Garbage grab bucket crane

A technology for cranes and garbage, which is applied in the direction of cranes, trolley cranes, load hanging components, etc., can solve the problems of crane load limit and low work efficiency, and achieve increased cargo capacity, increased grabbing area, and improved The effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

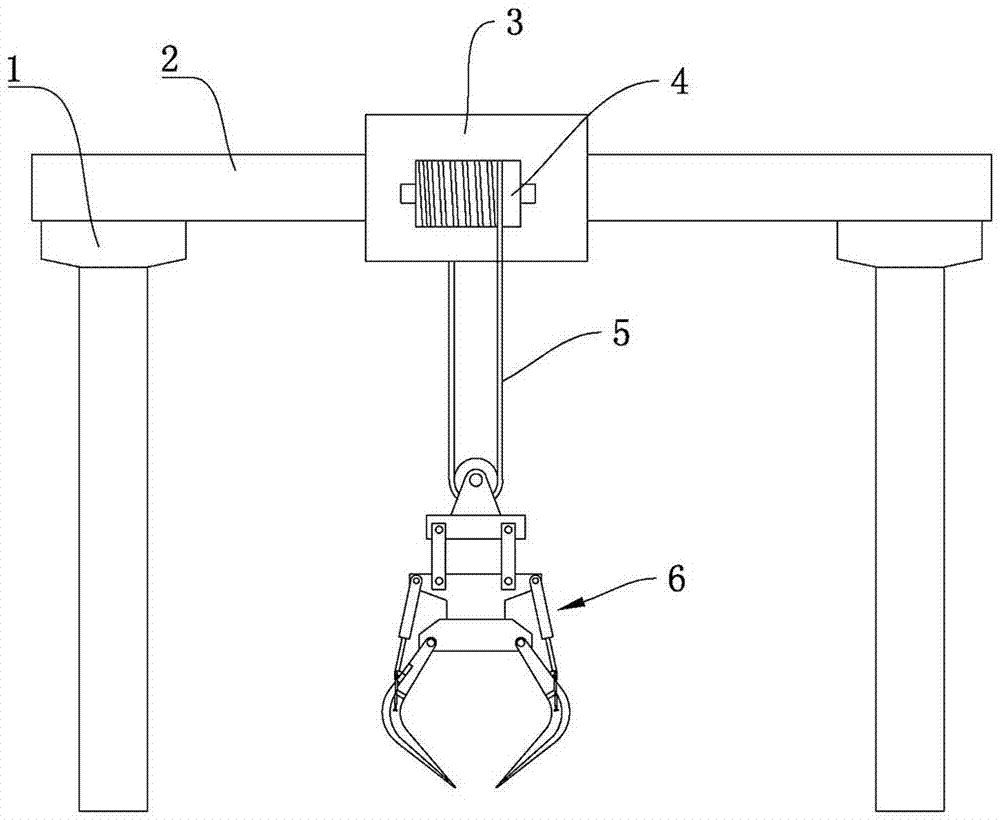

[0022] Embodiment 1: as Figure 1-3 Shown, a kind of rubbish grab crane comprises track beam 1, the main beam 2 that moves along track beam 1, the mobile trolley 3 that moves along main beam 2 and the hoisting device that is installed on the mobile trolley 3, and described hoisting device comprises Lifting reel 4, grab bucket 6 and steel wire rope 5, described lifting drum 4 is installed on the described moving trolley 3, and described steel wire rope 5 is connected between lifting drum 4 and described grab bucket 6,

