Light-emitting backlight source of annular vertical separation double-different-surface cathode rear dragging oblique curve gating structure

A technology of backlight source and cathode, which is applied to the field of light-emitting backlight source with a dragging oblique gate control structure behind a ring-vertical separation double-heteroplane cathode, can solve the problems of small cathode current and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to this embodiment.

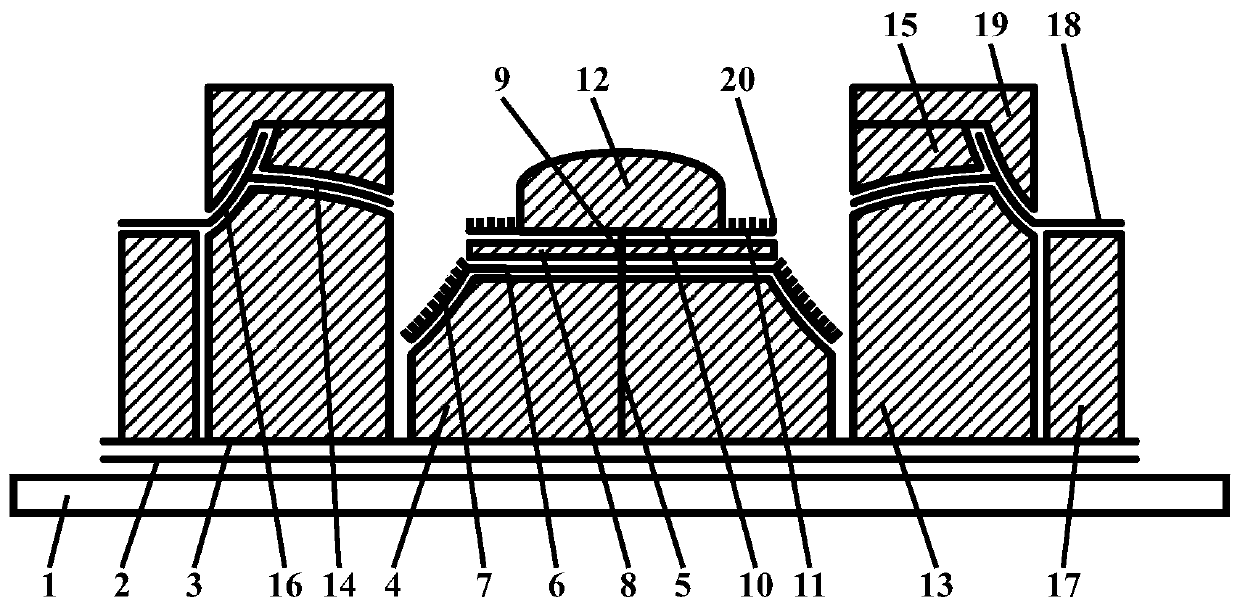

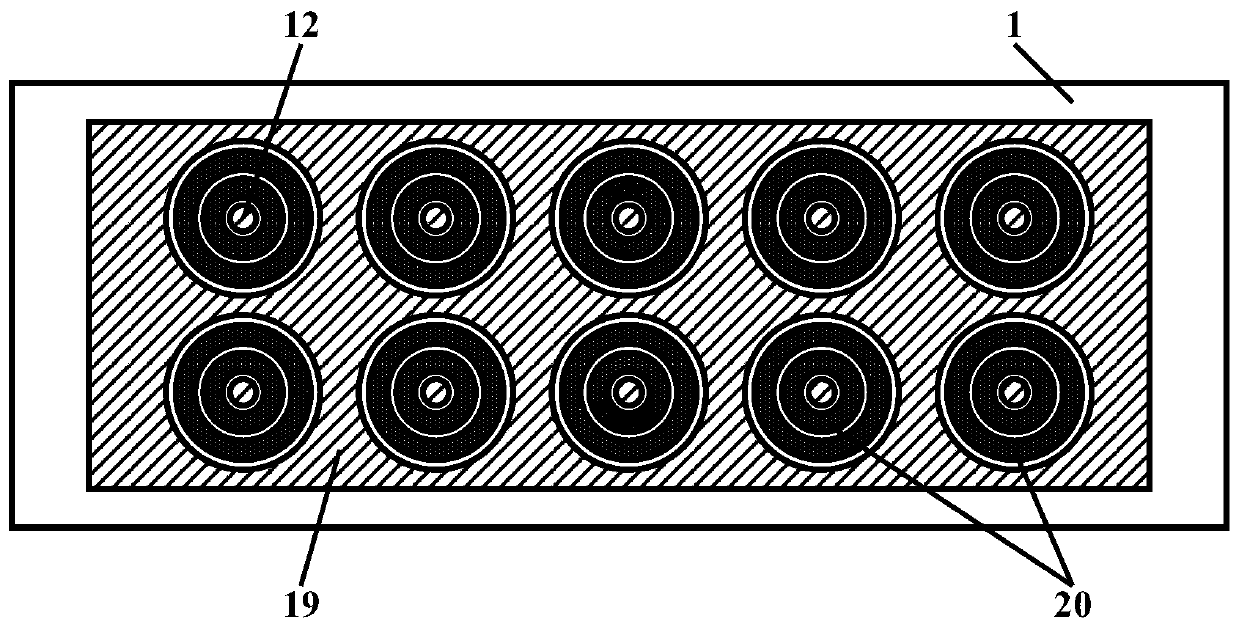

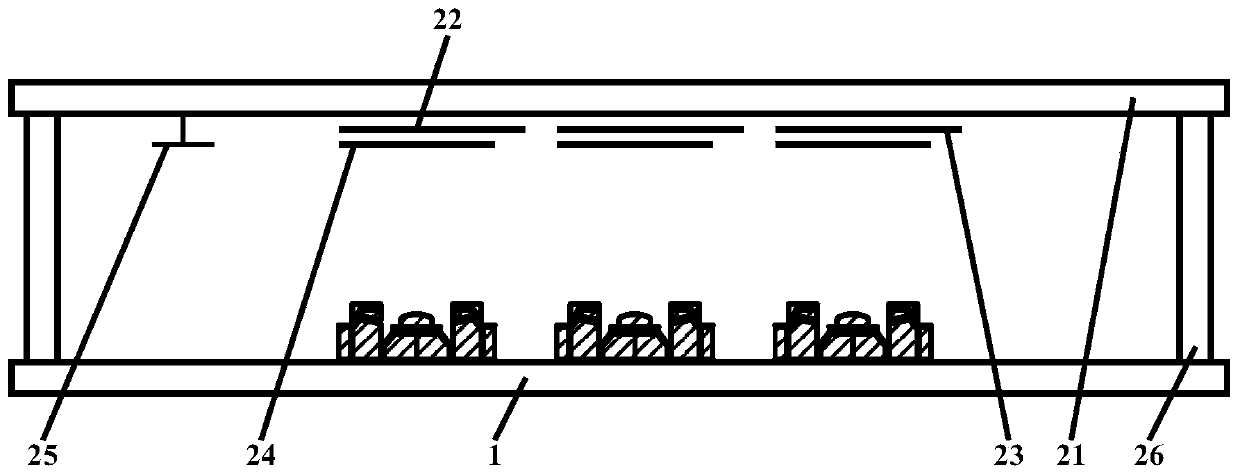

[0050] In this embodiment, the light-emitting backlight of the oblique gating structure is dragged after the double-different-plane cathode is separated by a ring vertically. figure 1 , figure 2 with image 3 As shown, it includes a vacuum enclosure and a getter 25 accessory components located in the vacuum enclosure. The vacuum enclosure is composed of a front hard transparent glass plate 21, a rear hard transparent glass plate 1 and a glass narrow frame strip 26; The transparent glass plate 1 has an anode low object film block layer 22, an anode interextended trace layer 23 and a thin luminescent layer 24, and the anode low object film block layer 22 is connected to the anode interextended trace layer 23, and the The thin light-emitting layer 24 is made on the anode low-material film bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com