Oil-water composite cabin for ship

A technology for marine oil and liquid tanks, applied in the field of ships, can solve the problems of aggravated ship swaying motion and affect the seaworthiness performance, and achieve the effects of reducing pollution, facilitating daily maintenance, and suppressing sloshing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

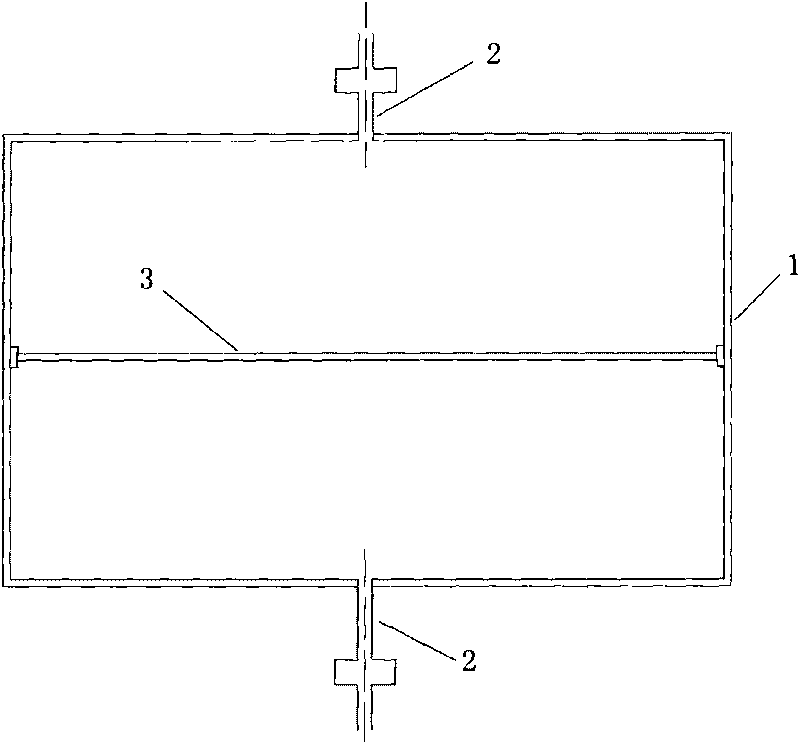

[0029] Embodiment 1: see figure 1 , The marine oil-water composite tank described in this embodiment includes a liquid tank 1, an infusion pipeline 2, a rigid partition 3, slide rails, a pressurization system and a push-pull system. Wherein, the liquid tank 1 is a cavity with a constant cross-section, the cross-section remains unchanged along the vertical direction, and slide rails are arranged on the vertical bulkhead. The rigid partition 3 is horizontally arranged in the liquid tank 1, cooperates watertightly with the bulkhead of the liquid tank 1, divides the liquid tank into two along the vertical direction of the liquid tank, the upper side is the fuel tank, and the lower side is the ballast water tank or Slop tank. The two ends of the rigid partition 3 cooperate with the slide rails provided on the bulkhead, and can move along the slide rails. The infusion pipeline 2 communicates with the compartments on both sides of the rigid partition 3 respectively. The pressuriza...

Embodiment 2

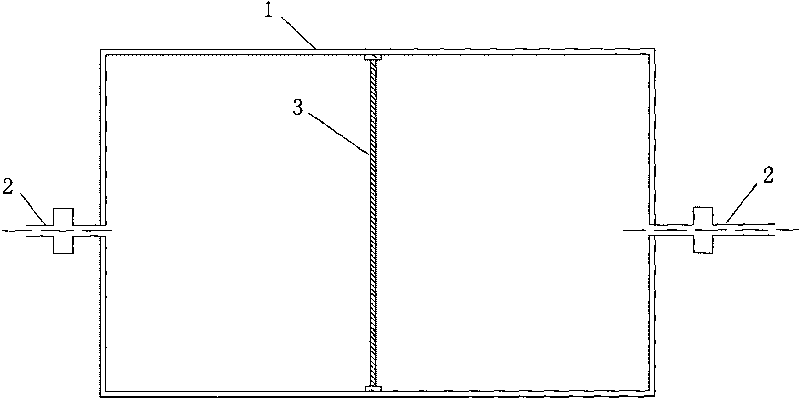

[0033] Example 2: see figure 2 , this embodiment is basically the same as Embodiment 1, except that the section of the liquid tank 1 along the horizontal direction remains unchanged, and slide rails are provided on the horizontal bulkhead. The rigid partition 3 is vertically arranged in the liquid tank 1, and cooperates watertightly with the bulkhead of the liquid tank 1, and divides the liquid tank into two along the horizontal direction of the liquid tank, one side is the fuel tank, and the other side is the ballast water tank or sewage tank.

Embodiment 3

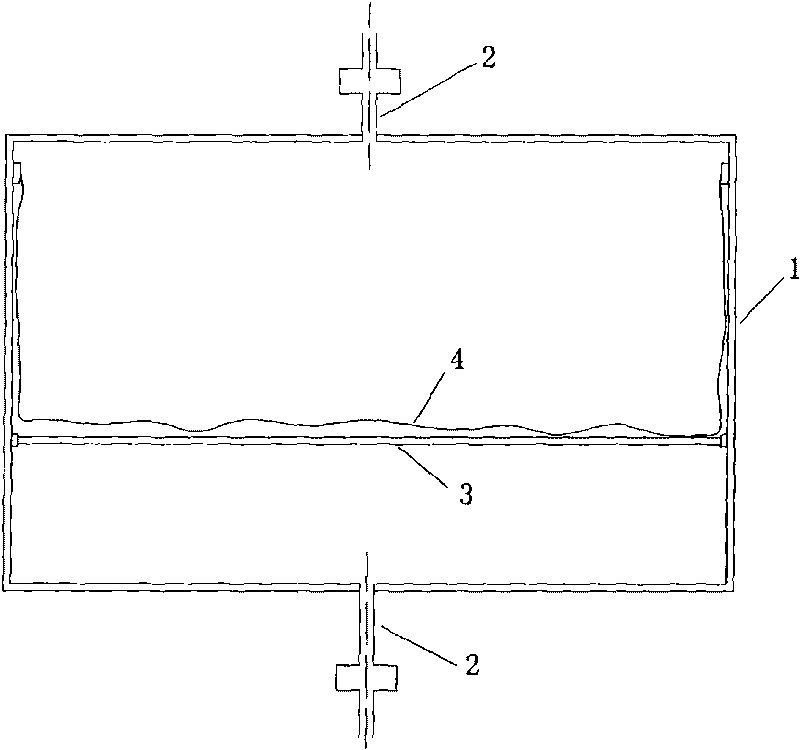

[0034] Embodiment 3: see image 3 , The marine oil-water composite tank described in this embodiment includes a liquid tank 1, an infusion pipeline 2, a rigid partition 3, an elastic bladder 4, slide rails, a pressurization system and a push-pull system. Wherein, the liquid tank 1 is a cavity with a constant cross-section, the cross-section remains unchanged along the vertical direction, and slide rails are arranged on the vertical bulkhead. The rigid partition 3 is horizontally arranged in the liquid tank 1, and divides the liquid tank into two along the vertical direction of the liquid tank. The upper side is a fuel tank, and the lower side is a ballast water tank or sewage tank. The two ends of the rigid partition 3 cooperate with the slide rails provided on the bulkhead, and can move along the slide rails. The infusion pipeline 2 communicates with the compartments on both sides of the rigid partition 3 respectively. The elastic bag 4 has high elasticity, corrosion resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com