Patents

Literature

144results about How to "Increase cargo capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

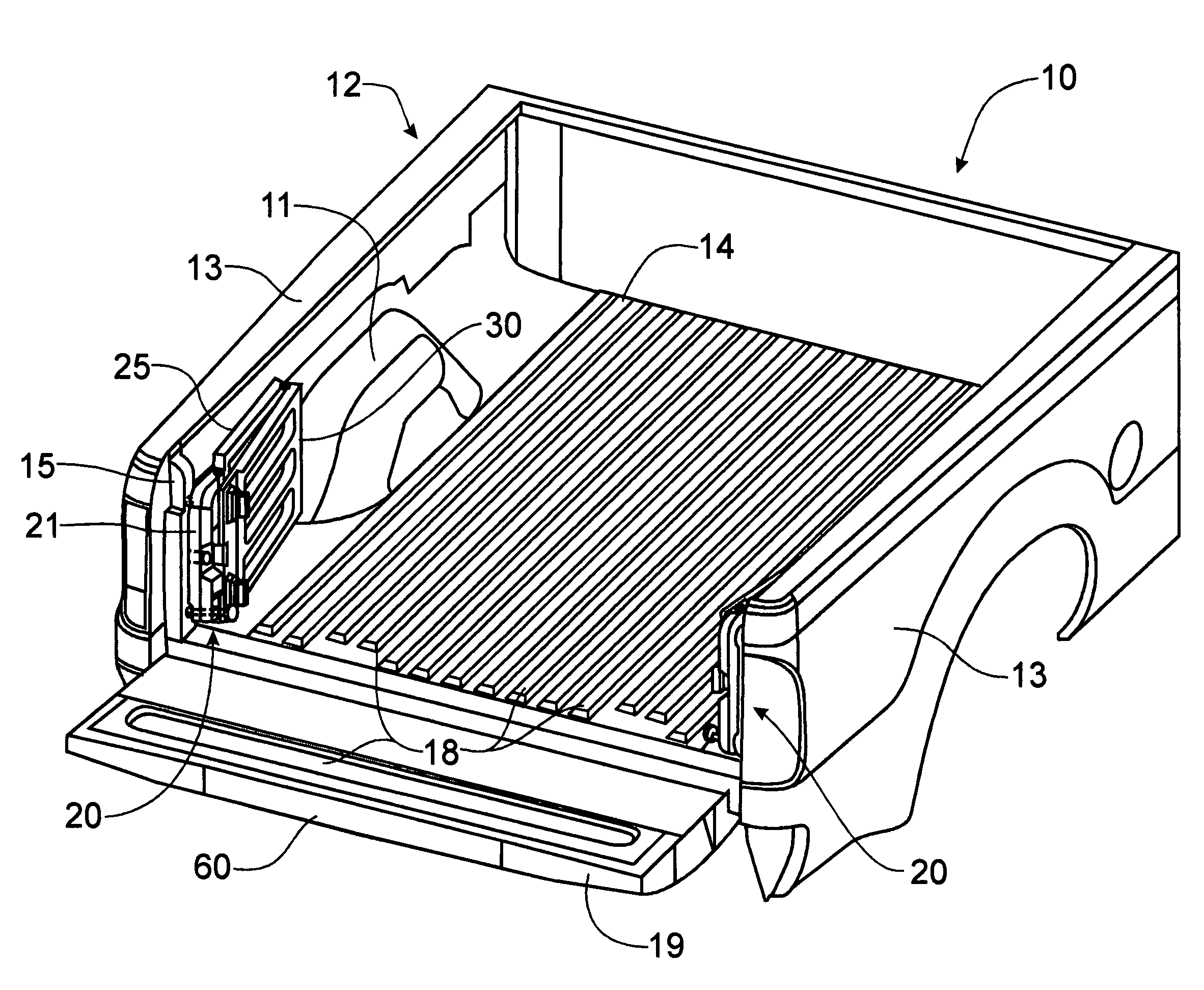

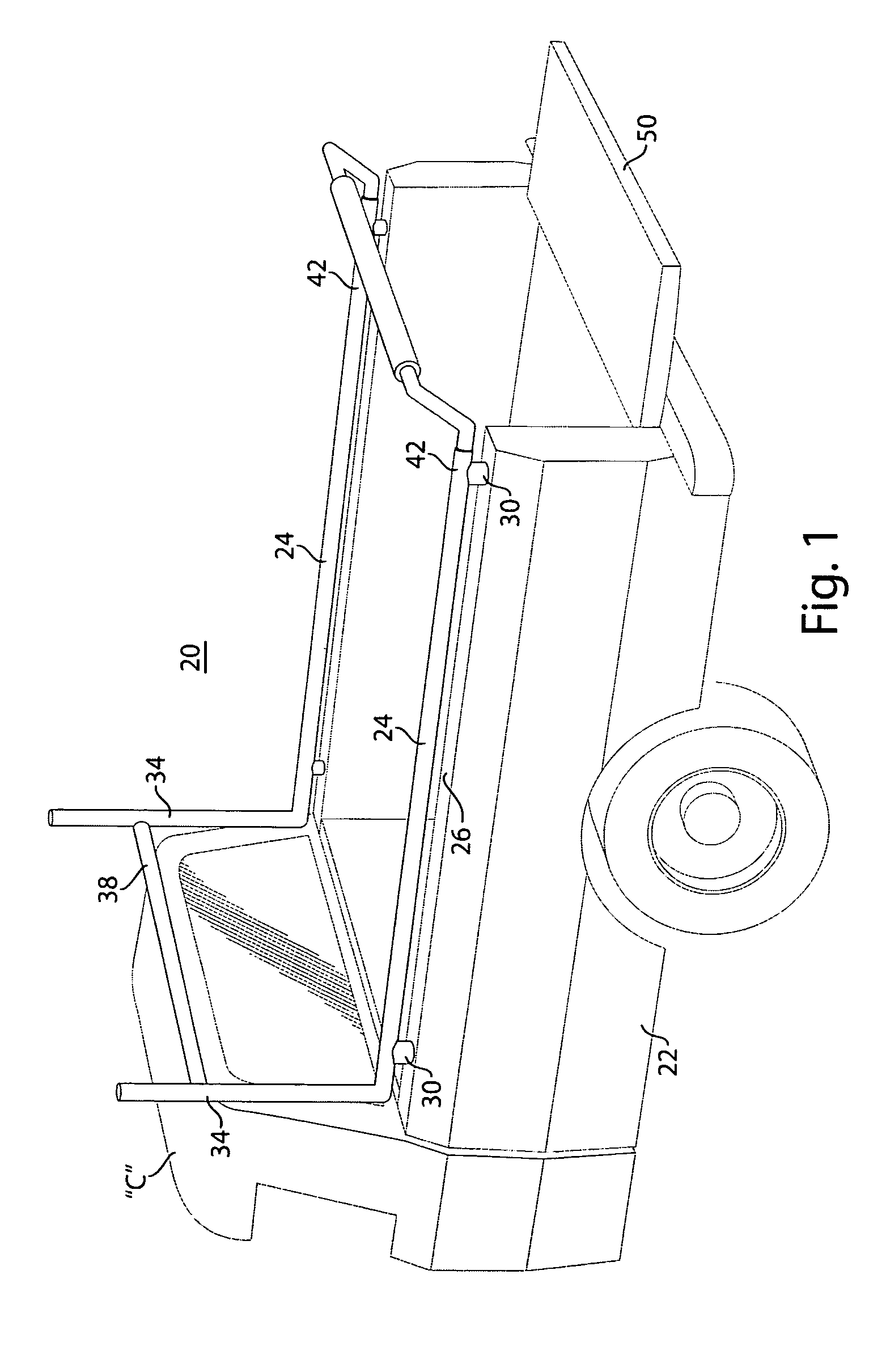

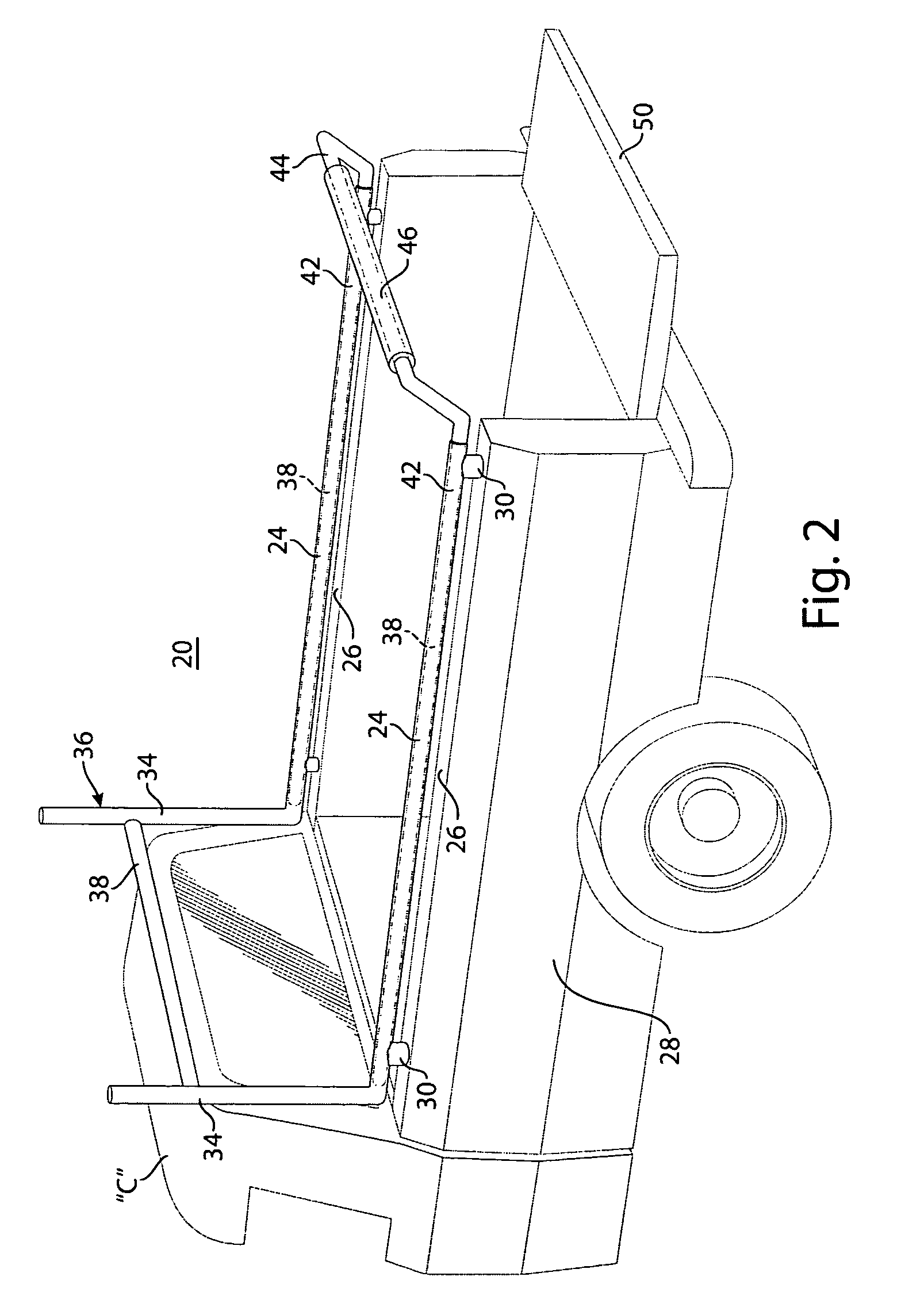

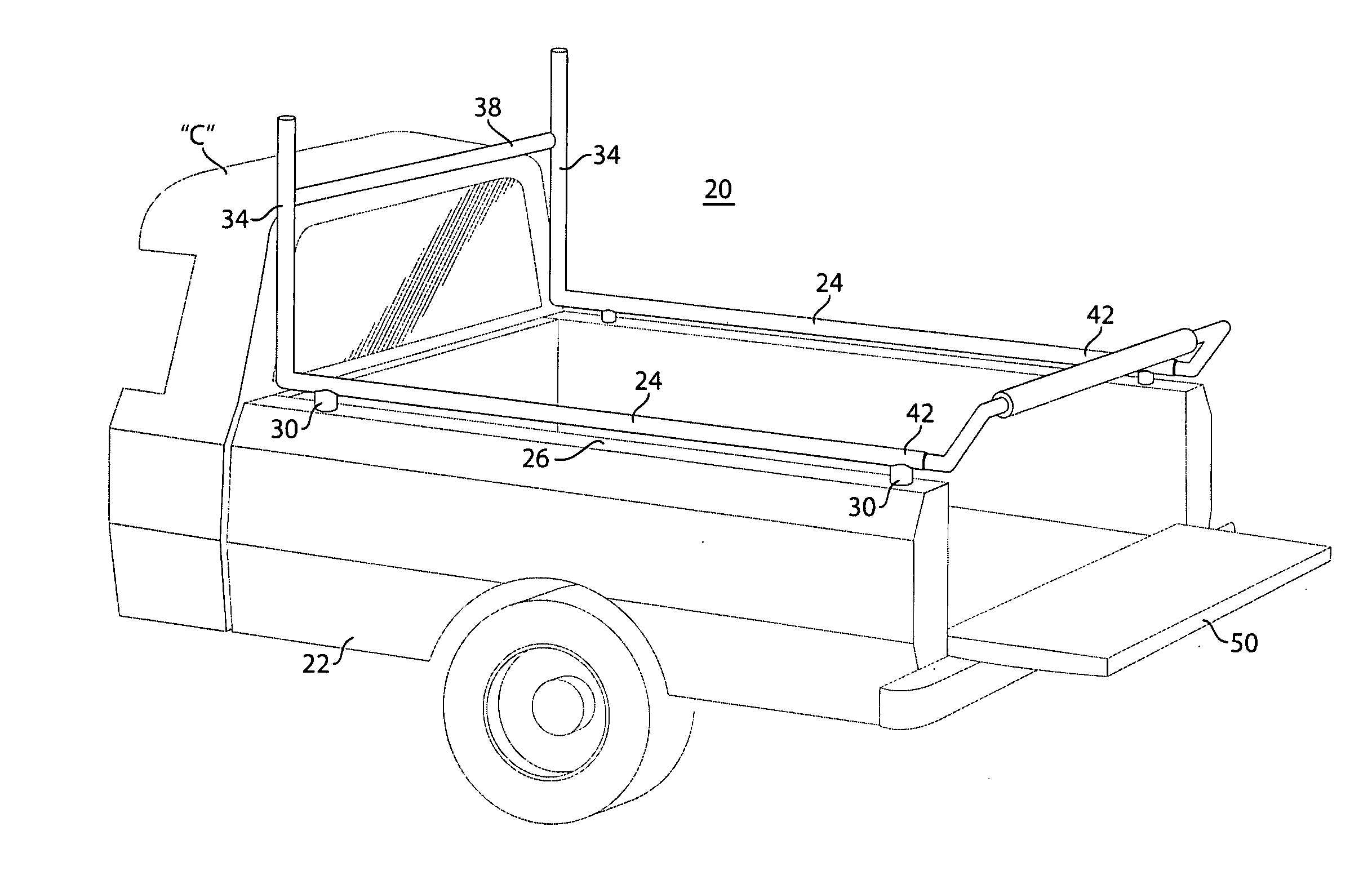

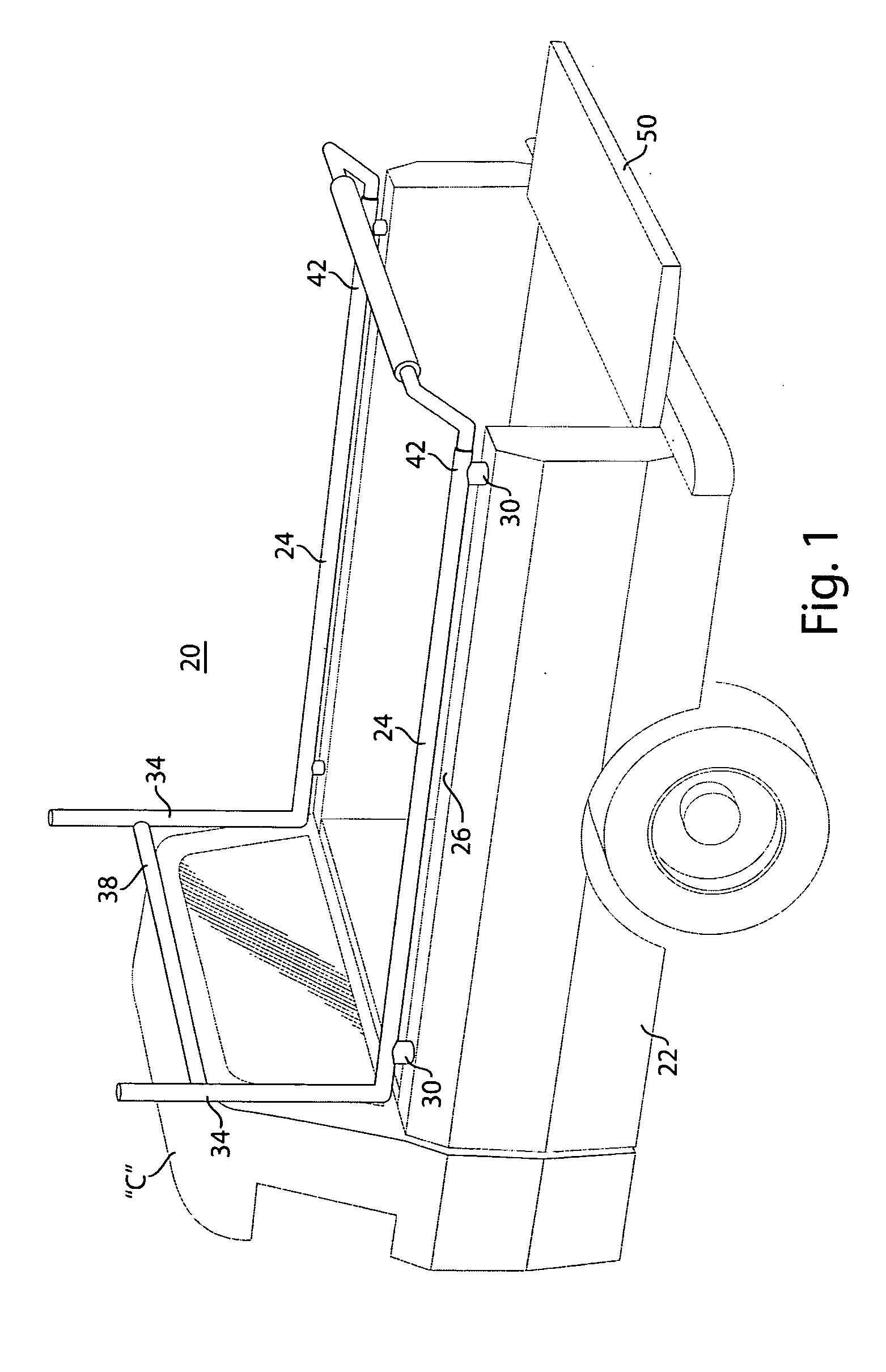

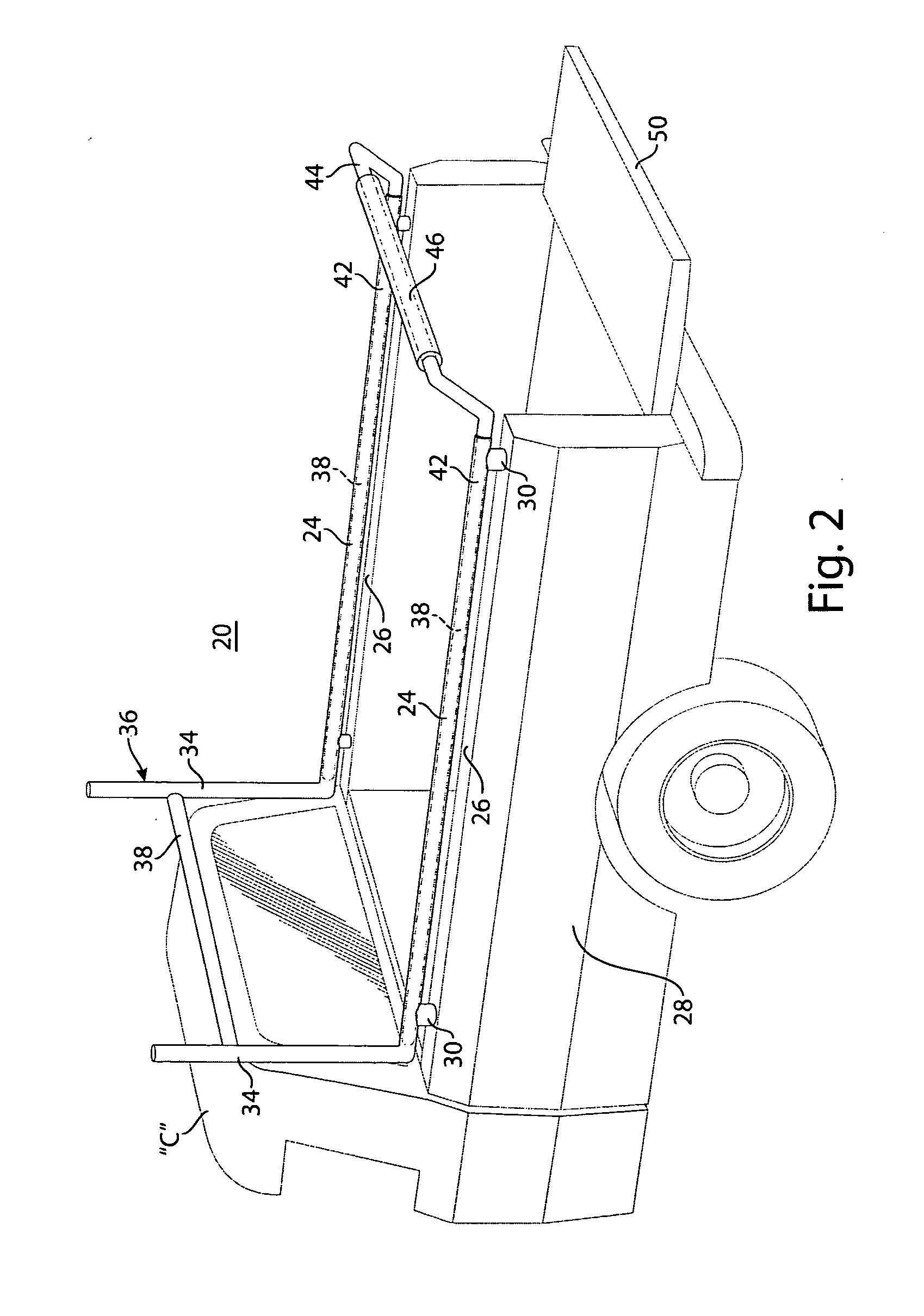

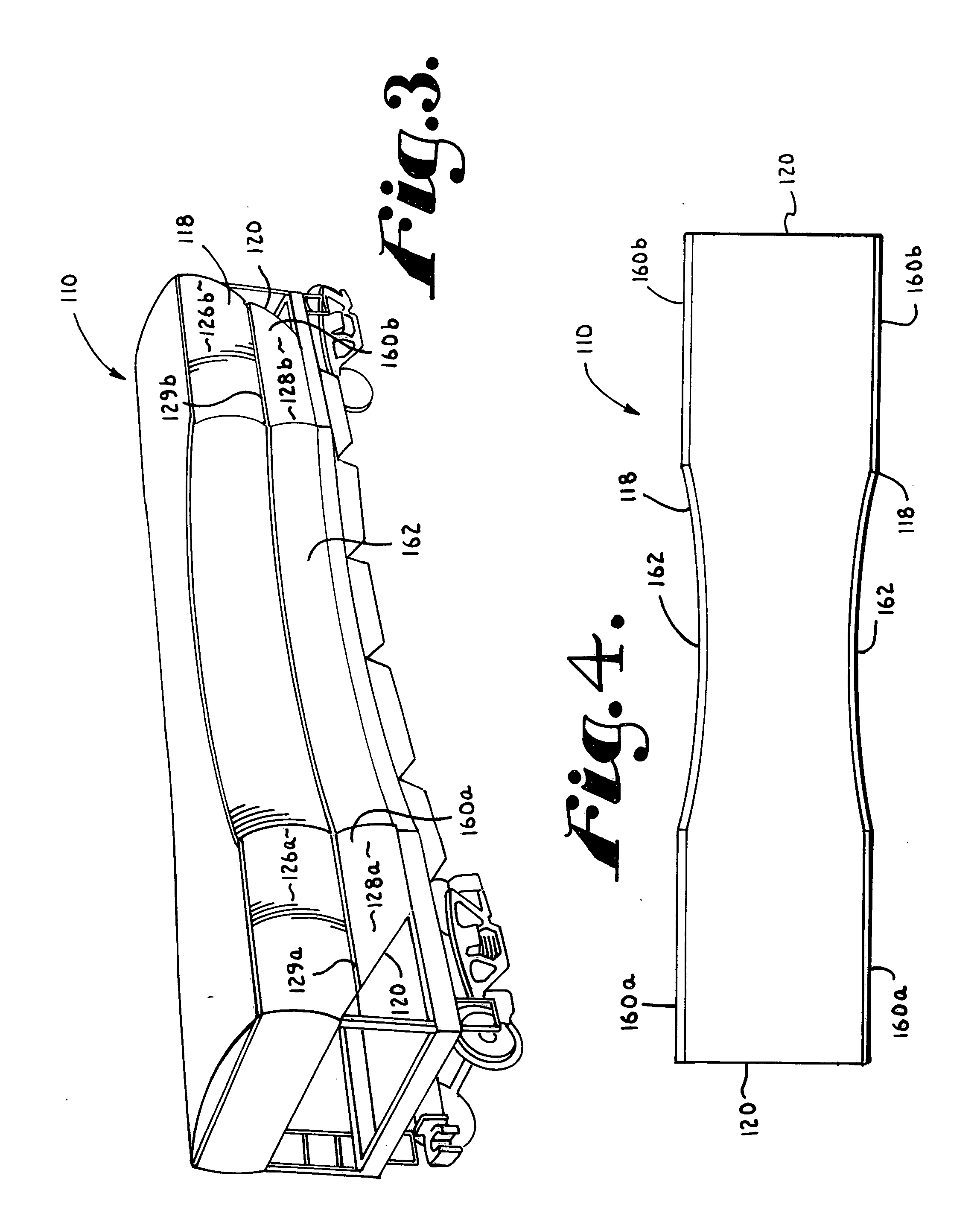

Pivoting cage cargo retainer for pick-up trucks

ActiveUS7111886B1Reduce wind resistanceIncrease capacityVehicle to carry long loadsVehicle with living accommodationPick-up truckEngineering

A pivoting cage cargo bed extender is pivotally mounted to the D-pillars of a pick-up truck to be pivotally movable between a forward position and a rearward position. In the rearward position, the pivoting cage serves as a supplemental tailgate structure that rests on the open tailgate to extend the operative area of the cargo bed. The pivoting cage is formed of individual segments that are hinged together and separable at the center into two halves that are each collapsible into a stowed position adjacent the respective side wall of the cargo bed. The two halves of the cargo bed are connectable with a latching mechanism at the center to form a pivoting cage structure that spans transversely across the floor of the cargo bed. The latching mechanism compresses an internal O-ring to provide a tight connection between the two halves.

Owner:FORD GLOBAL TECH LLC

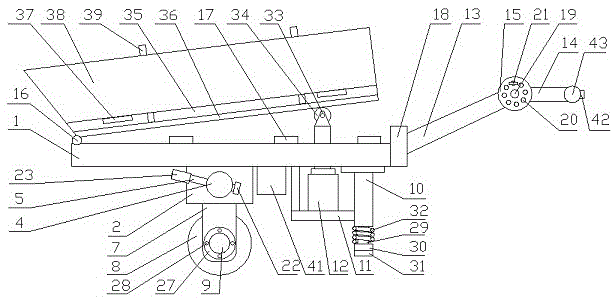

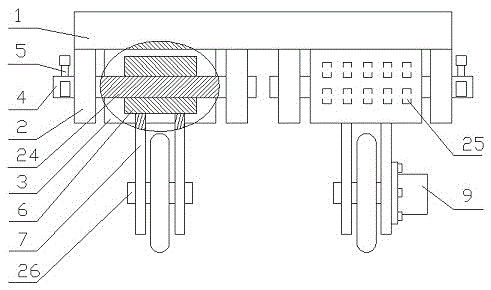

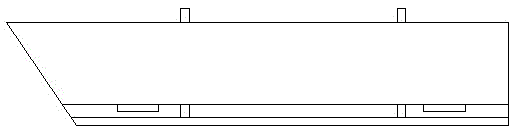

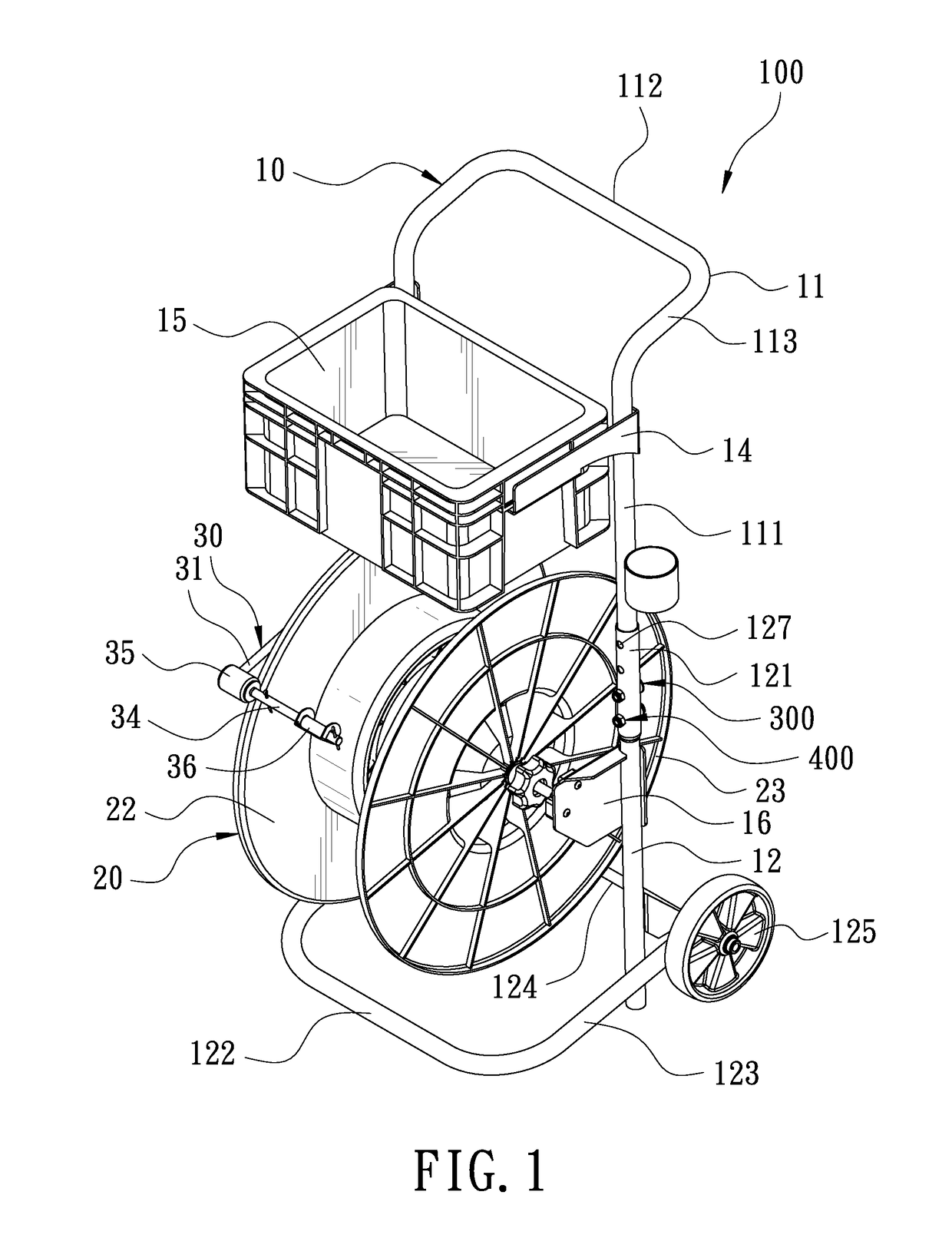

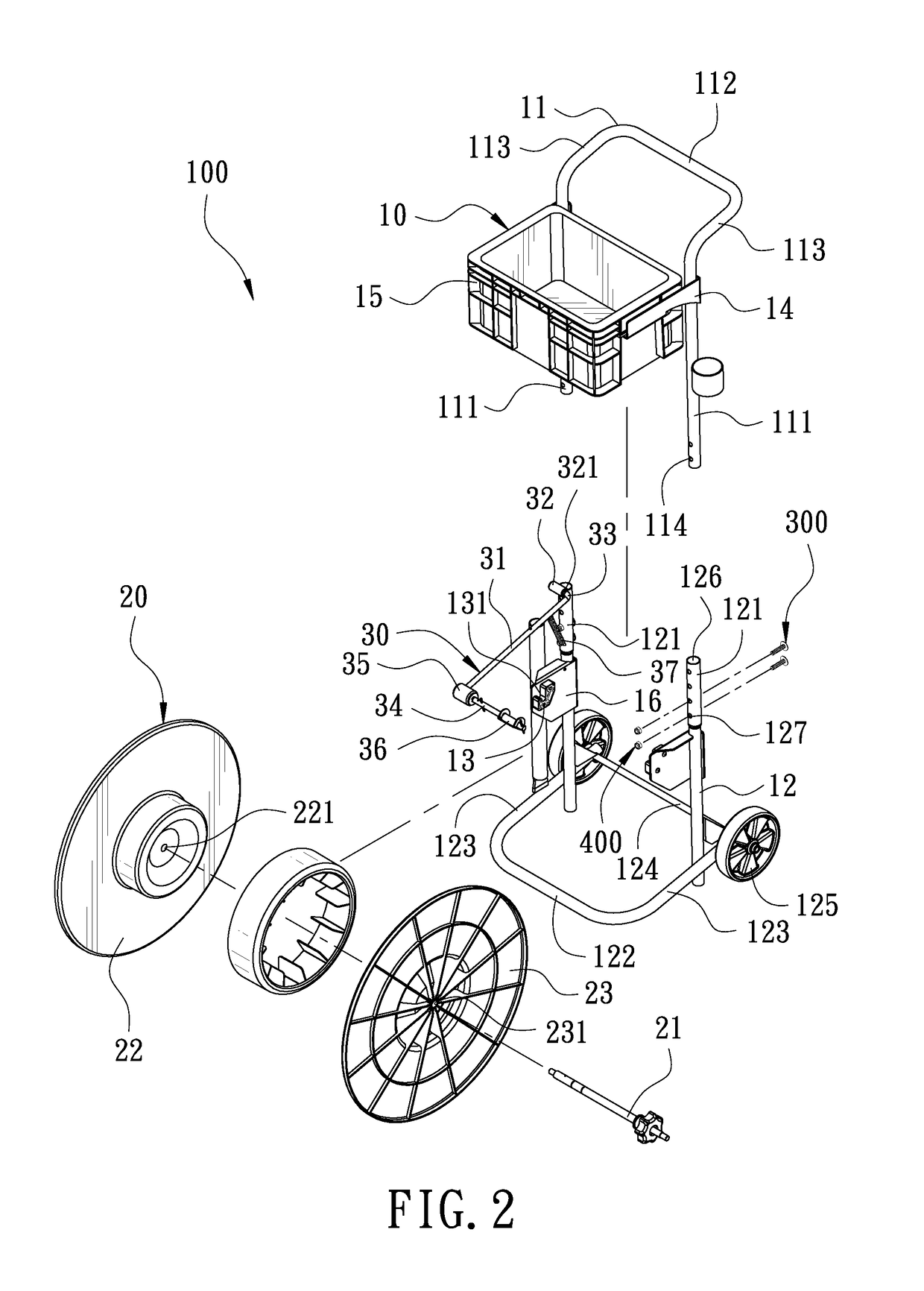

Electrically-driven tread-adjustable hand-held material transfer trolley

ActiveCN105644595AWith shock absorbing effectAvoid shock damageHand carts with one axisChildren carriages/perambulatorsCylinder blockMaterial transfer

The invention discloses an electrically-driven tread-adjustable hand-held material transfer trolley, comprising a body. A set of adjusting shaft plates and sliding block baffles are arranged on the lower part of the body, adjusting shafts are installed on the adjusting shaft plates in a penetrating way and matched with sliding blocks, the sliding blocks are connected with shaft holders, the shaft holder on one side is provided with a motor, a landing leg is arranged at one end of the lower part of the body and matched with an oil cylinder block arranged below the body, an oil cylinder is arranged on the oil cylinder block, a fixed handle is arranged at one end of the body, and connected with a movable handle through an adjusting disc, and the other end of the body is hinged to a loading box through a connecting shaft. The tread between wheels of the electrically-driven tread-adjustable hand-held material transfer trolley is adjustable, so that the device can be freely adjusted according to different road conditions, advancing is more convenient, the wheels are driven by the motor, the device can be conveniently pushed in a labor-saving manner through the assistance of the motor, the loading box can be jacked to unload through the jacking force of the oil cylinder, and thus safety and reliability are realized.

