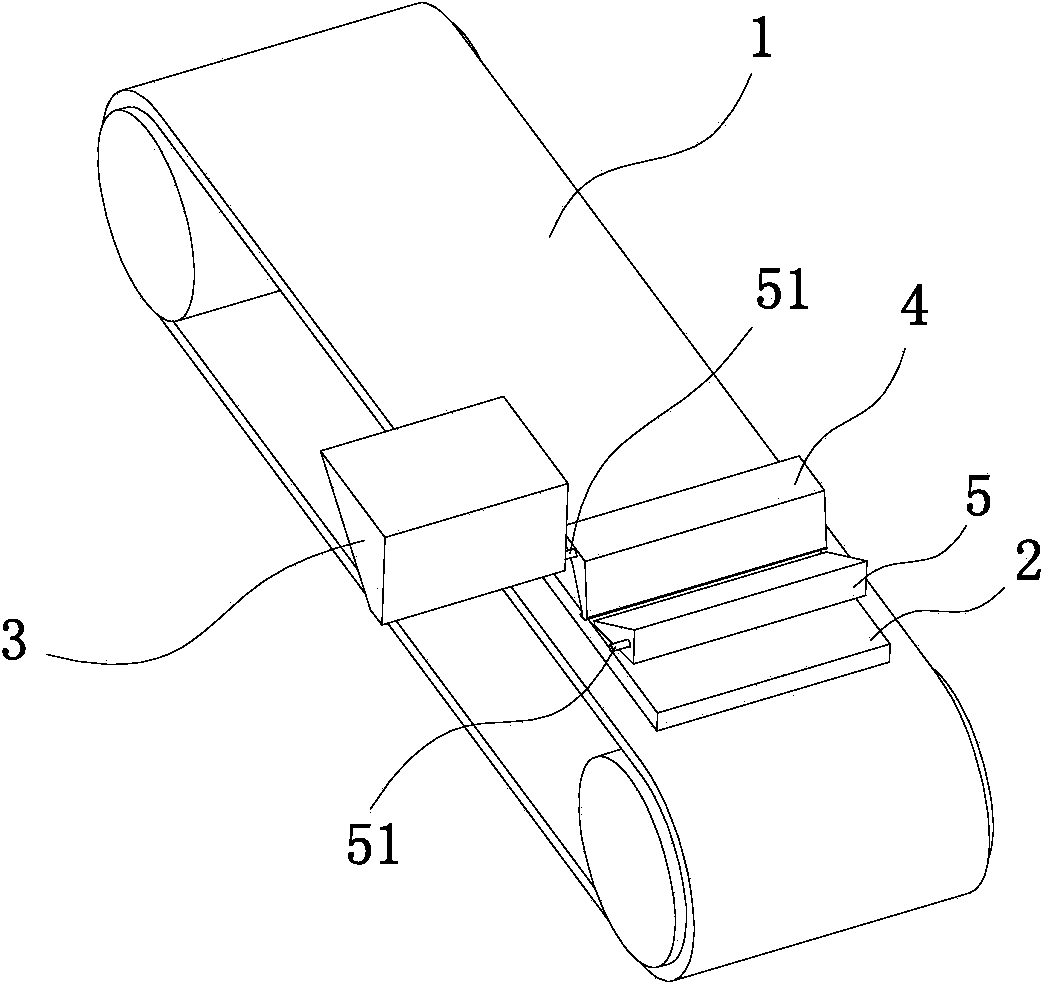

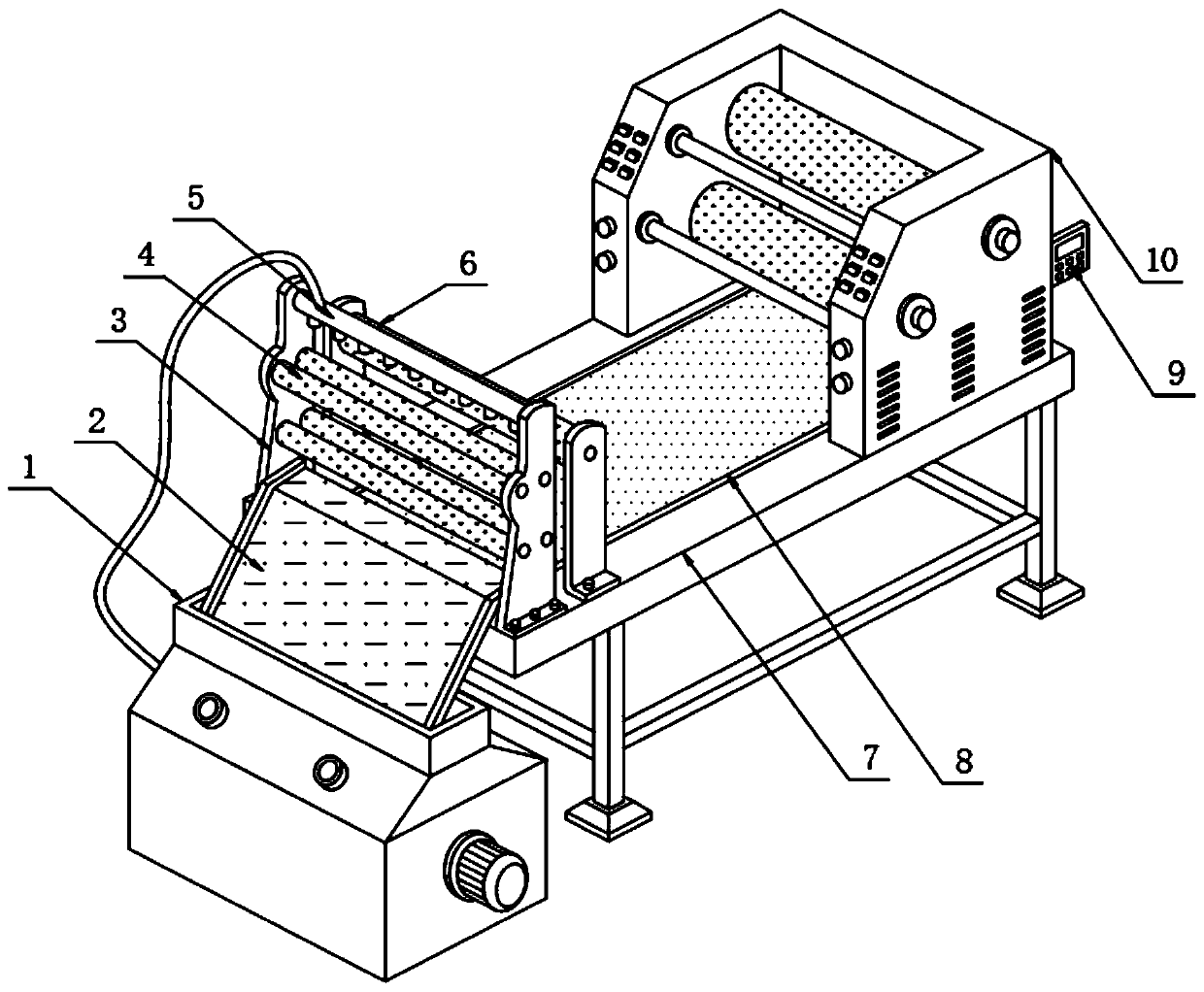

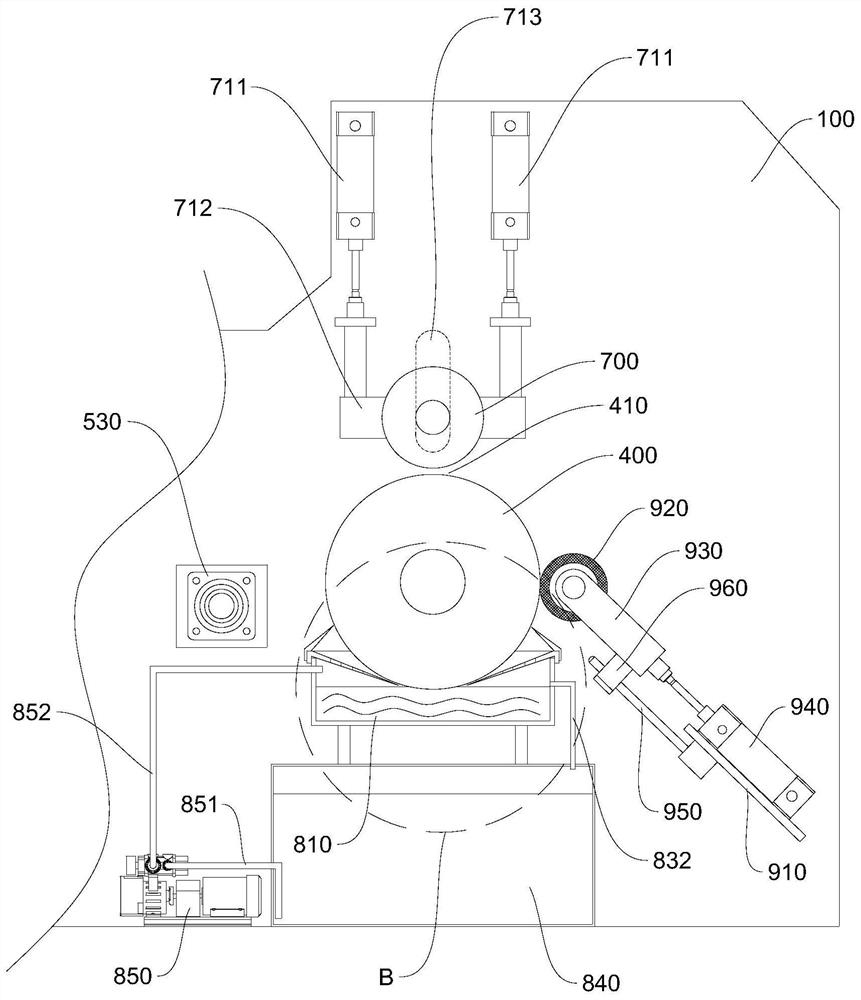

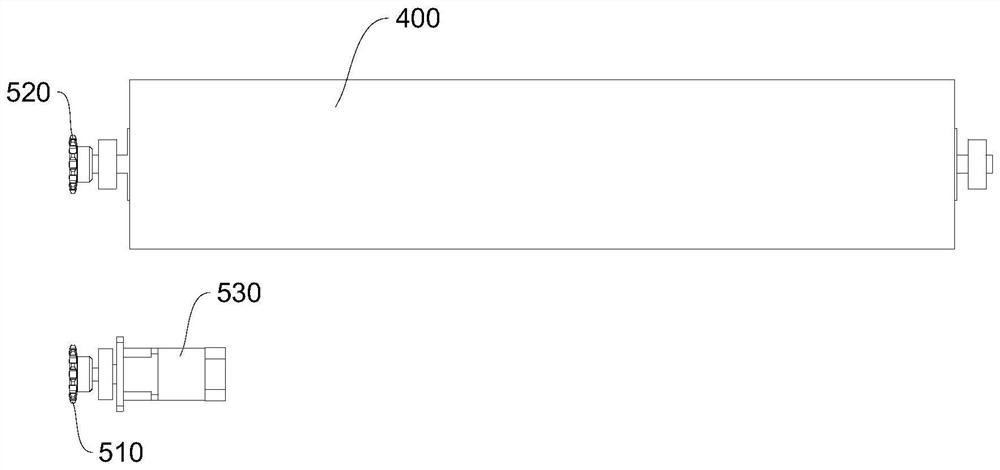

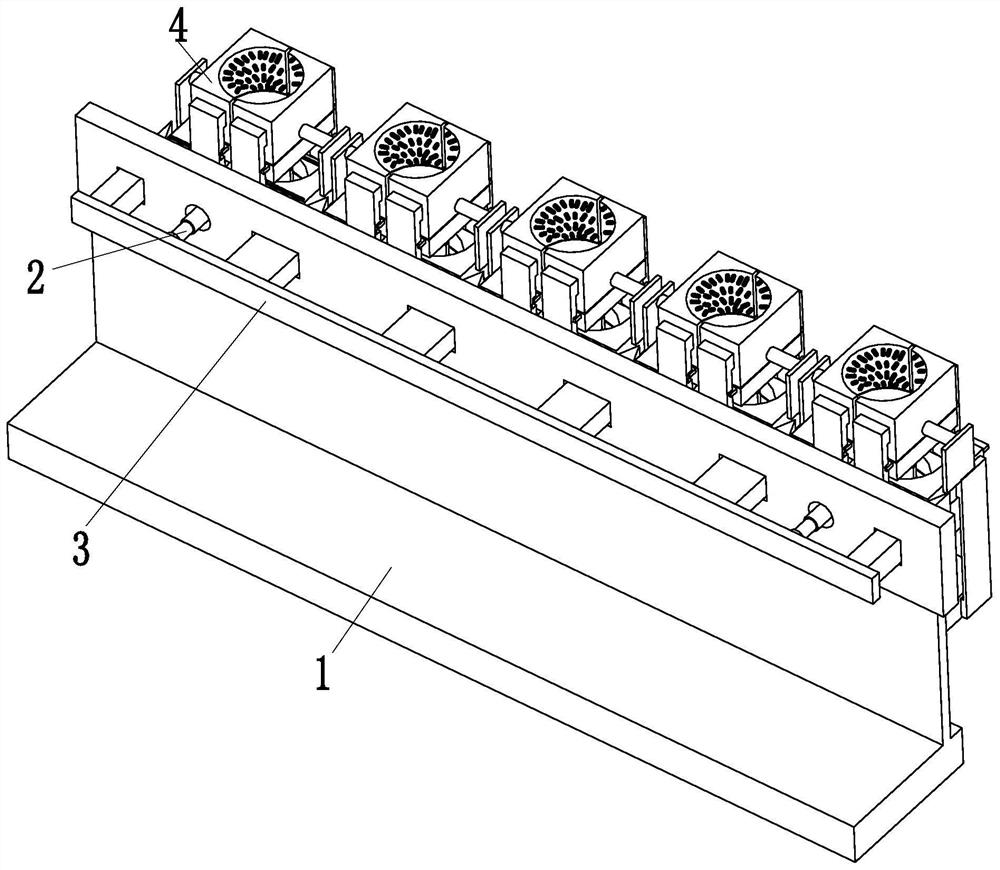

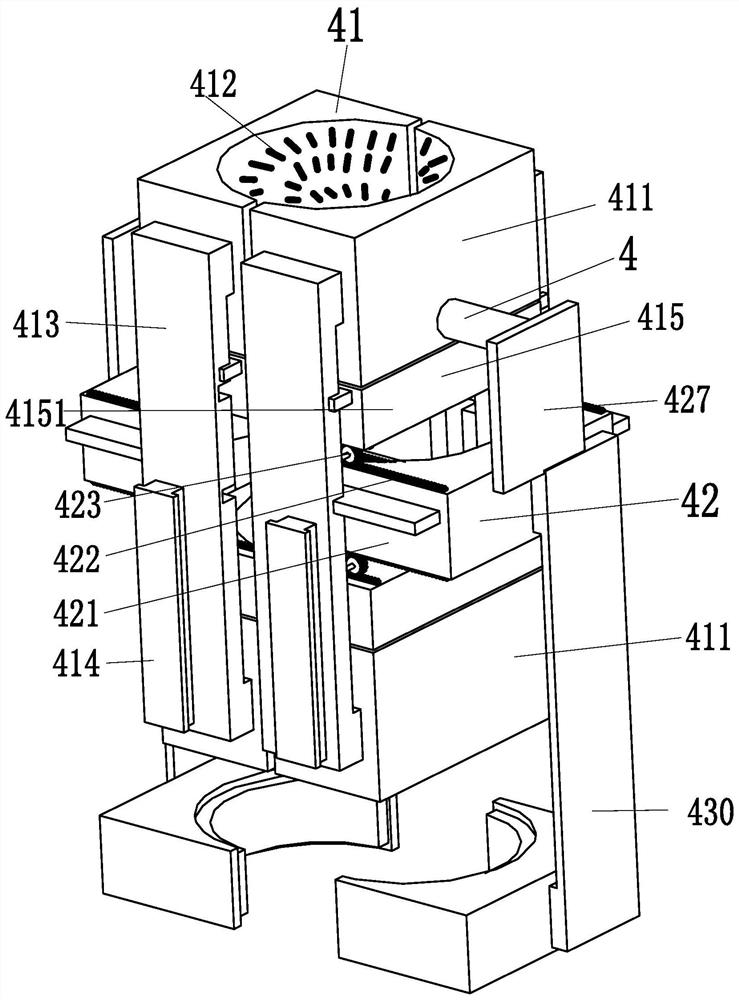

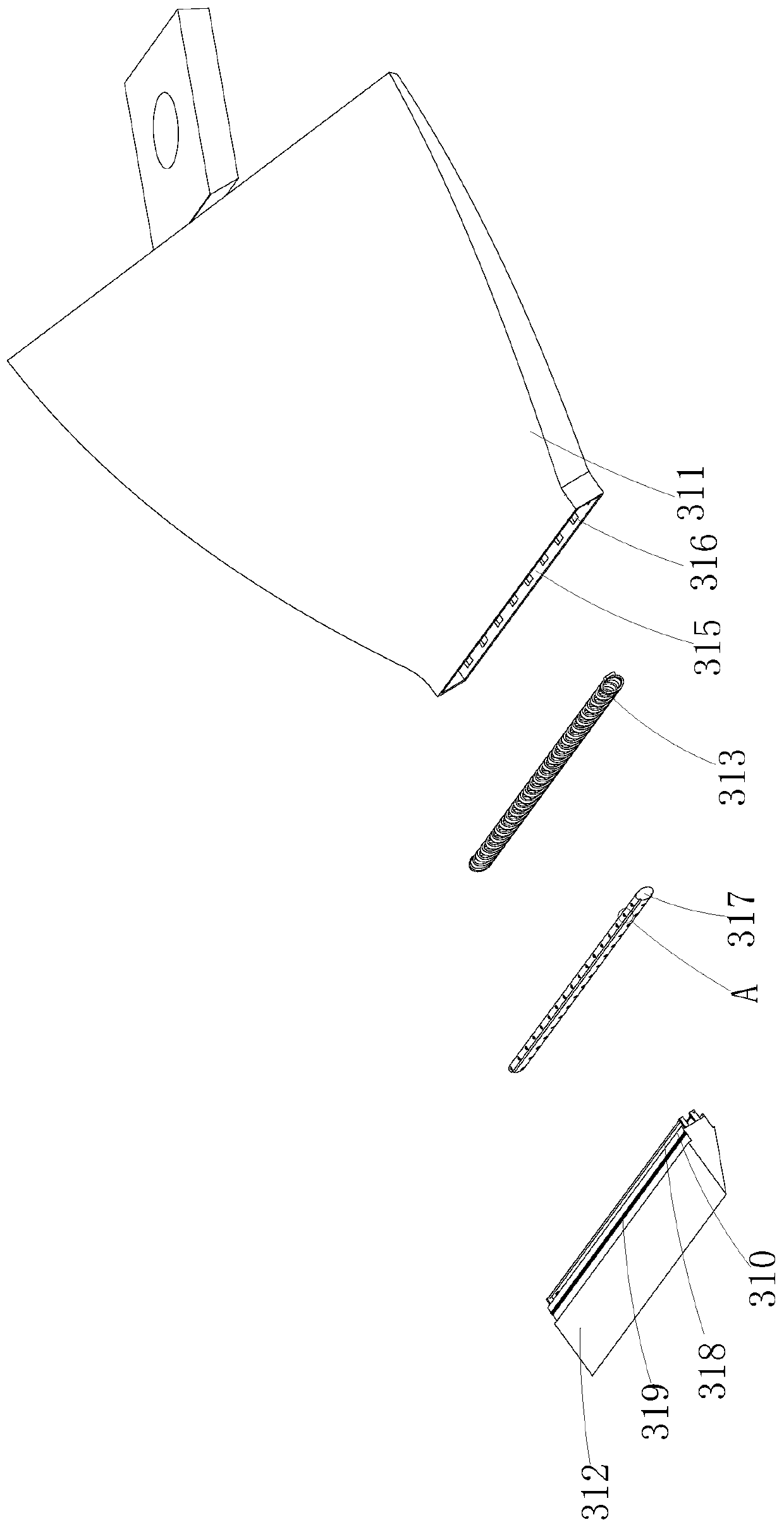

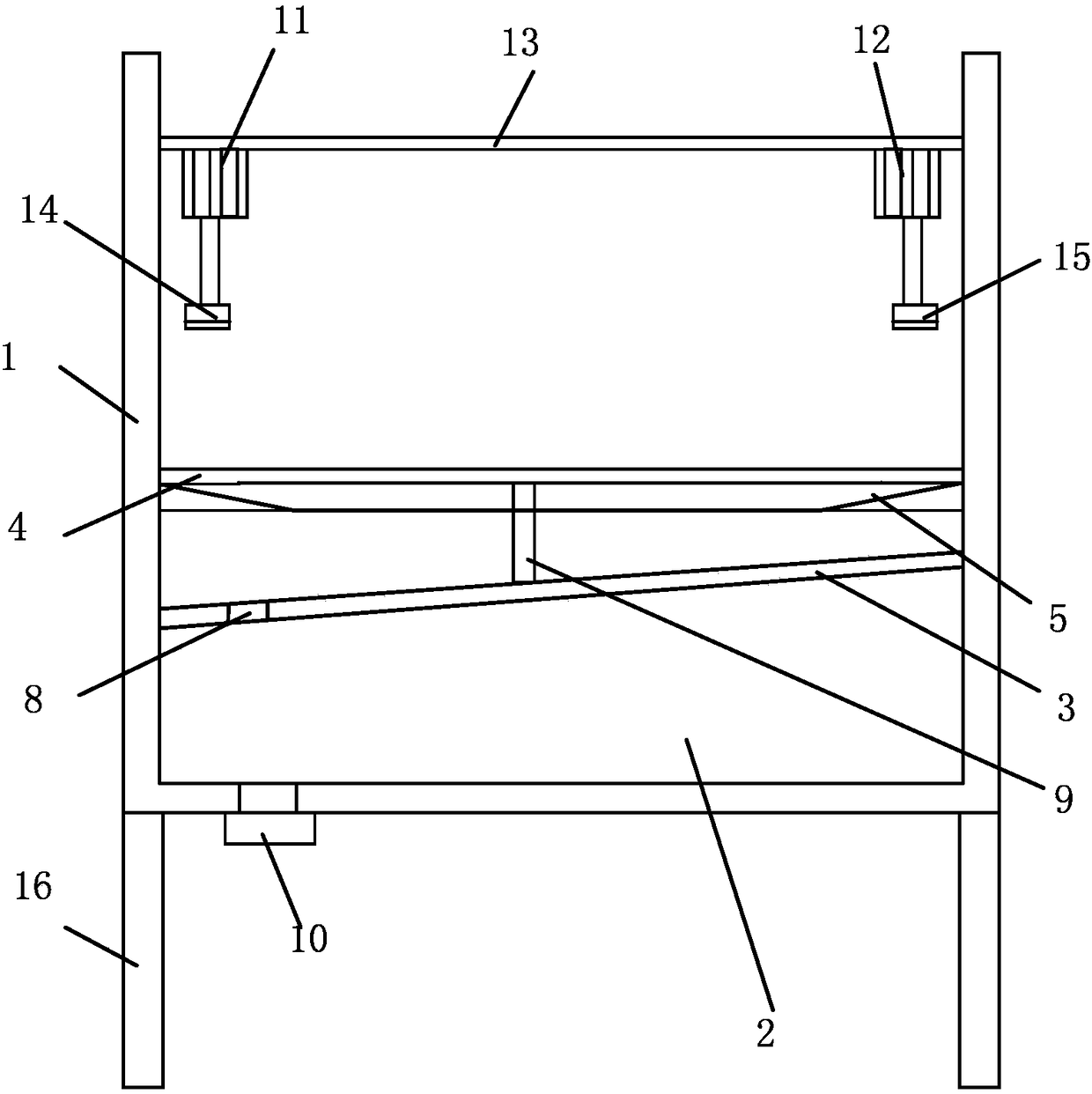

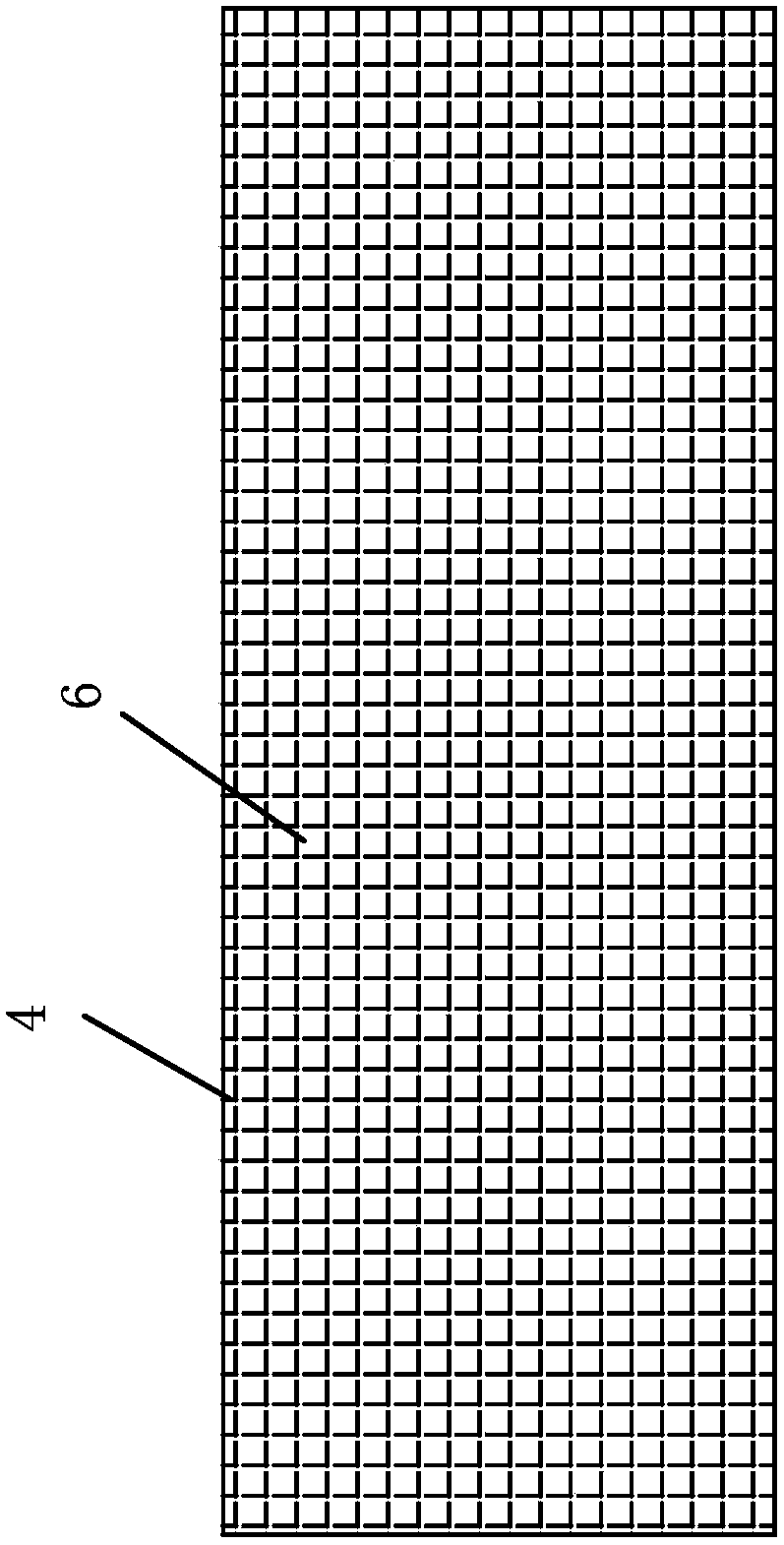

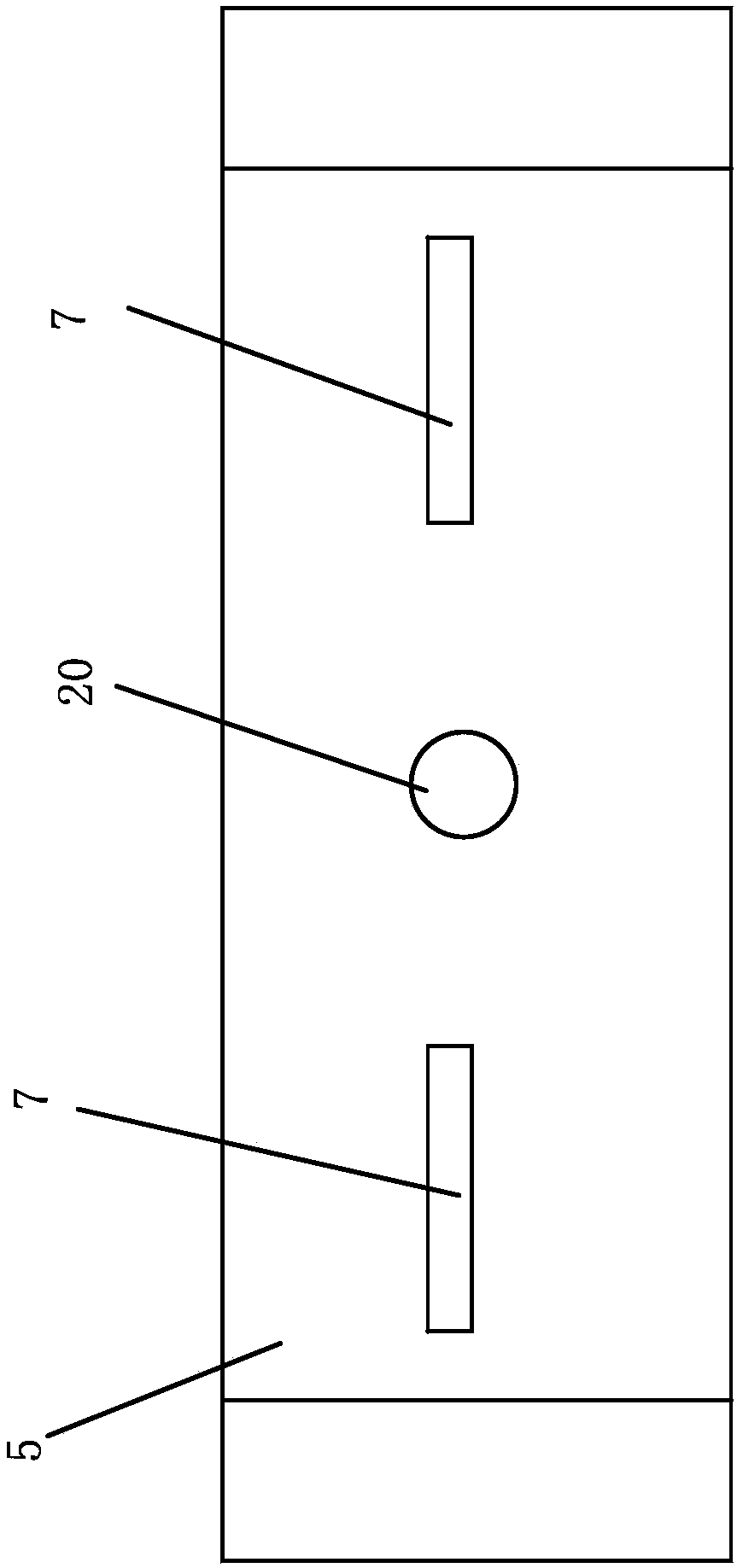

Automatic edge banding machine for plywood manufacturing

ActiveCN110524670ASolve the problem that the edge banding efficiency is low and cannot be processed in batchesImprove edge banding efficiencyOther plywood/veneer working apparatusDomestic articlesEngineeringEdge banding

The invention relates to an automatic edge banding machine for plywood manufacturing. The machine comprises a conveying belt, clamping mechanisms, electric sliding rails, workbenches, a laminating device and a shearing mechanism, the conveying belt is fixed to the ground through a support. The clamping mechanisms are arranged above the conveying belt; the clamping mechanisms are uniformly arrangedat the top of the conveying belt; the electric sliding rails are symmetrically arranged above the clamping mechanisms; the tops of the electric sliding rails are mounted on a fixed surface such as awall surface; the tops of the clamping mechanisms are connected with the middles of the electric sliding rails in a sliding fit mode. The workbenches are symmetrically arranged on the front side and the rear side of the left end of the conveying belt, the lower ends of the workbenches are installed at the lower end of the left side of the conveying belt, the bottom of the attaching device is installed on the right side of the tops of the workbenches, the shearing mechanism is arranged on the right side of the attaching device, and the bottom of the shearing mechanism is installed on the left sides of the tops of the workbenches. The machine can solve the problems that when plywood edge sealing is conducted manually, the steps are tedious, and edge sealing treatment of large-batch plywood cannot be conducted.

