Patents

Literature

46results about How to "Not easy to passivate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Amino acid-containing water-soluble fertilizer added with sugar alcohol and preparation method thereof

The invention provides an amino acid-containing water soluble fertilizer added with sugar alcohol and a preparation method thereof. The amino acid-containing water-soluble fertilizer added with sugar alcohol is prepared from the following raw materials: amino acid, calcium salt and water as well as 5-10wt% of sugar alcohol. The amino acid-containing water-soluble fertilizer is of a calcium element type, the sugar alcohol is added to be used as a chelating agent of the calcium element; by virtue of reasonable ratio of sugar alcohol to amino acid to calcium salt, the sugar alcohol and the calcium element are chelated to form a stable micromolecule chelate; since sugar alcohol has permeation and wetting properties, absorption and transportation efficiency of the chelated calcium element is improved; meanwhile, amino acid can promote calcium absorption and also can promote photosynthesis, so that chlorophyll content is increased. Therefore, under the combined action of sugar alcohol and amino acid, the amino acid-containing water-soluble fertilizer added with sugar alcohol has high utilization rate, can improve the conveying speed of plant nutrients, can enhance calcium absorption of plants and can increase sugar content of the plants.

Owner:BEYONDCHEM LIFE TECH

Hot dipping aluminium and aluminium alloy inactivation process of plating

InactiveCN1392283ASimple processEasy to implementHot-dipping/immersion processesRoom temperatureSurface chemical

The present invention belongs to the field of iron and steel material surface chemical and heat treatment technology. The technological process is that before hot dipping, the workpiece surface is filming treated with the inactivation solution compounded by using CrO3 0.2-5 wt%, K2MnO4 0.05-3 wt%, NaNO2 0.05-6 wt% and water, at room temperature for 0.5-5 min. The present invention features the repeated use of the inactivation solution, good filming effect, simple technological process, low cost and capacity of forming smooth, level plated coating without pinhole and leakage.

