Patents

Literature

34 results about "Upward shift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

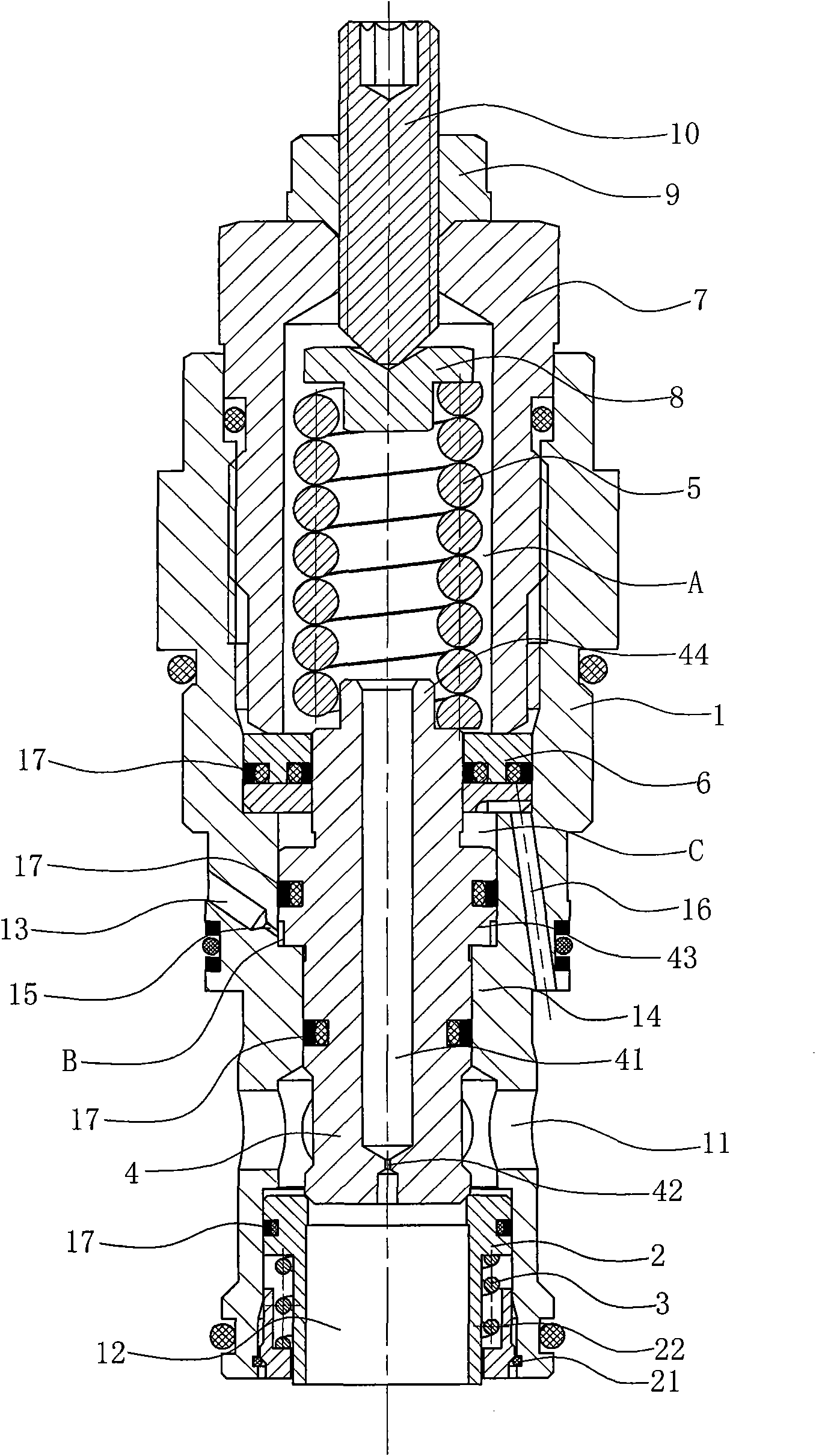

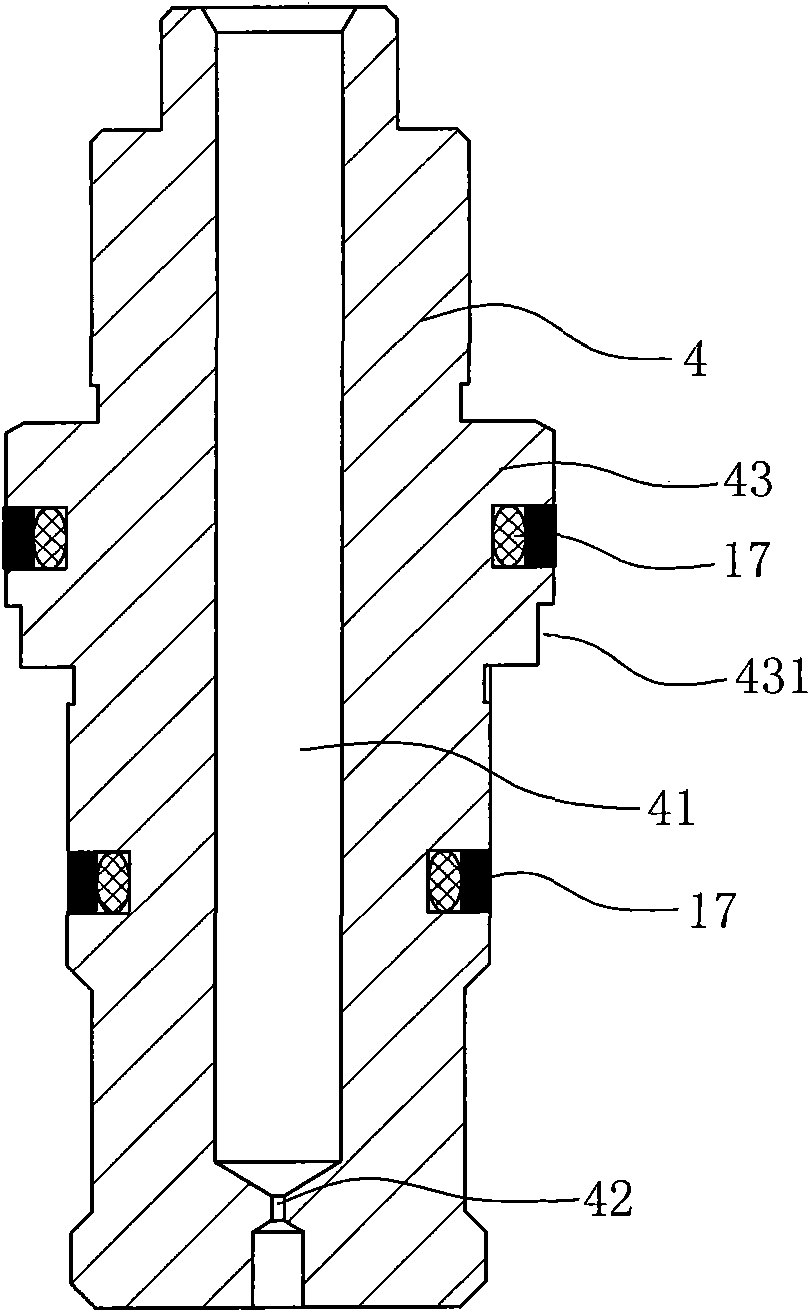

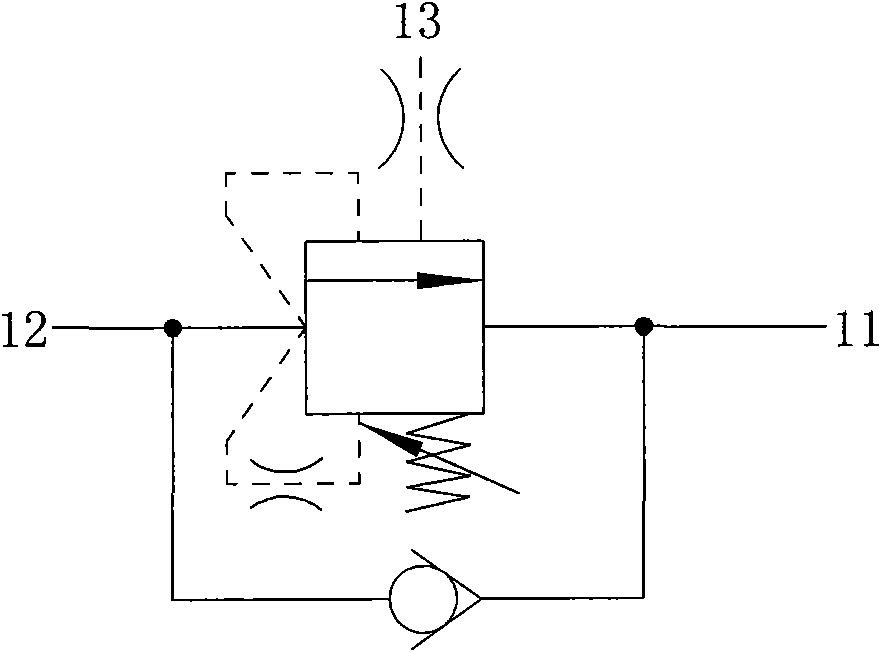

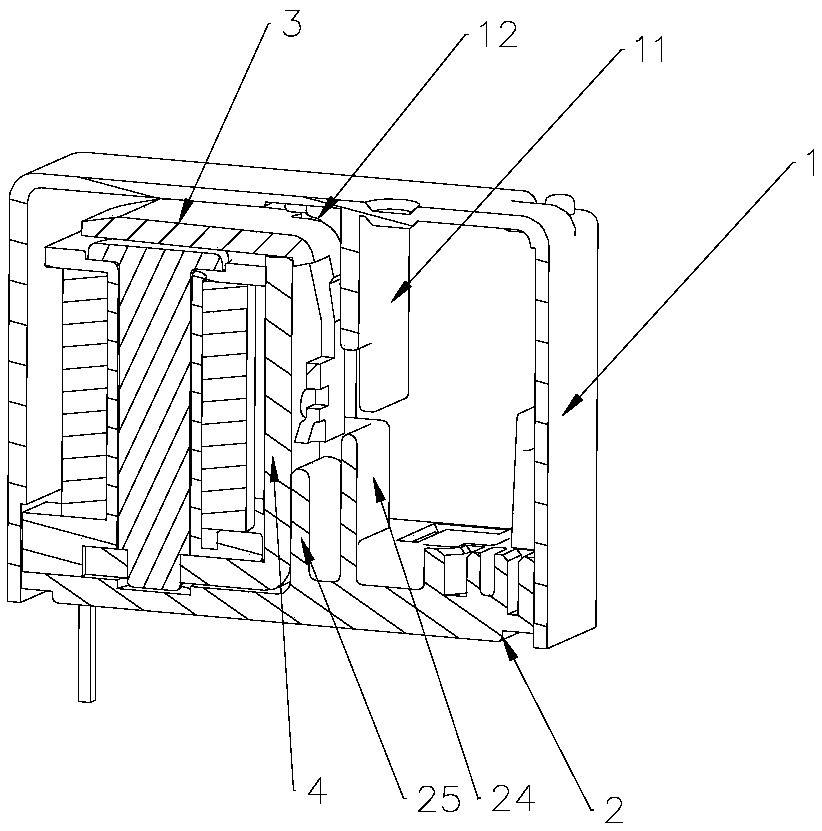

Plug-in type balance valve

InactiveCN101634317AReduce heat treatment requirementsReduce material requirementsServomotor componentsShoulder BladesThermal treatment

The invention relates to a plug-in type balance valve which comprises a valve body, a one-way valve core and a balance valve core, wherein a first oil opening, a second oil opening and a third oil opening are arranged on the valve body; the one-way valve core is arranged at the second oil opening and pushed by a first spring to maintain the trend of axial upward shift; the balance valve core is installed in the valve body and can be matched with a valve opening of the one-way valve core, and a second spring is arranged in a spring cavity of the valve body; the upper part in the balance valve core is provided with an axial passage and a first damping hole; the middle position of the balance valve core is provided with an axial convex shoulder; an annular notch is arranged on the periphery surface of the axial convex shoulder; the inner wall of the valve body is provided with an annular inner shoulder blade; an oil inlet cavity is formed among the annular notch, the inner wall of the valve body and the annular inner shoulder blade; and the third oil opening is communicated with the oil inlet cavity by a second damping hole on the side wall of the valve wall. The balance valve core and the one-way valve core are in an integral structure, and the structure is simple; the balance valve core and the one-way valve core are relatively independent on the relative position relationship, the assembly is convenient, and the requirements on heat treatment and materials of the balance valve core are lowered.

Owner:NINGBO HANSHANG HYDRAULIC

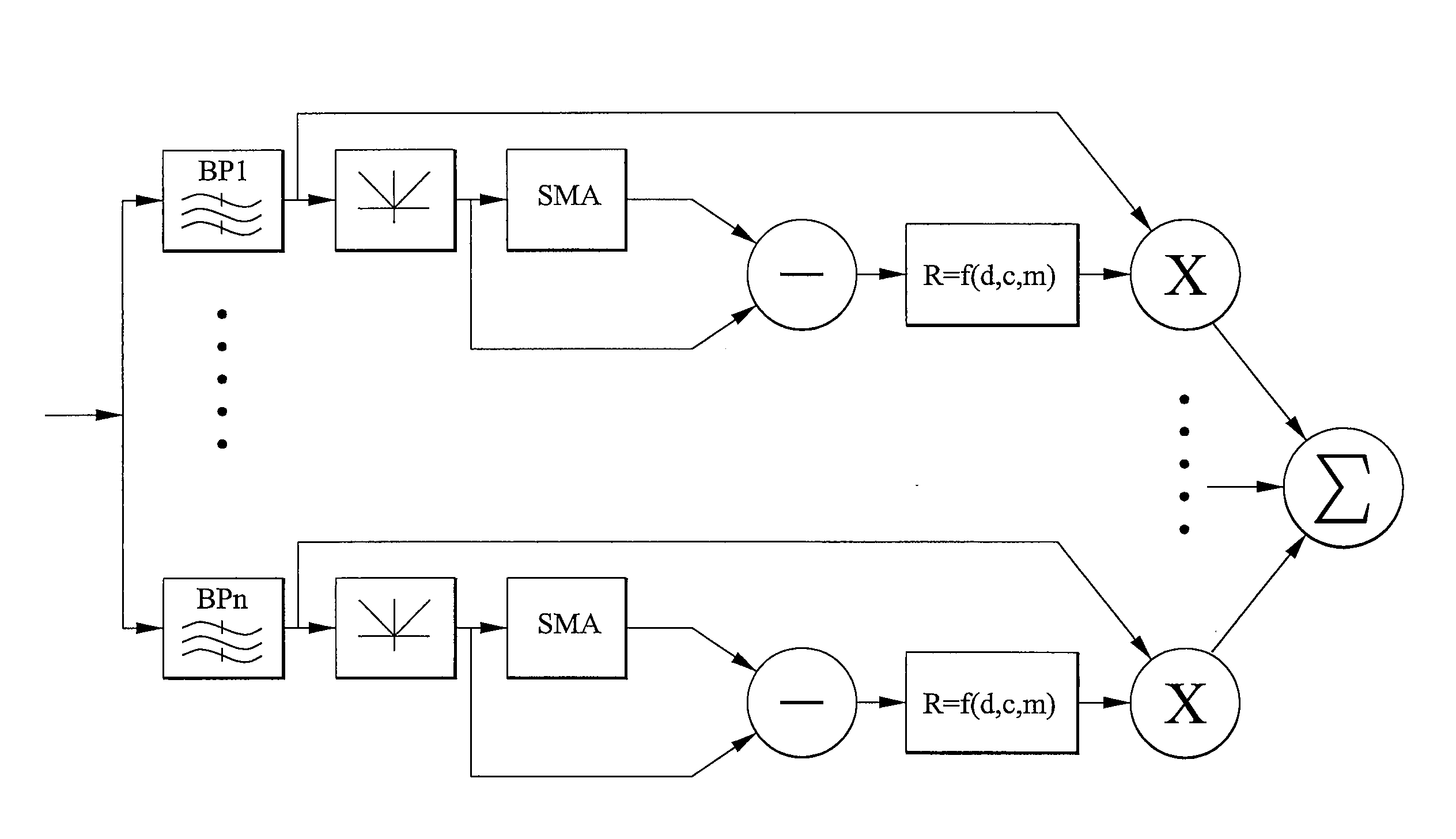

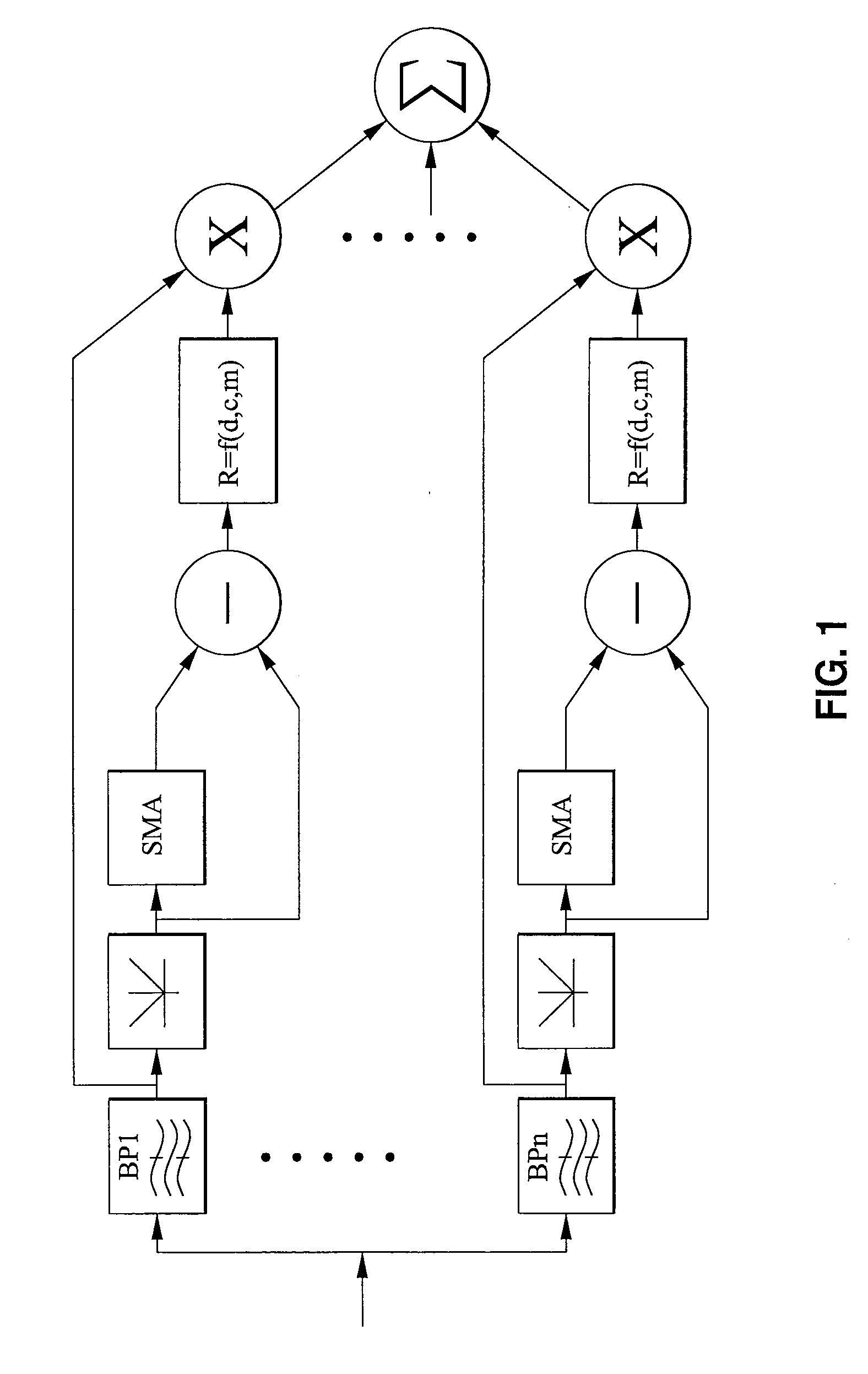

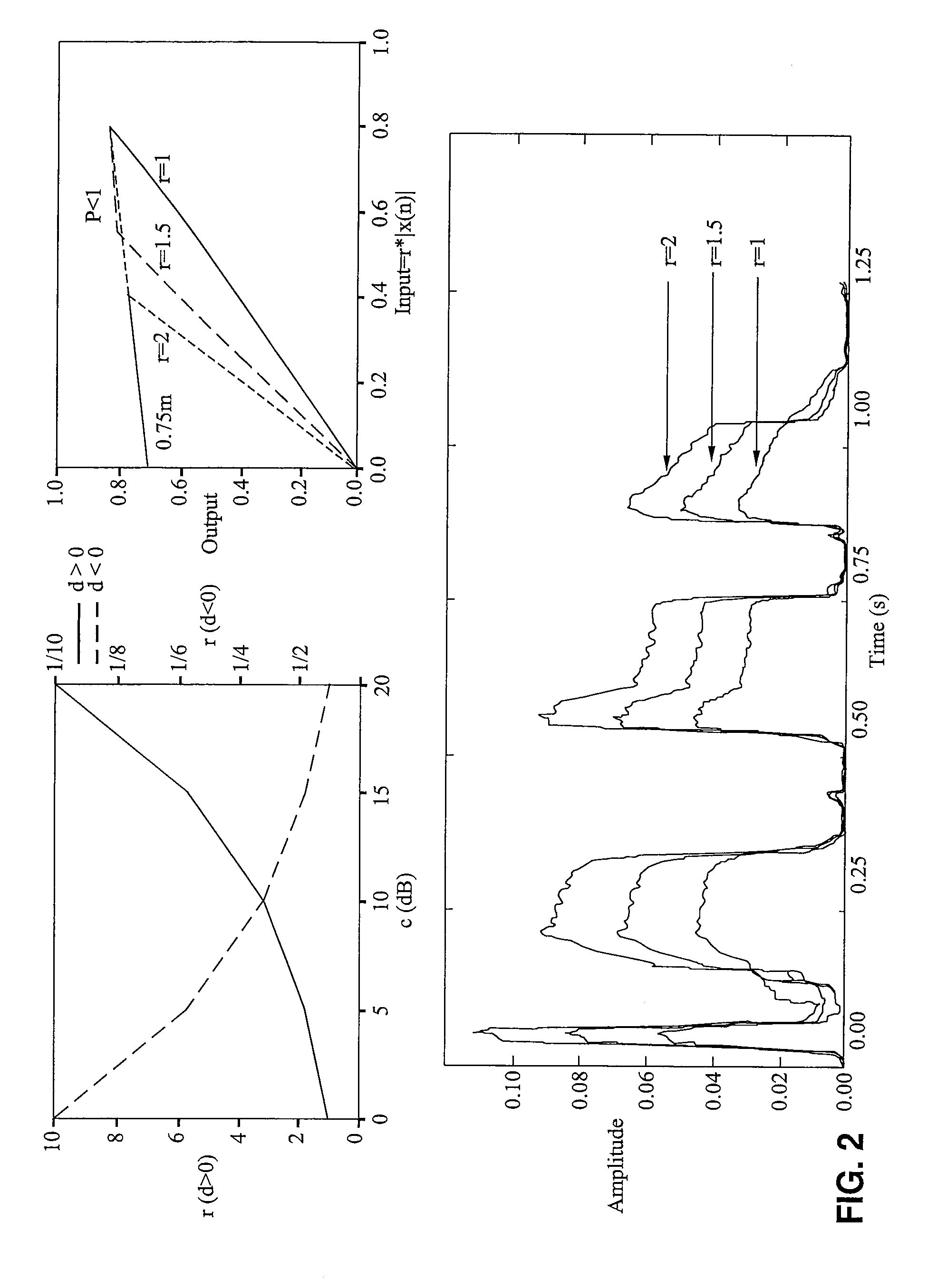

Methods, devices and systems using signal processing algorithms to improve speech intelligibility and listening comfort

ActiveUS20090226015A1Improve naturalnessWell maintained structureElectrotherapyEar treatmentAuditory neuropathyHearing perception

Methods, devices and systems for improving hearing and for treating hearing disorders, such as auditory neuropathies. A hearing enhancement system of this invention generally comprises; an amplitude modulation processor, a frequency high-pass processor, a frequency upward-shifting processor and a formant upward-shifting processor.

Owner:RGT UNIV OF CALIFORNIA

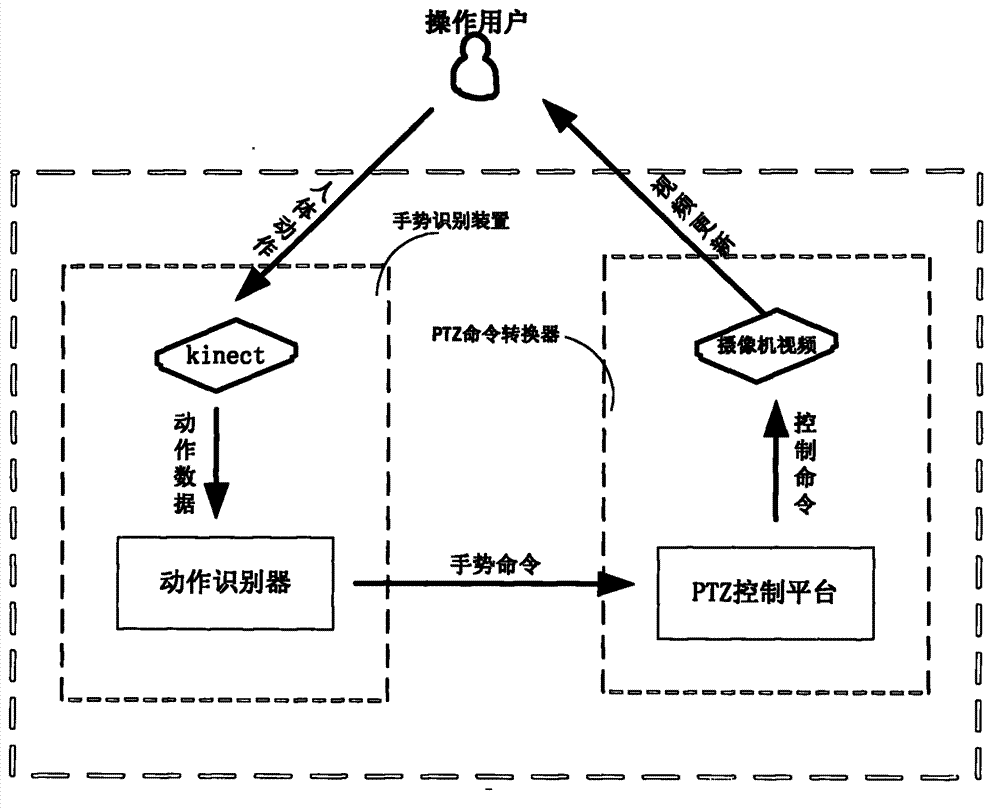

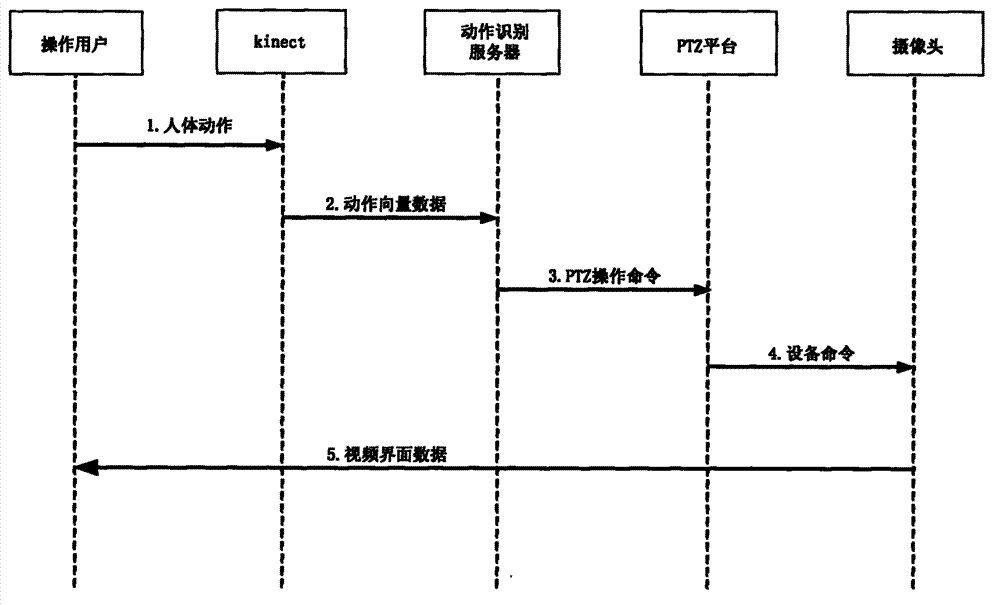

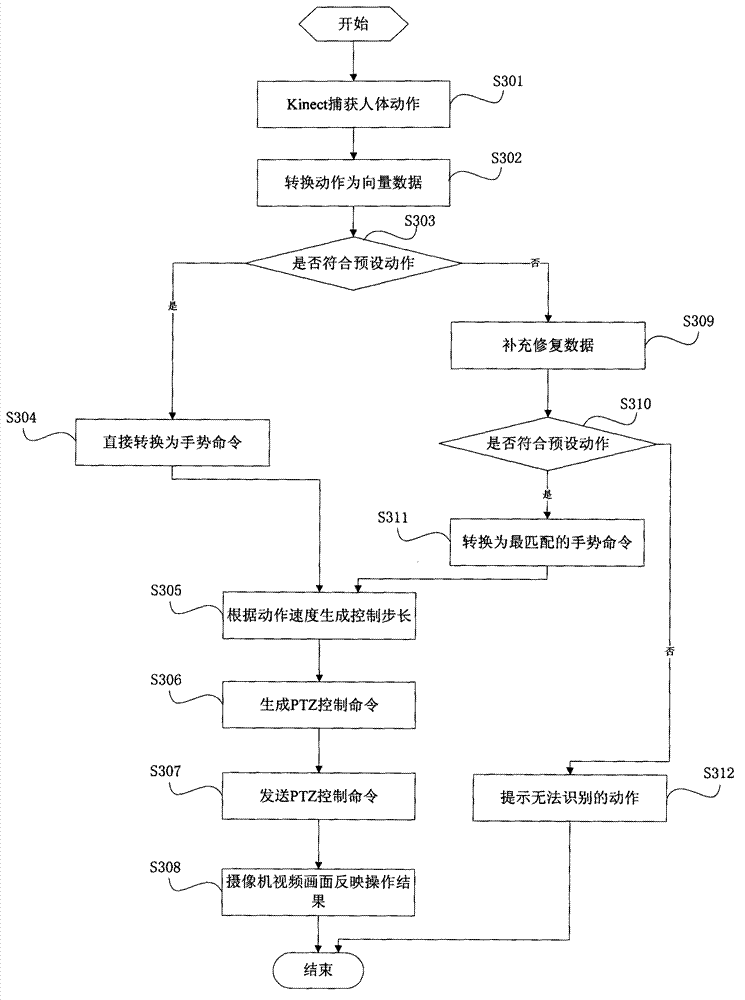

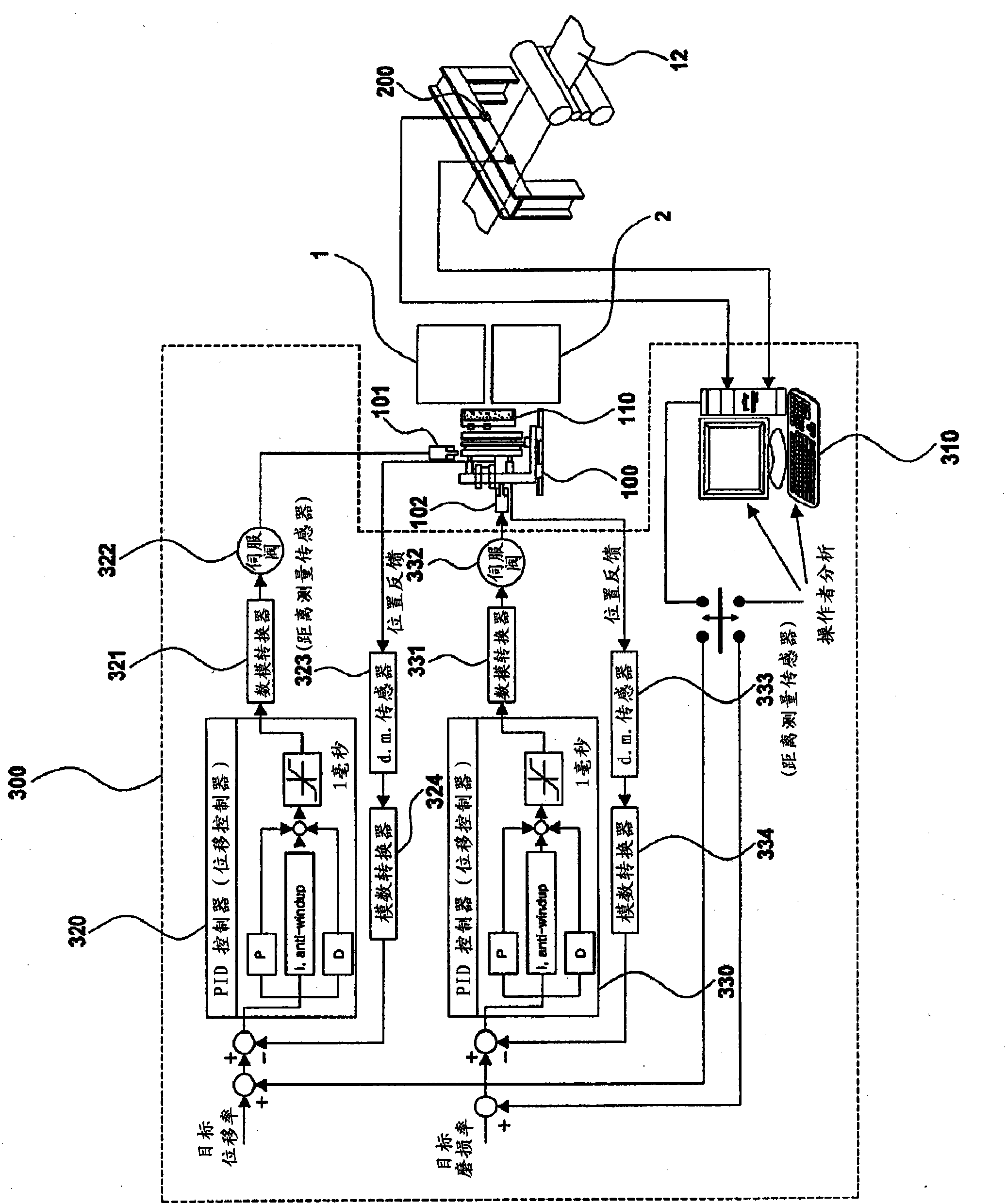

Method, device and system of pan tilt zoom (PTZ) control of video camera based on kinect

InactiveCN103118227AInput/output for user-computer interactionTelevision system detailsVideo monitoringPan tilt zoom

The invention discloses a method, a device and a system of pan tilt zoom (PTZ) control of a video camera based on kinect. PTZ control of the video camera for security and protection monitoring can be achieved through human movements, complex operation interfaces are not required, and PTA control of the video camera is operated simply and conveniently through a video monitoring system. The method, the device and the system comprise that the human movements are caught through the kinect, human movement vector quantity data are input into behavior identification software, after corresponding data optimization, data conversion and behavior judgment, the human movements are converted into PTZ control commands of the monitoring video camera, the PTZ control commands include upward shift, downward shift, left shift, right shift, picture enlargement, picture shrink, preset position switchover, windshield wiper starting and the like, the control commands are sent to the video camera to conduct PTZ control, the video executes corresponding movements, and operation results are displayed in real time through real-time video frames.

