Truck axle production line

A production line and axle technology, which is applied in metal processing and other directions, can solve the problems of manpower consumption, achieve the effects of reducing the risk of failure, good working stability, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

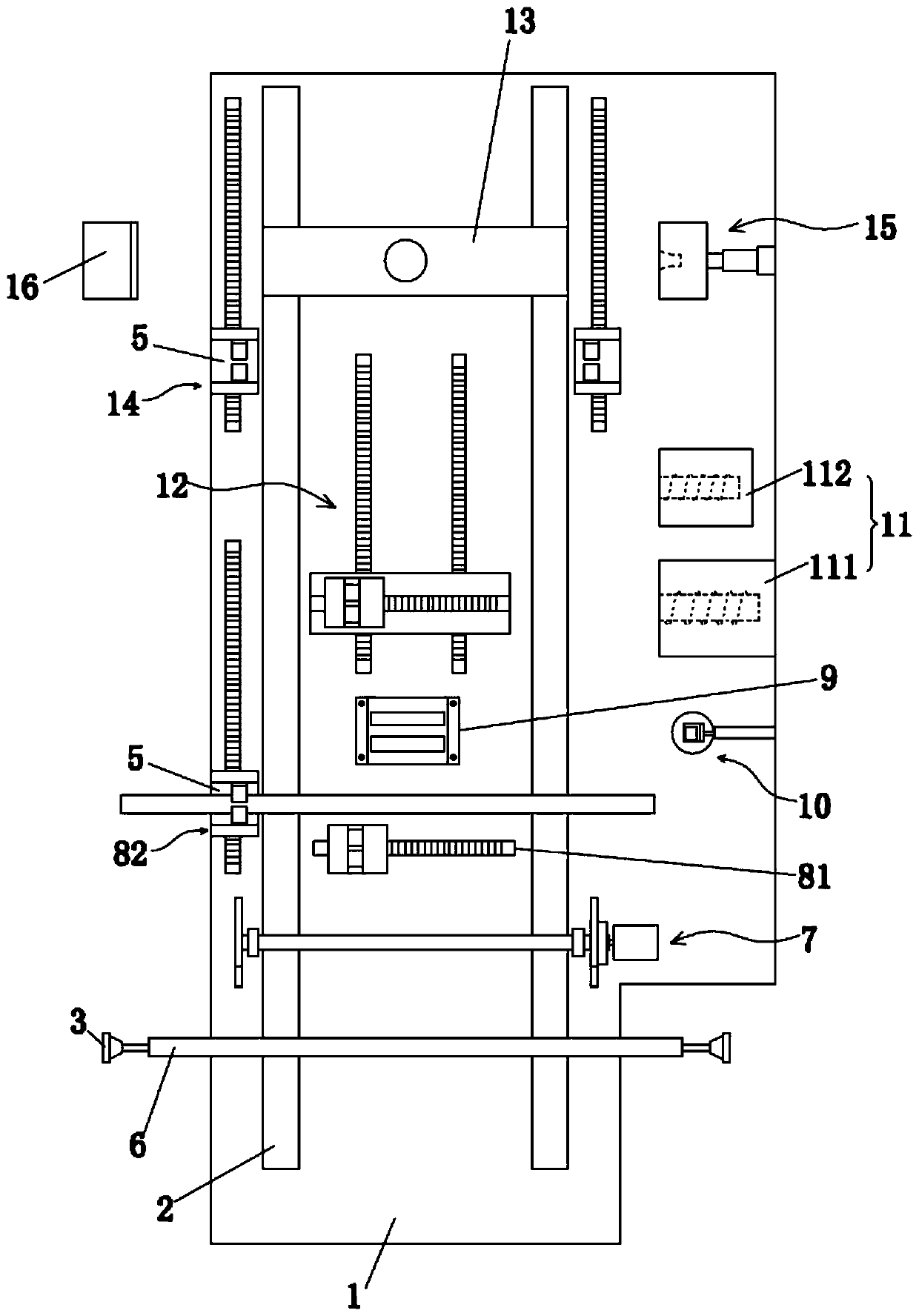

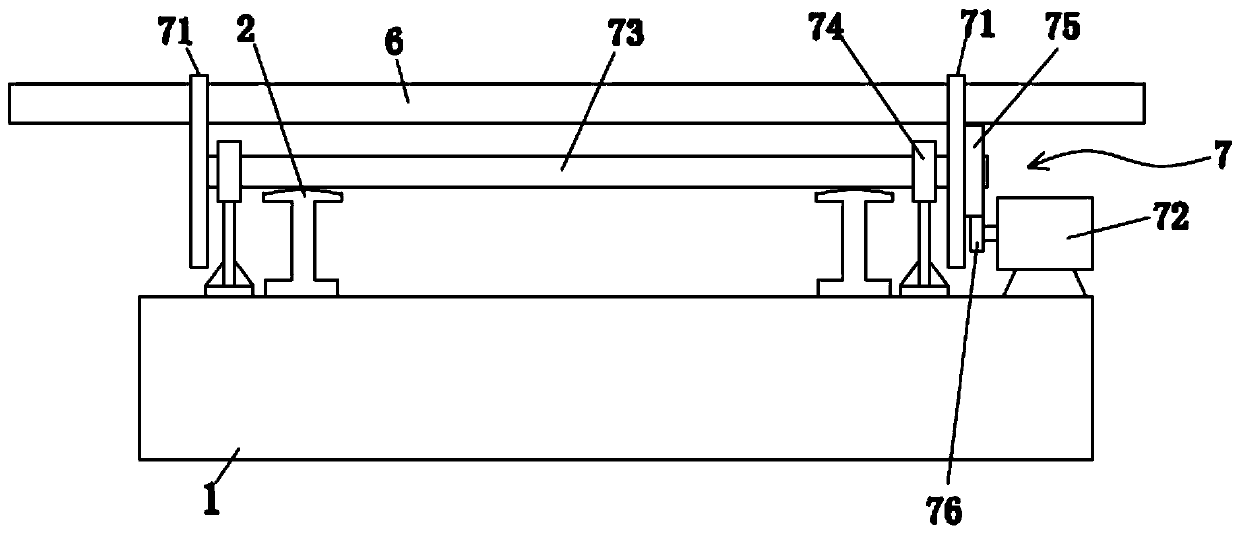

[0044] The specific embodiment of the present invention is as Figure 1 to Figure 13As shown, a load axle production line includes a base 1 on which a slide rail 2 is arranged. Along the arrangement direction of the slide rail 2, the base 1 is provided with a centering positioning device, a material distribution mechanism 7, a release agent application