Gas-making workshop integrated control system for synthesis ammonia production and use method thereof

A technology of comprehensive control and gas production workshop, applied in electrical program control, ammonia preparation/separation, comprehensive factory control, etc., can solve the problems of lack of coordination, few parameters, unfavorable energy saving and consumption reduction, etc., to improve the optimal controllability , the effect of accurate operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

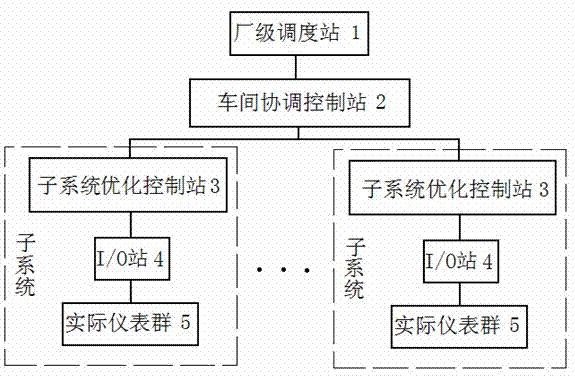

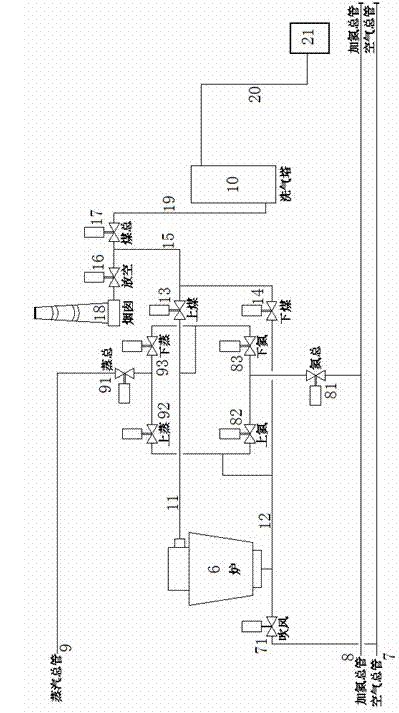

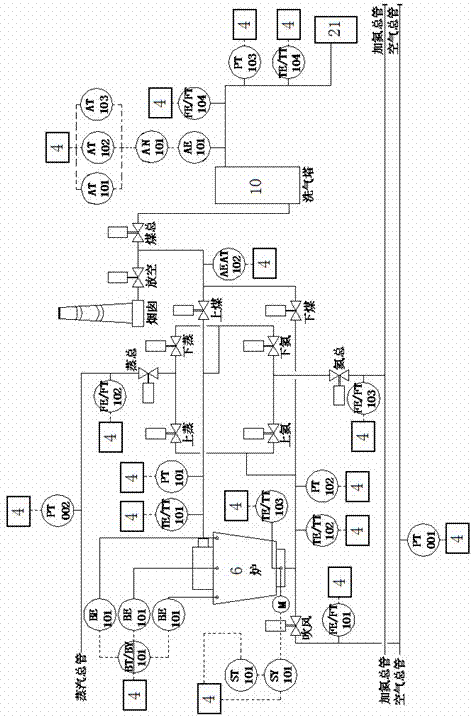

[0036] see figure 1 – image 3 , the comprehensive control system of the gas-making workshop used for the production of synthetic ammonia, the comprehensive control system includes multiple subsystems, each subsystem includes a plurality of gas-making furnaces 6, and the two ends of each gas-making furnace 6 are respectively connected to the upper gas channel of the gas furnace 11. The lower gas channel 12 of the gas furnace is connected to each other. The other ends of the gas furnace upper gas channel 11 and the gas furnace lower gas channel 12 respectively pass through the upward gas valve 13 and the downward gas valve 14, respectively, and are connected to the gas main pipe 15. The gas main pipe 15 The other end of the vent valve 16 is connected with the gas master valve 17, the other end of the vent valve 16 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com