Owner:PCI TECH GRP CO LTD

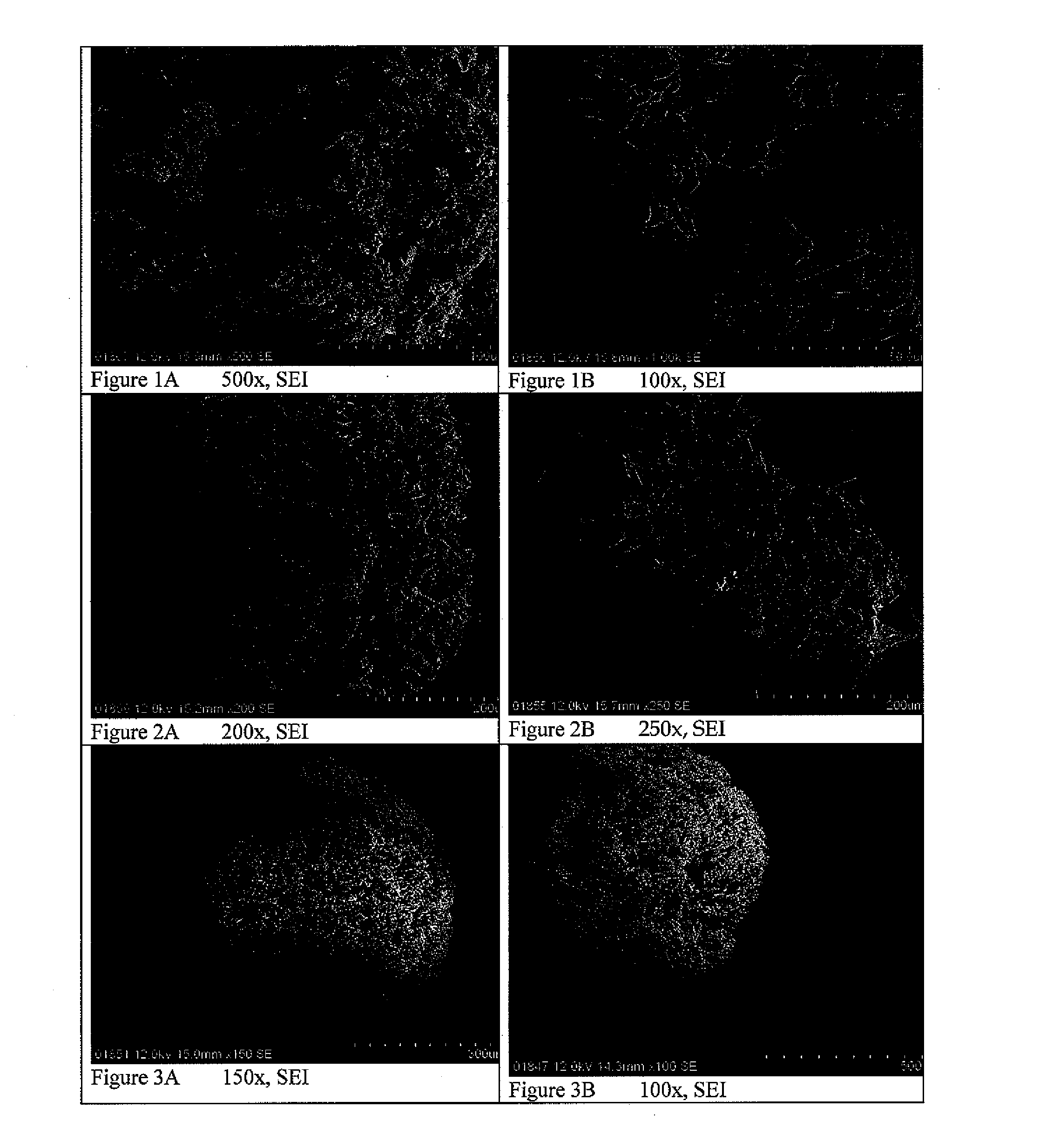

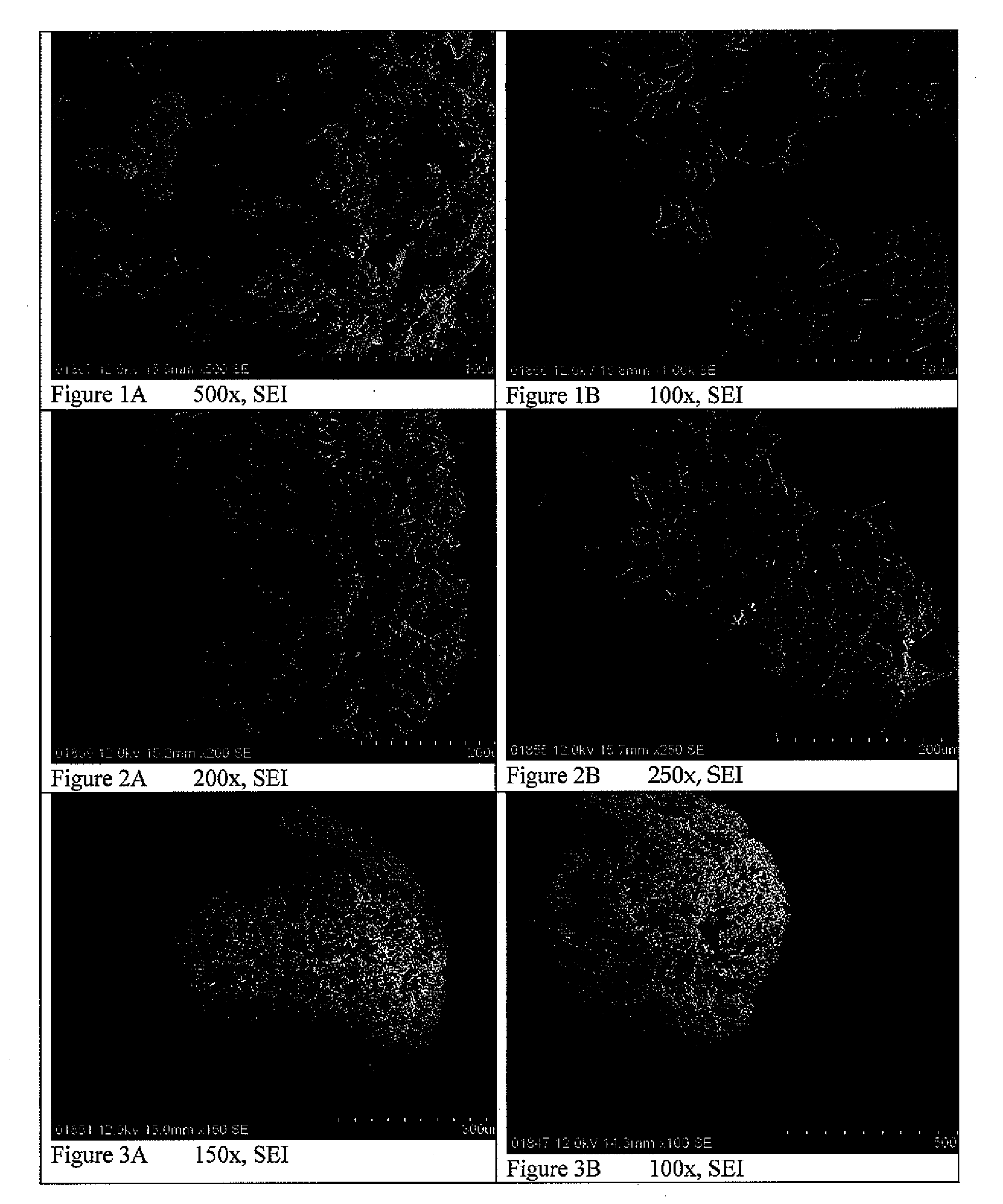

Composition and method for improved aluminum hydroxide production

ActiveUS20070172405A1Gallium/indium/thallium compoundsBeryllium compoundsAluminium hydroxideImproved method

An improved method and composition for producing aluminum hydroxide crystals from precipitation liquor, involves the addition of an emulsified crystal growth modifier comprising a C8-C10 fatty acid, precursors, salts or blends thereof. The emulsified crystal growth modifier also facilitates an upward shift in particle size distribution of aluminum hydroxide and an upward shift in oxalate ball size.

Owner:ECOLAB USA INC

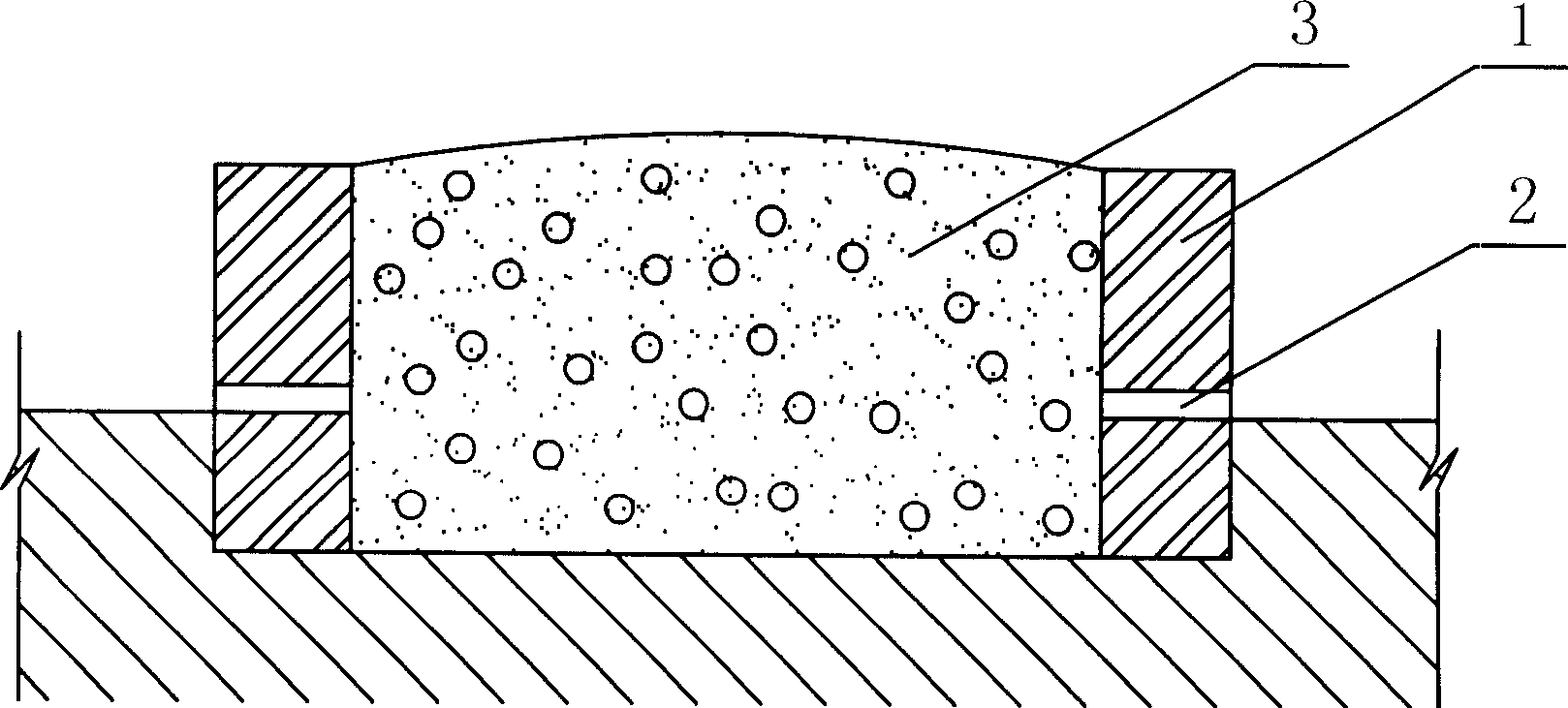

Soil salt unidirectional down-moving method for treatment of saline alkaline land

The invention relates to a method for modifying saline-sodic soil, especially to a method of modifying saline-sodic soil through the unidirectional downward shift of the salt in soil, comprising the following steps: constructing annular stationary pool on the surface of the low-level saline-alkali land, setting water-guiding pore lower than the surface out of pool on the wall of the stationary pool, digging the surface inside pool and making it lower than that of out of pool, filling covering material in the stationary pool, with the upper surface higher than the top of the stationary pool wall. The invention solves the problems of only suited for the treatment for episodic soil modification or for light saline-alkali land by current technique, reducing the salt content in the plant root area but not making salt upward shift, preventing salt out of pool brought by wind dropping in the pool and increasing the salt content, the cost of the covering material is low and easy to get. Forest plantation or fell-plant plantation can be carried out in saline-alkali dry and virgin land with salt content higher than 0.5%; the method is especially suited to be applied in areas with the groundwater level higher than 1m.

Owner:河北省农林科学院农业经济研究所

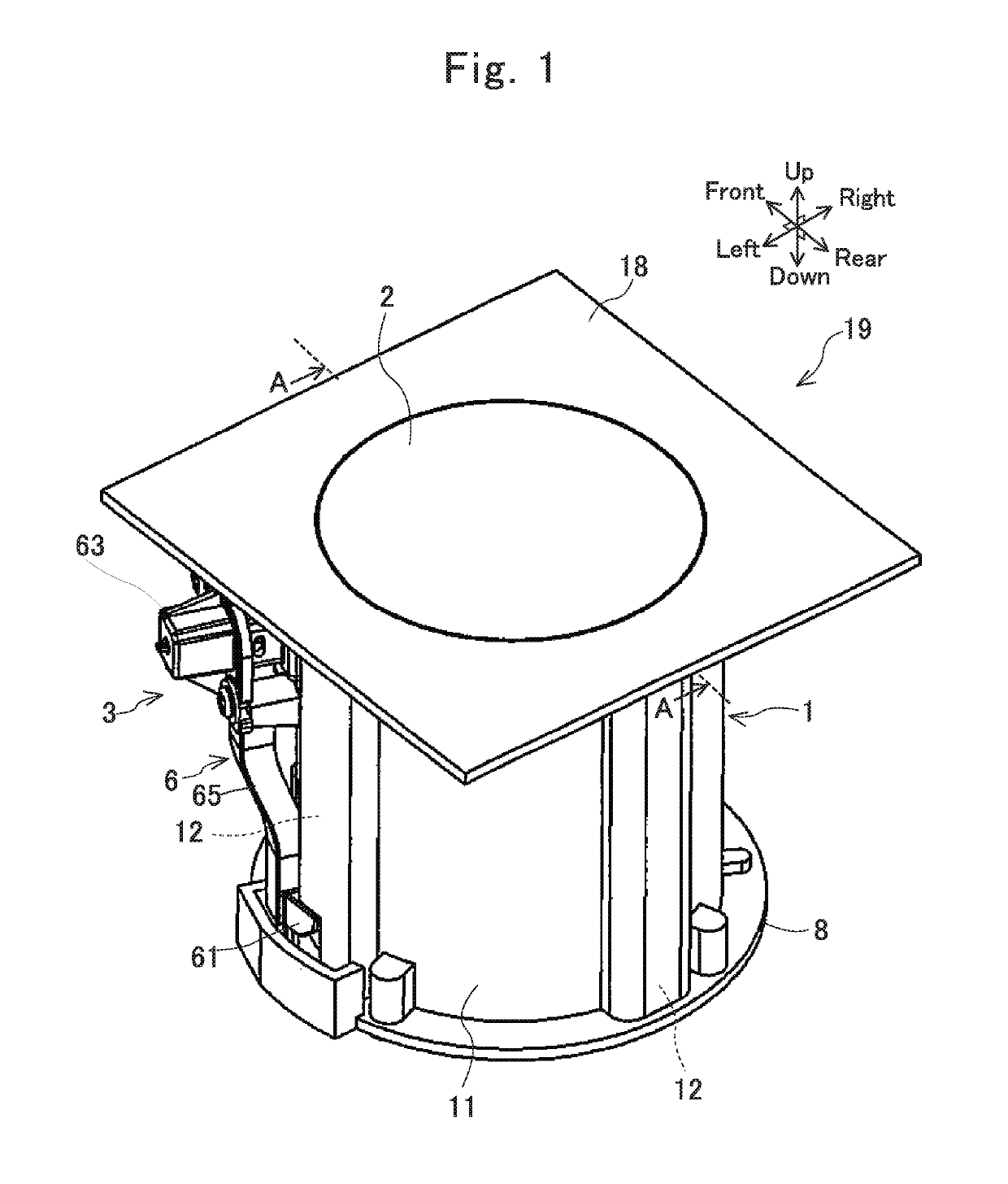

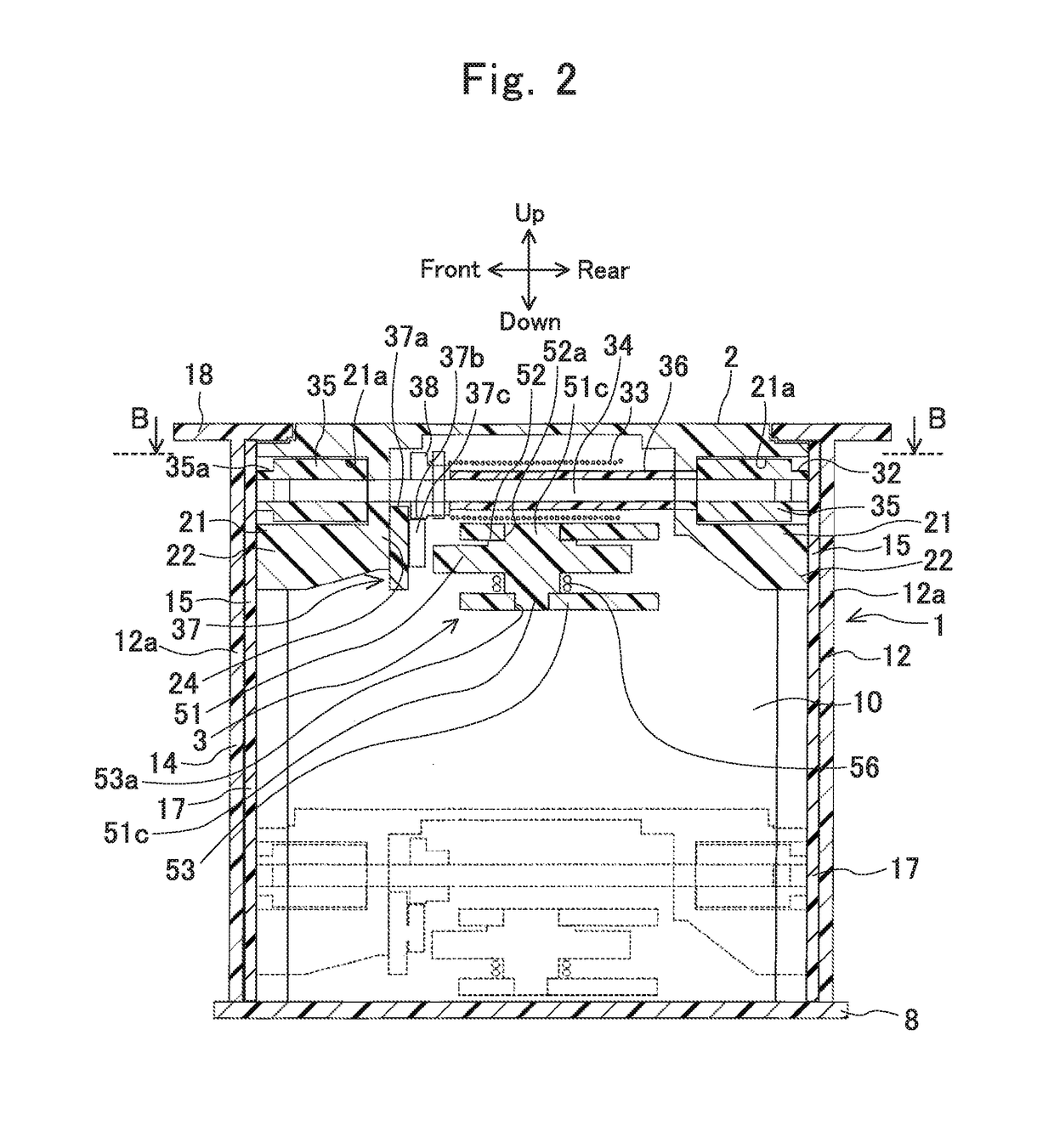

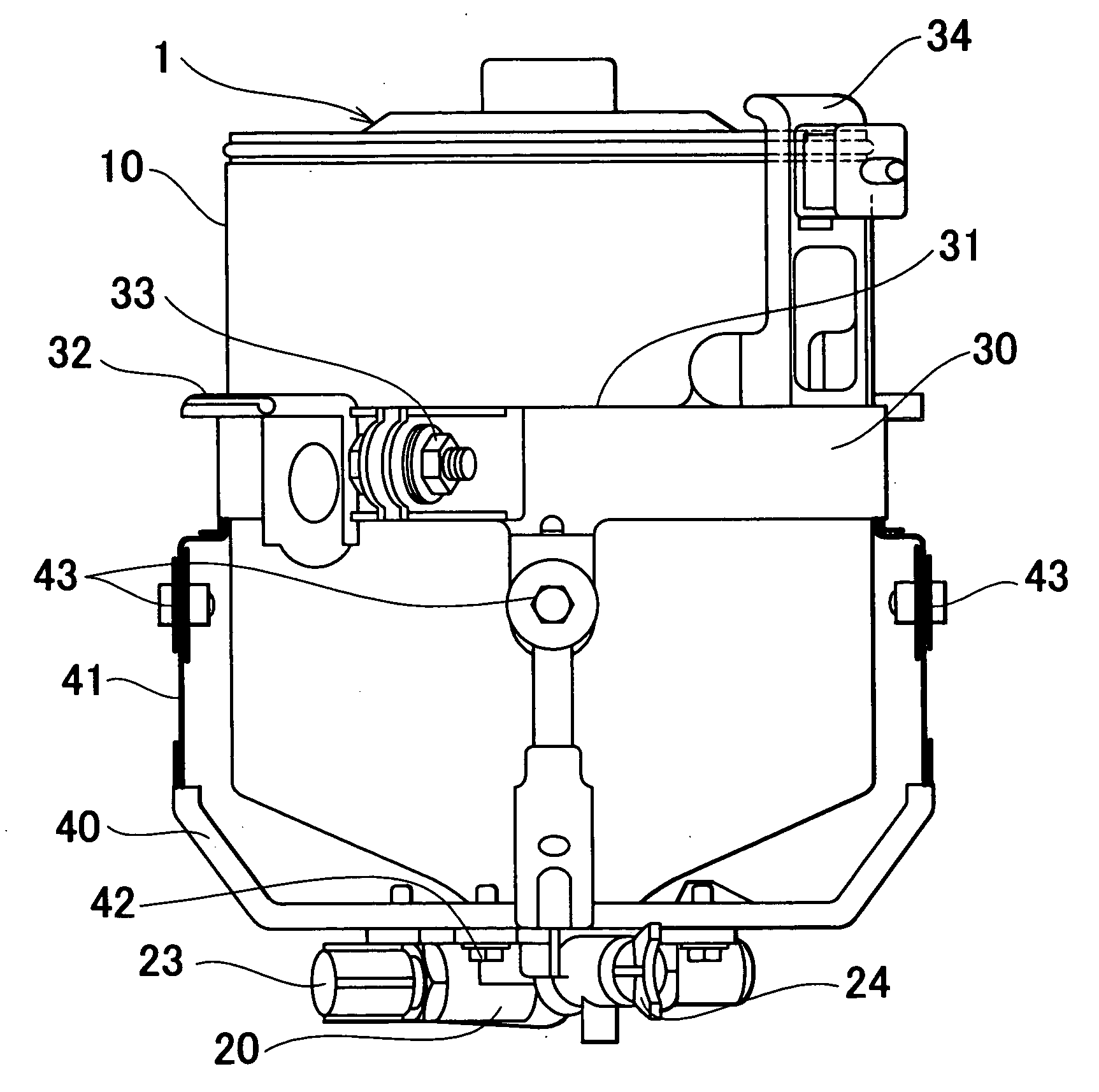

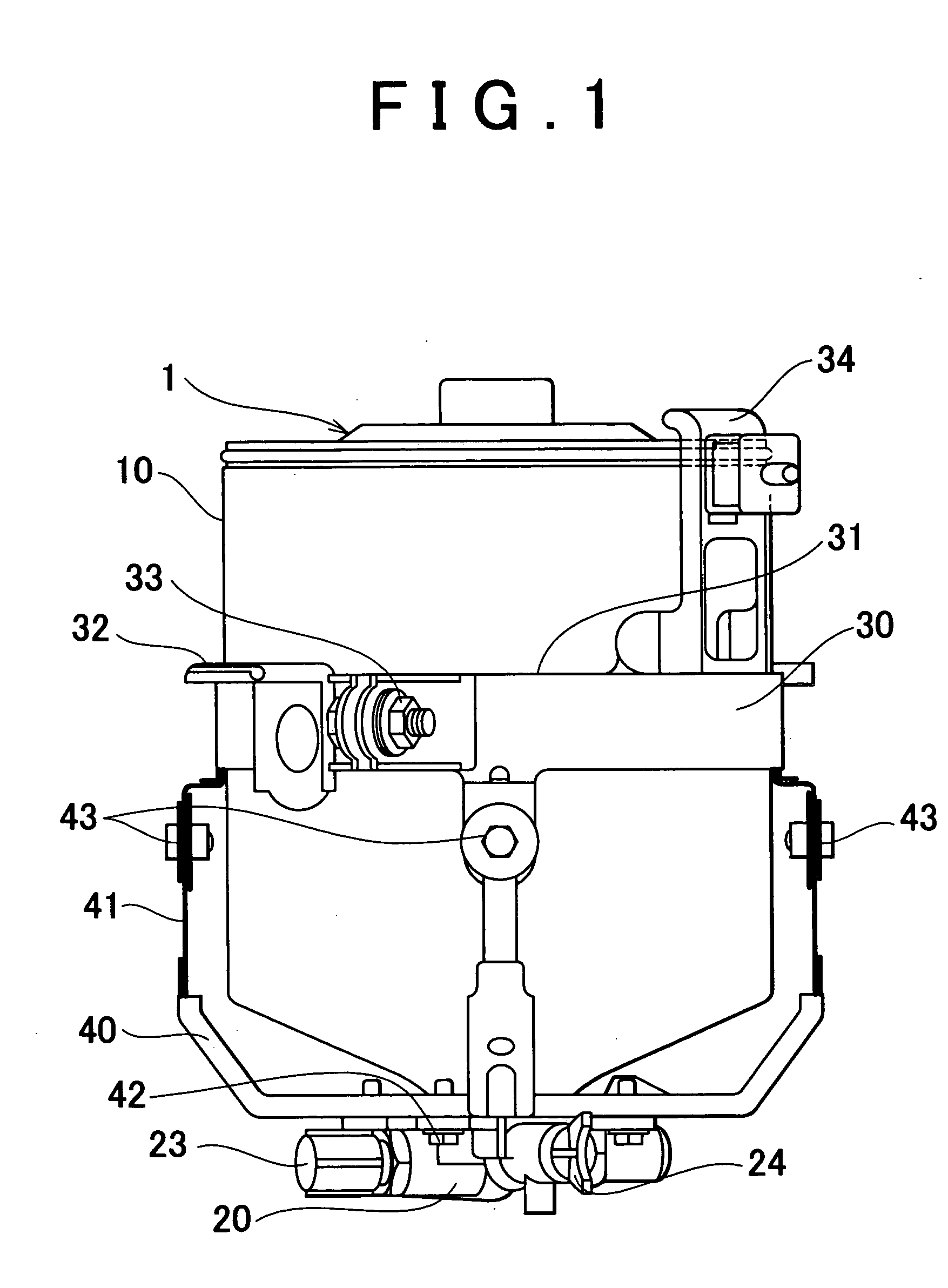

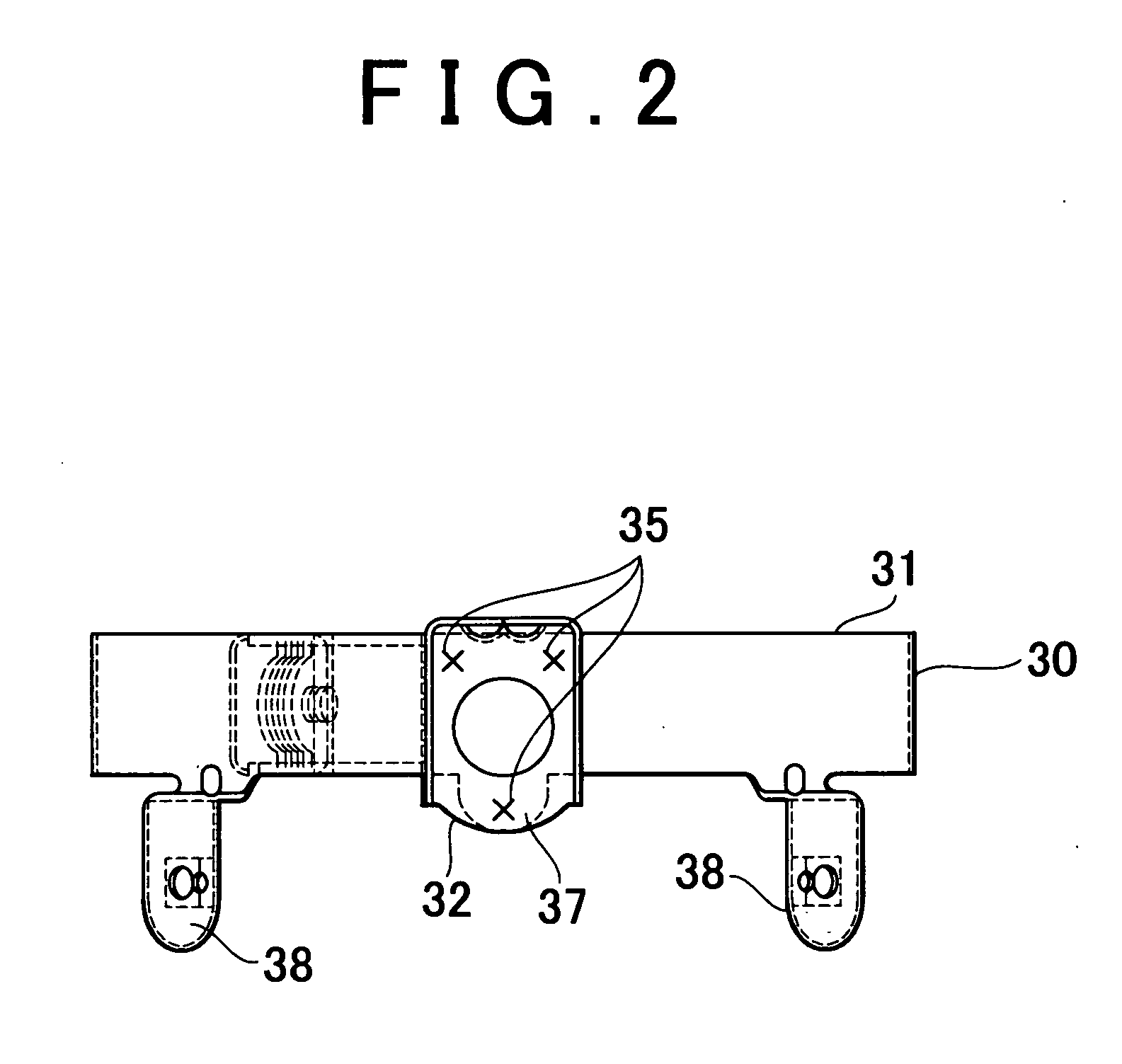

Cup holder

ActiveUS10506890B2Increase flexibilityVehicle arrangementsBottle holdersPinionMechanical engineering