Owner:广东优逸智能家私有限公司

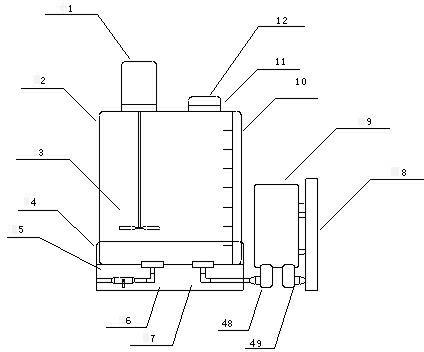

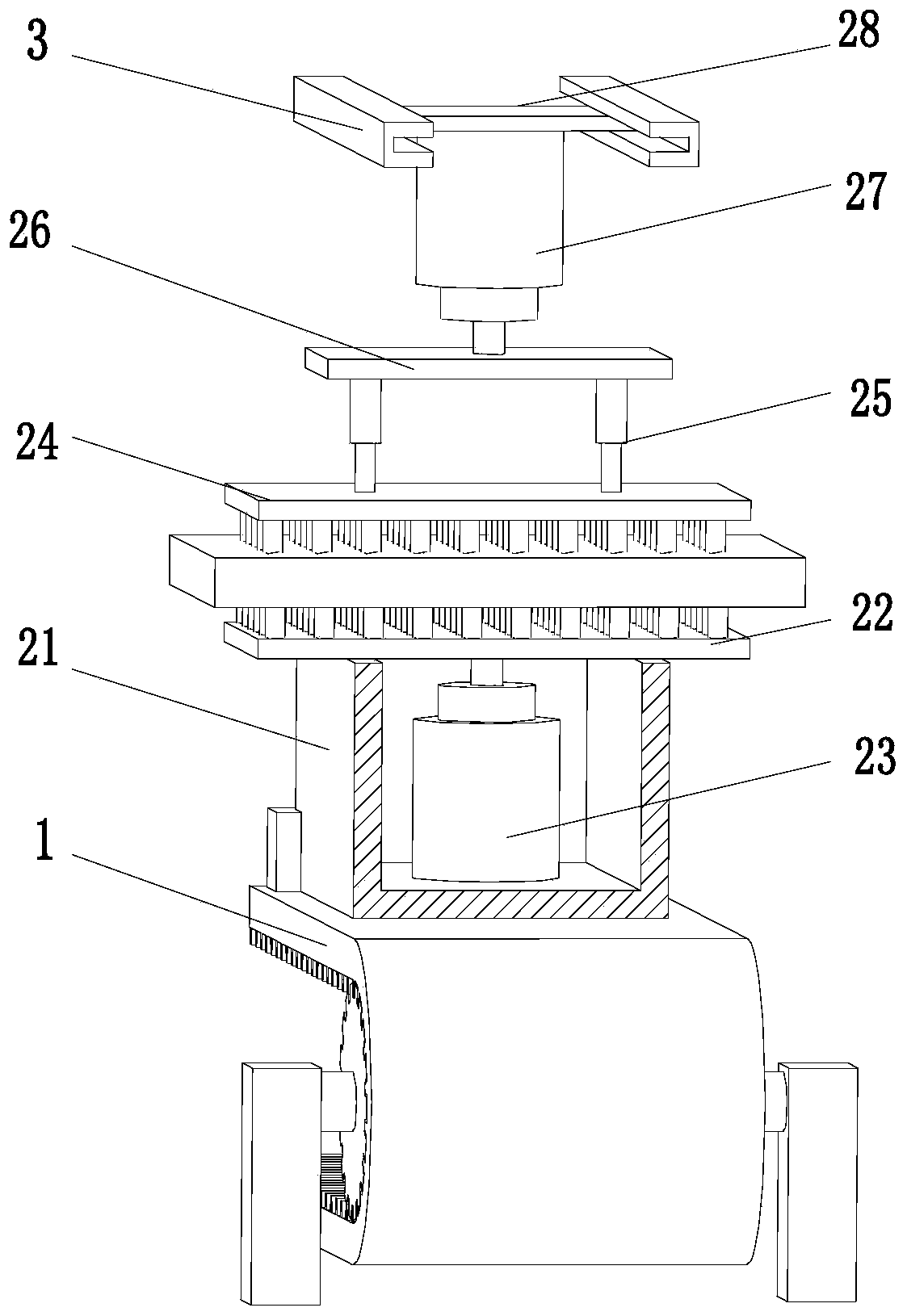

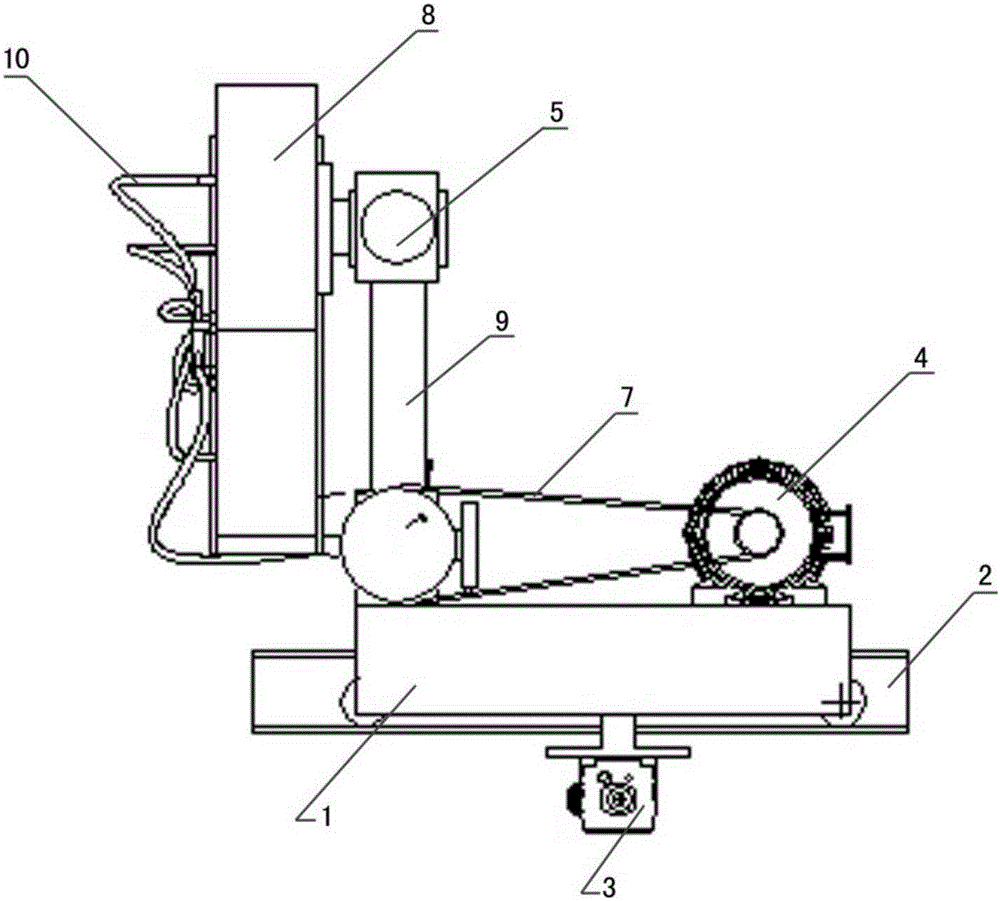

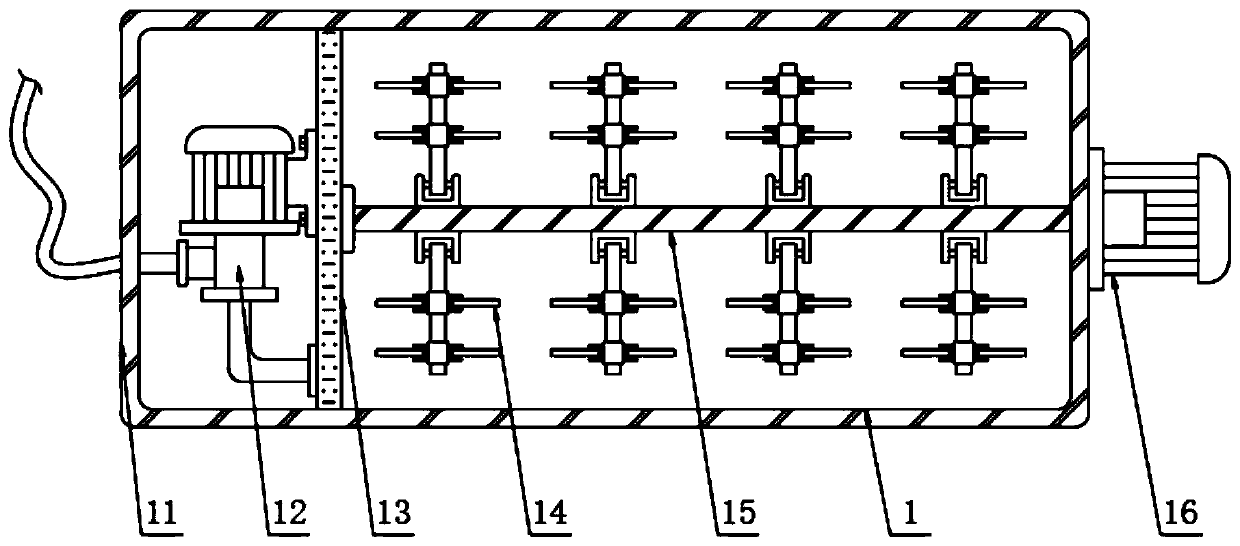

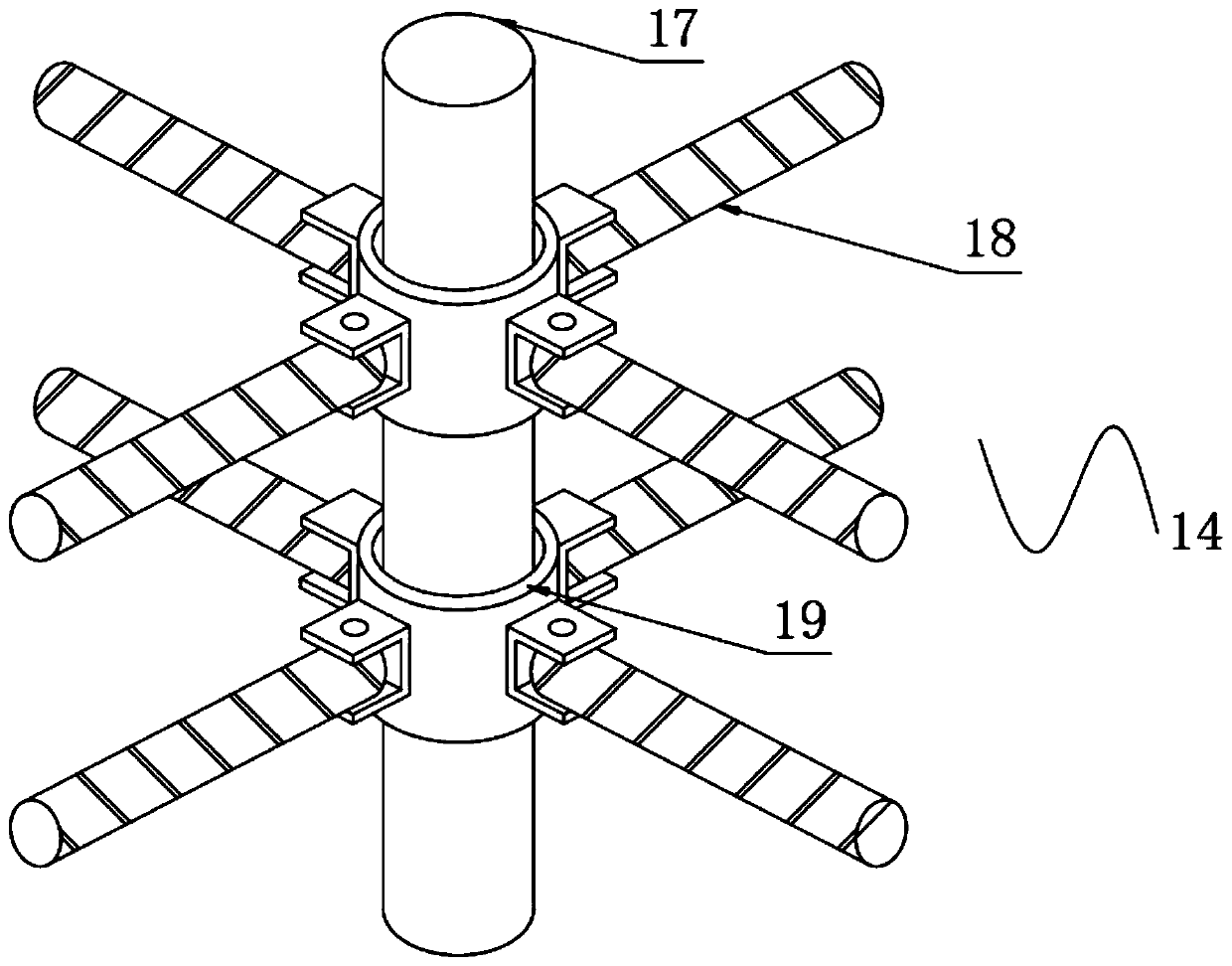

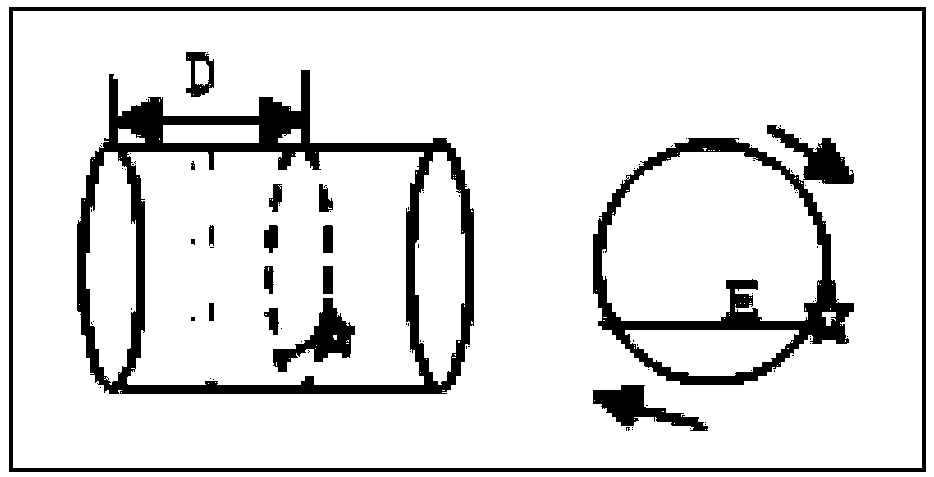

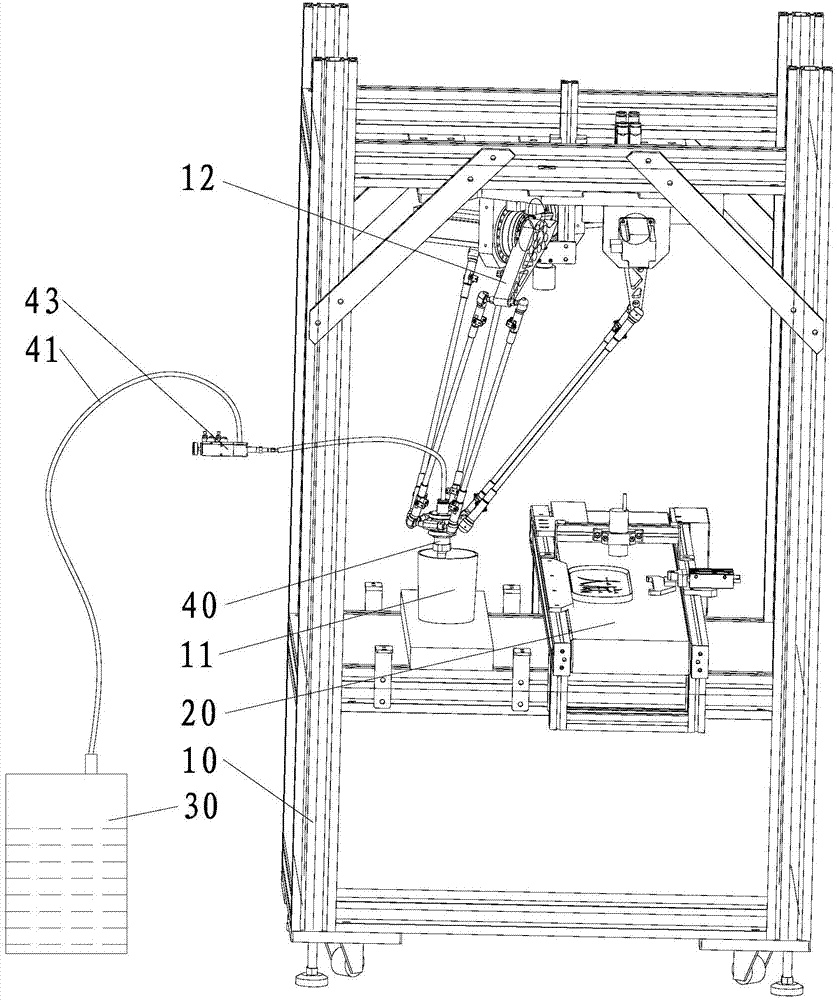

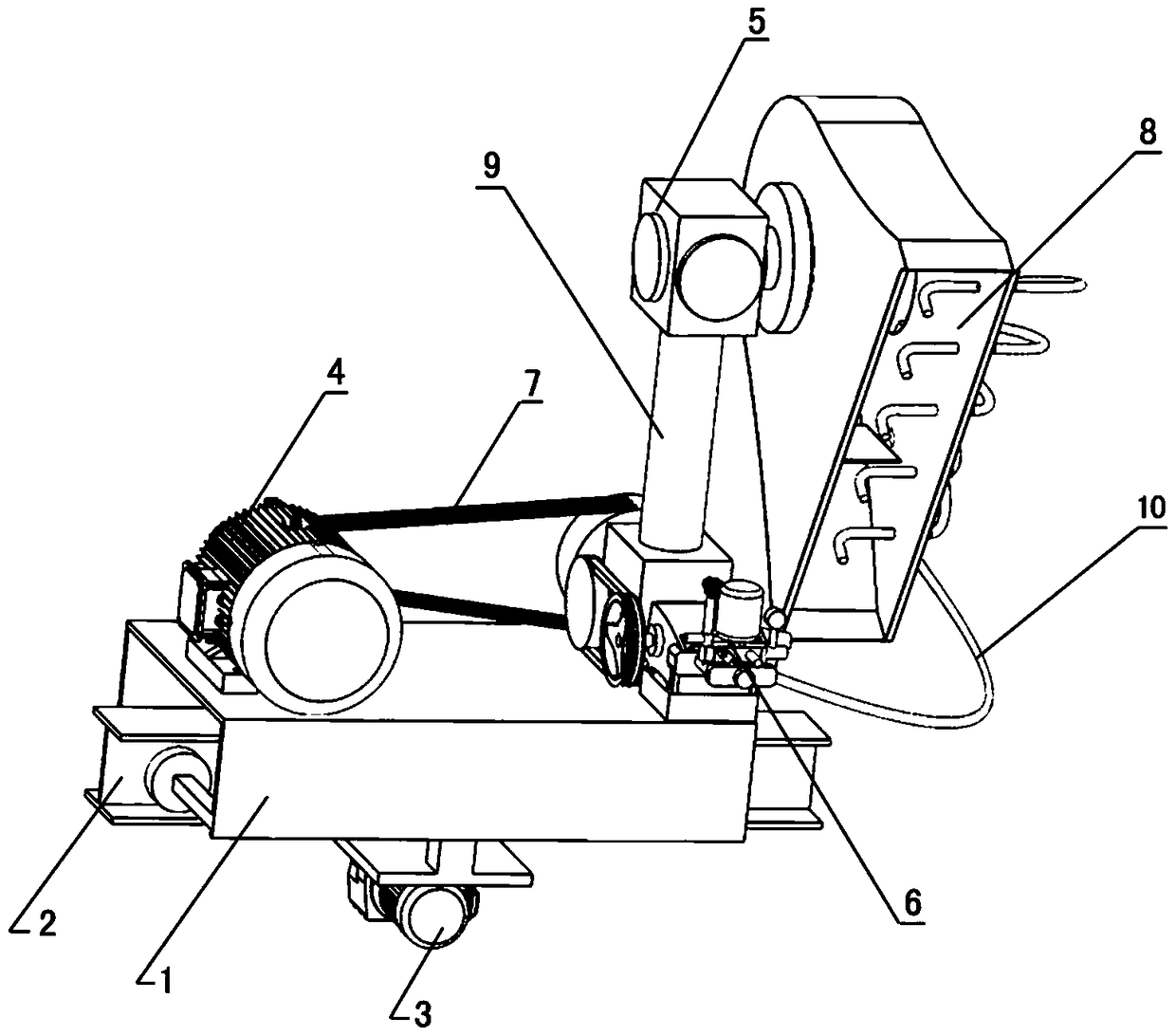

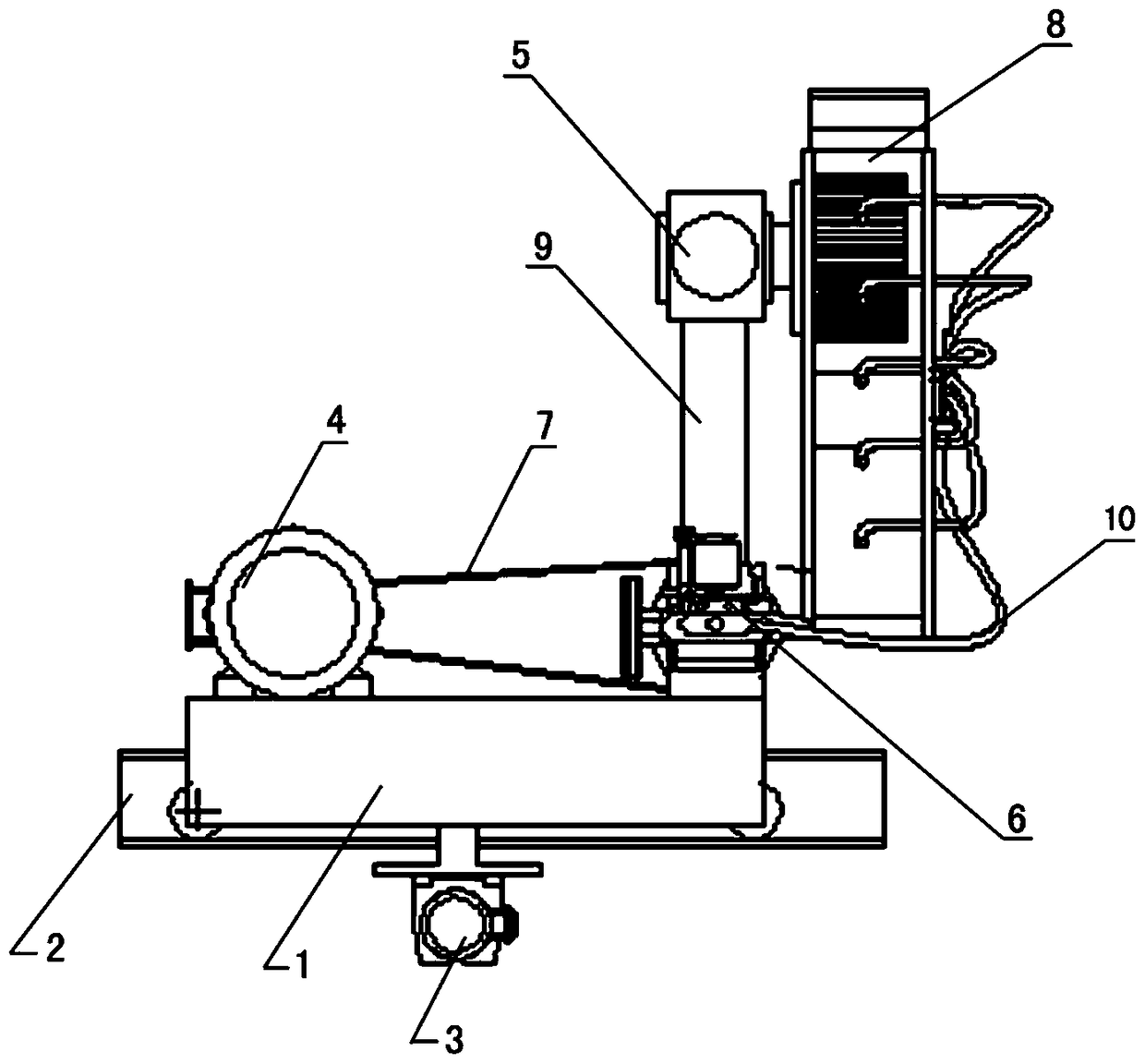