device, an axle end heating device and an axle end extruding device. A moving device for pipe blanks is also provided on the base 1 . In this embodiment, there are two slide rails 2 parallel to each other.

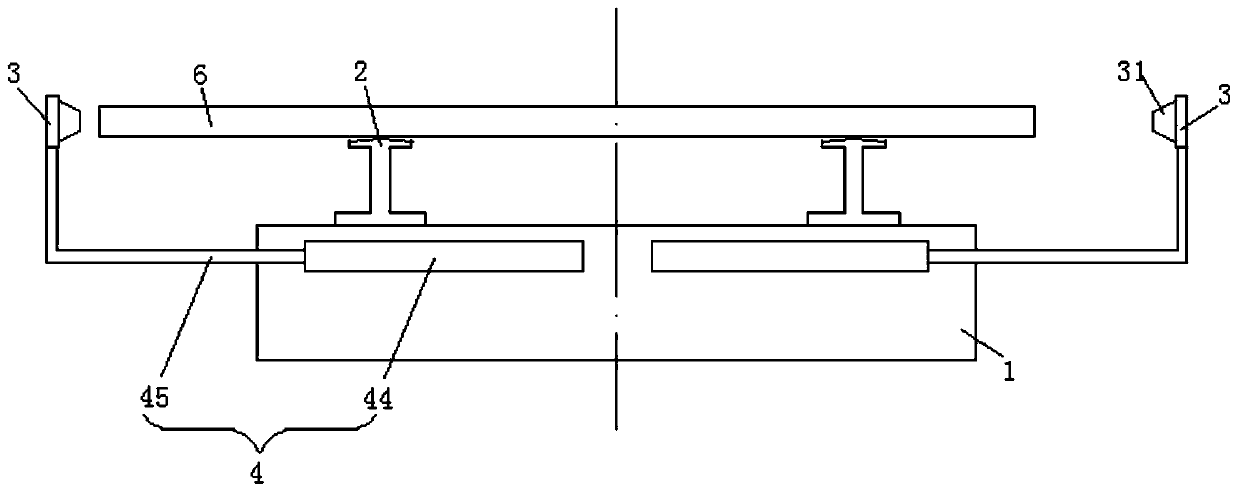

[0045] The centering positioning device includes two pressing blocks 3 arranged horizontally opposite each other, and the base 1 is provided with a pressing mechanism 4 that enables the two pressing blocks 3 to perform synchronous relative linear reciprocating motion. The slide rail 2 is located between the two pressing blocks 3 and is perpendicular to the moving direction of the pressing blocks 3 . The pressing mechanism...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com