Helical lubrication type harmonic wave reducer

A harmonic reducer and spiral lubrication technology, which is applied in gear lubrication/cooling, mechanical equipment, friction transmission devices, etc., can solve problems such as the influence of lubrication efficiency and the structure damage of flexible external gear cups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

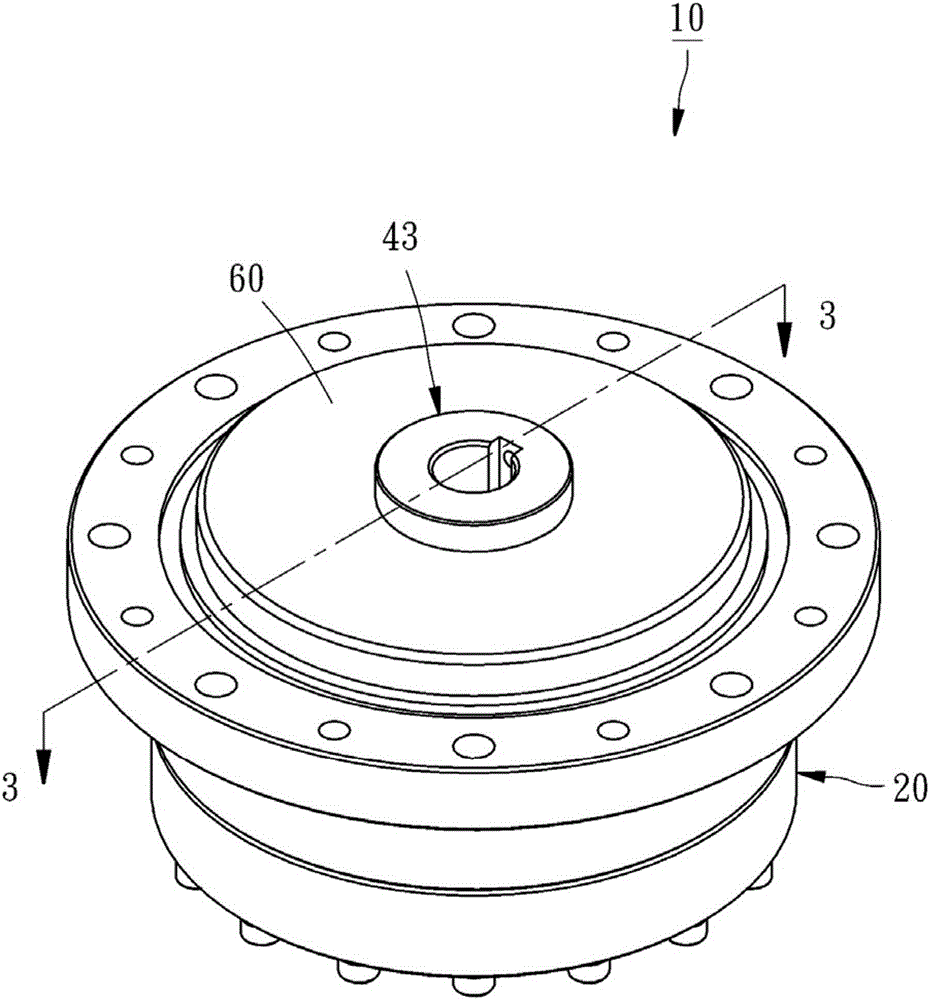

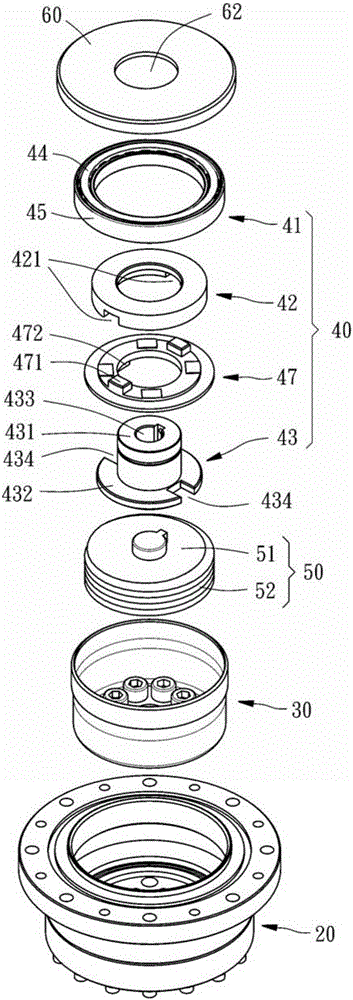

[0031] Please see first figure 1 and figure 2 , The spiral lubricated harmonic reducer 10 of the first embodiment of the present invention includes a rigid inner gear ring 20 , a flexible outer tooth cup 30 , a wave generator 40 , and a spoiler 50 .

[0032] The flexible outer gear cup 30 is disposed in the rigid inner gear ring 20 and engages with the rigid inner gear ring 20 .

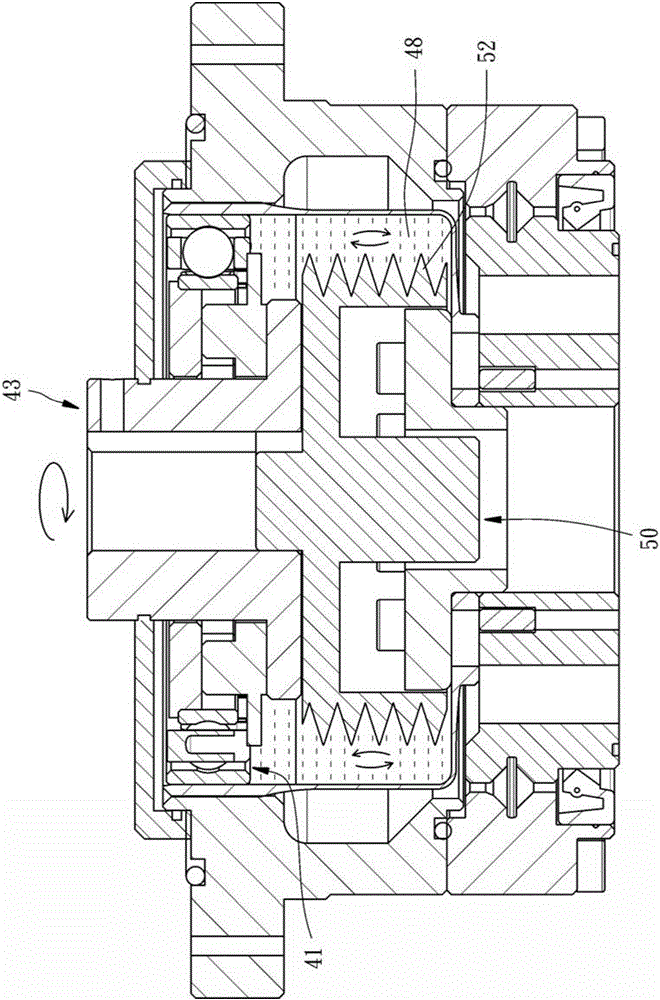

[0033] Such as figure 2 and image 3 As shown, the wave generator 40 has a bearing 41 , an elliptical wheel 42 , and a coupling 43 . The bearing 41 is located in the flexible outer gear cup 30 and has an inner ring 44 and an outer ring 45 surrounding the inner ring 44; the oval wheel 42 is located in the inner ring 44 of the bearing 41; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com