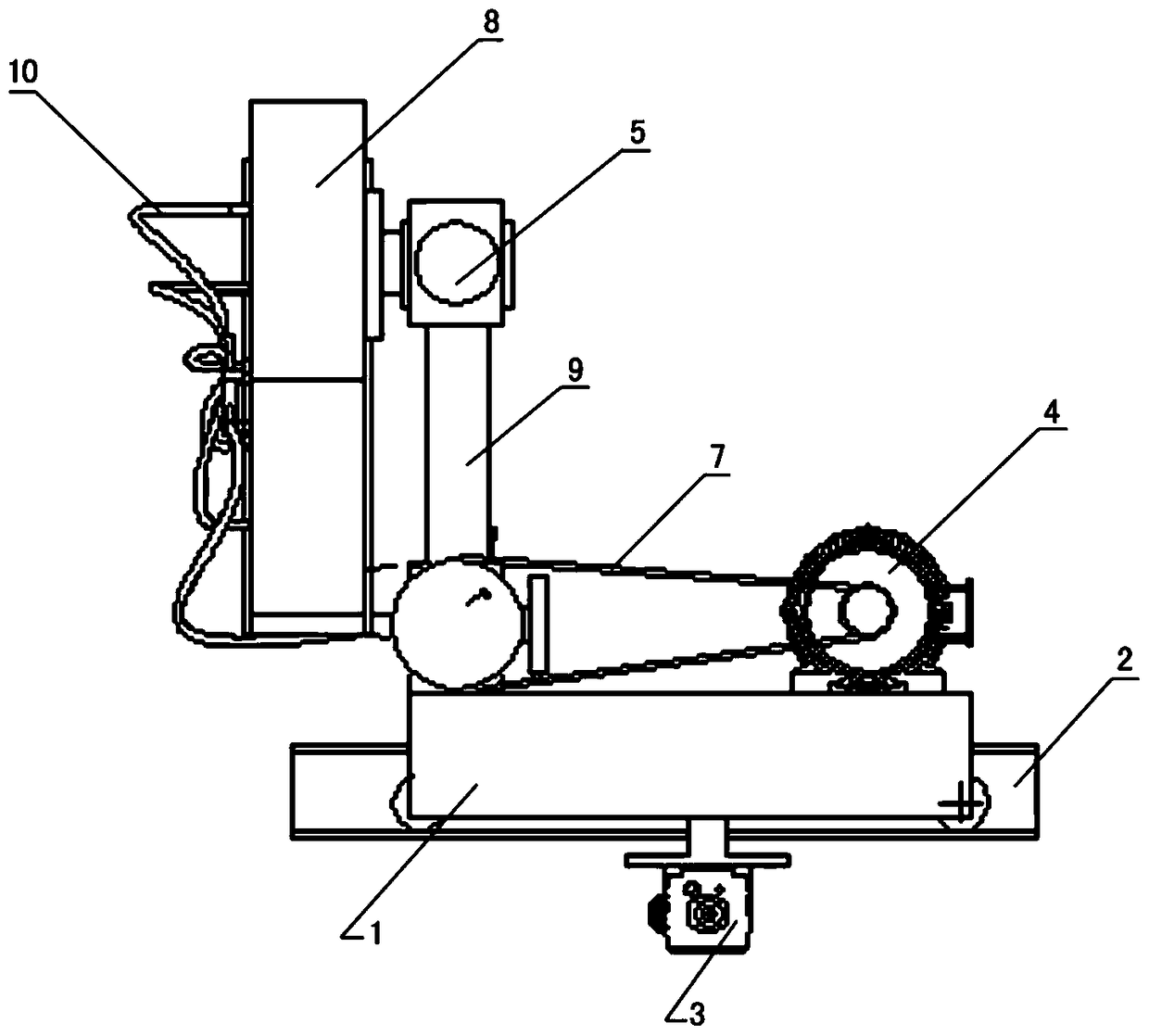

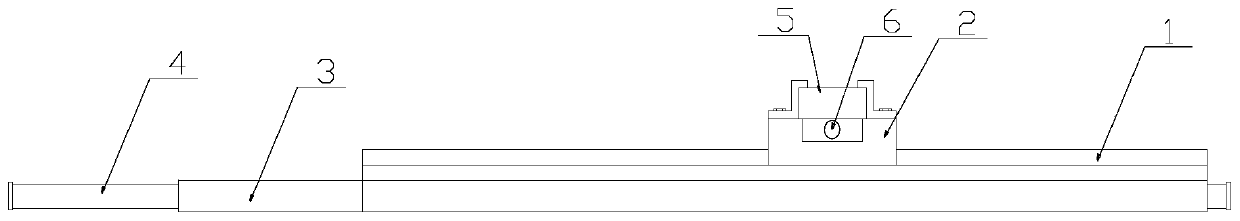

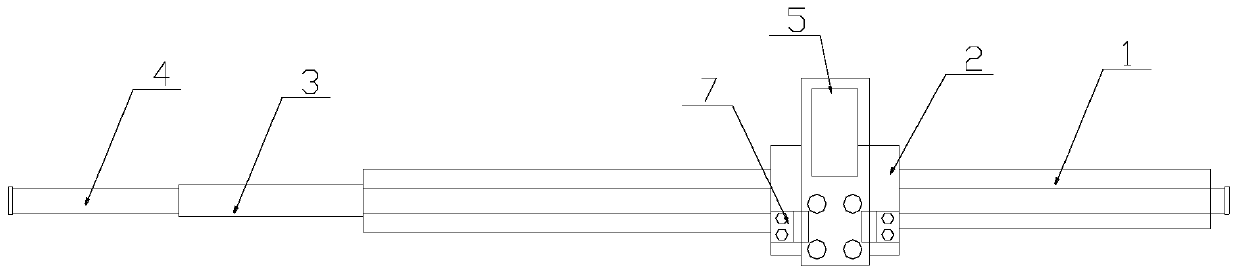

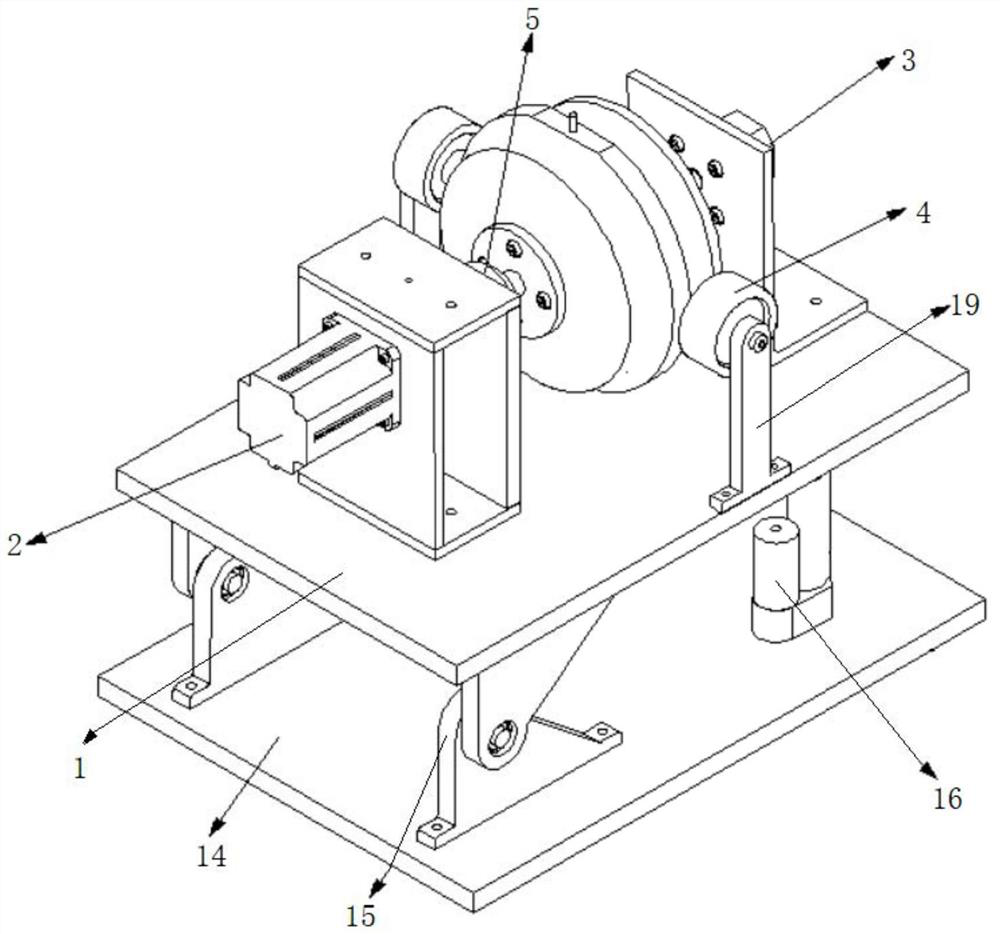

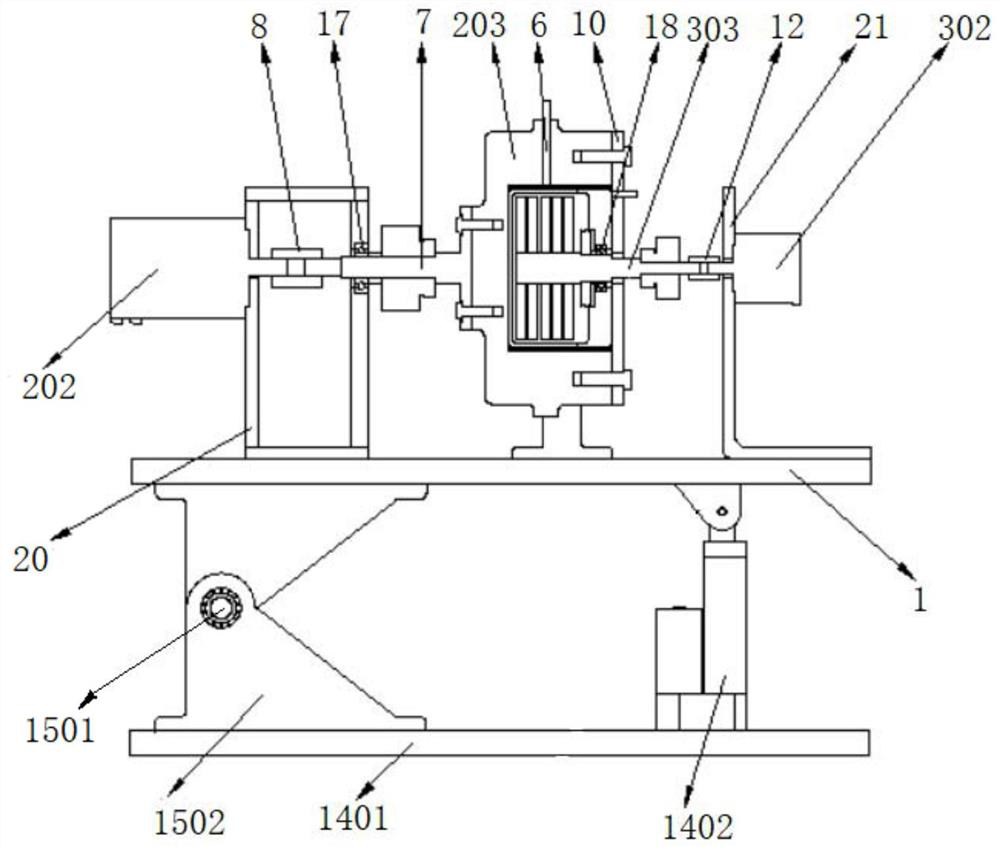

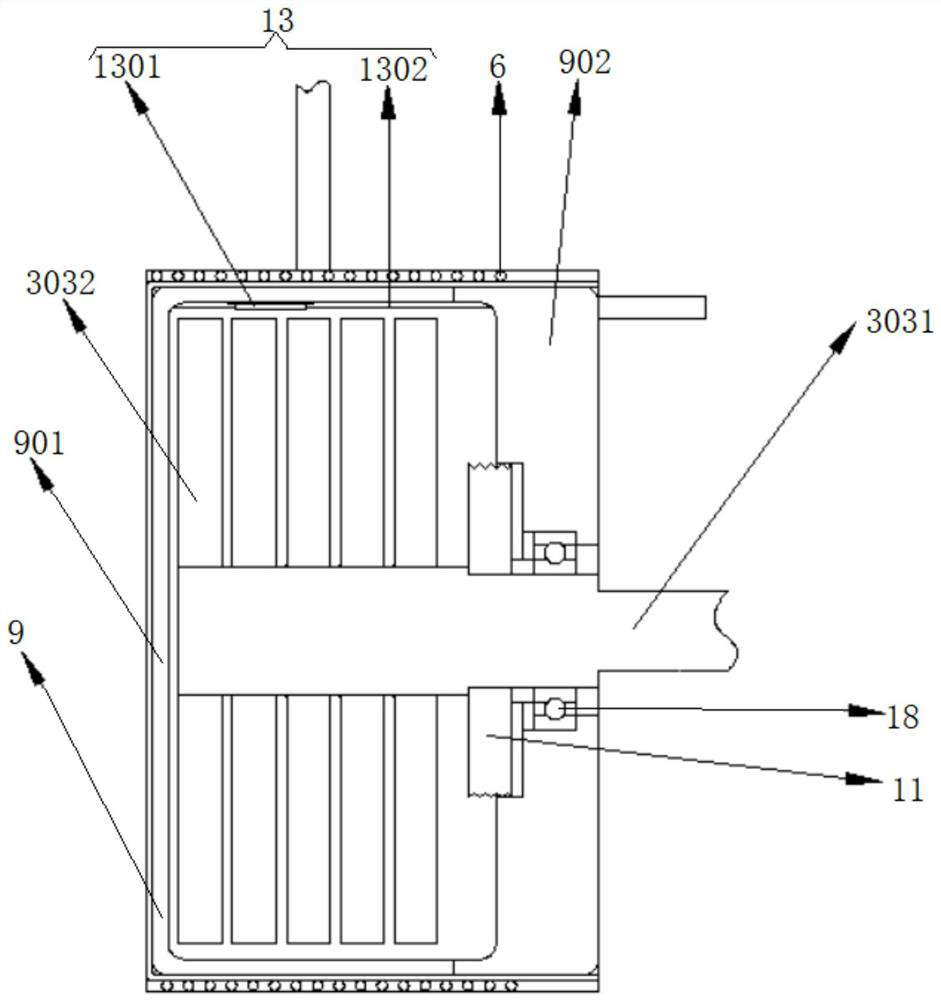

Self-propelled type automatic spraying machine for greenhouse

InactiveCN105165776AReduce dosageSmall particle sizeInsect catchers and killersSolenoid valveEngineering

