Horizontally pushing type dumper

A dump truck, flat push technology, applied in the direction of vehicles with a chain/ring belt, etc., to achieve the effect of improving stability, reducing permanent deformation, and lowering the center of gravity of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

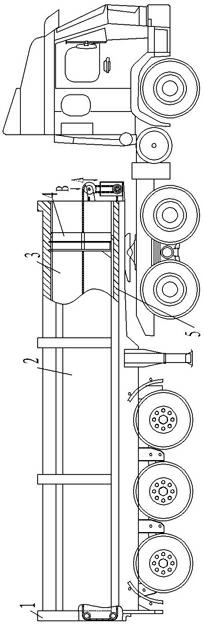

[0043] In order to introduce the structure of the present invention in detail, and to make those skilled in the art form a unified understanding, the following definitions are now made: taking the front and rear directions of the carriage as the longitudinal direction, and the directional attributives such as front and rear mentioned in the present invention are all based on the front and rear directions of the carriage. as the benchmark. figure 1 Shown the overall structure of the present invention, from structural point of view, the structure of engine, chassis and driver's cab of flat-push type dump truck is the same as general dump truck, but, its characteristic flat-push type unloading goods (comprising compartment and unloading power) System) mechanism is completely different from the traditional dump truck lifting mechanism.

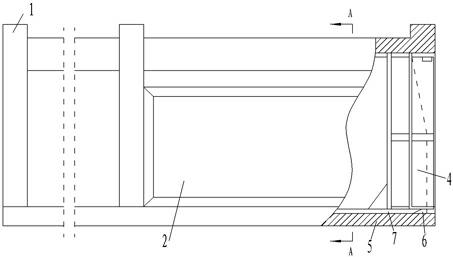

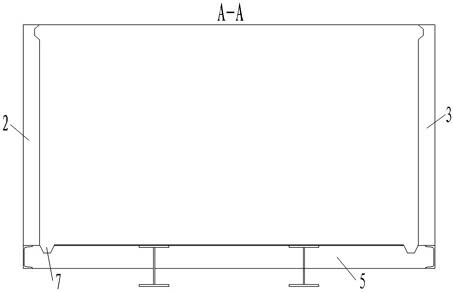

[0044] Figure 2-5 Clearly shows the structure of the compartment, the compartment is a flat-bottomed compartment, the same as the existing com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com