Owner:平湖市宸信机械有限责任公司

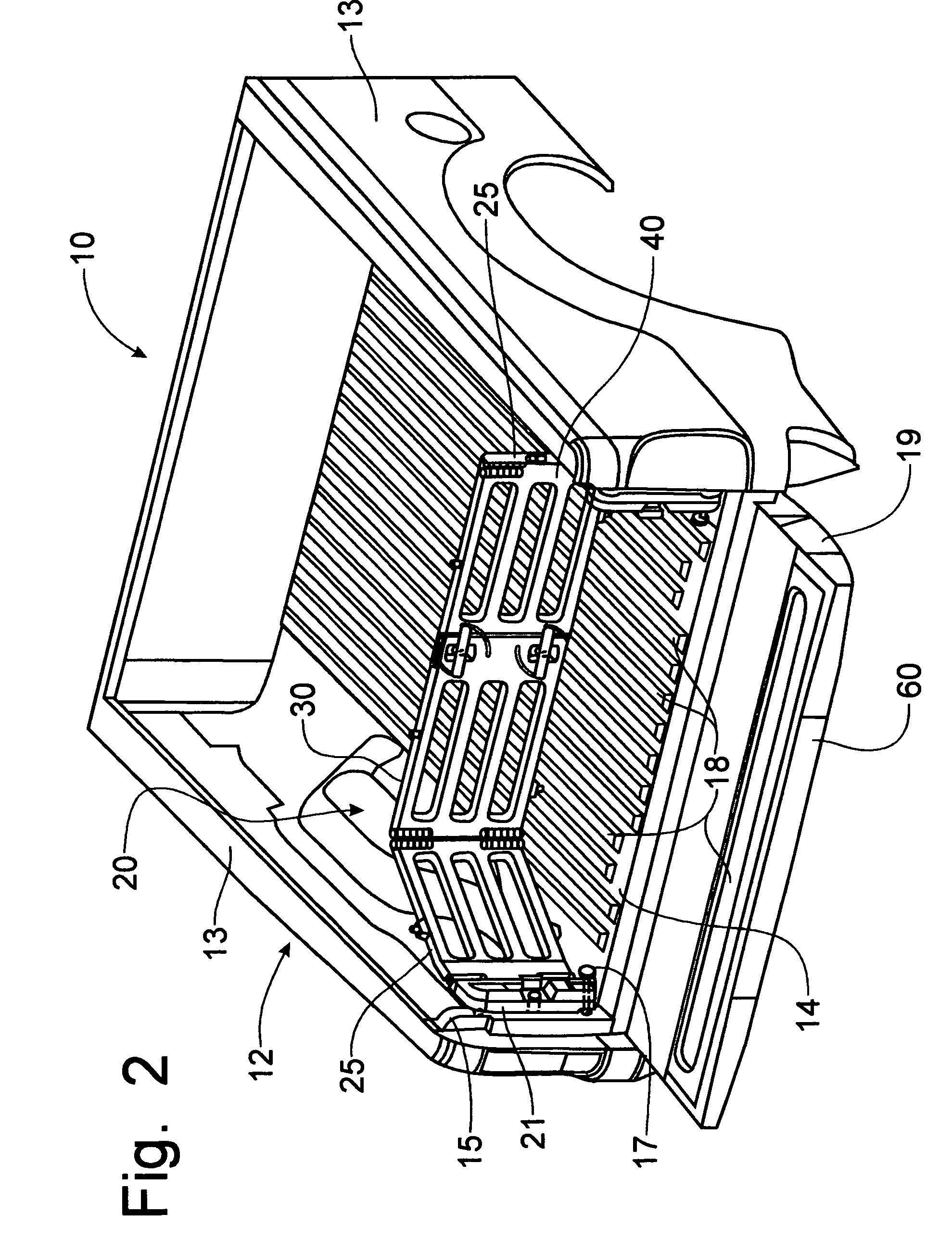

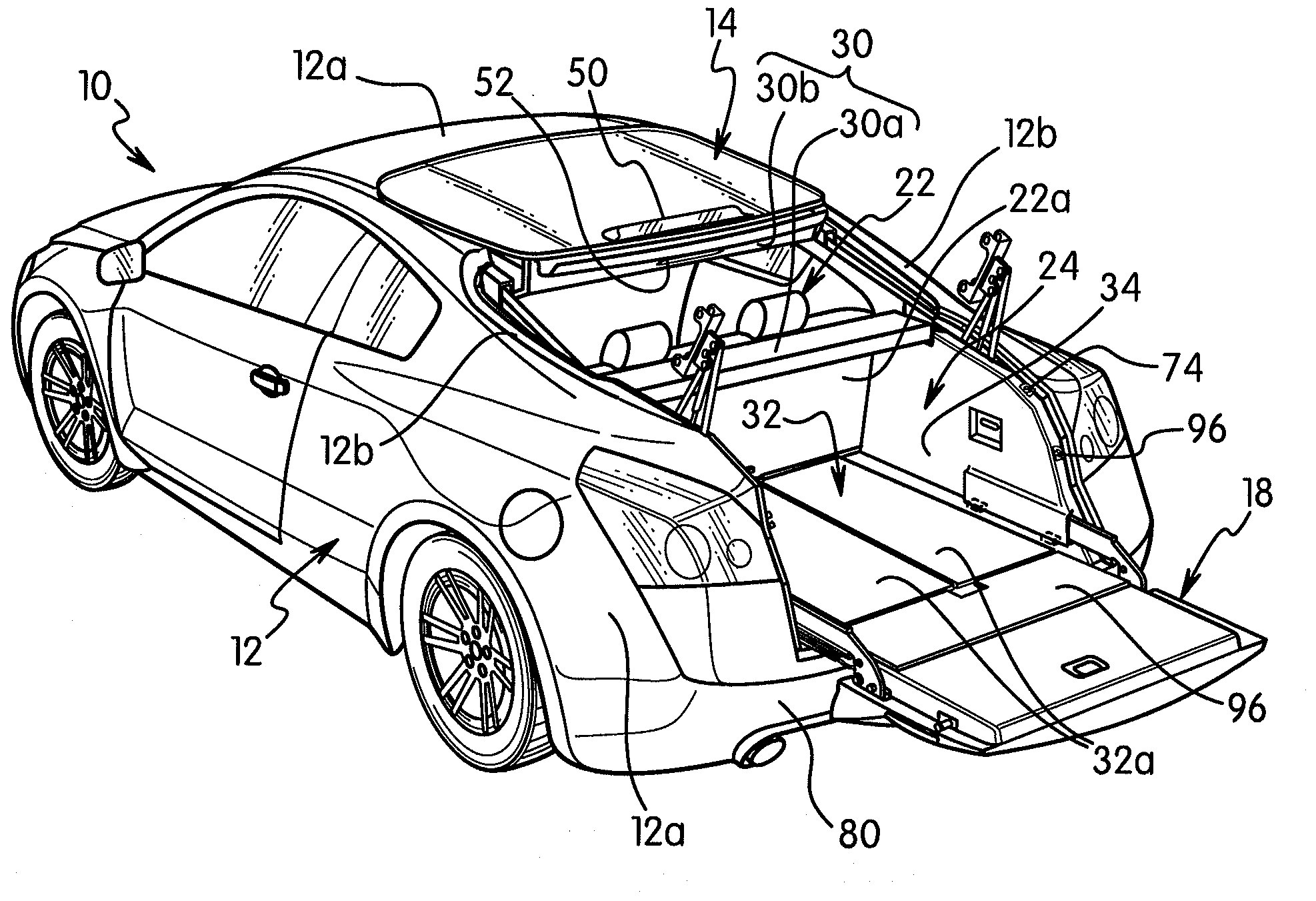

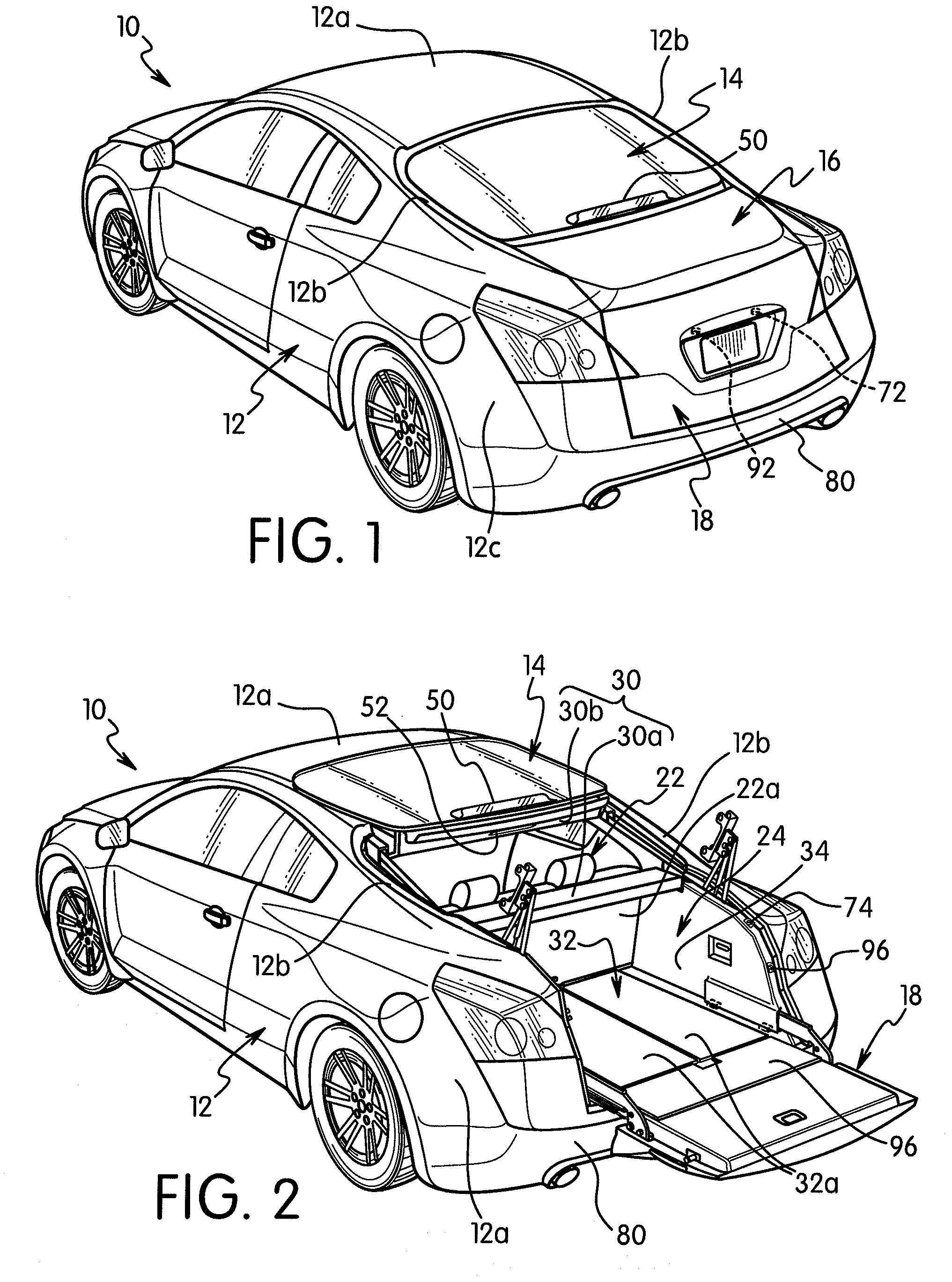

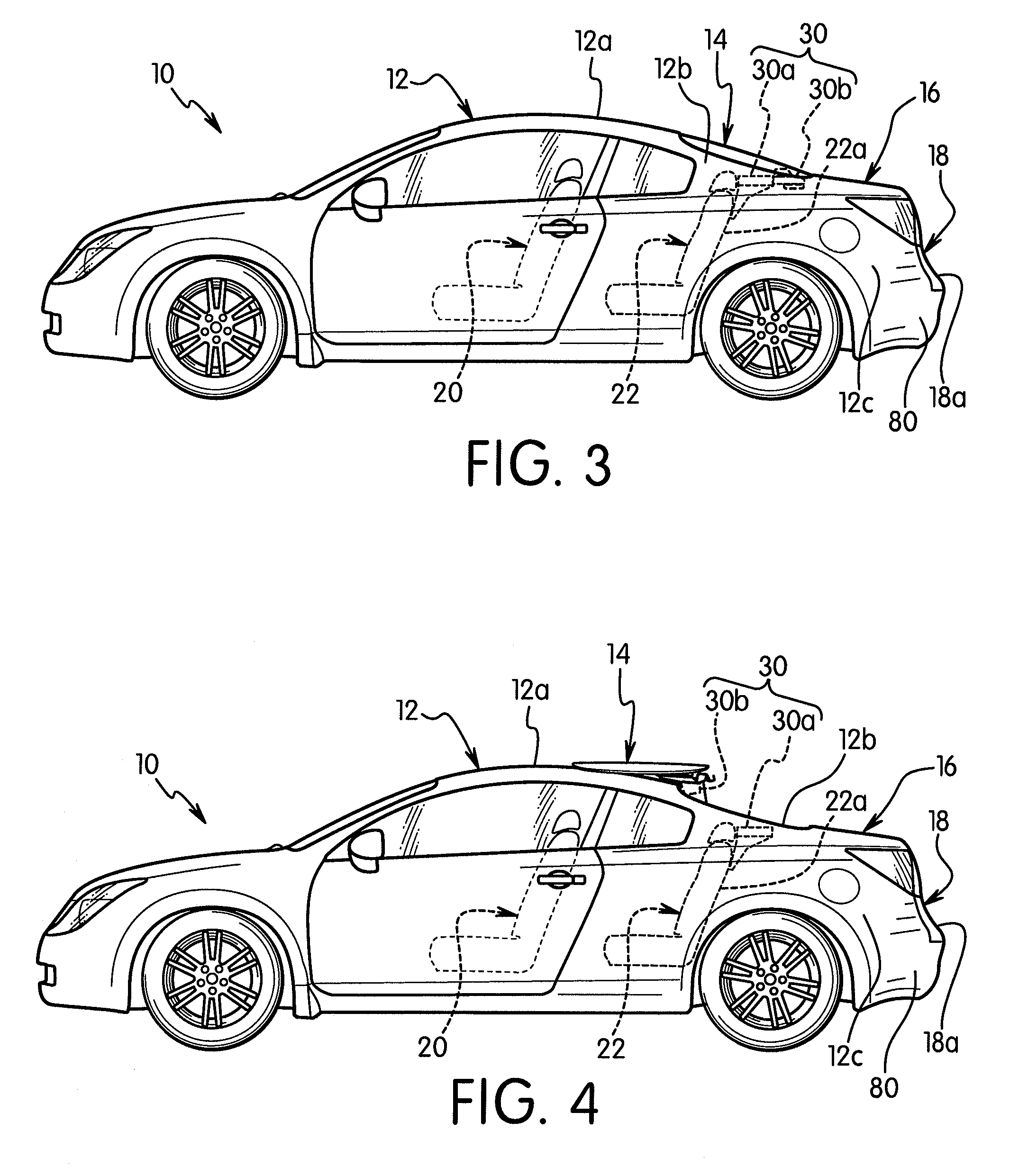

Passenger vehicle rear end structure

InactiveUS20090243342A1Increase cargo capacityImprove utilizationVehicle seatsWindowsAutomotive engineeringBody surface

A passenger vehicle rear end structure is provided with a vehicle body, a rear body panel and connection arrangement. The vehicle body includes an interior cargo area having a rear exterior trunk access opening and a rear exterior body surface. The rear body panel is movably with respect to the vehicle body between an upright orientation and a horizontal orientation with the rear body panel forming a rear exterior panel surface that mates with the rear exterior body surface. The connection arrangement couples the rear body panel to the vehicle body for movement of the rear body panel between the upright orientation and the horizontal orientation. The rear exterior surface of the rear body panel is disposed rearward of a portion of the rear exterior body surface that mates with a bottom ledge of the rear body panel when the rear body panel is in the horizontal orientation.

