Cement raw material taking machine capable of lubricating tracks

A cement raw material and reclaimer technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of round pile reclaimers not working, affecting cement production efficiency, roller and track damage, etc., to maintain Work efficiency, low power, and reduce the effect of replacement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

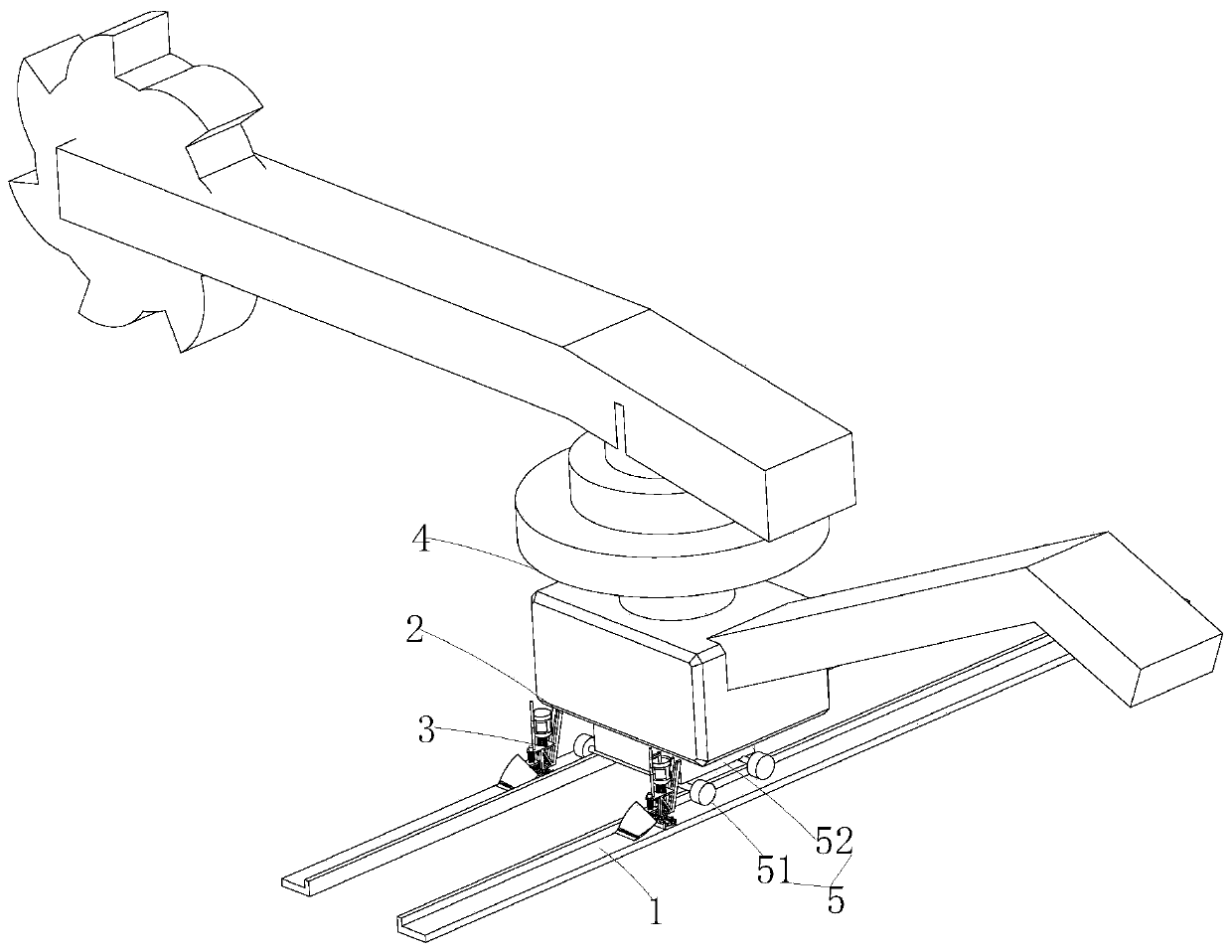

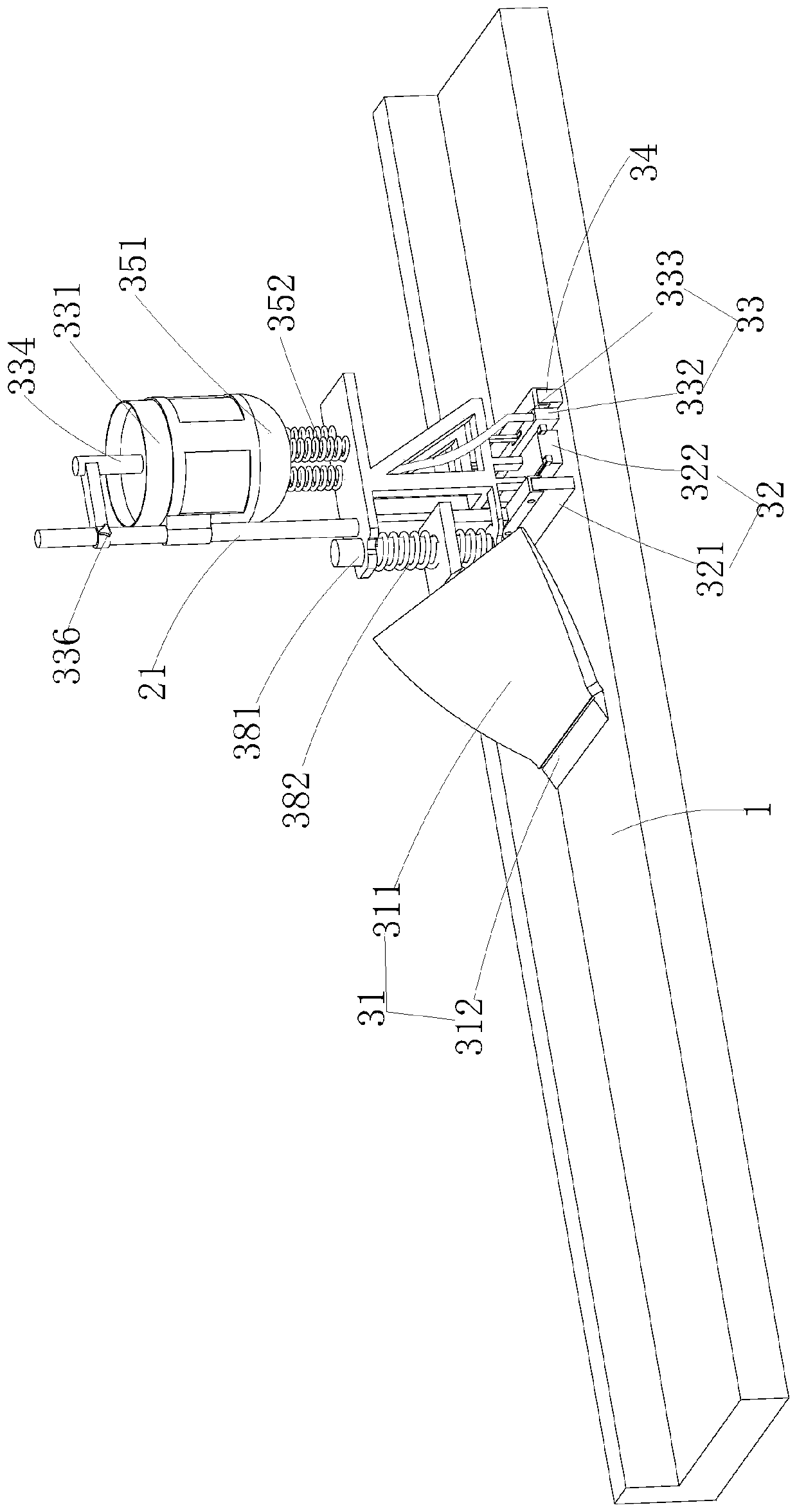

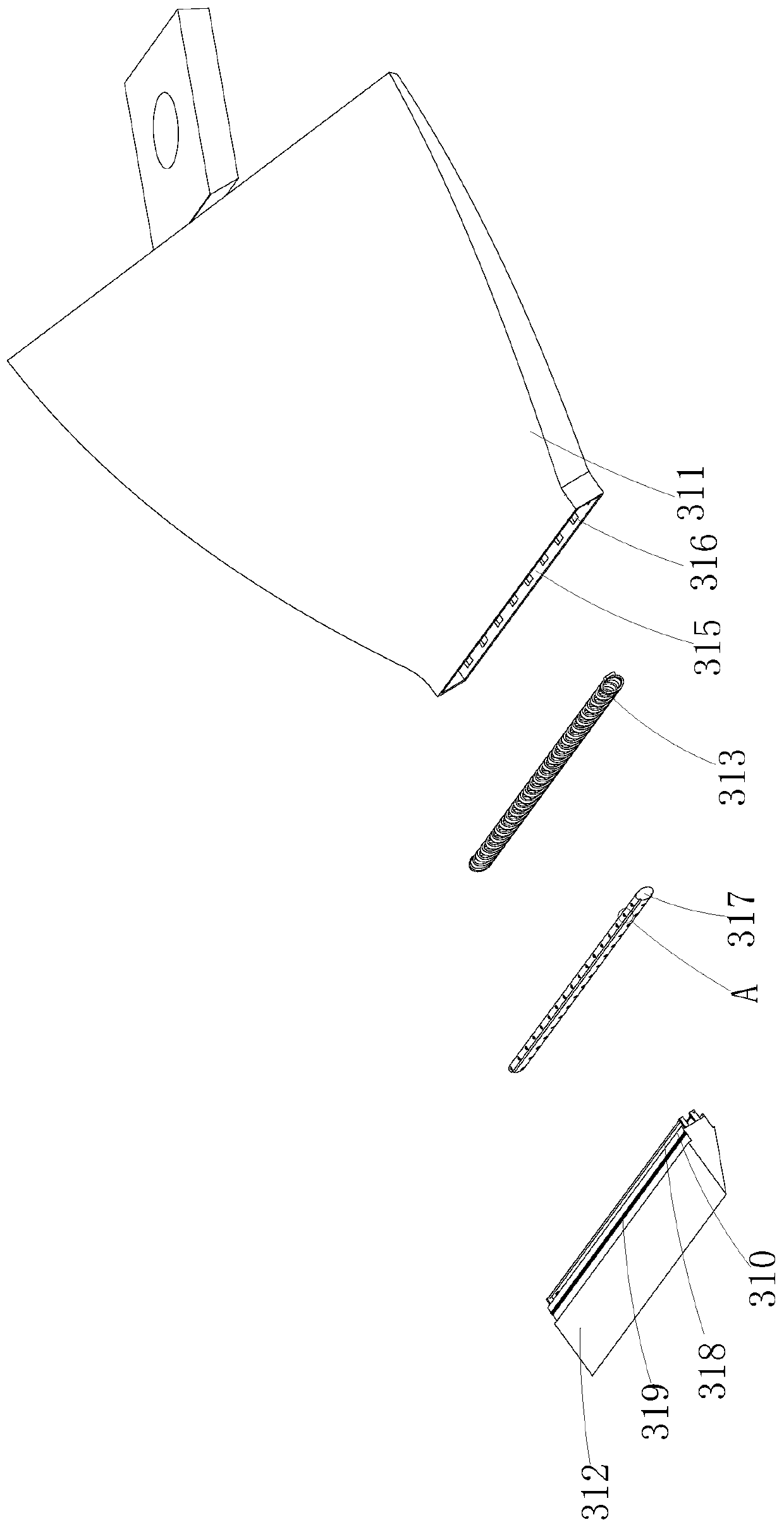

[0030] Such as Figure 1-7 Shown, a kind of cement raw material reclaimer that can lubricate track, comprises track 1, frame 2, reclaiming device 4, motion device 5 and lubricating device 3, wherein said track 1 is a metal track, and said frame 2 is a metal frame, and the retrieving device 4 is used to remove cement raw materials, that is, to remove limestone; the retrieving device 4 is installed on the frame 2, and the retrieving device 4 is an existing The reclaiming system on some round pile reclaimers is a prior art, so it will not be described in detail here. The moving device 5 is used to drive the reclaimer 4 on the frame 2 and the frame 2 along the Moving along the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com