A cup holder includes a holder body having a peripheral wall surrounding an accommodation space, a tray provided in the accommodation space and vertically shiftably supported by the peripheral wall, and a height adjuster configured to vertically shift the tray. The height adjuster includes at least one rack gear extending vertically on the peripheral wall, at least one pinion gear rotatably supported by the tray and meshing with the rack gear, and an energizing member provided at the tray and energizing to rotate the pinion gear for upward shift of the tray.

Owner:TOYODA GOSEI CO LTD

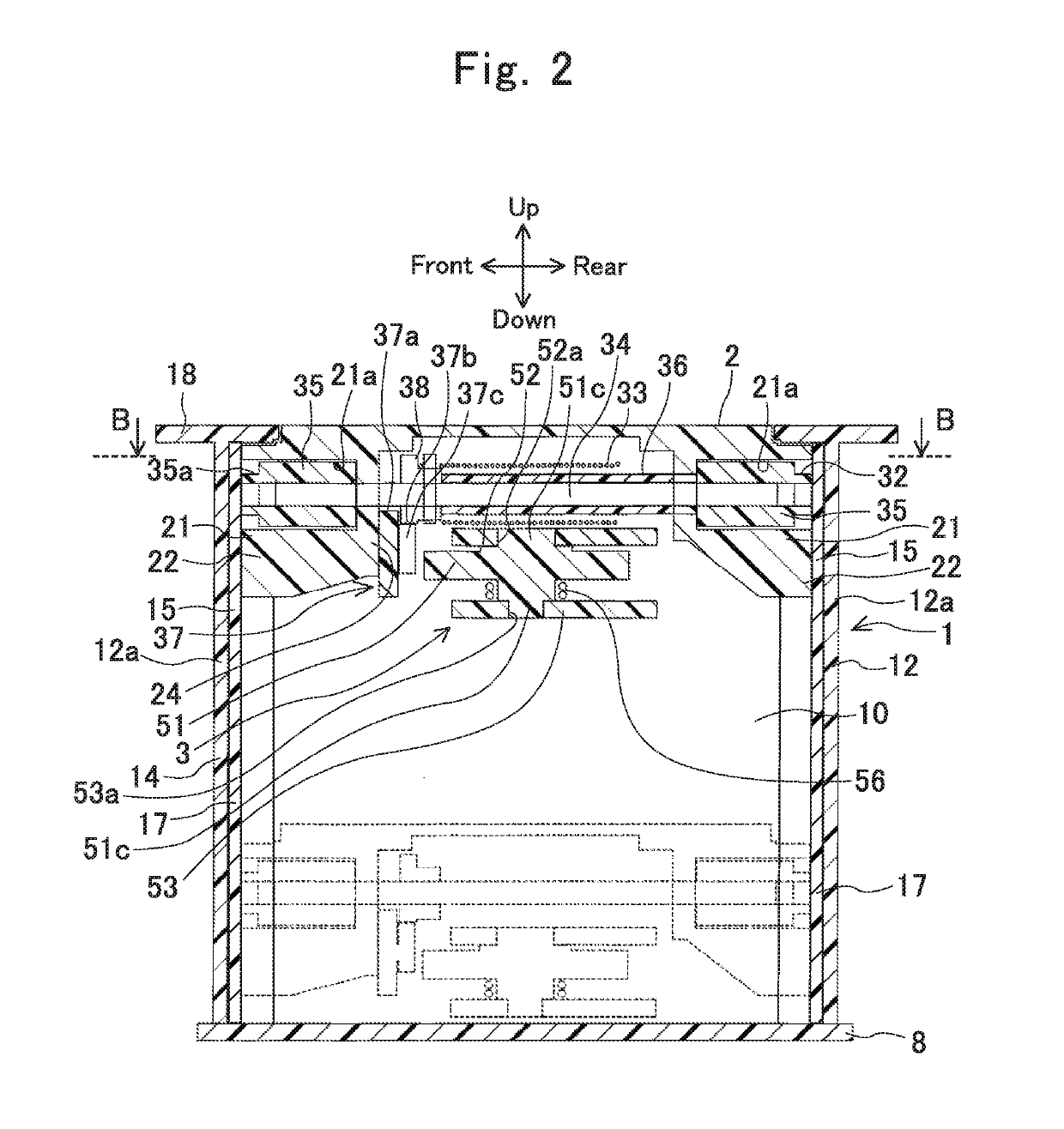

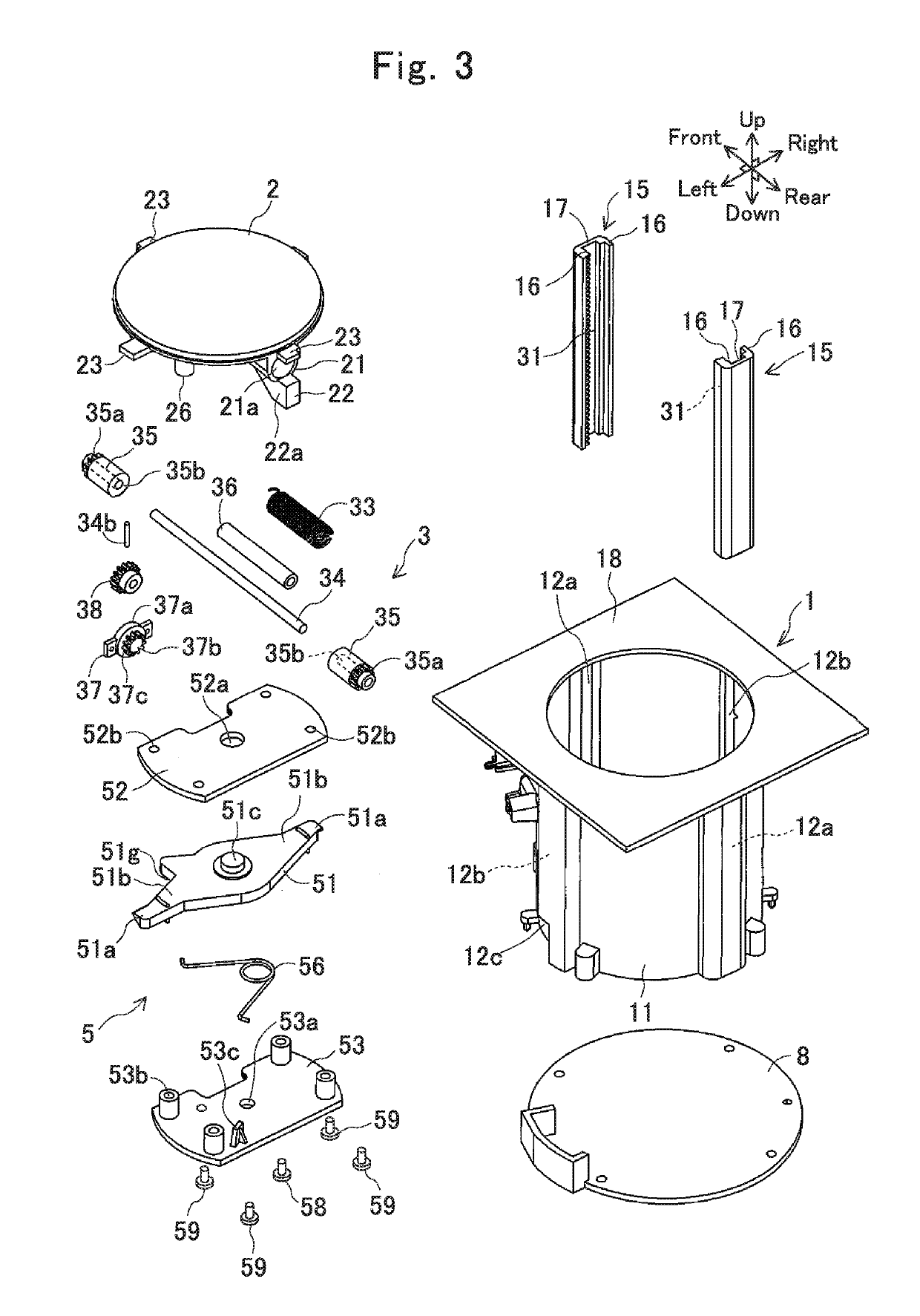

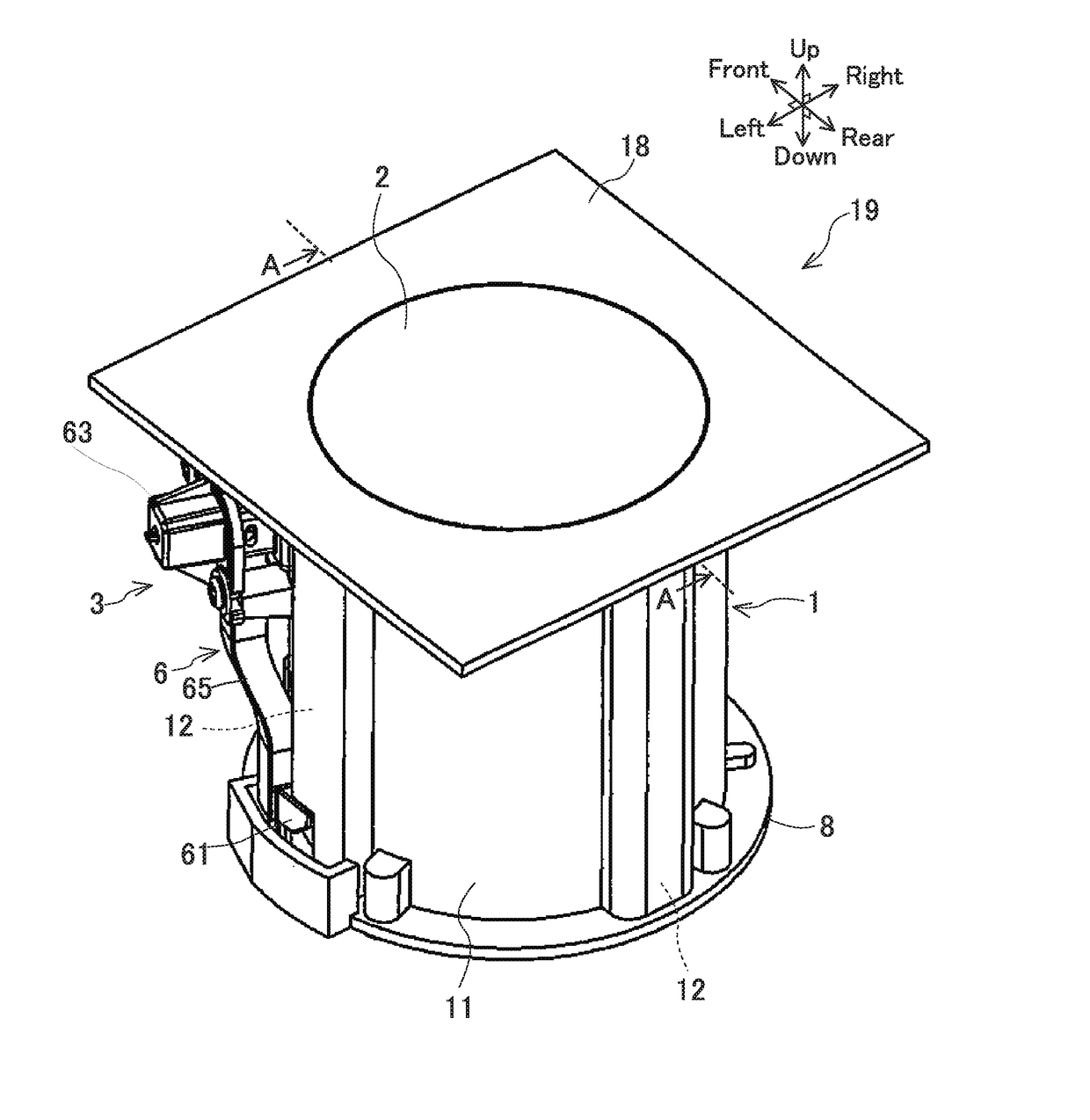

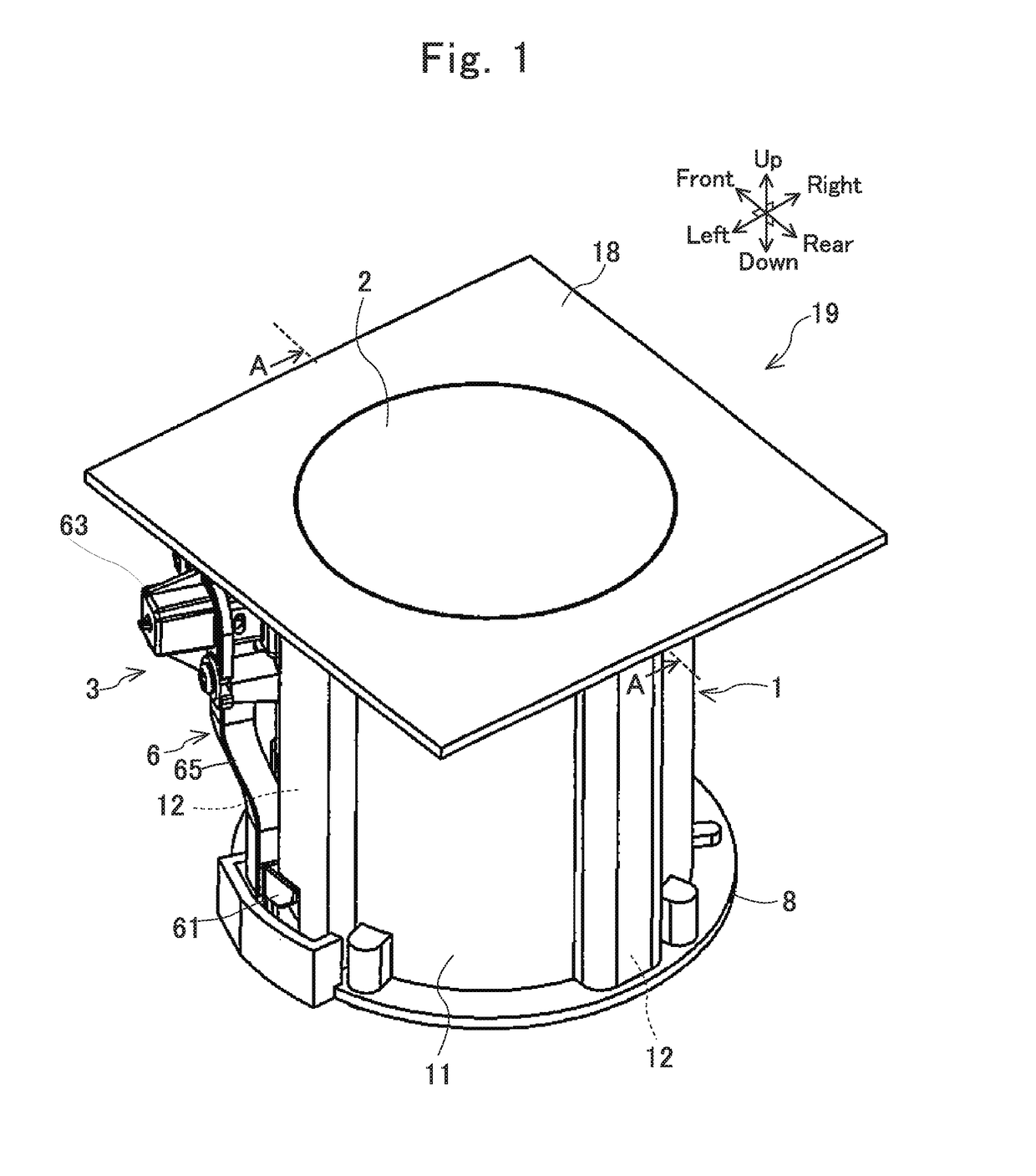

Cup holder

A cup holder includes a holder body having a peripheral wall surrounding an accommodation space, a tray provided in the accommodation space and vertically shiftably supported by the peripheral wall, and a height adjuster configured to vertically shift the tray. The height adjuster includes at least one rack gear extending vertically on the peripheral wall, at least one pinion gear rotatably supported by the tray and meshing with the rack gear, and an energizing member provided at the tray and energizing to rotate the pinion gear for upward shift of the tray.