Owner:NISSAN TECHN CENT NORTH AMERICA

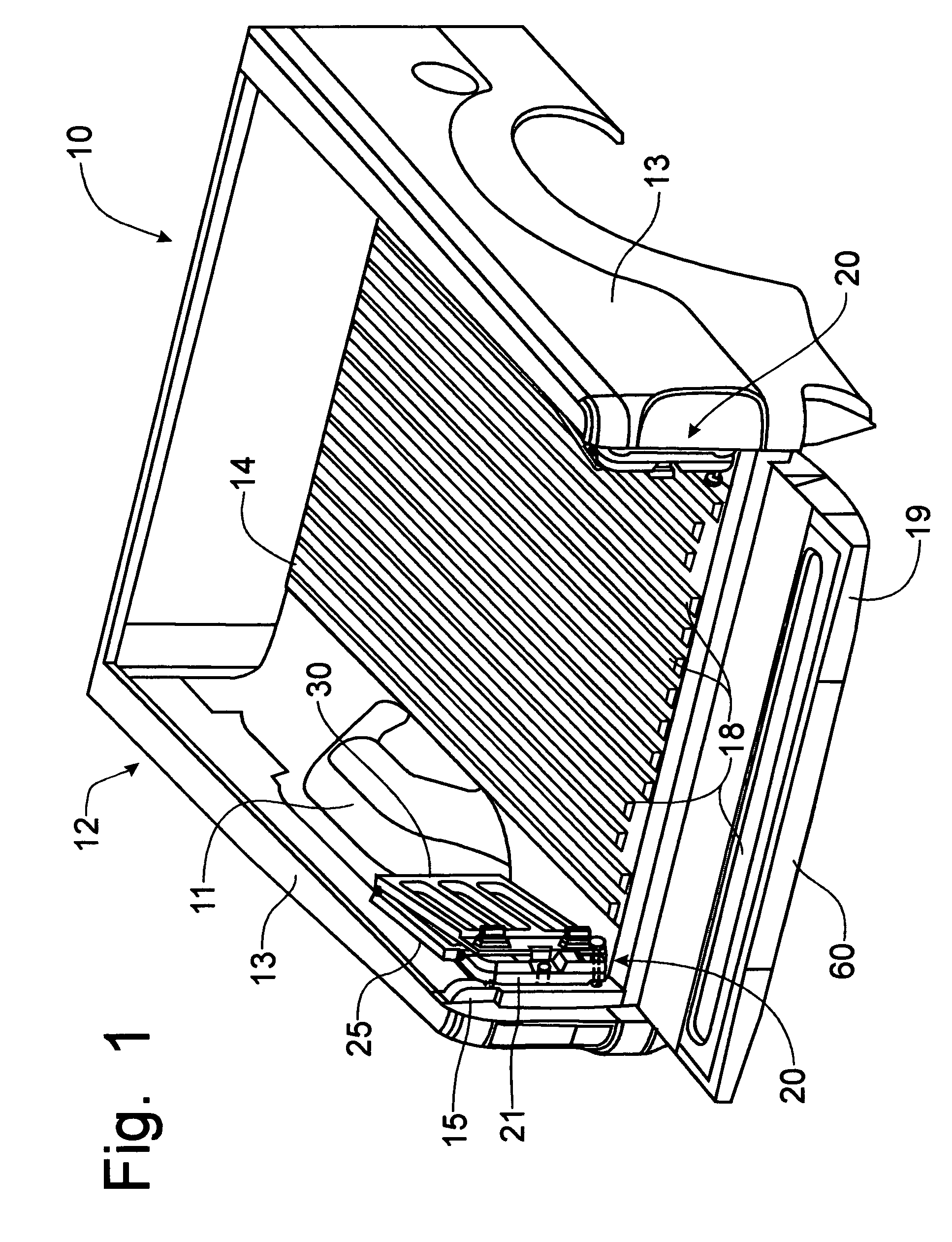

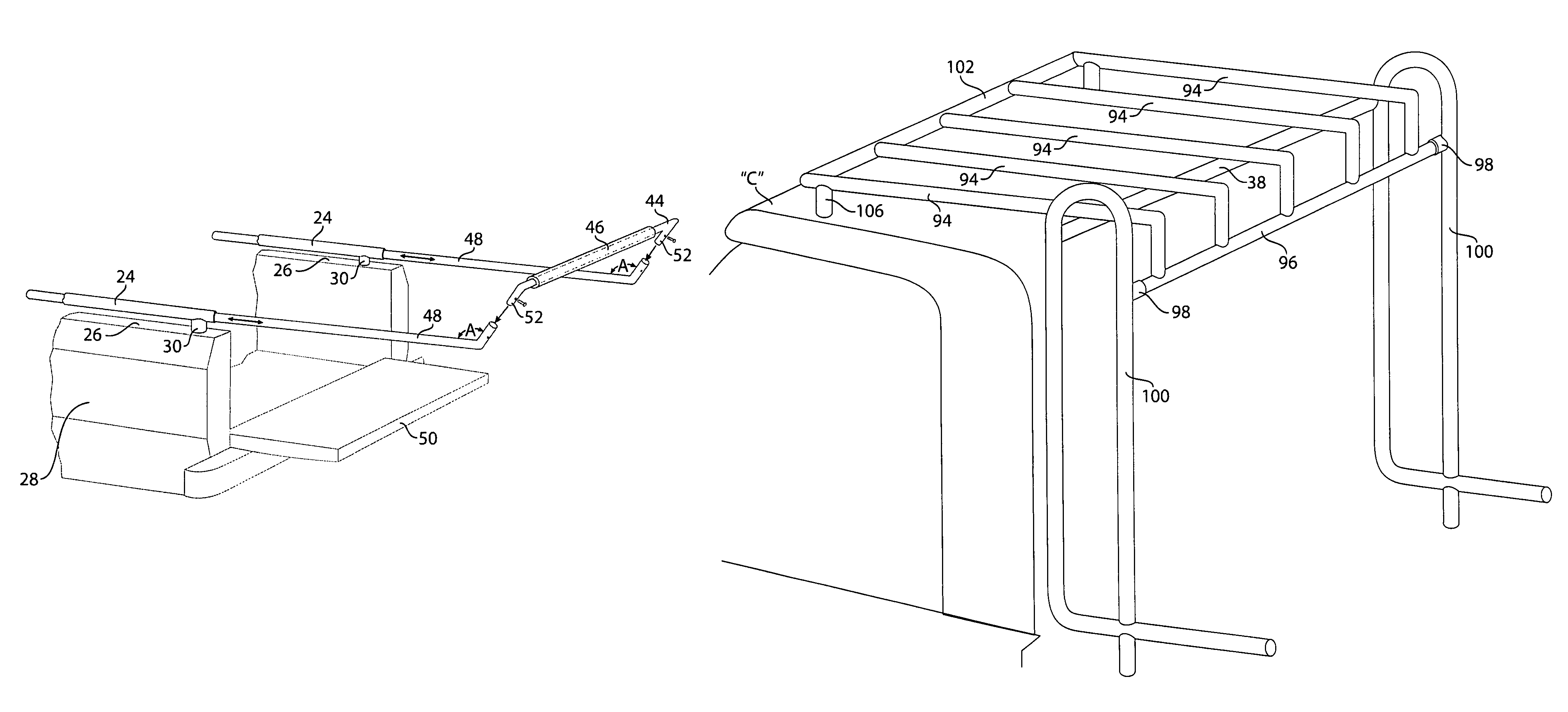

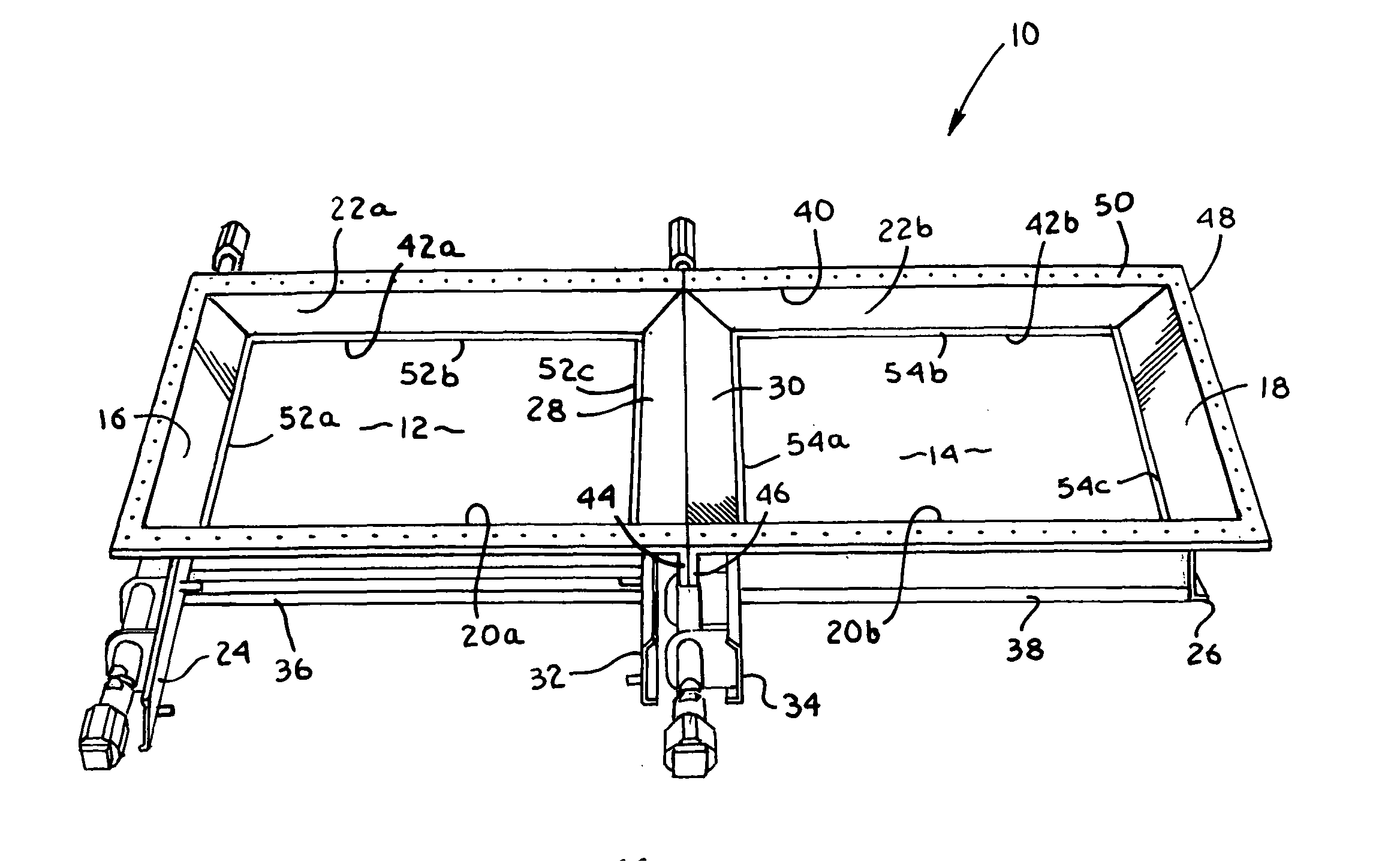

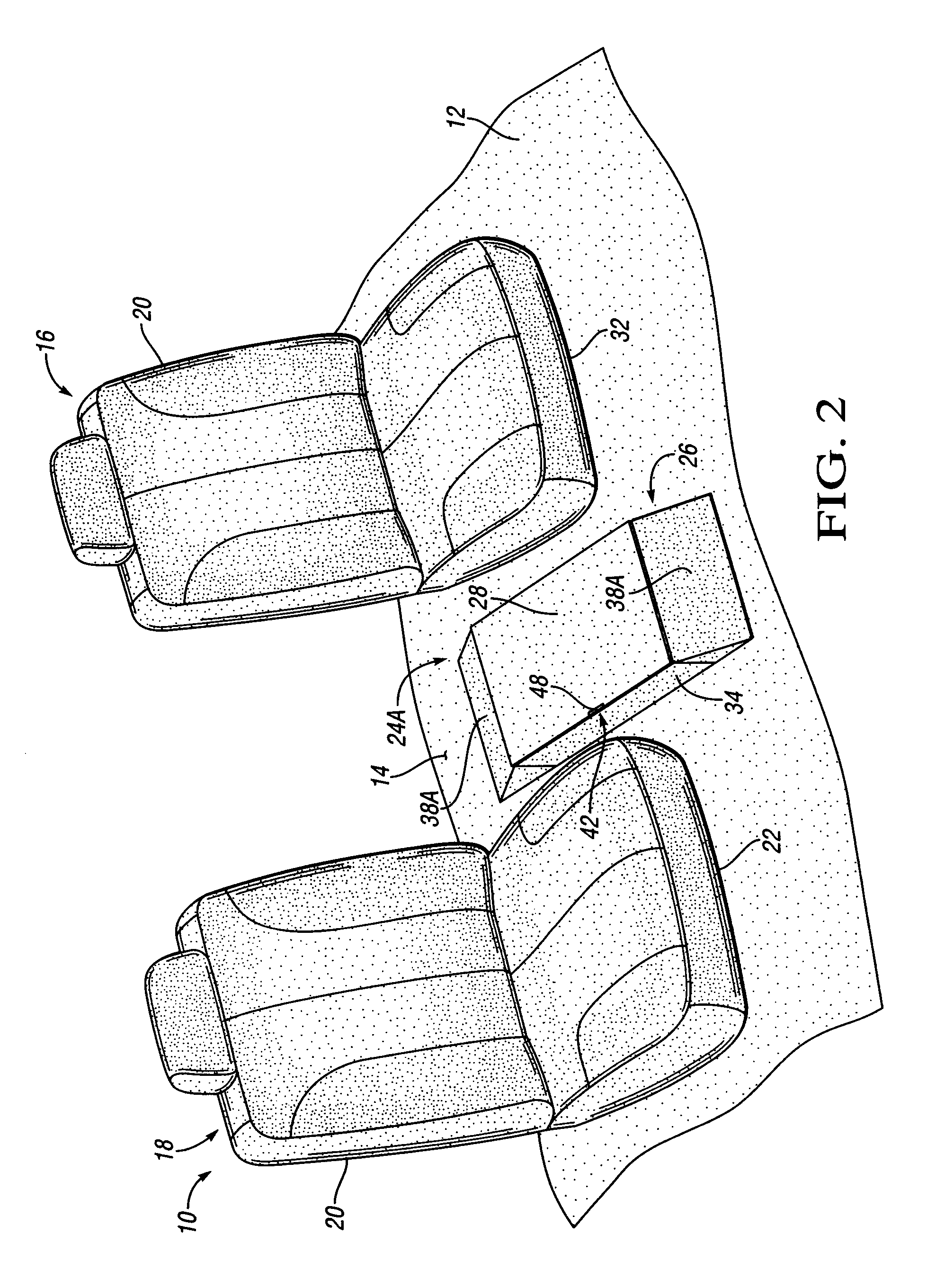

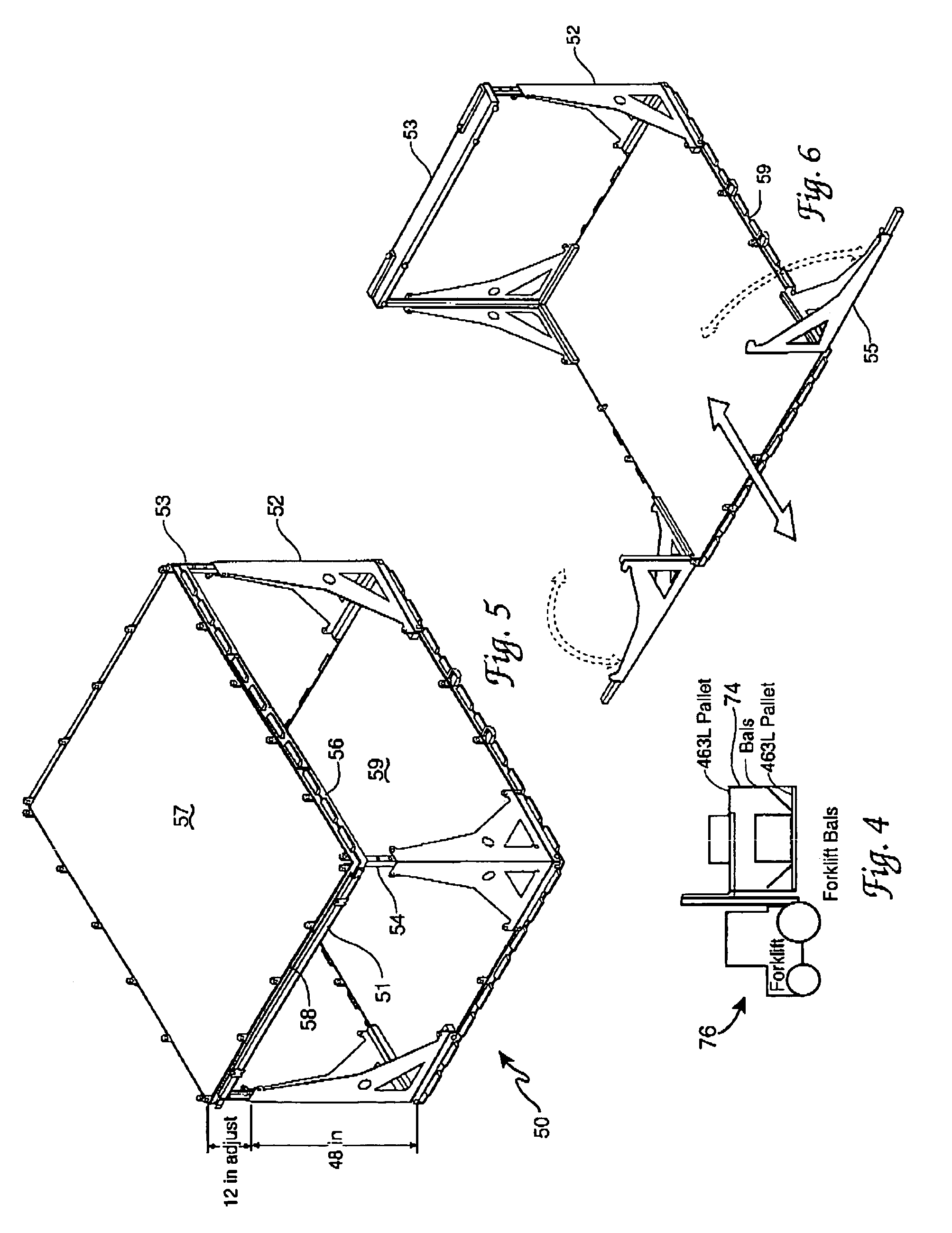

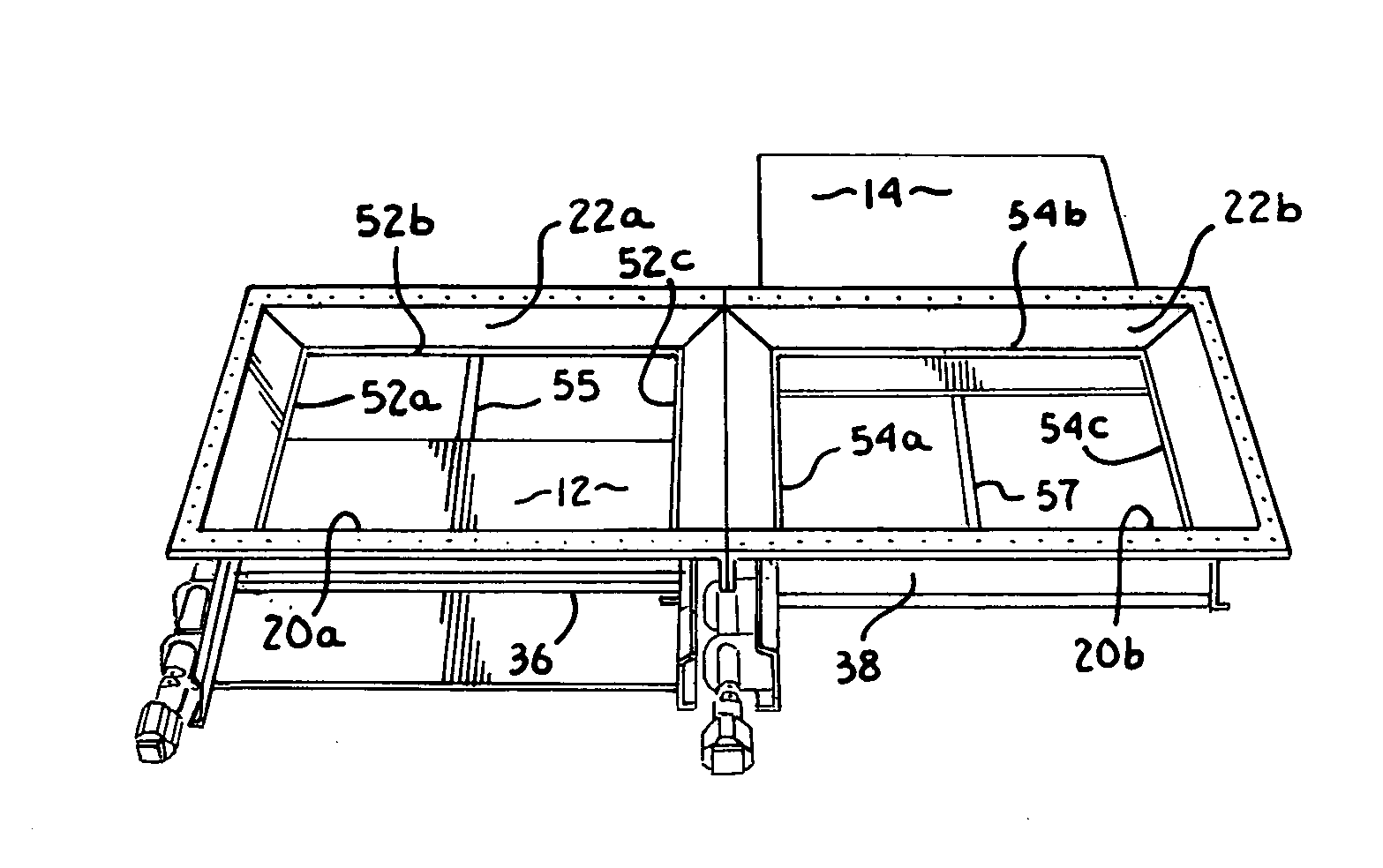

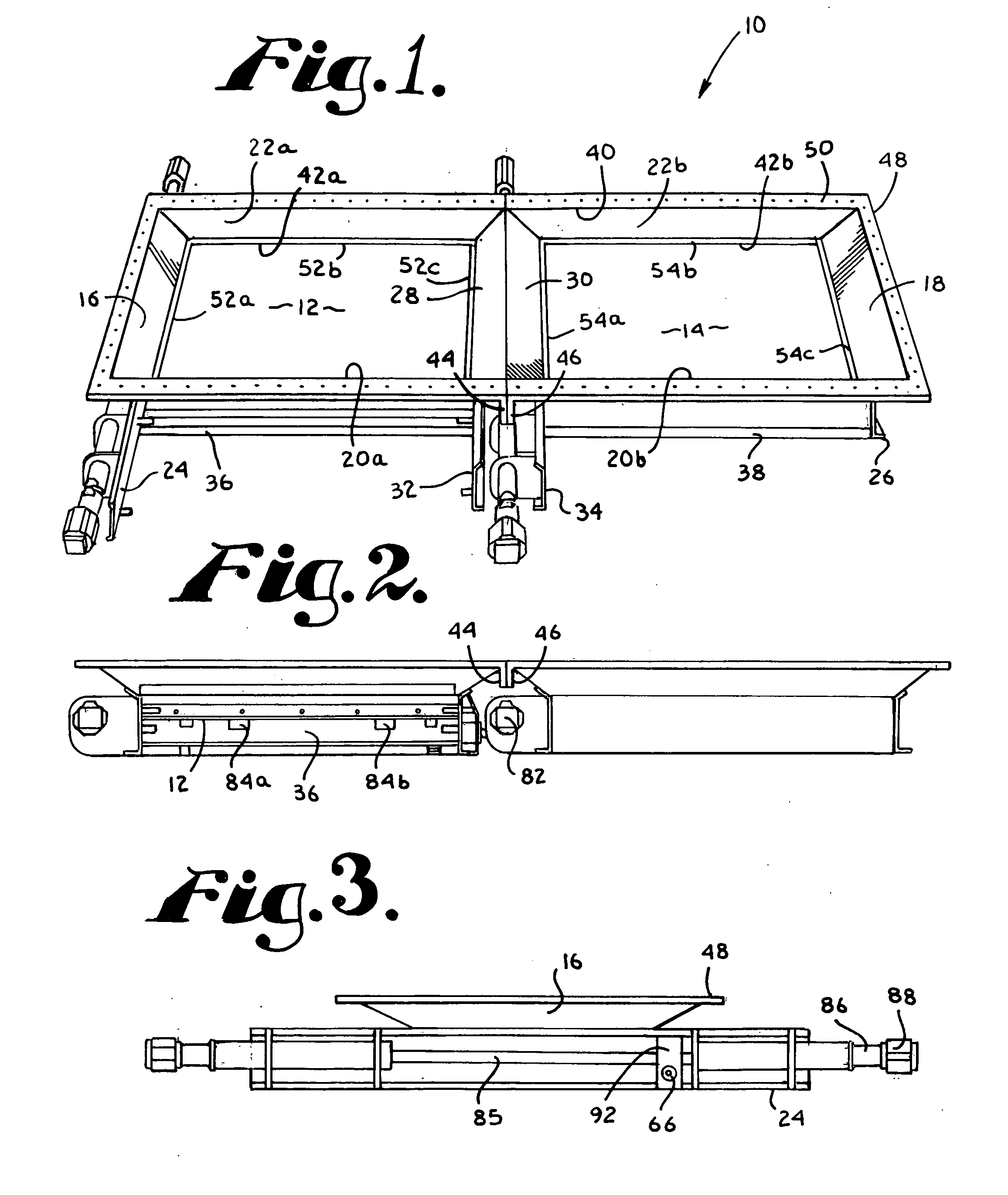

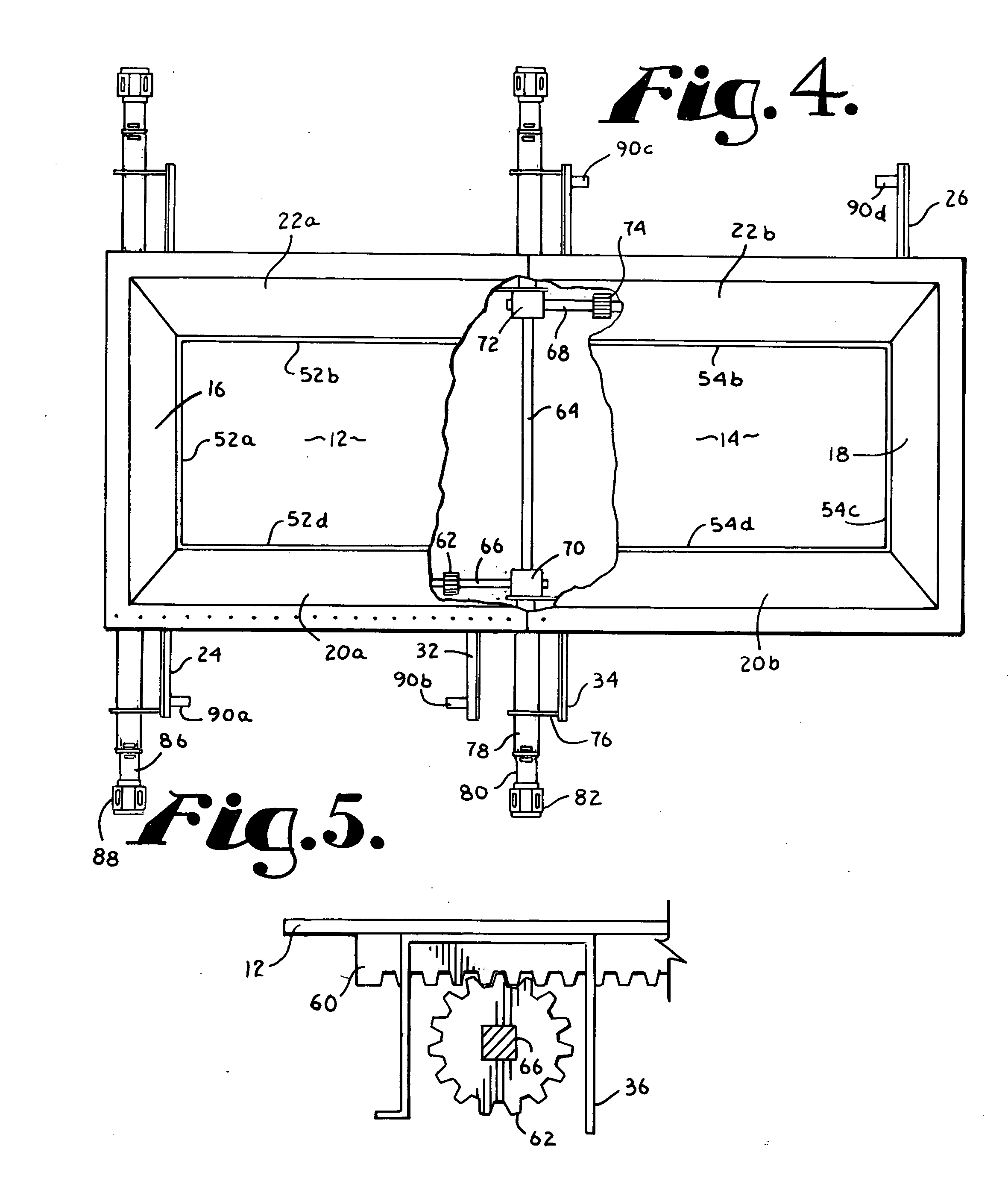

Adaptable support arrangement for a pickup truck

ActiveUS8864001B2Improve carrying capacityIncrease cargo capacityVehicle to carry long loadsVehicle with living accommodationPickup truckEngineering

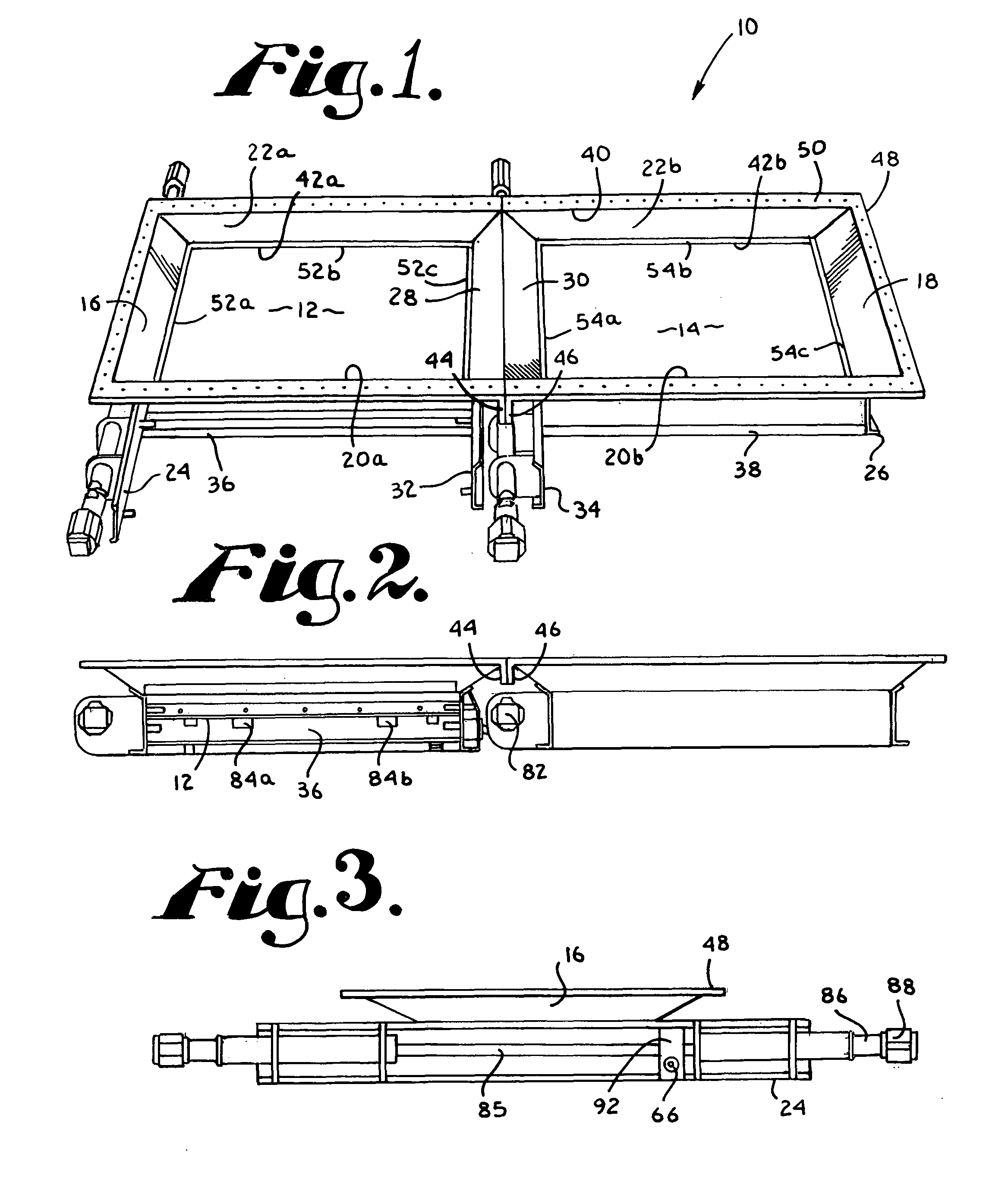

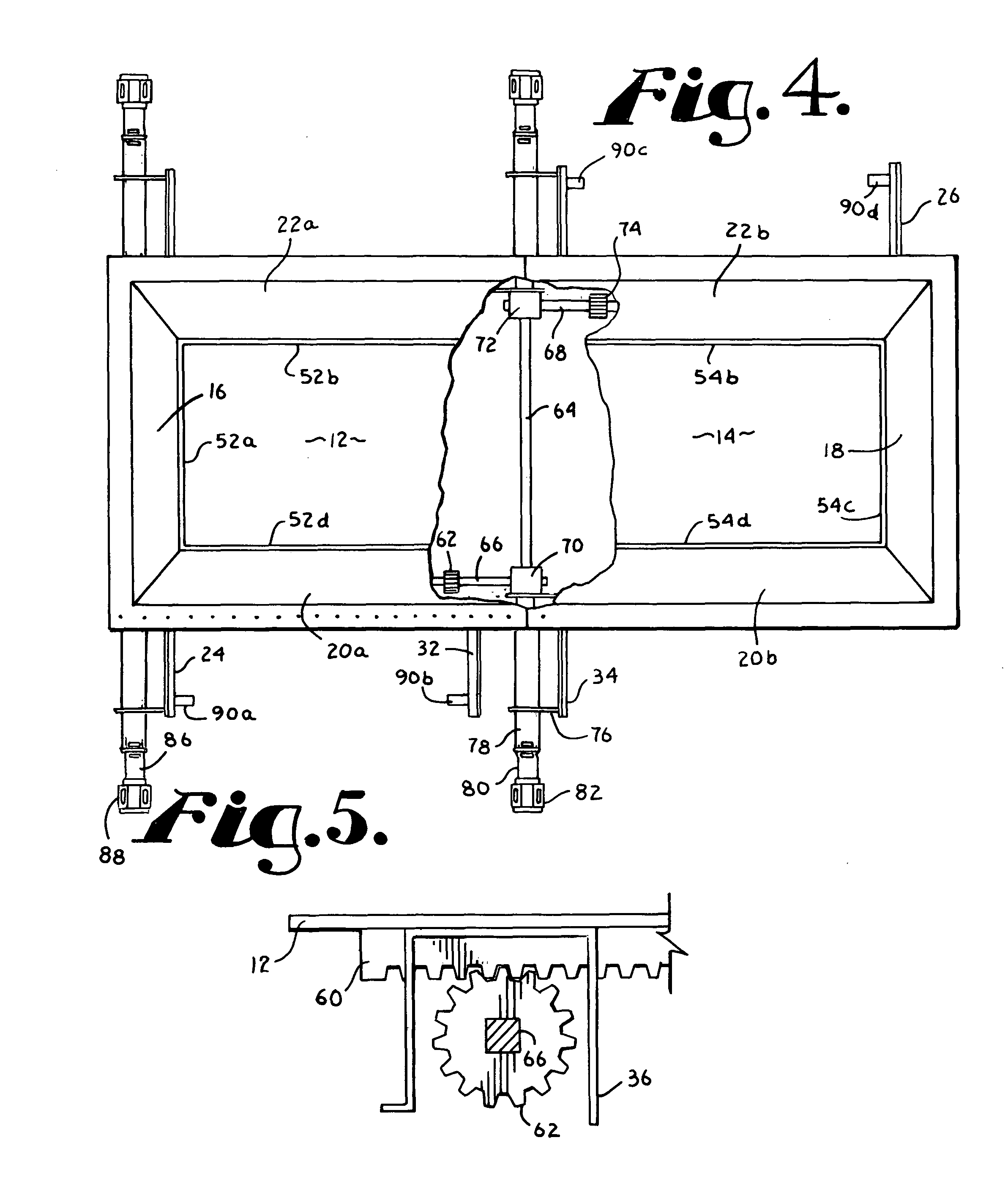

A variable load support system for enhancing the load carrying capabilities of a bed of any one of a variety of variously sized pickup trucks, the support system comprising a first pair of elongated, longitudinally-extendable pickup truck sidewall engageable side rails, a forwardly arranged first and a rearwardly arranged second, elongated, longitudinally-extendable pickup-truck-bed-traversing transverse rails, and a roller member housingly arranged about the rearwardly arranged pickup truck bed traversing transverse rail so as to permit the widthwise adaptability of the second transverse rail to a pickup truck side wall.

Owner:LANGSEDER JAY

Adaptable support arrangement for a pickup truck

ActiveUS20130306694A1Improve carrying capacityIncrease cargo capacityVehicle to carry long loadsSupplementary fittingsSupporting systemPickup truck

A variable load support system for enhancing the load carrying capabilities of a bed of any one of a variety of variously sized pickup trucks, the support system comprising a first pair of elongated, longitudinally-extendable pickup truck sidewall engageable side rails, a forwardly arranged first and a rearwardly arranged second, elongated, longitudinally-extendable pickup-truck-bed-traversing transverse rails, and a roller member housingly arranged about the rearwardly arranged pickup truck bed traversing transverse rail so as to permit the widthwise adaptability of the second transverse rail to a pickup truck side wall.

