Flexible electronic function layer preparation device and preparation method under multiple composite fields

A technology for preparing devices and functional layers, which is applied in the field of flexible electronic functional layer preparation devices and preparations, can solve the problems of inability to realize material patterning and dynamic adjustment of functions at the same time, achieve enhanced macroscopic external field, improve coating uniformity, and facilitate preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

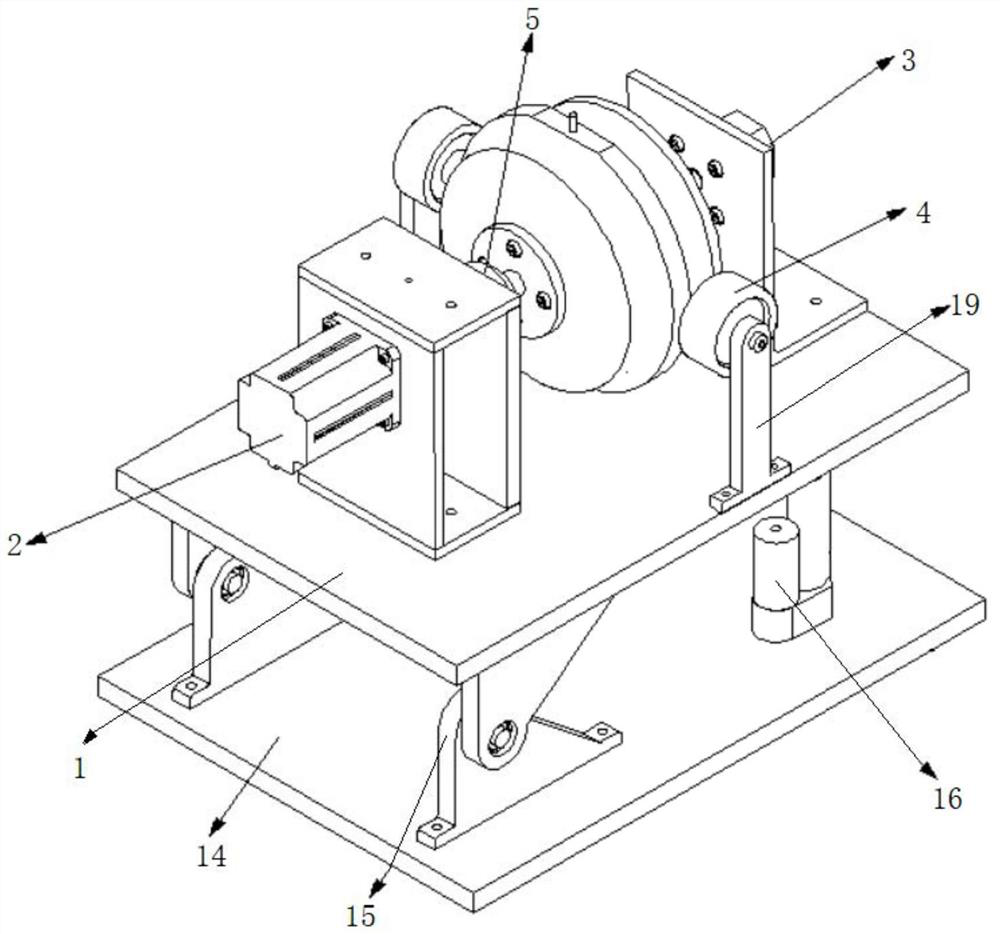

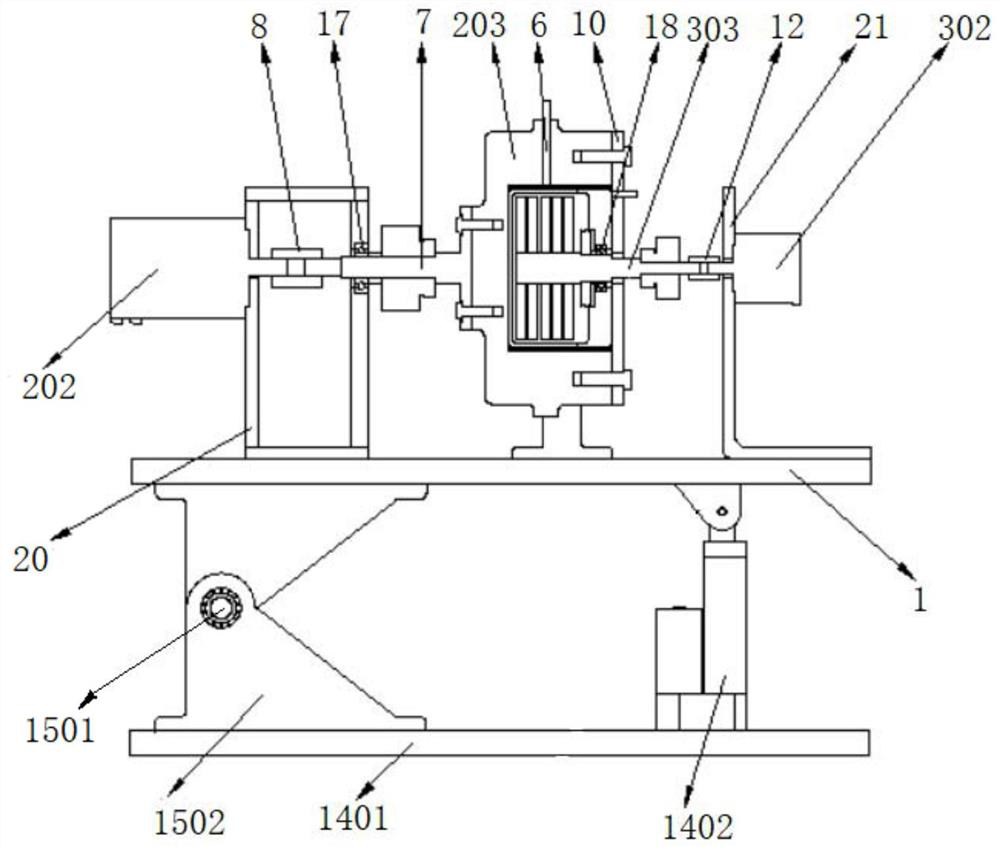

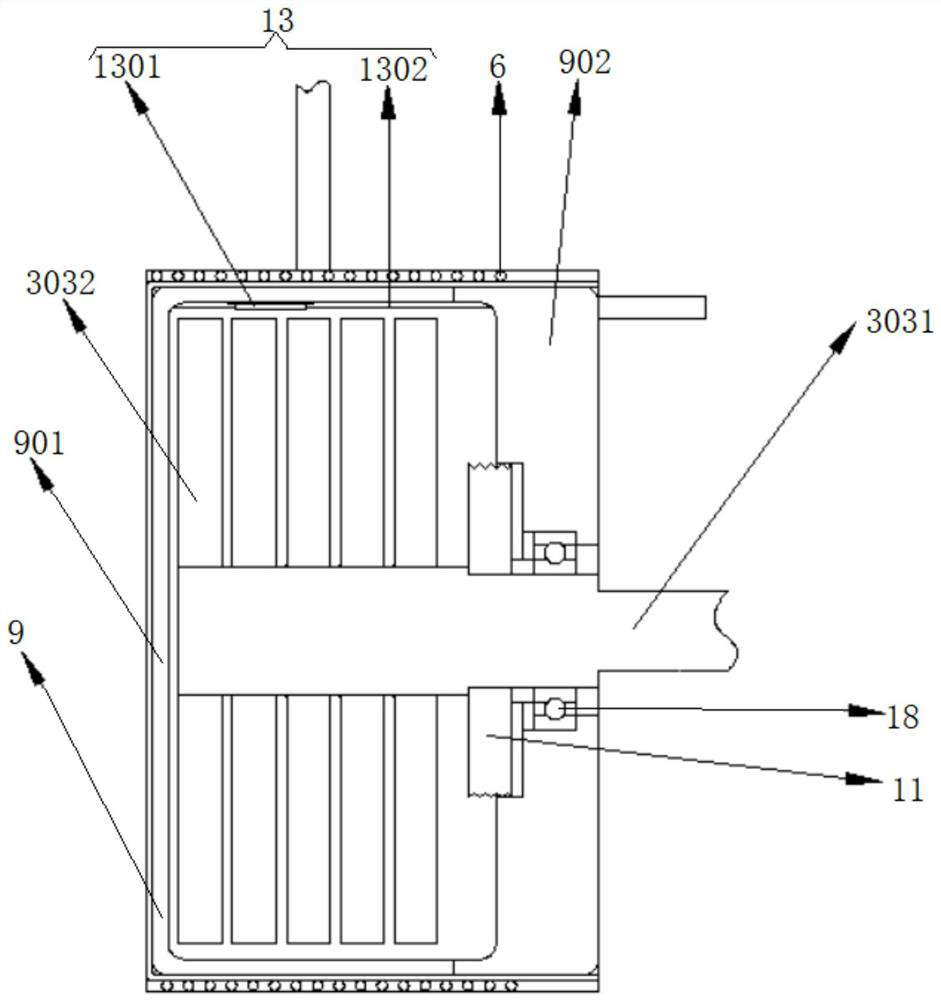

[0034] The invention discloses a flexible electronic functional layer preparation device under a multi-composite field. figure 1 , 2 , including a base plate 1, a first rotating unit 2, a second rotating unit 3, a magnetic field generating unit 4, an electric field generating unit 5, and a thermal field generating unit 6; the first rotating unit 2 includes a first support base 20, a first motor 202 and a heating Cavity 203, the first support base 20 of the first motor 202 is connected to the base plate 1 through the first support base 20, the first support base 20 is connected with the base plate 1 by bolts, the output shaft of the first motor 202 is parallel to the surface of the base plate 1, the second The housing of a motor 202 is bolted to the first support base 20 , and the output shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com