Production process of high-opaqueness carbonless carbon paper

A technology of carbonless copying paper and production process, which is applied in the field of copying paper, which can solve the problems that the original paper cannot copy the copying effect, and the carbonless copying paper has low opacity, so as to improve the production effect, improve the production quality, and enhance the effect of smearing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

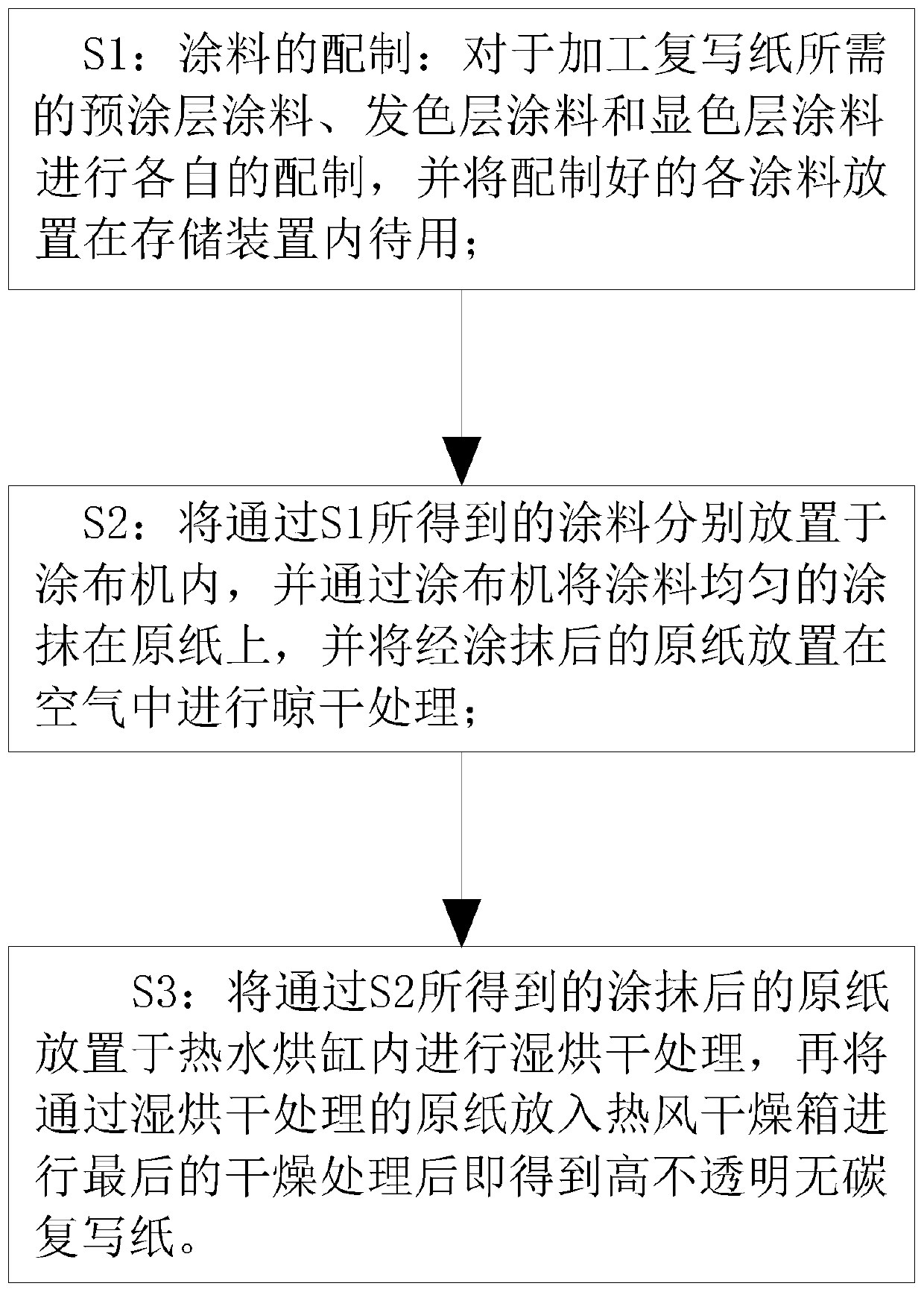

Method used

Image

Examples

Embodiment approach

