Diamond dice and method for producing wire using diamond dice

A technology of a diamond wire drawing die and a manufacturing method, which is applied in the direction of the wire drawing die, etc., can solve the problems of insufficient lubrication effect, poor straightness, and reduced quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

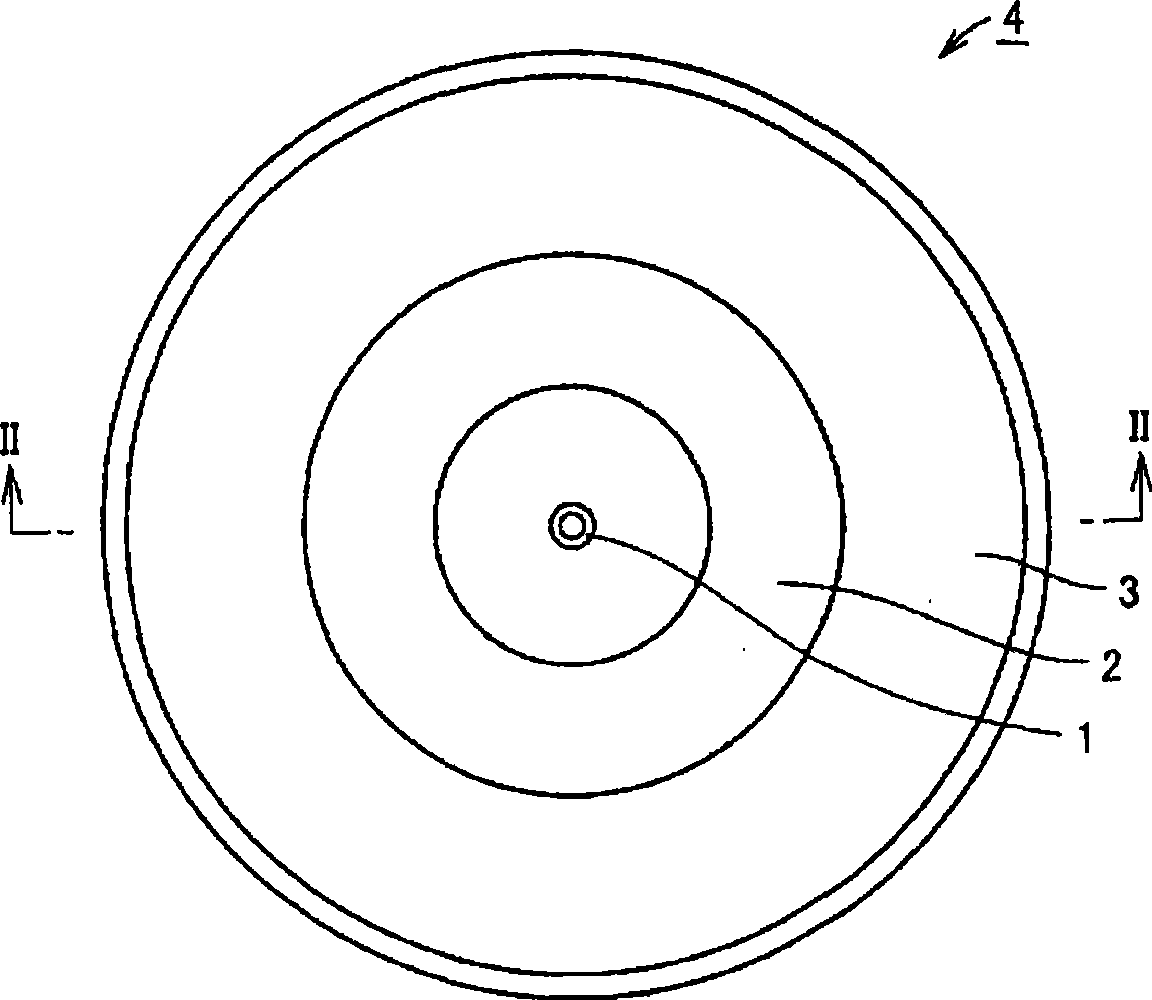

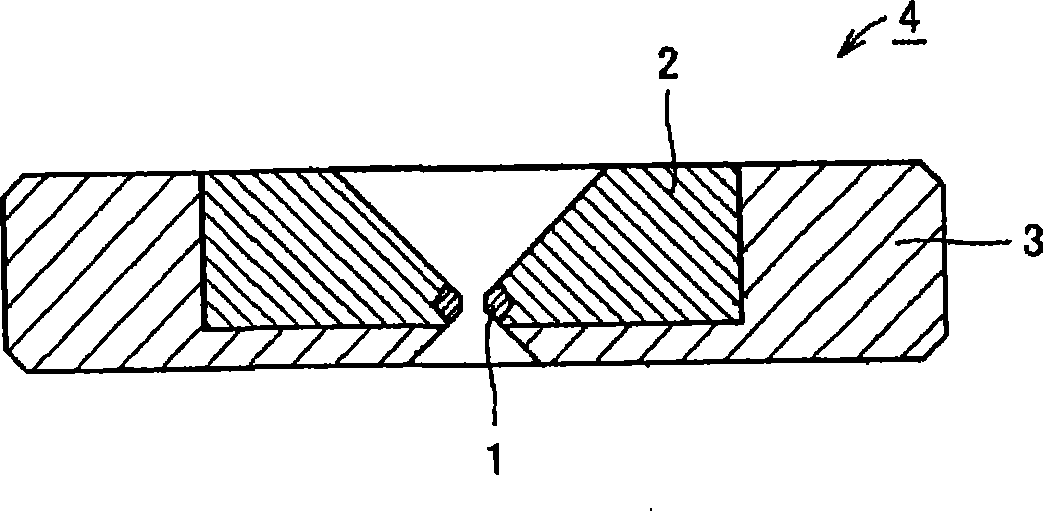

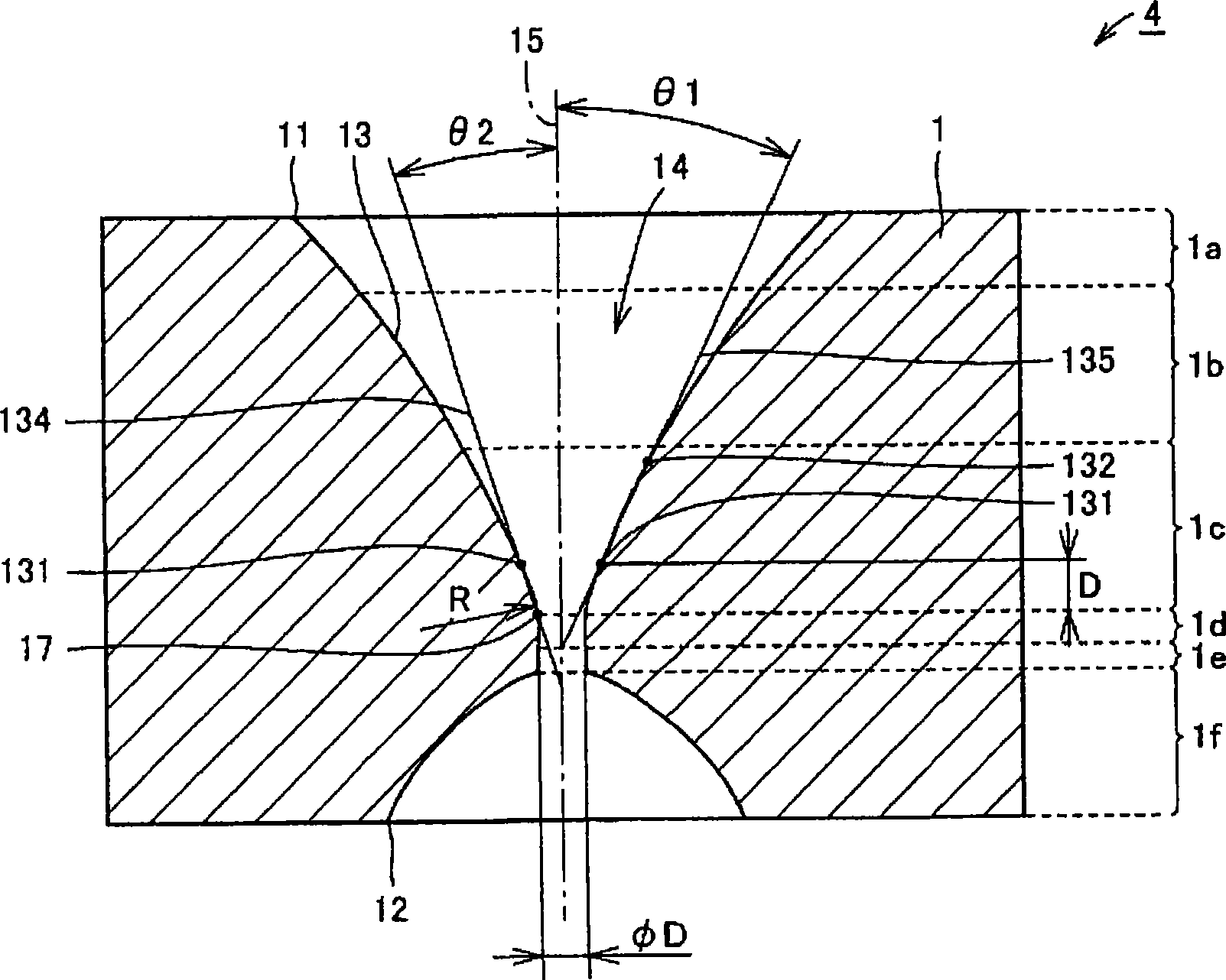

[0042] About the present invention and the conventional diamond wire drawing die, making has Figure 1 to Figure 4 (the present invention) and Figure 5 (Conventional Example) A diamond wire drawing die with the hole shape shown. Three types of wire diameters Φ are produced: 15 μm, 30 μm, and 50 μm. In addition, a diamond of 1.0 mm was used for the thickness (length in the axial direction) of the diamond 1 .

[0043] Using these diamond wire drawing dies, wire drawing is performed on tungsten wire, stainless steel wire, and copper wire respectively. The specifications and experimental results of the diamond wire dies of the present invention and conventional examples are shown in Tables 1 to 12 according to differences in wire rods, wire diameters, and crystal orientations of diamond.

[0044] The crystal orientation indicates the crystal orientation of the plane in the direction perpendicular to the axis 15 of the hole, that is, the upper surface and the lower surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com