High-voltage power cable for rail transit vehicle and technological process of high-voltage power cable for rail transit vehicle

A technology for rail transit vehicles and power cables, which is applied to power cables with shielding layers/conductive layers, insulated cables, and cable/conductor manufacturing. Threat and other issues, to achieve the effect of weight reduction, lower vehicle weight, compactness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

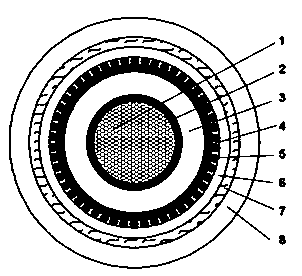

[0037] Such as figure 1 As shown, a high-voltage power cable for rail transit vehicles, including a tinned flexible conductor 1, a semi-conductive conductor shielding layer 2, an ultra-clean ethylene-propylene rubber insulating layer 3, a semi-conductive insulating shielding layer 4, a metal shielding layer 5, and an isolation sleeve 6. Interlocking armor layer 7 and protective cover 8, tinned soft conductor 1 for cable transmission, tinned soft conductor 1 is covered with semiconductive conductor shielding layer 2 in turn, ultra-clean ethylene propylene rubber insulation layer 3, semiconductive insulation Shielding layer 4, metal shielding layer 5, isolation sleeve 6, interlocking armor layer 7 and protective sleeve 8.

[0038] Tin-plated soft conductor 1 is produced by tin-plating process to improve the oxidation resistance and corrosion resistance of the conductor. At the same time, the maximum section of the power cable conductor section of the current rail transit vehicl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com