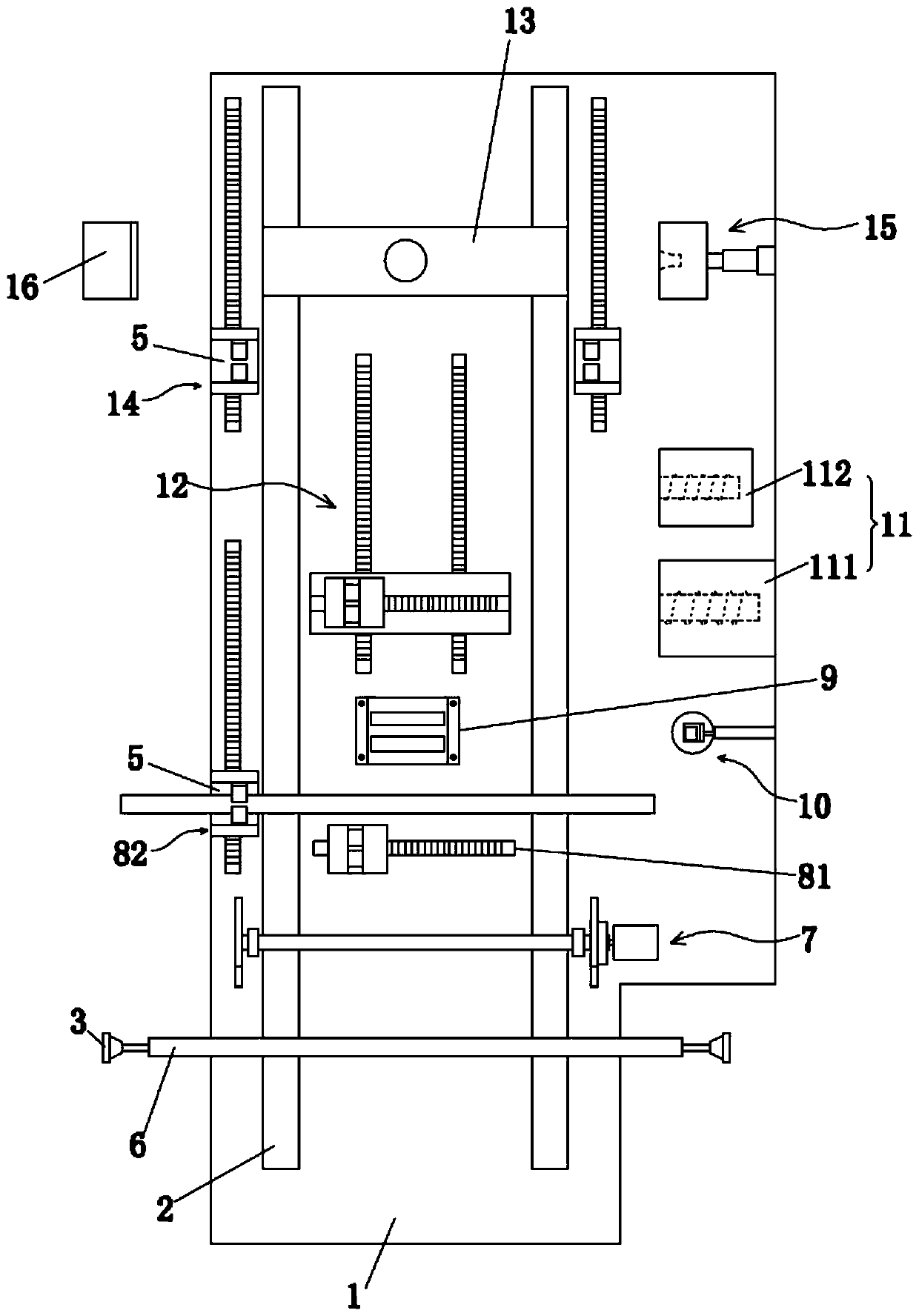

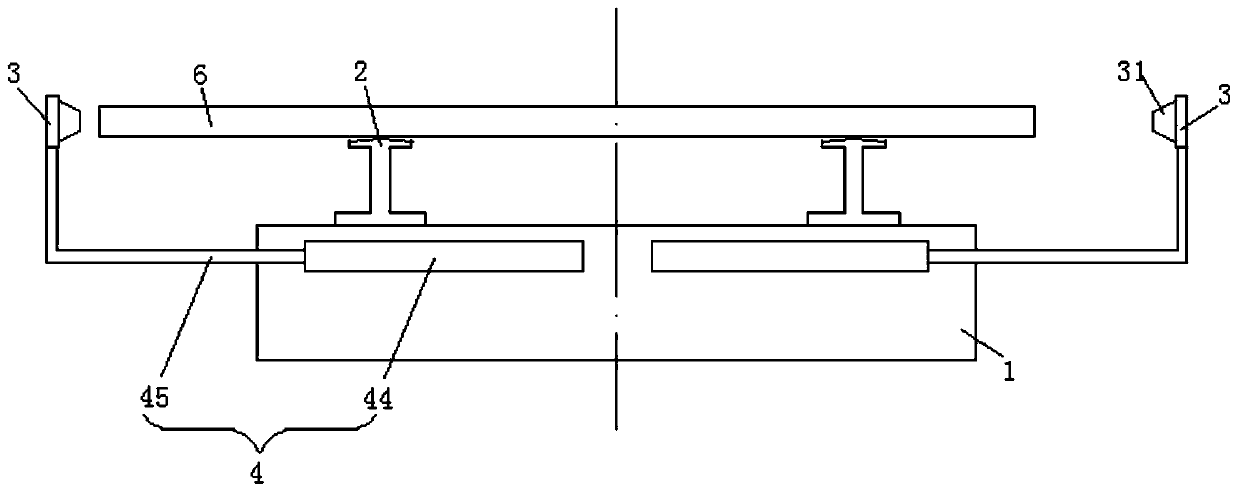

The invention discloses a self-propelled type automatic spraying machine for a greenhouse. The self-propelled type automatic spraying machine comprises a mobile platform, a spraying system and a control device. The mobile platform comprises a cart and a mobile guide rail, wherein the cart is loaded with the spraying system. A three-in-one deceleration motor is installed on the mobile guide rail. The spraying system comprises a chemical tank, a stepping motor, a motor, a transmission device, a plunger pump, a driving belt, a spray head, a water inlet pipe, a backflow pipe, a water outlet pipe and a solenoid valve. In the control device, a single-chip microcomputer serves as a controller, and by controlling the three-in-one deceleration motor on the mobile guide rail and the stepping motor and the solenoid valve in the spraying system, the forward and backward movement of the cart, the lifting, the descending and the starting and stopping of the spraying operation are achieved. The spraying machine is simple to operate, works stably and is high in controllability, not only achieves the mechanization and automation of the greenhouse chemical application and is low in manufacturing cost, but also has good chemical liquid coverage rate, fog drip deposition density and fog drip distribution uniformity in chemical application, and meets the requirements for pest and disease control.

Owner:NINGXIA UNIVERSITY

Self-controlled efficient and electrostatic-spraying pesticide application machine for greenhouses

InactiveCN102166548BIncrease profitGuaranteed control effectLiquid spraying apparatusSpray discharge apparatusHuman–machine interfaceEngineering

Owner:镇江和盛环境科技有限公司 +2

Lightweight high-strength inorganic shaving board and preparation method thereof

InactiveCN108608549AHigh mechanical strengthLow densityDomestic articlesFlat articlesWood shavingsAdhesive

The invention discloses a lightweight high-strength inorganic shaving board. The lightweight high-strength inorganic shaving board is prepared by mixing at least wood or non-wood shavings, an inorganic adhesive and sponge particles in the weight ratio of (40 to 60) to (100 to 120) to (1 to 3). A preparation method of the lightweight high-strength inorganic shaving board approximately comprises thefollowing steps: spraying the inorganic adhesive in the surfaces of the sponge particles and mixing uniformly; adding the wood or non-wood shavings and mixing uniformly; paving a mixture into a plateblank, and performing hot pressing to obtain a semi-finished product; and drying, edging and performing sanding treatment to obtain the lightweight high-strength inorganic shaving board after the semi-finished product is stacked. According to the lightweight high-strength inorganic shaving board disclosed by the invention, the application uniformity of the inorganic adhesive is effectively improved, and the density of the inorganic shaving board is effectively reduced to 0.8 to 1.0 g / m<3>, so that the weight of the inorganic shaving board is reduced; and moreover, the lightweight high-strength inorganic shaving board does not release free formaldehyde, and is waterproof, fireproof, high in mechanical strength and suitable to be popularized and applied in furniture production.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

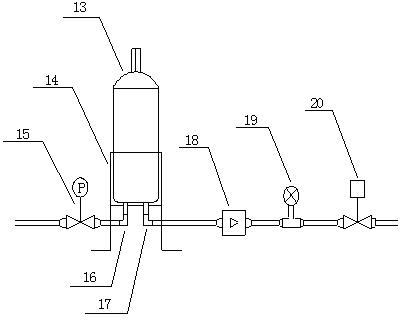

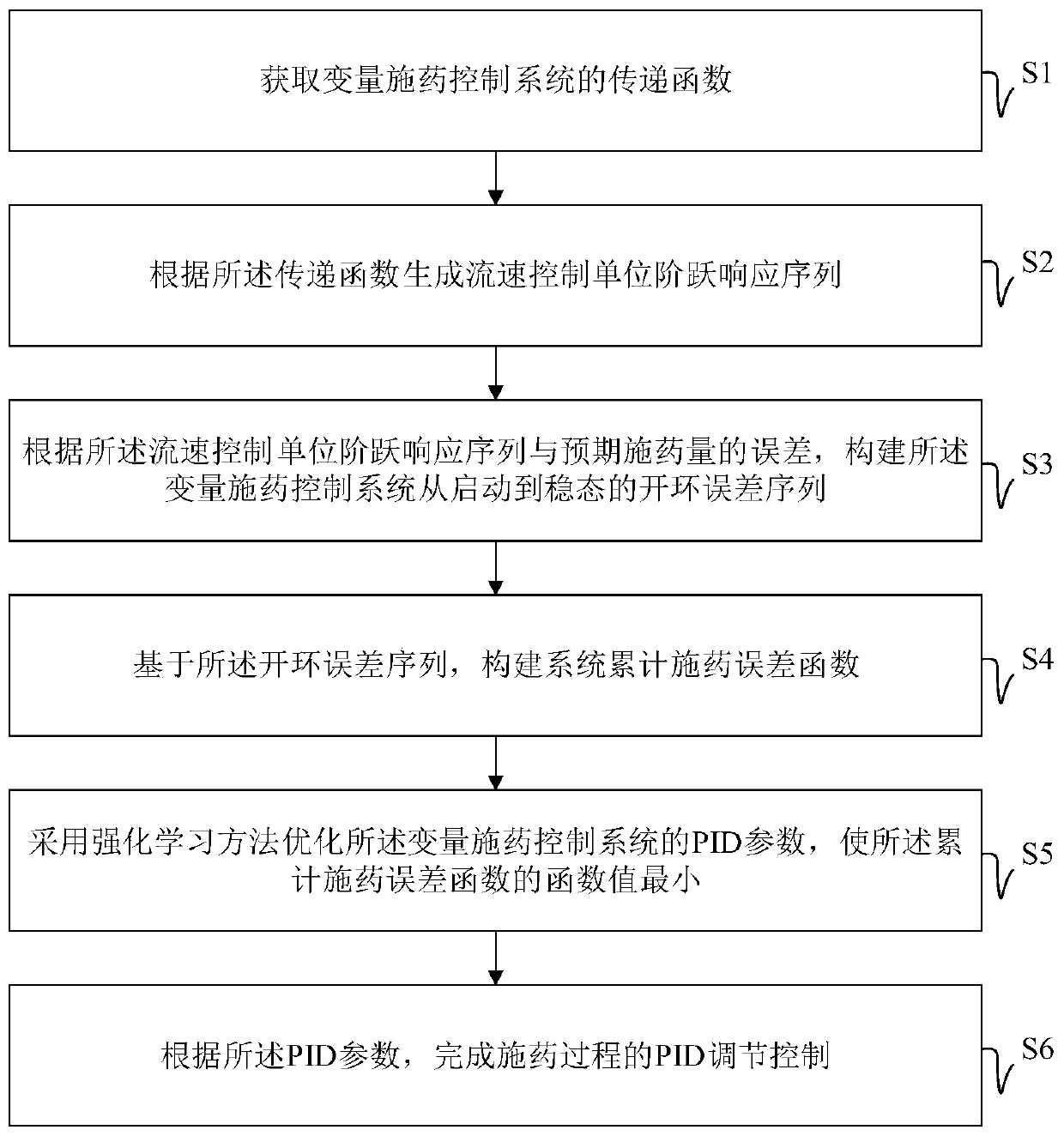

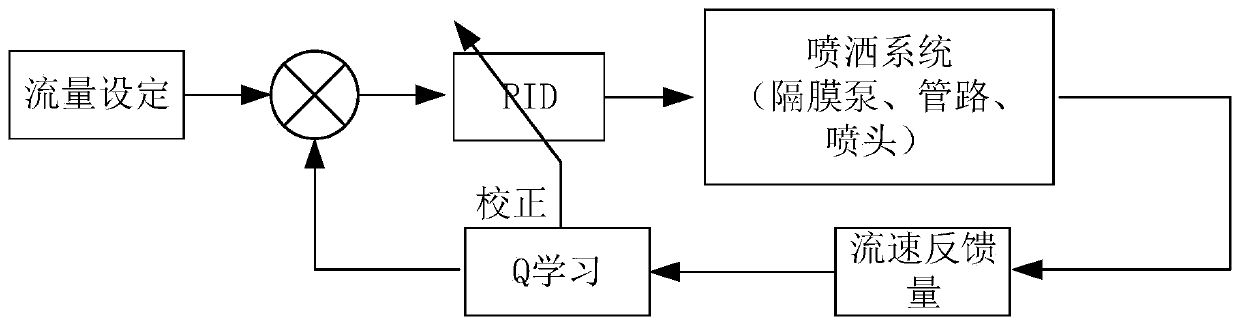

Minimum error variable pesticide application control method and system

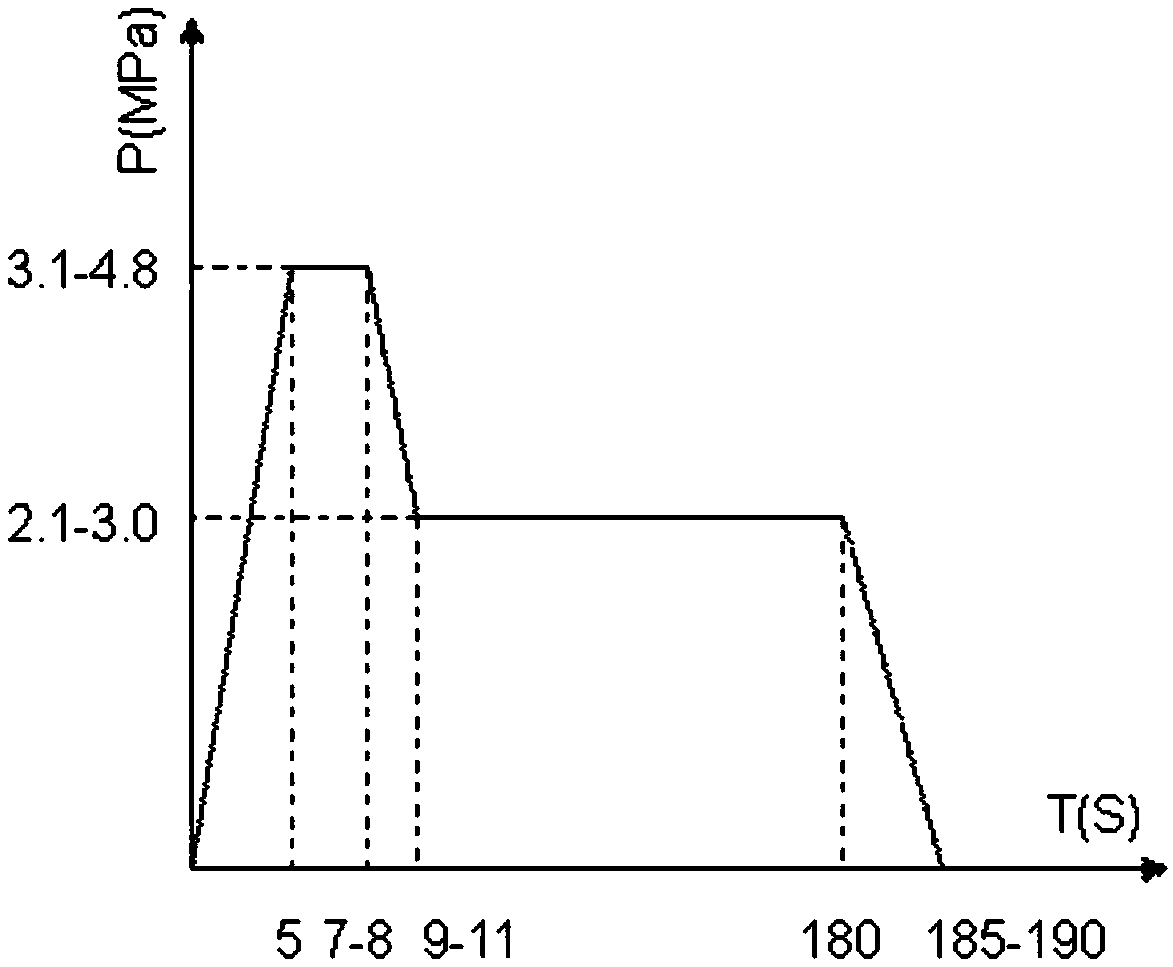

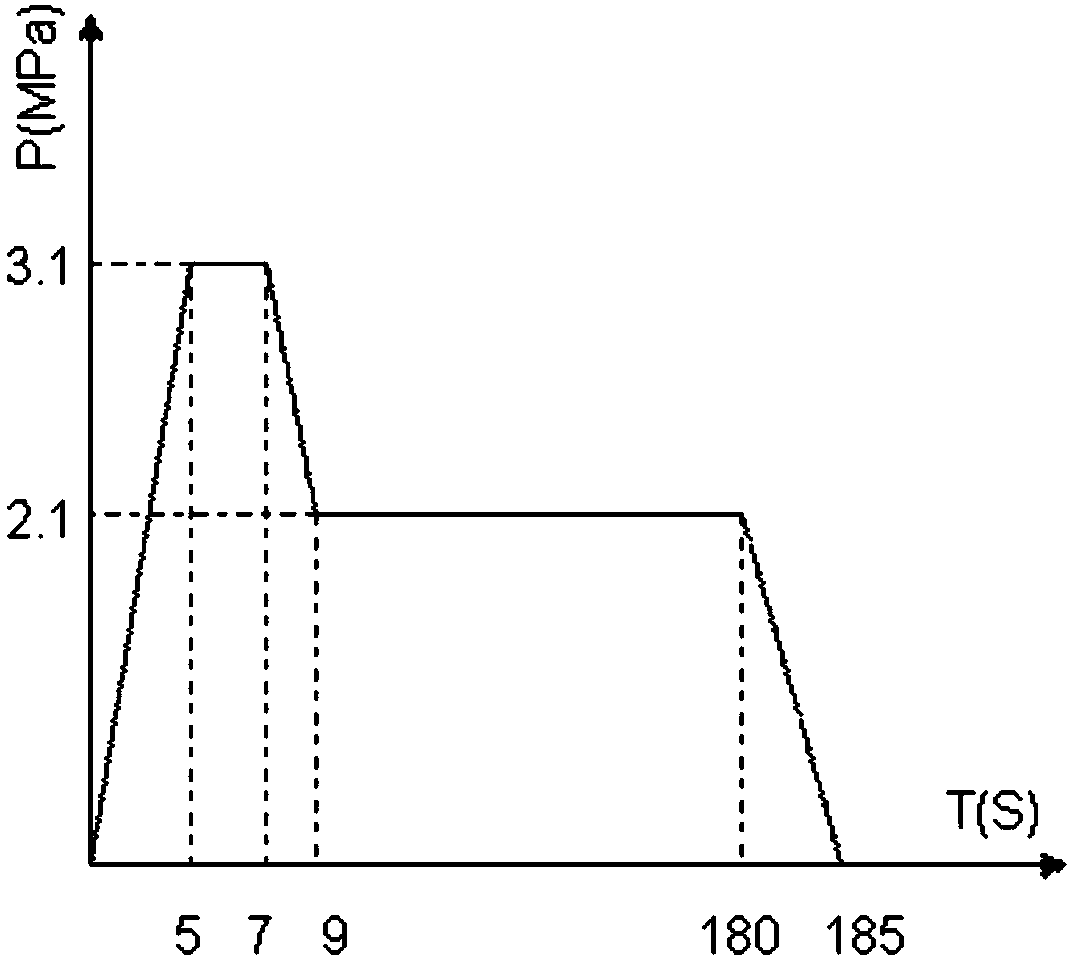

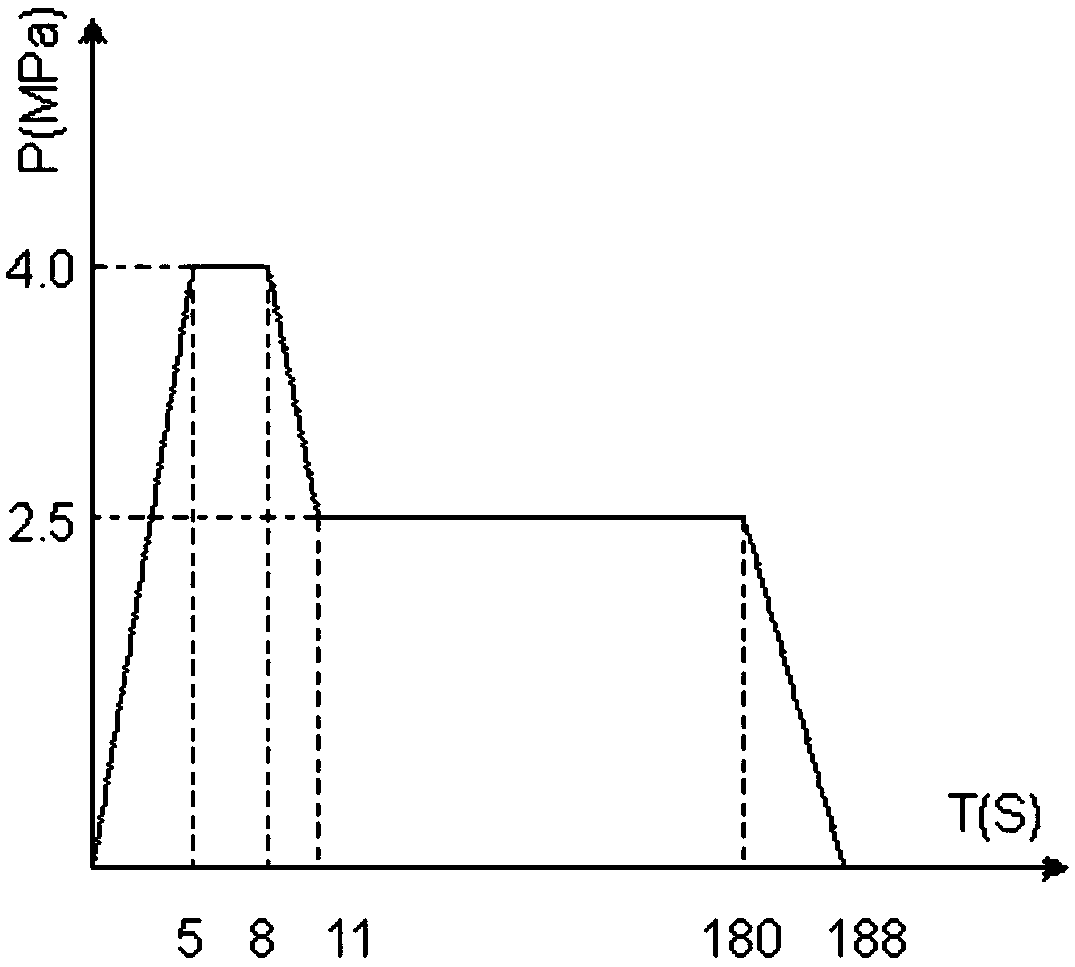

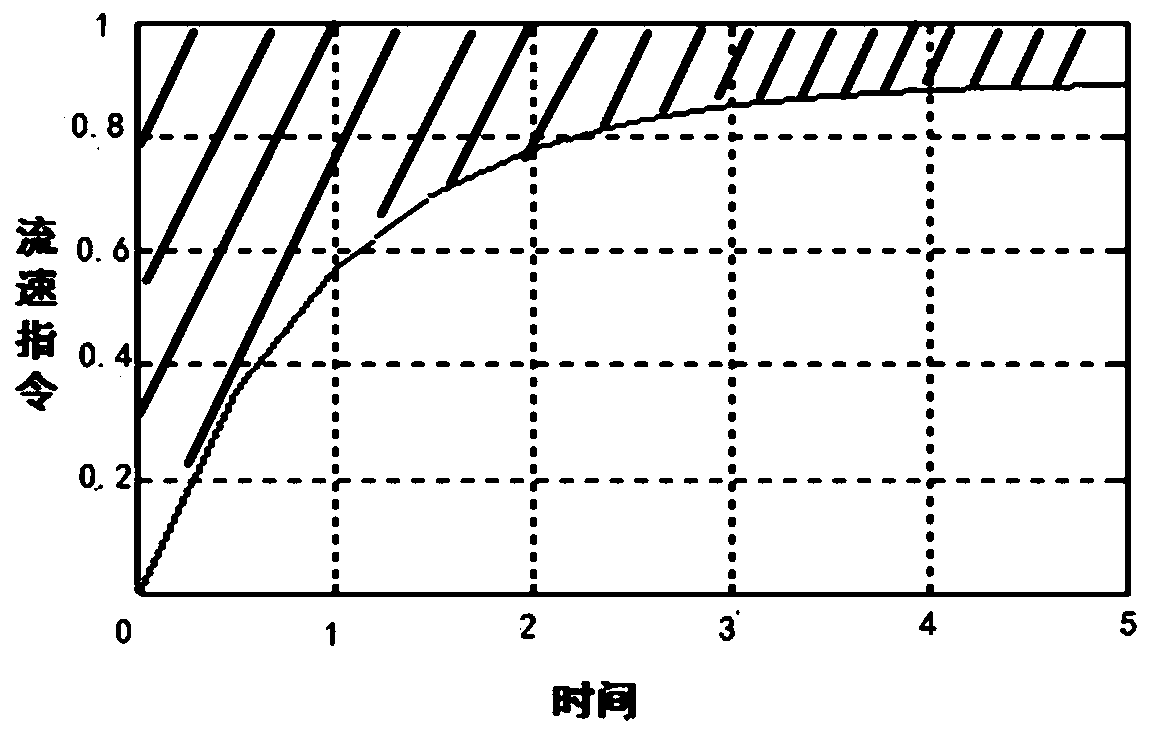

ActiveCN111449040AReduce spray flow rate errorImproves application uniformityData processing applicationsHorticulture methodsControl systemControl engineering

A minimum error variable pesticide application control method and system provided by the invention comprises: acquiring a transfer function of a variable pesticide application control system; generating a flow rate control unit step response sequence according to the transfer function; constructing an open-loop error sequence of the variable pesticide application control system from startup to steady state according to an error between the flow rate unit step response sequence and an expected pesticide application amount; constructing a cumulative pesticide application error function of the system based on the open-loop error sequence; optimizing PID parameters of the variable pesticide application control system by using a reinforcement learning method to make a function value of the cumulative application error function be the smallest; and completing the PID adjustment control of a pesticide application process according to the PID parameters. According to the minimum error variablepesticide application control method and system provided in the embodiment of the invention, the PID parameters of the variable pesticide application control system are optimized by using the reinforcement learning method, so that a spraying flow rate error caused by the process of automatic opening of spraying when an unmanned aerial vehicle performs spraying is effectively reduced, and therebythe pesticide application uniformity of a field edge during the automatic spraying operation is improved.

