A method for increasing the exposure area of a 4-inch plate produced by a step-and-repeat compacting machine

A technology of exposure area and shrinking machine, which is applied in the field of improving the exposure area of 4-inch plates produced by step-and-repeat shrinking machines, and can solve the problem that the Y-direction length cannot exceed 76mm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

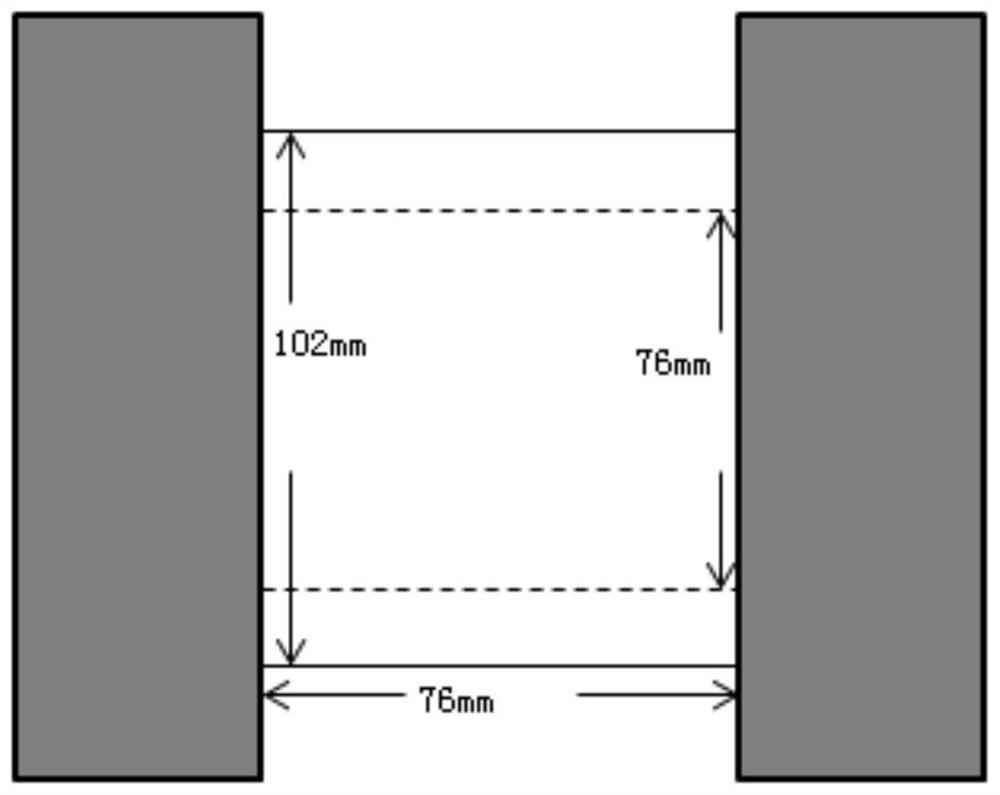

[0024] Such as figure 1 Shown is a 4-inch version of the present invention to make an area diagram.

[0025] The shaded area represents the plate holder, under which the mask is vacuumed. The solid line part of the X-axis represents the size of the reticle restricted in the plate frame of 76 mm, and the length of the solid line part of the Y-axis represents the size of the 4-inch reticle of 102 mm. The part inside the dotted line represents the size of the miniature version made without using the patent of the present invention.

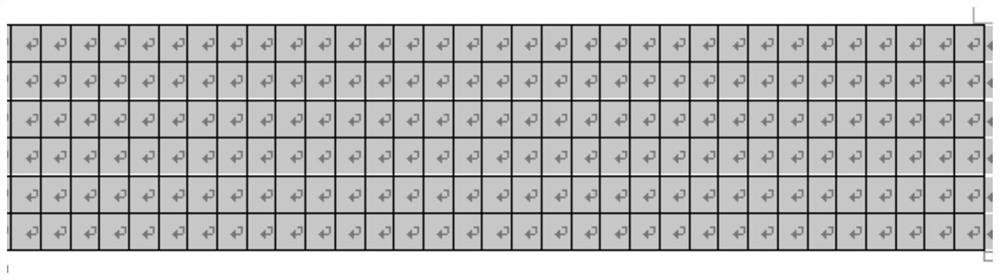

[0026] Such as figure 2 Shown is a miniature schematic of the exposure of the present invention.

[0027] Taking the production of a 4-inch version of graphic data with a step distance of 2300*10000μm as an example, three program menus and shift exposure are used to make a mask. The production method is as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com