Debugging and verification method and equipment for a dual-medium nozzle

A dual-media nozzle and verification method technology, applied in the field of debugging and verification of dual-media nozzles, can solve problems such as errors, multiple rework, inability to guarantee the consistency of nozzle angle and atomization effect, etc., achieve rapid positioning, save labor costs, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

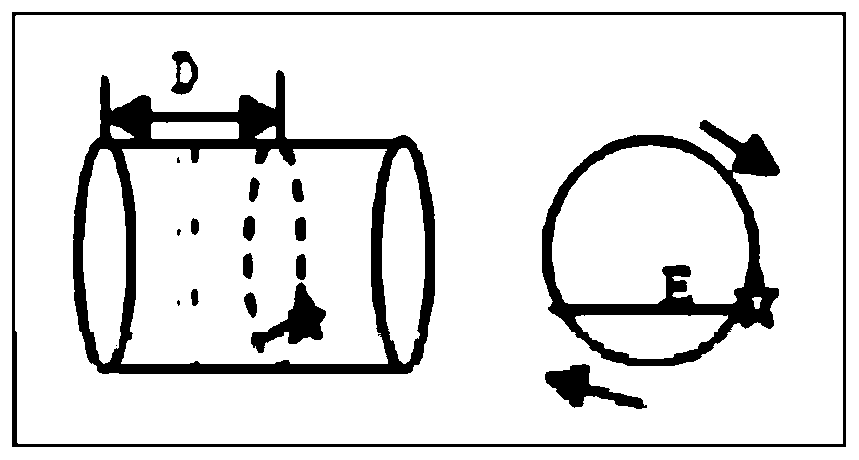

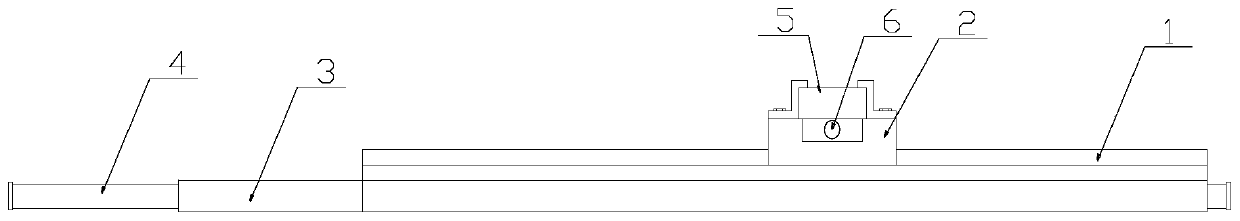

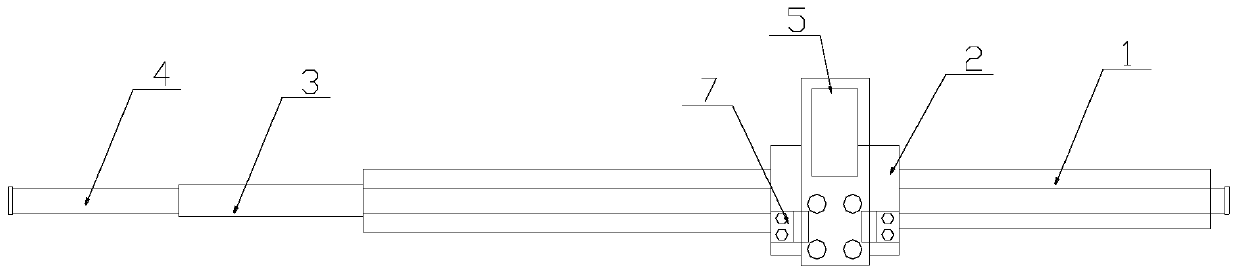

[0041] A device for adjusting the angle of the nozzle of a tobacco cylinder, the device includes an axial and radial positioning device, a laser pointer 8 and a nozzle fixing device. Such as figure 2 , image 3 The axial and radial positioning device includes an optical axis cylindrical guide rail 1, a slider 2, a scaled telescopic rod, a laser rangefinder 5, and an embedded level 6; the slider 2 can be linearly slid and arranged on the optical axis On the cylindrical guide rail 1, the slider 2 is provided with a fixed frame 7, the laser range finder 5 is fixedly arranged on the fixed frame 7, the embedded level 6 is arranged on the side wall of the slider 2, and the described belt The scale telescopic rod includes an outer rod 3 and an inner rod 4, the outer rod 3 is fixedly arranged at one end of the optical axis cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com