Owner:清远市智慧农业研究院 +2

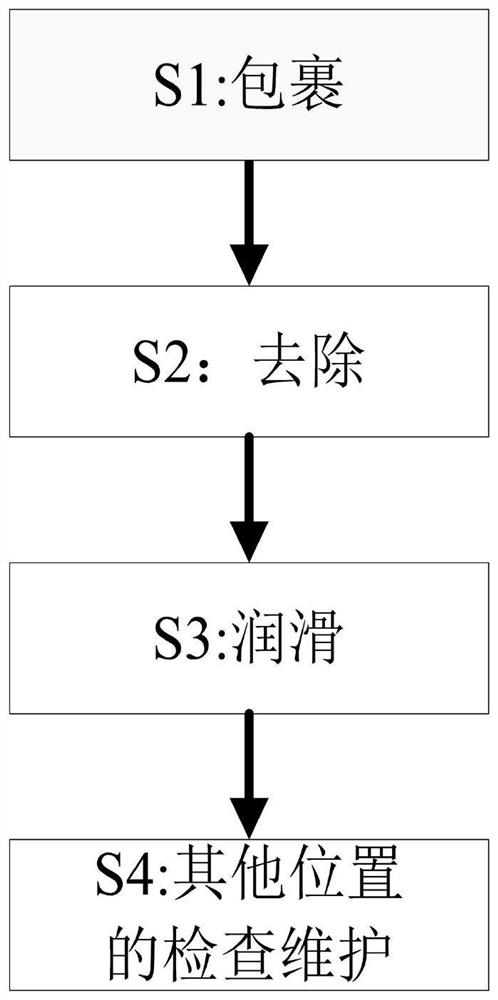

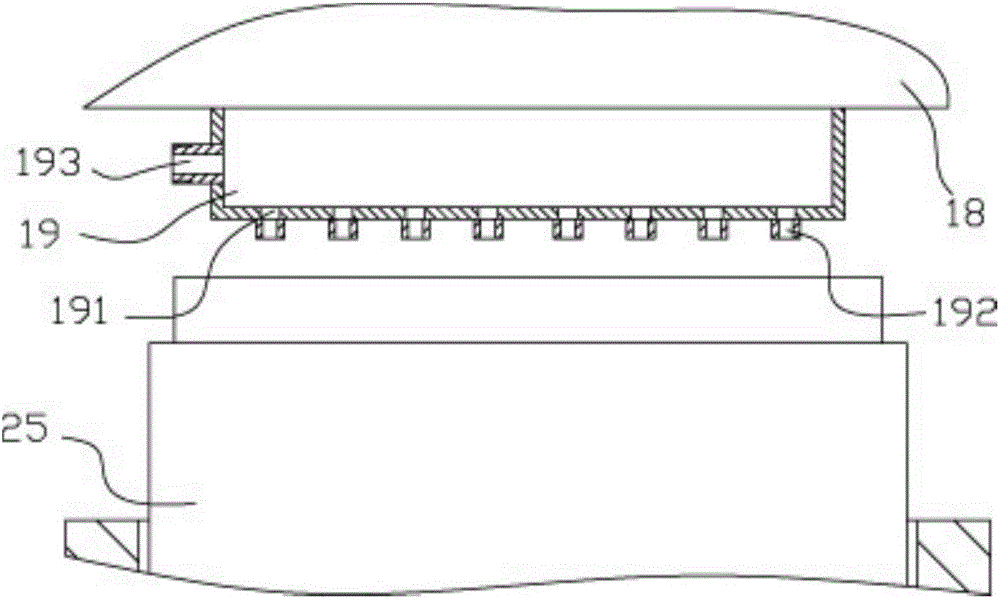

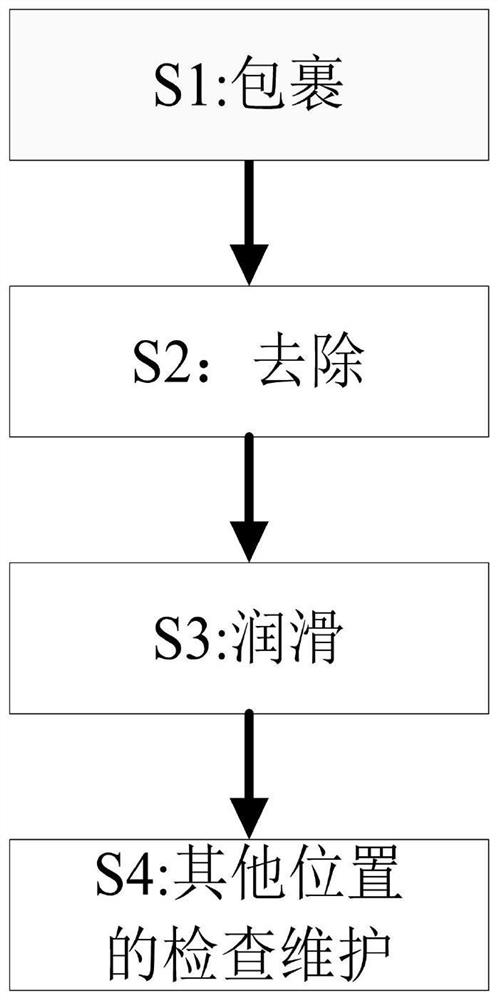

Daily maintenance processing method for pulling steel wire ropes during operation of intelligent elevator

ActiveCN111762660AGuaranteed decontaminationGuaranteed lubrication effectElevatorsProcess engineeringWire rope

The invention provides a daily maintenance processing method for pulling steel wire ropes during operation of an intelligent elevator. The daily maintenance processing is completed by the cooperationof a weighted base, cylinders, an extrusion frame and maintenance units. The daily maintenance processing method can solve the problems that the maintenance of the steel wire ropes mainly depends on manual operation of maintainers, the manual maintenance is poor in effect, low in efficiency and long in time, which causes the elevator to stop for a long period of time to bring great inconvenience to users, and at the same time, the waste of lubricating oil is caused easily in oiling.

Owner:广东恒伟电梯有限公司

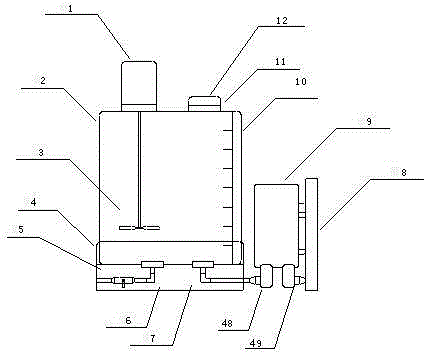

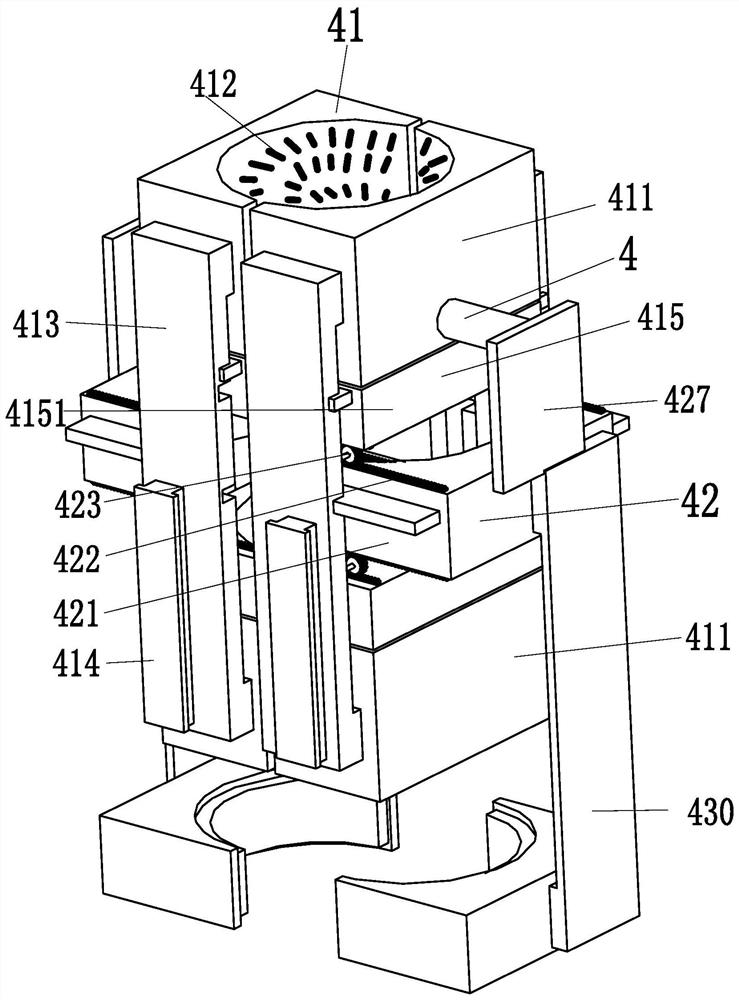

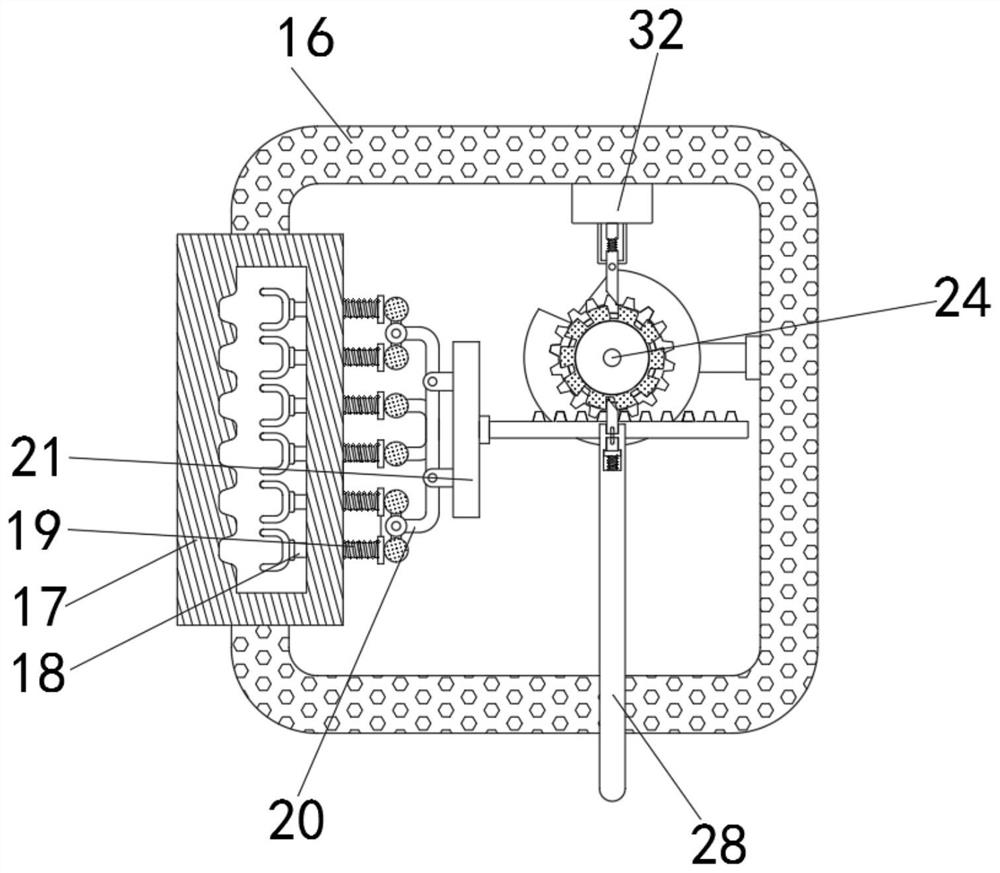

Fine adjustable type cake sauce painting mechanism

InactiveCN106857744ASatisfy the use requirements of smearingImproves application uniformityBaked articles handlingEngineeringDrive motor

The invention discloses a finely adjustable cake coating mechanism, which includes a frame, the frame includes two vertical support plates, the middle bottom plate is fixed on the lower part of the two vertical support plates, and the two sides of the top surface of the middle bottom plate are fixed There is an adjustment support plate, and the two ends of the horizontal screw are hinged on the two adjustment support plates. A drive motor is fixed on the outer wall of one of the adjustment support plates. The output shaft of the drive motor is a spline shaft, and the spline shaft is inserted into the horizontal In the spline hole provided at one end of the screw rod, the moving support block is screwed in the horizontal screw rod, the top surface of the moving support block is provided with an upper support frame body, the middle part of the upper support frame body is provided with a middle partition, and the middle partition board is provided with a middle partition. A main adjusting screw is connected, and the lower end of the main adjusting screw protrudes downward from the intermediate partition. It can automatically spread the sauce, and the distance between the cake block and the spray sleeve can be fine-tuned, so as to meet the application requirements of the spread, and the spread is even and the effect is good.

Owner:叶伟然

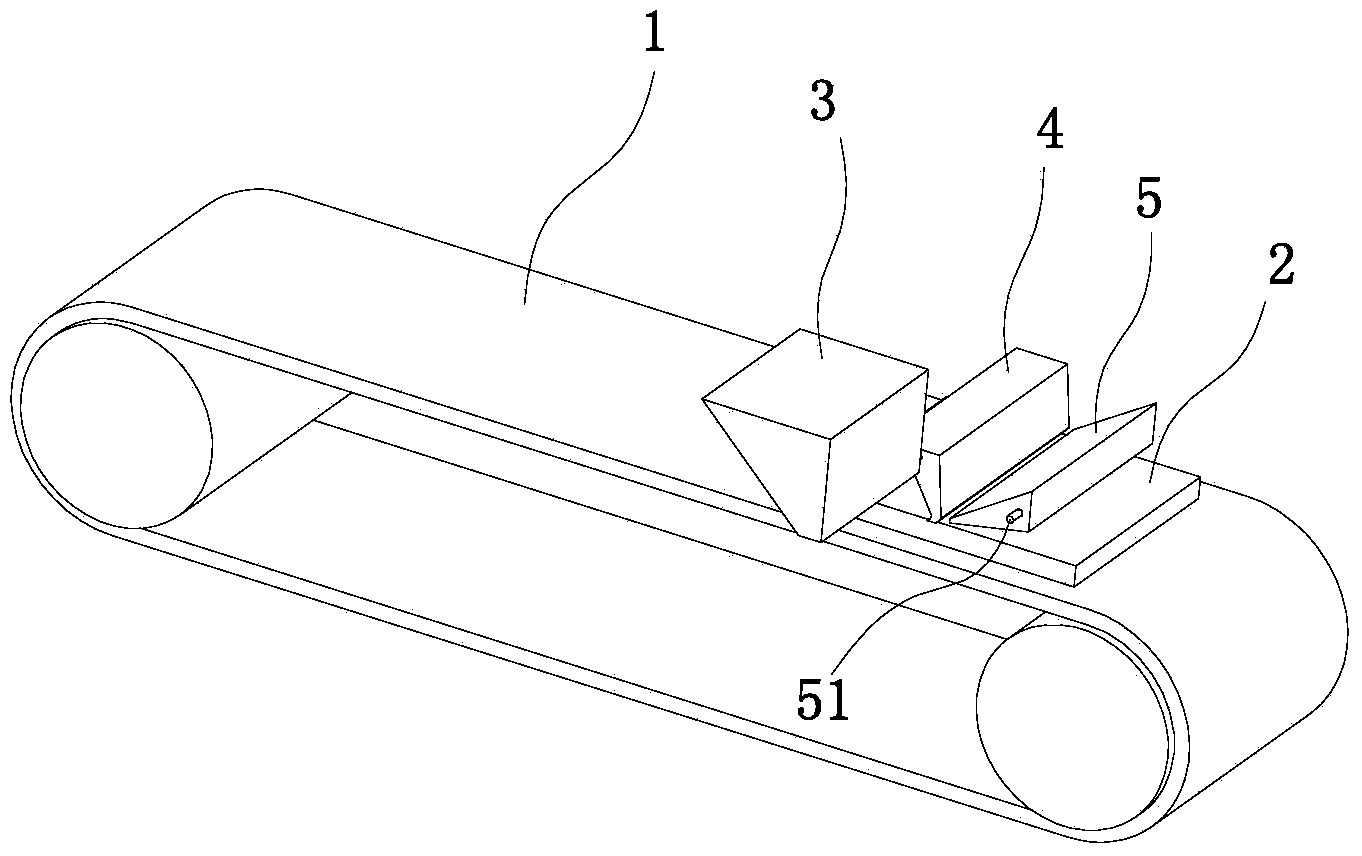

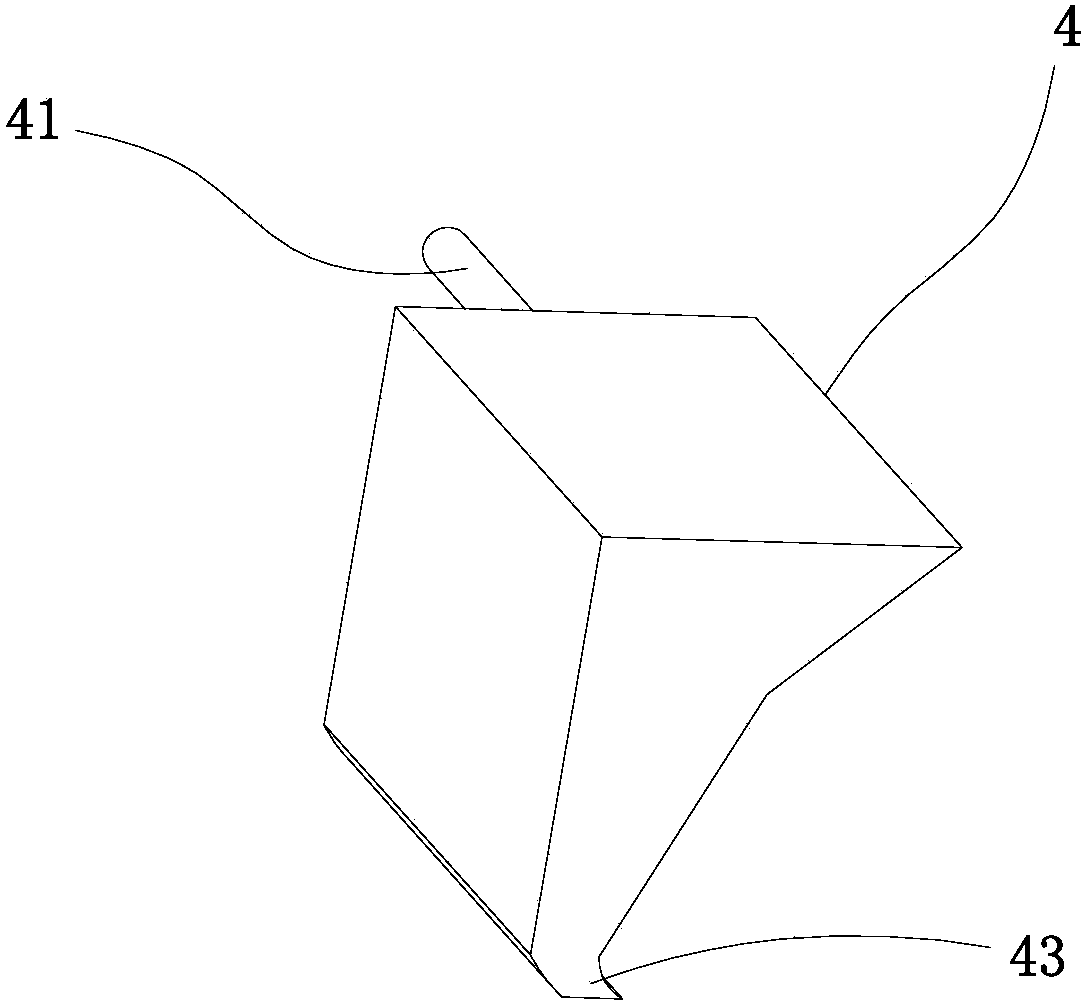

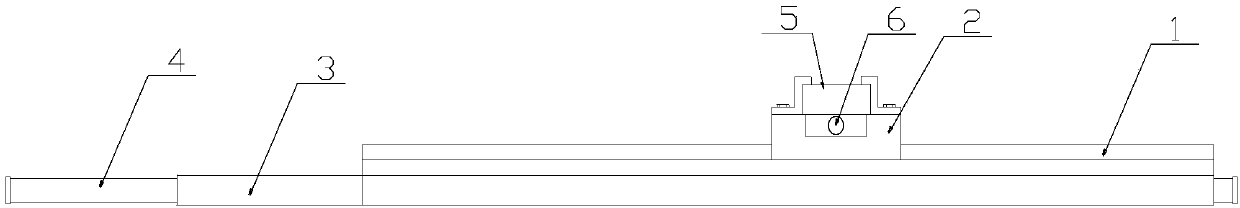

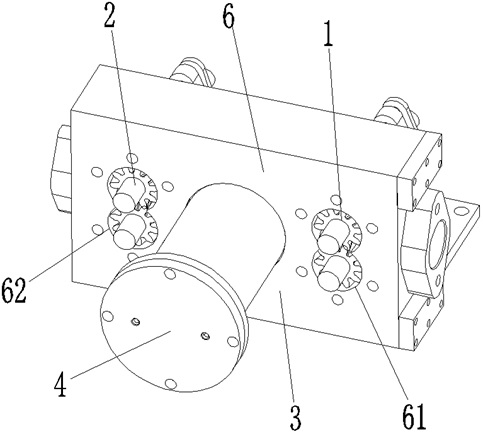

Material strip lubricating device

InactiveCN104174773AImproves application uniformityImprove the sticking effectShaping toolsLiquid surface applicatorsFuel tankEngineering

The invention relates to a material strip lubricating device. The material strip lubricating device comprises a conveyor belt; a material strip is placed on the conveyor belt; a dripping nozzle is arranged above the material belt and communicated with an oil tank; the dripping nozzle is of a casing structure with the large upper end and the small lower end; the outer side of the upper end of the dripping nozzle is provided with an oil pipe which is communicated with the oil tank; the inner wall of the dripping nozzle is fixedly connected with an oil guide plate in an inclined mode; the high end of the oil guide plate is provided with an arc-shaped oil guide area and located below an oil inlet of the oil pipe; a plurality of oil leakage holes are uniformly formed in the oil guide plate; the lower end of the dripping nozzle is provided with an oil guide portion with an oil falling groove, wherein the oil guide portion is bent towards the conveying direction of the conveyor belt; the material strip lubricating device also comprises a blow head which is arranged above the material belt and located on the front side of the dripping nozzle; an air nozzle of the blow head is towards the oil falling groove of the dripping nozzle. According to the material strip lubricating device, the oil flow is uniformly guided to drip to the oil guide portion through the oil guide plate, oil droplets are uniformly daubed on the material belt through the oil falling groove due to the oil guide portion, and accordingly the daub uniformity is high and an auxiliary oil layer is attached to the upper surface of the material belt due to the blowing effect of the blow head which is arranged on the front side and accordingly the attachment capability is improved.

