Plug-in type balance valve

A balancing valve, cartridge technology, applied in the direction of fluid pressure actuation device, servo motor assembly, mechanical equipment, etc., can solve the problems of easy vibration, less damping links, increased processing cost, etc., to reduce the overall size , The effect of reducing heat treatment requirements and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

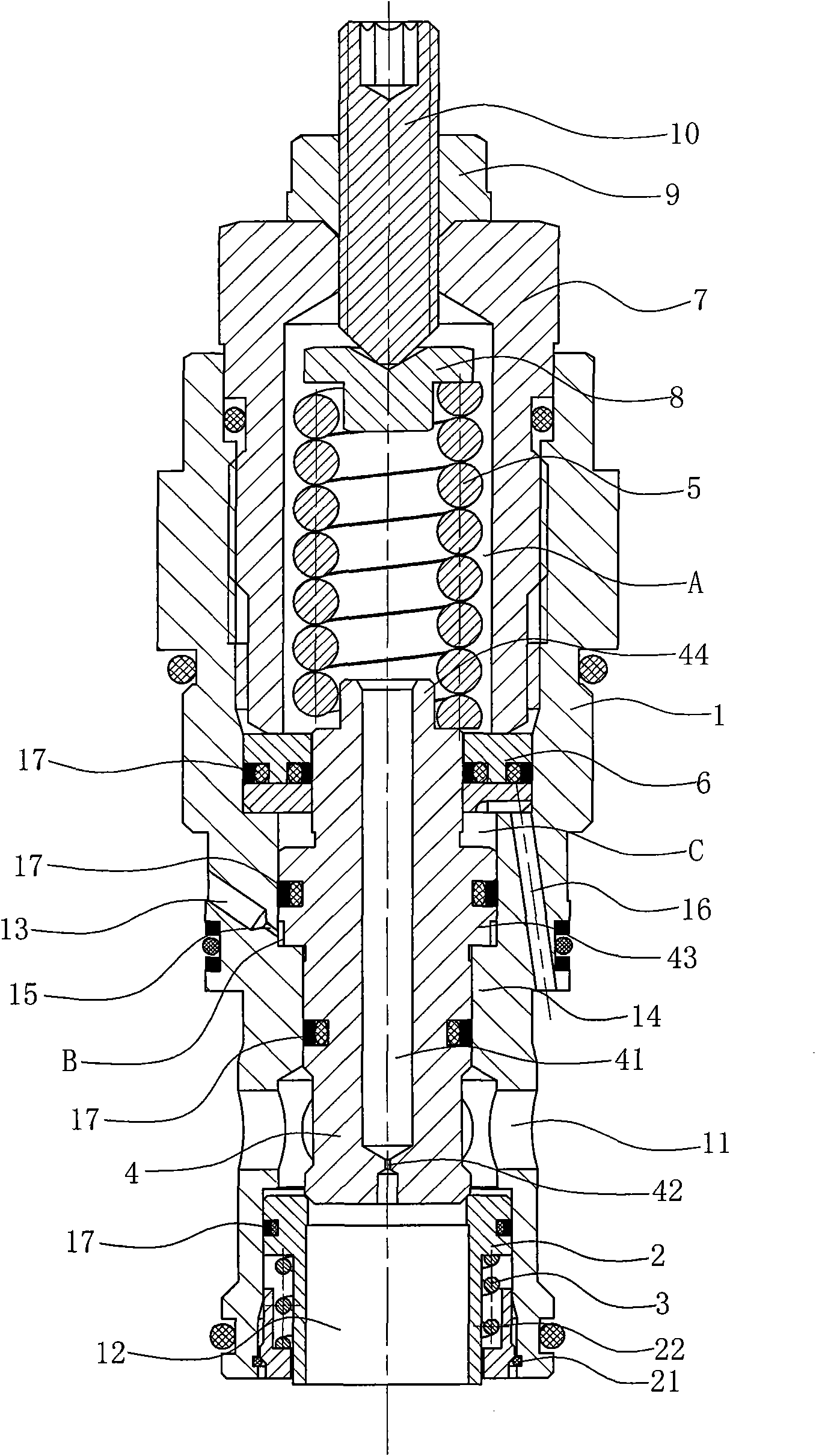

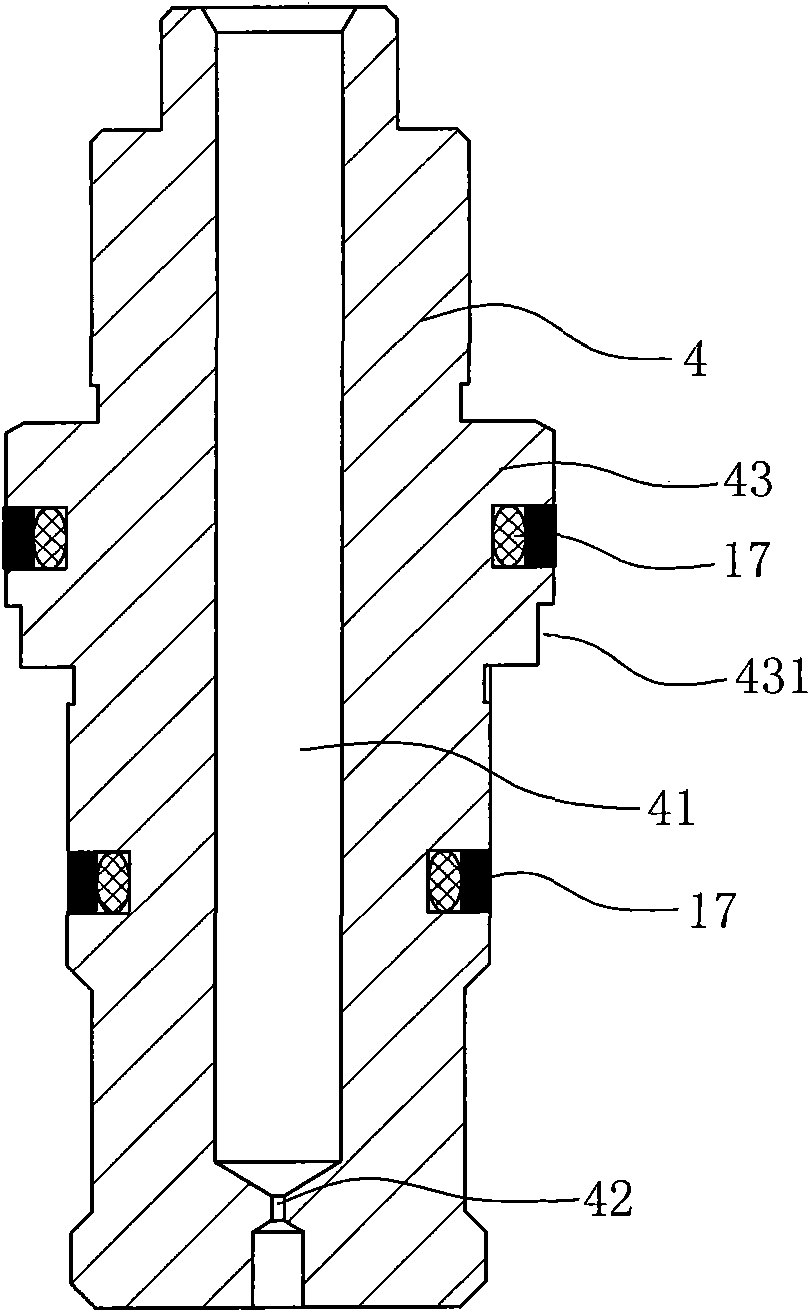

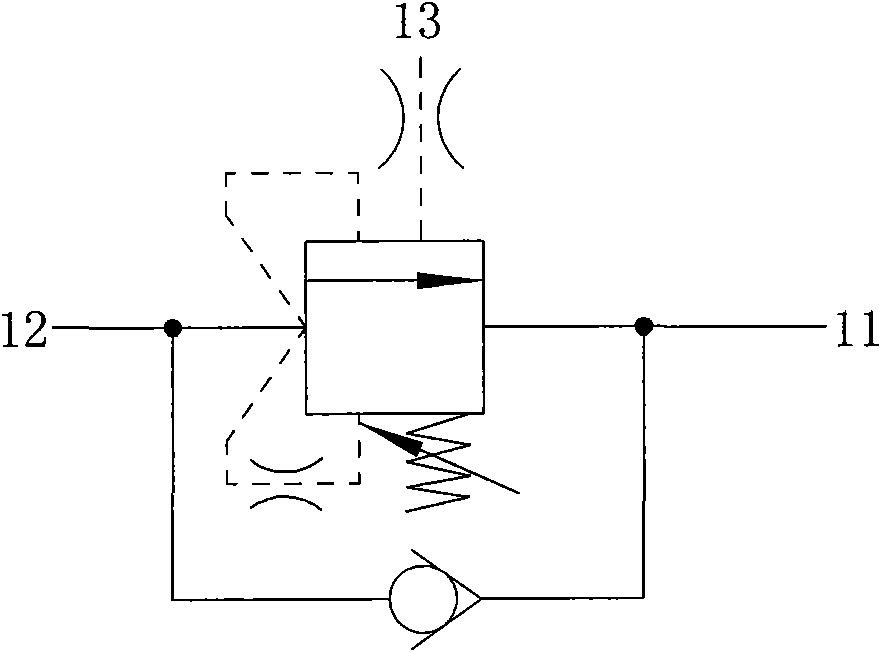

[0029] Such as Figure 1~3 Shown is a preferred embodiment of the present invention.

[0030] A plug-in balance valve, characterized in that: the balance valve includes

[0031] Valve body 1, the shape of the valve body 1 is a stepped shaft shape, the first oil port 11 and the second oil port 12 communicated with each other are opened on the valve body 1, the third oil port 13 is also opened on the valve body 1, the first The oil port 11 and the third oil port 13 are located on the side wall of the valve body 1 , and the second oil port 12 is located on the lower end surface of the valve body 1 .

[0032] The one-way valve core 2 is set in the second oil port 12 and can slide up and down axially relative to the valve body 1. The one-way valve core 2 is supported by the first spring 3 to keep the axial upward movement trend. The lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com