A New Type of Heavy Truck Air Suspension

An air suspension and suspension technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve the problems of high vibration frequency, poor shock absorption ability, driver fatigue, etc., to protect the driver and improve the overall Performance, comfort-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

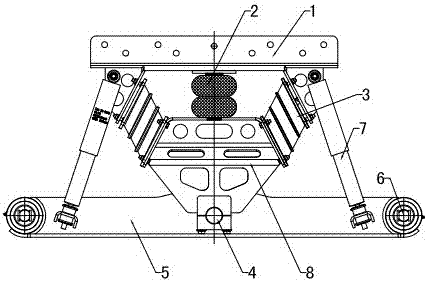

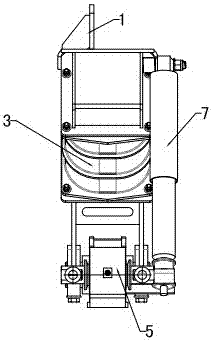

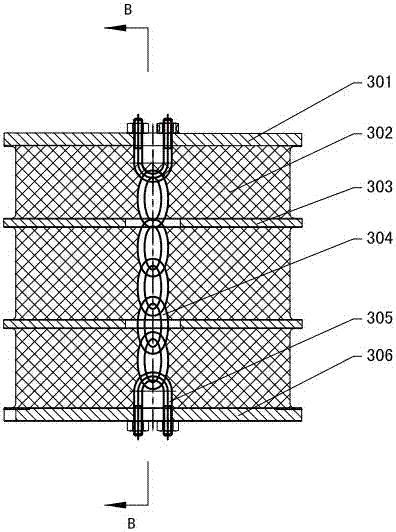

[0035] Figure 1-7 It is the best embodiment of the present invention, below in conjunction with attached Figure 1-7 The present invention is described further:

[0036] Refer to attached Figure 1-3 : The new heavy-duty truck air suspension includes the rubber suspension main installation plate 1 and the rubber suspension main welding equalization beam 5 arranged in parallel, and the rubber suspension main installation plate 1 and the rubber suspension main welding equalization beam 5 are welded with steel plates Forming, the rubber suspension main mounting plate 1 is provided with a plurality of bolt connection holes.

[0037]The rubber suspension main spring 3 is installed between the rubber suspension main installation plate 1 and the rubber suspension main welded equalization beam 5, and the upper left and right sides of the rubber suspension main spring 3 are respectively provided with support frames, and the support frames are connected to the rubber suspension main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com