Owner:LANGSEDER JAY

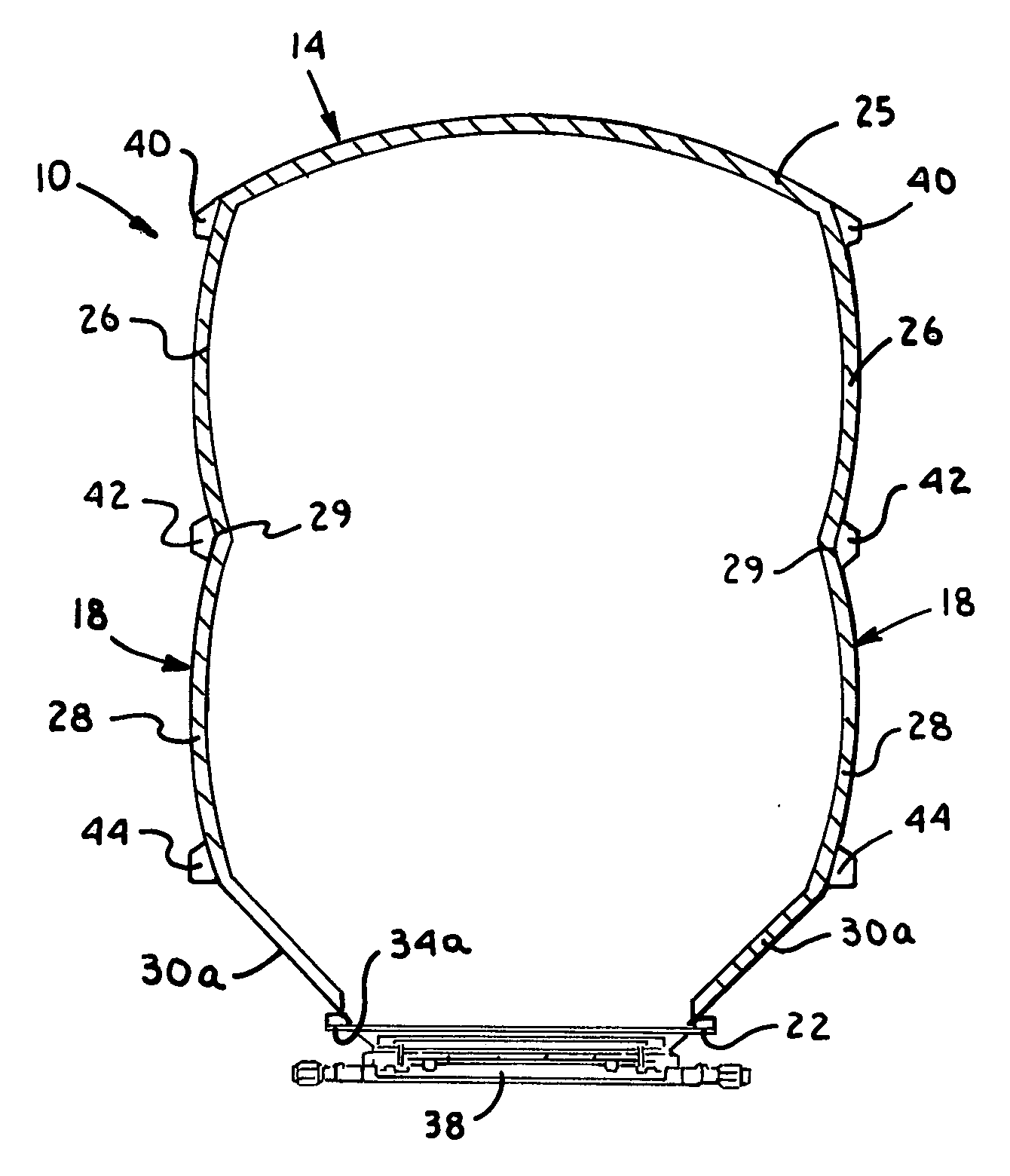

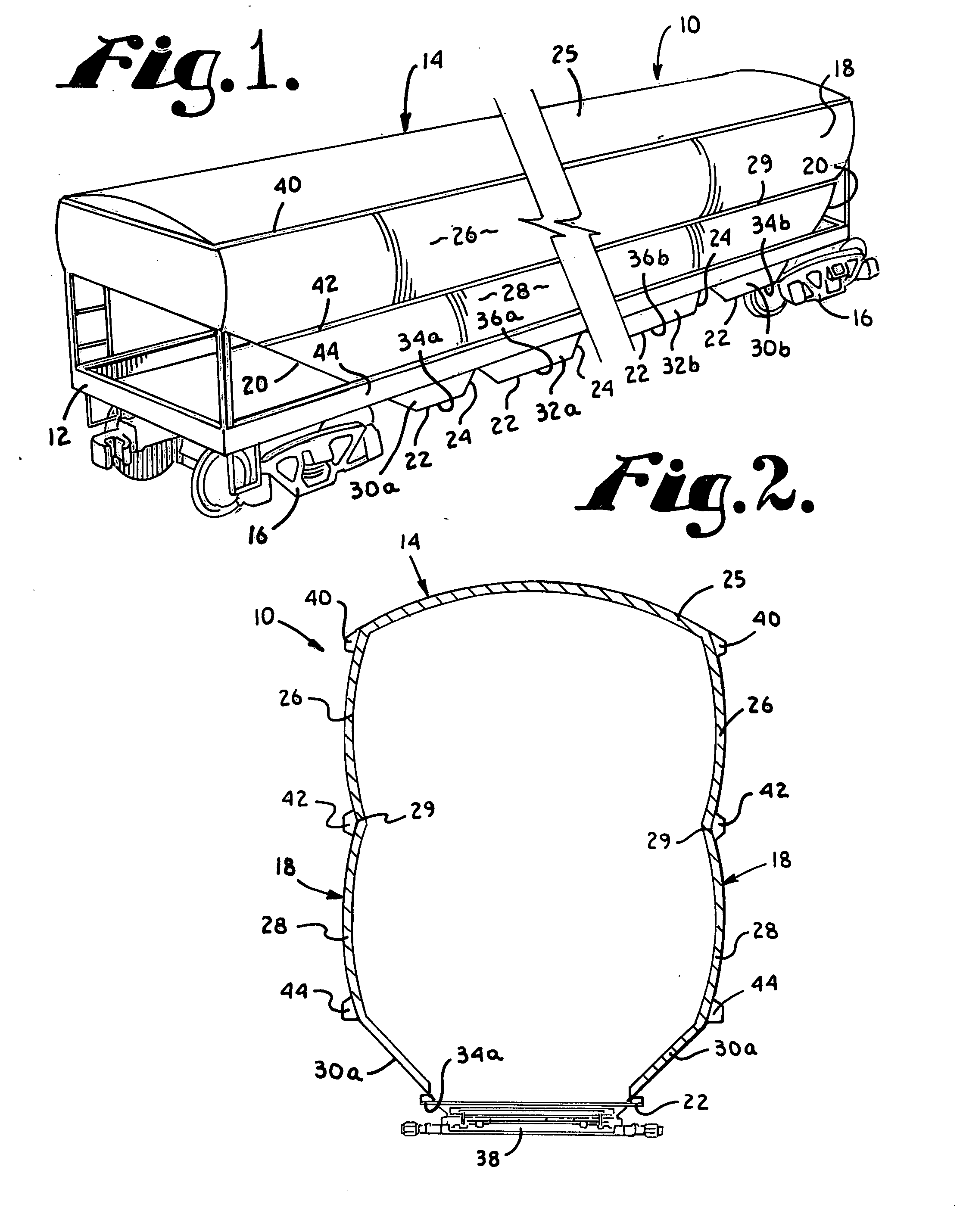

Hopper car gate with a laterally opening door

Owner:AERO TRANSPORTATION PRODS

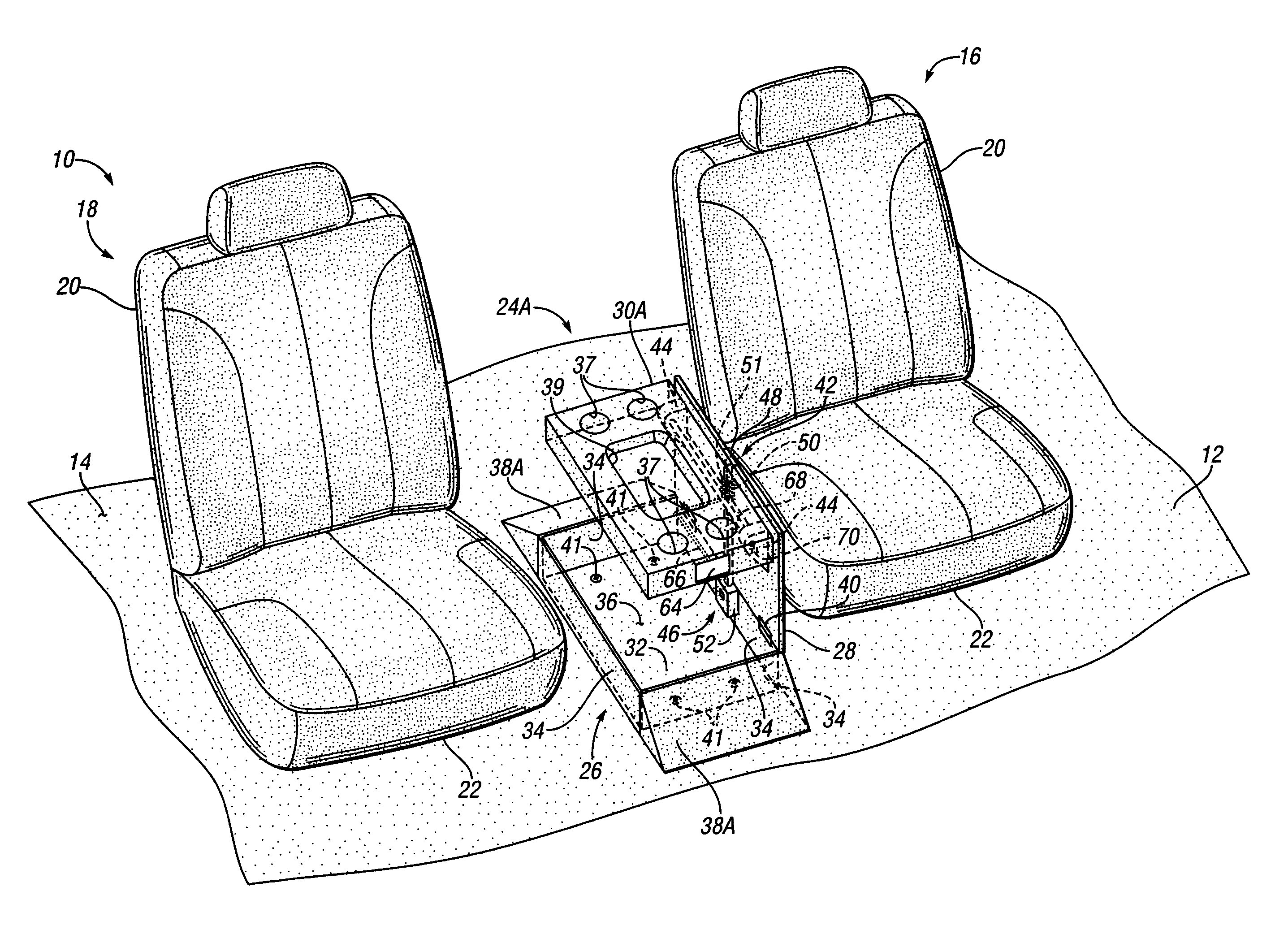

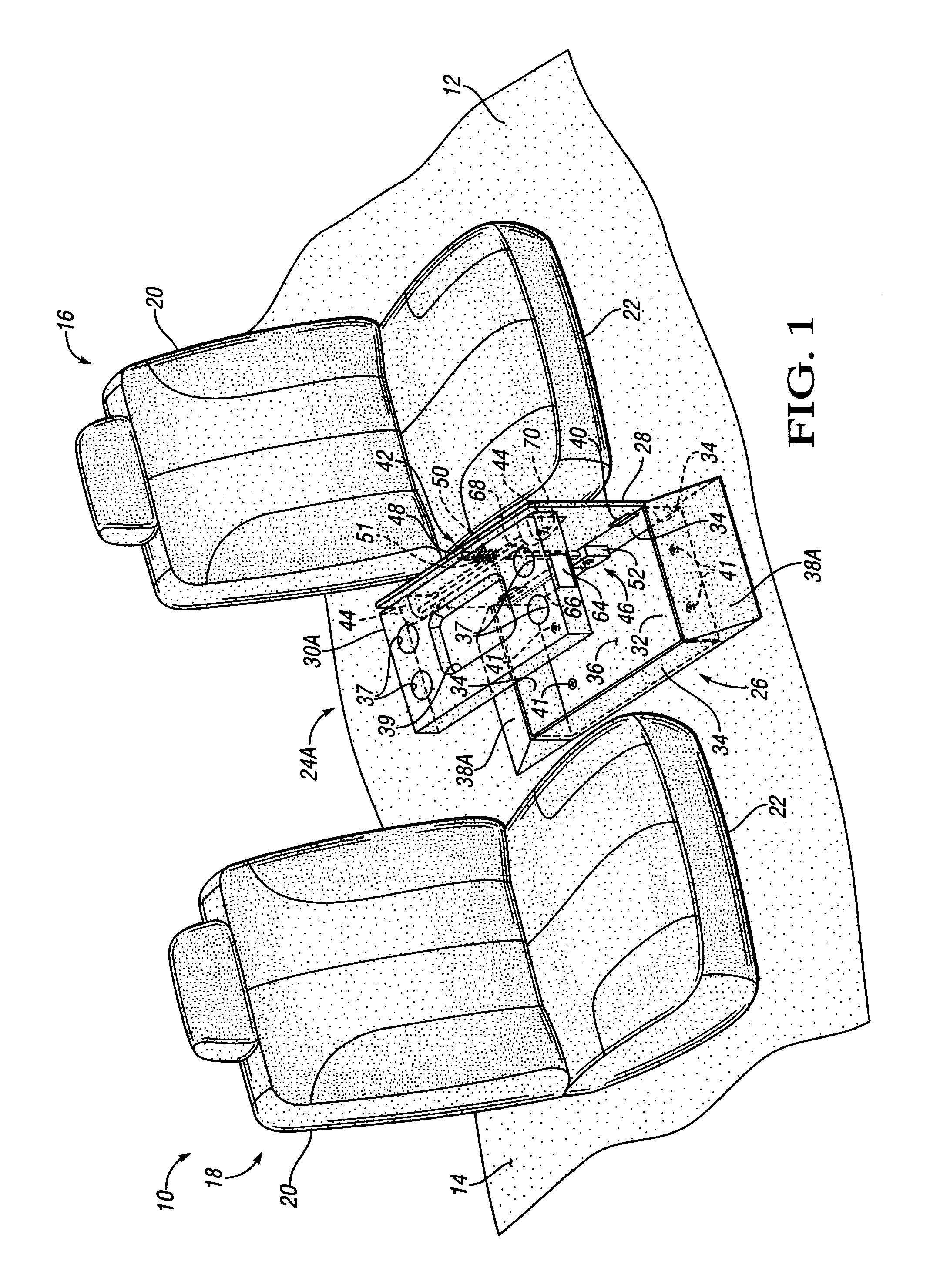

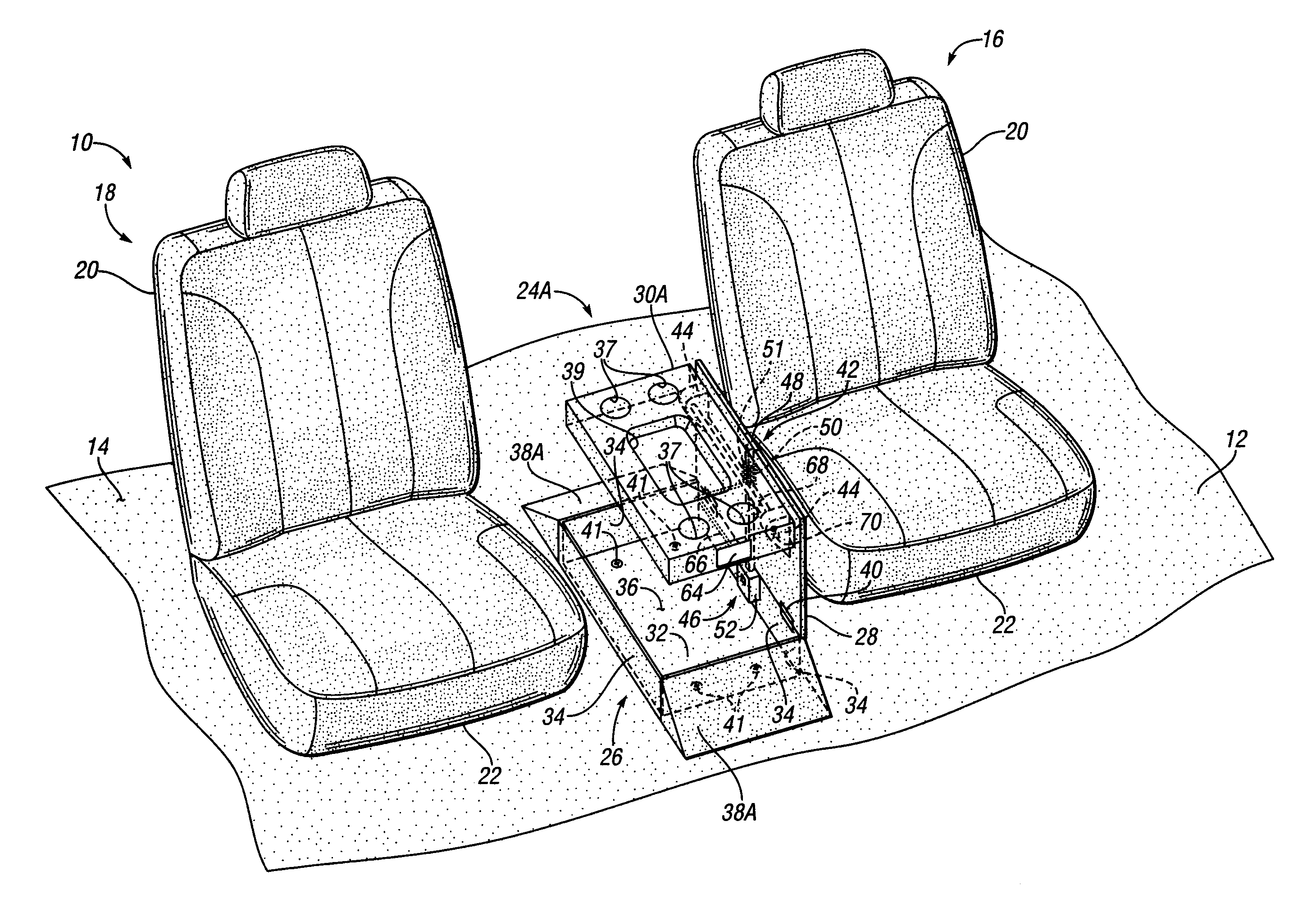

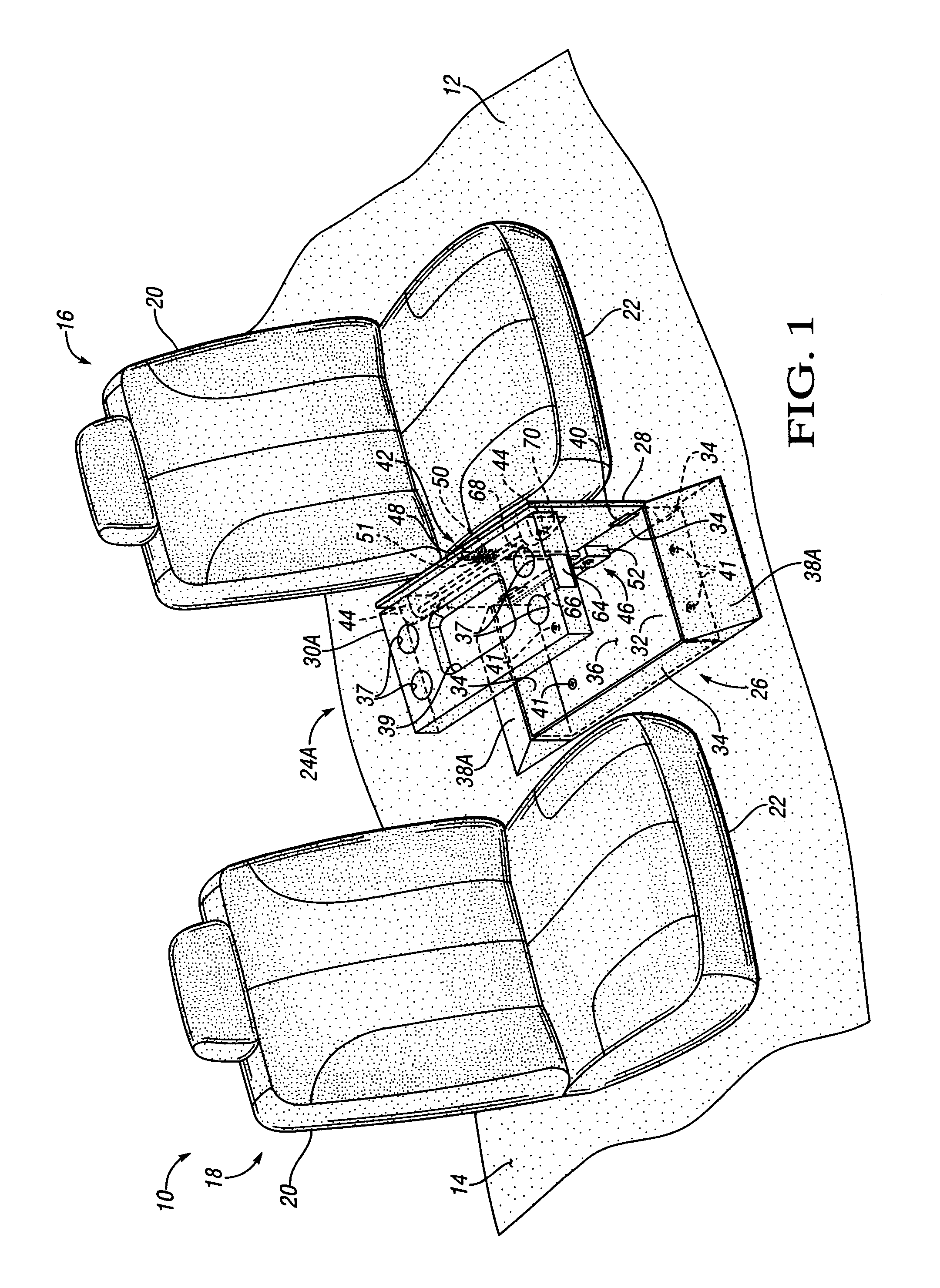

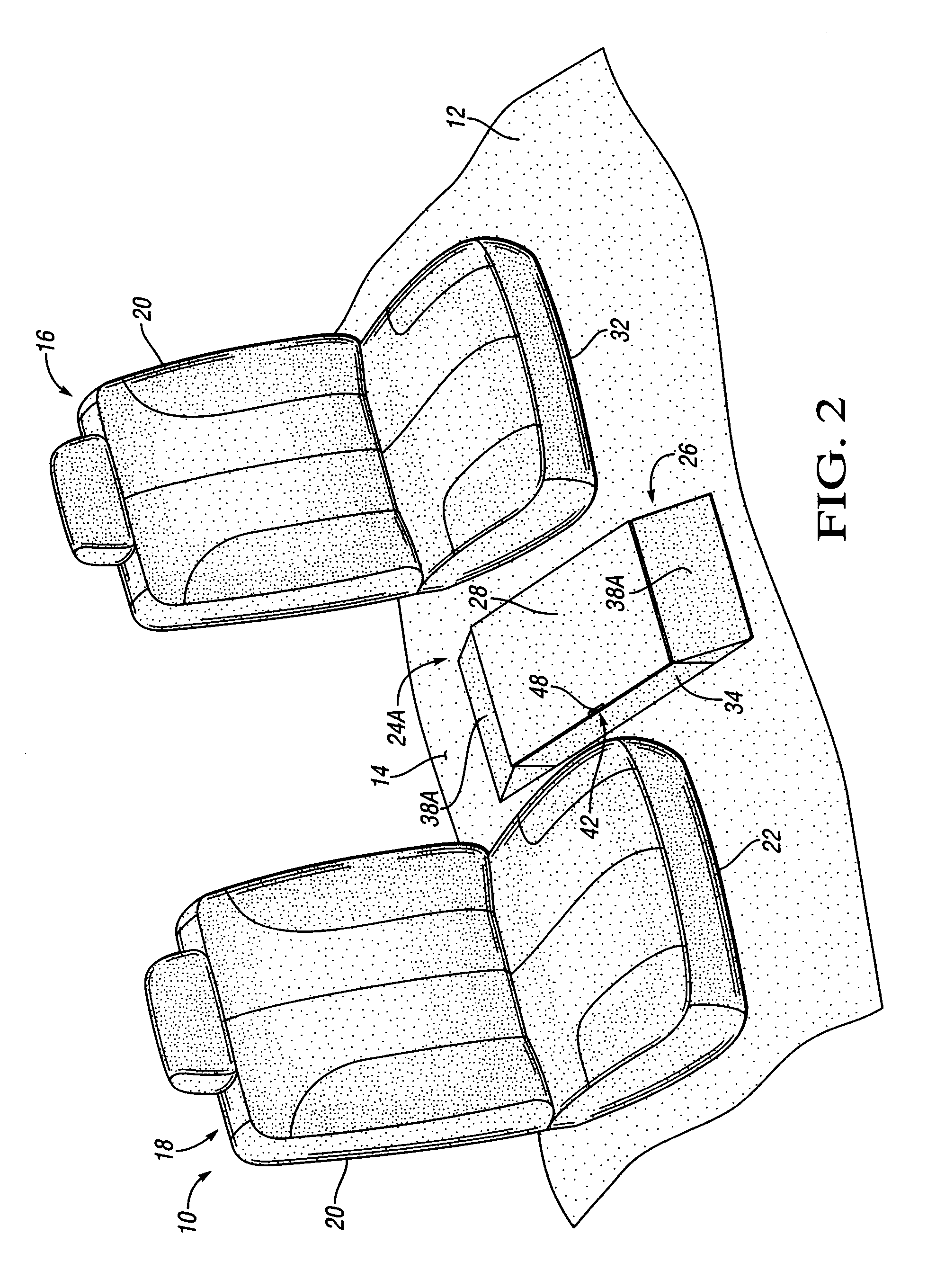

Stowable cup holder tray assembly

A stowable cup holder tray assembly is provided for a vehicle having an interior floor structure. The cup holder assembly includes a stowage compartment having a bottom portion with a plurality of opposing sidewalls extending therefrom and defining a stowage volume. The stowage compartment is mounted substantially adjacent to the interior floor structure. A cover member is hinged to one of said plurality of opposing sidewalls and operates to substantially close said stowage volume. A cup holder tray member is movable between a stowed position and a deployed position. The stowage volume is sufficiently configured to receive said cup holder tray member when in said stowed position. A vehicle incorporating the disclosed cup holder tray assembly is also provided. The cup holder tray assembly is configured to be sufficiently close to the floor when in the stowed position to provide limited barriers within the interior of the vehicle.