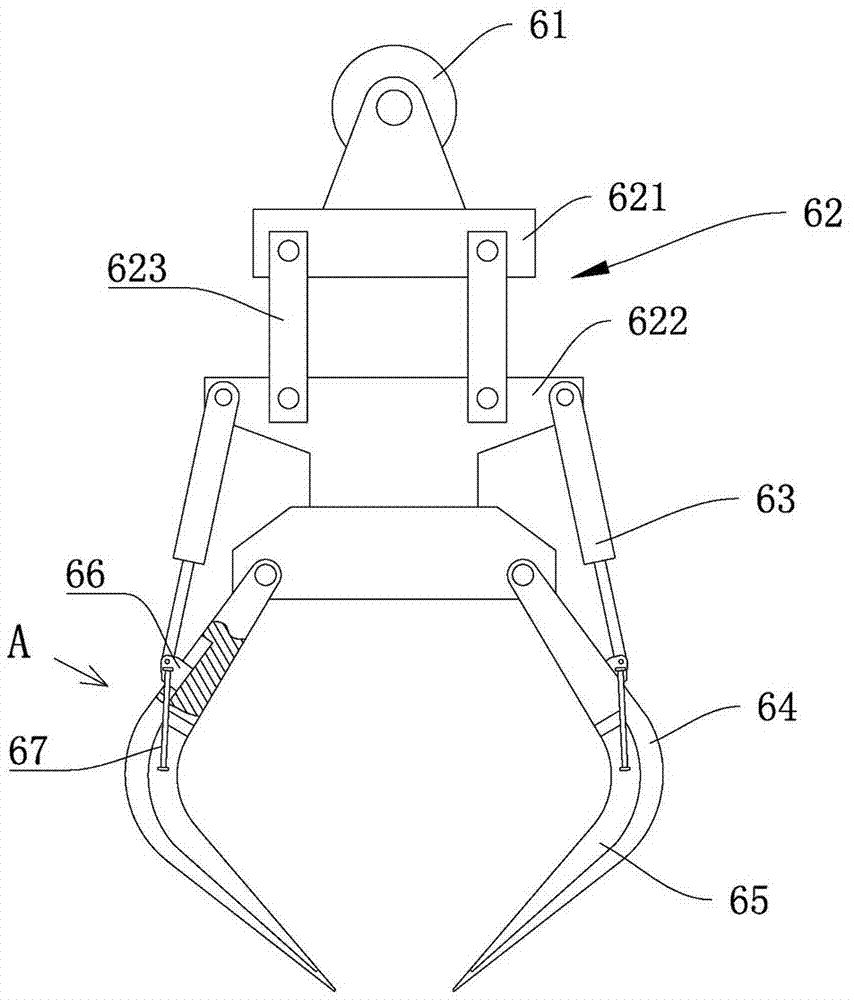

[0023] Such as figure 2 with image 3 As shown, the grab bucket 6 includes a support 62, several claw arms 64 circumferentially distributed on the support 62, and a hydraulic cylinder 63 that pushes a single claw arm 64 to swing. The upper end of the support 62 is provided with a movable pulley 61. One end of the wire rope 5 is wound on the lifting drum 4, and the other end is wound around the movable pulley 61 and fixedly connected to the mobile trolley 3; t...

Embodiment 2

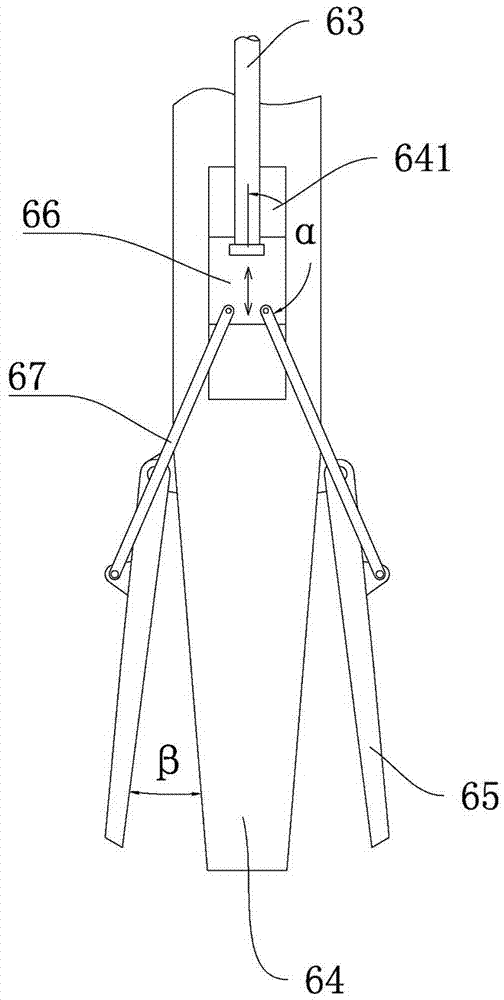

[0025] Embodiment 2: as Figure 4 As shown, the difference from Embodiment 1 is that the slider 66 is a split structure, including a first slider 661 and a second slider 662 arranged up and down, and the first slider 661 and the second slider The block 662 is connected with an elastic piece 663 which makes the two move away from each other, and the elastic piece 663 is a spring. The hydraulic cylinder 63 is hinged on the first slider 661 , and the first connecting rod 67 is hinged on the second slider 662 .

[0026] The first connecting rod 67 includes a hinged first rod body 671 and a second rod body 672, the first rod body 671 is hinged on the side jaw 65, and the second rod body 672 is hinged on the second slider 662 , there is a second connecting rod 68 between the second rod body 672 and the first slider 661, when the second slider 662 moves relative to the first slider 661, the second connecting rod 68 drives the side claw 65 to rotate relative to the claw arm 64 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com