Plaster making machine

A technology for making machine and plaster, which is applied in the direction of making medicine into a device in a special physical or taking form, etc., can solve the problems of difficult to achieve precision, difficult to control the temperature of the plaster, and unsightly appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

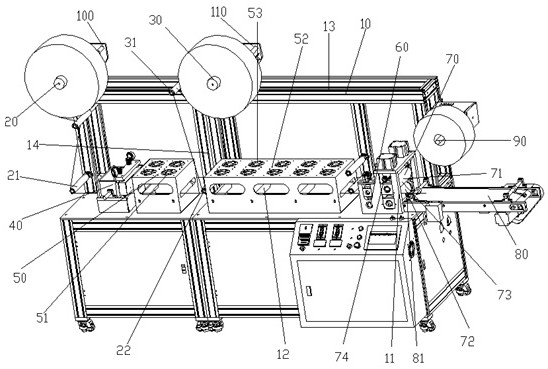

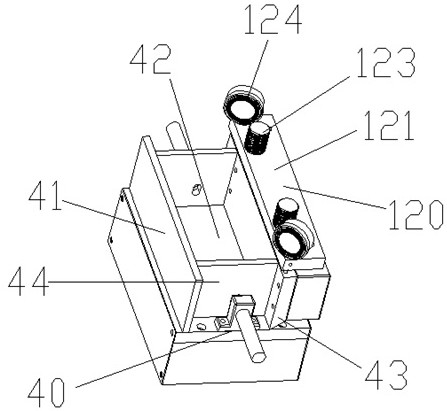

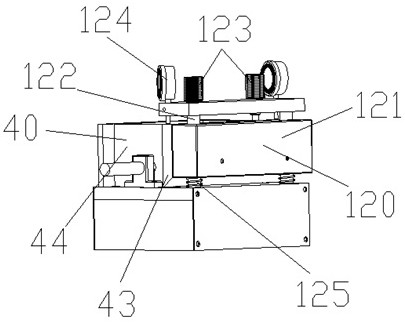

[0021] like figure 1 , figure 2 , image 3 , Figure 4As shown, the plaster making machine includes a base 10, and the length direction of the base 10 is defined as the left-right direction, that is, the conveying direction of the plaster. The base 10 is provided with the first unwinding roller 20, the first unwinding guide roller 21, the second unwinding roller 30 and the second unwinding guide roller for placing the plaster face paper roll 31. Coating mechanism 40, cooling mechanism 50, laminating traction roller group 60, slicer knife group 70, conveyor belt 80 for conveying cut plaster sheets, winding roller 90, first deviation correction mechanism 100 and second deviation correction mechanism 110, wherein the coating mechanism 40, the cooling mechanism 50, the laminating traction roller group 60, the slicing knife group 70 and the conveyor belt 80 are sequentiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com