Owner:TOYODA GOSEI CO LTD

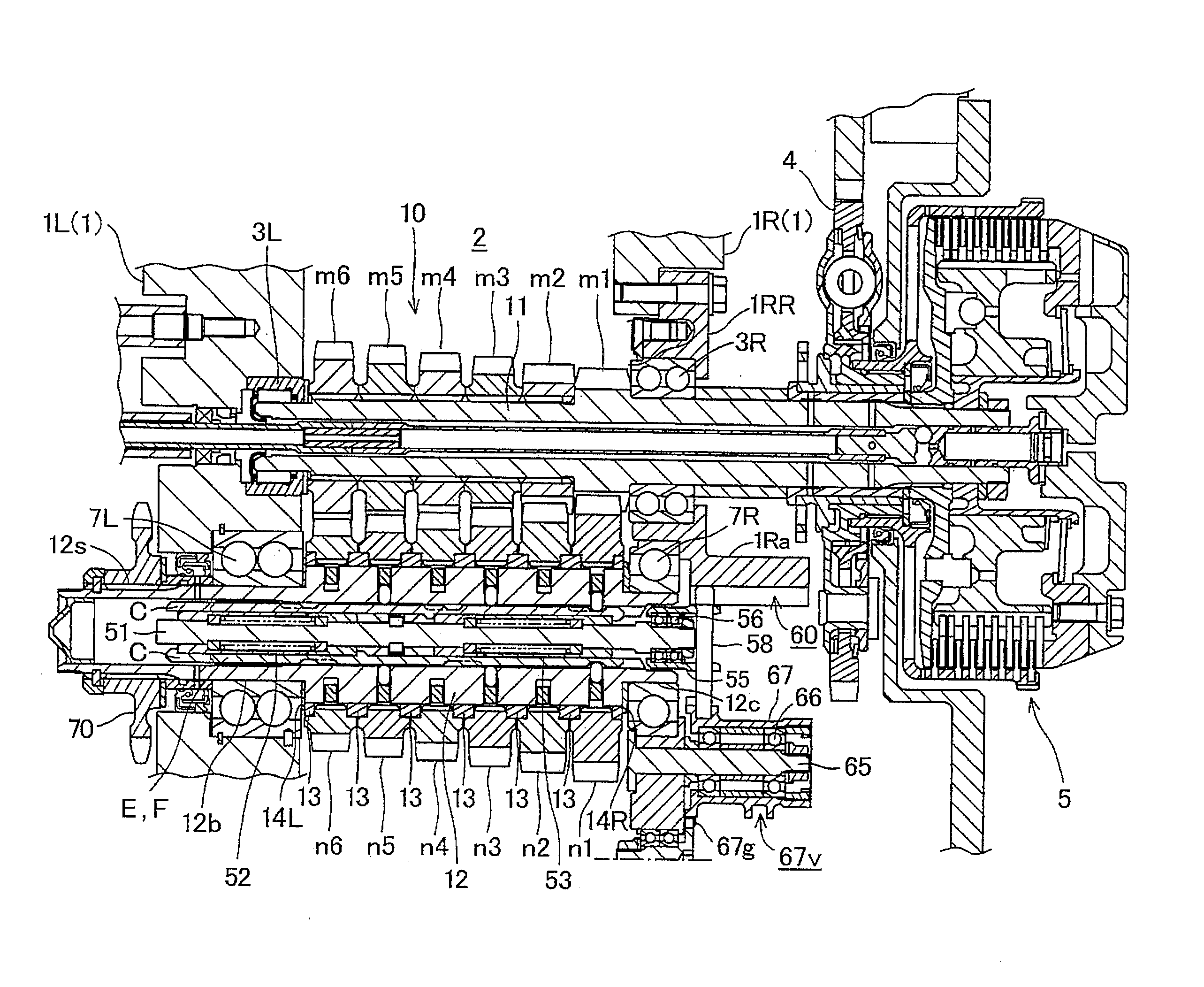

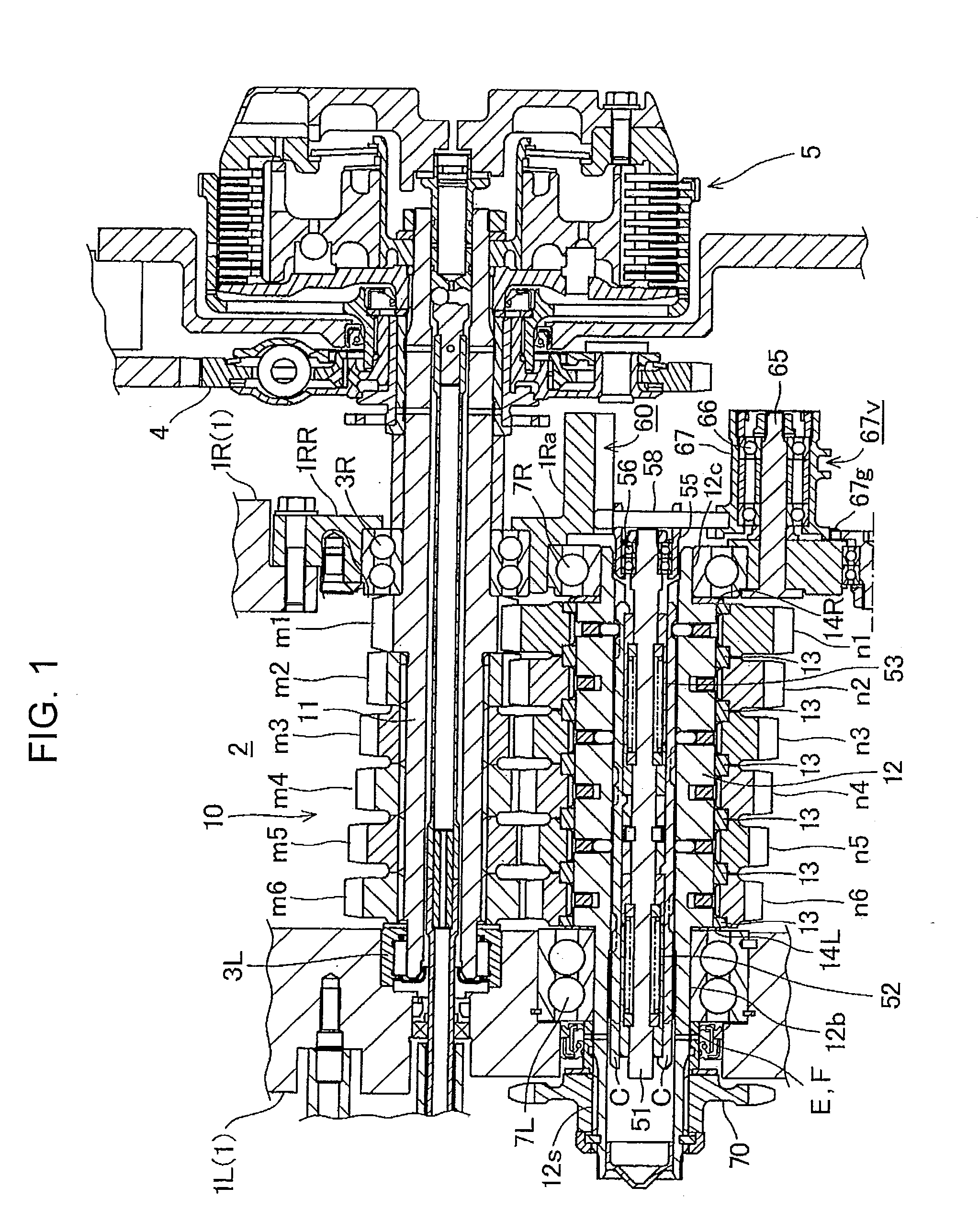

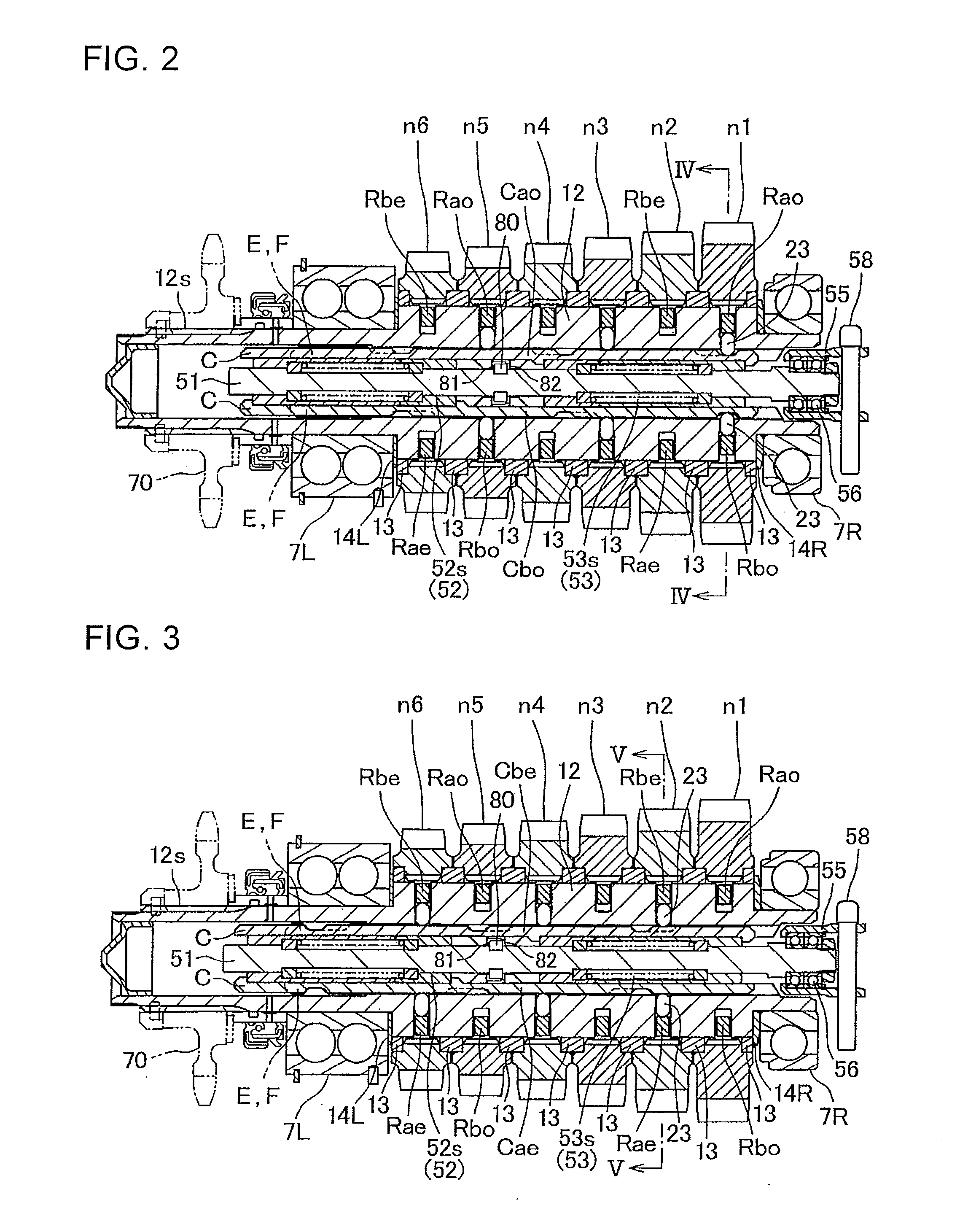

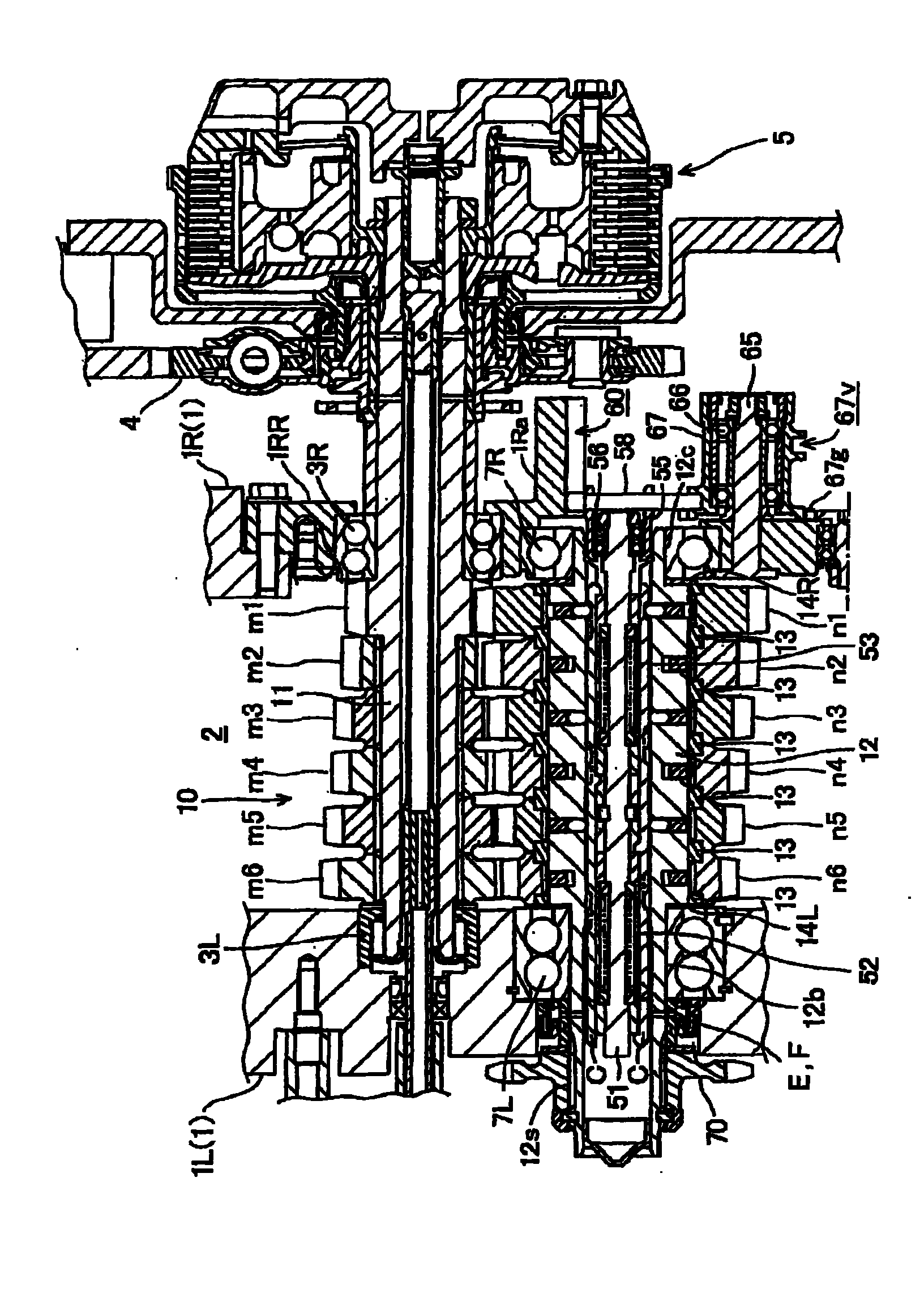

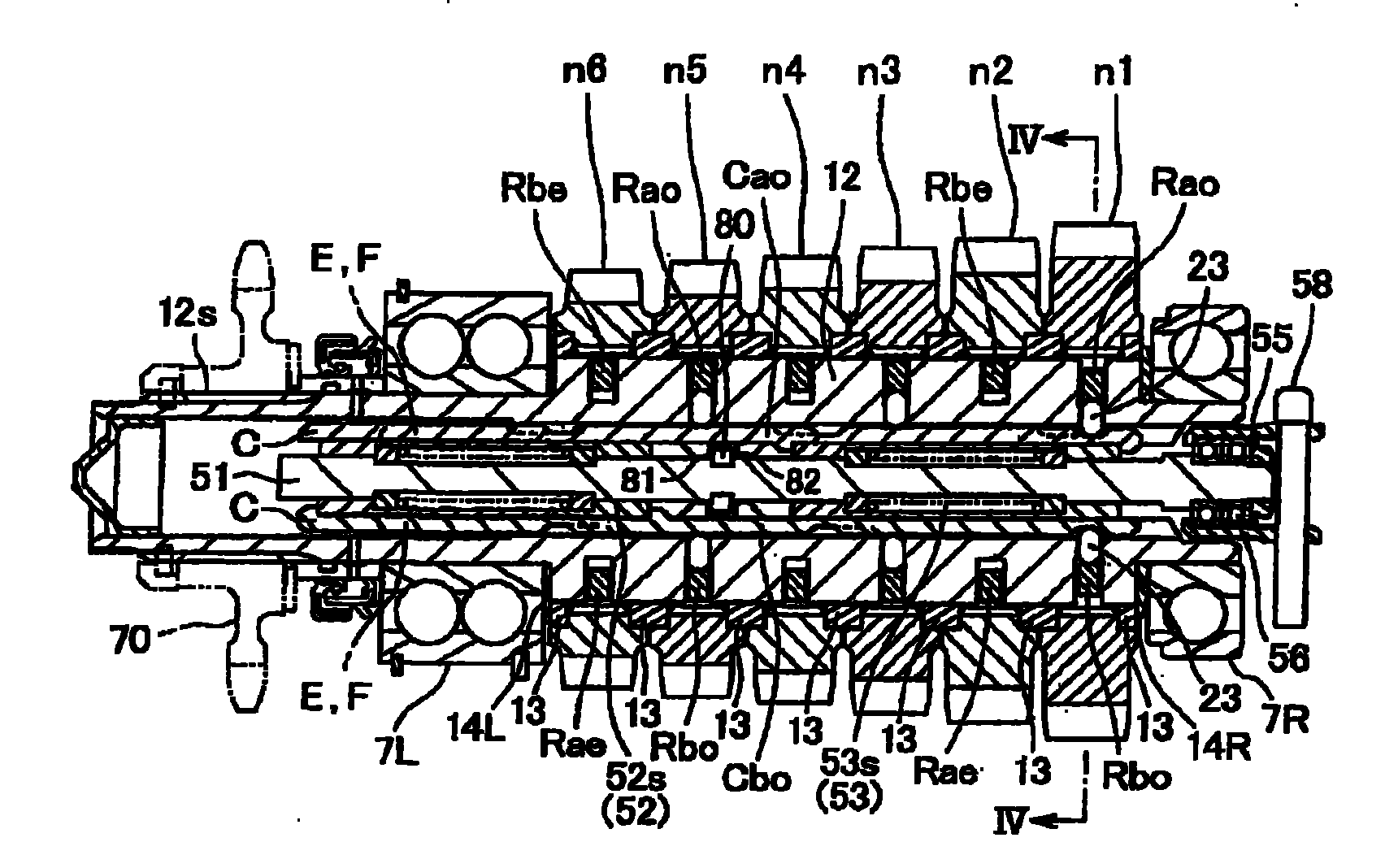

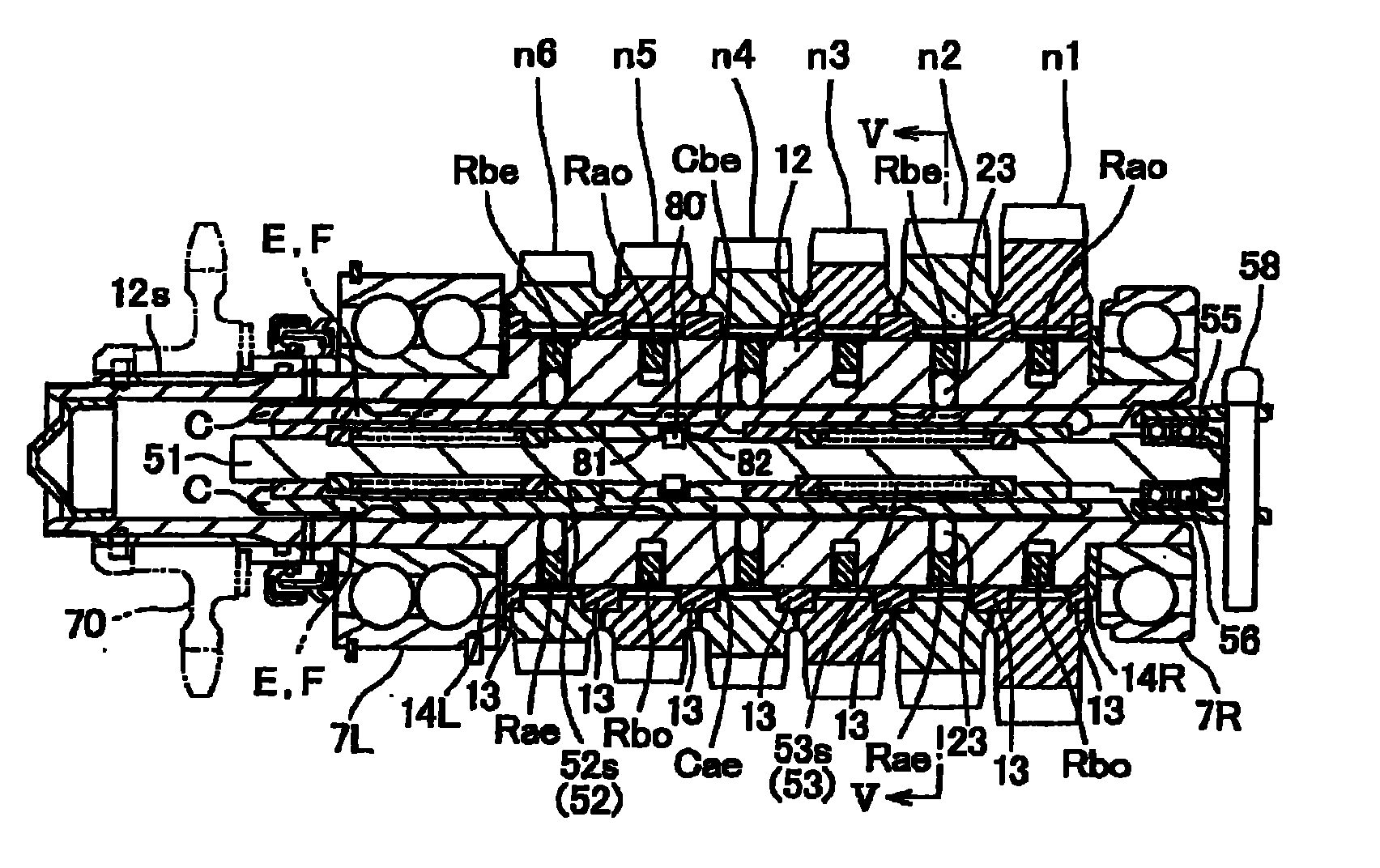

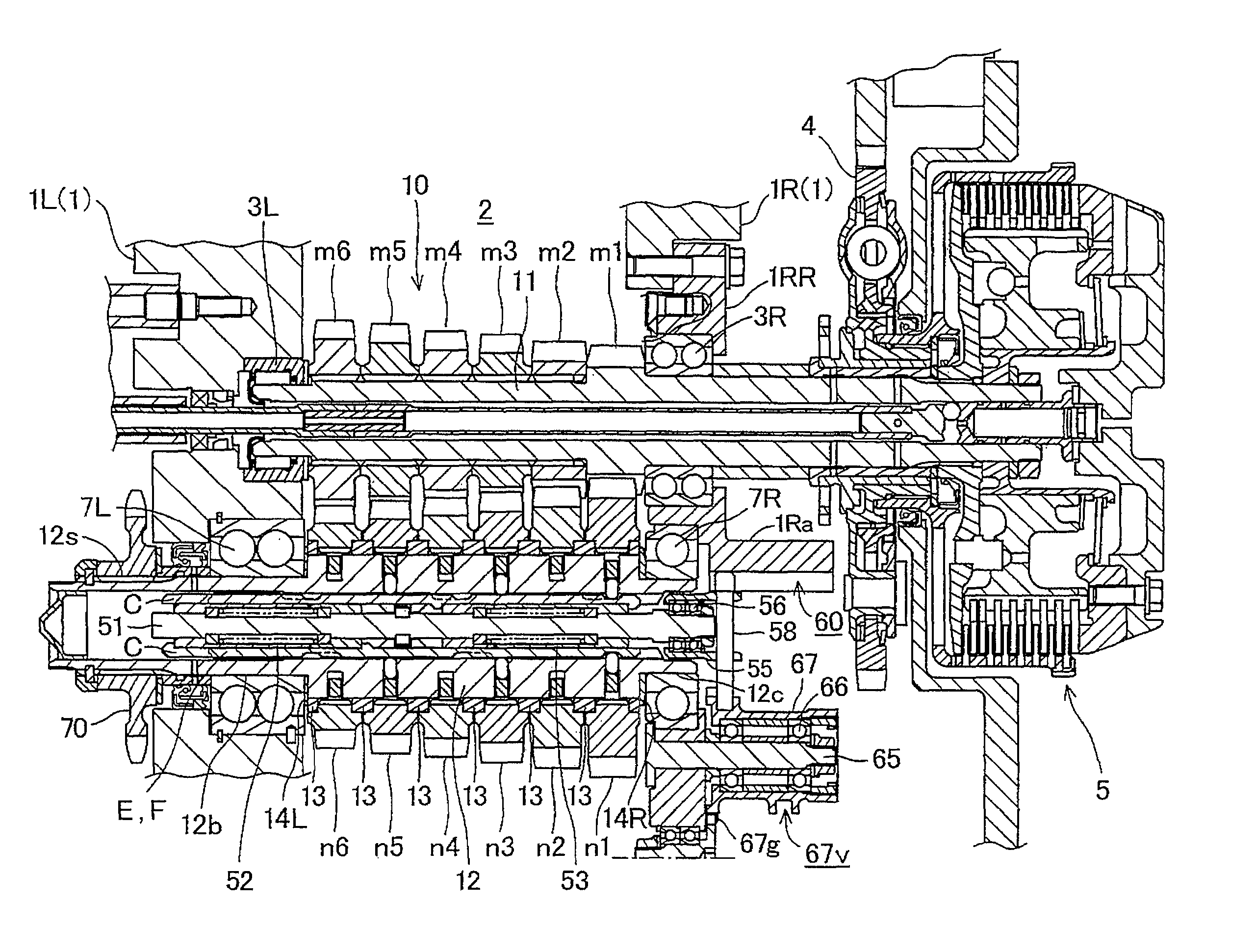

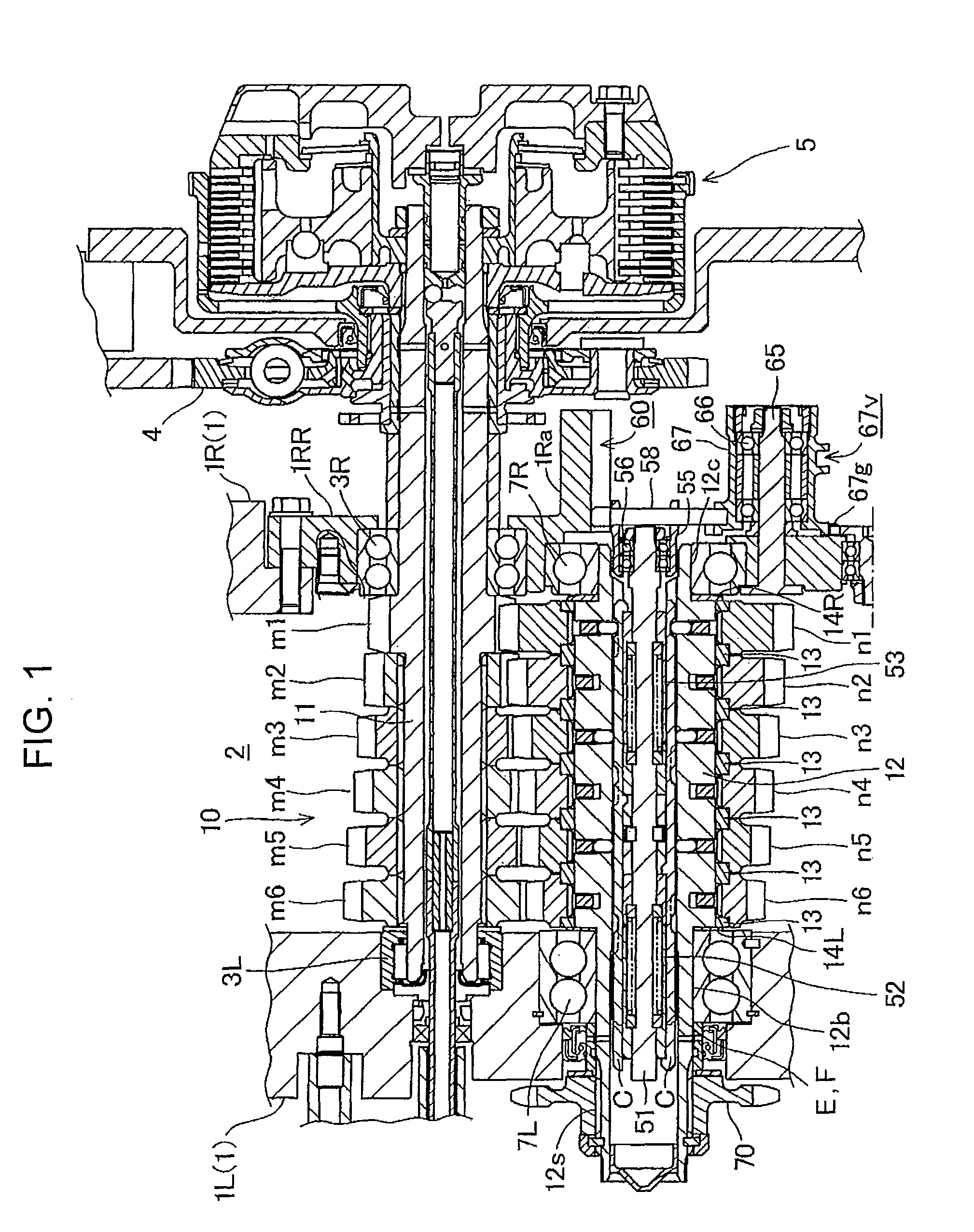

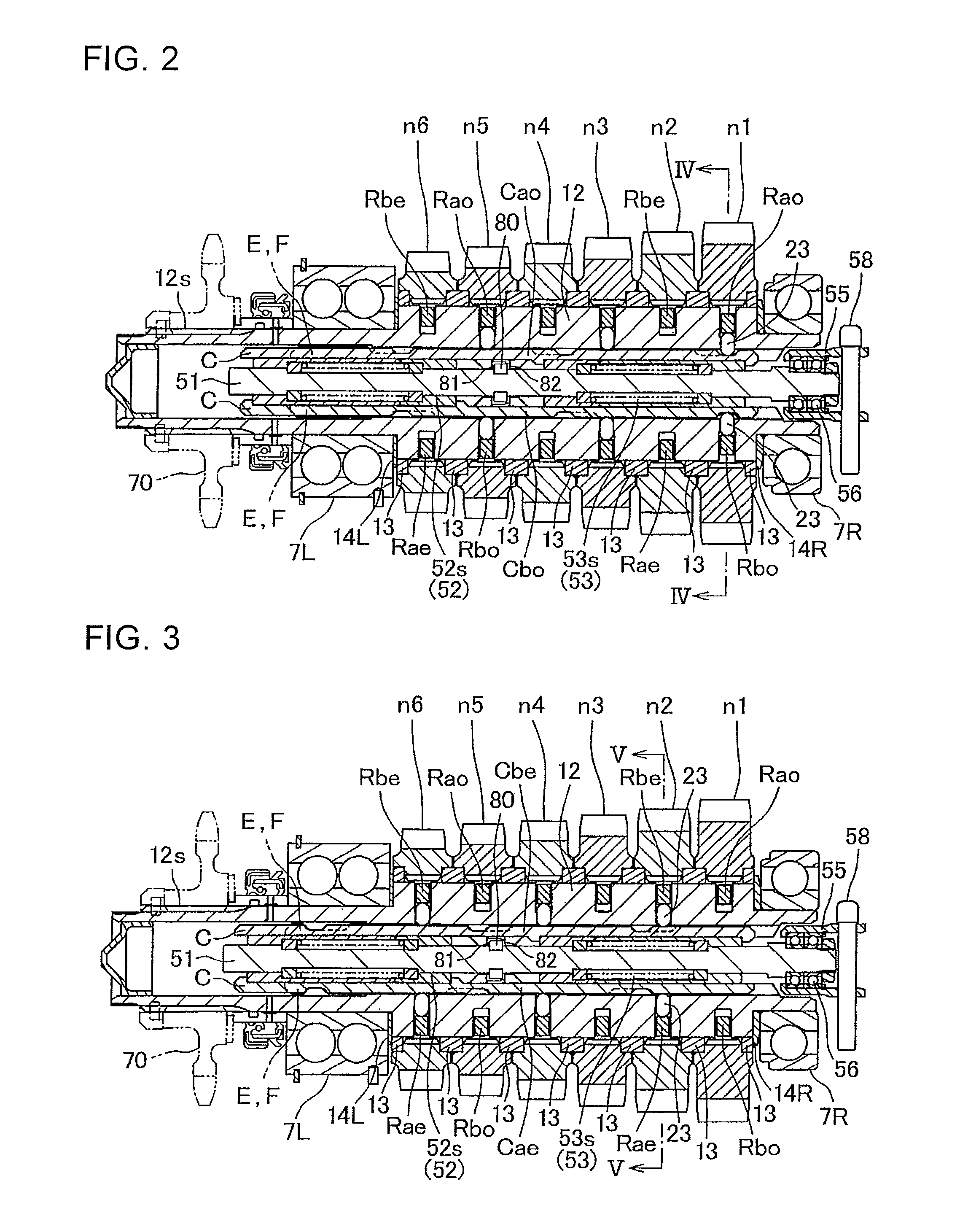

Multistage transmission

A multistage transmission includes a lost motion mechanism for regulating the operation for a downward shift in acceleration and for an upward shift in deceleration. Regulating rods are integrally moved with a control rod. A cutout into which a pin can be fitted together with a cam groove of the slidingly touched cam rod is formed corresponding to each cam groove in the regulating rods. The cutout of the regulating rods corresponding to the cam groove of the cam rod for normal rotation is formed longer than the corresponding cam groove on the reverse side to a moving direction of the control rod in an upward shift in a state in which shifted speed is established. The cutout of the regulating rods corresponding to the cam groove of the cam rod for reverse rotation is formed longer than the corresponding cam groove on the reverse side to a moving direction.

Owner:HONDA MOTOR CO LTD

Multistage transmission

A multistage transmission includes a lost motion mechanism for regulating the operation for a downward shift in acceleration and for an upward shift in deceleration. Regulating rods are integrally moved with a control rod. A cutout into which a pin can be fitted together with a cam groove of the slidingly touched cam rod is formed corresponding to each cam groove in the regulating rods. The cutout of the regulating rods corresponding to the cam groove of the cam rod for normal rotation is formed longer than the corresponding cam groove on the reverse side to a moving direction of the control rod in an upward shift in a state in which shifted speed is established. The cutout of the regulating rods corresponding to the cam groove of the cam rod for reverse rotation is formed longer than thecorresponding cam groove on the reverse side to a moving direction.

Owner:HONDA MOTOR CO LTD

Composition and method for improved aluminum hydroxide production

ActiveUS7976821B2Gallium/indium/thallium compoundsAluminium hydroxide preparationAluminium hydroxideImproved method

An improved method and composition for producing aluminum hydroxide crystals from precipitation liquor, involves the addition of an emulsified crystal growth modifier comprising a C8-C10 fatty acid, precursors, salts or blends thereof. The emulsified crystal growth modifier also facilitates an upward shift in particle size distribution of aluminum hydroxide and an upward shift in oxalate ball size.