Owner:寇兴国 +1

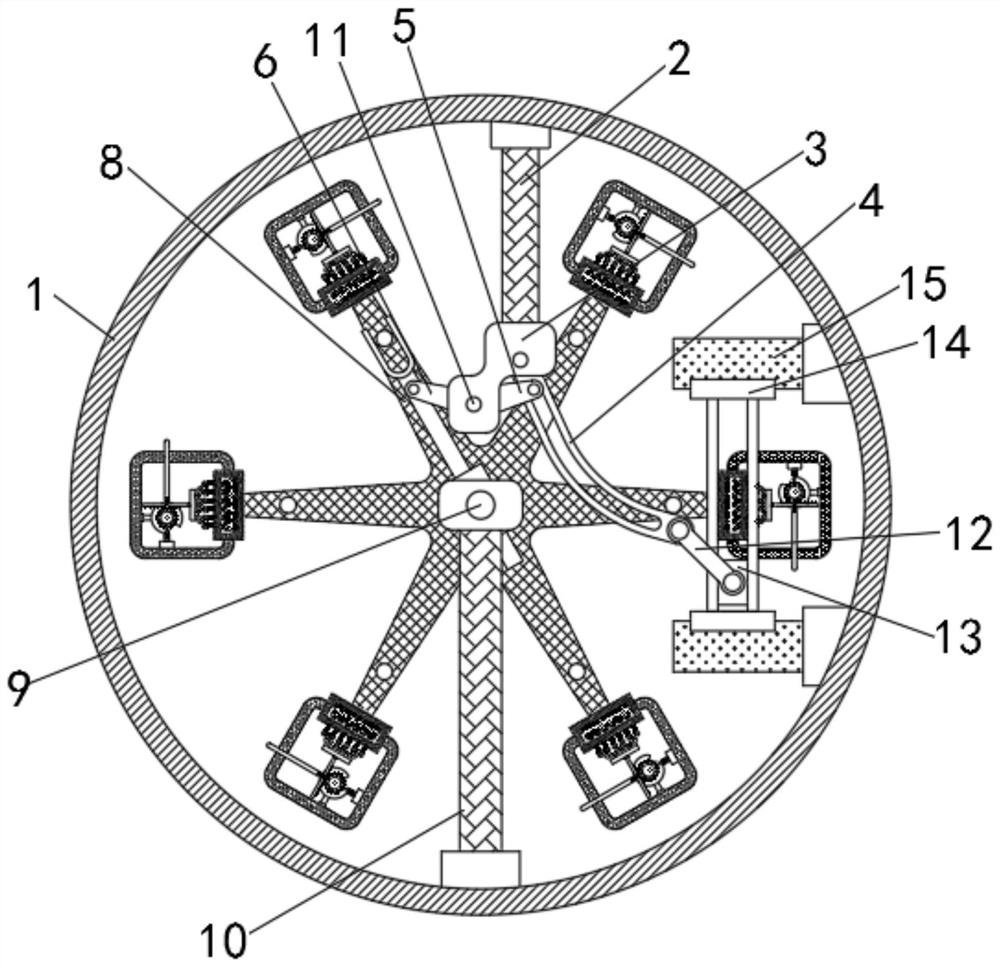

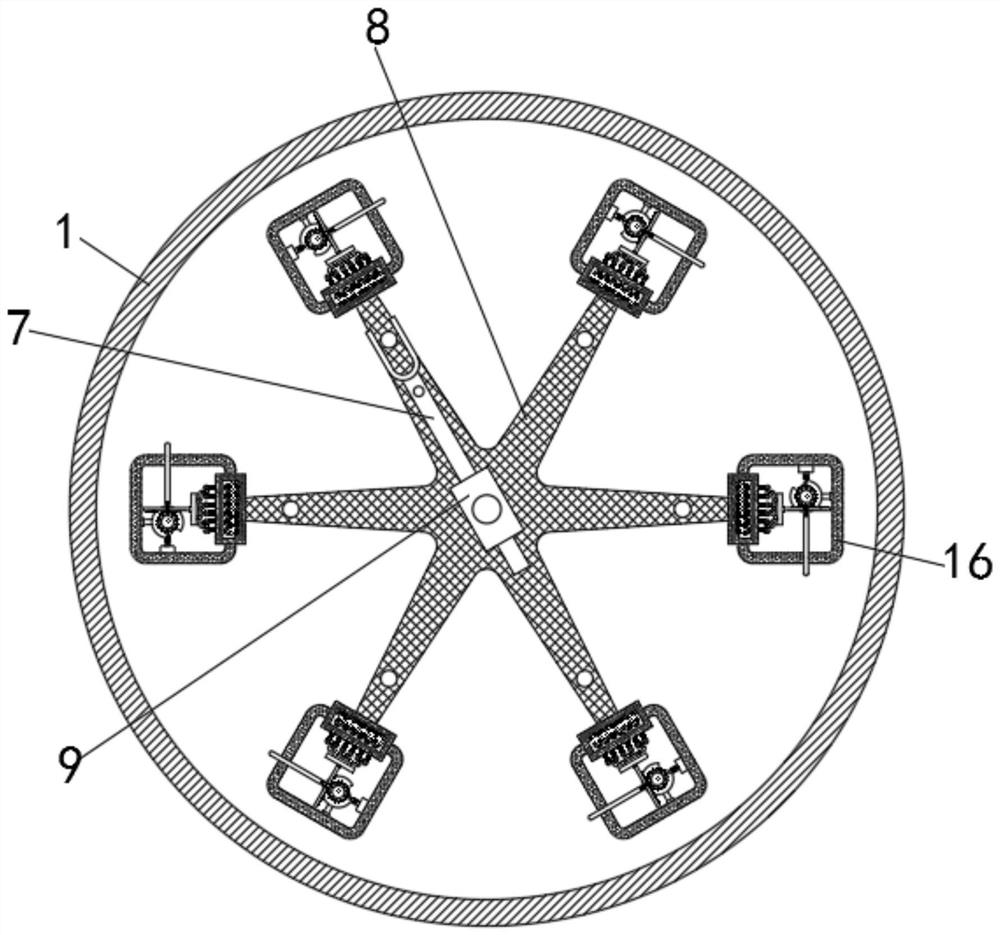

Automatic transistor heat dissipation paste smearing device for high-end equipment manufacturing

ActiveCN112566729AIncrease productivityReduce manpower consumptionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to the technical field of integrated circuit design, and discloses an automatic transistor heat dissipation paste smearing device for high-end equipment manufacturing, which comprises a round box, the inner side of the round box is fixedly connected with a first connecting rod, the front side of a rotating block is rotatably connected with a second connecting rod, and the lower side of a first arc-shaped rod is rotatably connected with a first connecting rod; a first sliding block is rotatably connected to the lower side of the first connecting rod, a first rail is slidably connected to the outer side of the first sliding block, second fixing blocks are arranged on the upper side and the lower side of the first rail, a connecting frame is fixedly connected to the outer side of the *-shaped rod, and a containing chamber is fixedly connected to the left side of the connecting frame. According to the invention, the first sliding block is driven to slide up and down in the first rail, so that heat dissipation paste of the first sliding block repeatedly smears a transistor on the lower side, and the effects of reducing manpower consumption, improving smearing uniformity, being high in production efficiency and achieving automatic smearing are achieved through the structure.

Owner:HANGZHOU JIRUI IND & TRADE CO LTD

Plate surface laminating device for aluminum-plastic plate machining

InactiveCN111070704AImproves application uniformityImprove lamination qualityFlat articlesAdhesive glueMechanical engineering

The invention relates to the technical field of aluminum-plastic plate machining laminating equipment, and discloses a plate surface laminating device for aluminum-plastic plate machining. A conveyingpipeline and a glue feeding assembly are sequentially arranged at the joint of a first installing bracket and a second installing bracket from top to bottom, a stainless steel discharging plate is arranged below the glue feeding assembly, and a conveying assembly is connected to the bottom of the stainless steel discharging plate. According to the plate surface laminating device for aluminum-plastic plate machining, glue can be uniformly applied to an aluminum-plastic plate through the glue feeding assembly, the applying uniformity of the glue on the aluminum-plastic plate can be improved, strong guarantee is provided for sequent aluminum-plastic plate laminating, and the laminating quality of the aluminum-plastic plate is improved; and the automatic glue conveying process can be completed through the conveying assembly, redundant glue can be collected and treated, in the collecting process, on the one hand, the glue can be mixed through auxiliary stirring rods to be prevented from being cured, on the other hand, the collected glue can be re-injected into a conveying channel to be used, and the purpose of energy conservation is achieved.

Owner:张柱琼

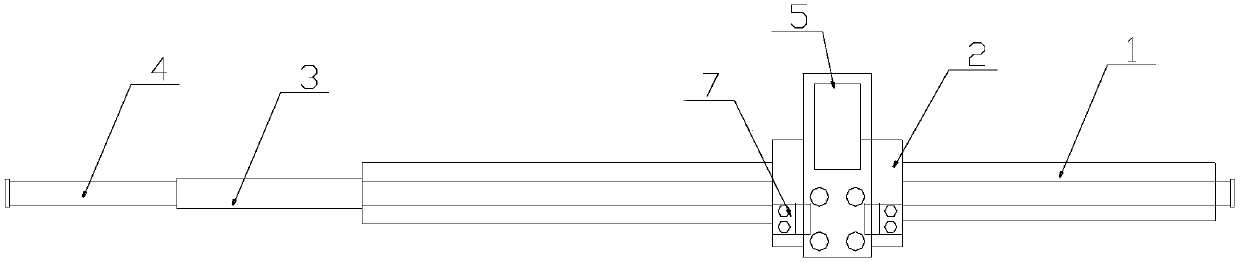

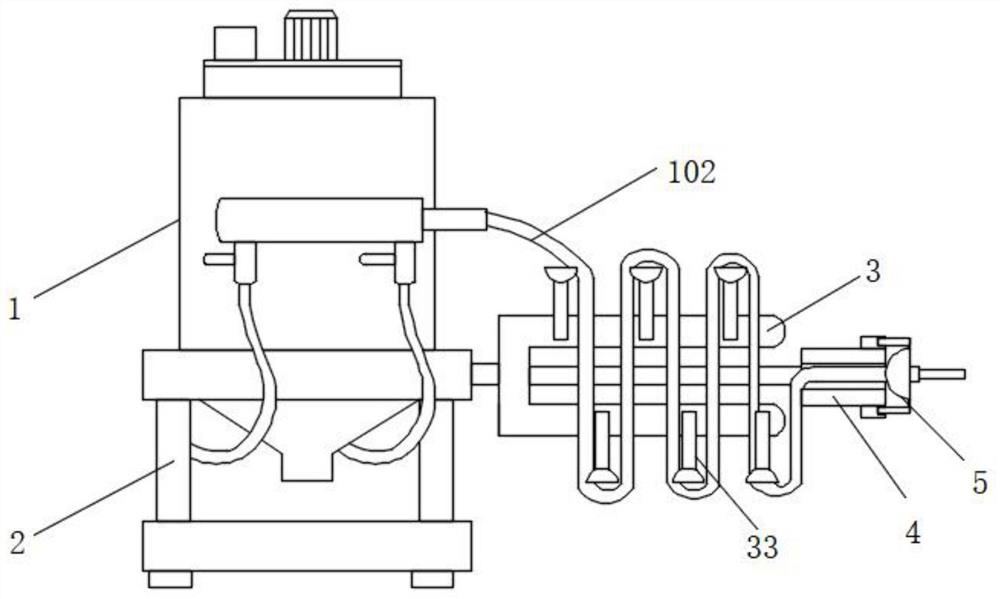

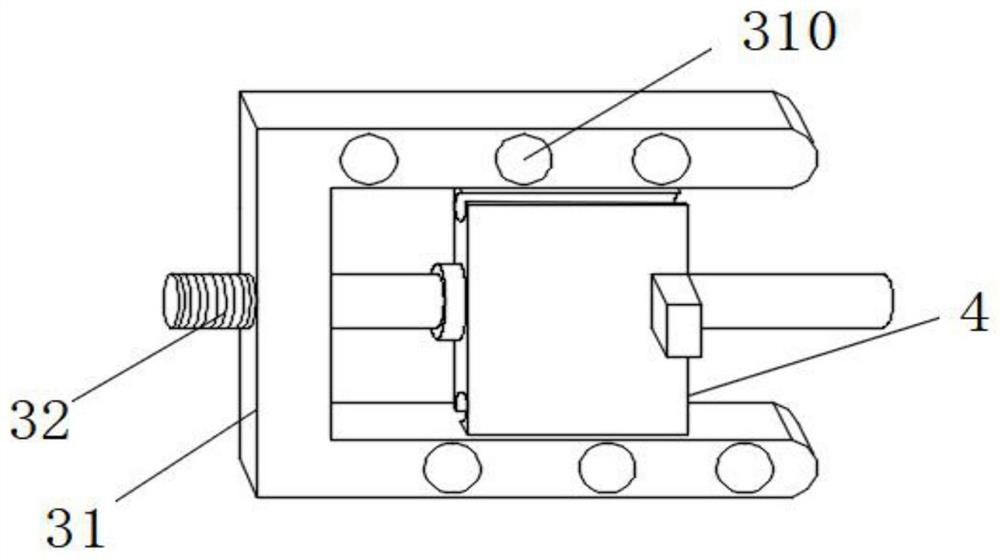

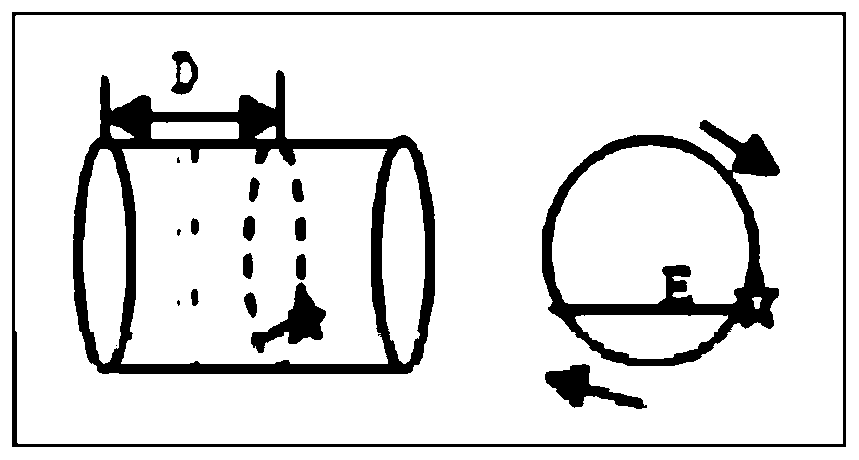

Method and device for debugging and verifying dual-medium nozzle

The invention relates to a method and a device for debugging and verifying a dual-medium nozzle. The method comprises the following steps: 1, firstly, determining atomization effect of the dual-mediumnozzle; 2, determining an optimal injection angle of the dual-medium nozzle by two directions of a radial direction and an axial direction. The method is characterized by efficient, simple, and accurate, and maintenance time and verification time are greatly shortened in equipment process verification and ordinary maintenance. The method ensures the nozzle to have no variations in atomization dimension in long-term use process, and liquid applying uniformity is improved.

Owner:CHINA TOBACCO ZHEJIANG IND

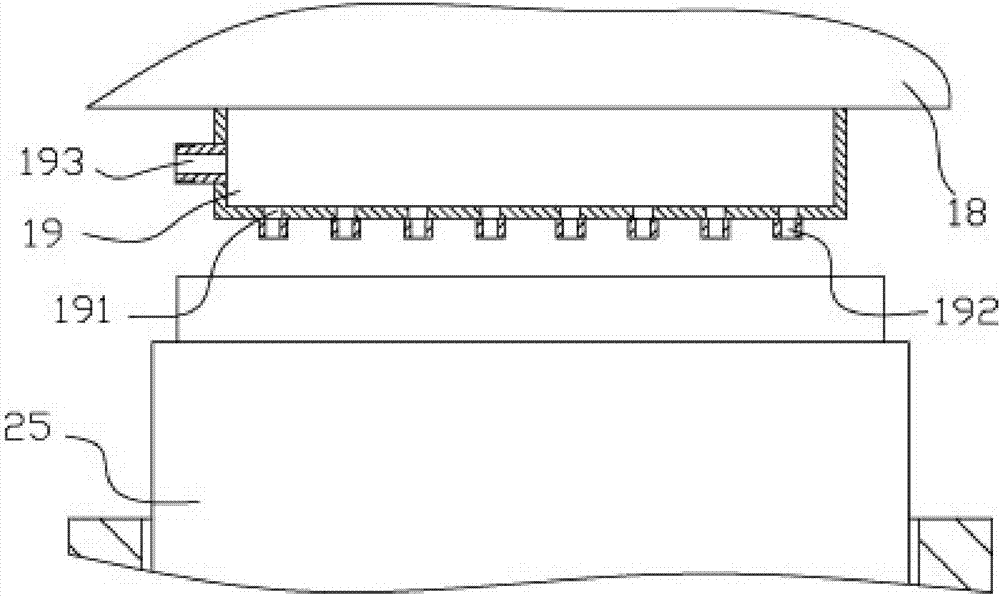

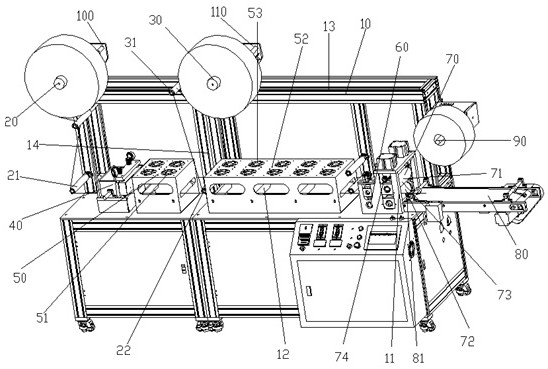

Plaster making machine

InactiveCN113440414ANot well bondedAccurate fitPharmaceutical product form changeProcessing costPhysics

The invention discloses a plaster making machine which comprises a machine base, a first unwinding roller, a first unwinding guide roller, a second unwinding roller and a second unwinding guide roller are arranged on the machine base, the first unwinding roller is used for placing a plaster bottom paper roll, the second unwinding roller is used for placing a plaster surface paper roll, and the plaster making machine further comprises a coating mechanism, a cooling mechanism, a laminating traction roller set, a slicing knife set, a conveying belt, a winding roller, a first deviation rectifying mechanism and a second deviation rectifying mechanism, the coating mechanism, the cooling mechanism, the laminating traction roller set, the slicing knife set and the conveying belt are sequentially arranged on the right side of the first unwinding guide roller, and the second unwinding roller is movably arranged above the coating mechanism. And the winding roller is arranged at the upper right part of the slicing knife set. The plaster making machine can meet the requirements for small-batch making of various departments, small clinics or experimental research institutions in hospitals, and is low in processing cost, high in plaster smearing uniformity, simple and convenient in plaster amount control, high in plaster surface paper and plaster bottom paper conveying precision and good in fitting effect.