Owner:GM GLOBAL TECH OPERATIONS LLC

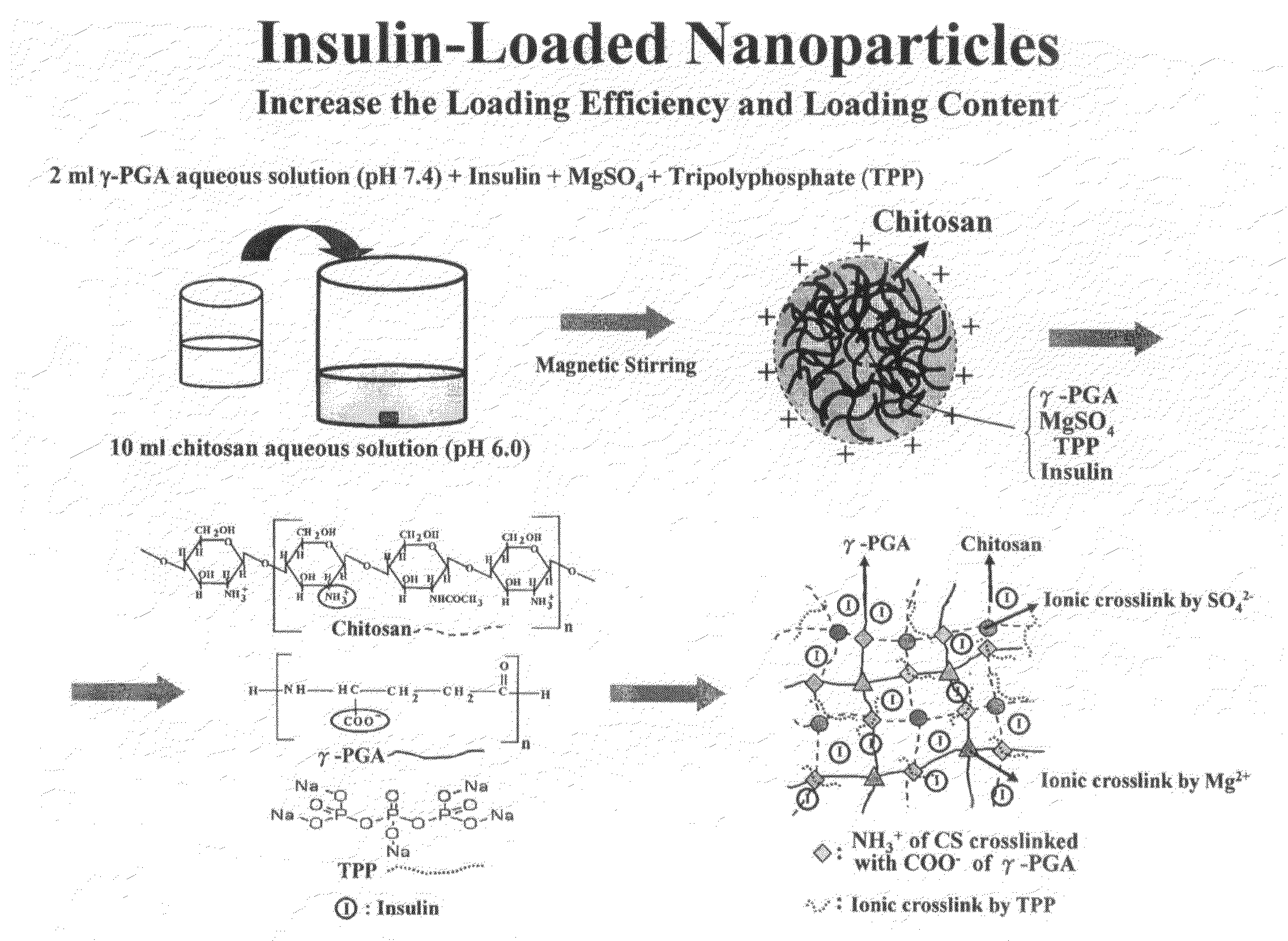

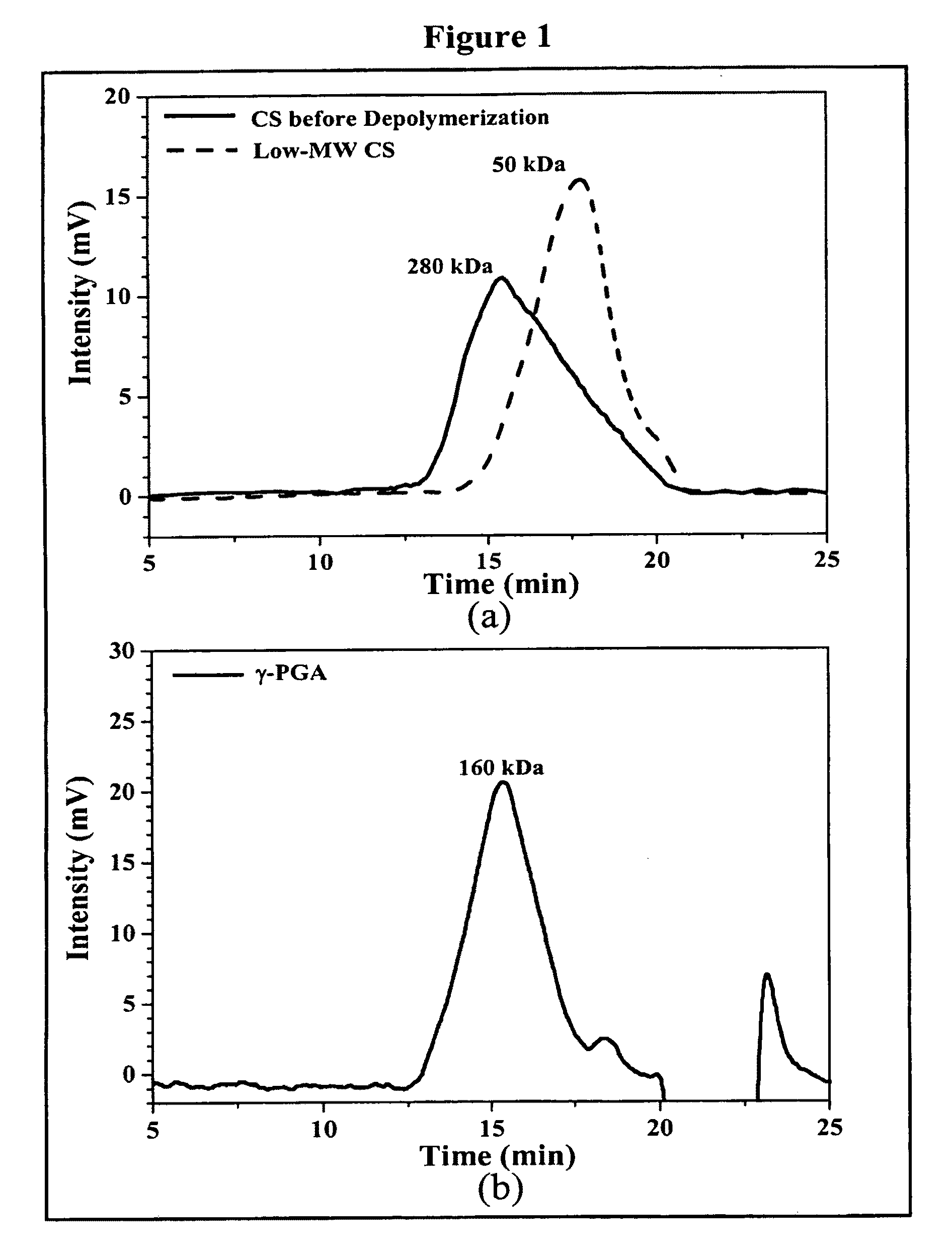

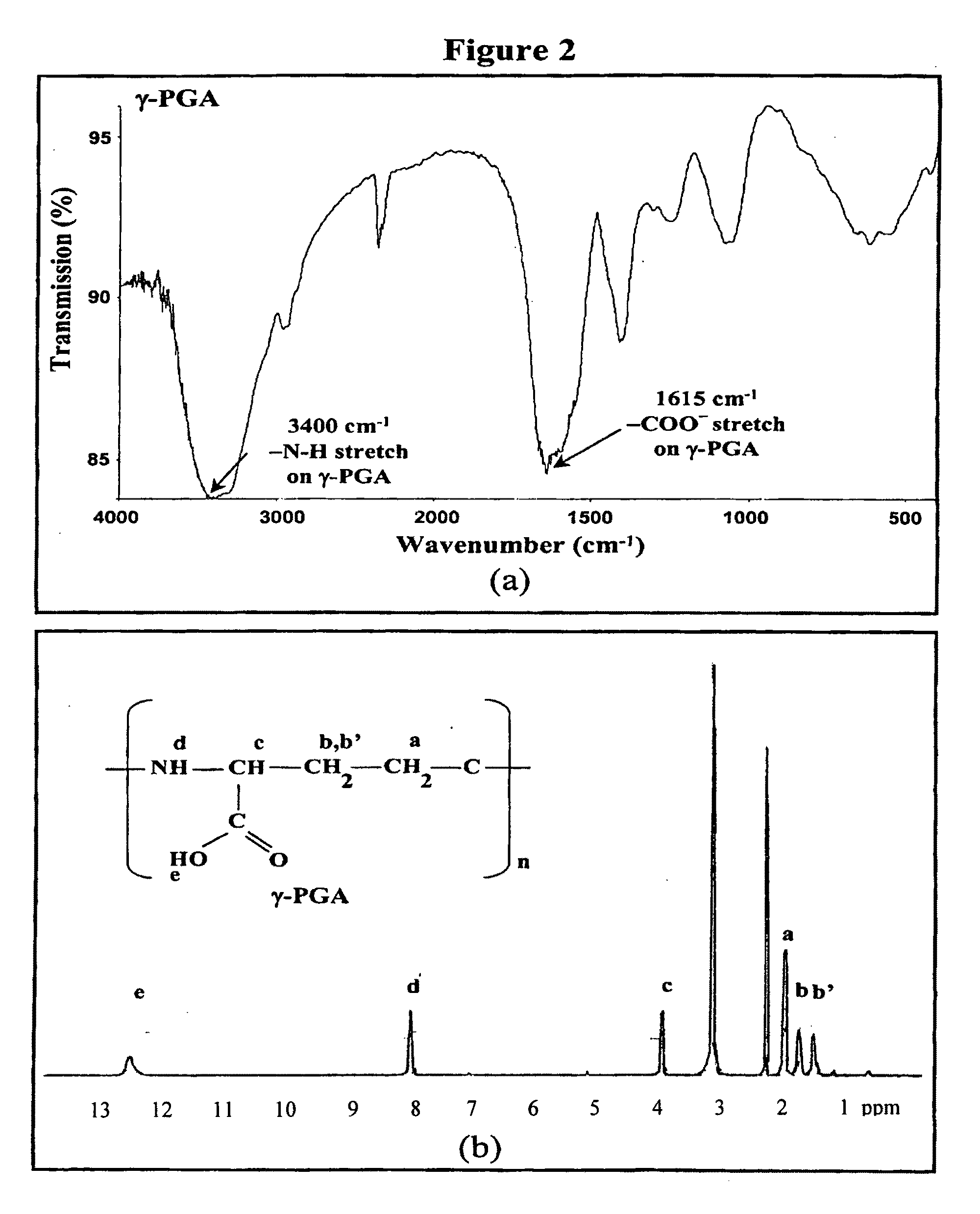

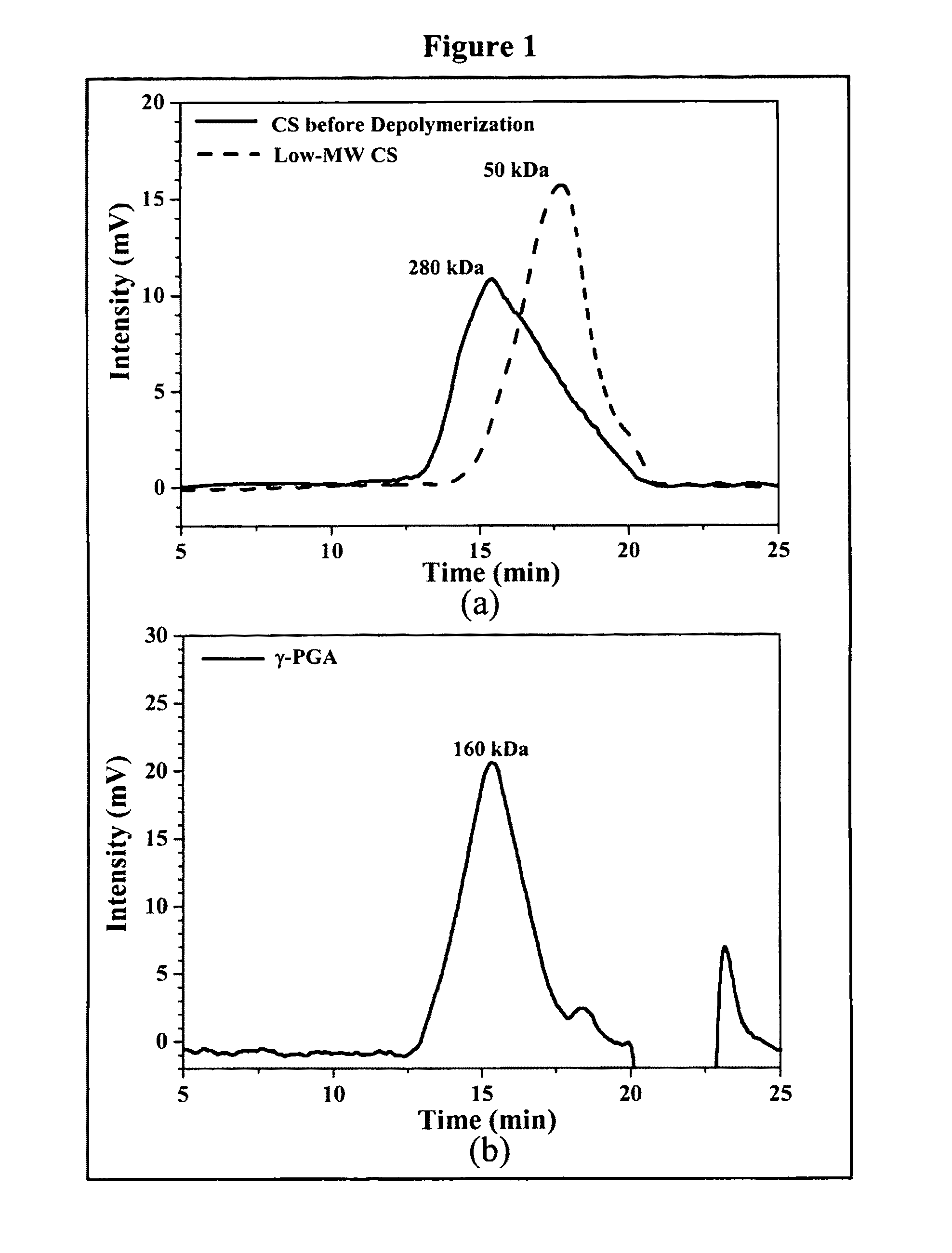

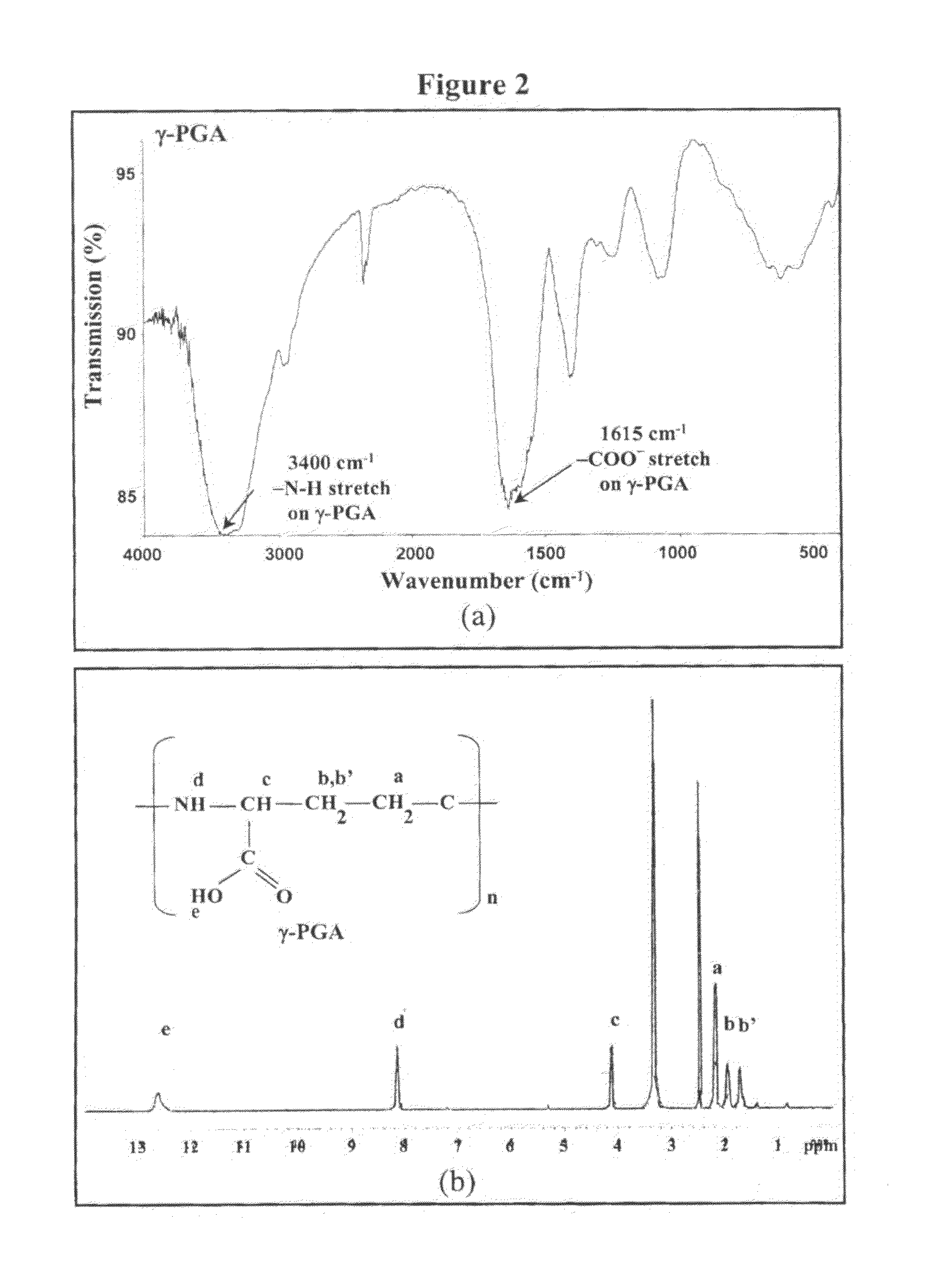

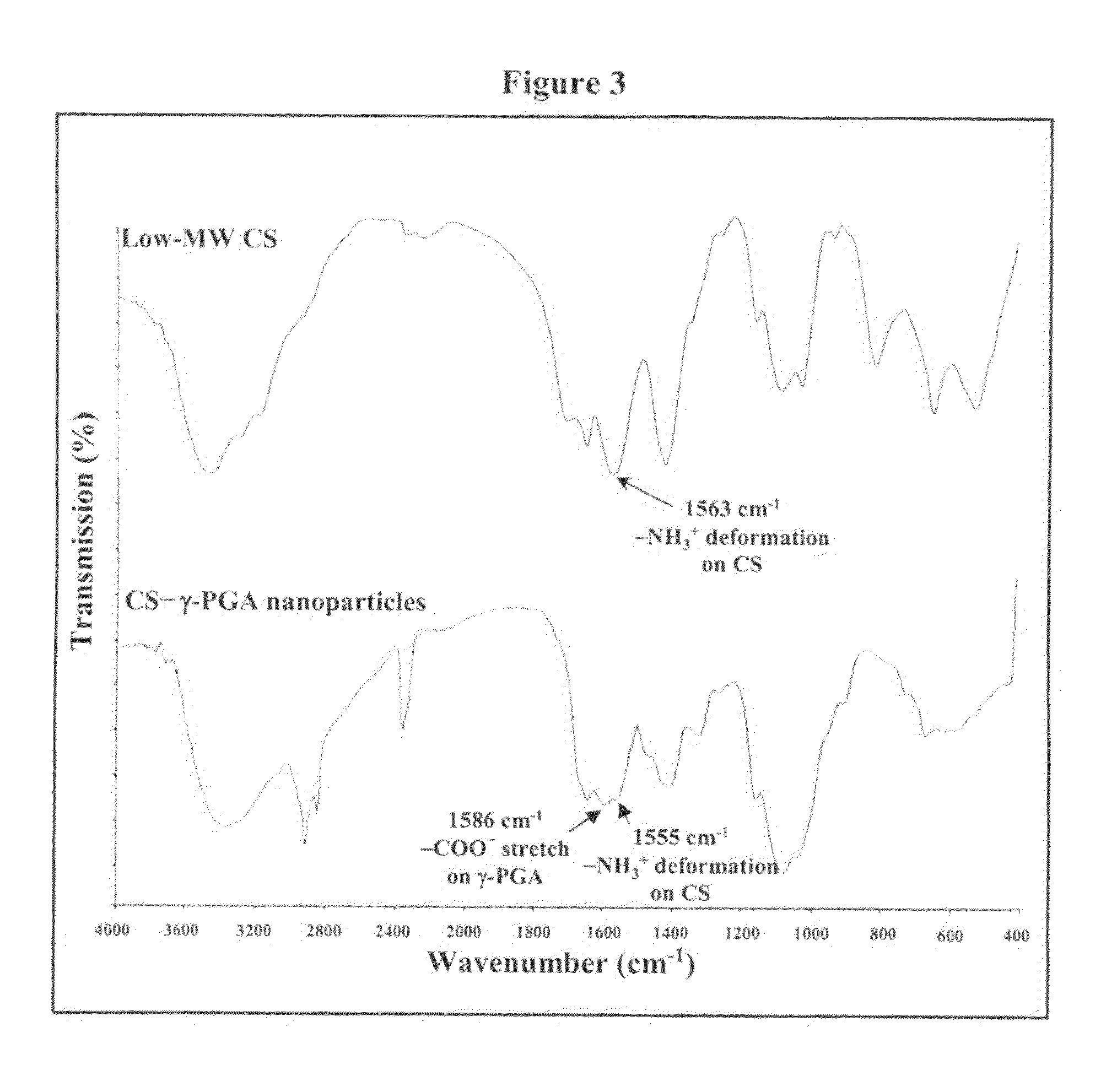

Nanoparticles for protein drug delivery

InactiveUS20090155374A1Enhance transportEnhance contentBiocidePowder deliverySurface chargesProtein formation

The invention discloses the nanoparticles composed of chitosan, poly-glutamic acid, and at least one protein drug or bioactive agent characterized with a positive surface charge and their enhanced permeability for paracellular protein drug and bioactive agent delivery.

Owner:NANOMEGA MEDICAL CORP

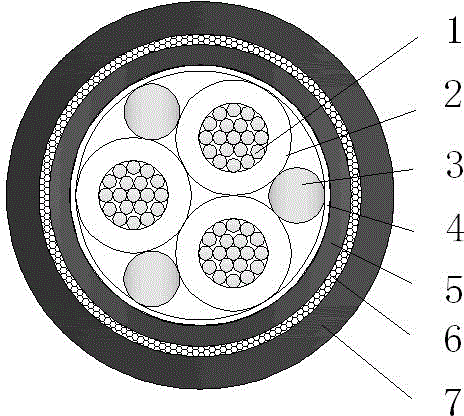

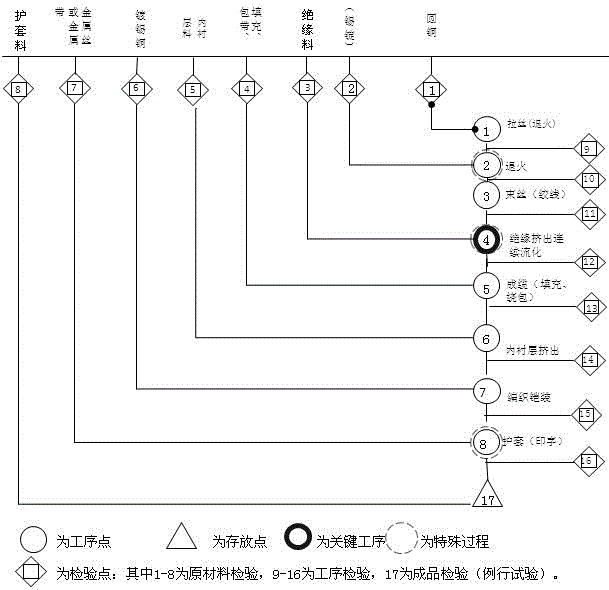

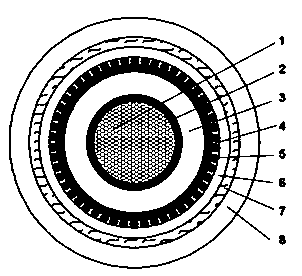

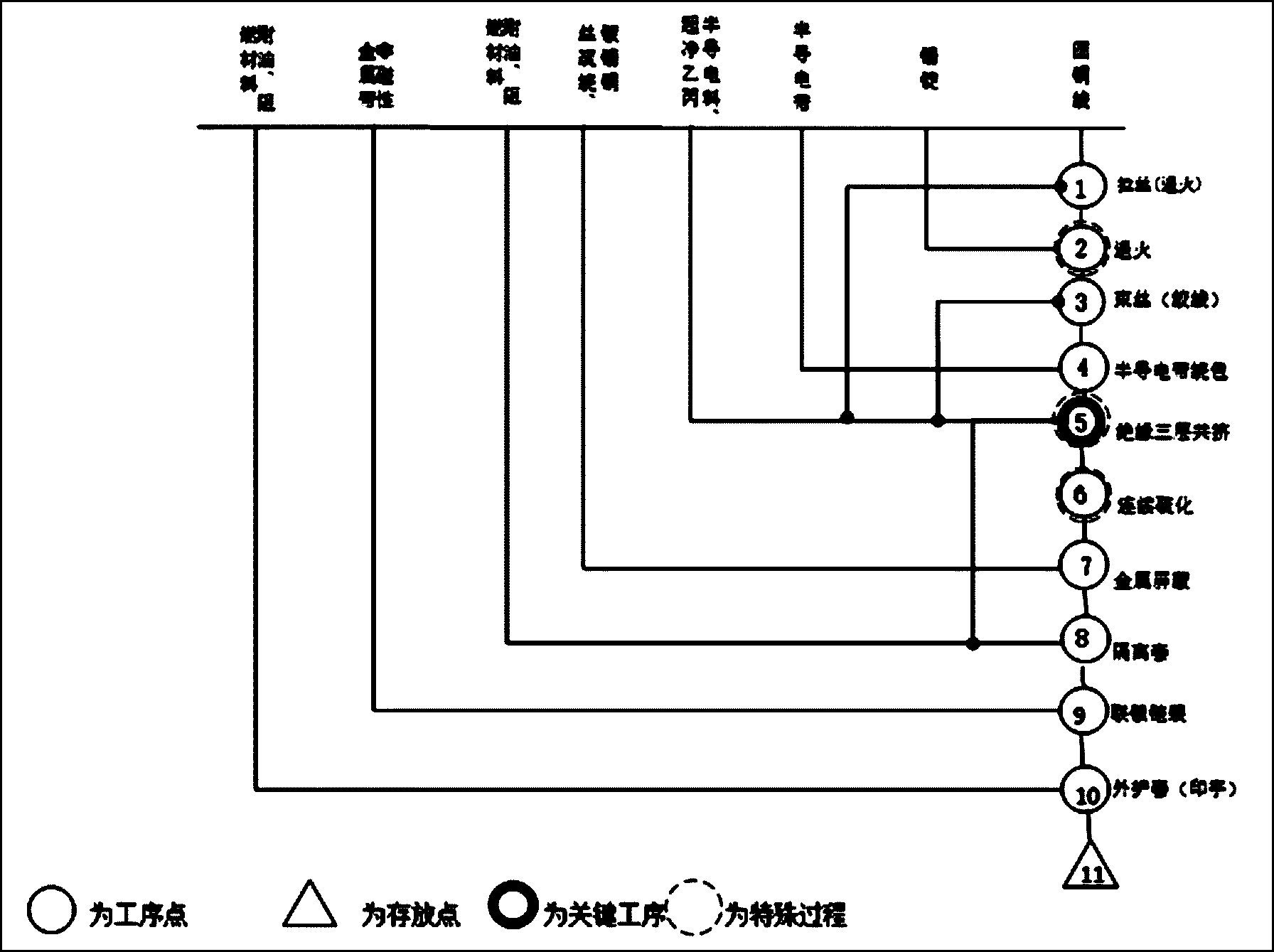

Lightweight flexible LSOH (Low Smoke Zero Halogen) fire-resistant low-voltage marine cable and process flow thereof

InactiveCN104681159ASmall heat insulationImprove insulation performanceFlexible cablesCable/conductor manufactureLow voltageShock resistance

The invention discloses a lightweight flexible LSOH (Low Smoke Zero Halogen) fire-resistant low-voltage marine cable and a process flow thereof. The lightweight flexible LSOH fire-resistant low-voltage marine cable comprises a tin-plated flexible conductor, a ceramic silicone rubber insulating layer, an LSOH flame-retardant filling material, an LSOH wrapping tape layer, an LSOH flame-retardant isolating sleeve, a metal braid armor shielding layer and an LSOH flame-retardant protection sleeve. The cable disclosed by the invention has the advantages of heat insulation, fire insulation, waterproofness, shock resistance, low thermal weight loss, low smoke, zero halogen, flame retardance and the like. In case of a fire, a hard shell formed by the insulating layer can take good effects of flame retardance, fire resistance, fire prevention and fire insulation and effectively ensures smoothness of a line. The cable has the advantages of being flexible, small in size, light in weight and excellent in mechanical property and electrical property, meets the requirement of a complex laying environment in a ship, can effectively save a ship space and reduce a light ship weight of the ship and improves a cargo dead weight of the ship.

Owner:ZHONGTIAN TECH IND WIRE&CABLE SYST CO LTD

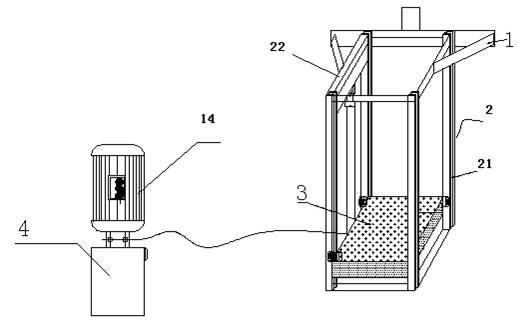

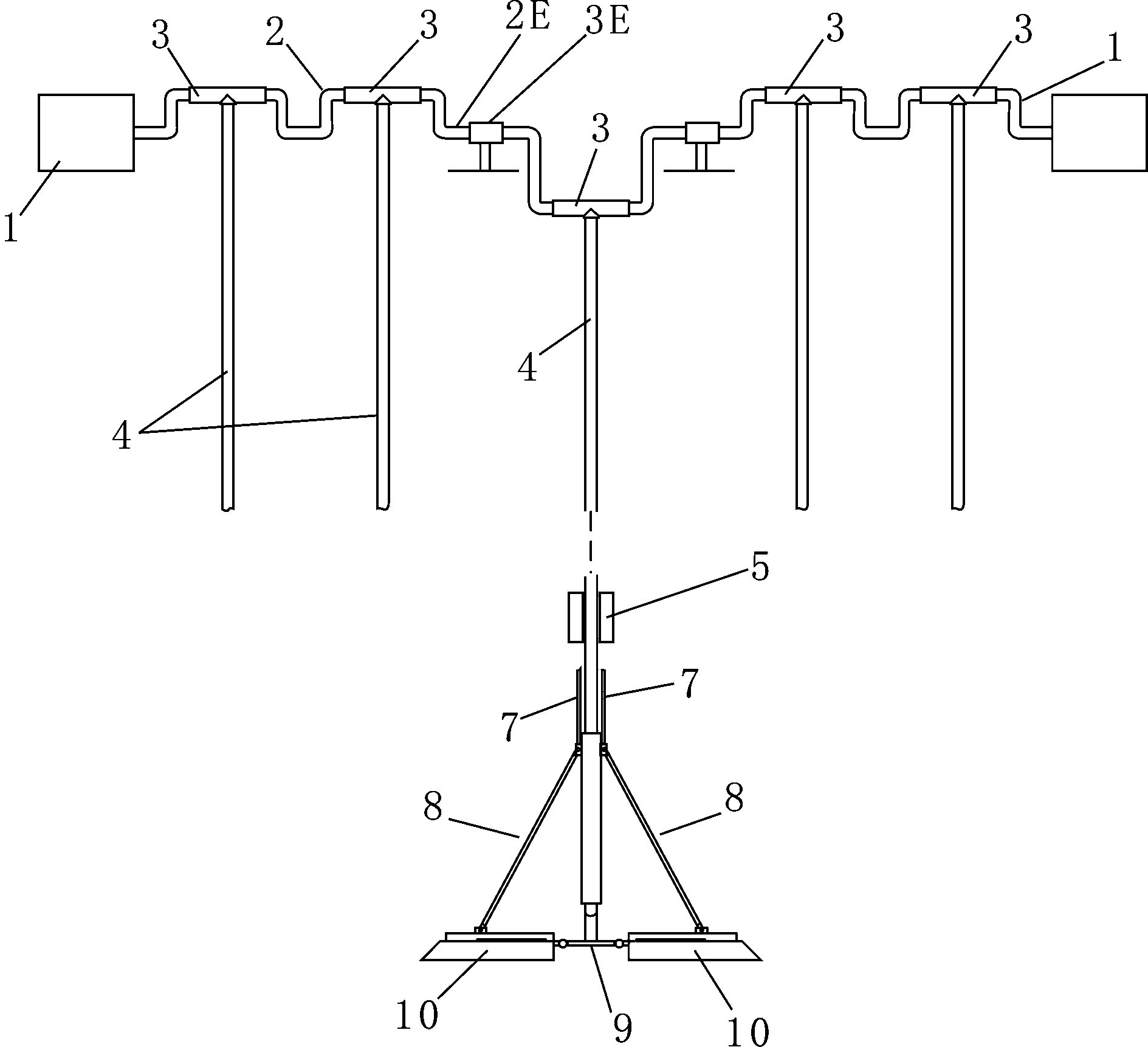

Cargo delivery device for laneway stacking machine as well as cargo sorting and delivering method

The invention discloses a cargo delivery device for a laneway stacking machine as well as a cargo sorting and delivering method. The device comprises upright posts, a cross beam, traveling wheels, a traveling motor, a winch, an electronic control cabinet, vertical sliding rails and a cargo carrying table, wherein the winch comprises a winch motor, a driving roller and traction steel cables; one end of the traction steel cable is connected with the cargo carrying table; lateral rotating plates, gear lifting plates and a partitioning plate are arranged on the cargo carrying table; the lateral rotating plates and the gear lifting plates are connected with a rotation mechanism and a lifting mechanism; and a clamped telescopic cargo fork is mounted on the partitioning plate. The method comprises the following steps: transporting cargoes to a cargo platform from a conveyor belt by adopting the cargo fork when the stacking machine enters into a warehouse and works; putting the cargoes in storage on designated positions of a cargo shelf; transporting the cargoes arranged on the cargo shelf to the cargo carrying table by adopting the cargo fork when the cargoes are delivered out of the warehouse; putting the cargoes on the conveyor belt when the cargoes are delivered so as to ensure that the transportation volume and the transportation efficiency of the stacking machine are high; and due to a variety of the cargoes which are clamped and supported by the cargo fork as well as reasonable and ordered steps of in-warehousing operation and ex-warehousing operations, guarantee is providedfor high-efficiency transportation of the cargoes, and the transportation risk of the cargoes is low.

Owner:无锡承方科技有限公司

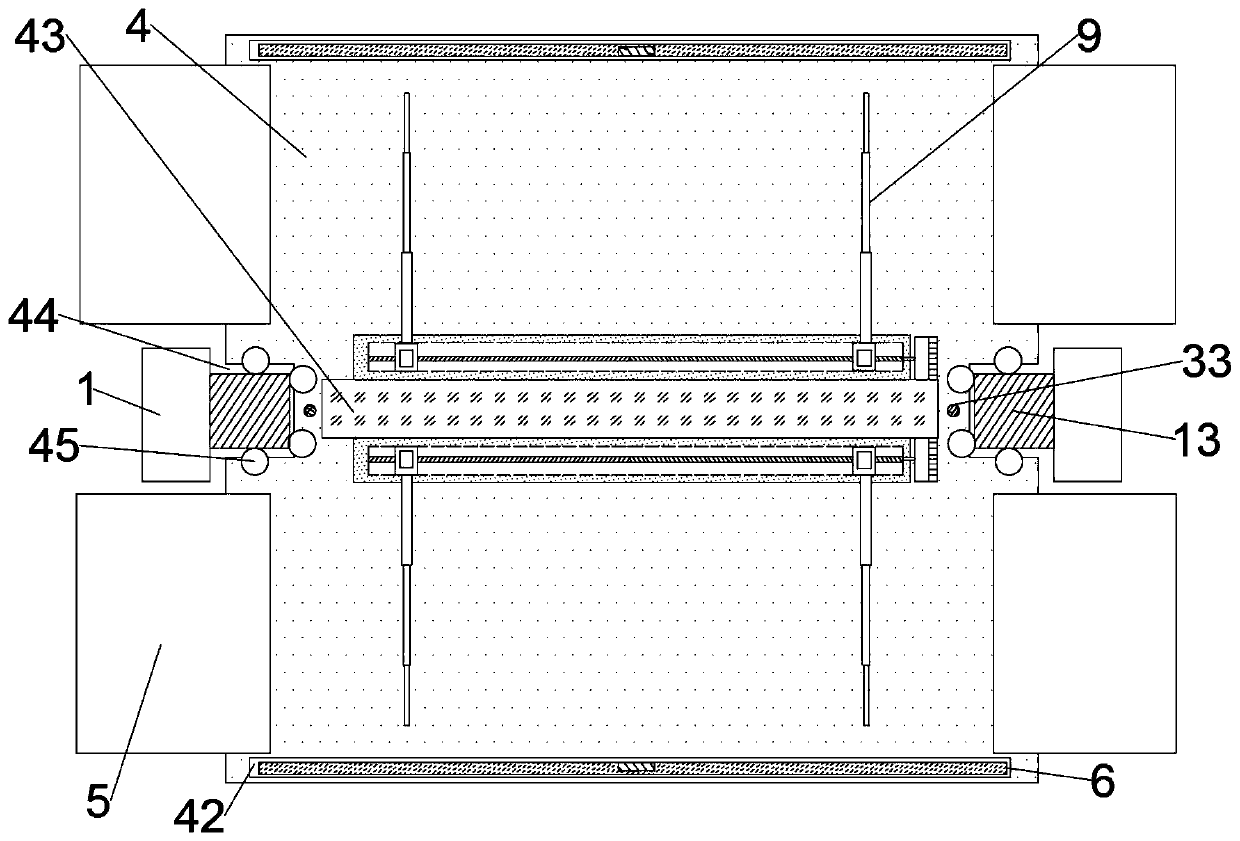

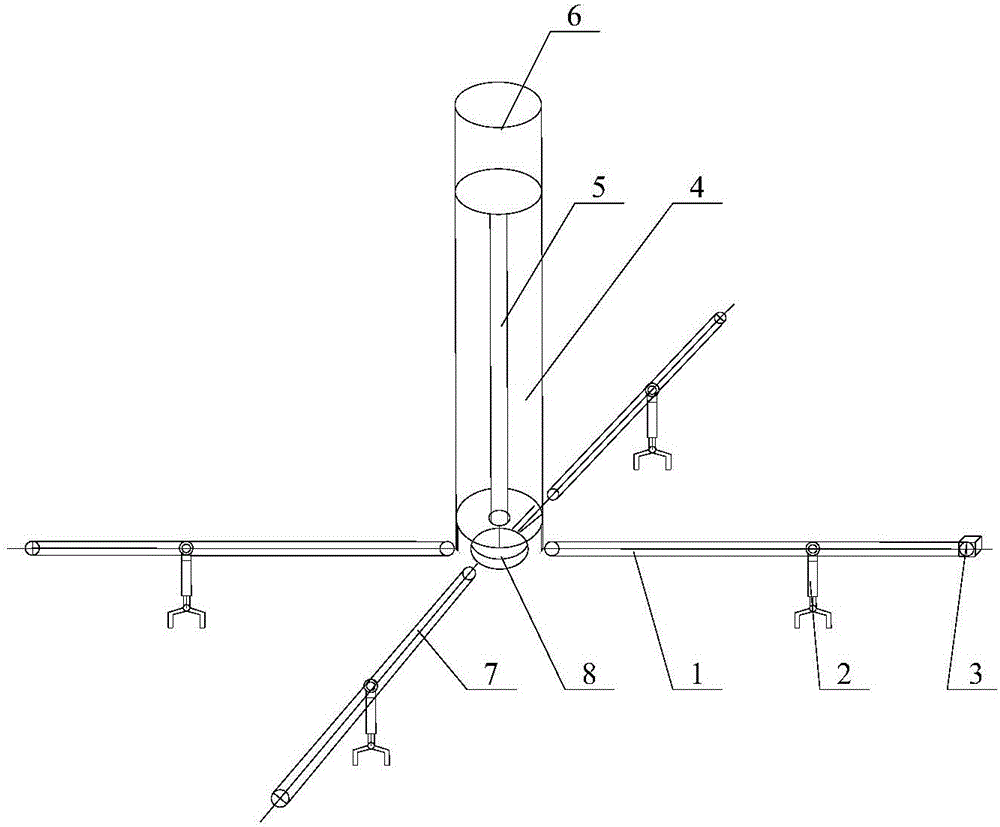

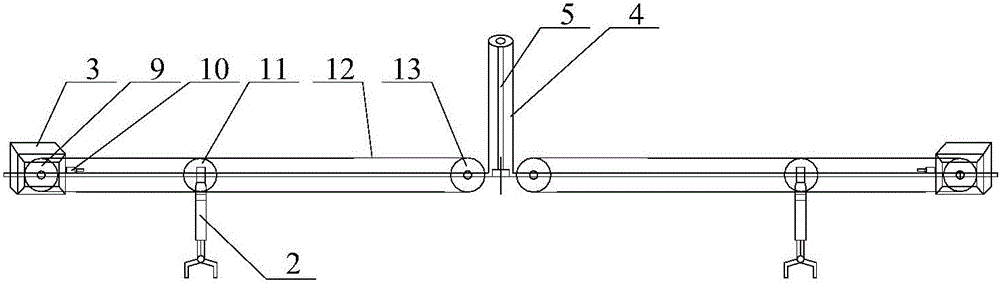

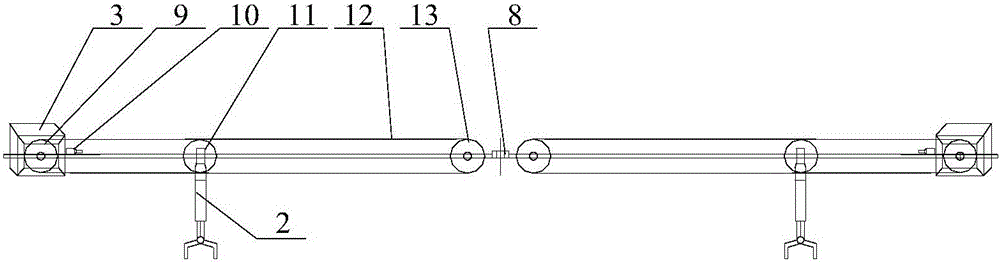

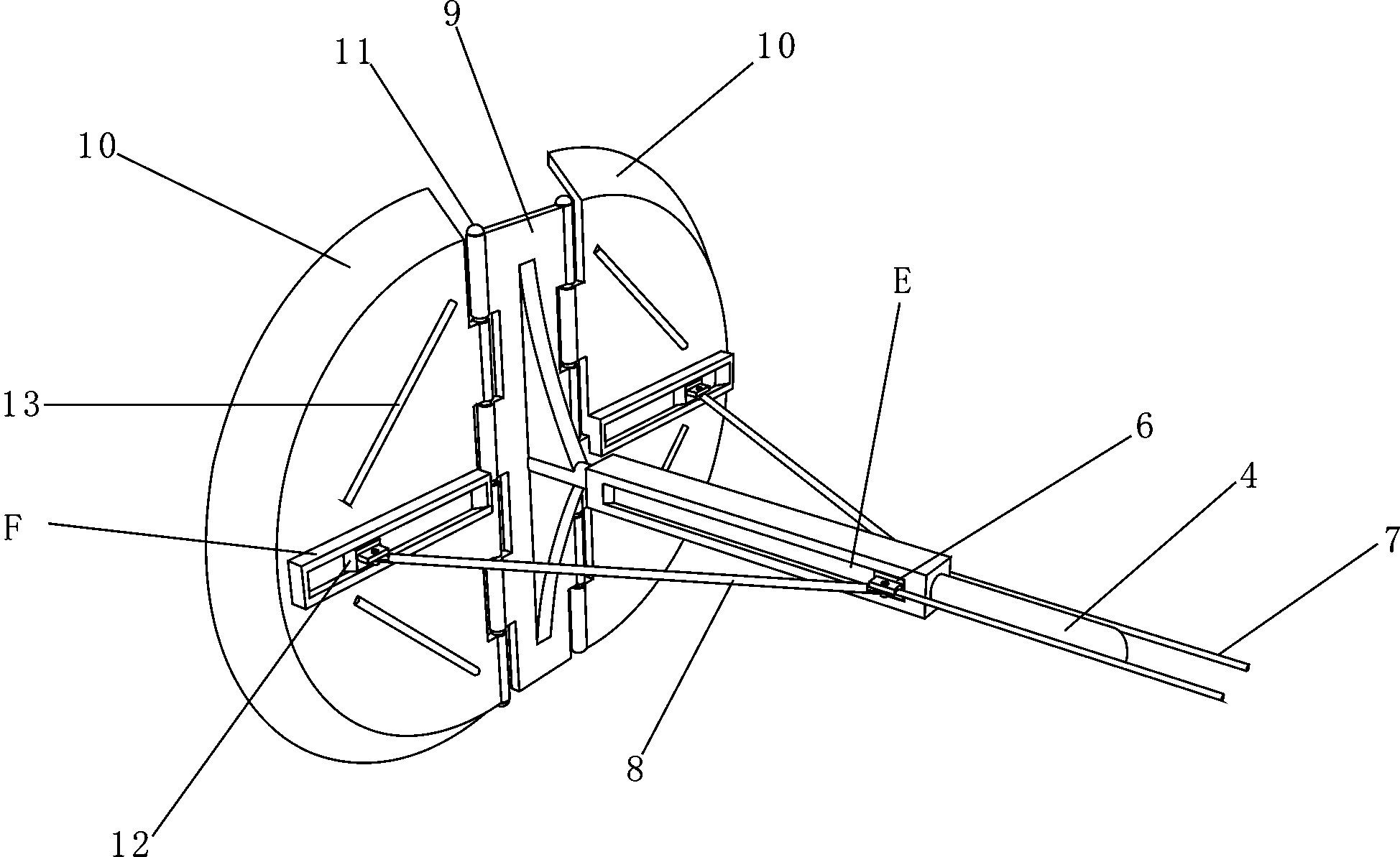

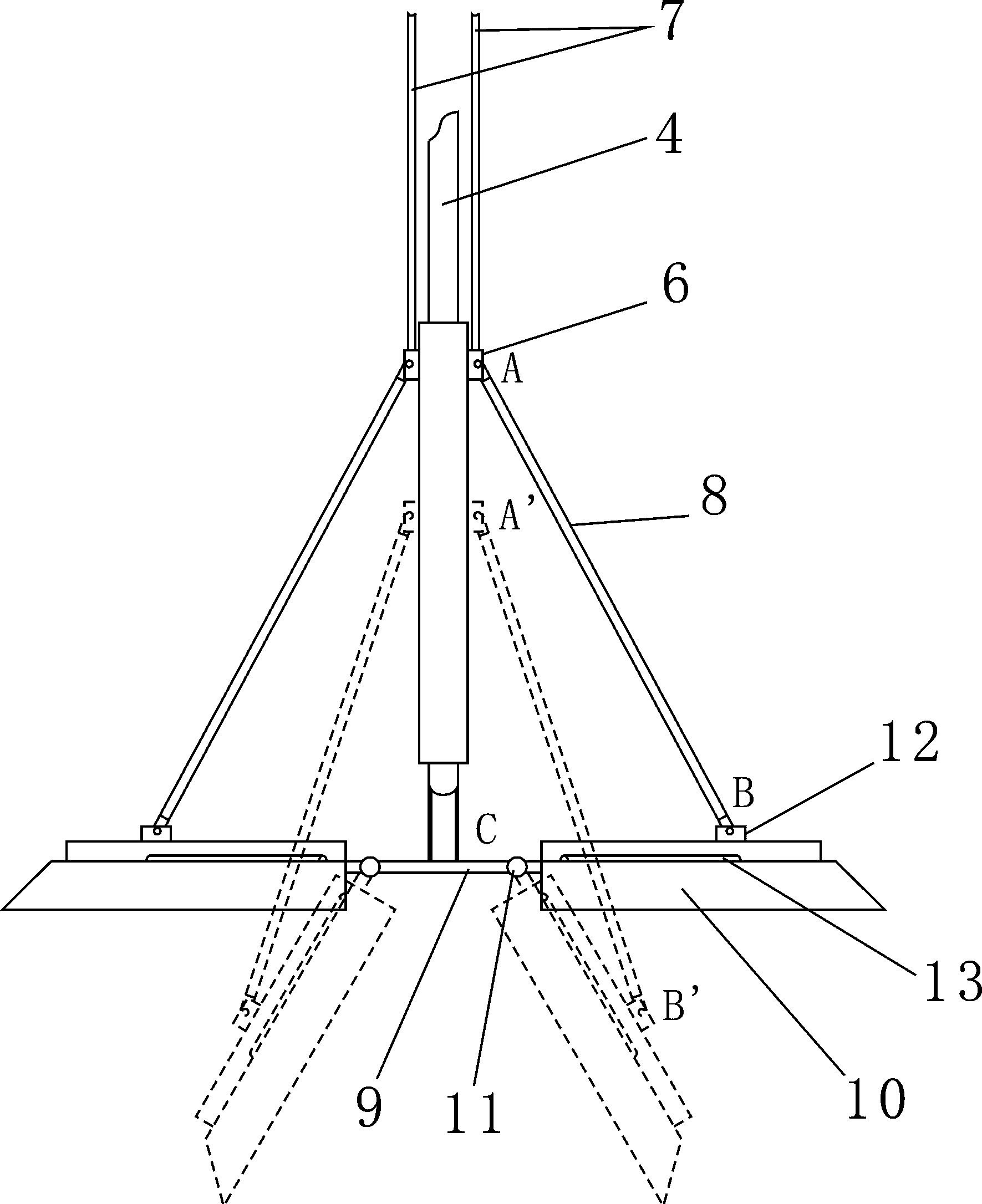

Guide rail type counterweight device and cargo conveying unmanned aerial vehicle

InactiveCN105857610AIncrease cargo capacityImprove delivery efficiencyFreight handlingAircraftsUncrewed vehicleGravity center

The invention discloses a guide rail type counterweight device, which is used for a cargo conveying unmanned aerial vehicle. The guide rail type counterweight device comprises a fixed guide rail and a rotary guide rail, wherein the fixed guide rail is fixedly arranged on a vehicle body of the cargo conveying unmanned aerial vehicle; at least one rotary guide rail is arranged and can rotate relative to the fixed guide rail to form an X-shaped structure with the fixed guide rail; at least one slidable mechanical arm is arranged at each of the parts, located on the two sides of the rotary guide rail, of the fixed guide rail and at each of the parts, located on the two sides of the fixed guide rail, of the rotary guide rail respectively; in a utilization process, cargoes are grasped through the mechanical arms; when the grasped cargoes influence the center of the unmanned aerial vehicle, the rotary guide rail can rotate relative to the fixed guide rail and the mechanical arms slide along the rotary guide rail or the fixed slide rail to overlap the general gravity center of the plurality of cargoes with the gravity center of the cargo conveying unmanned aerial vehicle, so that the cargo conveying unmanned aerial vehicle keeps balance under the condition that the plurality of cargoes are carried; the cargo capacity of the cargo conveying unmanned aerial vehicle is improved so that the cargo conveying efficiency of the cargo conveying unmanned aerial vehicle is improved. The invention further discloses the cargo conveying unmanned aerial vehicle.