Owner:ECOLAB USA INC

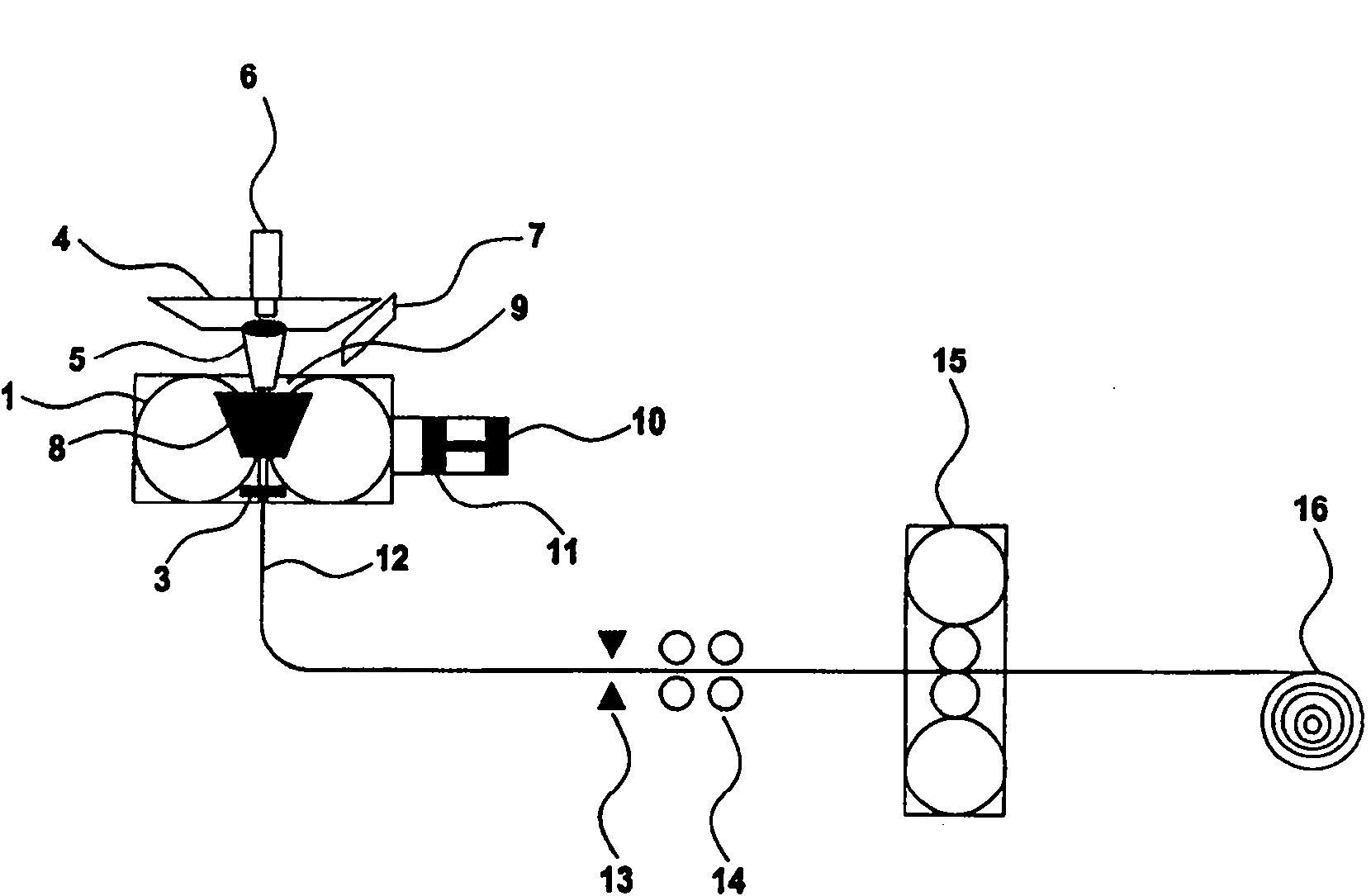

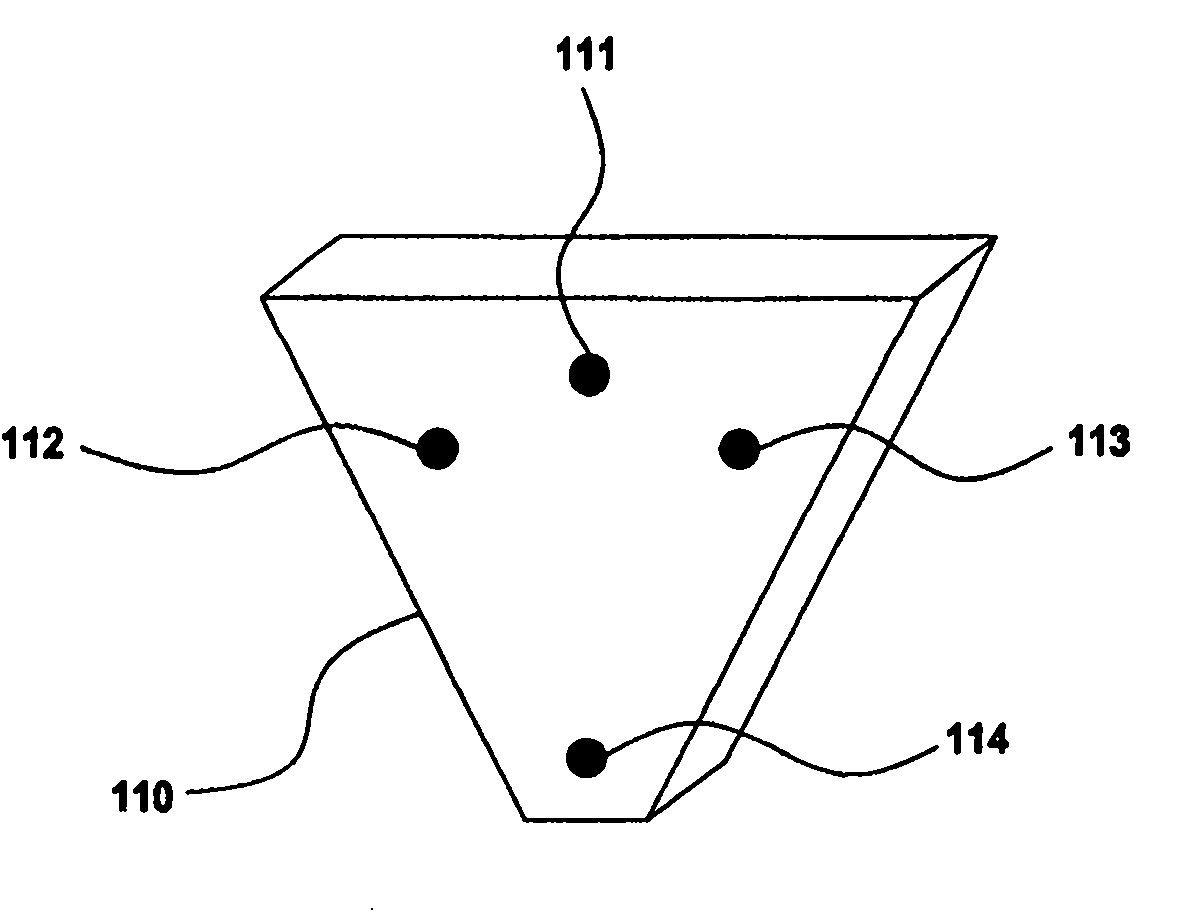

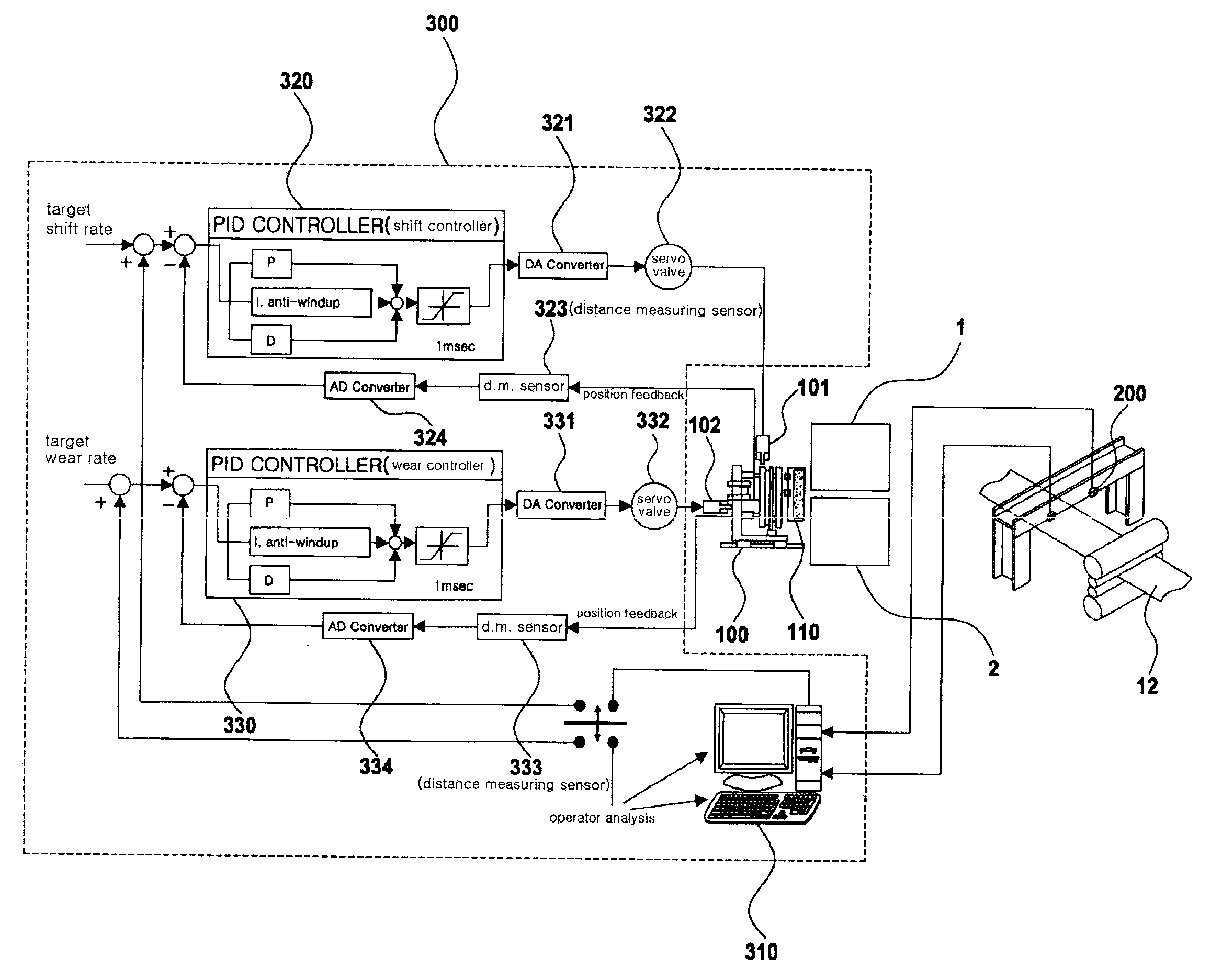

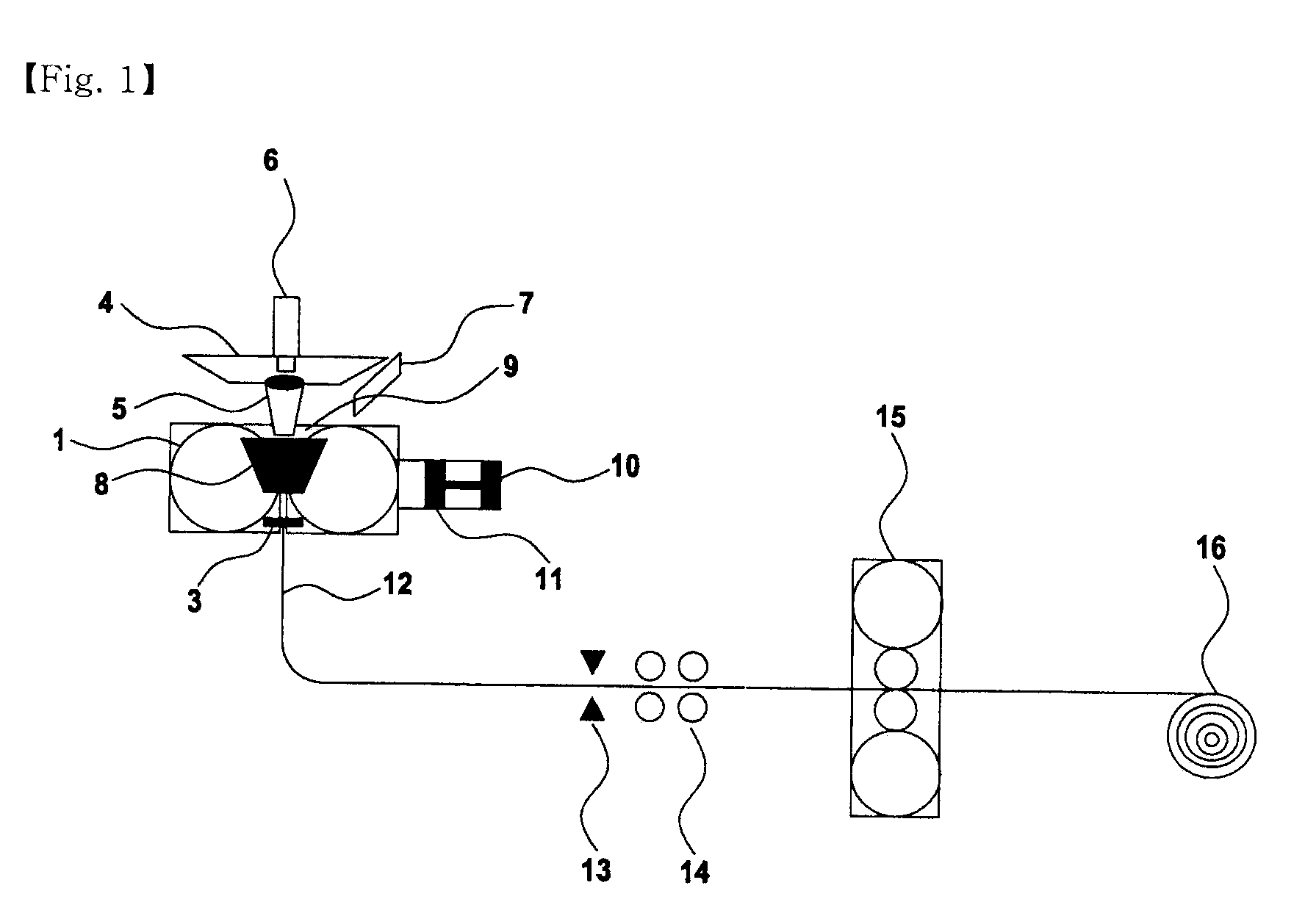

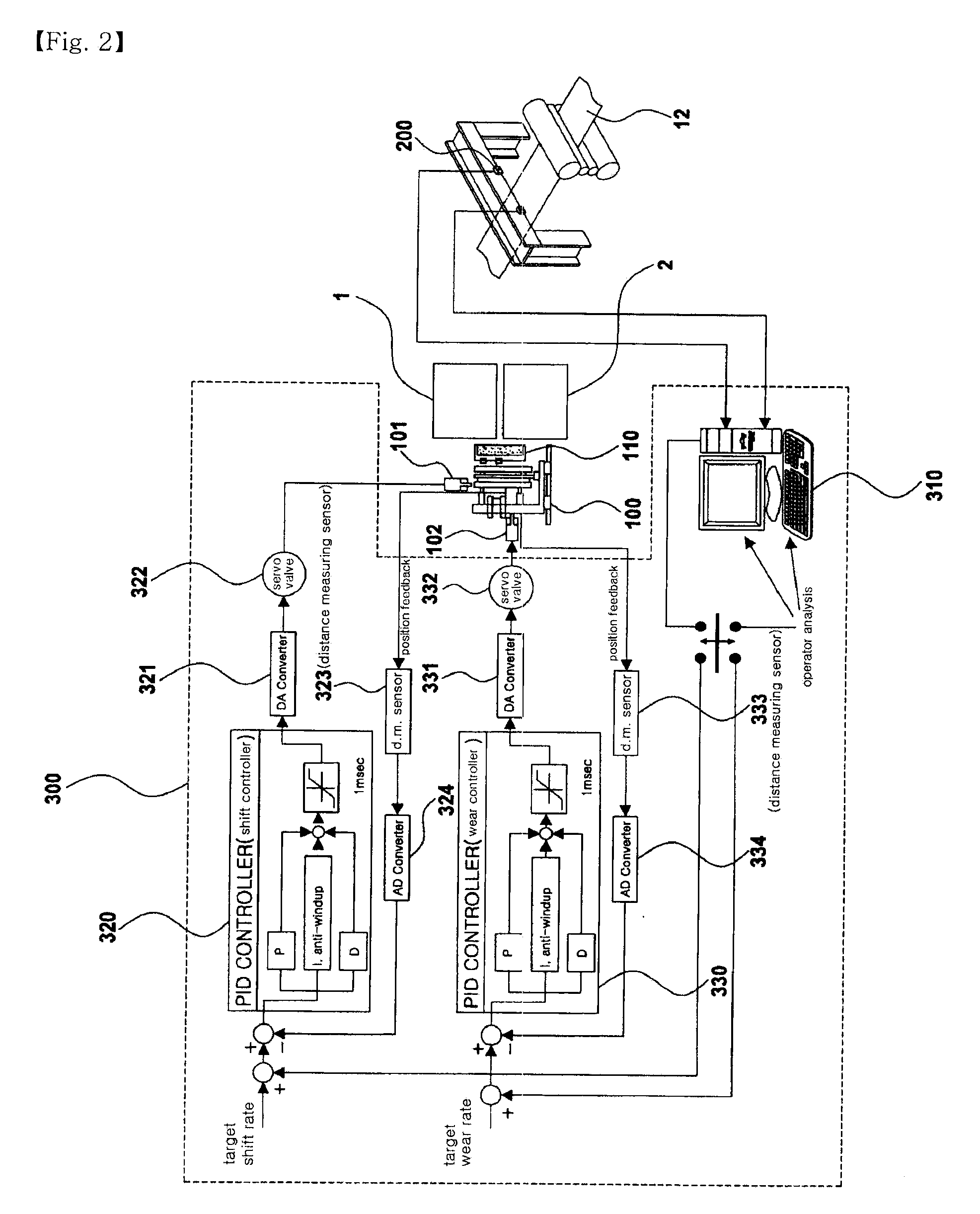

Strip edge shape control apparatus and method in strip casting process

InactiveCN101801562AQuality improvementImprove productivityMelt-holding vesselsStrip steelUpward shift

Disclosed herein are an apparatus and method for controlling the edge shape of a strip in a twin-roll strip casting process, which improve the quality of the strip by using cameras to photograph the edge portions of the strip being cast by strip casting, analyzing the photographs, and then controlling edge dams according to the edge shape of the strip. The apparatus comprises: an edge dam driving unit which is attached to edge dams attached to both sides of casting rolls so as to control the pressing force of the edge dams against the casting rolls and the upward shift of the edge dams according to the wear and upward shift rate of the edge dams; cameras which are disposed at the strip outlet side of the casting rolls so as to photograph the edge portions of the strip; and a control unit which analyzes the edge shape of the strip from images photographed by the cameras and outputs a signal controlling the wear and upward shift of the edge dams.

Owner:POHANG IRON & STEEL CO LTD

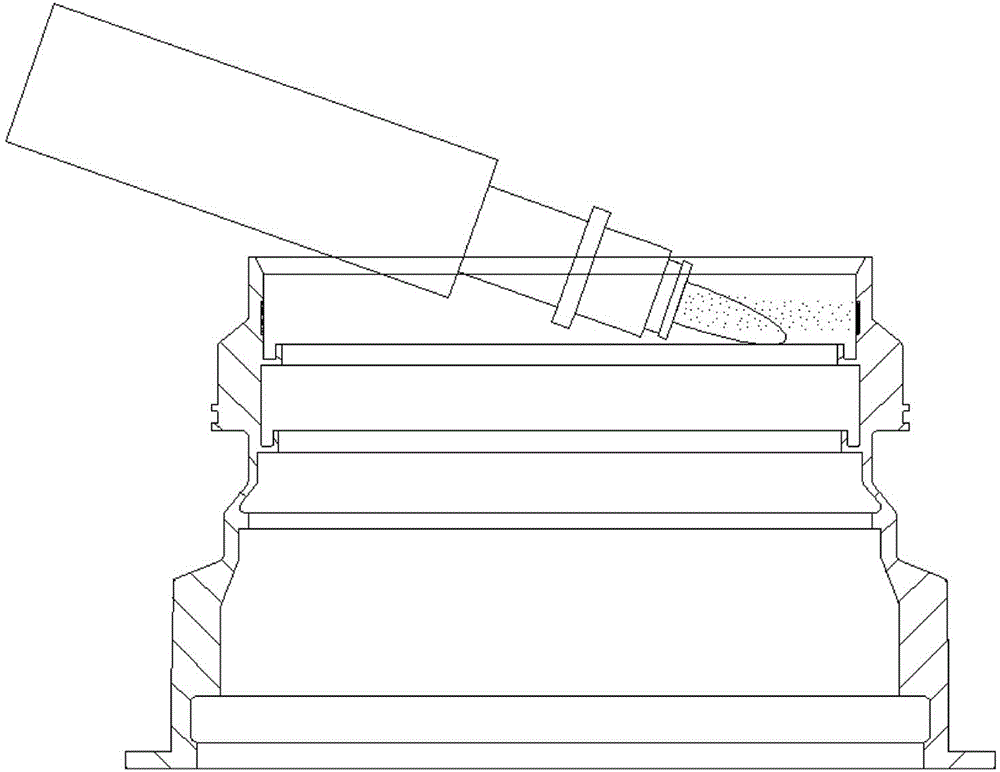

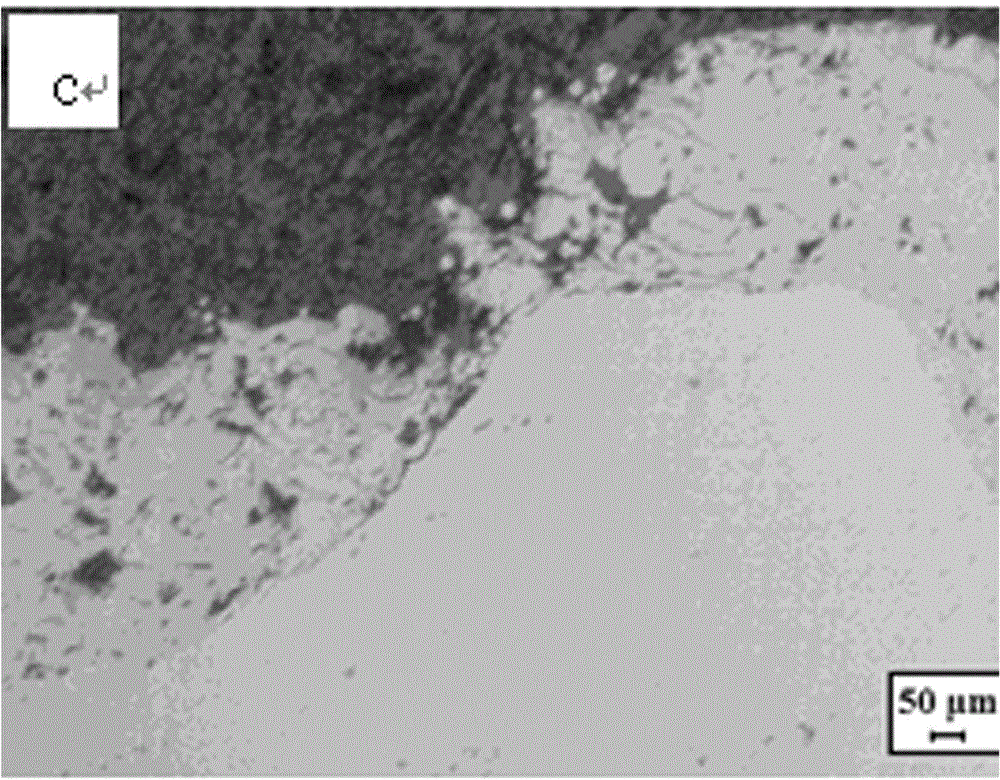

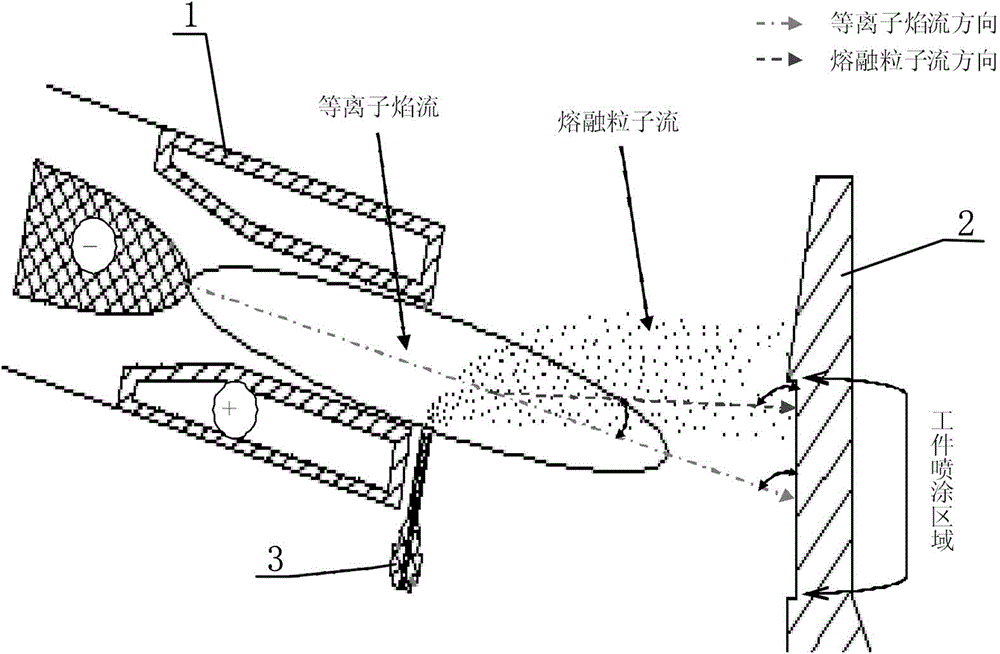

Inner bore plasma spraying method

ActiveCN104087886AGood coating performanceEasy to operateMolten spray coatingMetallurgyPlasma sprayed

An inner bore plasma spraying method comprises the following steps: first, adjusting the spraying position between a plasma cylindrical spray gun and a workpiece inner bore; then sending powder by a radial upward powder sending manner from the lower part of the pray gun; finally, according to the different spraying powder adjusting the flow amount of a powder sending gas to enable the powder to be fully heated and melted in the flame and upward shift a right angle. The inner bore plasma spraying method uses the radial upward powder sending manner from the lower part of the pray gun for powder sending, and the flow amount of the powder sending gas can be adjusted according to the different spraying powder, so that the powder can be fully heated and melted in the flame and upward shifts a right angle, the formation of spraying dead angles on the upper edge of the inner bore can be avoided, the coating performance of a coating on the upper edge of the inner bore can be improved, the hollow and empty spray problems of the coating can be avoided, and the inner bore plasma spraying method has the advantages of simple operation and strong practicability, and is suitable for the atmospheric pressure plasma or low pressure (vacuum) plasma spraying.

Owner:GUANGDONG YUEKE NEW MATERIALS TECH CO LTD

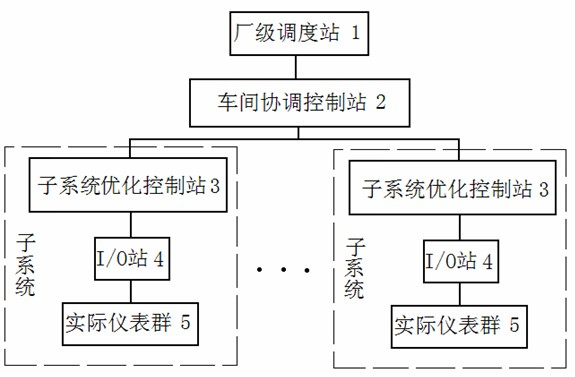

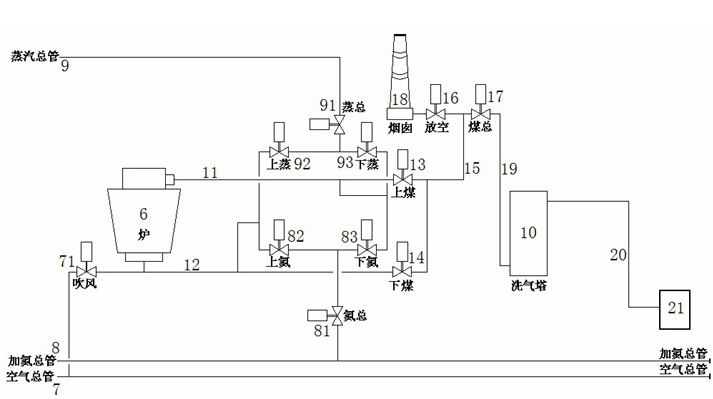

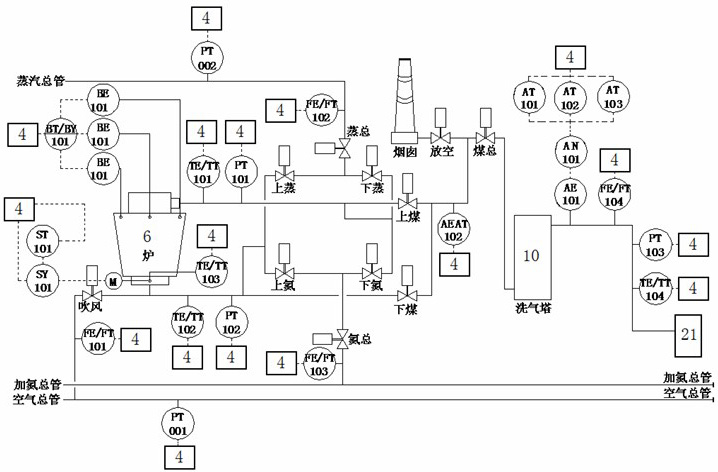

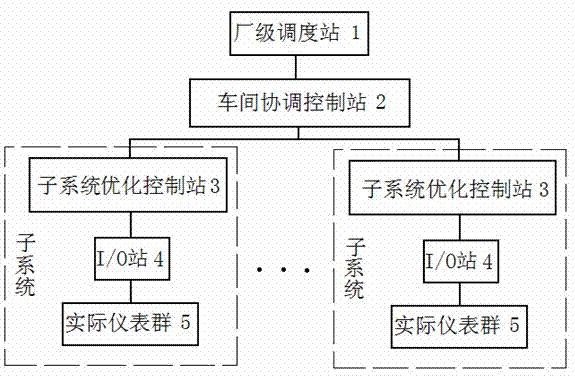

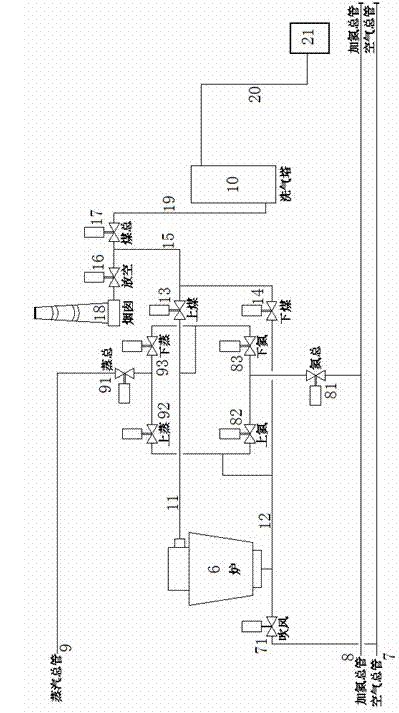

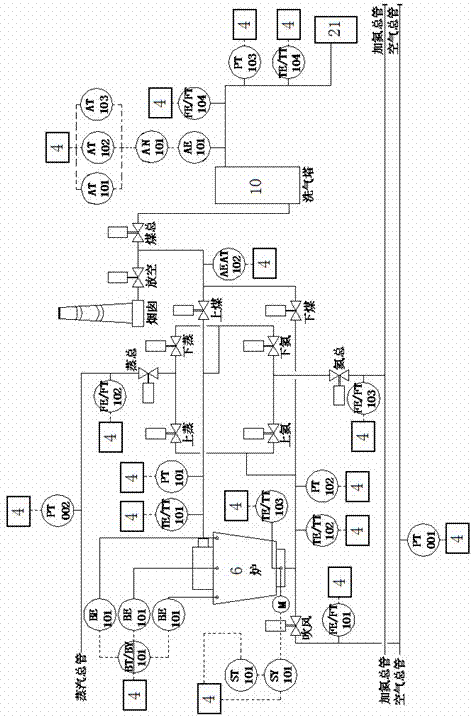

Gas-making workshop integrated control system for synthesis ammonia production and use method thereof

InactiveCN102323809AAccurately grasp the operation situationRealize energy saving and consumption reductionTotal factory controlProgramme total factory controlControl systemAmmonia production

The invention provides a gas-making workshop integrated control system for synthesis ammonia production and a use method thereof. The system comprises a workshop coordination control station, subsystem optimization control stations corresponding to a plurality of gas-making furnaces and I / O (Input / Output) stations, wherein the subsystem optimization control stations are connected with a plant-level dispatching station by the workshop coordination control station via signals; when in use, the subsystem optimization control stations firstly reckon dummy parameters such as flame layer upward shift, flame layer downward shift, oxide layer thickness increase, oxide layer thickness decrease, deflected burning, scabbing and the like according to the procedure parameters measured by actual instrument clusters, and then carry out optimization control with a self-learning function on subsystems according to the actual procedure parameters and the dummy parameters; and the workshop coordination control station realizes coordination between a gas-making workshop and the whole synthesis ammonia production process according to the signal of the plant-level dispatching station and the operation conditions of the subsystems. The system and the use method have the following beneficial effects: the parameter measuring points are more comprehensive, and the optimization controllability of singlefurnace operation is more perfect; and moreover, the system and the method have stronger coordination with all parts of the whole process, and are beneficial to gas making and stable operation of thewhole process in high efficiency and low consumption states.