Owner:HEBEI HUASHENG PLASTIC & RUBBER MACHINERY

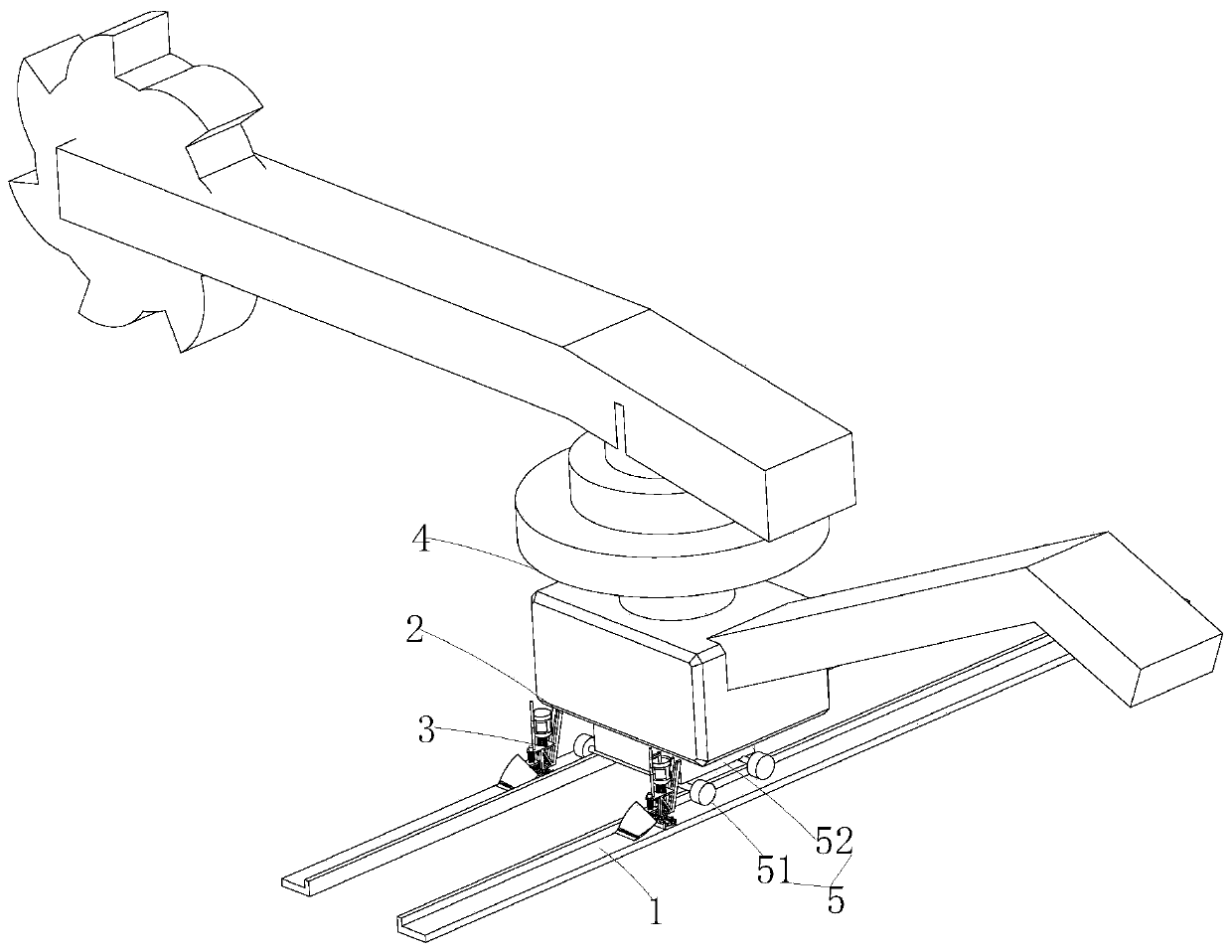

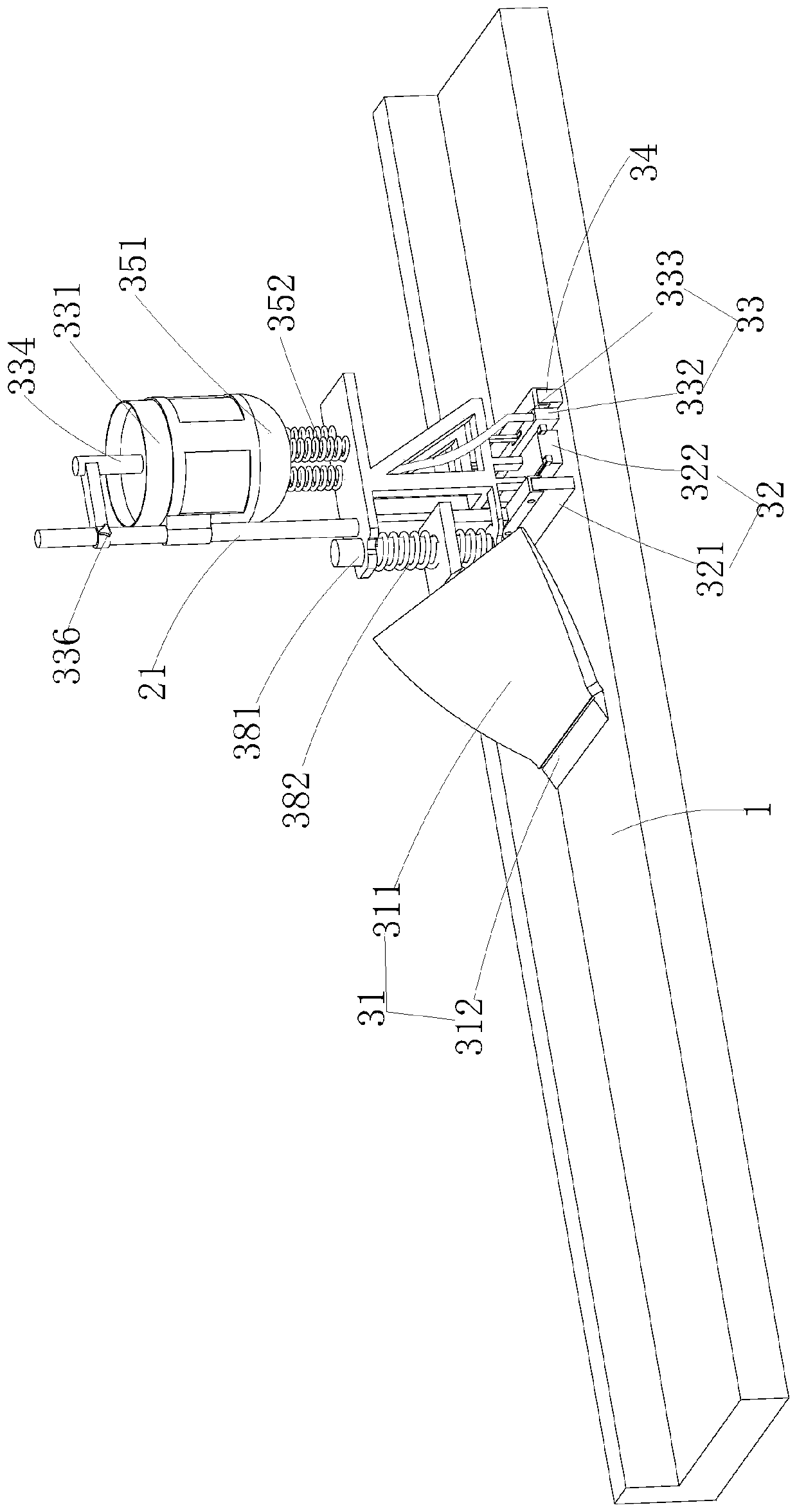

Truck axle production line

PendingCN110293374AGuaranteed accuracyNo manual operationMetal working apparatusProduction lineMaterial distribution

The invention discloses a truck axle production line. The production line involves a base, wherein a sliding rail is arranged on the base; a centering positioning device, a material distribution mechanism, a release agent coating device, an axle end heating device and an axle end extrusion device are sequentially arranged on the base in the arrangement direction of the sliding rail; and the base is further provided with a moving device for pipe blanks. According to the truck axle production line, the pipe blanks can be automatically moved to all stations and subjected to the steps of positioning, release agent coating, end heating and end extrusion molding, manual operation is not needed, the labor cost is saved, and the safety is high.

Owner:国智科学技术研究院(广州)有限公司

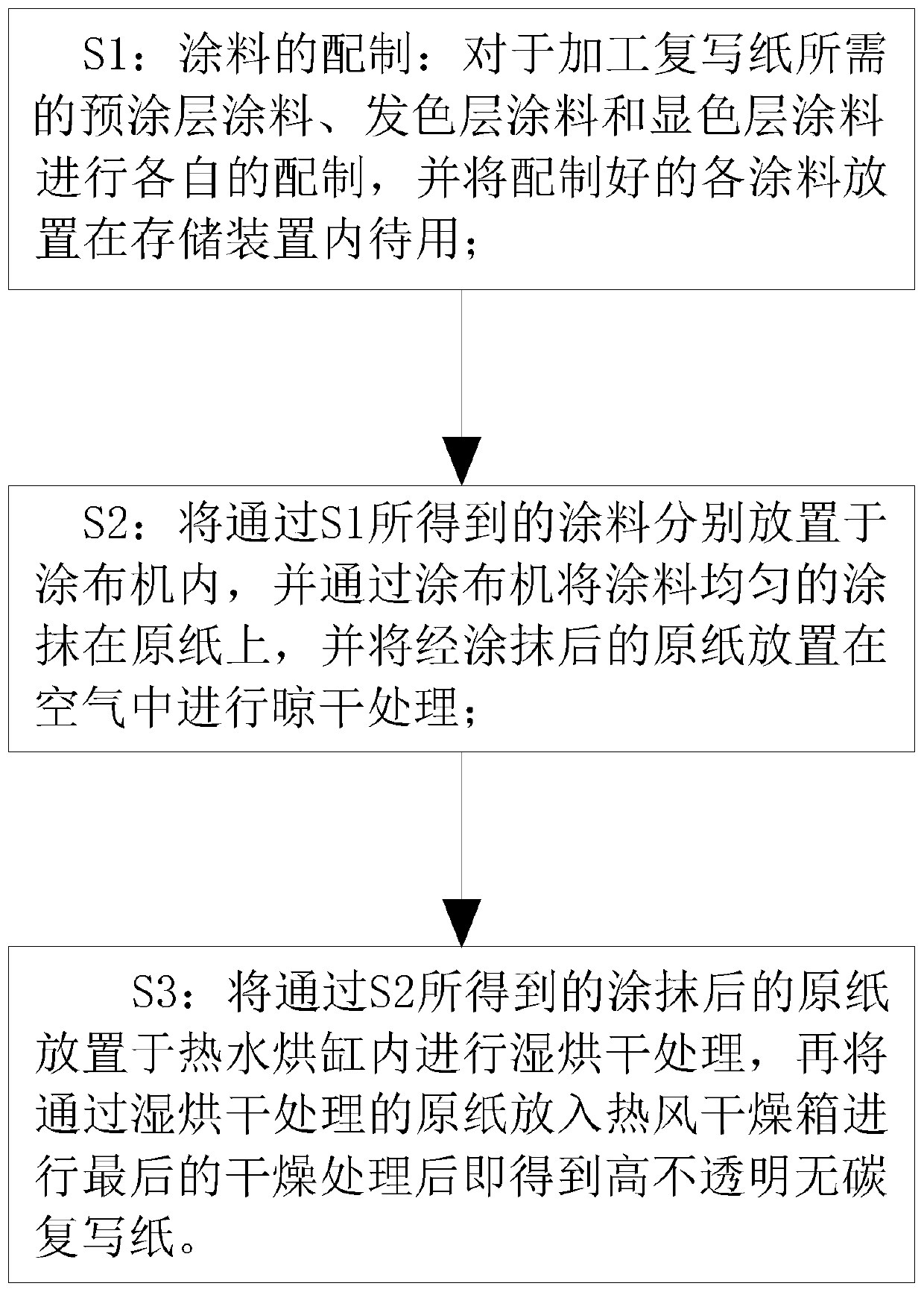

Production process of high-opaqueness carbonless carbon paper

InactiveCN110644284AImprove product qualityIncrease production capacityPaper coatingPaper/cardboardBar pressingIndustrial engineering

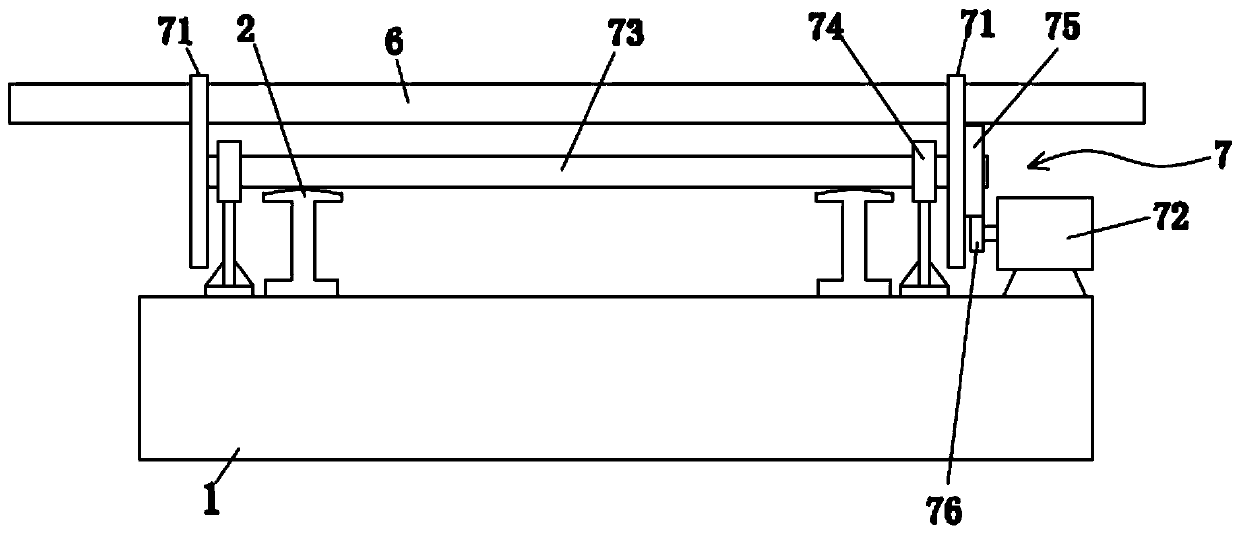

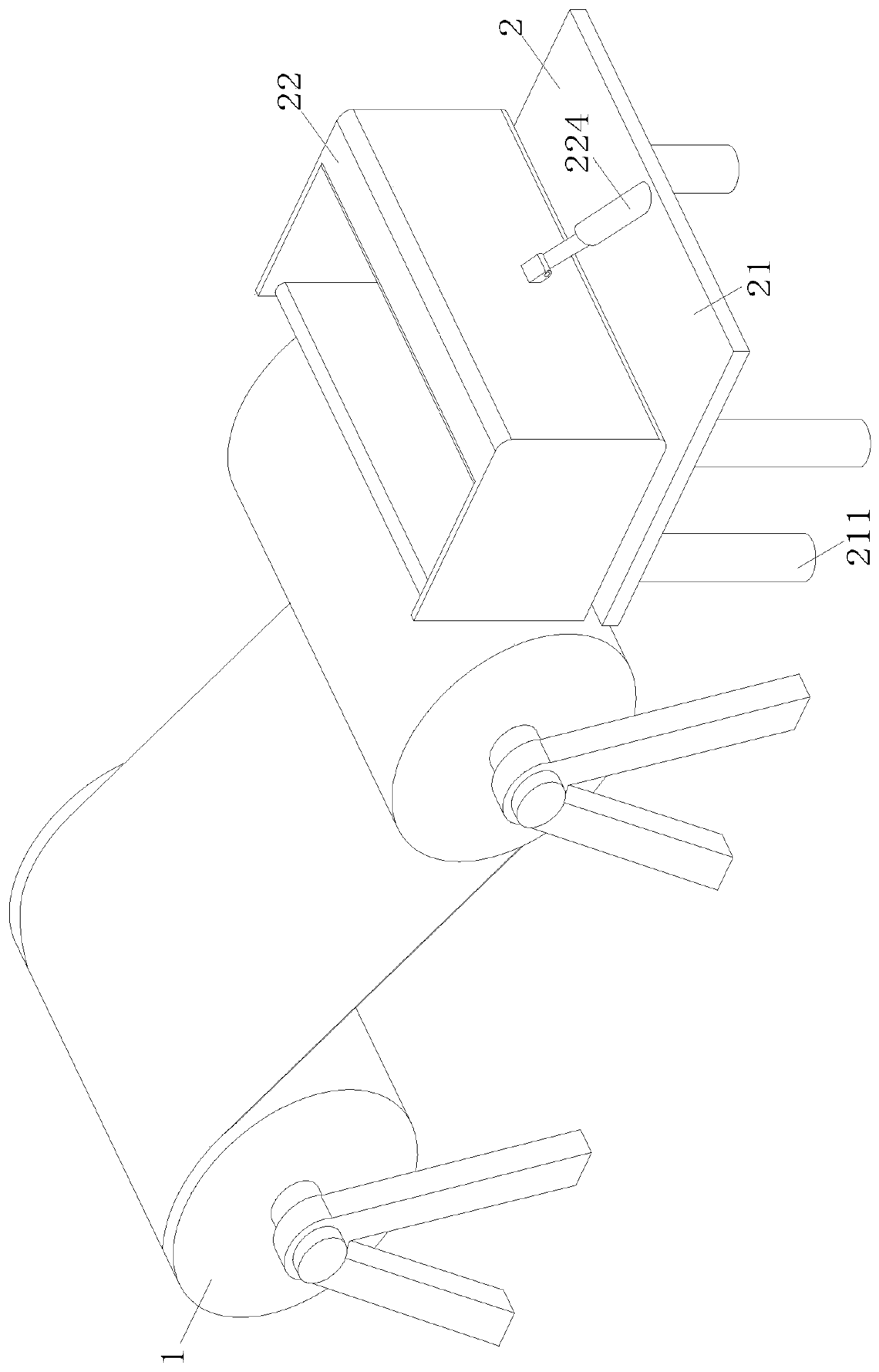

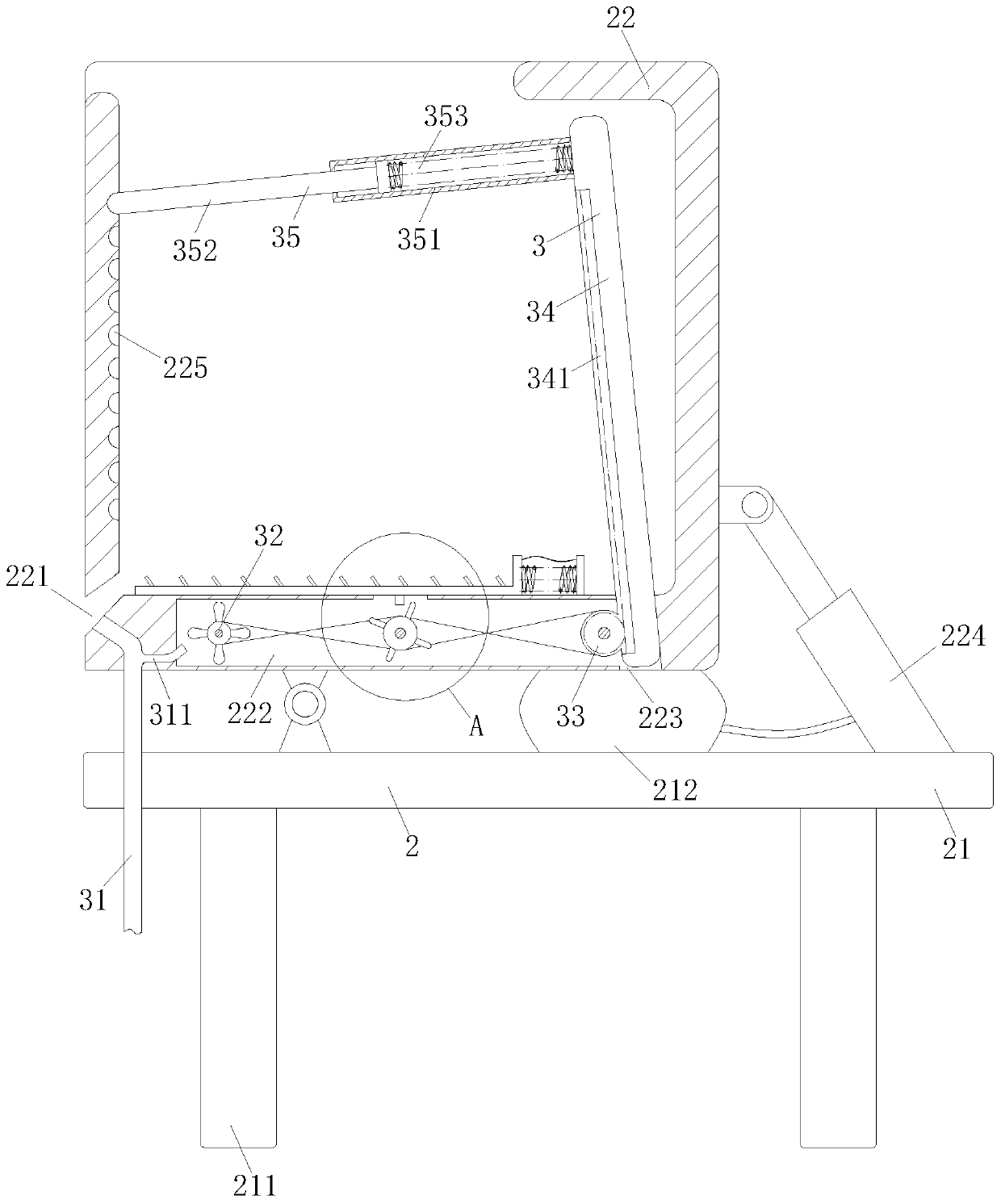

The invention belongs to the technical field of carbon paper, and particularly relates to a production process of high-opaqueness carbonless carbon paper. A coater adopted in the technological methodcomprises a paper rolling cylinder and a coating machine. The coating machine comprises a base, a shell and a discharging unit. The shell is installed on the base, and a discharging port is formed inthe position, close to the paper rolling cylinder, of the shell. The discharging unit comprises an air pipe, a first wheel, a second wheel, a push rod and a pressing rod. The side wall of the air pipeis provided with a diversion port pointing to the first wheel, so that the air pipe can blow the first wheel to rotate after ventilation; the push rod is slidably connected into the opening, and a rack is arranged on the side wall of the push rod and engaged with the second wheel; through cooperation of the base, the shell, the air pipe, the first wheel, the second wheel, the push rod and the pressing rod, coating is evenly smeared on raw paper, the production quality and the production effect of the carbon paper are improved, and the use effect of the coater is improved.

Owner:刘二梦

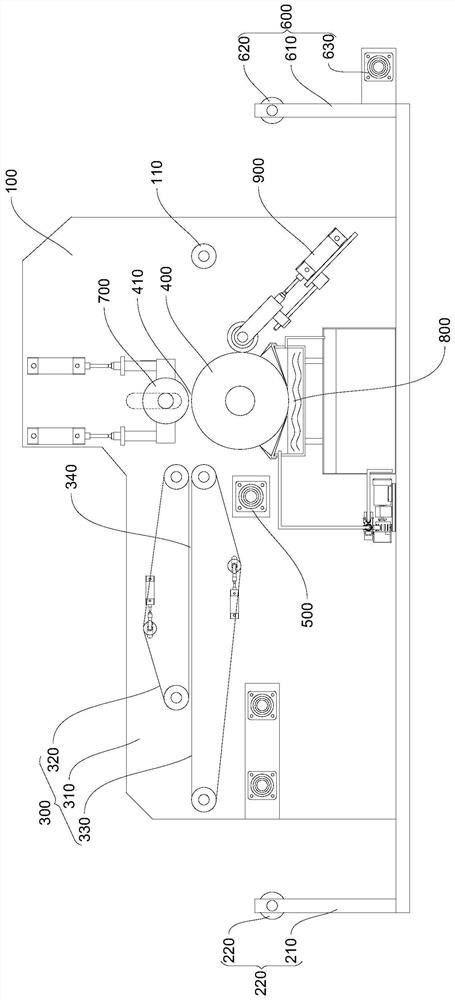

Compound enzyme preparation, tobacco lamina treatment method, material adding and storage method and penetration inspection method

InactiveCN111334491AImprove effective utilizationImproves application uniformityTobacco preparationHydrolasesCelluloseHydrolysis

The invention discloses a compound enzyme preparation, a tobacco lamina treatment method, a material adding and storage method and a penetration inspection method. According to the core of the compound enzyme preparation, the tobacco lamina treatment method, the material adding and storage method and the penetration inspection method, by starting from the nature of tobacco lamina and through the technical concepts of enzyme liquid formula improvement, process flow optimization, material adding mode improvement, absorption effect verification and the like, the uniformity of the application of tobacco material liquid and the effective utilization of the material liquid are improved, specifically, by adding the certain amount of compound enzyme preparation of a specific formula on the surfaceof the tobacco lamina with the help of the enzymolysis effect of the formula, a wax layer and a cellulose layer on the surface of the tobacco lamina are hydrolyzed so as to improve the permeability and hydrophilia of the surface of the tobacco lamina, the effective absorption rate of the material liquid is promoted, so that the loss during subsequent processing is reduced, and the effective utilization of the material liquid is improved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Coating device

ActiveCN112238029AImproves application uniformityImprove product qualityLiquid surface applicatorsCoatingsSlurryMechanical engineering

The invention belongs to the technical field of coating machinery, and particularly relates to a coating device. The coating device comprises a rack, a material containing frame, a conveying mechanism, a coating embossing roller and a receiving frame, wherein the material containing frame, the conveying mechanism, the coating embossing roller and the receiving frame are sequentially arranged on the rack. The two ends of the coating embossing roller are rotationally connected to the two sides of the rack, and the coating embossing roller is driven by a coating embossing roller driving mechanismto rotate. A positioning roller is arranged at the position, above the coating embossing roller, of the rack, and a coating gap is formed between the positioning roller and the coating embossing roller. A slurry mechanism is arranged at the position, below the coating embossing roller, of the rack. The slurry mechanism comprises a slurry containing box. A liquid groove communicating with the slurry containing box is formed in an upper cover of the slurry containing box, and the upper cover of the slurry containing box forms two first slurry scrapers on the two sides of the liquid groove correspondingly. The lower side of the coating embossing roller stretches into the liquid groove and is immersed into slurry in the slurry containing box, and a first slender liquid passing gap is formed between each first slurry scraper and the outer wall of the coating embossing roller. A coiled base material placed on the material containing frame sequentially penetrates through the conveying mechanism and the coating gap to be connected to the receiving frame.

Owner:安徽富印新材料股份有限公司

Anti-oxidation treatment equipment for steel structure material

PendingCN112518591AReduce jitterEasy to storeRotary stirring mixersTransportation and packagingSand blastingWorking environment

The invention discloses anti-oxidation treatment equipment for a steel structure material. The anti-oxidation treatment equipment comprises a tank body, the tank body is provided with a feeding port,a sand outlet pipe, rotating blocks, a fixing mechanism and a stirring mechanism, the feeding port is formed in the upper end of the tank body, the sand outlet pipe is fixedly arranged at the position, close to the middle, of the outer surface of the front end of the tank body, the number of the rotating blocks is two, and the two rotating blocks are fixedly arranged at the positions, close to thelower end, of the outer surfaces of the two sides of the tank body and are connected to the fixing mechanism. According to the anti-oxidation treatment equipment, damage to a pipe body caused by reverse twisting of the sand outlet pipe can be prevented, the sand outlet pipe is convenient to fold and store, so that abrasion to the surface of the pipe body is reduced, winding of the pipe body is reduced in a cyclic folding mode, shaking of the sand outlet pipe is reduced, the smearing uniformity in the sand blasting process can be improved, sand splashing can be reduced during operation, the working environment is kept clean, and finally, the stirring efficiency and the mortar quality are improved, so that the sand blasting quality is improved.

