Hopper car having double-curved side walls

a hopper car and side wall technology, applied in the field of hopper cars, can solve the problems of weakening the side walls, lengthening the distance between the trucks or wheels, etc., and achieve the effects of enhancing the rigidity of the side walls, reducing the width of the car's midsection, and increasing the cargo carrying capacity of the hopper car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

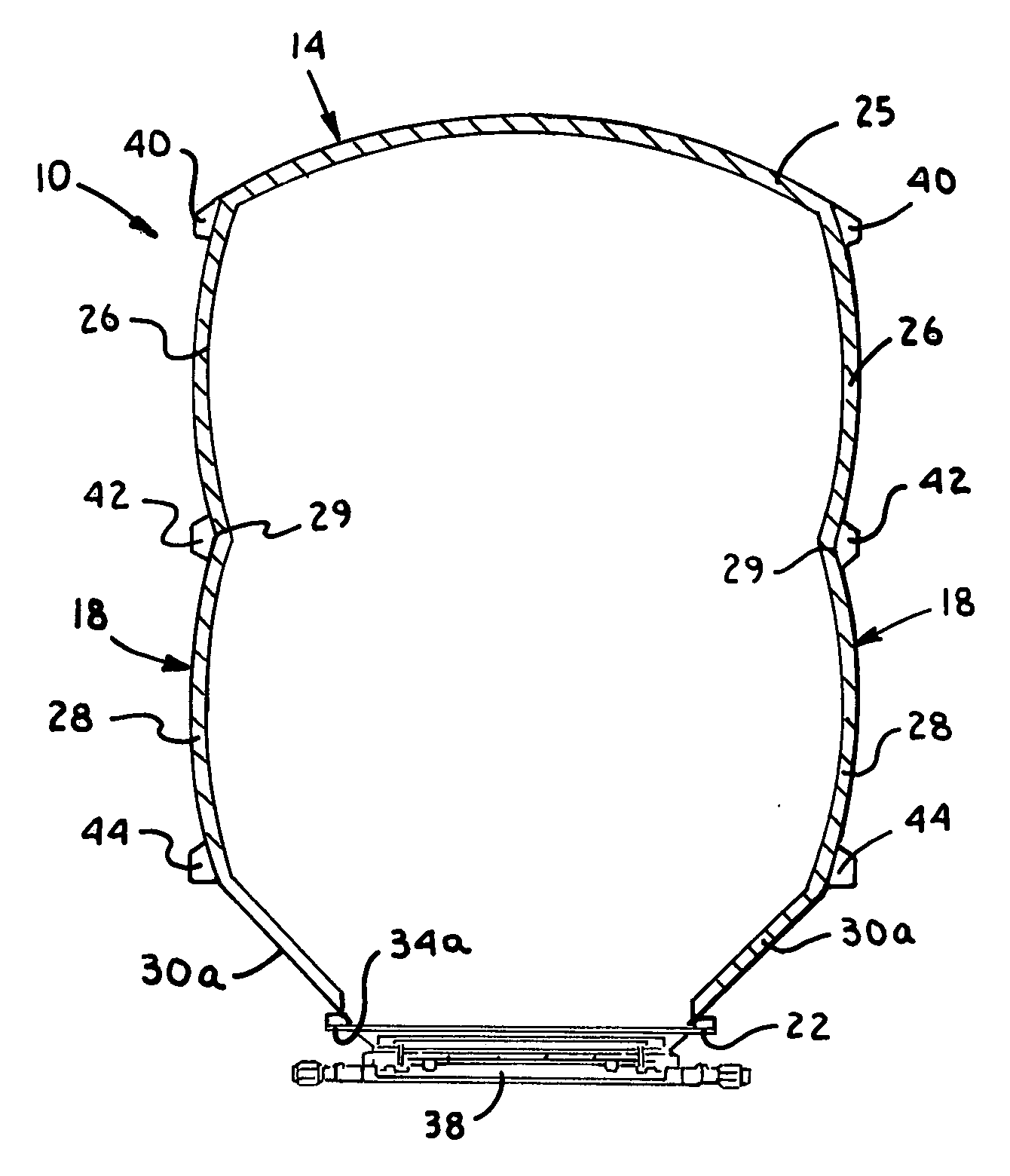

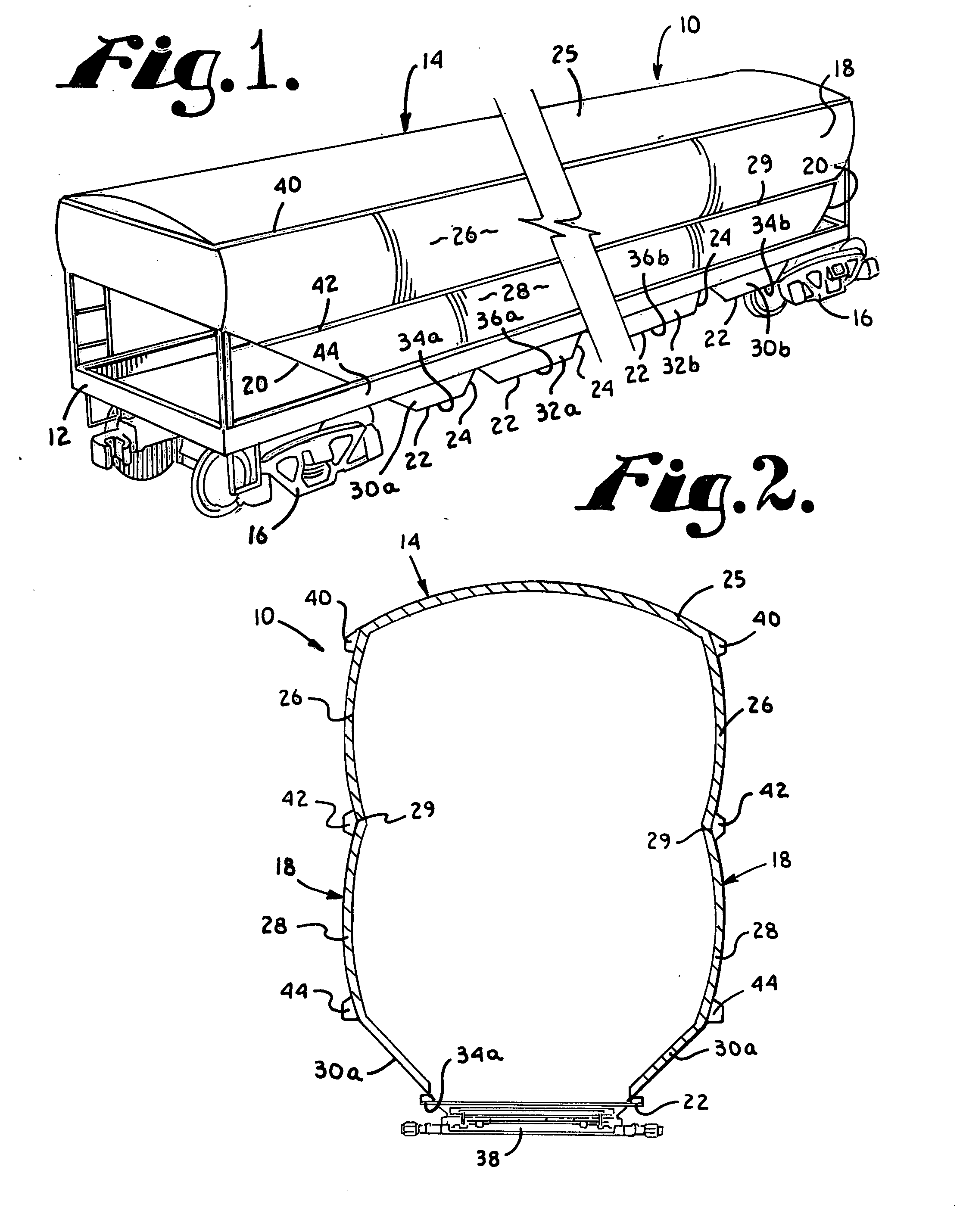