Owner:武汉世纪凤飞节能环保技术工程有限公司

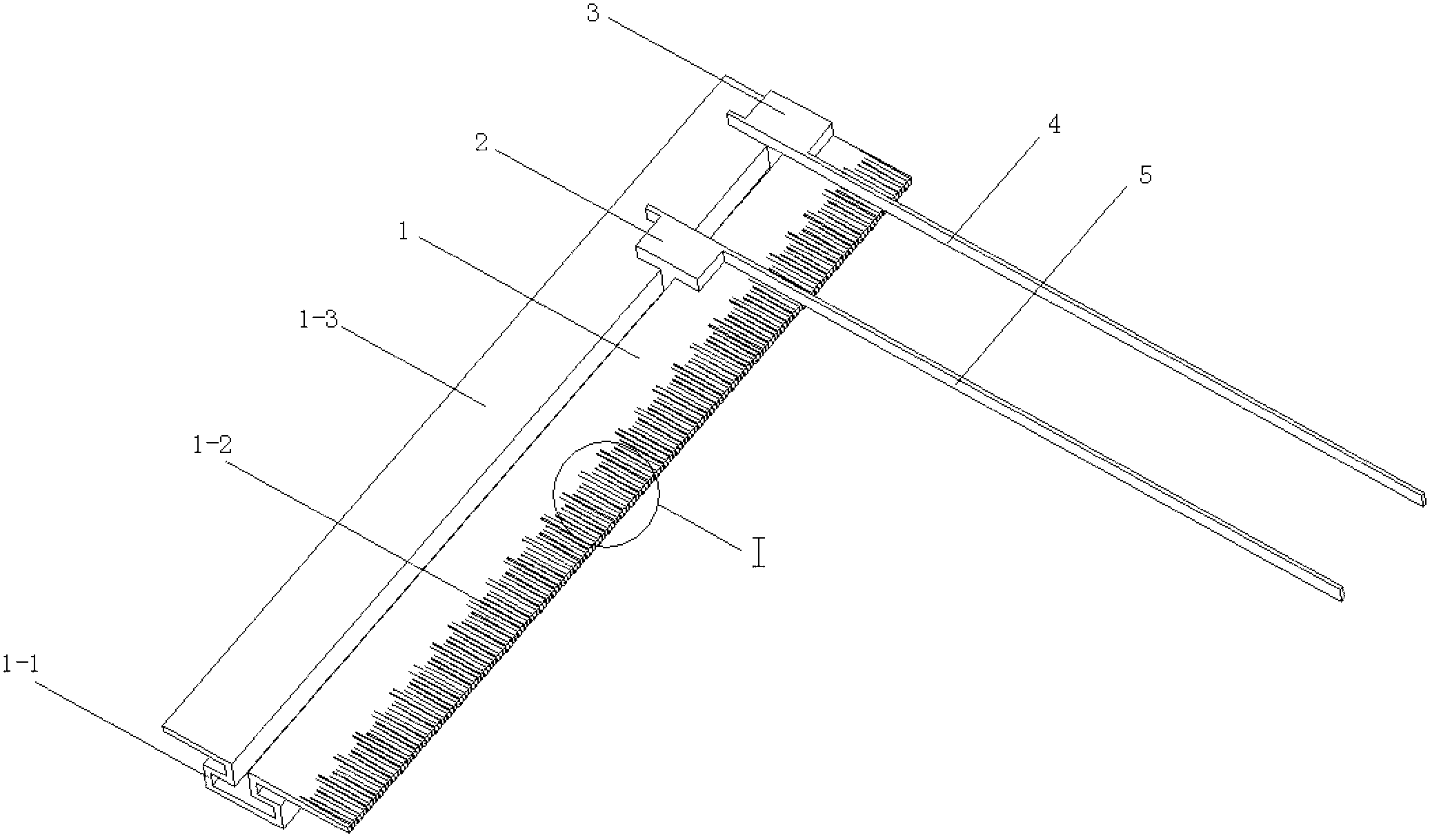

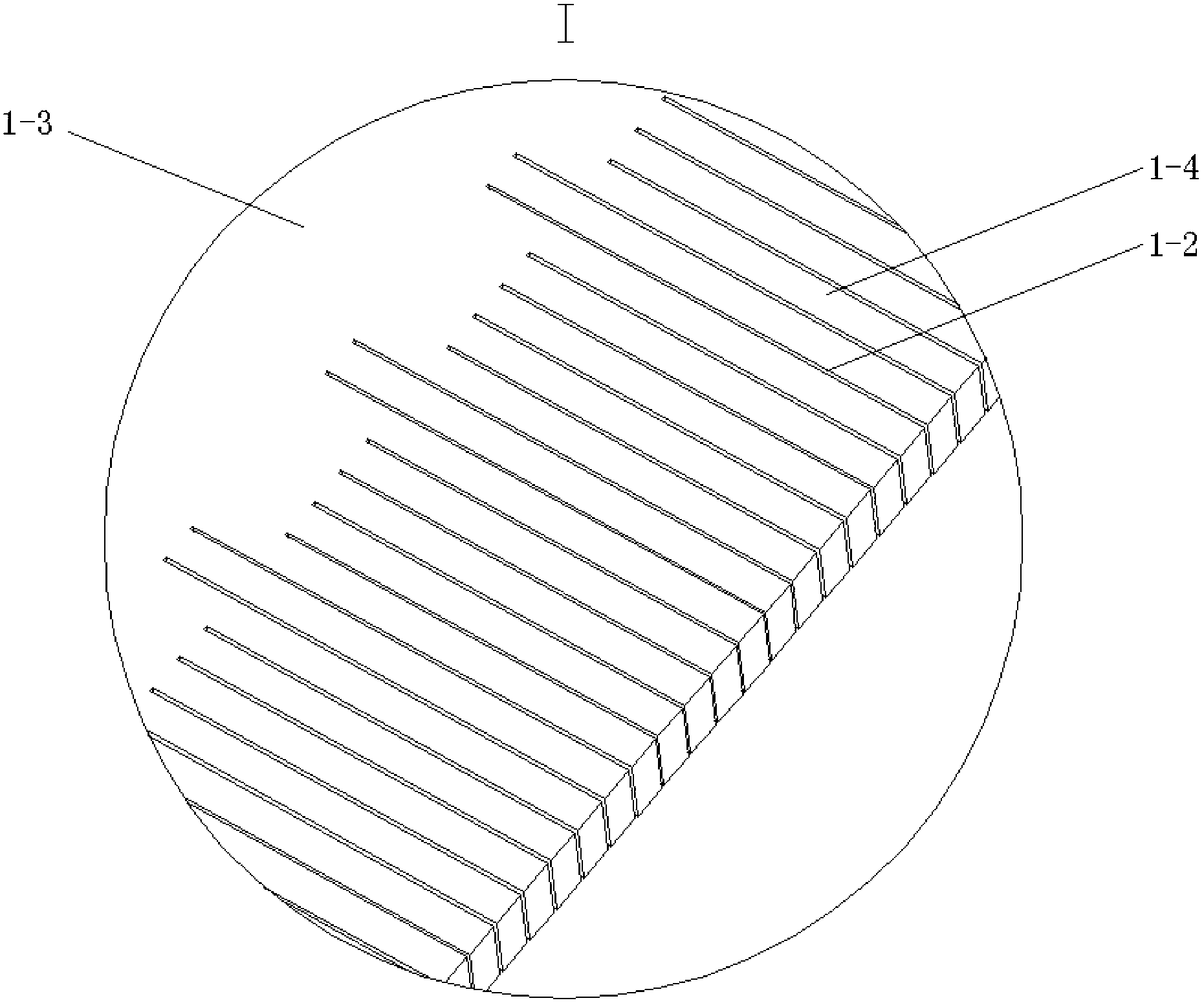

Simple measuring tool of vehicle suspension buffer block air travel

ActiveCN103017632AHigh measurement accuracyPrecise wheel hopping parametersMechanical measuring arrangementsModel parametersUpward shift

The invention discloses a simple measuring tool of a vehicle suspension buffer block air travel and belongs to the field of vehicle suspensions. The measuring tool at least comprises a measuring panel, a downward shift block, an upward shift block, an upper scale and a lower scale which are used for measuring the buffer block air travel of the vehicle suspension. The tool can measure the distance between the upper end surface of a shock absorber outer cylinder and an upward jumping buffer block when a real vehicle is in a loading condition at present to obtain an accurate round jump parameter of a real vehicle buffer block air travel. The round jump parameter of the buffer block air travel can be measured to judge whether the whole vehicle loading state is normal, so as to be beneficial to improving the measurement accuracy of a following-up simulation suspension model and real measured suspension model parameters, so that a scientific basis for the force distribution of the whole vehicle can be provided.

Owner:CHERY AUTOMOBILE CO LTD

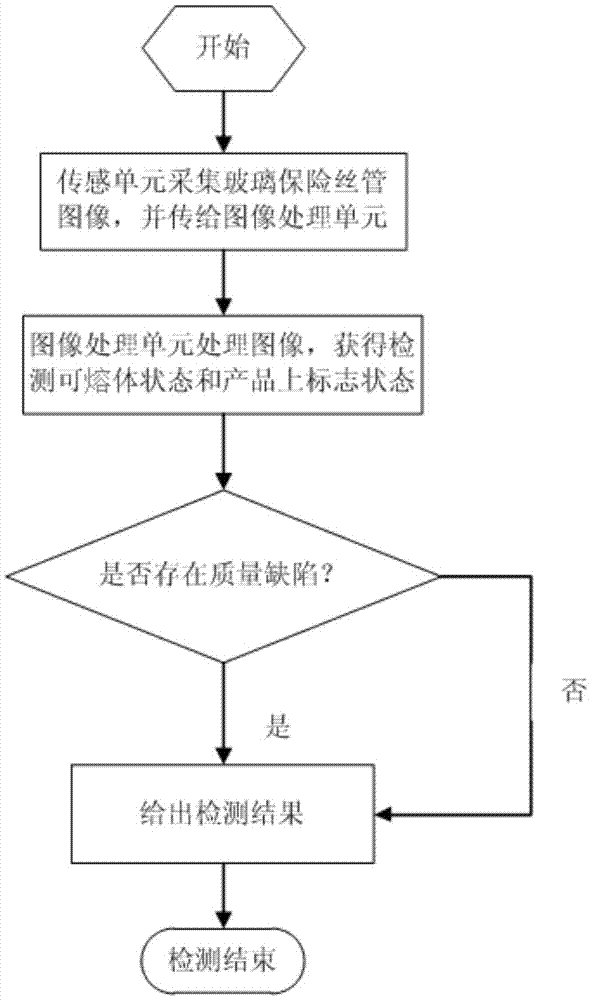

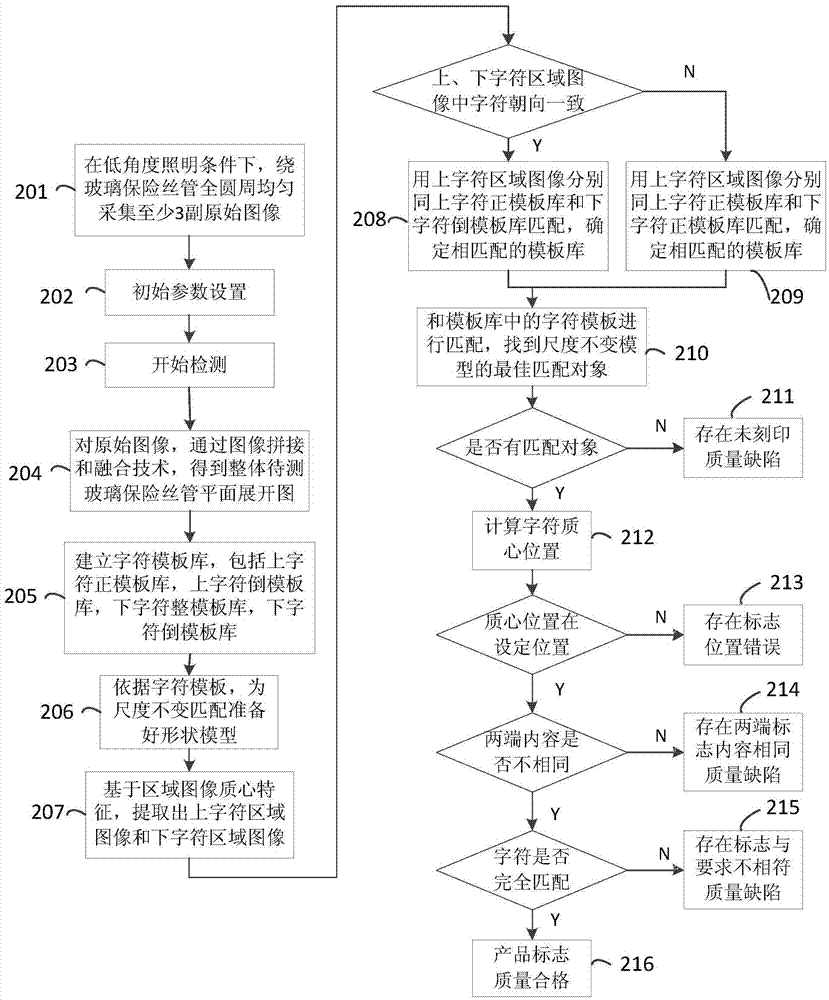

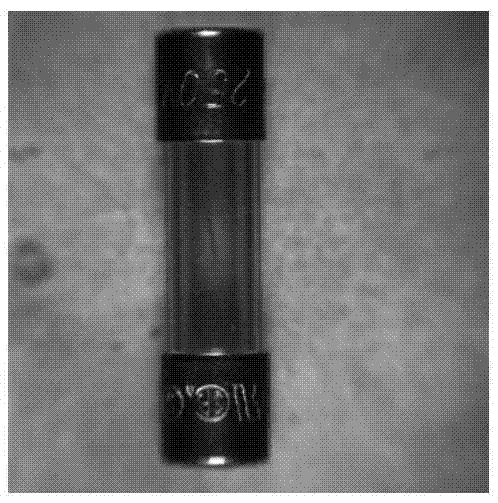

Method and device for detecting quality defects of mark on glass fuse tube products

InactiveCN105445286ARealize appearance quality defect detectionGuaranteed reliabilityMaterial analysis by optical meansImaging processingImaging Feature

The invention relates to a method and a device for detecting quality defects of a mark on glass fuse tube products. The method comprises the following steps: collecting and acquiring an original image of a to-be-detected glass fuse tube through a sensing unit and sending the collected original image to an image processing unit; treating and analyzing the collected original image of the to-be-detected glass fuse tube by the image processing unit; detecting the quality defects of the marks on the products, namely, non-countermark, upward shifting mark position, identical mark contents at two ends and mark inconsistent to the requirement, thereby judging the appearance quality of the glass fuse tube. A low-angle loop illuminating method is adopted according to the invention, the online image collection for multiple defects of the glass fuse tube is realized, the image cutting and target identification are realized on the basis of regional image feature parameter method, the automatic and online detection for appearance quality defects of the glass fuse tube is realized, the detection speed and the detection precision are greatly increased and the reliability of the detection result is ensured.

Owner:SHENYANG JIANZHU UNIVERSITY

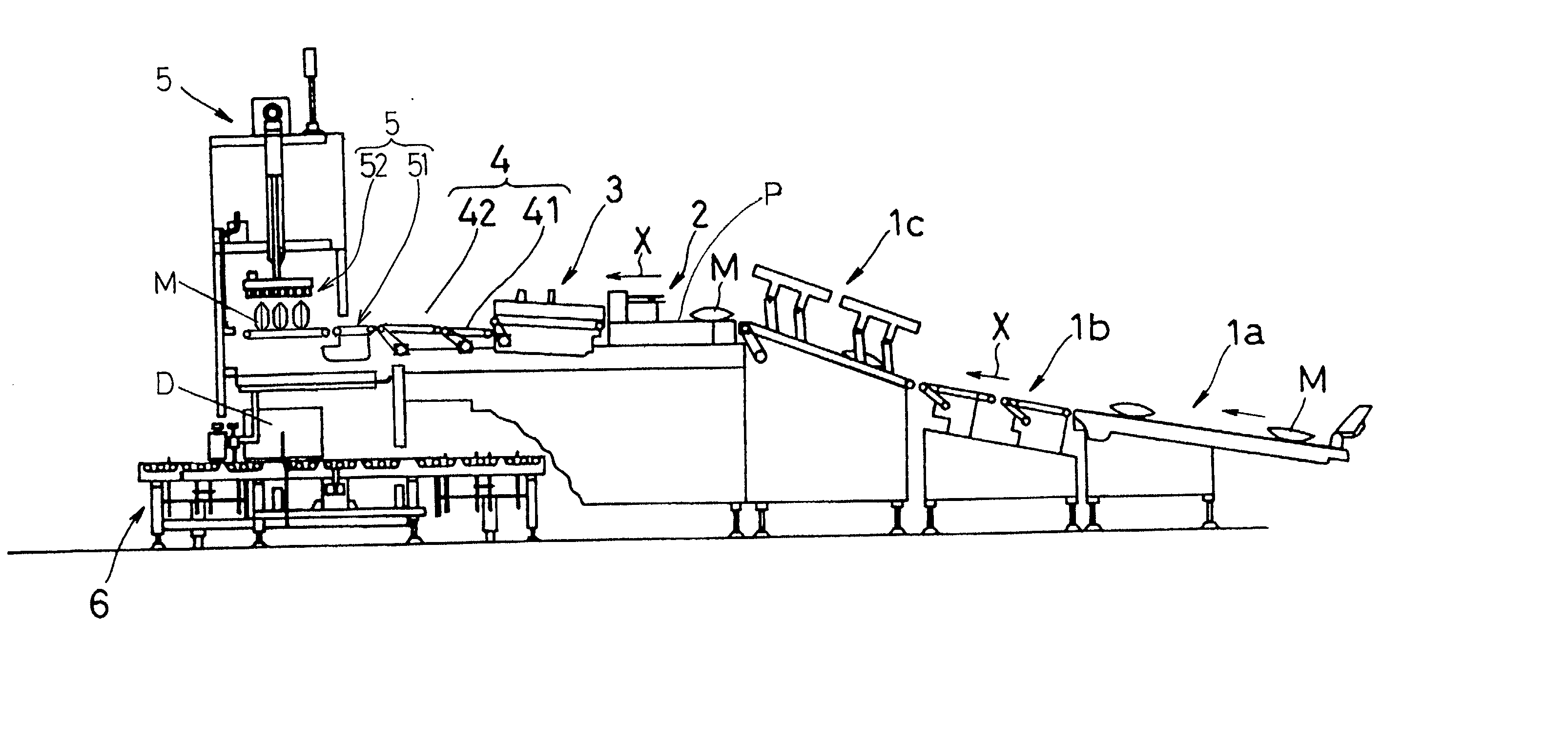

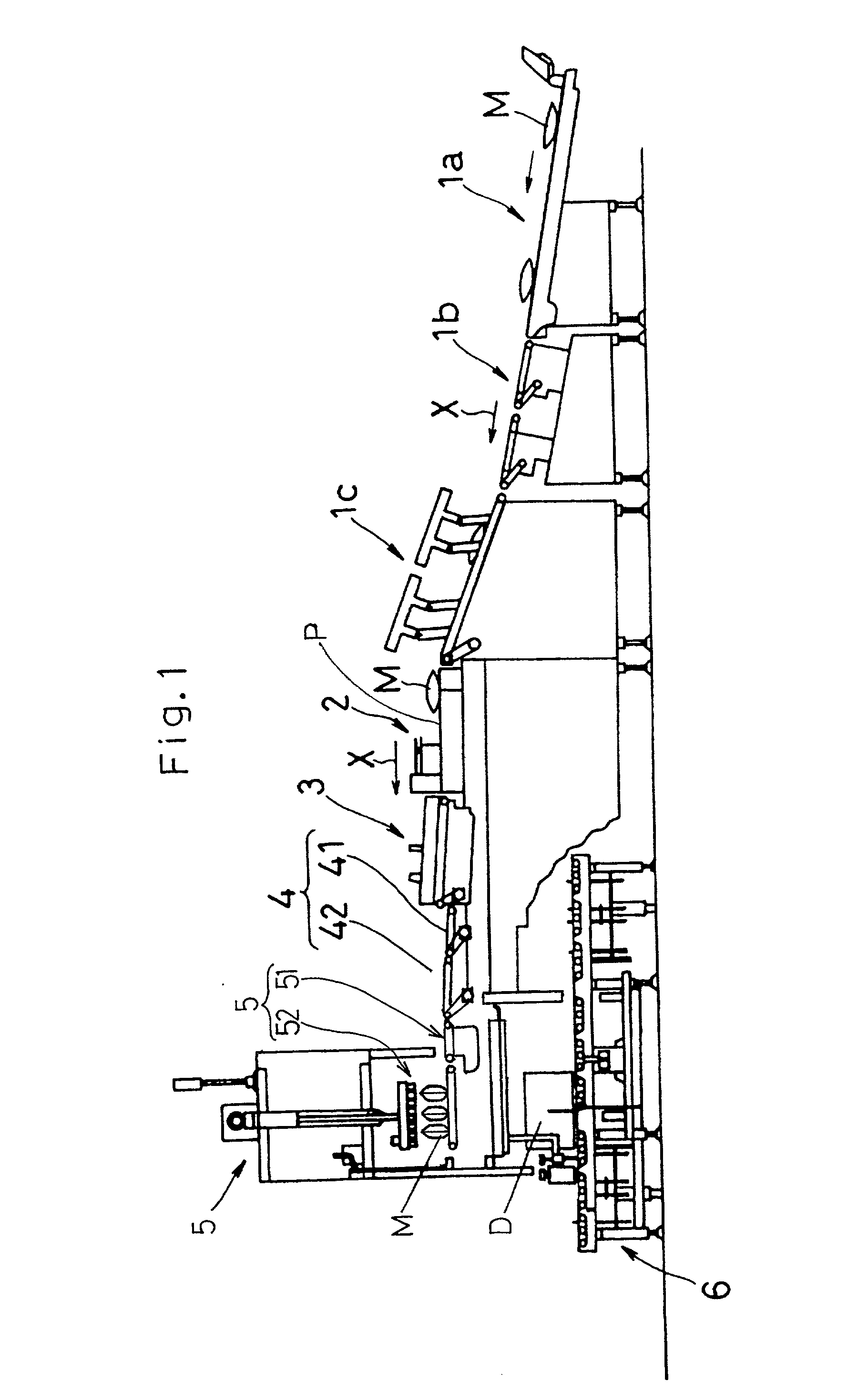

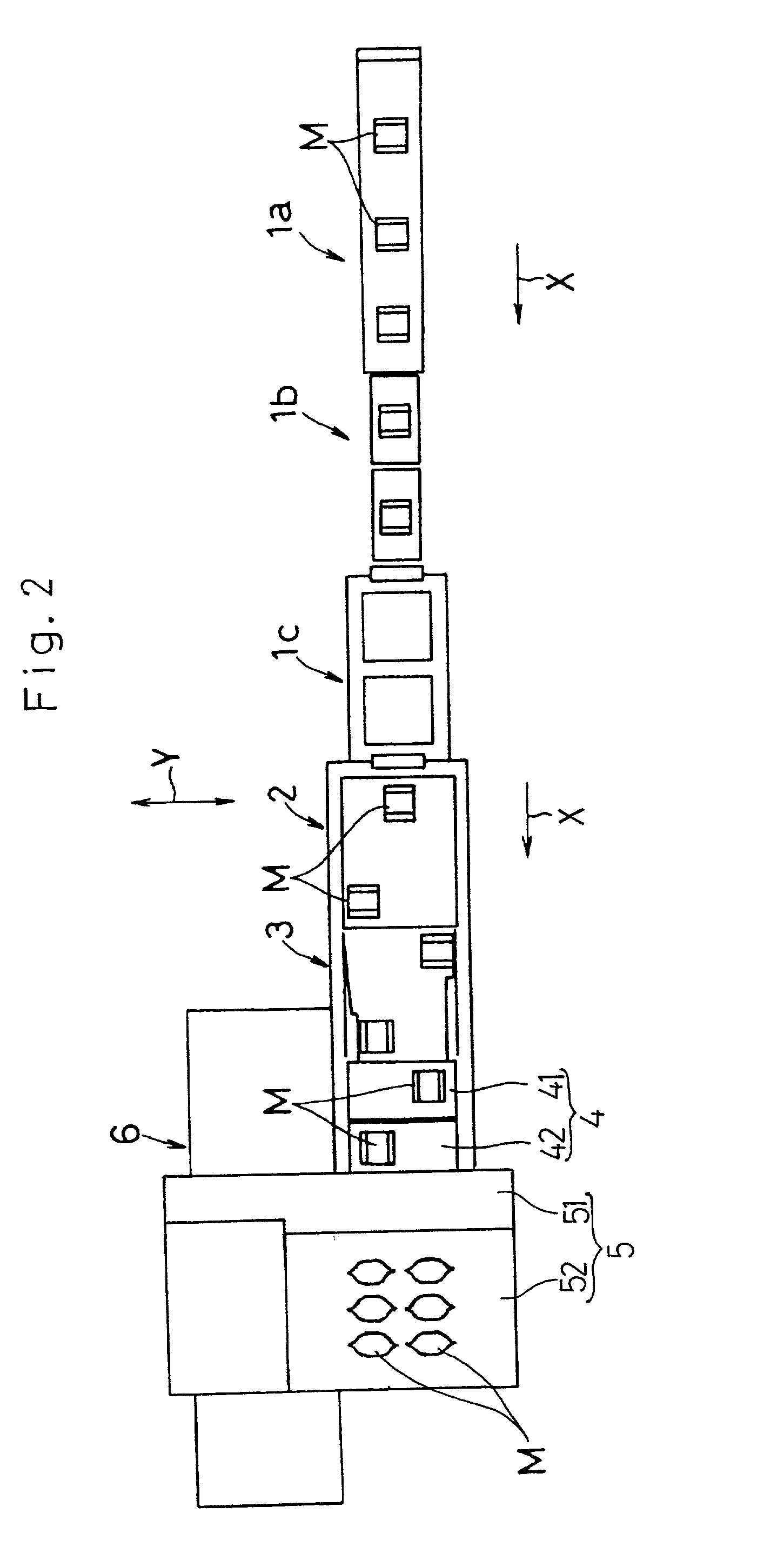

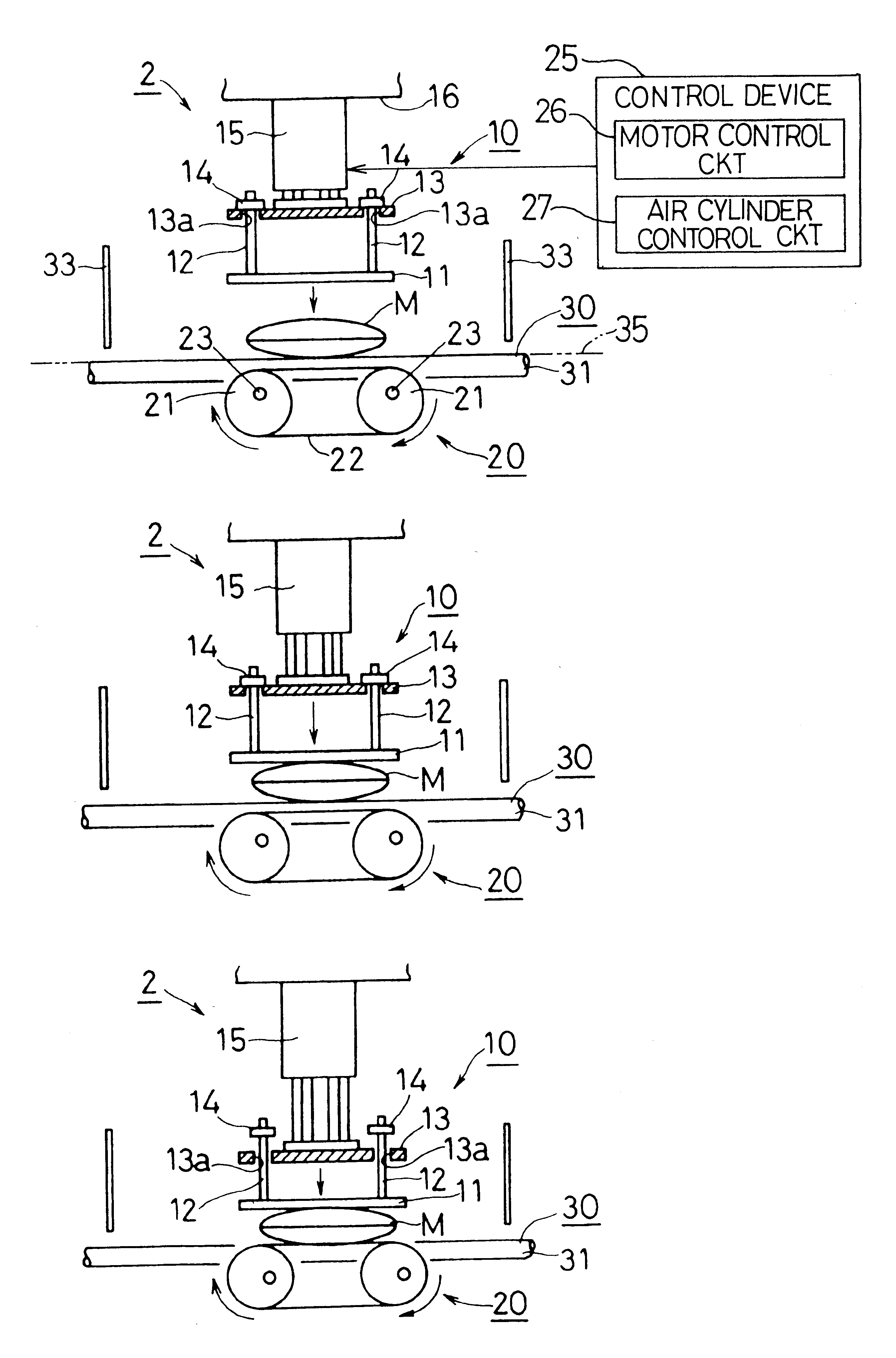

Product diverting mechanism in packaging system

A product diverting mechanism used in a packaging system, which is effective to increase the speed at which the products are successively diverted, includes a force applicator 20 for applying a force, containing a force component acting in a horizontal direction, to the products M transported from a preceding station, in a direction transverse to a direction of transport of the products, a suppressor 10 disposed above a transport means 30 for suppressing an upward shift of the products M which occurs when the force applicator 29 applies the force to the products M, and an elevator 15 for moving the suppressor 10 up and down. The suppressor 10 is lowered during an operation to divert the products M so as to contact an upper surface of the products M.