Owner:GUANGDONG UNIV OF TECH

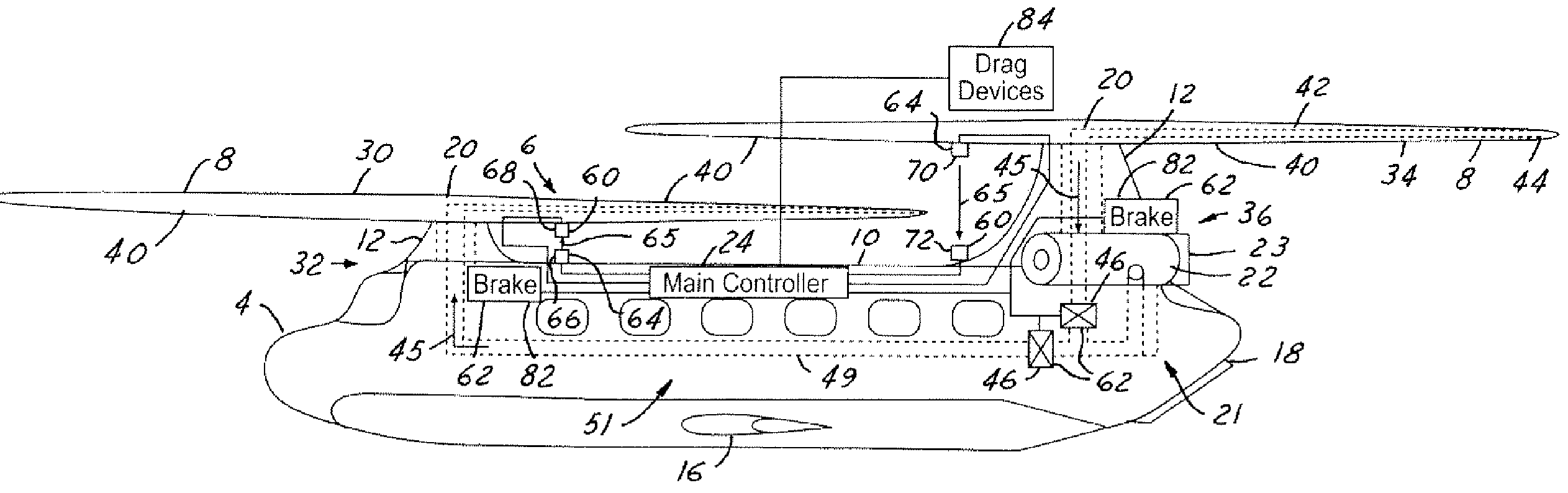

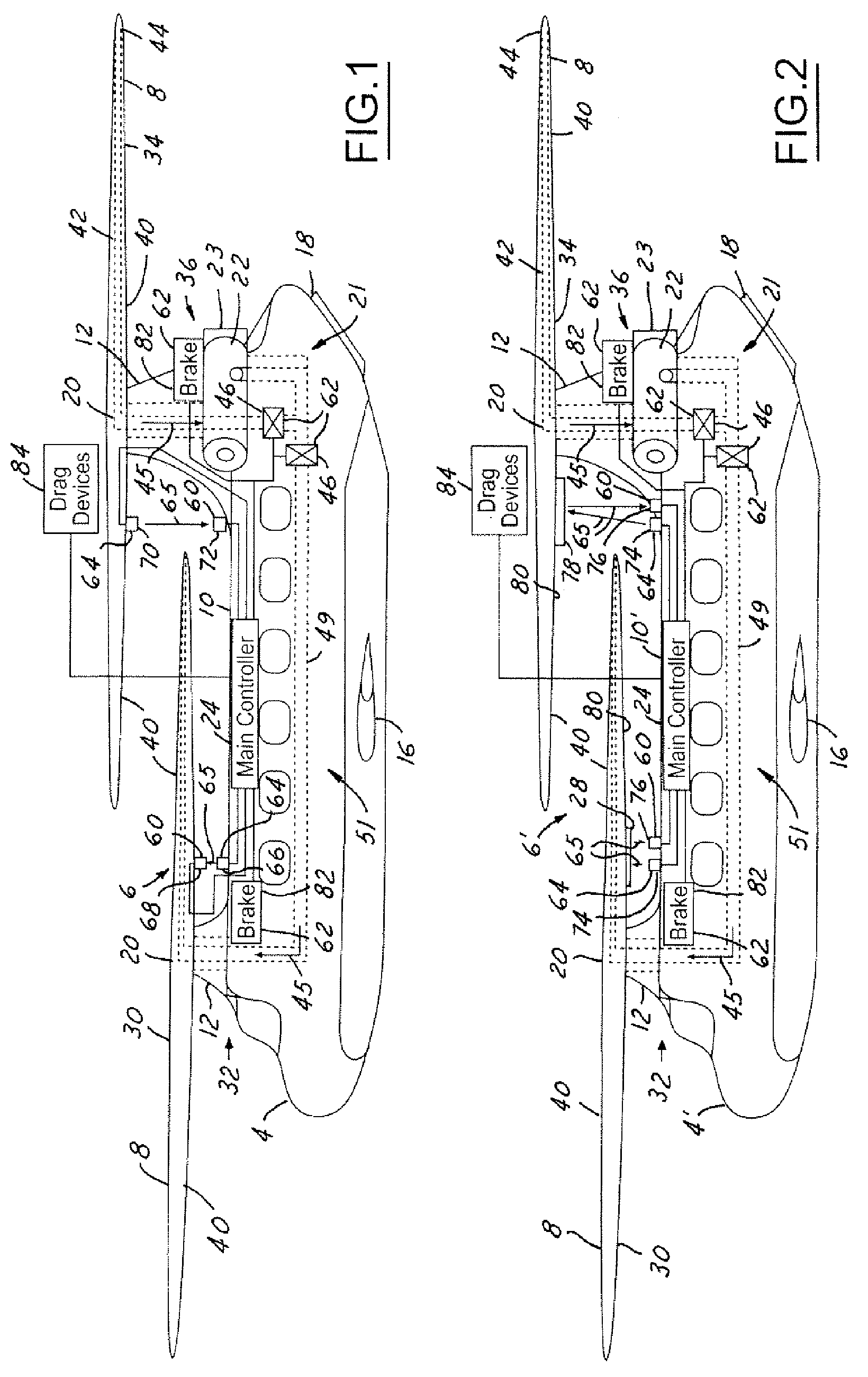

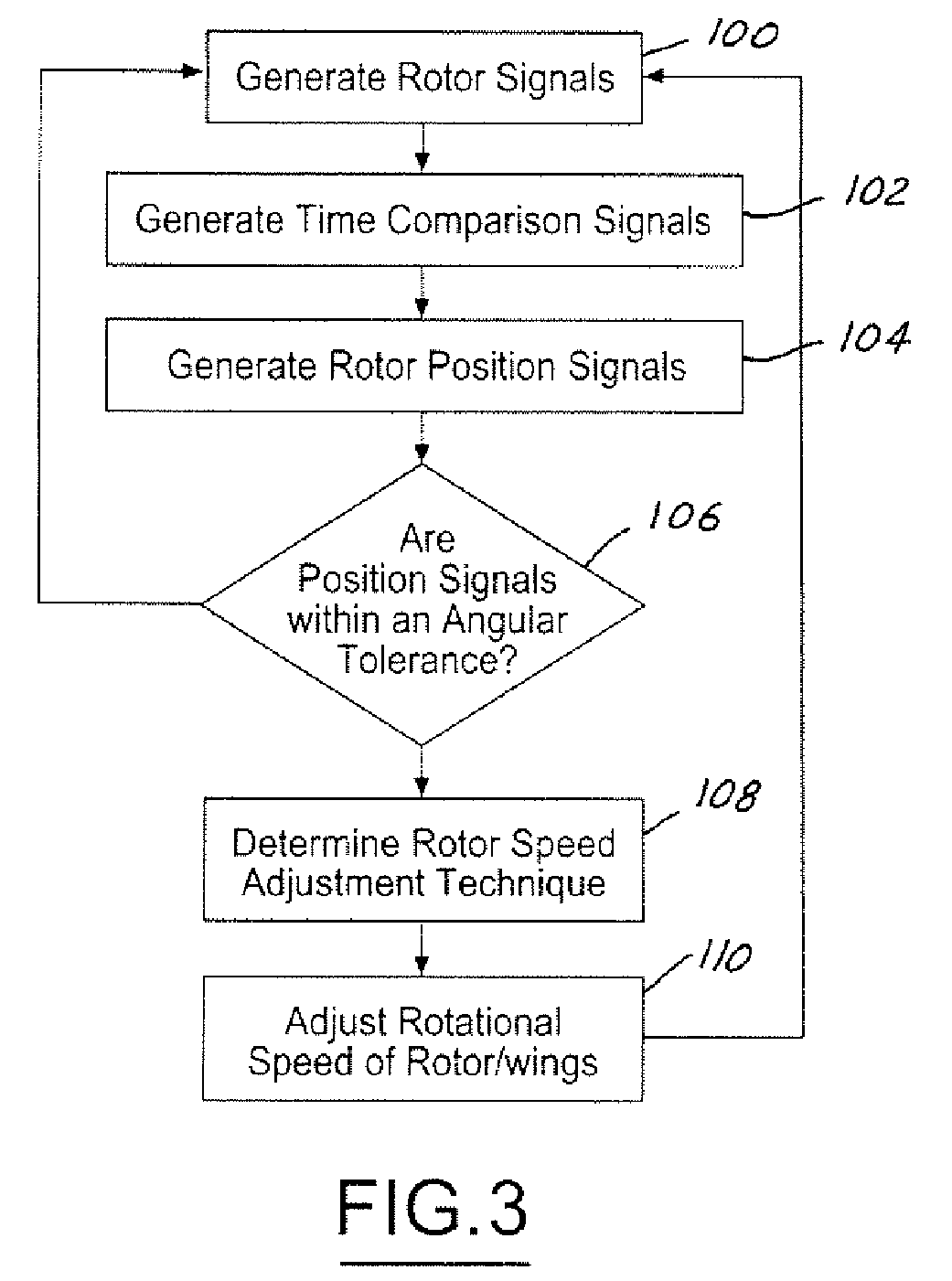

Tandem rotor wing rotational position control system

ActiveUS7546975B2Reduce weightIncrease cargo capacityAircraft navigation controlPropellersEngineeringAirplane

A rotational position-adjusting system (6) for a vertical takeoff and landing aircraft (4). The system (6) includes multiple detectors (60) that generate rotor signals. The rotor signals are indicative of the position of each rotor (8) of the aircraft (4). The rotors (8) provide lift to the aircraft (4). A controller (24) is coupled to the detectors (60) and adjusts the rotational speed of one or more of the rotors (8) in response to the rotor signals.

Owner:THE BOEING CO

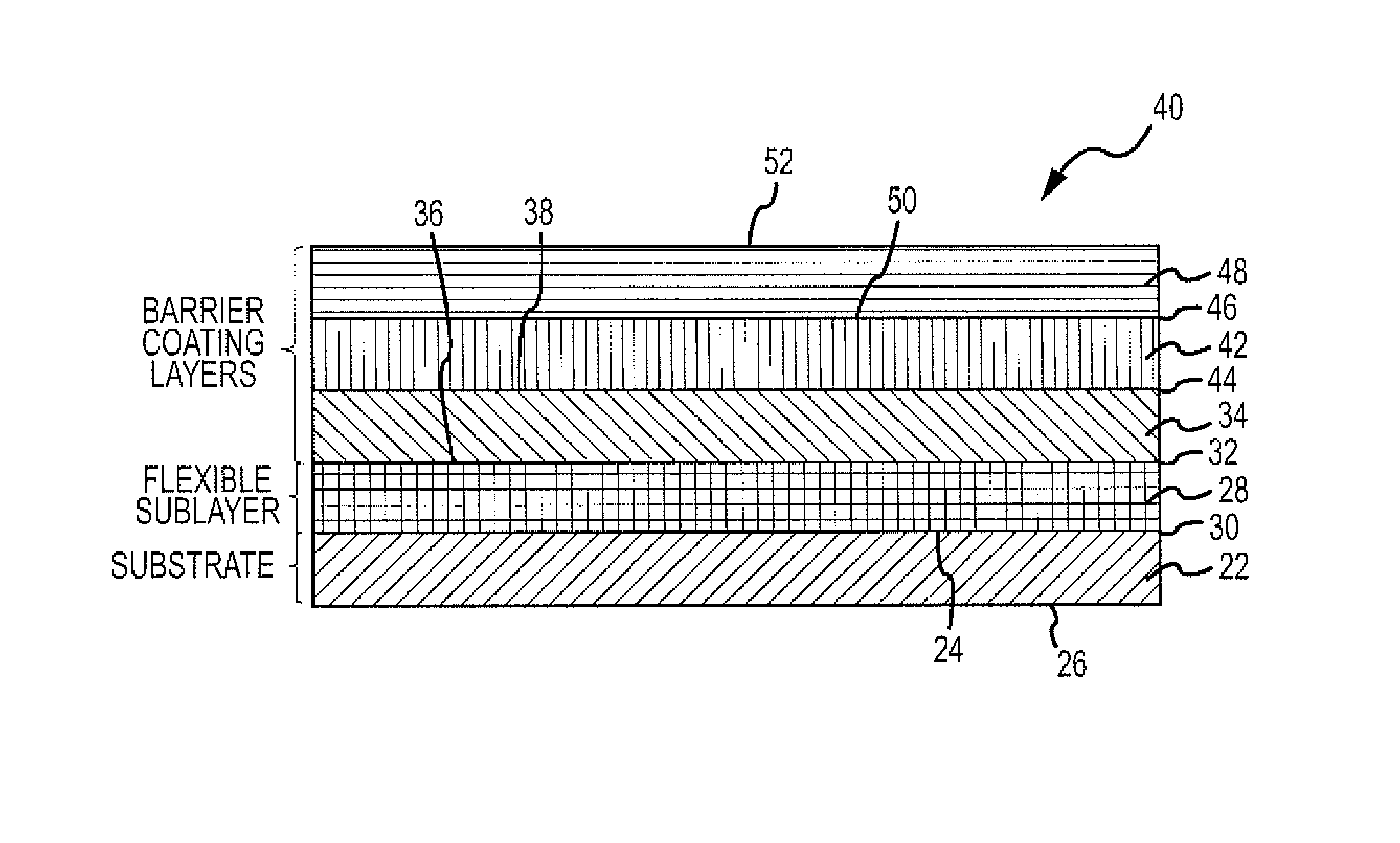

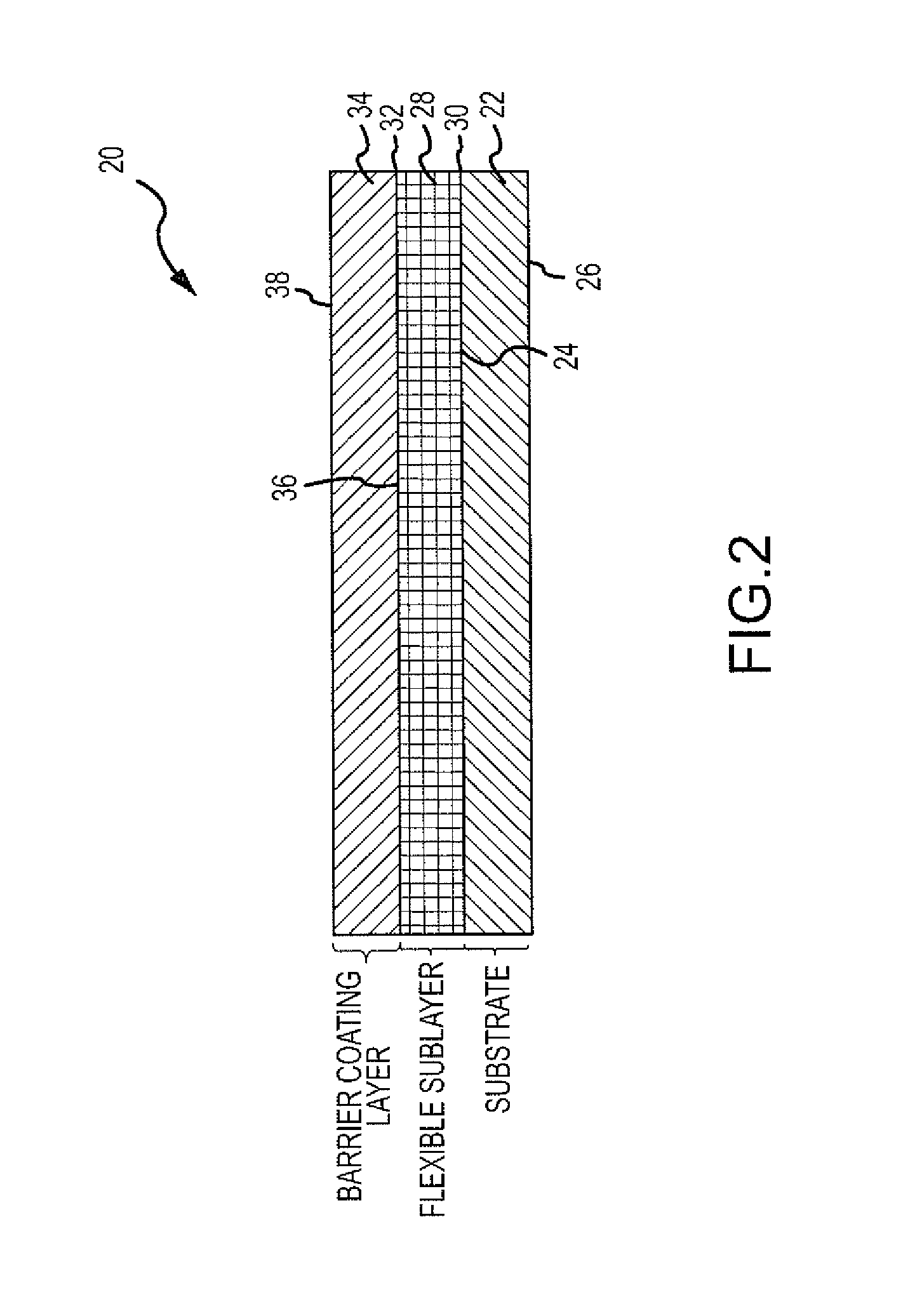

Dense barrier-coating system and method

ActiveUS8778498B1Reduce heat transferReduce the temperatureLamination ancillary operationsSynthetic resin layered productsCoating systemMetallic materials

The disclosure provides for a system and method for dense barrier coatings for oxidation protection. In an embodiment of the disclosure, there is provided a dense barrier-coating system for use with a dry polymer-matrix composite (PMC) substrate having a first coefficient of thermal expansion. The system comprises a flexible sublayer free of water, wherein a first surface of the flexible sublayer is bonded to a first surface of the PMC. The system further comprises an oxygen-impervious, dense barrier-coating layer, wherein a first surface of the oxygen-impervious, dense barrier-coating layer is bonded to a second surface of the flexible sublayer, and further wherein the oxygen-impervious, dense barrier-coating layer is selected from the group consisting of metallic materials and ceramic materials each having a respective second coefficient of thermal expansion. The flexibility of the flexible sublayer protects the respective bonds when the first and second coefficients of thermal expansion are unequal.

Owner:THE BOEING CO

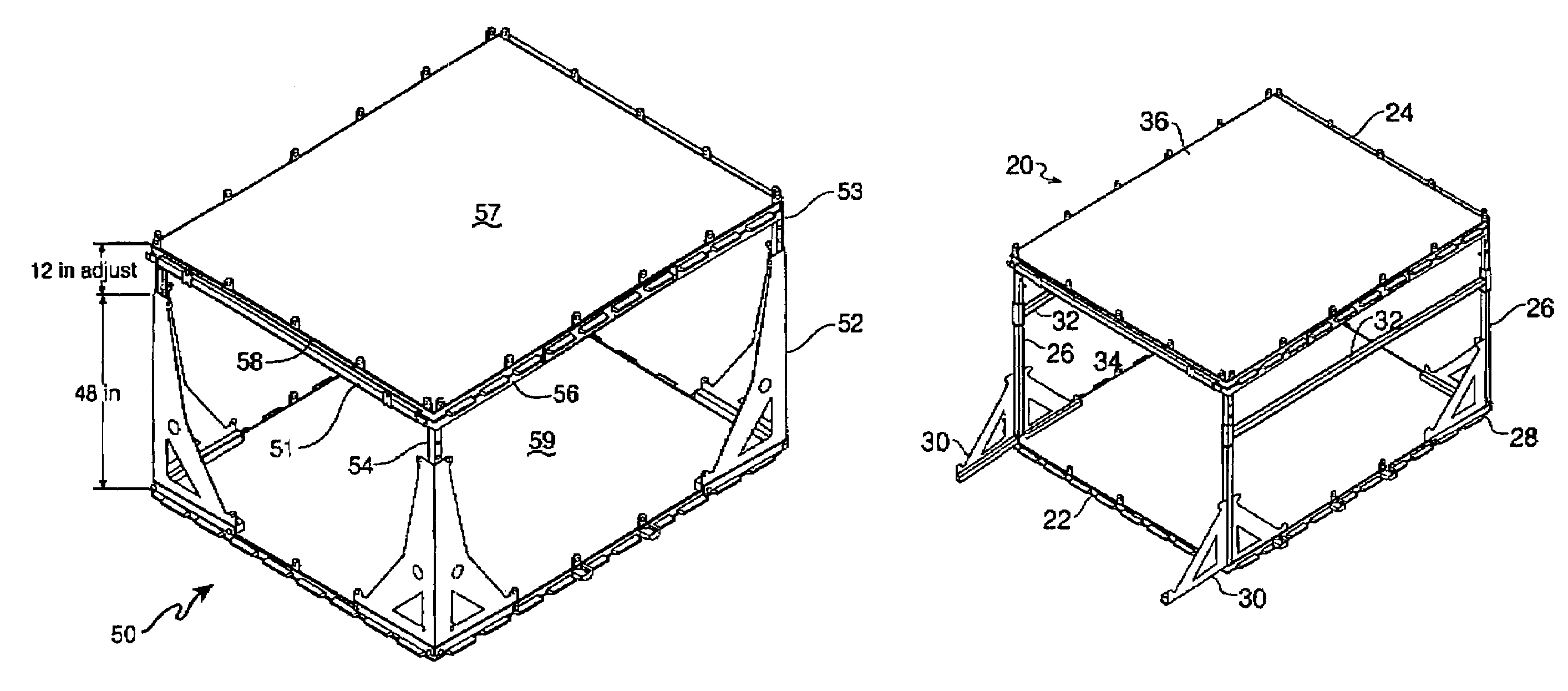

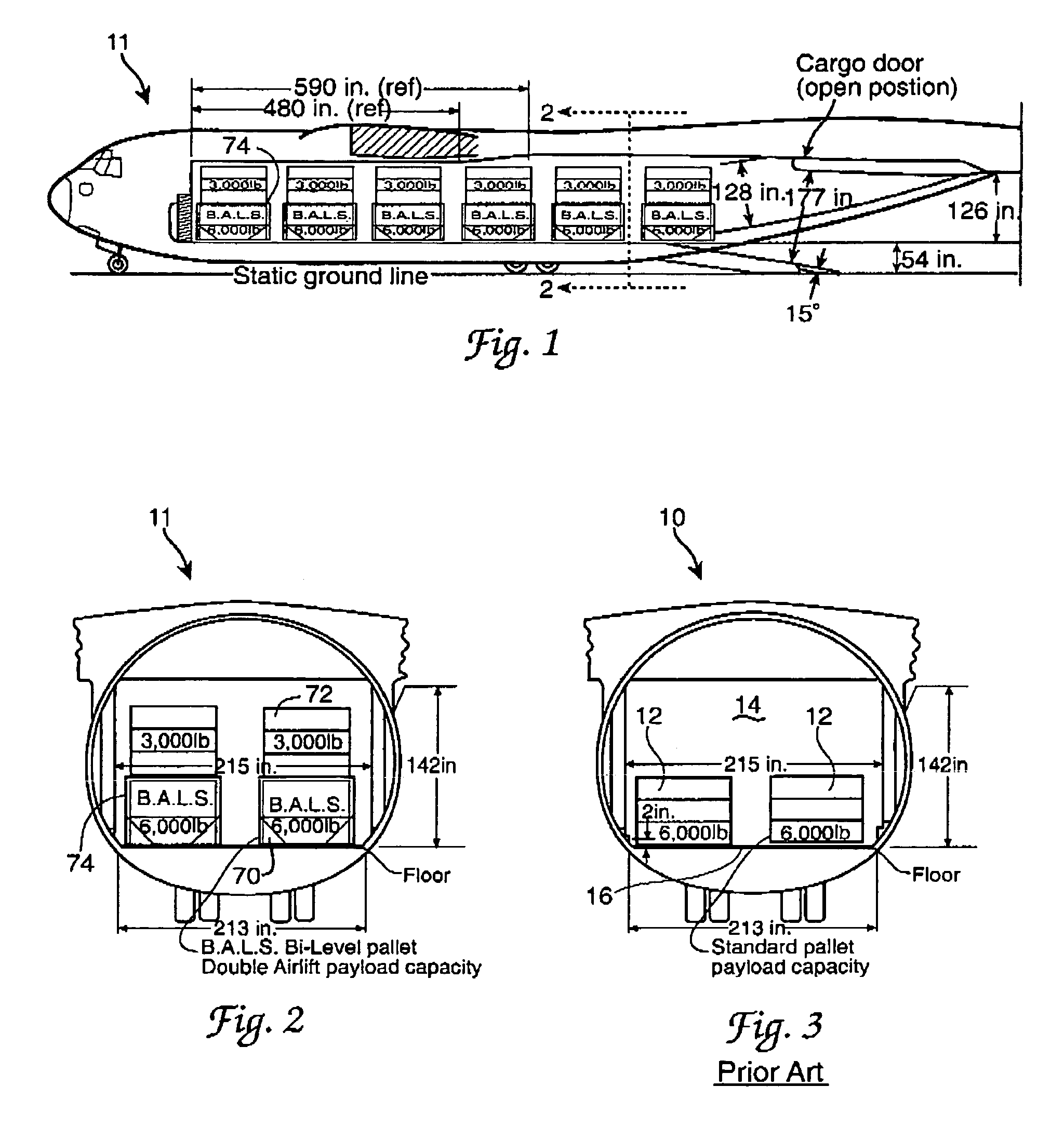

Increasing cargo loading of vehicles

InactiveUS7258231B1Reduce in quantityConsiderable loadLarge containersOther accessoriesCarrying capacityAirplane

Provided is a bi-level pallet assembly wherein a pallet is mounted over another on posts supported by corner braces or on posts supported by panels therebetween so that the two pallets are married bunk-bed style together. Cargo is stored on each of the upper and lower pallets and driven by a forklift onto a cargo aircraft to double the normal cargo carrying capacity of such aircraft by utilizing formerly unused space above the first level of cargo. The bi-level pallet assembly of the invention can potentially double the cargo capacity of such aircraft and free up cargo aircraft to meet other demands with a considerable savings of dollars over traditional deployment costs.

Owner:THE GOVERNMENT OF THE US SEC THE AIR FORCE

Hopper Car Gate with a Laterally Opening Door

ActiveUS20100107924A1Cargo carry capacity of be greatly increasedFacilitate dischargeHopper carsWagons/vansCar doorEngineering

Owner:AERO TRANSPORTATION PRODS

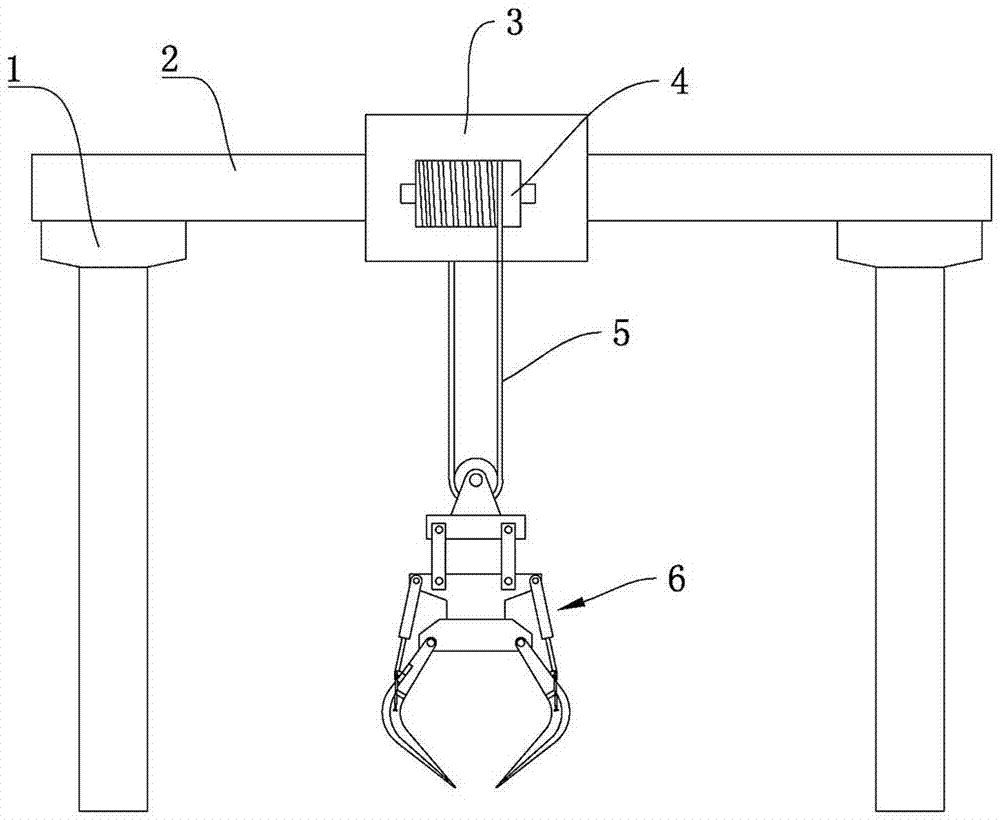

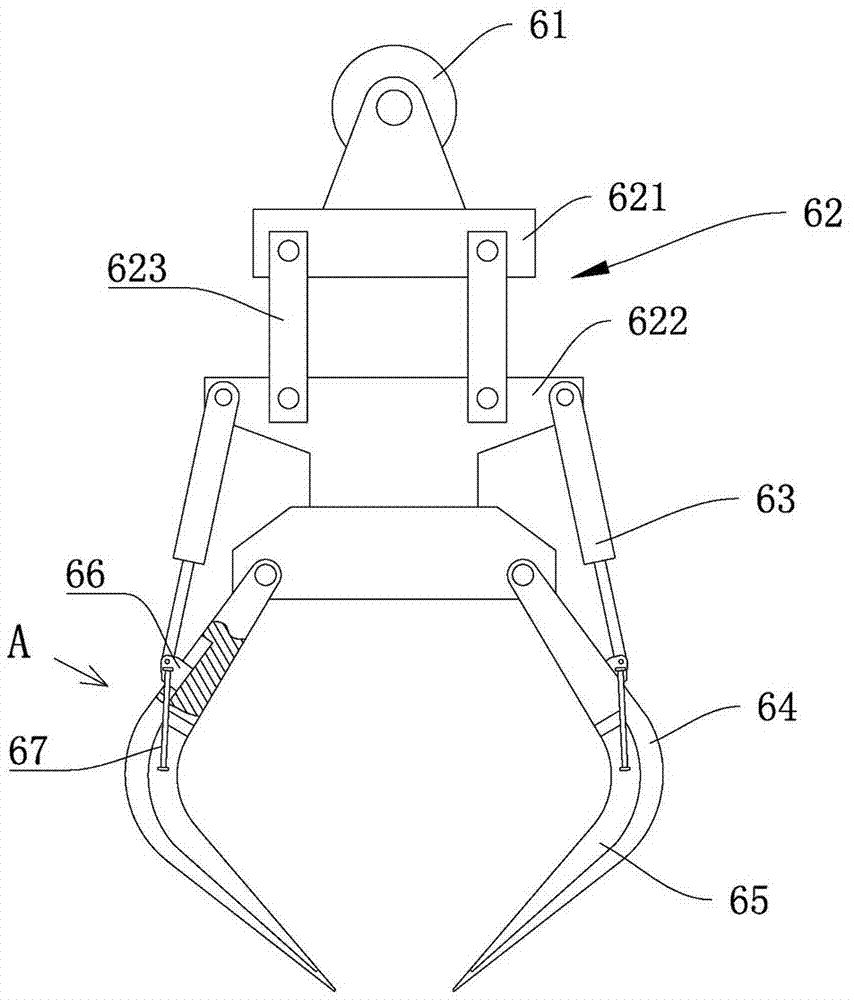

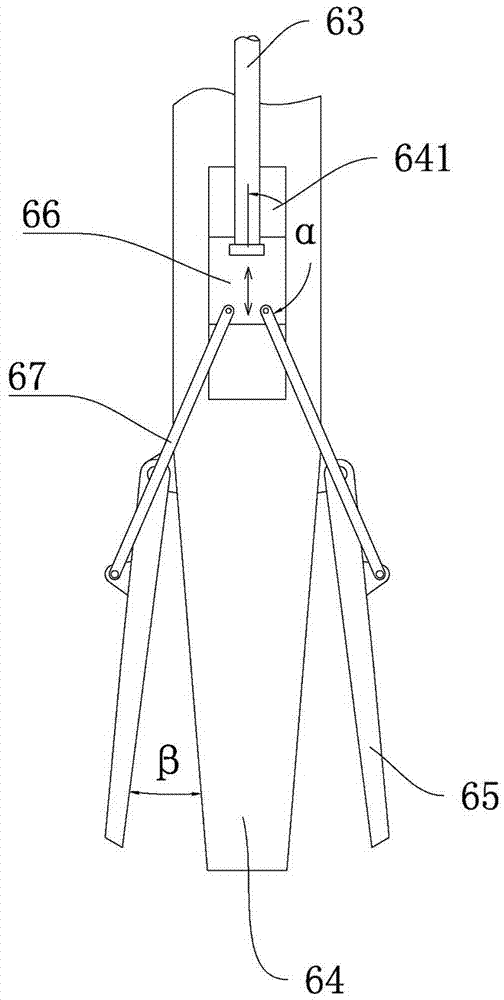

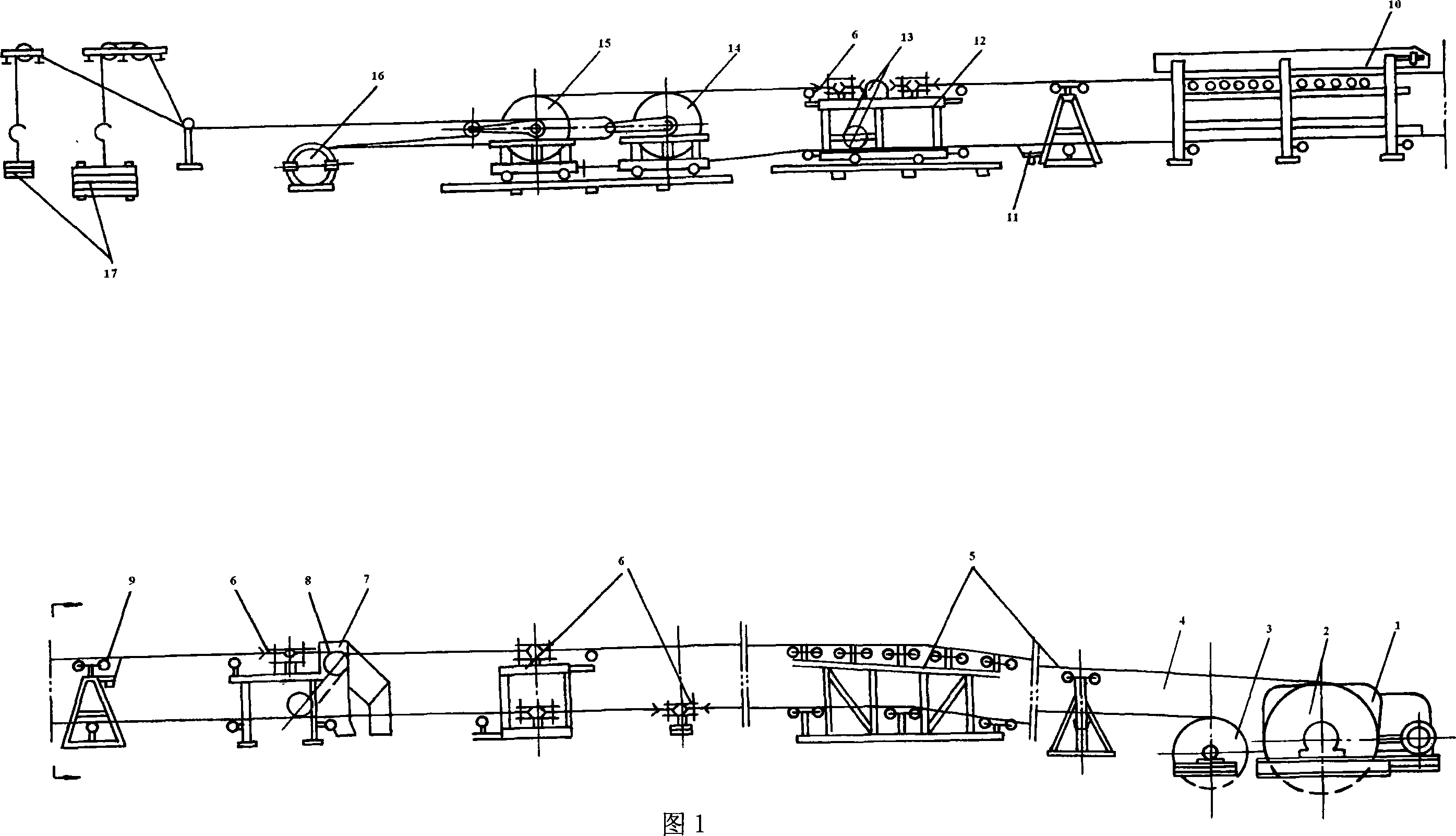

Garbage grab bucket crane

PendingCN108002243AQuick releaseImprove cleaning efficiencyTrolley cranesLoad-engaging elementsHydraulic cylinderEngineering

