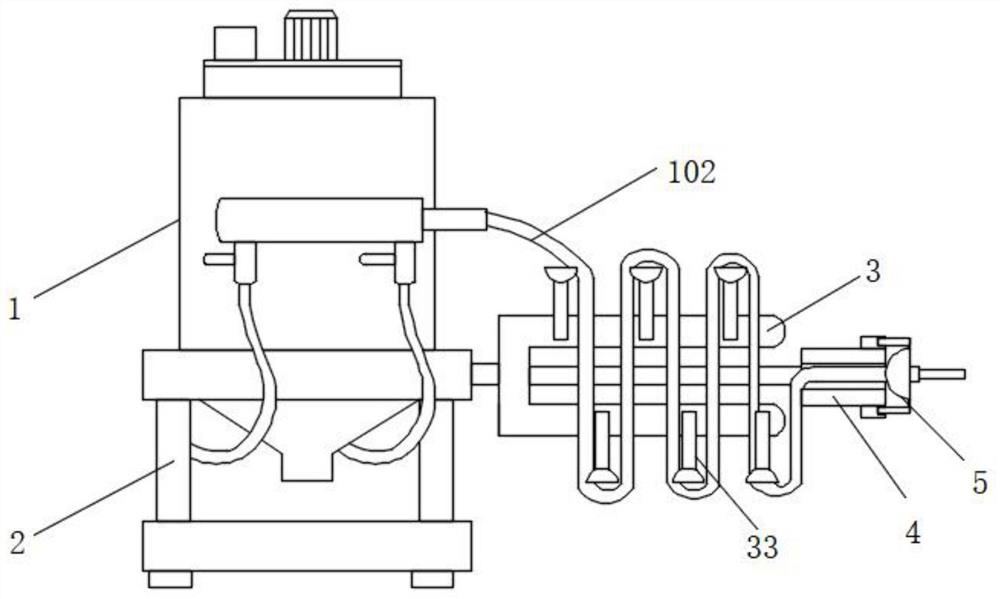

Anti-oxidation treatment equipment for steel structure material

A processing equipment and anti-oxidation technology, which is applied to used abrasive processing equipment, metal processing equipment, chemical/physical processes, etc. Improve the uniformity of application, reduce the splash of sand particles, and facilitate the storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

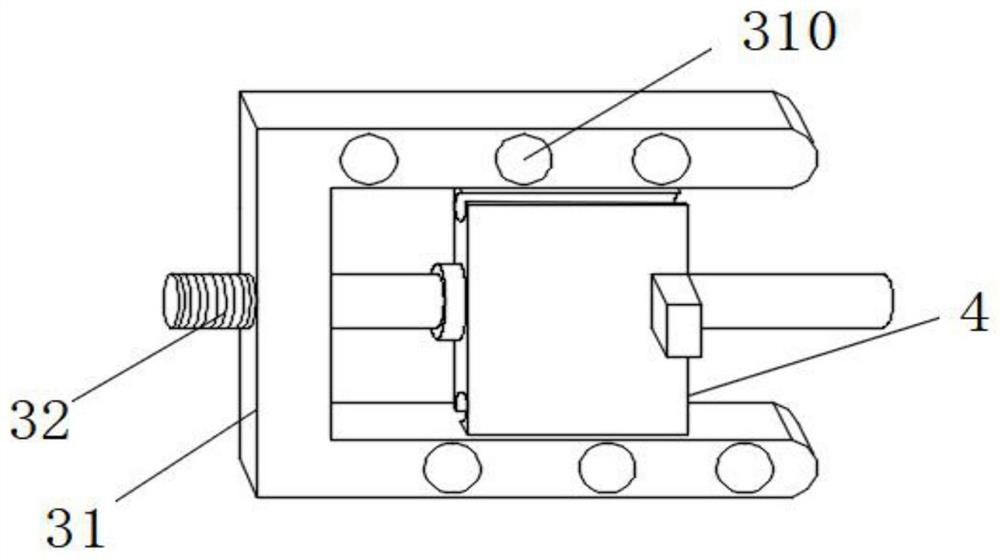

[0048] As an embodiment of the present invention, the clamping mechanism 4 includes a rectangular plate 41, a circular groove 42, a C-shaped card groove 43, a fixed block 44, and a card hole 45, and the circular groove 42 is opened in the rectangular plate 41. The outer surface is adjacent to the middle, and the crossbar 32 penetrates the inside of the circulation 42, the number of the C-shaped card groove 43 is two, and the two C-shaped card grooves 43 are opened at the rectangular plate 41. Location, the outer surface of the exterior tube 102 is adjacent to the end of the end, and the outer surface of the outer surface of the exterior tube 102 is attached to the position of the end to the end activity, and the fixed spray mechanism 5 is connected. The number of blocks 44 is two, and the two of the fixed blocks 44 are fixedly mounted on the lower end of the rectangular plate 41 near one side, and the card holes 45 are opened on one side surface of the fixed block 44, the spray me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com