Owner:张琪

Anti-curing brush coating device and brush coating method

PendingCN107570370AEasy curingNo frequent replacementLiquid surface applicatorsCoatingsEngineeringManipulator

The invention provides an anti-curing brush coating device which comprises a frame, a conveying device and a glue pot. A glue cup is arranged on the frame and a manipulator is arranged in a position,above the conveying device, of the frame; and a brush assembly is mounted at the tail end of the manipulator. As the glue cup is arranged, a glue brush can be soaked in the glue cup when the glue brush does not perform a brush coating action, and is unlikely to cure, so that the glue brush is not needed to be replaced frequently and the cost is relatively low; meanwhile, compared with existing glue spraying and glue injecting modes, the smearing uniformity is relatively good. The invention also provides a brush coating method. The brush head of the glue brush before or after brush coating of aworkpiece is soaked in the glue cup filled with glue liquor and is stirred continuously. By continuously stirring, a curing film can be prevented from being formed on the surface of glue in the gluecup so as to prevent deterioration of the glue, so that the glue brush is not stuck to the curing film in a process of soaking the glue cup, and therefore, the replacing frequency of the glue brush isfurther reduced.

Owner:福建省华宝智能科技有限公司

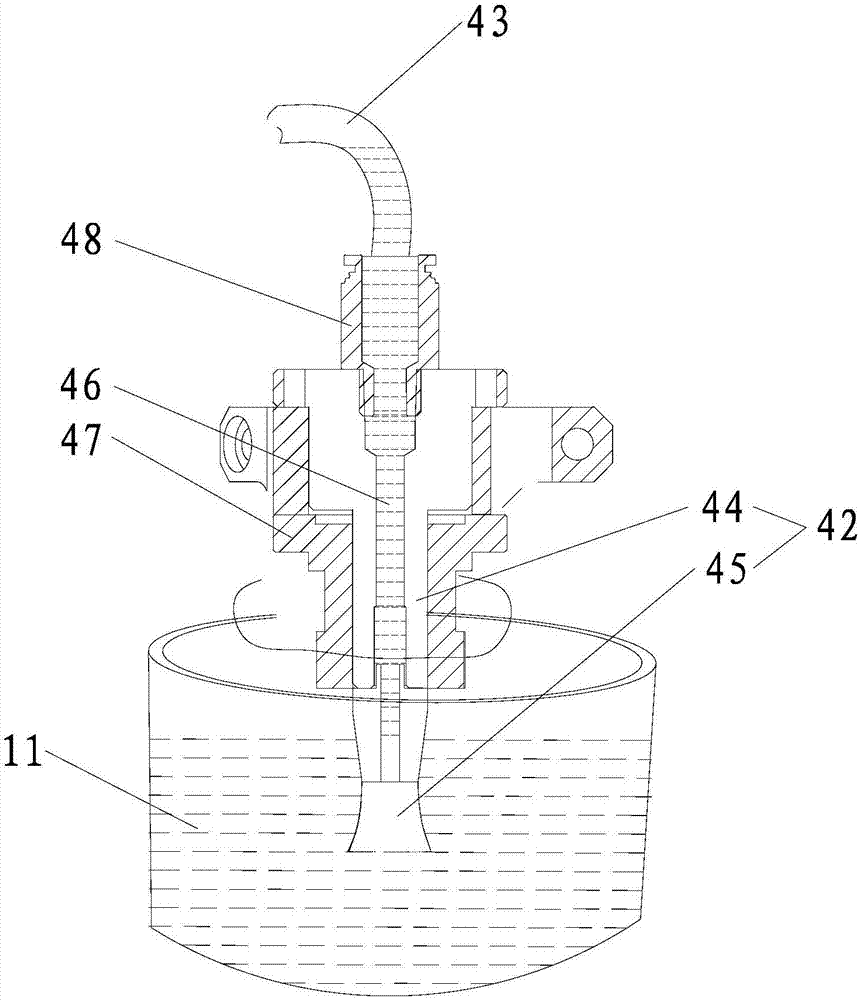

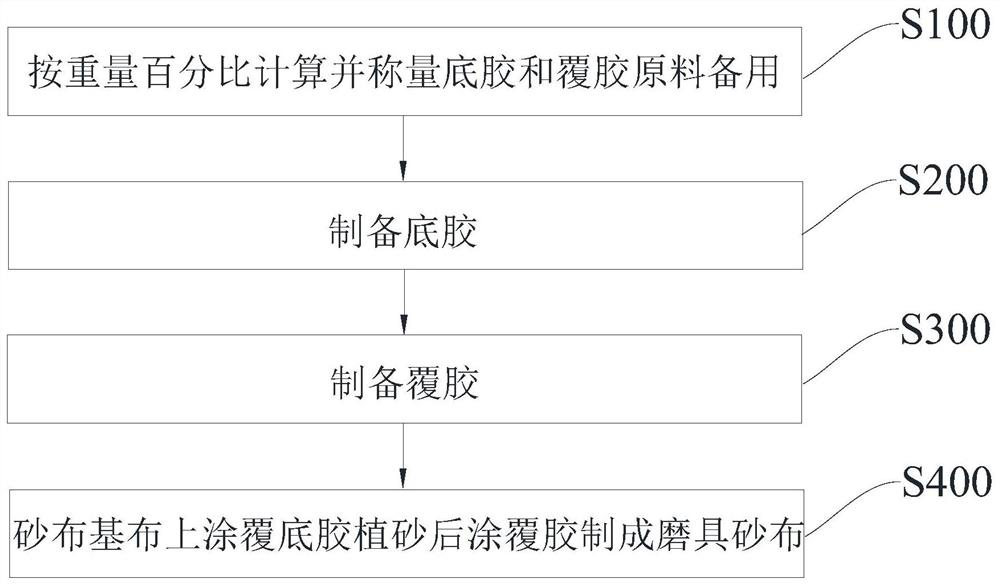

Heavy-load high-temperature-resistant precision grinding abrasive cloth primer and coating adhesive and preparation method thereof

PendingCN111941297AEfficient and stable grindingEfficient stabilization of uneven strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEthyl EthersOrganosilicon

The invention discloses a heavy-load high-temperature-resistant precision grinding abrasive cloth primer and coating adhesive. The heavy-load high-temperature-resistant precision grinding abrasive cloth primer and the coating adhesive comprise an abrasive cloth base cloth, a primer and a coating adhesive. The primer and the coating adhesive are coated on the abrasive cloth base cloth. Two high-strength polymer water-soluble phenolic resins with different cross-linked network structures, silicone grease, ethylene glycol diethyl ether and organic silicon are used for modification to prepare high-strength, high-bonding-strength and high-toughness primer. Cryolite, titanium dioxide, Span, nonionic polyurethane and ethylene glycol diethyl ether are used for modifying grease to prepare the high-strength excellent-heat-resistance coating adhesive. The invention discloses a preparation method of grinding abrasive cloth primer and the coating adhesive. The preparation method comprises the stepsthat primer and coating adhesive raw materials are calculated and weighed in percentage by weight for later use; the primer is prepared; the coating adhesive is prepared; and the primer is coated onthe abrasive cloth base cloth, and the coating adhesive is coated after sand planting, so that a coated abrasive tool abrasive cloth is prepared. According to the grinding abrasive cloth primer and the coating adhesive and the preparation method, the bonding strength and toughness of a colloid base material and an abrasive material can be effectively improved, coating is uniform, and excellent heat resistance is achieved.

Owner:江苏瑞和磨料磨具有限公司

Rotating adjustable cake coating mechanism

The invention discloses a rotary adjustable cake coating mechanism, which comprises a frame, the frame includes two vertical support plates, the middle bottom plate is fixed on the lower part of the two vertical support plates, and the middle part of the bottom surface of the middle bottom plate is fixed with a rotating Cylinder, the rotating rod of the rotary cylinder passes through the middle bottom plate and is fixed with a connecting block, the side wall of the connecting block is fixed with a side connecting rod, and the outer end of the side connecting rod is fixed with a moving support block, which is pressed against the middle On the bottom plate, an upper support frame is provided on the top surface of the movable support block, and a middle partition is provided in the middle of the upper support body, and a main adjustment screw is screwed in the middle partition, and the lower end of the main adjustment screw protrudes downward from the middle partition. plate, the upper end of the main adjusting screw extends upwards from the middle partition and is hinged with a lifting plate. It uses a rotating cylinder to automatically adjust the position of the cake. At the same time, it can automatically spread the sauce, and the distance between the cake piece and the spray sleeve can be fine-tuned to meet the application requirements.

Owner:叶伟然

A daily maintenance and treatment method for pulling wire ropes in intelligent elevator operation

ActiveCN111762660B9Guaranteed decontaminationGuaranteed lubrication effectElevatorsControl theoryLubricant

The invention provides a daily maintenance and treatment method for the pulling wire rope of an intelligent elevator. The operation is completed by the cooperation of the weighted base, the cylinder, the extrusion frame and the maintenance unit. Manual maintenance is ineffective, inefficient, and takes a long time, which causes the elevator to stop for a long period of time, which brings great inconvenience to users. At the same time, it is easy to cause problems such as waste of lubricating oil during oiling.

Owner:GUANGDONG HENGWEI ELEVATOR CO LTD

Greenhouse self-propelled automatic sprayer

InactiveCN105165776BReduce dosageSmall particle sizeInsect catchers and killersSprayerSolenoid valve

The invention discloses a greenhouse self-propelled automatic sprayer, which includes a mobile platform, a spray system and a control device, wherein: the mobile platform includes a trolley carrying a spray system and a moving guide rail, and a three-in-one decelerating motor is installed on the moving guide rail; The spraying system includes a medicine box, a stepper motor, an electric motor, a transmission device, a plunger pump, a transmission belt, a nozzle, a water inlet pipe, a return pipe, a water outlet pipe and a solenoid valve; The three-in-one geared motor and the stepping motor and solenoid valve in the spraying system realize the forward and backward, rising and falling of the trolley and the start and stop of the spraying operation. The sprayer is simple in operation, stable in work and strong in controllability. It not only realizes the mechanization and automation of pesticide application in the greenhouse, but also has low manufacturing cost, and can make the spraying have good liquid coverage, droplet deposition density and droplet distribution. Uniformity, to meet the requirements of pest control.

Owner:NINGXIA UNIVERSITY

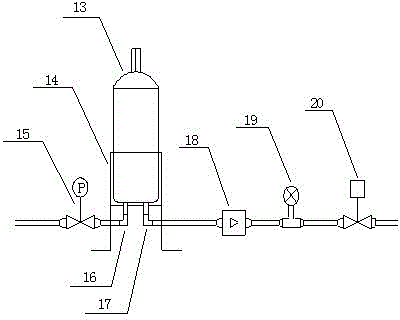

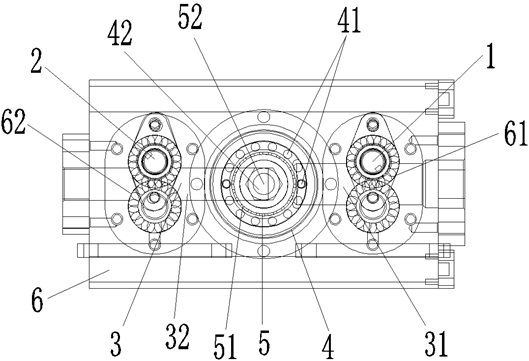

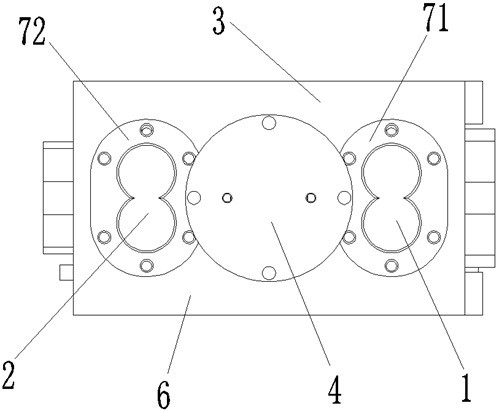

Steady-flow conveying system

ActiveCN113145407AAvoid cloggingAvoid enteringLiquid surface applicatorsSpraying apparatusMechanical engineeringMechanics

The invention discloses a steady-flow conveying system. The steady-flow conveying system comprises a first pump body, and further comprises a second pump body, a connecting channel and a steady-flow cavity, wherein the connecting channel comprises a first connecting channel and a second connecting channel; a steady-flow inlet and a steady-flow outlet are formed in the steady-flow cavity; the inlet of the first connecting channel is connected to the outlet of the first pump body; the outlet of the first connecting channel is connected to the steady-flow inlet; the steady-flow outlet is connected to the inlet of the second connecting channel; and the outlet of the second connecting channel is connected to the inlet of the second pump body. The steady-flow conveying system can continuously and stably output plaster, is uniform in plaster coating, is convenient and quick in replacing a filter screen, and is convenient in cleaning parts.

Owner:HEBEI HUASHENG PLASTIC & RUBBER MACHINERY

Cement raw material taking machine capable of lubricating tracks

ActiveCN111038943AEnsure adequate lubricationReduce lubricationMechanical conveyorsReclaimerMechanical engineering

The invention discloses a cement raw material taking machine capable of lubricating tracks. The cement raw material taking machine comprises the tracks laid on the ground, a rack, a material taking device arranged on the rack and used for taking down cement raw materials, a moving device arranged on the rack and used for driving the rack to act back and forth along the tracks and a lubricating device arranged at the front end of the rack and used for shoveling the cement raw materials located on the tracks and applying a lubricating agent to the tracks. The lubricating device comprises a shoveling component used for shoveling the large-grain-size cement raw materials, a cleaning component for cleaning small-grain-size cement raw materials, a lubricating component for dripping the lubricating agent to the tracks and a uniform applying component for evenly applying the lubricating agent, and the shoveling component, the cleaning component, the lubricating component and the uniform applying component are arranged at the front end of the rack. The lubricating device is arranged at the front end of the rack so that it can be guaranteed that an enough lubricating effect is achieved between wheels and the tracks, abrasion between the tracks and the wheels is little, and the service life of the wheels and the tracks is prolonged.

Owner:杭州山亚南方水泥有限公司

Oil nozzle structure with oil coating

InactiveCN104209197BImproves application uniformityAvoid pollutionLiquid surface applicatorsSpray nozzlesFuel tankDrop out

The invention relates to a nozzle structure for daubing a material strap with oil. The nozzle structure comprises a nozzle body; the nozzle body is arranged above the material strap; the nozzle body is of a shell structure of which the upper end is large and the lower end is small; an oil pipe communicated with an oil tank is arranged at the outer side of the upper end of the nozzle body; the inner wall of nozzle body is obliquely and fixedly connected with an oil guide plate; the high end of the oil guide plate is provided with an arc-shaped oil guide area and located below the oil inlet of the oil pipe; a plurality of oil leak holes are evenly distributed in the oil guide plate; the lower end of the nozzle body is provided with an oil guide part bent to the conveying direction of the material strap; the oil guide part is provided with a falling oil groove. According to the nozzle structure disclosed by the invention, oil flow is evenly guided to drop to the oil guide part by the oil guide plate; the material strap is evenly daubed with oil drops by the oil guide part through the falling oil groove; the daubing evenness of the nozzle structure is high; the falling oil width is limited by the width of the falling oil groove, and therefore the condition that the oil drops drop out of the material strap to cause pollution is avoided.

Owner:张学义 +1

Debugging and verification method and equipment for a dual-medium nozzle

ActiveCN107788566BNo change in atomization sizeImproves application uniformityTobacco preparationProcess engineeringElectrical and Electronics engineering

The invention relates to a method and a device for debugging and verifying a dual-medium nozzle. The method comprises the following steps: 1, firstly, determining atomization effect of the dual-mediumnozzle; 2, determining an optimal injection angle of the dual-medium nozzle by two directions of a radial direction and an axial direction. The method is characterized by efficient, simple, and accurate, and maintenance time and verification time are greatly shortened in equipment process verification and ordinary maintenance. The method ensures the nozzle to have no variations in atomization dimension in long-term use process, and liquid applying uniformity is improved.

Owner:CHINA TOBACCO ZHEJIANG IND

Cake sauce painting mechanism capable of automatically feeding and discharging

The invention discloses a cake coating mechanism for automatic loading and unloading, which includes a frame, the frame includes two vertical support plates, the upper and lower parts of the left vertical support plate are fixed with connecting plates, and the vertical screw The two ends of the two sides are hinged on the corresponding connecting plate, and the adjusting motor is fixed on the connecting plate below. Two adjustment blocks are screwed in the vertical screw rod, the right side walls of the two adjustment blocks are fixed on the upper support frame body, the middle part of the upper support frame body is provided with a middle partition, and the left side, the front part and the rear of the middle partition There are extended ribs extending upwards at all parts, and an iron plate is placed on the middle partition. On the iron plate, there is a cake bottom box to be processed, and cake pieces are placed in the cake bottom box to be processed. It uses a push cylinder to realize the up and down The material is adjusted up and down by adjusting the motor to realize the automatic spread of the sauce, and the spread is even and the effect is good.

Owner:ZHEJIANG XIAOERHEI FOOD

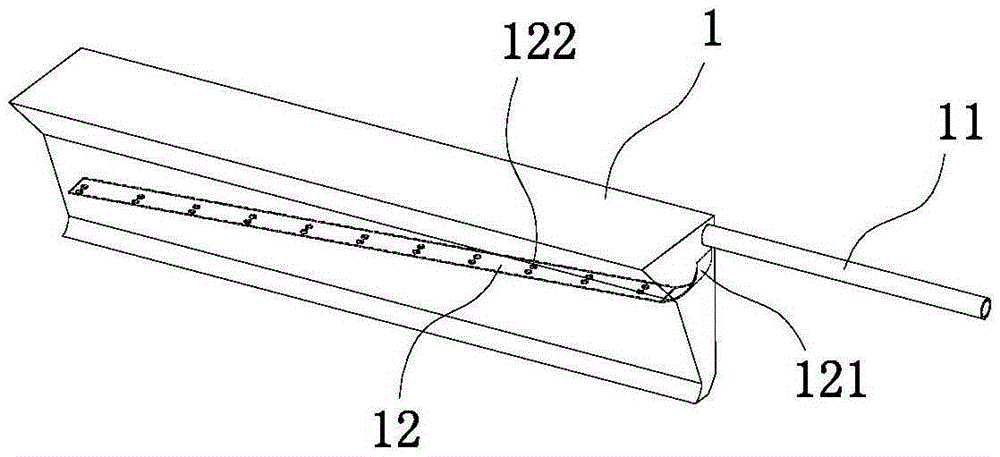

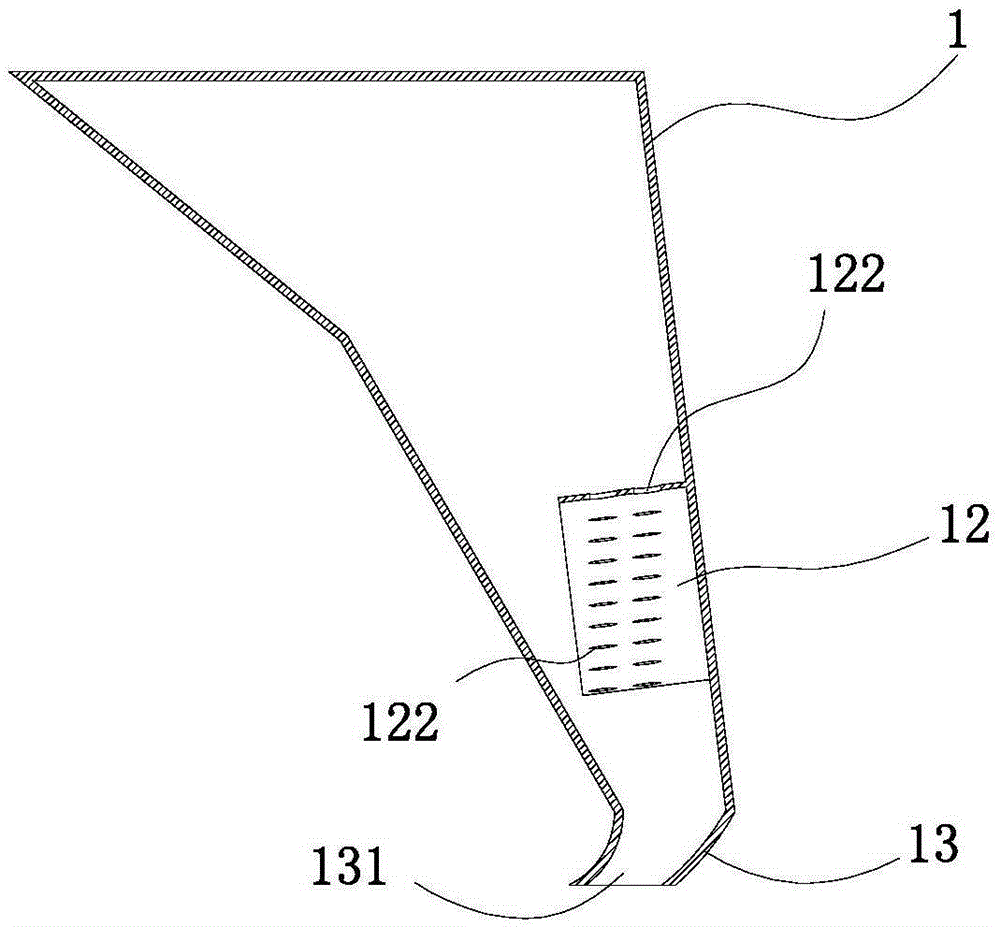

A feeding device for a leather roller coater

ActiveCN106223048BImproves application uniformityPlay a role in flatteningLiquid surface applicatorsTextile treatment machine arrangementsEngineeringMechanical engineering

The invention provides a material loading device of a leather roller-coating machine. The material loading device includes a U-shaped frame. In the conveying direction of a leather fabric in the U-shaped frame, a fabric wetting mechanism and a transmission mechanism are successively disposed. An edge pressing mechanism is arranged above the fabric wetting mechanism. The fabric wetting mechanism includes a wet board body, a trough body and an inclined plate. The wet board body includes a top bin body and a tapered hopper. The top bin body is formed on an opening on the top of the tapered hopper. The edge pressing mechanism includes two air cylinders and two pressing plates. Pistons of the first and second air cylinders are connected respectively to the first and second pressing plates. The first and second pressing plates are respectively arranged on the two sides of the upper surface of the wet board body. By means of the fabric wetting mechanism, the surface of the leather fabric can be wetted before coating the leather fabric, thereby preventing wrinkle, dry cracking and the like on the surface of the leather fabric. The device can improve coating uniformity of a coating and is more convenient to use. The edge pressing mechanism can press the surface of the leather fabric so as to prevent the phenomena of wrinkle, bending and the like.

Owner:浙江富邦汽车内饰科技有限公司

Flexible electronic function layer preparation device and preparation method under multiple composite fields

InactiveCN113731324AImproves application uniformityEnhance the macro fieldRotating receptacle mixersTransportation and packagingFlexible electronicsElectric field

The invention relates to the technical field of flexible electronic functional layer preparation, in particular to a flexible electronic functional layer preparation device under multiple composite fields. The device comprises a bottom plate, a first rotating unit, a second rotating unit, a magnetic field generation unit, an electric field generation unit and a thermal field generation unit, and enables a functional material to be in a composite external field of a magnetic field, an electric field and a thermal field at the same time, and accurate preparation of the flexible electronic functional layer can be realized in the composite field. The invention further relates to a preparation method of the flexible electronic functional layer under the multiple composite fields, dynamic regulation and control in the functional film preparation process can be achieved through global regulation and control over the composite force field and local regulation and control over the electric field and the magnetic field, and then large-scale and consistent preparation of the flexible electronic functional layer is achieved.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com