The invention relates to a garbage grab bucket crane which comprises a track beam, a main beam, a travelling car and a hoisting device, wherein the hoisting device comprises a lifting drum, a grab bucket and a steel wire rope; the grab bucket comprises a support, a claw arm and a hydraulic cylinder; a movable block is arranged at the upper end of the support; one end of the steel wire rope is wound on the lifting drum; the other end of the steel wire rope bypasses the movable block to be fixedly connected onto the travelling car; at least one side of the claw arm is provided with a side claw;a linkage mechanism is arranged between the claw arm and the side claw; the hydraulic cylinder pushes the claw arm to swing through the linkage mechanism and pushes the side claw to swing; and when the claw arm is closed up or stretched out, the side claw is enabled to be stretched out or closed up in the lateral direction of the claw arm. The garbage grab bucket crane increases the grabbing areaof the claw arm and the grabbing amount of the grab bucket; in addition, a fixed pulley mechanism is adopted between the grab bucket and the lifting drum, and part of weight of the grab bucket is dispersed on the travelling car to enable the steel wire rope to bear larger weight, so that the cargo dead weight of the crane is increased, the operating power of the lifting drum is reduced and the garbage cleaning efficiency is improved.

Owner:浙江邦博机械有限公司

Nanoparticles for protein drug delivery

InactiveUS7604795B1Easy to transportReduce resistanceNervous disorderIn-vivo radioactive preparationsNanoparticleMedicine

The invention discloses the nanoparticles composed of chitosan, poly-glutamic acid, and at least one protein drug or bioactive agent characterized with a positive surface charge and their enhanced permeability for paracellular protein drug and bioactive agent delivery.

Owner:NANOMEGA MEDICAL CORP

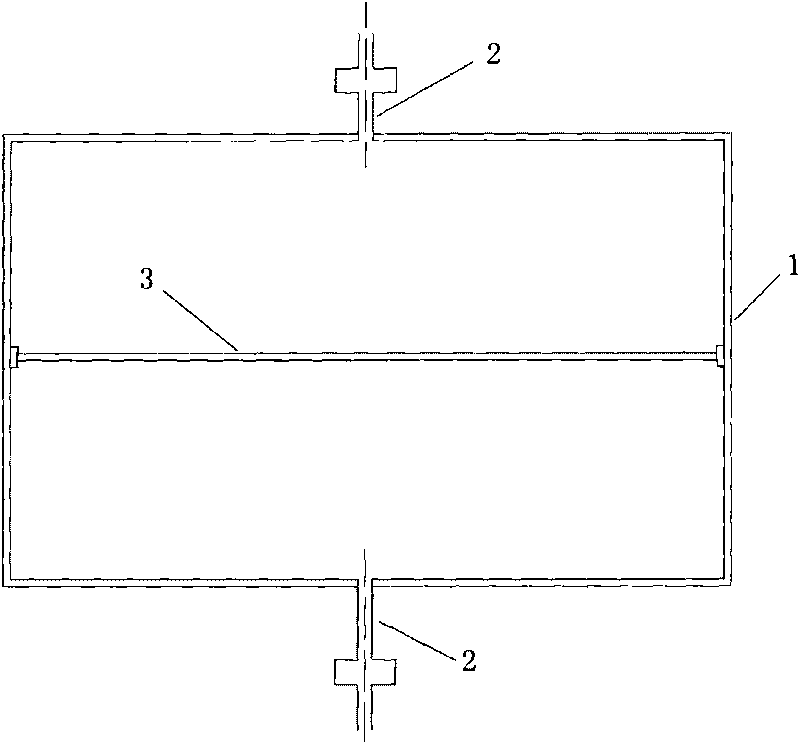

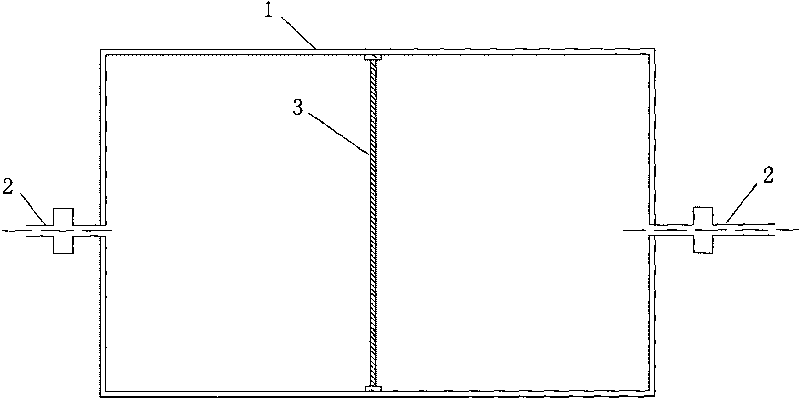

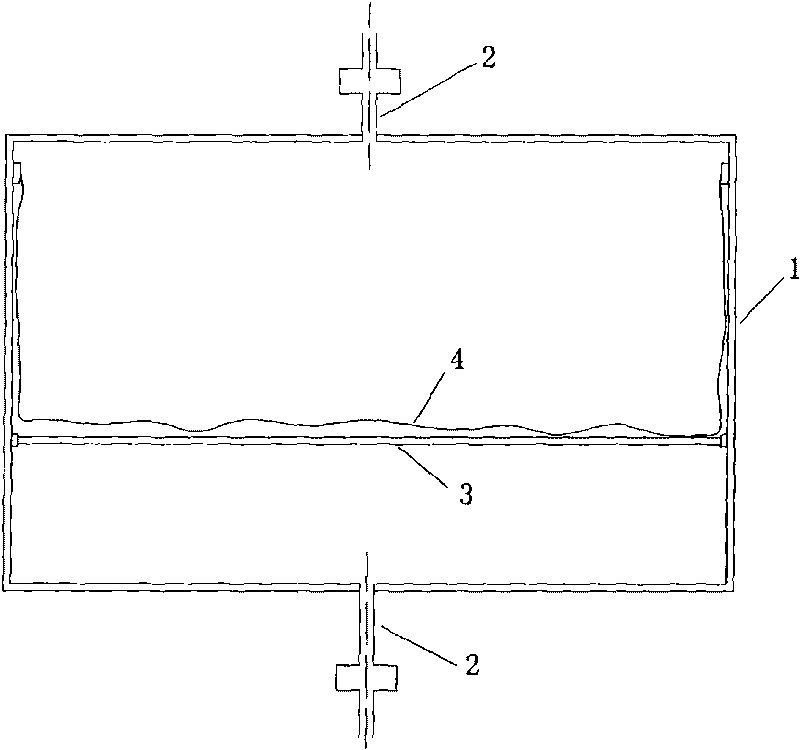

Oil-water composite cabin for ship

InactiveCN101700806ASimple structureCompact layoutHull interior subdivisionEconomic benefitsOil water

The invention relates to an oil-water composite cabin for a ship, comprising a liquid cabin and perfusion pipelines. A separation unit is arranged in the middle of the liquid cabin, is in watertight match with the cabin wall of the liquid cabin and separates the liquid cabin into two parts; and the perfusion pipelines are respectively arranged in and communicated with the liquid cabins at both sides of the separation unit which moves towards both sides or stretches or withdraws along with the volume variance of liquid at both sides. The oil-water composite cabin for a ship realizes the composite use of any functional liquid cabin on the ship, integrates economic benefits and environment-friendly benefits, has simple structure, compact arrangement and convenient production, processing and daily maintenance and can be widely applied to various ships and ocean structural objects with liquid cabins.

Owner:NAVAL UNIV OF ENG PLA

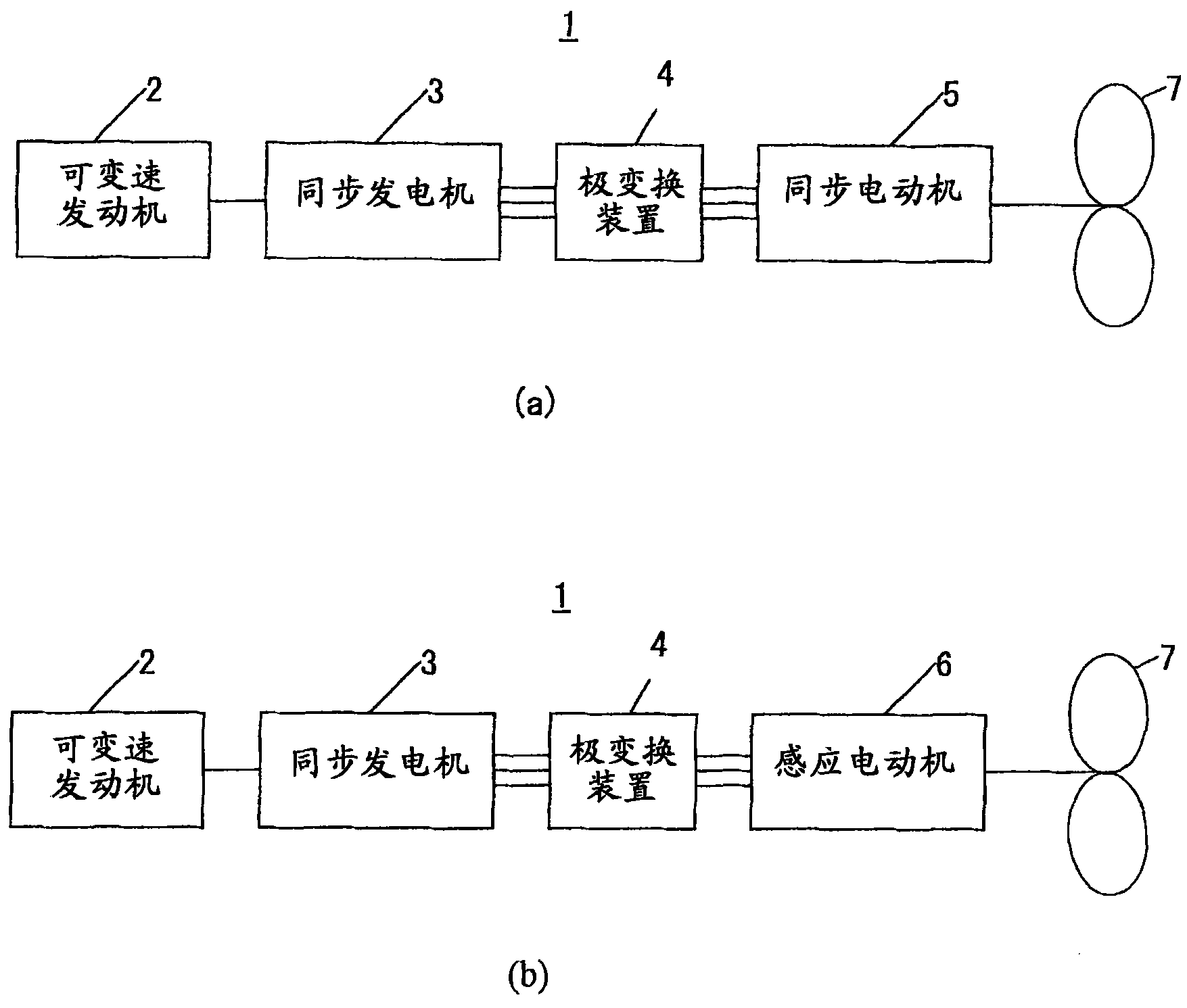

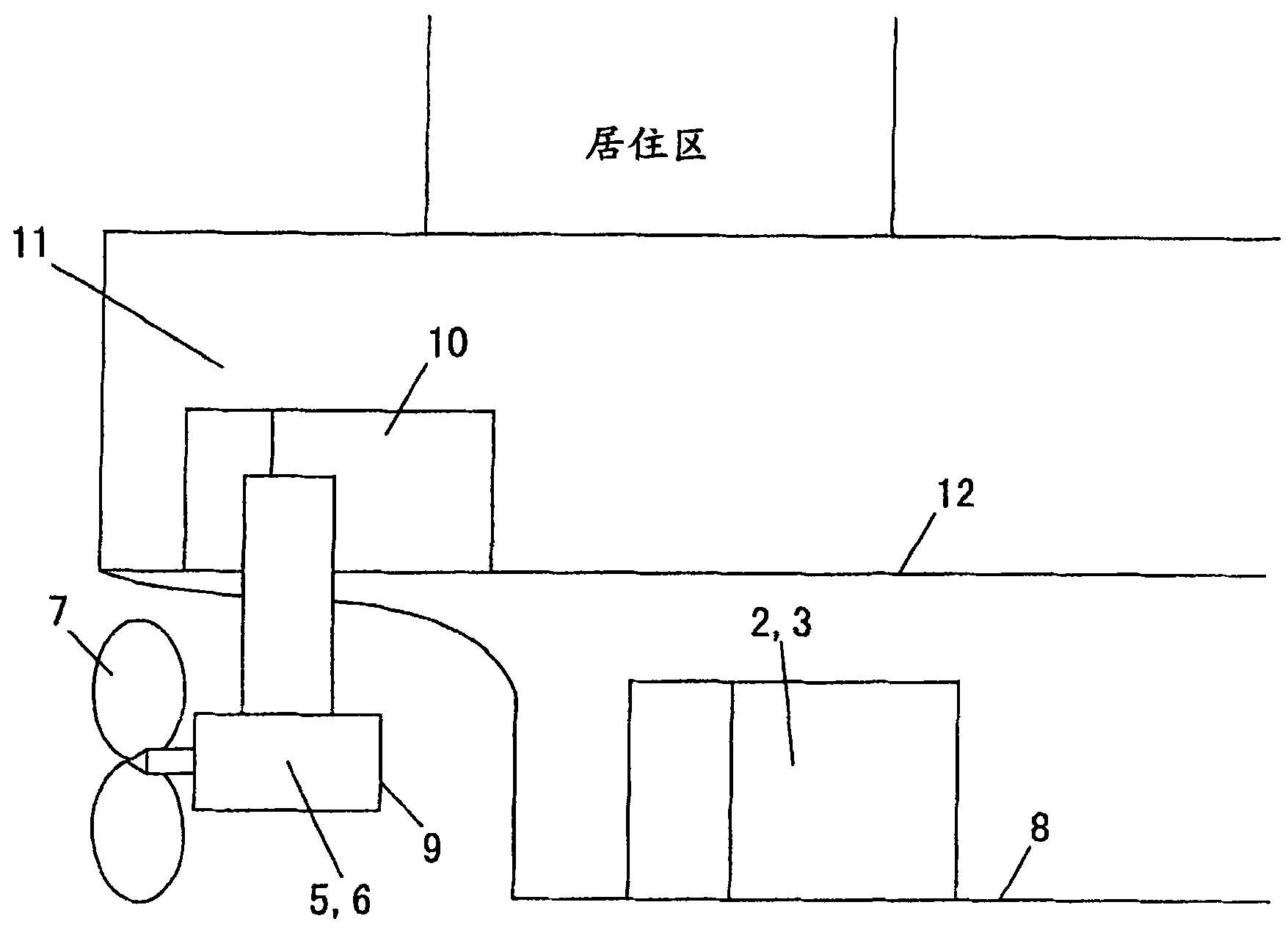

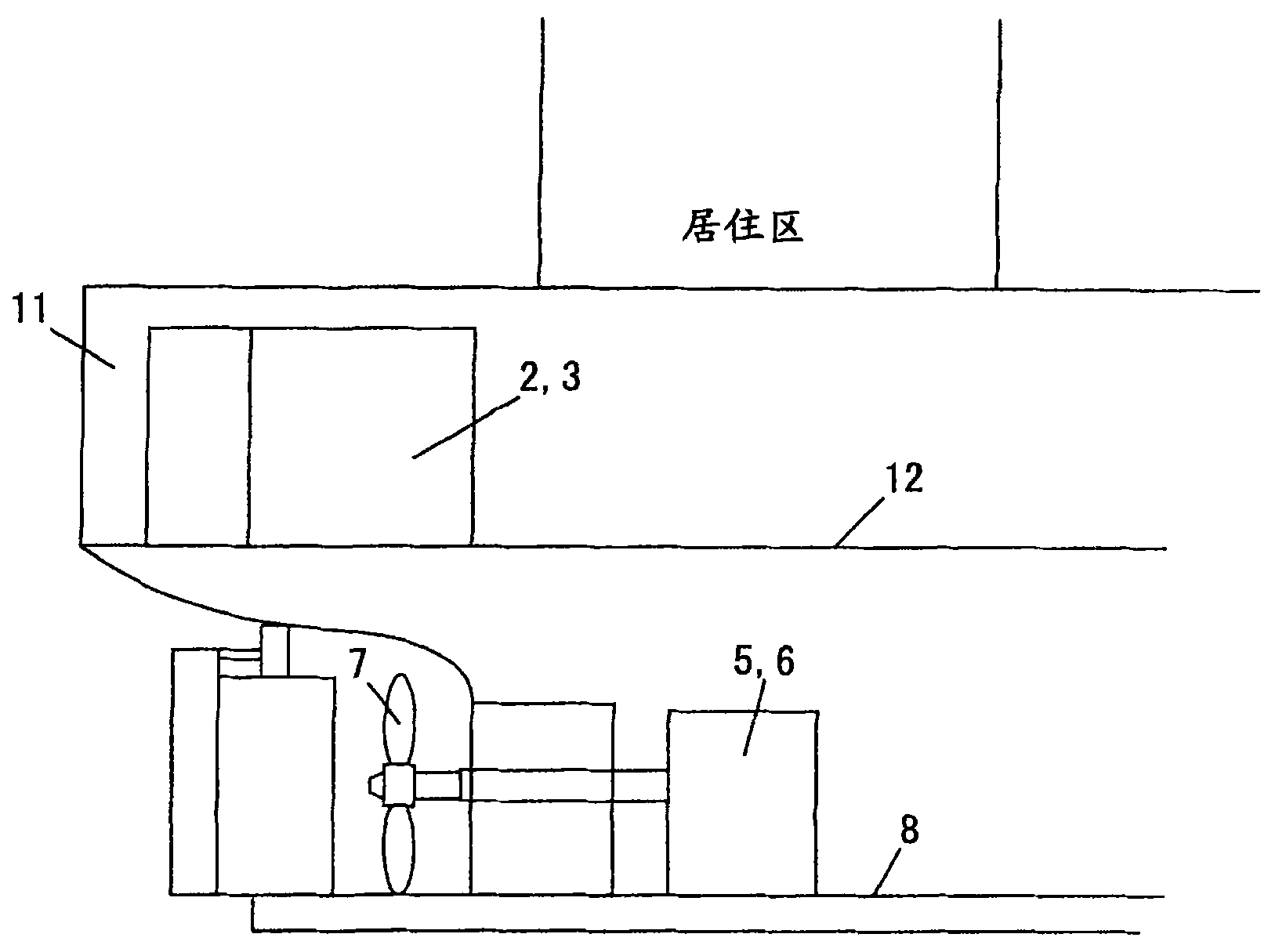

Electric propulsion system for ships

InactiveCN101857082AIncrease volumeAvoid the problem of poor combustionPropulsion power plantsPropulsive elementsElectricitySynchronous motor

There is provided an electric propulsion system for a ship in which the cargo capacity of the ship is enhanced while the ship speed of the dead slow or less can be controlled. The electric propulsion system includes a variable speed engine (2), a synchronous generator (3) that generates electricity by the variable speed engine, an induction motor (6) that is connected to the synchronous generator, and a fixed-pitch propeller (7) that is driven by the induction motor.

Owner:DAIICHI ELECTRIC

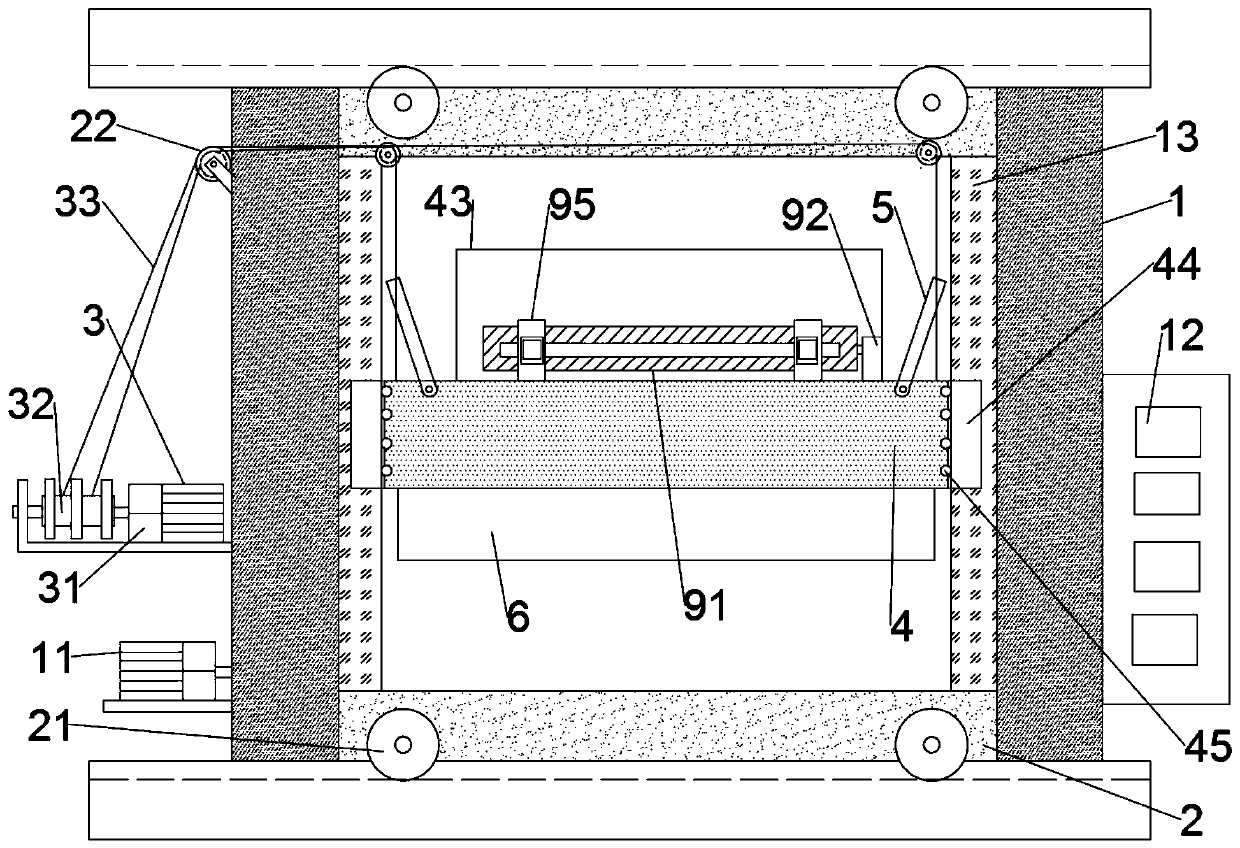

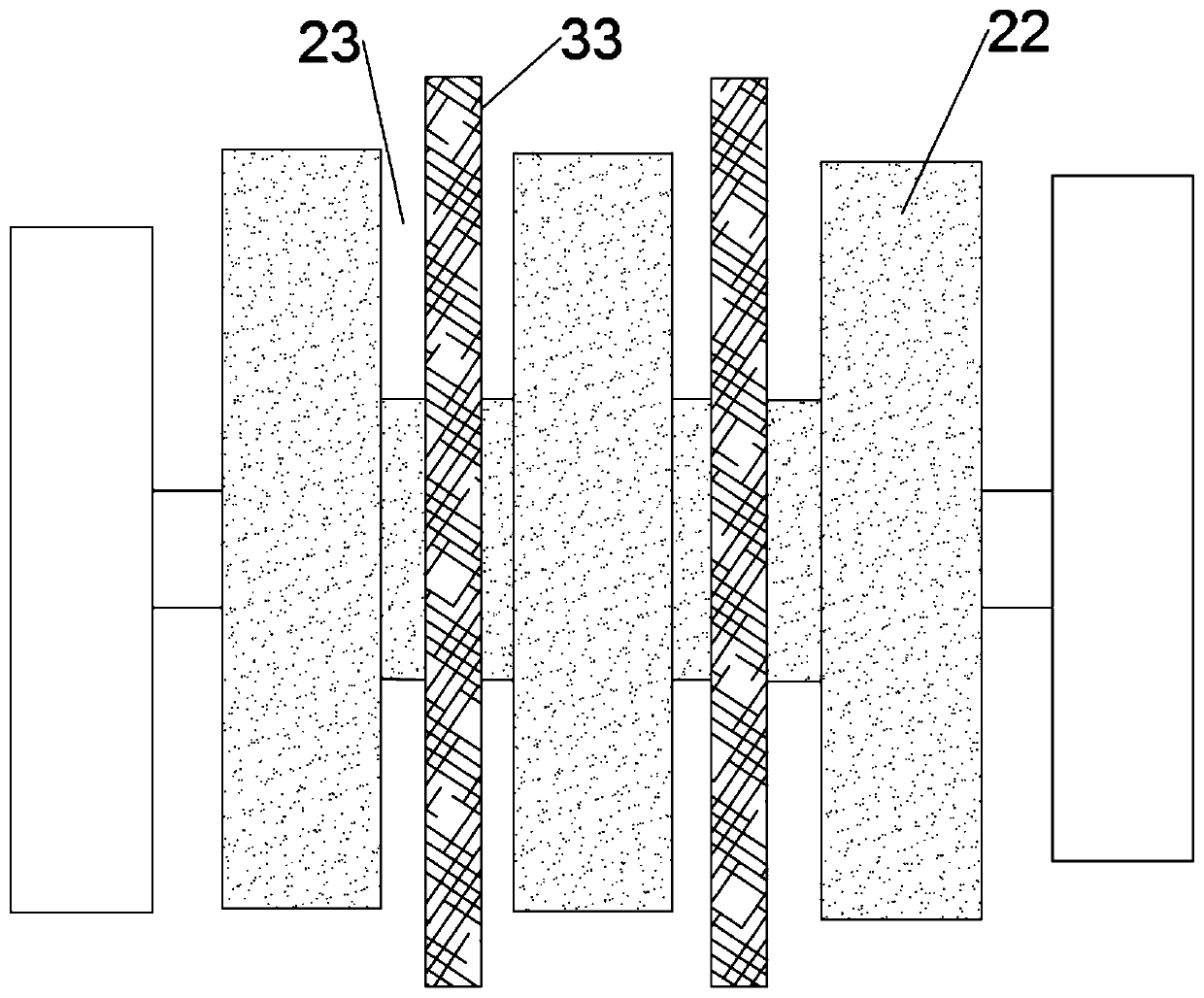

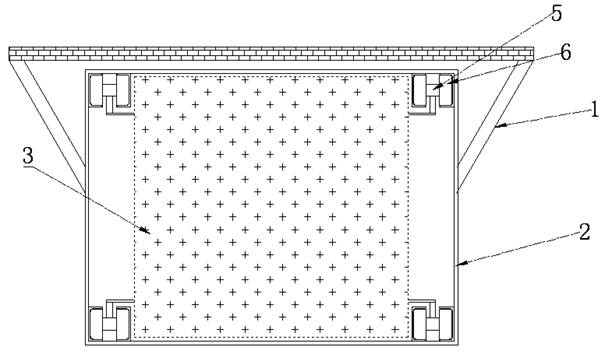

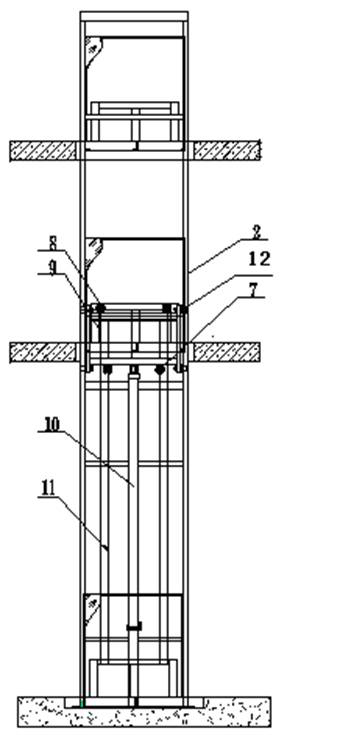

Wall mounted lift

InactiveCN102491220AStable structureIncrease cargo capacityLifting framesHydraulic cylinderEngineering

The invention discloses a wall mounted lift, which comprises a lifting platform, a lifting mechanism and a frame guide rail body, wherein the frame guide rail body comprises a support frame and a guide rail arranged on the support frame; the lifting platform is arranged in the center of the frame guide rail body, and the side faces of the lifting platform are provided with rollers capable of moving along the guide rail; the lifting mechanism comprises a plurality of chain rollers, a hydraulic cylinder, a moving frame and chains; two sides of the moving frame are respectively provided with pulleys moving up and down along the frame guide rail body; a cylinder body of the hydraulic cylinder is vertically arranged on the lifting platform; a cylinder rod of the hydraulic cylinder is connected with the moving frame; the chain rollers are arranged on the hydraulic cylinder; one end of each chain is connected to the lifting platform and the other end of each chain moves round each chain roller and is connected with the moving frame. The invention has the advantages that: the wall mounted lift has a firm structure and high cargo capacity, lifts stably, is easy to mount and maintain, and is operated easily and reliably; and a pit is not required to be dug and a ceiling is not required to be hung.