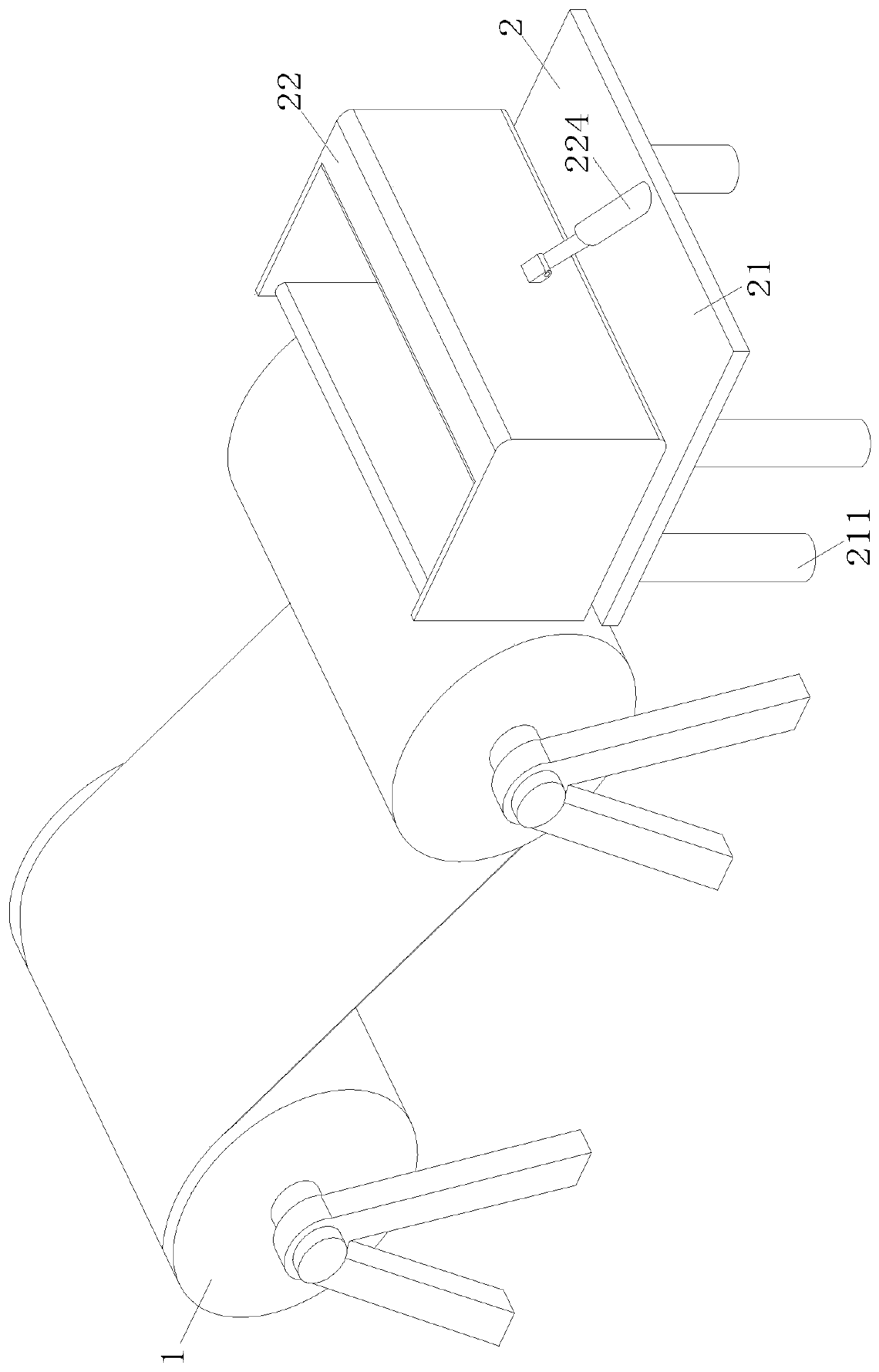

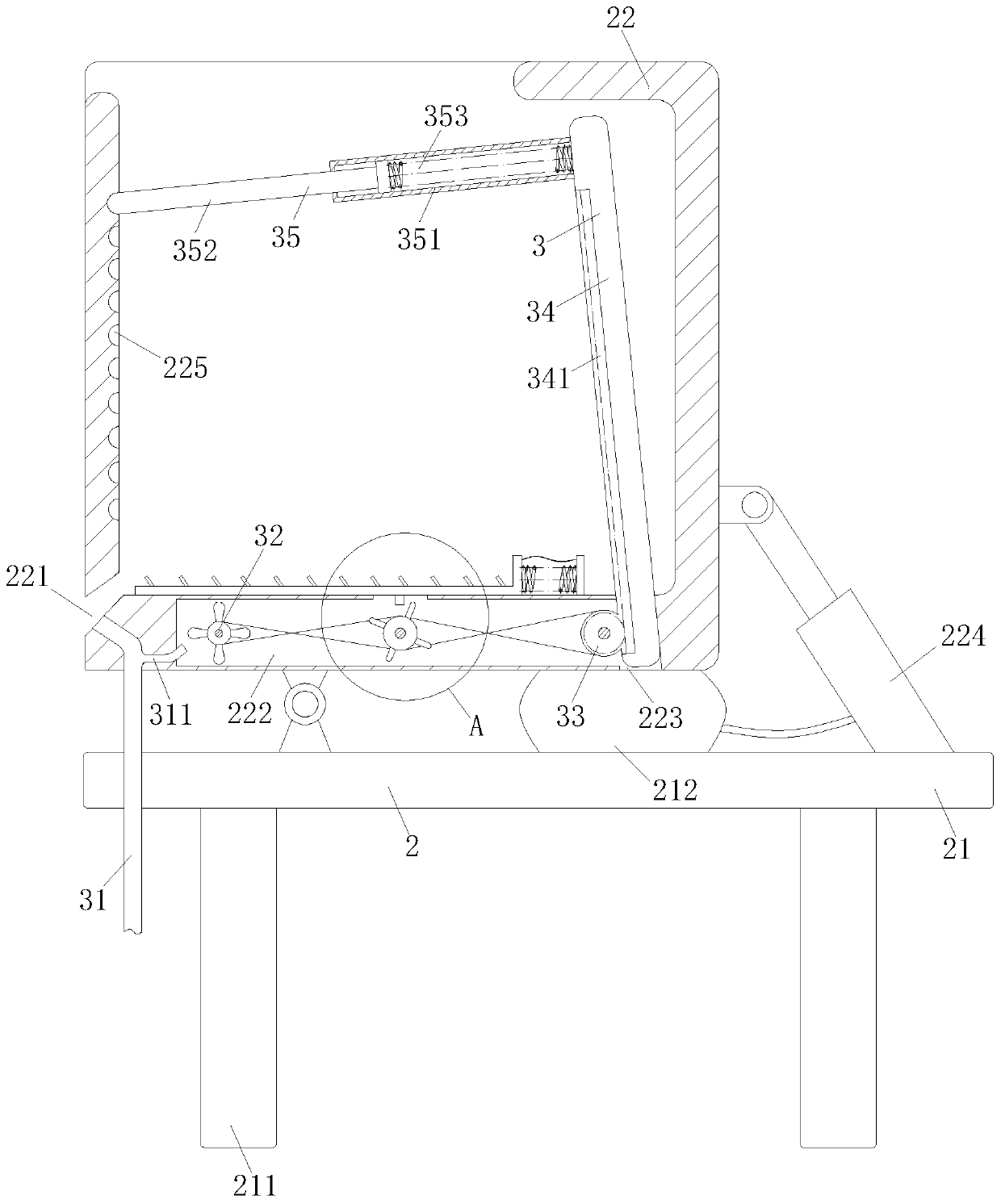

[0030] As an embodiment of the present invention, the housing 22 is hinged on the base 21, and the hinge is close to the discharge port 221, and the side wall of the housing 22 is provided with a piston rod 224; one end of the piston rod 224 is hinged on On the side wall of the housing 22, the other end of the piston rod 224 is installed on the base 21, so that when the piston rod 224 is extended, the housing 22 can be pushed to rotate around the hinge; the base 21 is provided with an air bag 212 near the opening 223, The airbag 212 is in contact with the end of the push rod 34, and the airbag 212 communicates with the piston rod 224 through the hose; the casing 22 is tilted through the cooperation of the housing 22, the piston rod 224, the push rod 34 and the airbag 212, thereby accelerating The flow of paint; when working, when the push rod 34 slides along the opening 223 to the outside of the housing 22, the bottom end of the push rod 34 will squeeze the airbag 212, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com