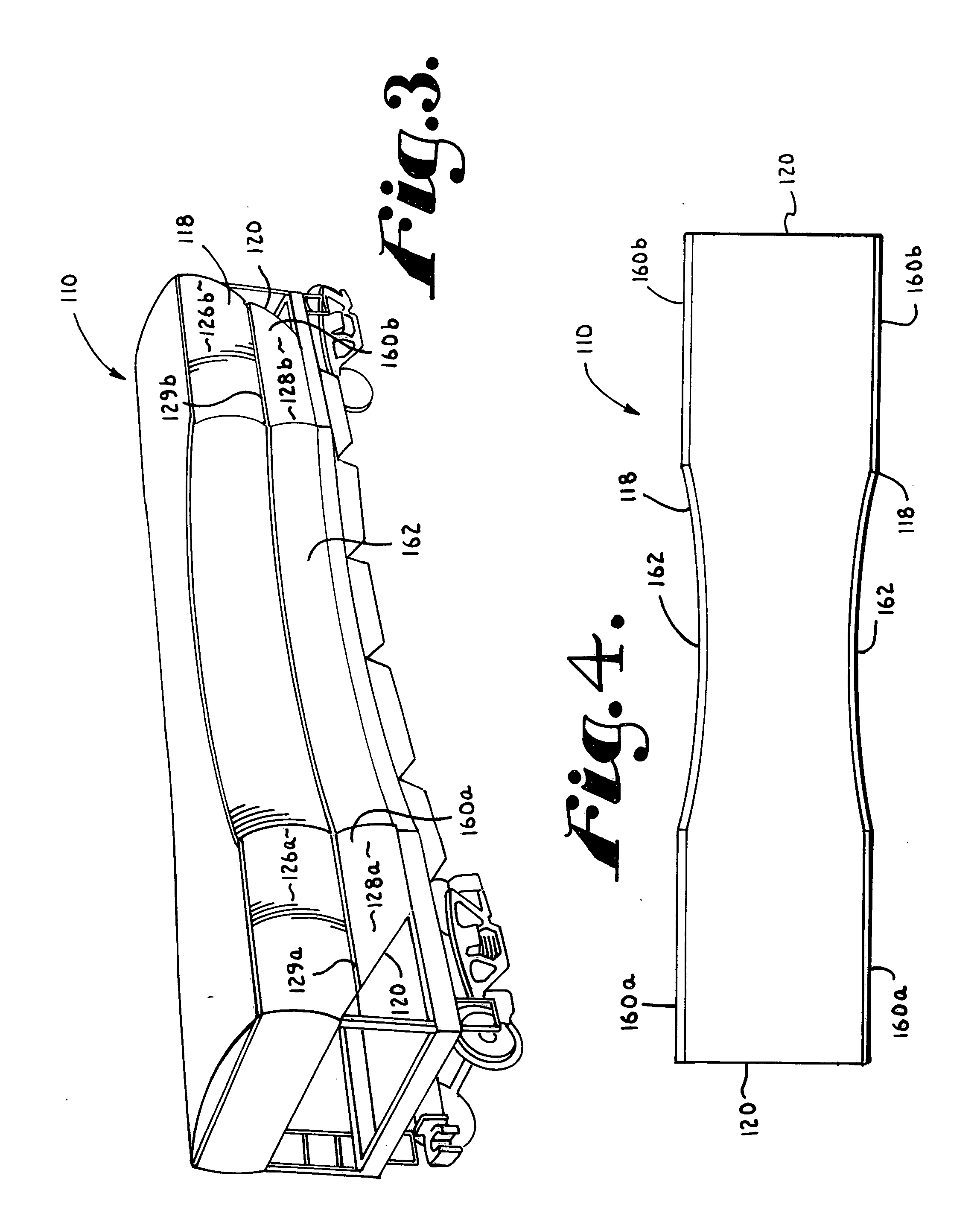

[0017]A railroad hopper car 10 for transporting bulk solids is depicted in FIG. 1. The hopper car has a frame 12, a container 14 mounted to the frame and truck assemblies 16 mounted to each end of the frame. As depicted in FIGS. 1 and 2, container 14 has opposed generally upright side walls 18, opposed generally upright end walls 20 joined to each side wall, a horizontal discontinuous bottom 22 joined with each side and end wall, inverted v-shaped structures 24 joined with the bottom and each side wall, and a convex cover 25 joined to each side and end wall. Side walls 18 extend in a longitudinal direction of the car between end walls 20.

[0018]As depicted in FIGS. 1 and 2, each side wall 18 presents an upper convex section 26, a lower convex section 28, and discharge sections 30a-b and 32a-b. As depicted in FIG. 1, bottom 22 has two end openings 34a-b and two intermediate openings 36a-b for discharge of the bulk solid. Each discharge section 30a-b and 32a-b extends down from lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com