Owner:济南华北升降平台制造有限公司

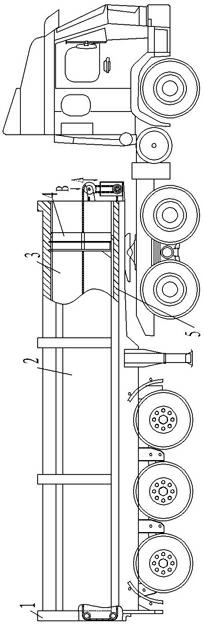

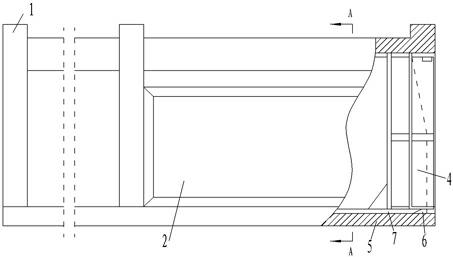

Horizontally pushing type dumper

InactiveCN102602319ALower center of gravityImprove stabilityVehicle with endless chains/beltsVehicle frameControl theory

The invention provides a horizontally pushing type dumper, which can move loaded cargoes backward as a whole to realize unloading. The horizontally pushing type dumper comprises a flat bottom type carriage; the flat bottom type carriage comprises a front breast board, a left side breast board, a right side breast board, a bottom board, front stand columns and rear stand columns; the carriage is internally provided with a push board which is in parallel to the front breast board; the left side breast board, the right side breast board and the bottom board are provided with longitudinal slideways or slide rails; correspondingly, the push board is provided with slide blocks or slide grooves; the left side breast board, the right side breast board and the bottom board form a movable pair with the push board; the push board can move backward and forward along the carriage under the drive of a push board driving device; when the cargoes are unloaded, the push board moves backward; and after the cargoes are unloaded, the push board moves forward to reset. According to the invention, when the cargoes are unloaded, the horizontally pushing type dumper does not need to lift the carriage and can unload the cargoes in the carriage completely only by moving the push board backward; unloading through tipping the carriage is changed to the unloading through horizontal movement, thereby promoting the cargo capacity and the vehicle stability and meanwhile reducing the probabilities that a vehicle frame suffers permanent deformation, and snap of welded joints happens in the carriage and an auxiliary frame.

Owner:LIANGSHAN TONGHUA SPECIAL PURPOSE VEHICLE

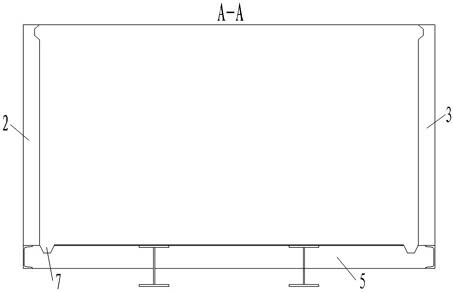

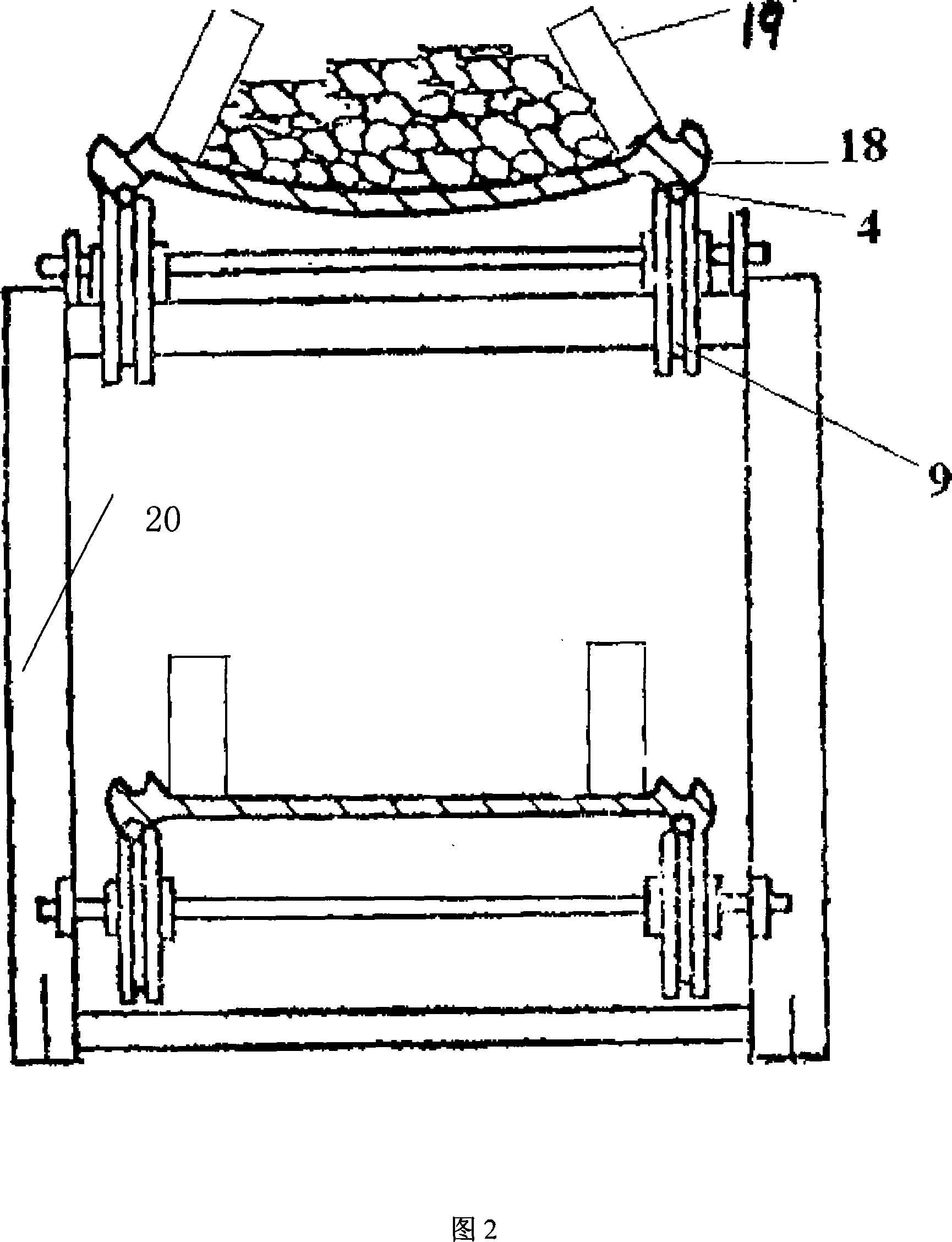

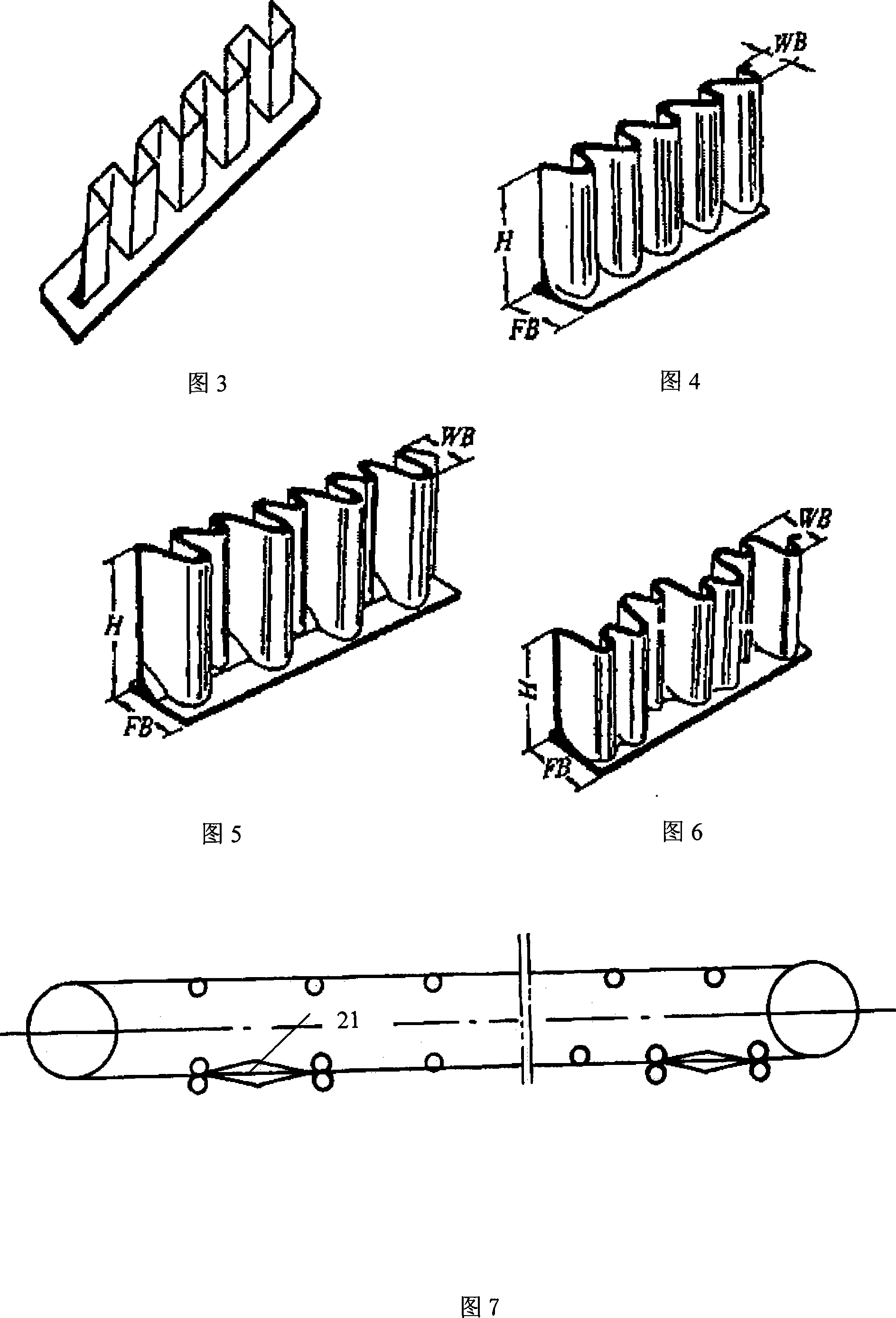

Steel cable traction wavy baffle edge belt conveyer

InactiveCN101100234AIncrease cargo capacityReduce the phenomenon of collapsing and scatteringConveyorsBogieElevation angle

The steel cable towed belt conveyer with wavy baffles includes a driving unit, towing steel cables, a conveying belt, wavy baffles set to the side edges, driving wheels, cable guiding wheels, a transition wheel set, a cable separating wheel set, an unloading unit, a head direction changing roller, a middle cable supporting wheel set, a loading unit, a conveying belt tensioner, bogies, a tail direction changing roller, a cable tensioning bogie, a tensioning cable pulley, a winch, a tightening weight, a support and a conveying belt turning mechanism. The steel cable towed belt conveyer has the features of great lifting elevation angle, great carrying capacity, smooth running, long conveying distance and high conveying speed, and is suitable for conveying bulk material in great inclination angle.

Owner:NORTHEASTERN UNIV

Stowable Cup Holder Tray Assembly

InactiveUS20070295875A1Increase cargo capacityTravelling carriersVehicle arrangementsEngineeringStowage

A stowable cup holder tray assembly is provided for a vehicle having an interior floor structure. The cup holder assembly includes a stowage compartment having a bottom portion with a plurality of opposing sidewalls extending therefrom and defining a stowage volume. The stowage compartment is mounted substantially adjacent to the interior floor structure. A cover member is hinged to one of said plurality of opposing sidewalls and operates to substantially close said stowage volume. A cup holder tray member is movable between a stowed position and a deployed position. The stowage volume is sufficiently configured to receive said cup holder tray member when in said stowed position. A vehicle incorporating the disclosed cup holder tray assembly is also provided. The cup holder tray assembly is configured to be sufficiently close to the floor when in the stowed position to provide limited barriers within the interior of the vehicle.

Owner:GM GLOBAL TECH OPERATIONS LLC

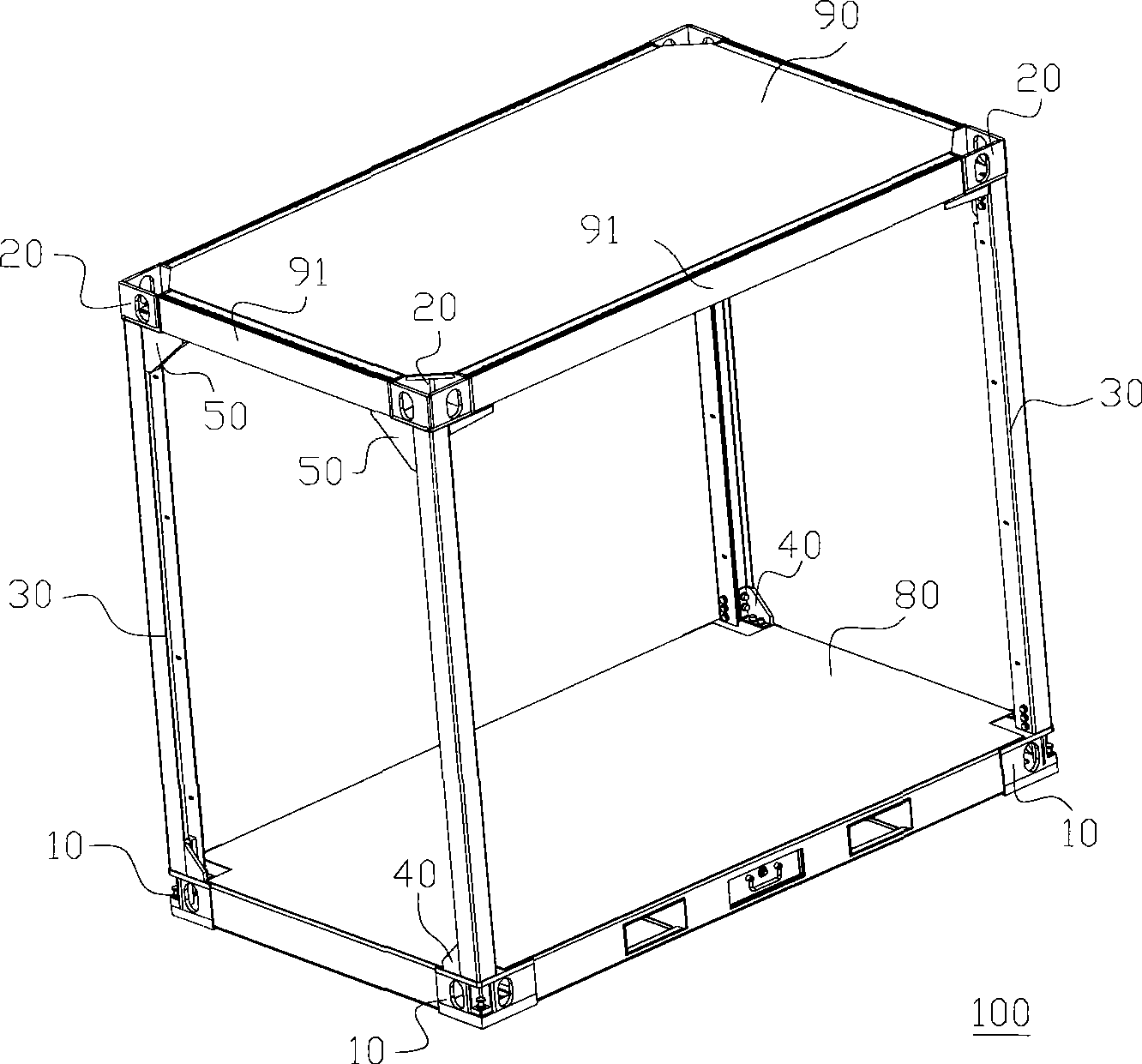

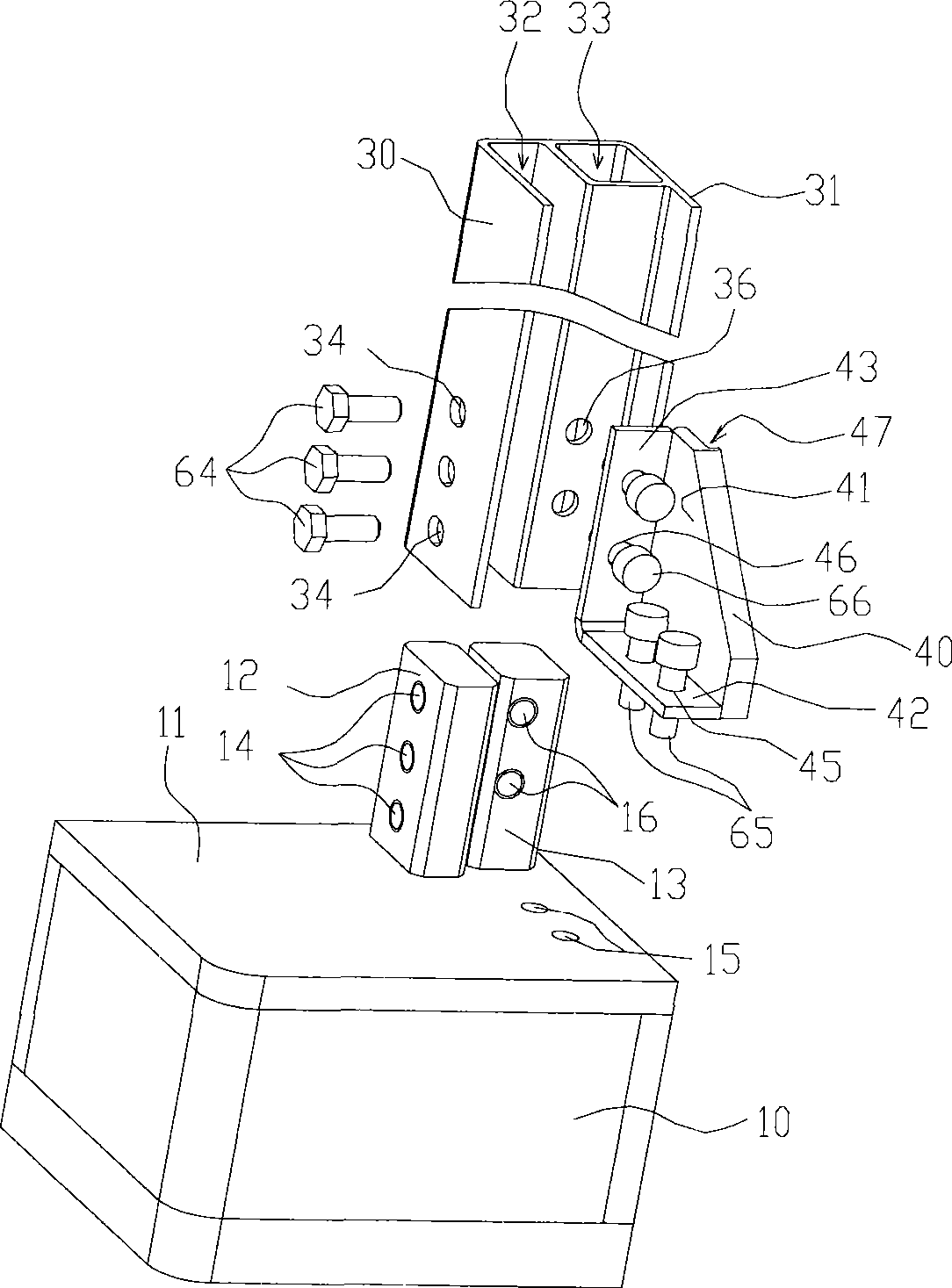

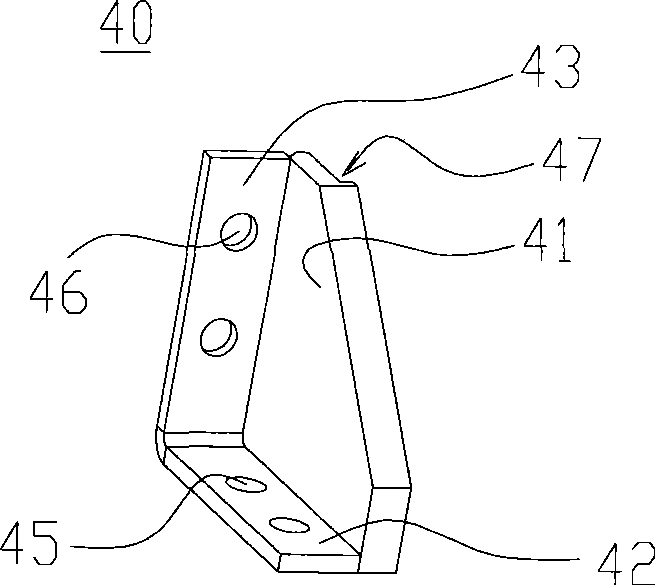

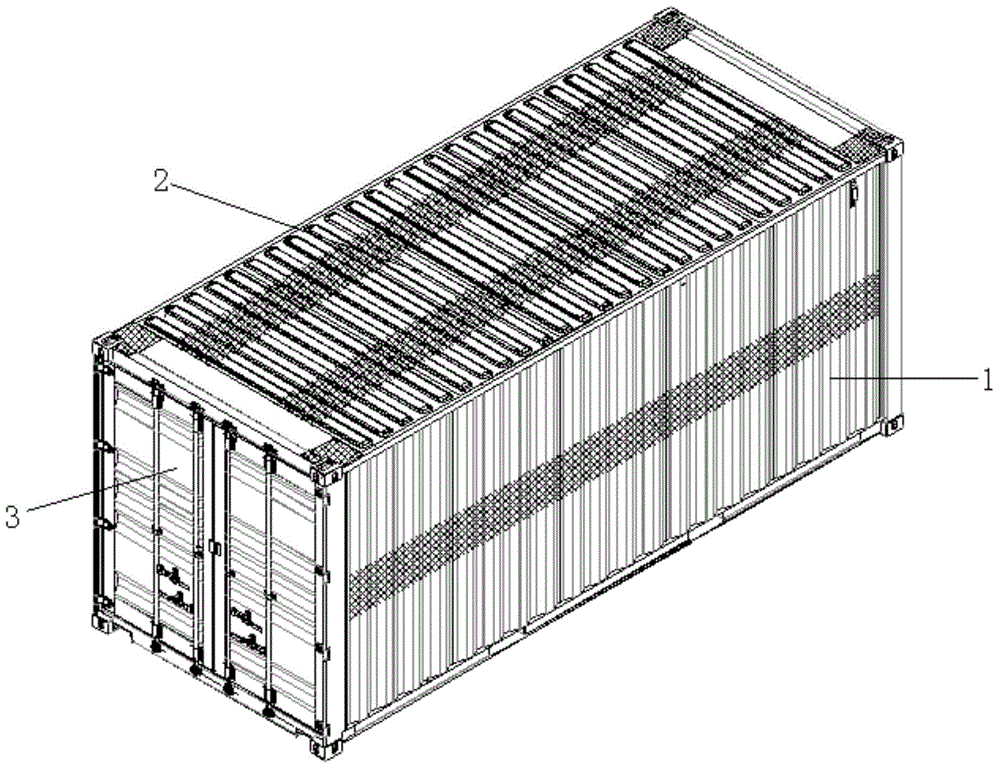

Corner member and container equipped therewith

The invention relates to a corner piece and a container with the corner piece. The corner piece is arranged in a corner part of the container and is matched with an upright post of the container; the corner piece comprises a matching surface and at least one insertion column vertical to the matching surface; and the corner piece is connected with the upright post through inserting the insertion column into the upright post. The corner piece is detachably connected with the upright post. The container with the corner piece can reduce the transportation volume of the empty container through detaching the upright post and can carry out air transportation. In addition, the corner piece has the advantages of simple structure, easy manufacture and uneasy deformation in the connection with the upright post.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

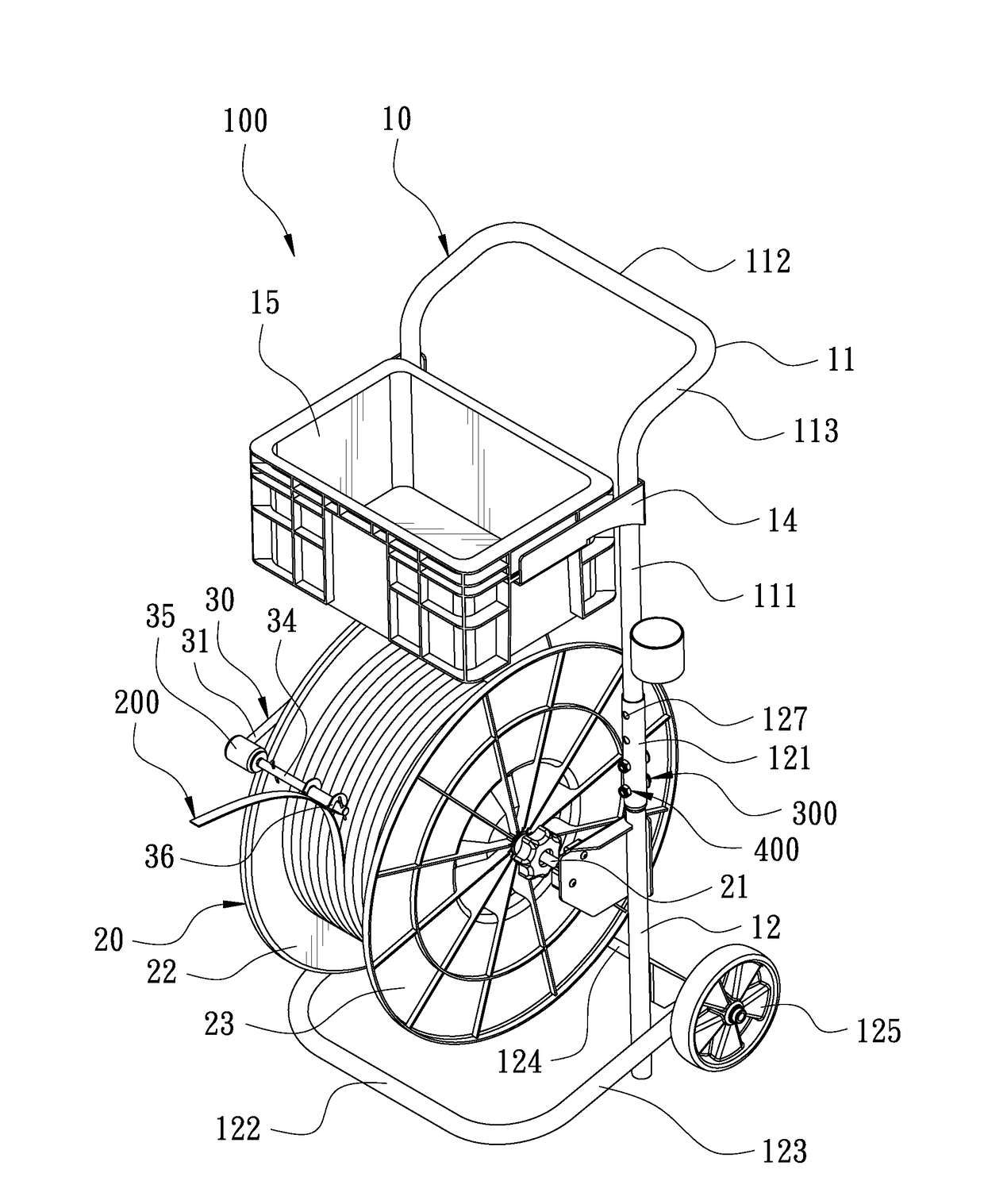

Upright strap dispenser

InactiveUS20170203937A1Small sizeIncrease cargo capacityFilament handlingMechanical engineeringTransportation cost

The upright strap dispenser has a main body. The main body includes a first frame and a second frame which are connected to each other. The upper frame can be moved up and down relative to the second frame for adjusting the height of the main body. The upright strap dispenser further includes a strap disc. The strap disc is provided with a pivot. Two ends of the pivot are pivotally connected to the first frame and the second frame. The second frame is pivotally connected with a brake device. The upright strap dispenser is detachable to reduce its size for transportation so as to increase cargo capacity and lower transportation cost.

Owner:YU CHEN HSIU MAN

Hopper car having double-curved side walls

InactiveUS20090090268A1Increase cargo capacityReduce widthHopper carsWagons/vansMechanical engineering

A hopper car having double-curved side walls for transporting bulk solids. The car has side walls, end walls, and a bottom which are all joined to present a container for transporting the bulk solids. The bottom presents at least one opening for discharge of the bulk solid. Each side wall presents upper and lower convex sections forming an indentation at approximately the vertical center of the side wall.

Owner:AERO TRANSPORTATION PRODS

High-voltage power cable for rail transit vehicle and technological process of high-voltage power cable for rail transit vehicle

ActiveCN104167252ASave spaceReduce weightPower cables with screens/conductive layersInsulated cablesCurrent electricElectrical conductor

The invention discloses a high-voltage power cable for a rail transit vehicle and a technological process of the high-voltage power cable for the rail transit vehicle. The high-voltage power cable comprises soft tinned conductors, a semiconductive conductor shielding layer, an ultra-clean ethylene-propylene rubber insulating layer, a semiconductive insulating shielding layer, a metal shielding layer, an isolation jacket, an interlocking armor layer and a protective jacket. The soft tinned conductors are used for electric energy transmission and are sequentially sleeved with the semiconductive conductor shielding layer, the ultra-clean ethylene-propylene rubber insulating layer, the semiconductive insulating shielding layer, the metal shielding layer, the isolation jacket, the interlocking armor layer and the protective jacket. By means of the high-voltage power cable, the condition that when high-power and large-current electric energy transmission or supplying is needed in use of power cables for the rail transit vehicle, the multiple existing cables, meeting the related standards, for the rail transit vehicle have to be used in a parallel-connection mode is avoided, and the potential safety hazards that when any cable is broken, power supply is unstable, and even breakdown of a power supply system occurs are avoided.

Owner:ZHONGTIAN TECH IND WIRE&CABLE SYST CO LTD

Ship power transmission device

InactiveCN103832568AReduce weightReduce power consumptionPropulsive elements of non-rotary typeTransmission with mechanical gearingPropellerMotive power

The invention discloses a ship power transmission device, belongs to the power field in the shipbuilding industry and particularly relates to ship power transfer and technical improvement of propellers. A speed reducing mechanism for traditional power transfer is omitted, navigational speed adjustment is replaced by speed adjustment of a power machine, a transmission rod shared by two synchronous power machines drives the propellers to produce acting force on water, the water produces reverse acting force on the propellers, a ship is driven to advance, the power conversion efficiency is high, the ship speed is improved, the noise is reduced, the ship weight is lightened, a space is increased, and the cargo capacity is increased. The ship power transmission device is suitable for providing of main power or auxiliary power of various ships and especially suitable for small and medium ships or warships.

Owner:WUHAN JINZHIYUAN TECH

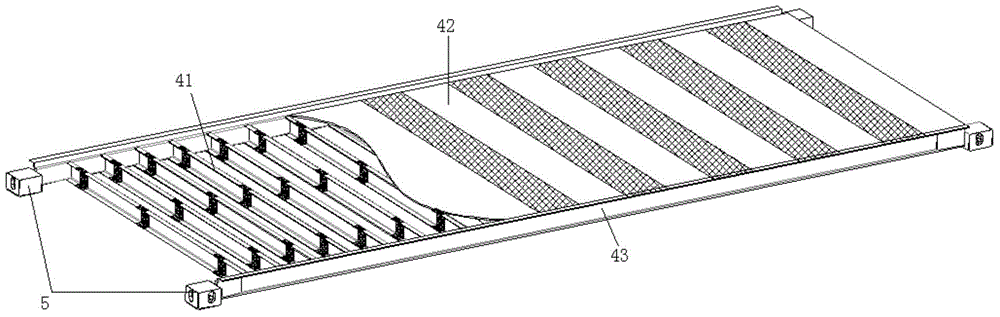

Container and manufacturing method thereof

The invention discloses a container and a manufacturing method thereof. The container comprises a bottom frame, a door end plate, a front end plate, side plates and a top plate. The bottom frame comprises bottom side beams, a front end beam, a rear end beam, a plurality of bottom cross beams and a floor laid on the bottom cross beams. The thickness of at least one structure part of the door end plate, the front end plate, the side plates, the top plate, the bottom side beams, the front end beam, the rear end beam and the bottom cross beams changes regularly in the length or width direction of the structure part, and a thin-walled zone and a thick-walled zone of the structure part are distributed in a spaced mode. Compared with the prior art, on the premise that the bending strength and rigidity of the container are kept unchanged, the steel consumption is reduced, raw material waste is avoided, resources are saved, cost is reduced, the self weight of the container is further reduced, the cargo capacity of the container is increased, and the container has the advantage of being environmentally friendly.

Owner:SHENGSHI CONTAINER MANAGEMENT SHANGHAI

Variable cross-section corrugated bulkhead assembly and ship including same

ActiveCN108438140ALarge capacitySimplify manufacturing stepsHull bulkheadsStress concentrationUltimate tensile strength

The invention discloses a variable cross-section corrugated bulkhead assembly and a ship including same. The variable cross-section corrugated bulkhead assembly comprises a first corrugated bulkhead which is vertically arranged between a main deck of a ship and the internal bottom plate of a cabin, wherein the cross section of the first corrugated bulkhead in the vertical direction is invariable;and the two ends of the first corrugated bulkhead in the vertical direction are correspondingly connected with the main deck and the internal bottom plate through a second corrugated bulkhead, whereinthe cross section of the second corrugated bulkhead in the vertical direction is gradually increased from one end close to the first corrugated bulkhead to one end far away from the first corrugatedbulkhead. Through adoption of the variable cross-section second corrugated bulkhead, the supporting strength of the whole variable cross-section corrugated bulkhead assembly can be met by using the variable cross-section structure, and the variable cross-section corrugated bulkhead assembly directly replaces a structure with an upper wall pier and a lower wall pier; and therefore, the manufacturing steps are simplified, the manufacturing difficulty is reduced, the large-area stress concentration situation is avoided, and the potential safety hazard is reduced; and moreover, an independent cabin structure does not need to be divided for the second corrugated bulkhead, the volume of the cabin is made large, and the loading capacity is greatly enhanced.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com