Owner:ISHIDA CO LTD

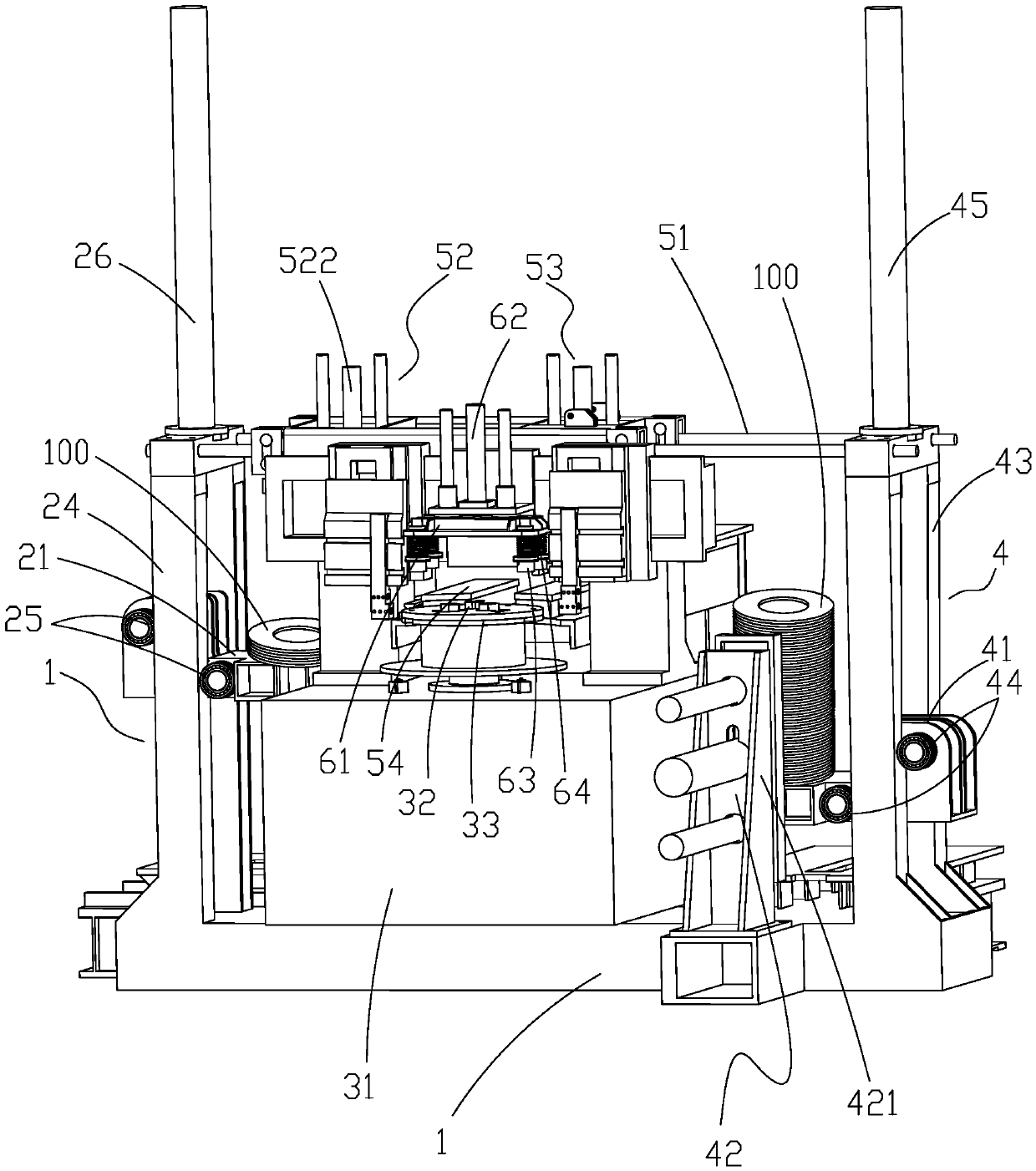

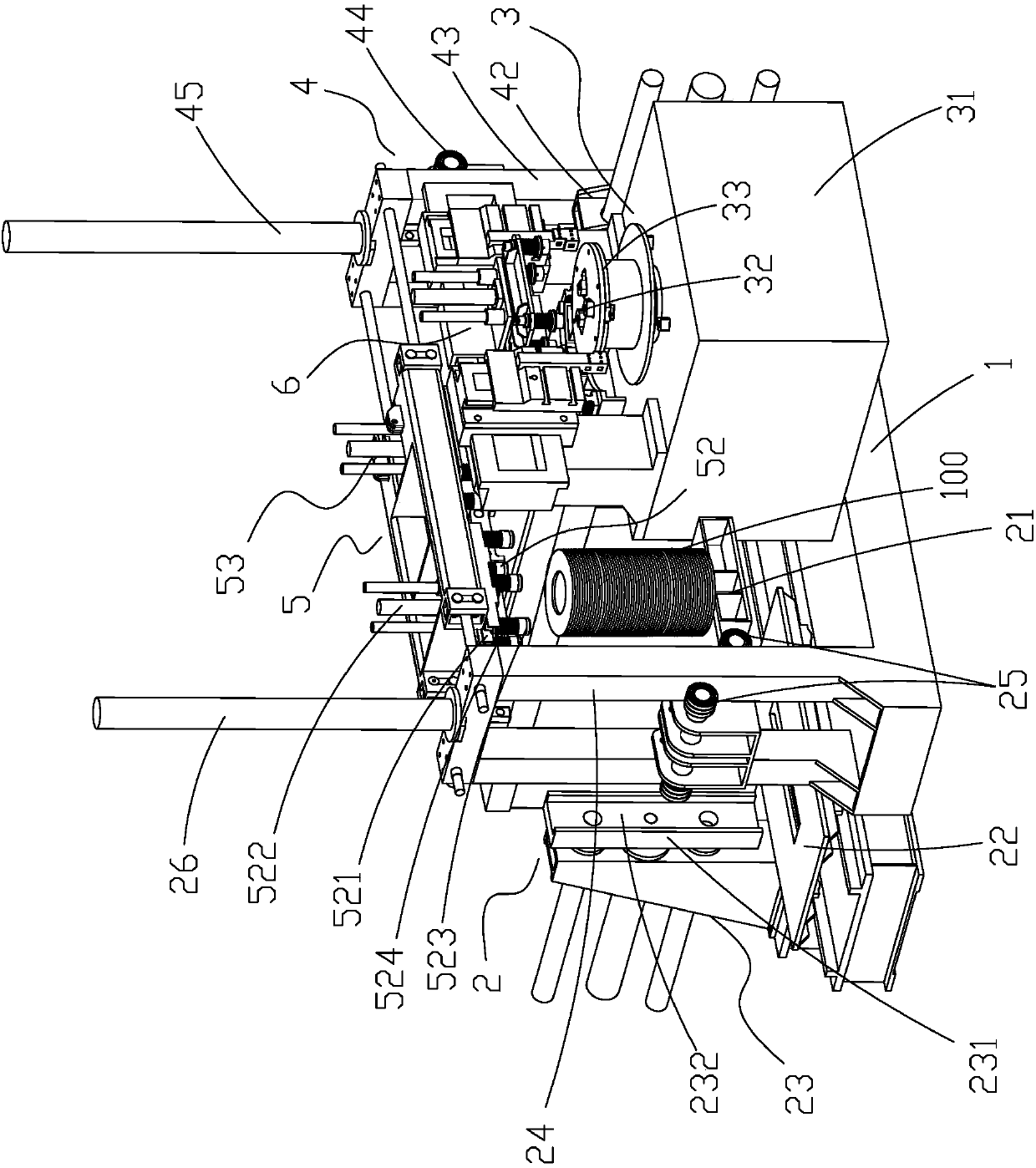

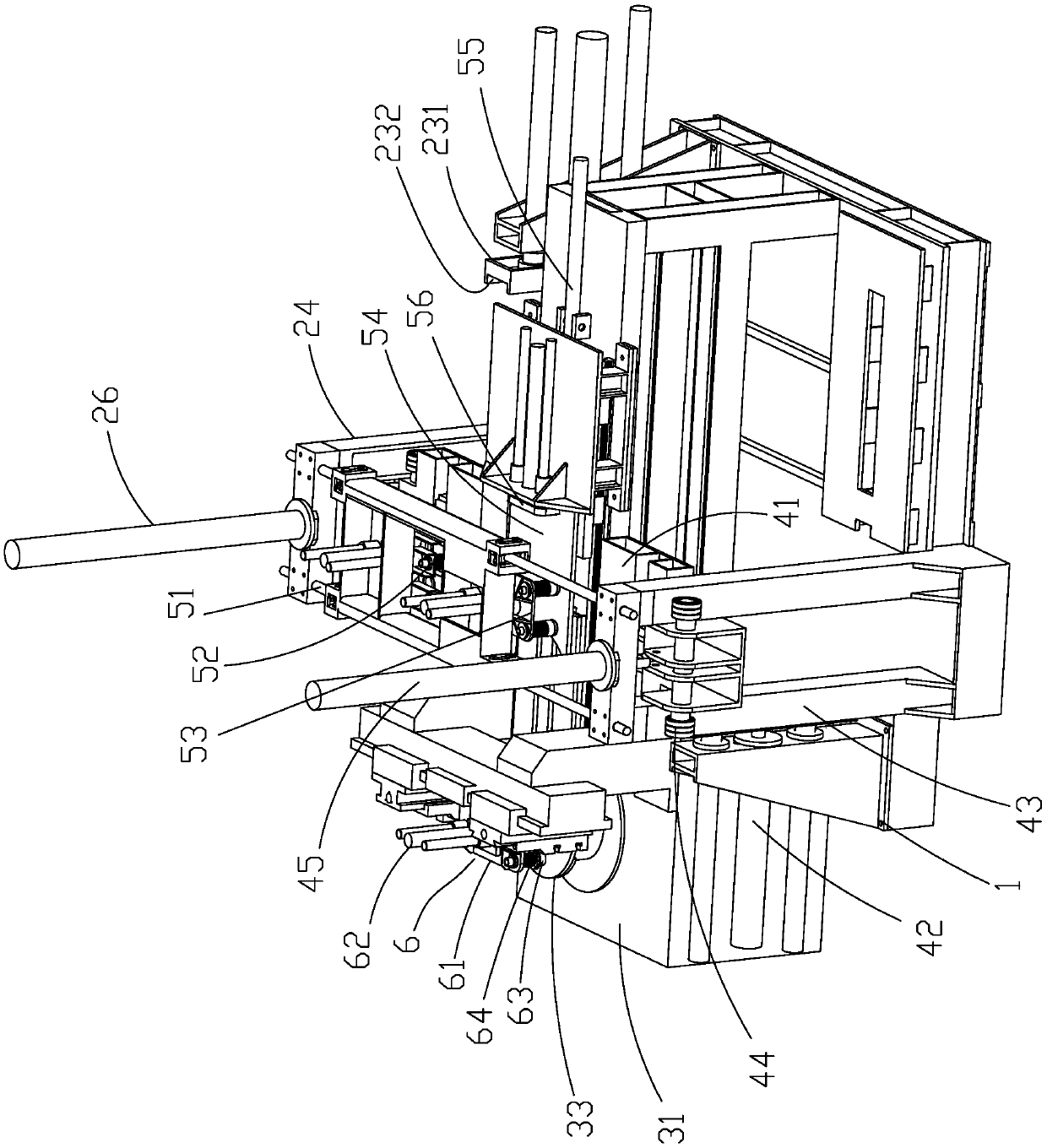

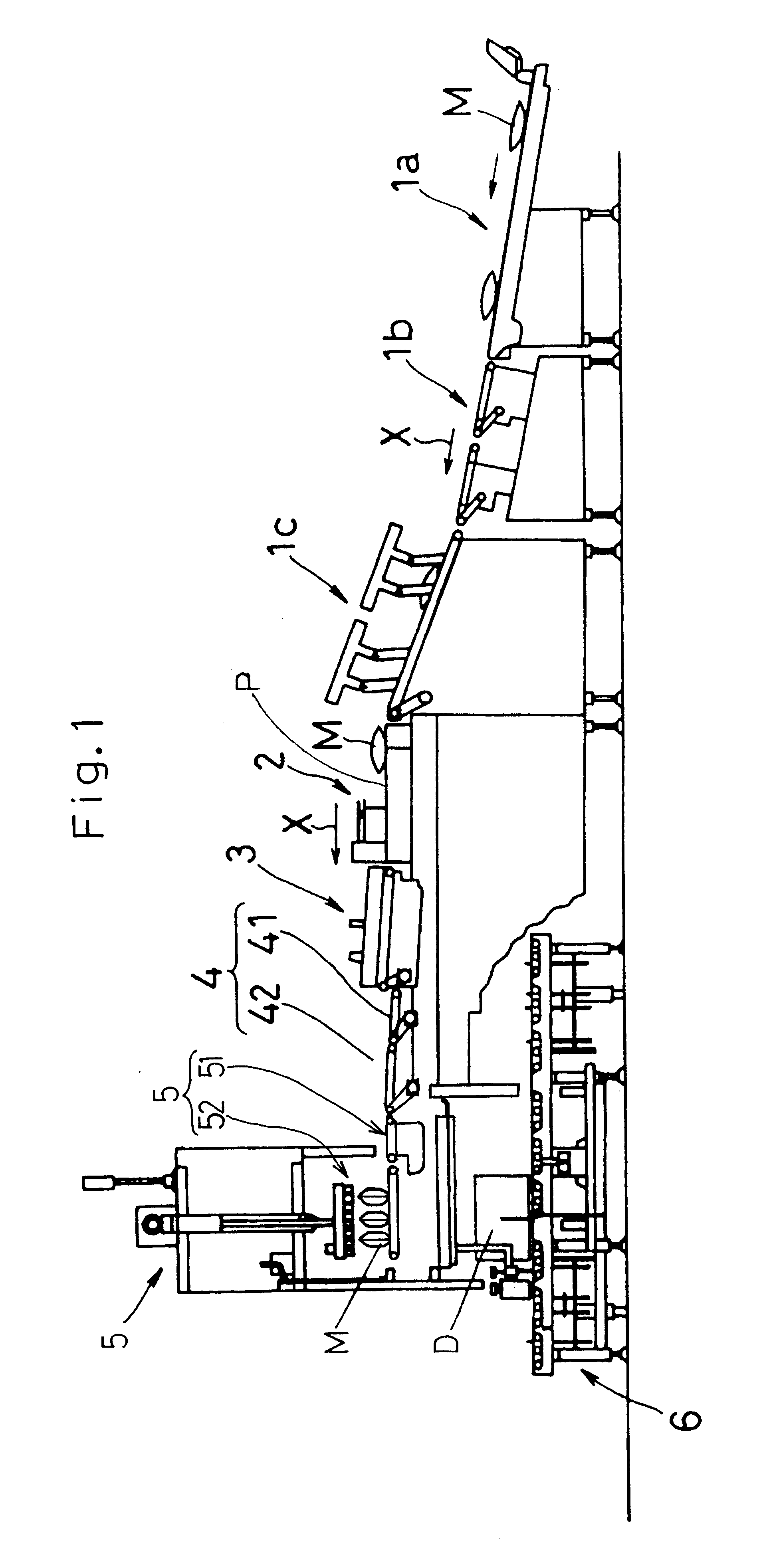

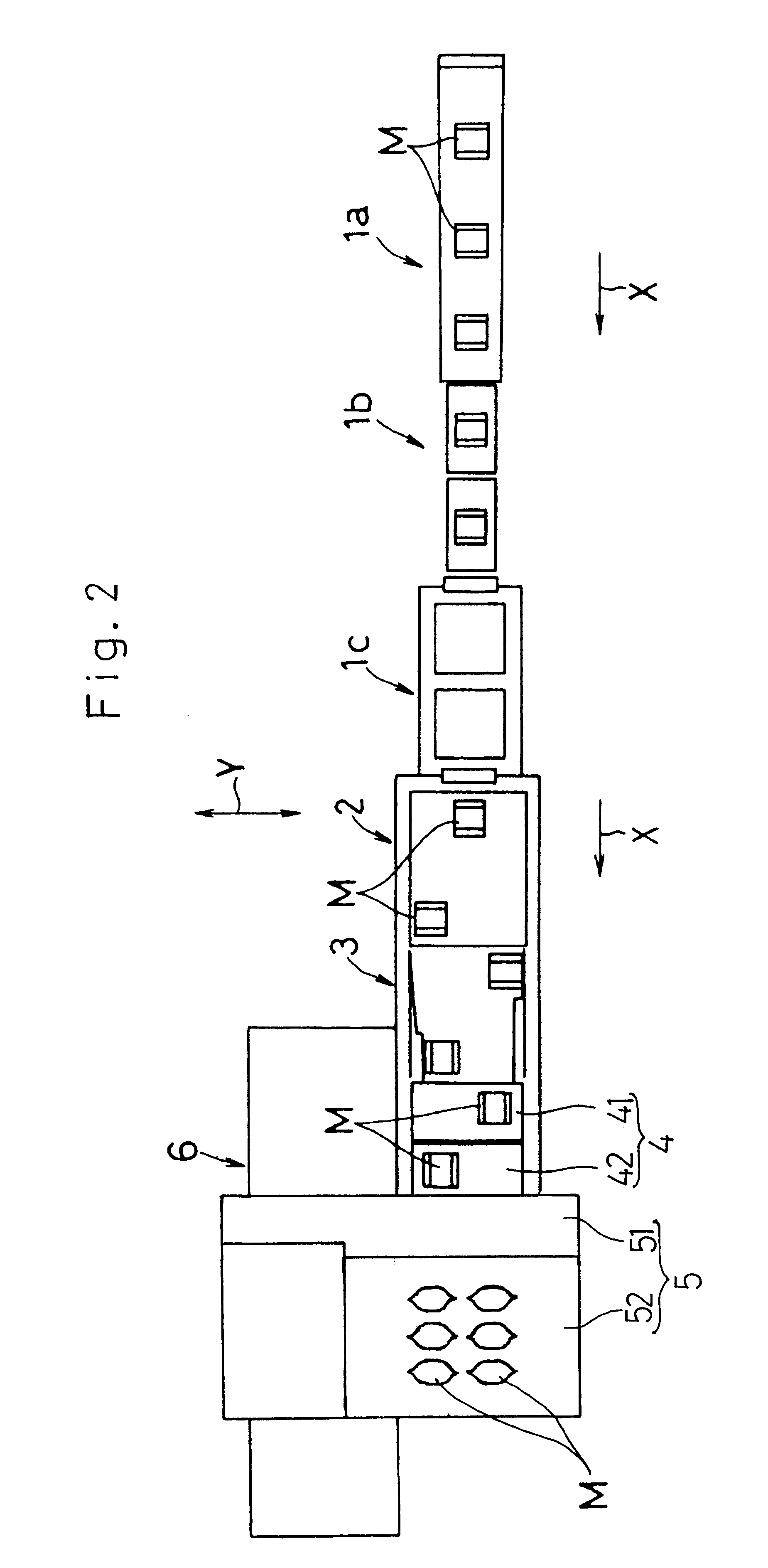

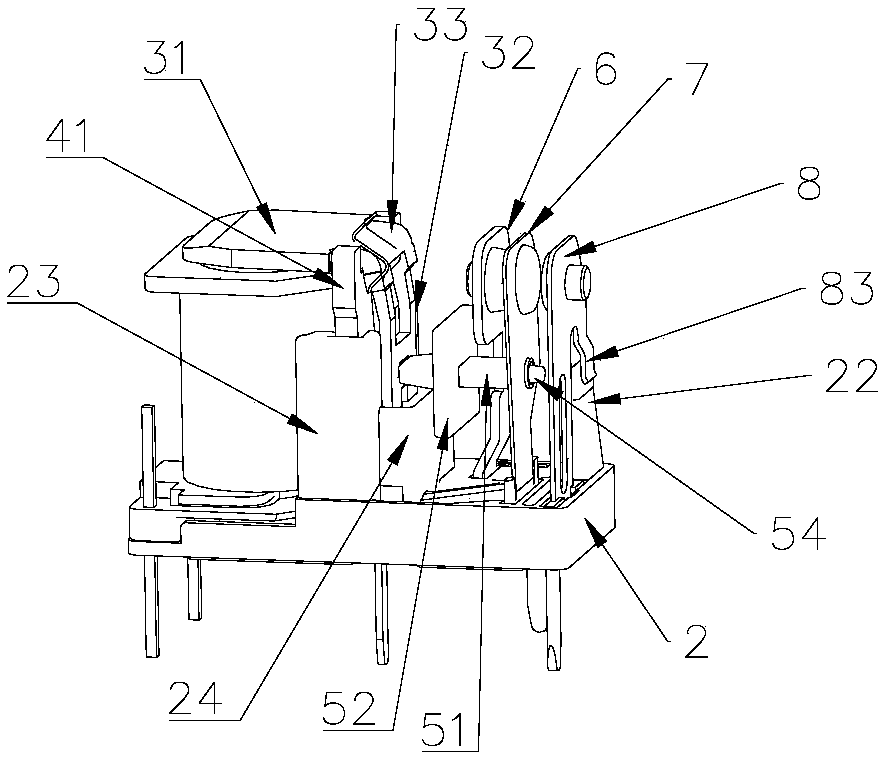

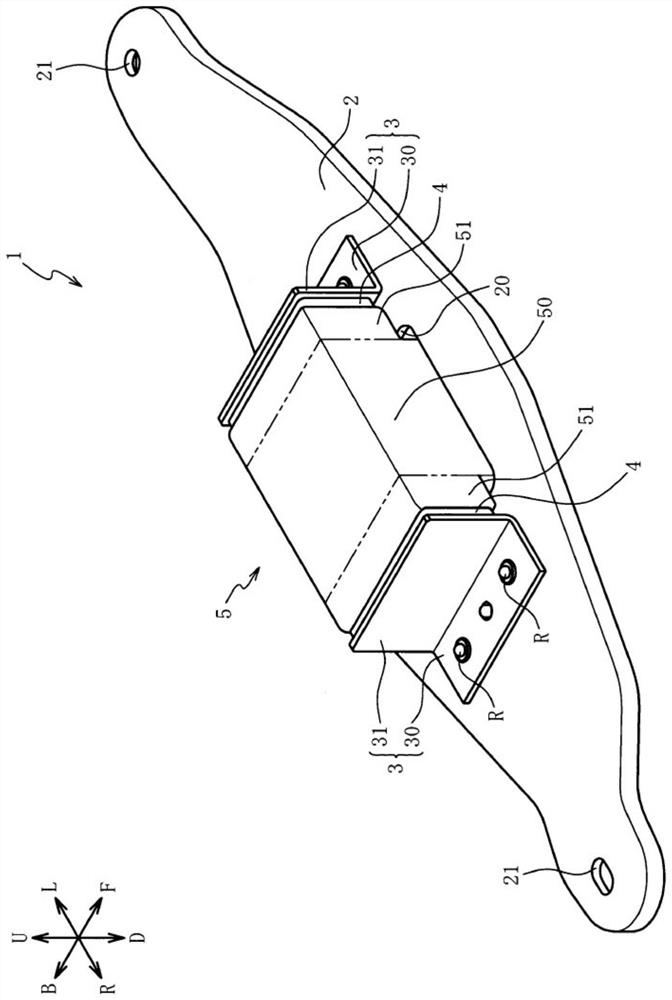

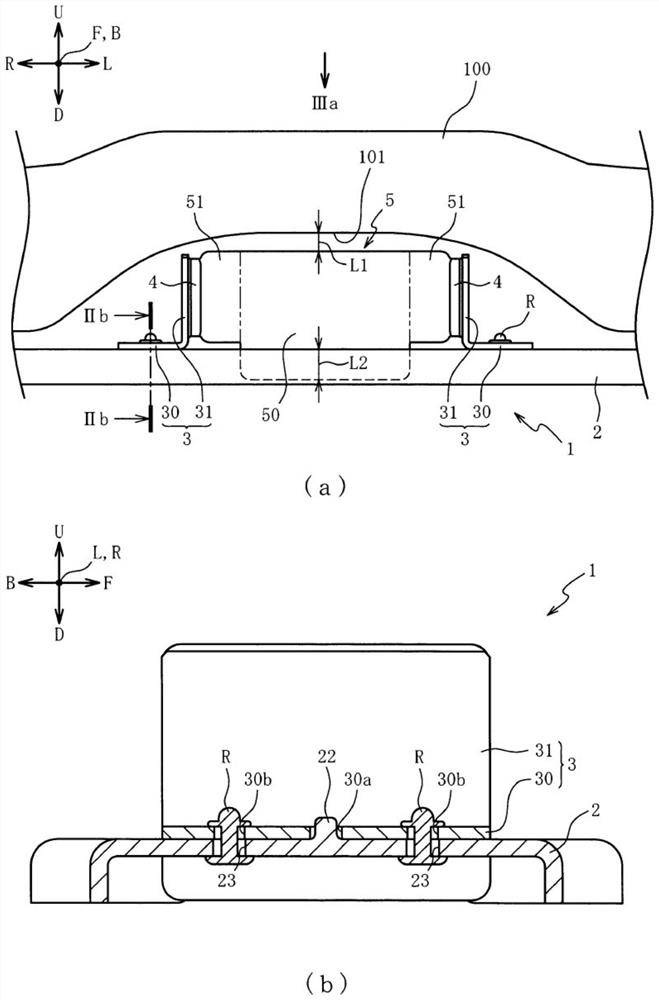

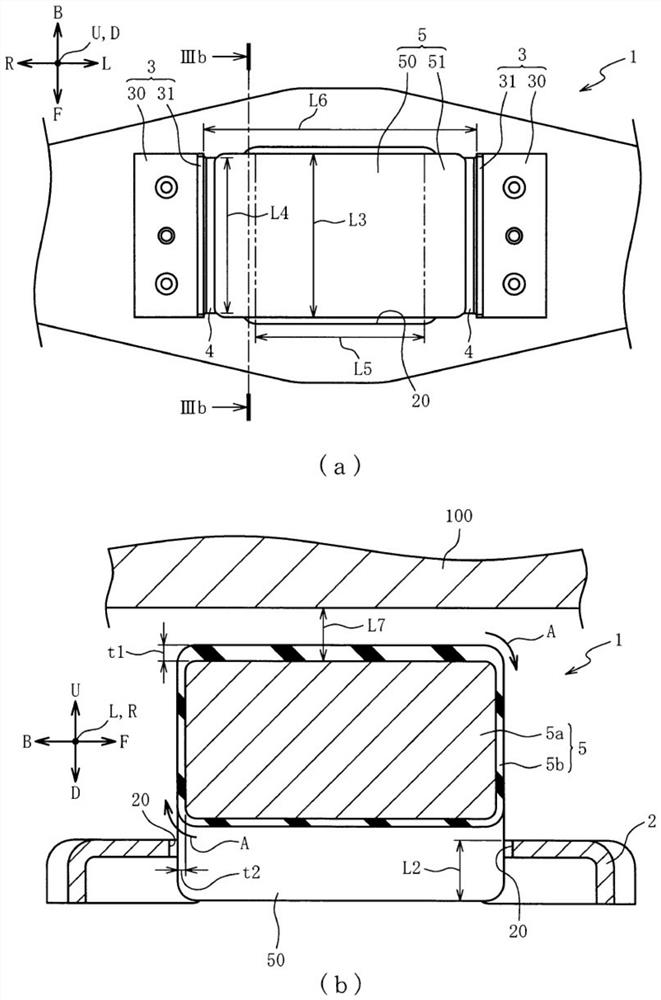

Automatic feeding and discharging vertical lathe

PendingCN107716947AIncrease productivitySave human effortAutomatic conveying/guiding stockEngineeringUpward shift

The invention discloses an automatic feeding and discharging vertical lathe. A feeding mechanism (2), an unloading mechanism (3) and a turning mechanism (4) are arranged on a machine frame (1). A material movement mechanism (5) capable of being matched with the feeding mechanism (2), the turning mechanism (3) and the unloading mechanism (4) is further arranged on the machine frame (1). A materialgrabbing mechanism (6) capable of grabbing workpieces (100) on the material moving mechanism (5) to the turning mechanism (4) to be turned and capable of grabbing the completely-turned workpieces (100) back to the material movement mechanism (5) is arranged above the turning mechanism (4). The turning mechanism (3) comprises a turning body (31). A clamping jaw (32) used for clamping the workpieces(100) is arranged on the turning body (31). A lifting tray (33) capable of rising, falling and transferring the workpieces (100) grabbed by the material grabbing mechanism (6) to the position of theclamping jaw (32) to be clamped is arranged outside the clamping jaw (32). The automatic feeding and discharging vertical lathe is simple in structure, capable of saving labor and high in production efficiency.

