Bearing retainer

A technology of bearing cages and cages, which is applied in the direction of bearing components, shafts, bearings, bearing cooling, etc., can solve the problems of heat dissipation due to frictional heat between rolling elements and cages, and improve heat dissipation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

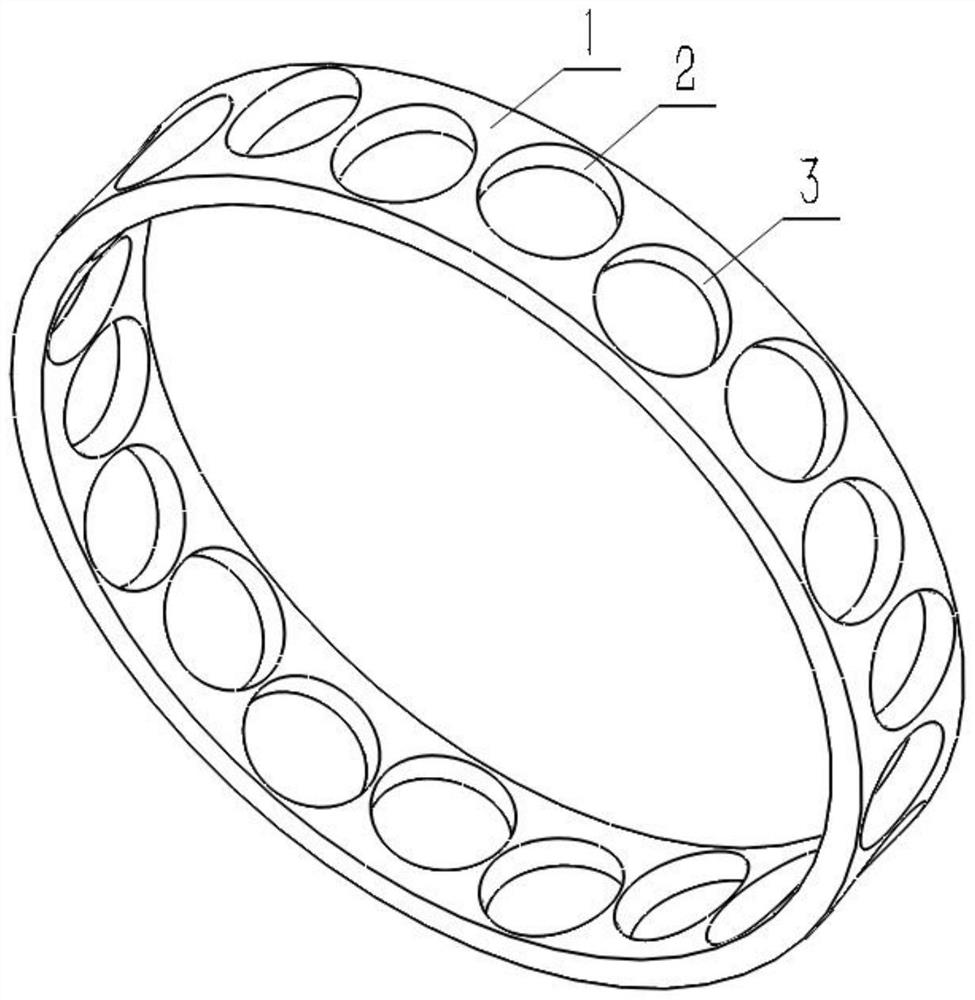

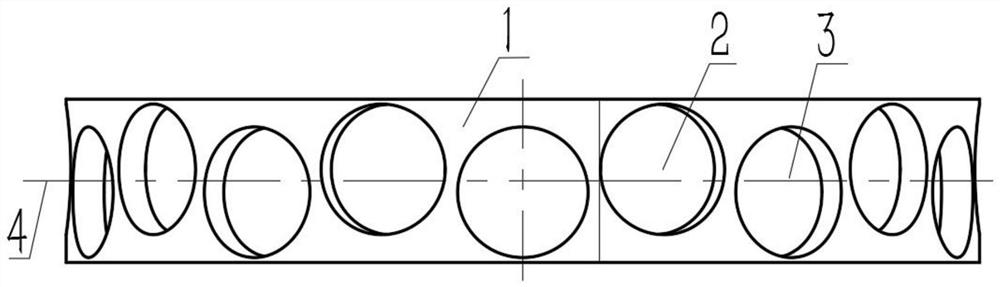

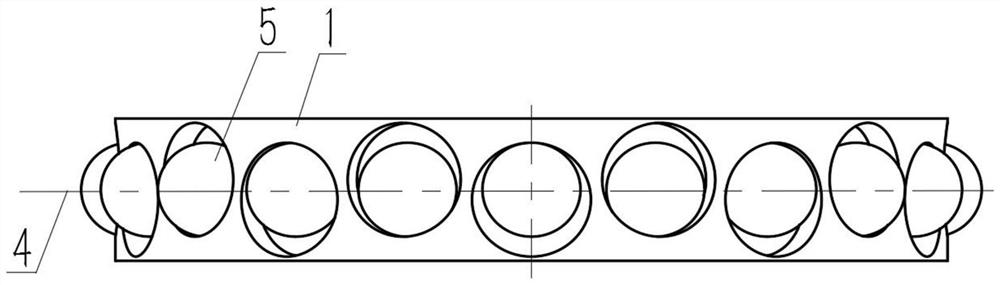

[0011] Such as figure 1 , figure 2 , image 3 As shown, the present invention discloses a bearing cage. The technical solution adopted is to include a cage body 1, and the cage body 1 is provided with an upper bias pocket 2 and a lower bias pocket for guiding the rolling elements 5. 3. The number of the upper partial pocket holes 2 and the lower partial pocket holes 3 is even in number and the intervals are evenly arranged.

[0012] The axial centerline 4 of the cage body 1 is at the same distance from both ends of the cage body 1 . The center of the upper eccentric pocket hole 2 is offset upward from the axial centerline 4, and the center of the lower eccentric pocket 3 is offset downward from the axial centerline 4. The offset distance is equal to the installed 2% of the length of the diameter of the rolling element 5.

[0013] Working principle of the present invention: the center of the upper partial pocket hole 2 and the lower partial pocket hole 3 designed by the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com