Owner:广东毅马集团有限公司 +4

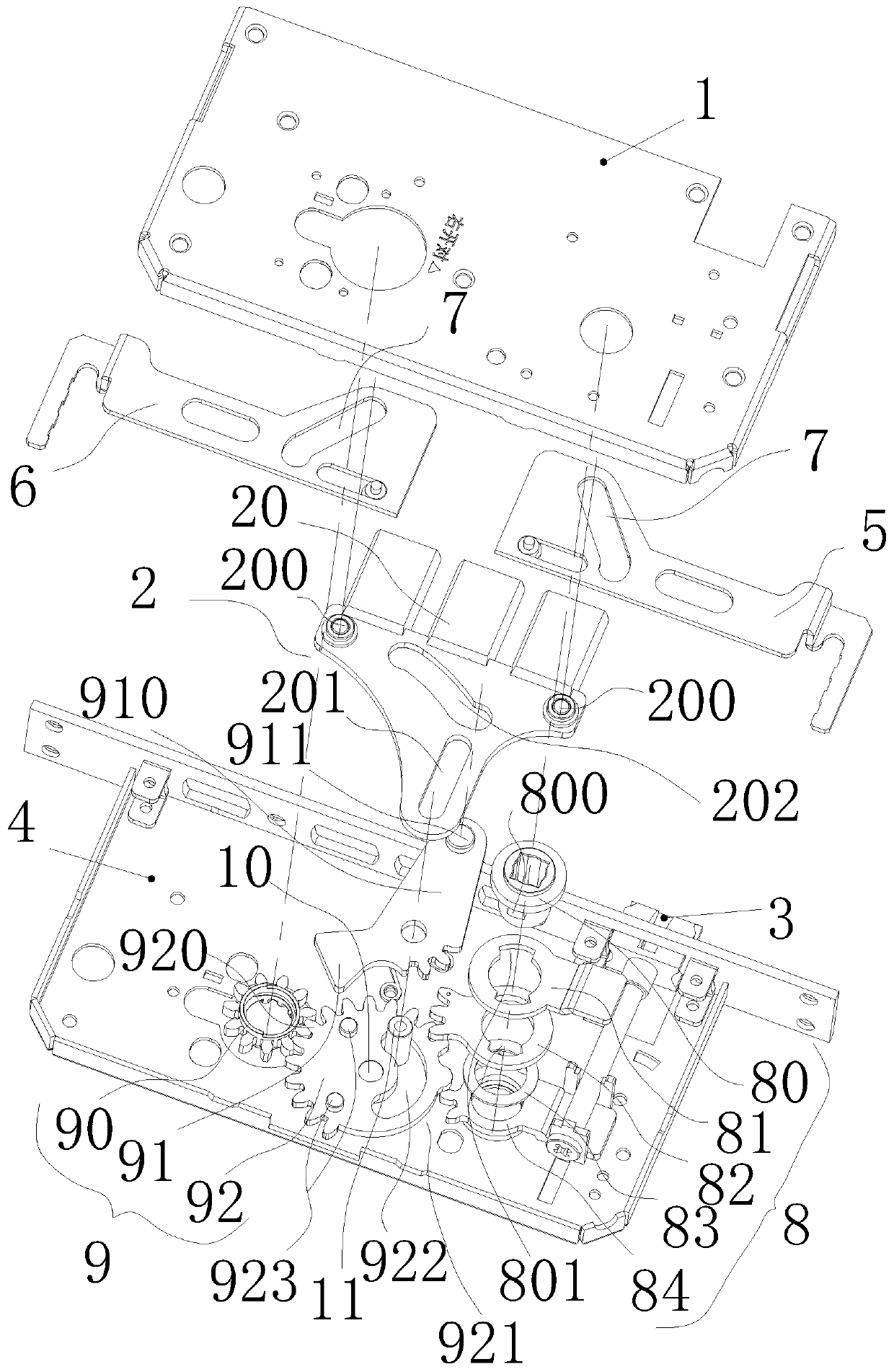

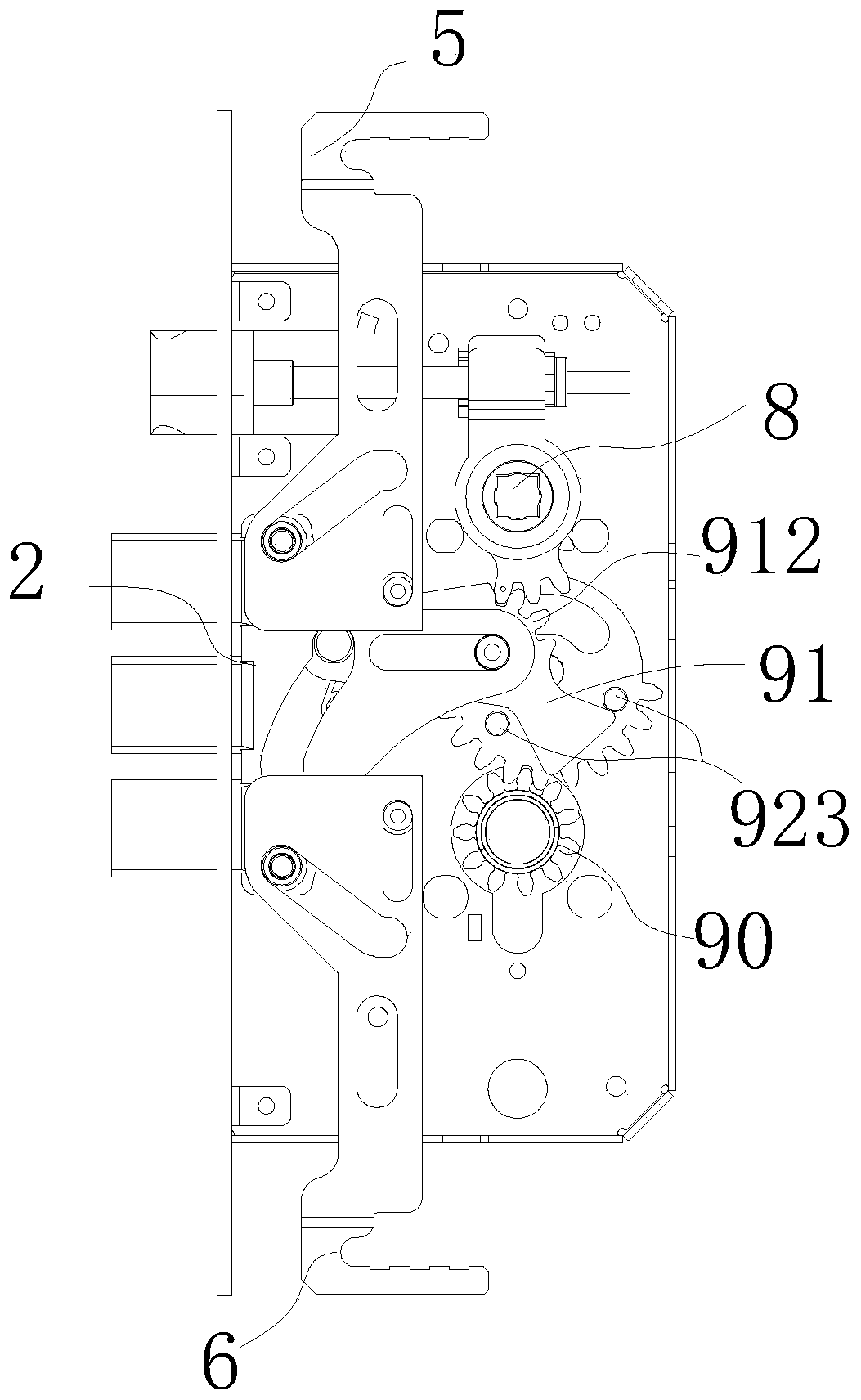

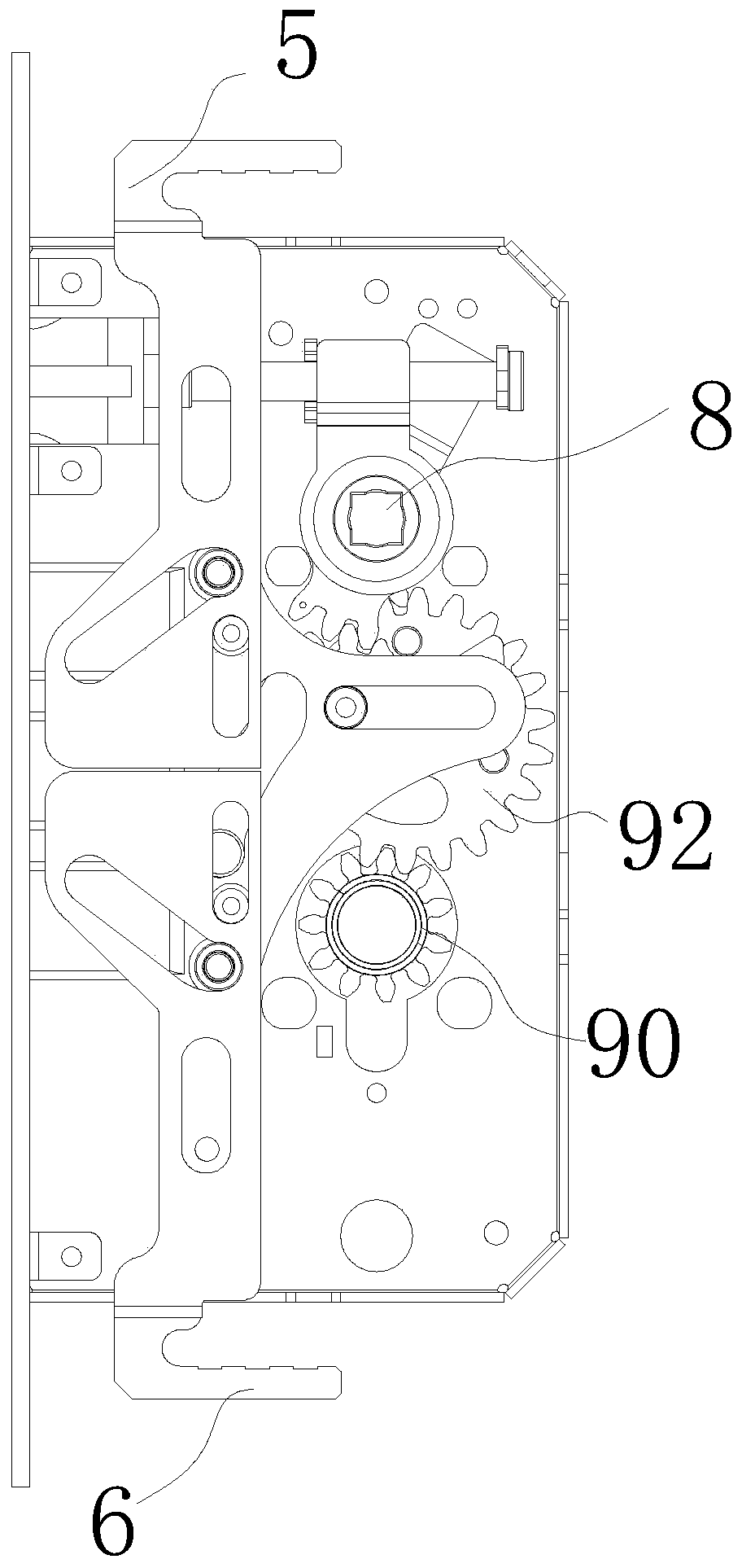

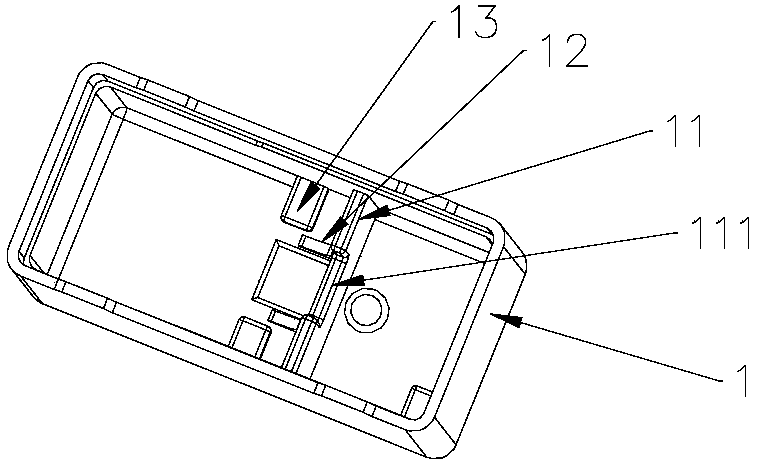

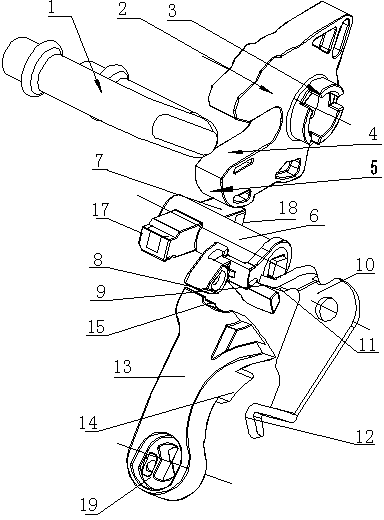

Full-automatic lock body

The invention discloses a full-automatic lock body. The full-automatic lock body comprises an upper covering plate, a dead bolt assembly, a latch bolt assembly and a lock body case; the lock body caseis further internally provided with a shifting fork device for driving the latch bolt assembly to retract back into the lock body case, and a transmission assembly is arranged between the shifting fork device and the dead bolt assembly; the shifting fork device comprises a latch bolt shifter, a latch bolt upward shifting plate, a reverse shifting plate, a middle gasket and a latch bolt lower shifting plate; the transmission assembly comprises a lock core gear, a main bolt shifting plate and a main gear; the lock body shell is further provided with a rotary supporting shaft which penetrates through the main gear, used for guiding the dead bolt assembly and used as a rotating supporting point synchronously; two protrusion blocks which are located on the outer edge of the rear side of the main bolt shifting plate correspondingly and push the main bolt shifting plate to forward and reversely rotate are arranged on the upper side surface of the main gear; a user can assemble a driving motor in the lock body to drive the lock core gear to realize movement of a whole mechanism in the lock body; and the lock core gear can further be assembled on a mechanical lock core, the user can assemble the mechanical type lock core or the driving motor to drive the lock core gear to rotate, and the movement of the whole mechanism in the lock body is realized.

Owner:庞飞 +1

Product diverting mechanism in packaging system

A product diverting mechanism used in a packaging system, which is effective to increase the speed at which the products are successively diverted, includes a force applicator for applying a force, including a force component acting in a horizontal direction, to the products transported from a preceding station, in a direction transverse to a direction of transport of the products, a suppressor disposed above a transporter for suppressing an upward shift of the products which occurs when the force applicator applies the force to the products, and an elevator for moving the suppressor up and down. The suppressor is lowered during an operation to divert the products so as to contact an upper surface of the products.

Owner:ISHIDA CO LTD

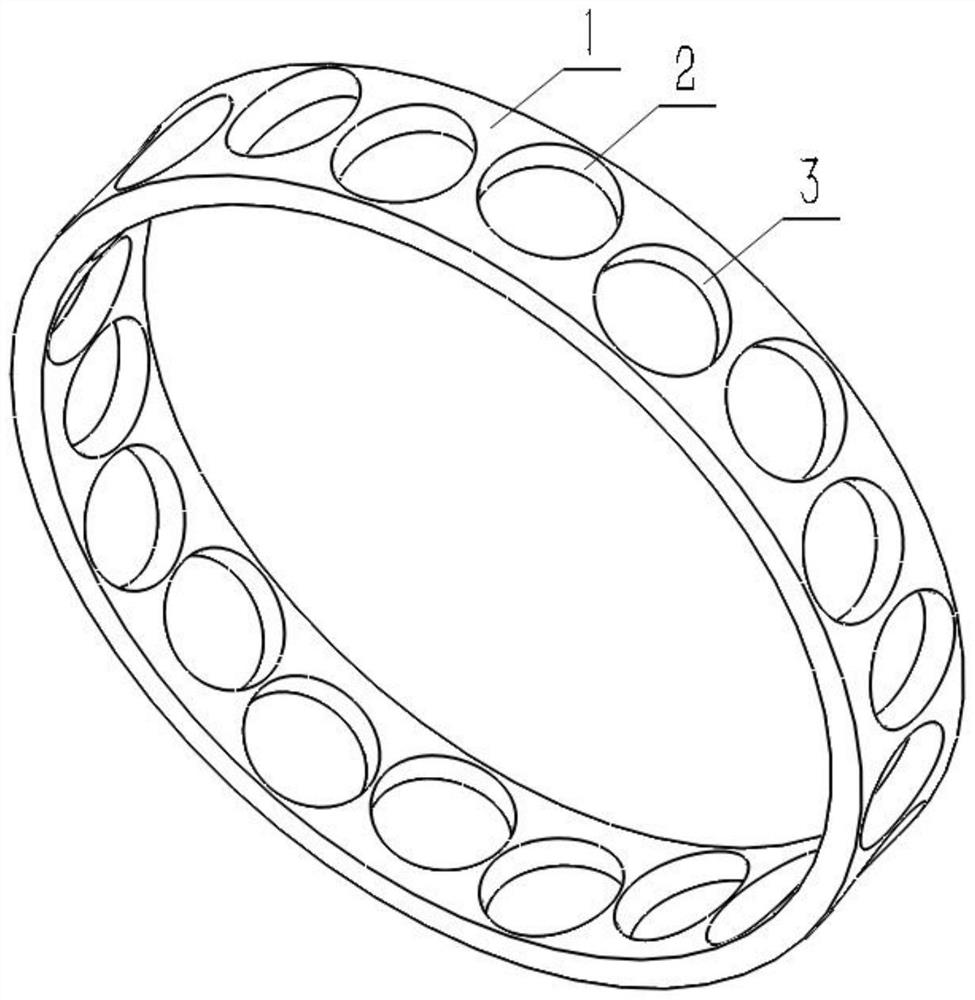

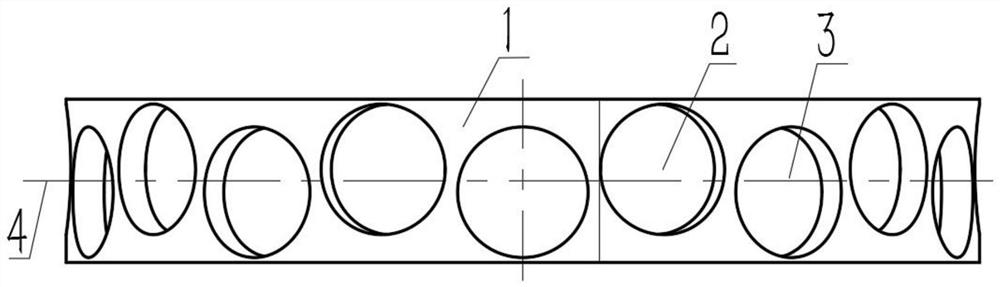

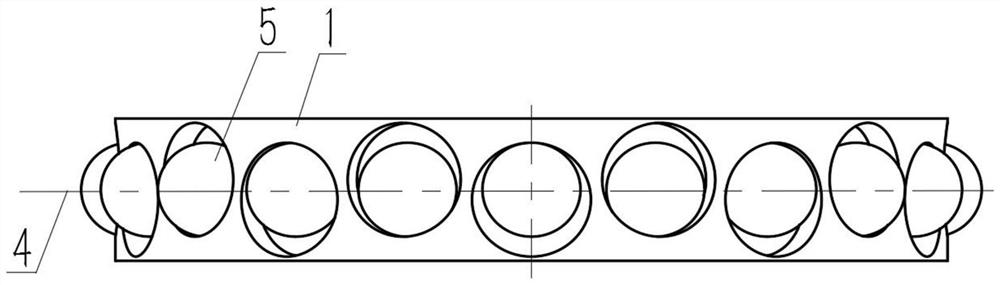

Bearing retainer

InactiveCN113124059AImprove cooling effectLarge eccentric clearanceBearing coolingEngineeringMechanical engineering

The invention discloses a bearing retainer. The bearing retainer comprises a retainer body, upward shifting pockets and downward shifting pockets. According to the bearing retainer, the positions of the pockets are shifted, and the centers of rolling bodies can still be in the same plane in the working process of a bearing, that is, the circle centers of the pockets coincide with the sphere centers of the rolling bodies, and the sphere centers of the rolling bodies are kept in the same plane, so that a large eccentric gap is formed between the rolling bodies and the retainer in the working process of the bearing, the heat dissipation performance of the bearing is improved, and the performance and the service life of the bearing are prevented from being influenced by overheating of the bearing.

Owner:洛阳德润精密机床轴承有限公司

Stable pharmaceutical composition useful for treating gastrointestinal disorders

InactiveCN1627950ASalicyclic acid active ingredientsHeavy metal active ingredientsBismuth compoundGastrointestinal disorder

The present invention provides a pharmaceutical composition comprising at least one pharmaceutically acceptable bismuth-containing compound, at least one pharmaceutically acceptable non-clay-derived suspending agent, and water. The suspension reduced the upward shift in pH compared to an otherwise similar suspension comprising a clay-derived suspending agent. Such compositions are useful in the prevention and treatment of gastrointestinal diseases and / or disorders.

Owner:MCNEIL PPC INC

Strip edge shape control apparatus and method in strip casting process

InactiveUS20110073271A1Quality improvementIncrease productivityMelt-holding vesselsMoulding machine componentsStrip steelStrip casting

Disclosed herein are an apparatus and method for controlling the edge shape of a strip in a twin-roll strip casting process, which improve the quality of the strip by using cameras to photograph the edge portions of the strip being cast by strip casting, analyzing the photographs, and then controlling edge dams according to the edge shape of the strip. The apparatus comprises: an edge dam driving unit which is attached to edge dams attached to both sides of casting rolls so as to control the pressing force of the edge dams against the casting rolls and the upward shift of the edge dams according to the wear and upward shift rate of the edge dams; cameras which are disposed at the strip outlet side of the casting rolls so as to photograph the edge portions of the strip; and a control unit which analyzes the edge shape of the strip from images photographed by the cameras and outputs a signal controlling the wear and upward shift of the edge dams.

Owner:POHANG IRON & STEEL CO LTD

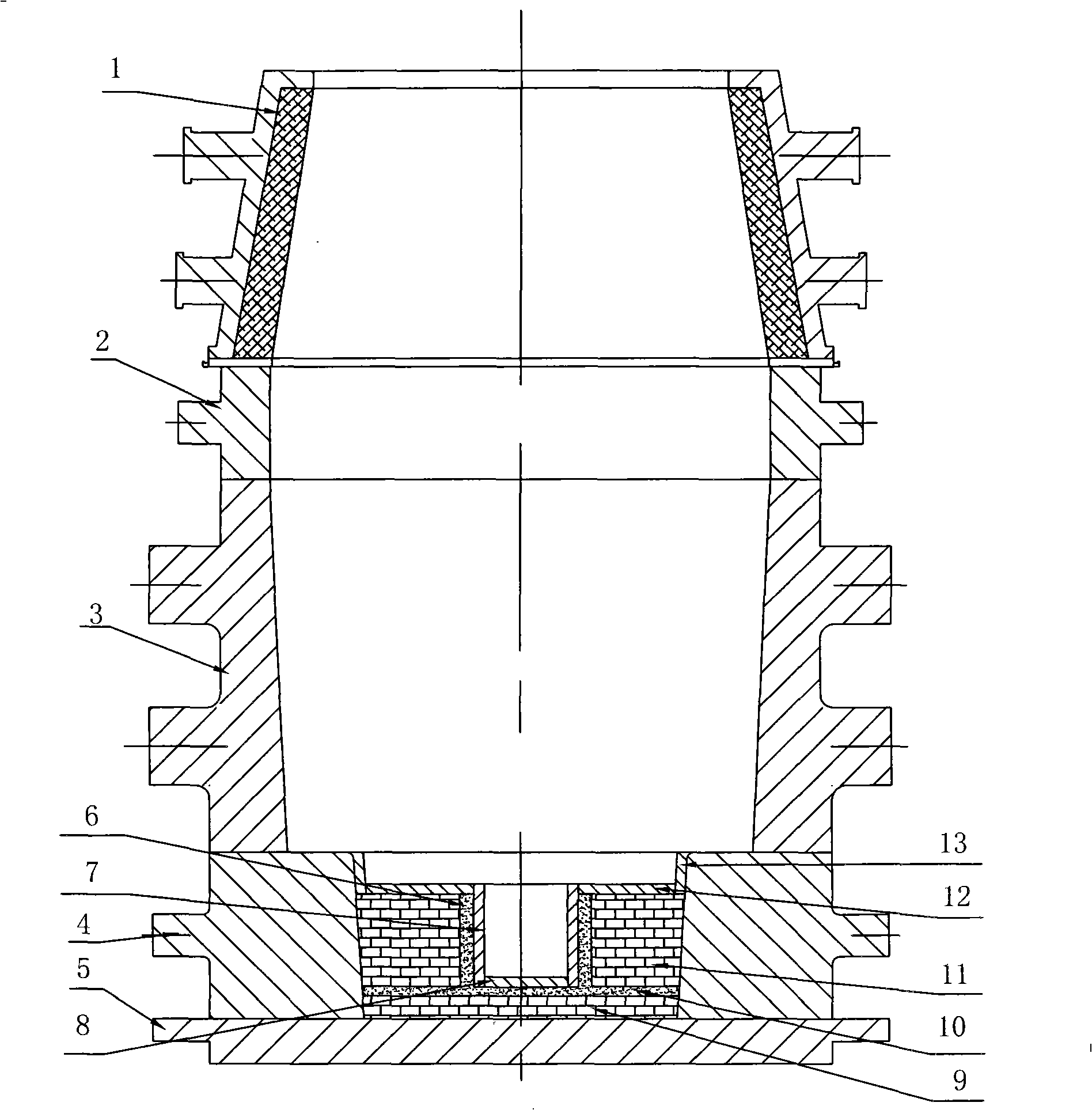

Integral running castings mold device of large-sized steel ingot clamp

The invention discloses a large steel ingot-clamper integral casting mould and belongs to the technology field of ingot mould in steel melting. A lower chassis seat is horizontally arranged on the ground, an upper chassis protective ring is arranged on the lower chassis seat, a multi-layer firebrick cushion is built inside the upper chassis protective ring, a sand lining is covered on the multi-layer firebrick cushion, a ring-shaped firebrick wall is built on the sand lining, a vertical resin-bonded sand lining is arranged in the inner ring of the ring-shaped firebrick wall, a steel ring is bonded with the vertical resin-bonded sand lining, a round steel plate mat is arranged inside the steel ring in a way that the bottom thereof is attached to the sand lining, a chassis cover is arranged on the top of the ring-shaped firebrick wall, a ring-shaped steel plate mat is arranged inside the chassis cover, a steel ingot mould is arranged on the upper chassis protective ring, a heightening ring is arranged on the steel ingot mould, and a heat-insulating cap is arranged on the heightening ring. The casting mould solves the problem that the upward shift of steel ingot depositions may affect the quality of steel ingot. The clamper and the steel ingot are integrally cast so as to prevent the clamper from stripping or loosening off the steel ingot during the following forging procedures.

Owner:CHINA FIRST HEAVY IND +1

Stable and voltage-resistant power relay

PendingCN110071017ACompact structureSimple structureElectromagnetic relay detailsEngineeringUpward shift

The invention discloses a stable and voltage-resistant power relay. The power relay comprises a casing, a base, an armature, a yoke, a pushrod, a normally-closed static spring, a normally-open staticspring and a dynamic spring, wherein the armature and the yoke are connected together through an elastic sheet, the yoke is installed on the base in an inserted mode, limit blocks at the bottom of thecasing prevents the yoke from shifting upwards, a baffle in the casing avoids lateral shift of the armature, arc-shaped stop blocks avoid upward shift of the armature, the tail of the armature and avoltage-resistant slot of the base are in clearance fit, the tail of the armature is connected with one end of the pushrod through a connecting hole, the other end of the pushrod is connected with a connecting hole of the dynamic spring, an insulation screen is arranged in the middle of the pushrod, the creepage distance between the dynamic spring and the armature is prolonged, the normally-open static spring with a buffer sheet is inserted into the base, a trapezoidal protective plate of the base is in fit with the buffer sheet, and limit protection of the normally-open static spring is realized. The stable and voltage-resistant power relay has the advantages of being compact in structure, small in size, excellent in insulating property, resistant to voltage, high in stability, long in product service life and the like; and moreover, the structure is simple, and it is convenient to perform processing and realize automatic assembling.

Owner:YUEQING MEISHUO ELECTRIC

Mounting structure and method for heat accumulation tank

A mounting structure for a heat accumulation tank is provided with an elastic member that wraps around a tank main body, and a heat accumulation tank mounting member which wraps around the outer peripheral surface of the elastic member and holds the tank main body by being tightened in the circumferential direction, and which attaches to a receiving member. The elastic member is a molded part. The length of the elastic member is shorter than length of the circumference of the outer peripheral surface of the tank main body. The heat accumulation tank mounting member includes a shift inhibiting portion which inhibits an upward shift of the tank main body. The outside diameter of the tank main body becomes increasingly wider in the upward direction.

Owner:TOYOTA JIDOSHA KK +1

Multistage transmission

Owner:HONDA MOTOR CO LTD

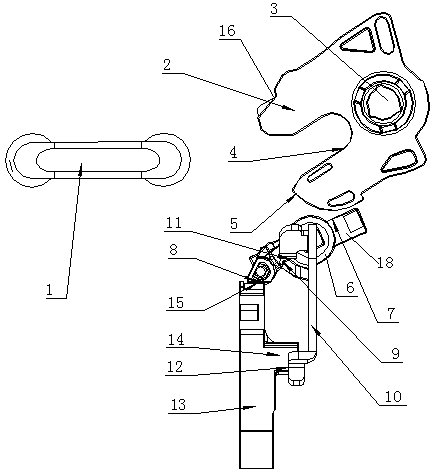

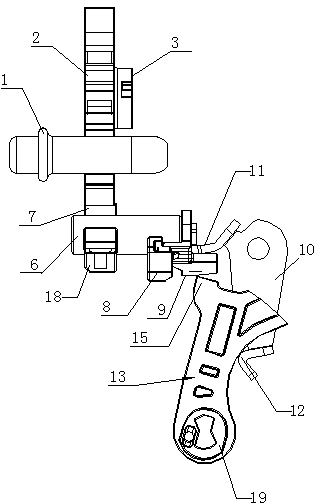

False-locking preventing mechanism of automobile door lock

ActiveCN102747894BWith anti-mislocking functionSpecial locking actionsMechanical engineeringUpward shift

Owner:凯毅德汽车系统(郑州)有限公司

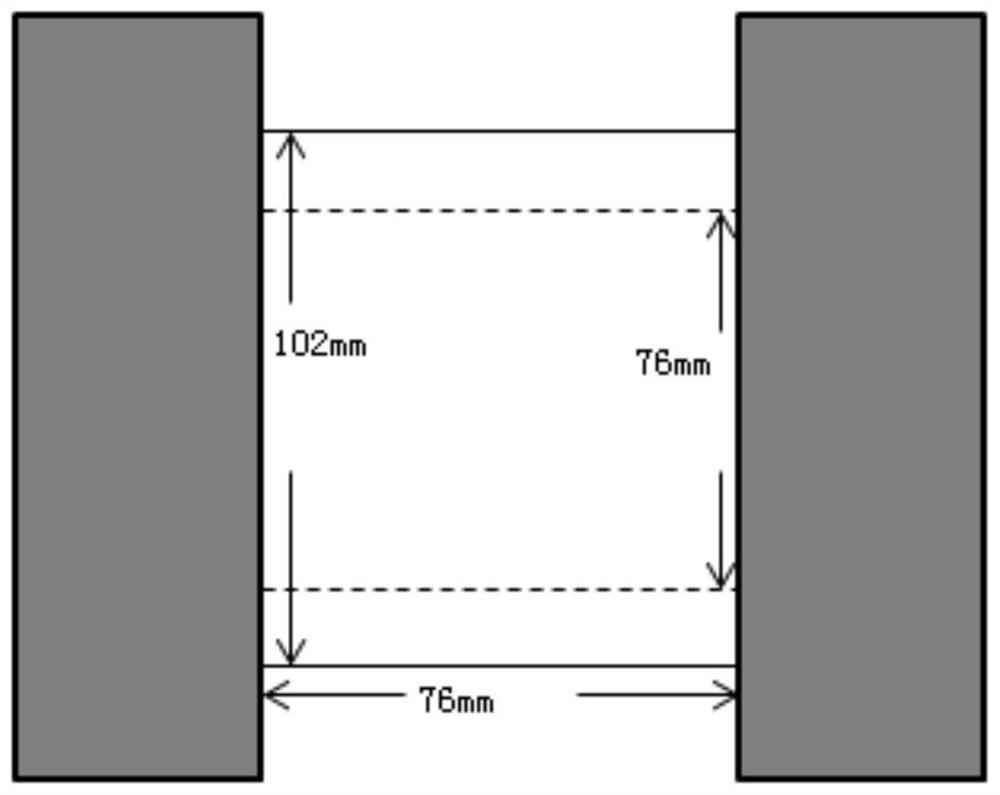

A method for increasing the exposure area of a 4-inch plate produced by a step-and-repeat compacting machine

ActiveCN108196422BLarge product areaTo satisfy the market's needsOriginals for photomechanical treatmentEconomic benefitsExposure

The invention relates to a method for improving the exposure area of a 4-inch plate produced by a step-by-step compacting machine. The exposure area is input in the exposure area of the mask plate, and a coordinate system is established according to the exposure area; Expose at the step distance in the direction to get the compact version; shift up the top line of the exposed compact version to obtain the coordinates after the upward shift; at the same time, shift down the bottom row of the exposed compact version, Get the coordinates after the downward shift; take the coordinates after the upward shift as the origin, and expose the compact version after the upward shift according to the step distance of the X-axis and Y-axis directions; take the coordinates after the downward shift as At the origin, exposure is performed on the compact version shifted down according to the step distance in the X-axis and Y-axis directions. The invention improves the production area of 4-inch mask, meets market demand, increases economic benefits, breaks through the limitation of equipment, and solves the problem that the Y-direction length cannot exceed 76mm under the limitation of 4-inch plate frame and focus.

Owner:NO 47 INST OF CHINA ELECTRONICS TECH GRP

Gas-making workshop integrated control system for synthesis ammonia production and use method thereof

InactiveCN102323809BAccurately grasp the operation situationRealize energy saving and consumption reductionTotal factory controlProgramme total factory controlAmmonia productionControl system

Owner:武汉世纪凤飞节能环保技术工程有限公司

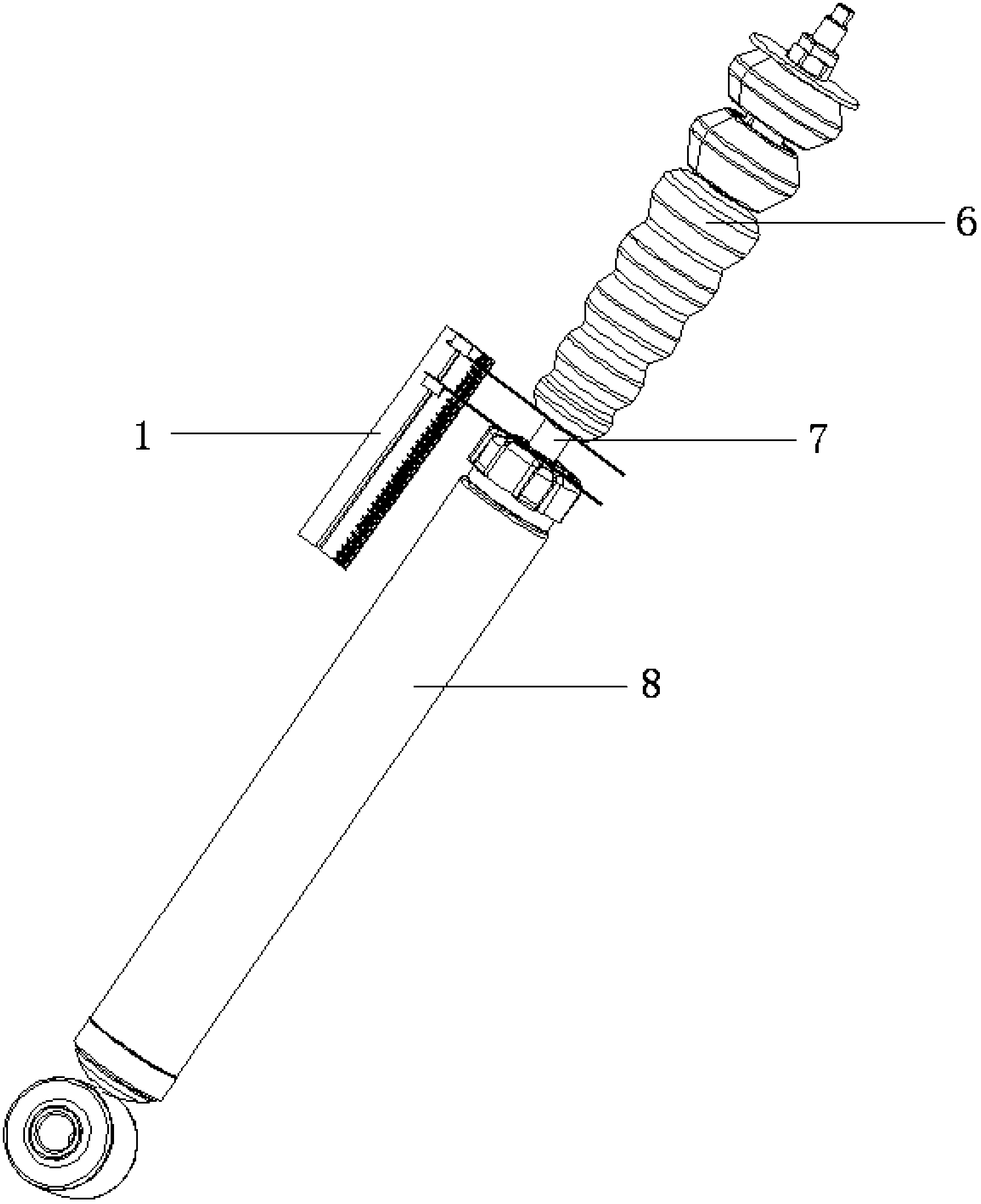

Mounting structure of dynamic damper

A mounting structure of a dynamic damper capable of effectively reducing the vibration of a vibration body is provided. The mounting structure includes a suspension member 100 inhibiting the upward shift of a mass member 5. The suspension member 100 and plates 3 are configured as separate members, so that as compared with the case where a pair of plates 3 are coupled, the opposite interval between the plates 3 can be determined without being affected by the dimension accuracy of such the coupling portion. Thus, the thicknesses of the rubber elastic bodies 4 can foe formed at high accuracy, so that the mass member 5 can be easily vibrated at the desired frequency. Therefore, the vibration of the suspension member 100 can be effectively reduced.

Owner:TOYO TIRE & RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com