Owner:HUAZHONG UNIV OF SCI & TECH

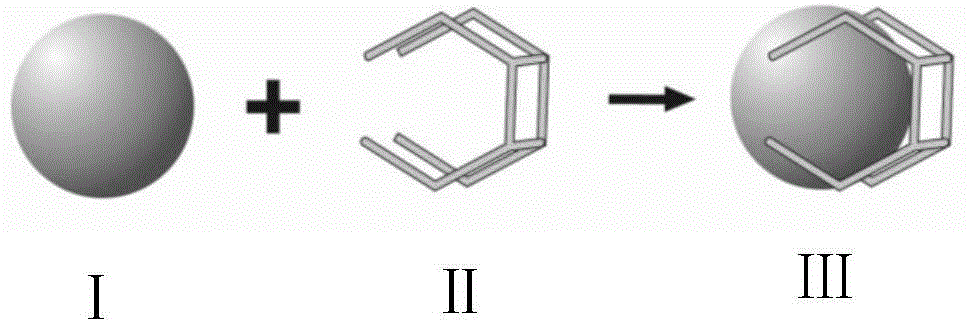

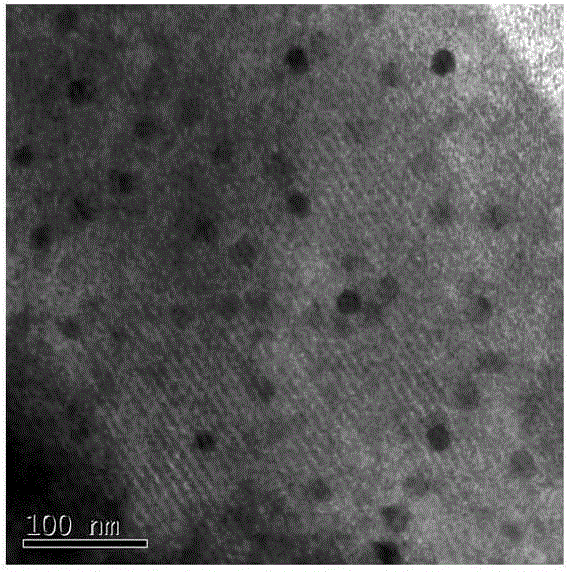

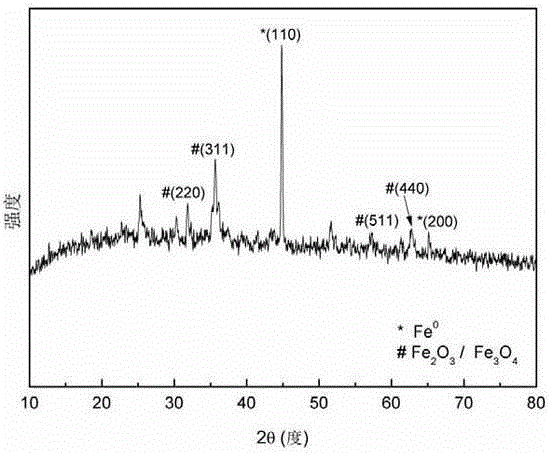

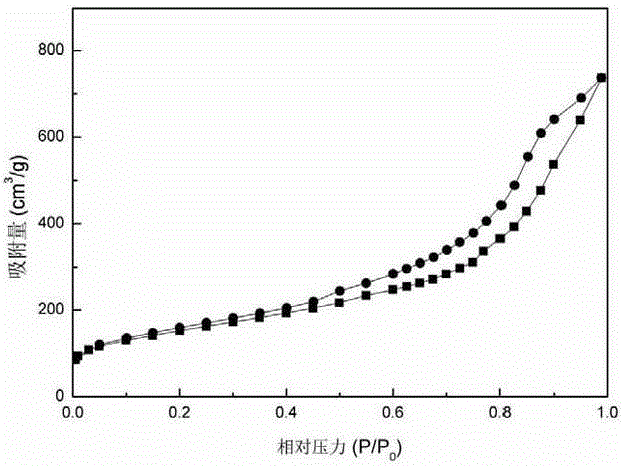

Magnetic nano ferrum-carrying ordered mesoporous carbon and preparation method and application thereof

ActiveCN105289500AIncrease the areaLarge pore volumeOther chemical processesWater contaminantsCarbonizationIron chloride

The invention discloses magnetic nano ferrum-carrying ordered mesoporous carbon and a preparation method and application thereof. The magnetic nano ferrum-carrying ordered mesoporous carbon is prepared by adopting a nano co-casting one-step method. The method comprises the following steps: mixing saccharose, ferric chloride hexahydrate and sulfuric acid solution, adding the mixed solution to ordered mesoporous silicon SBA-15, and carrying out two times of heat treatment, high temperature carbonization and desilicication treatment to obtain the magnetic nano ferrum-carrying ordered mesoporous carbon. The preparation method disclosed by the invention has the characteristics of being simple in steps, low in cost, high in production efficiency, and easy for large-scale production; the prepared material has relatively large specific surface area and pore volume and strong magnetism, can effectively remove bisphenol A in water, not only is large in adsorbing capacity for bisphenol A and high in removal rate of bisphenol A, but also is wide in pH application scope, simple in operation, short in treatment period, and easy for regeneration, and is favorable for efficient automated design in wastewater treatment.

Owner:HUNAN UNIV

Environment-friendly micro-electrolysis ceramsite and preparation method thereof

InactiveCN108178246ALarge specific surface areaImprove adsorption capacityWater/sewage treatmentElectrolysisSludge

The invention provides an environment-friendly micro-electrolysis ceramsite and a preparation method thereof. The environment-friendly micro-electrolysis ceramsite is prepared from the following raw materials in percentage by mass: 30 to 40% of nanometer zero-valent iron, 20 to 30% of activated carbon, 20 to 30% of river and lake sludge, 5 to 10% of dispersant, 5 to 10% of adhesive, 5 to 10% of perforating agent, 5 to 10% of catalyst, and 0.1 to 0.5% of graphene. The environment-friendly micro-electrolysis ceramsite has the advantages that by utilizing the river and lake sludge to prepare theenvironment-friendly micro-electrolysis ceramsite, the resources of the river and lake sludge can be utilized; the specific surface area is large, the adsorption property is good, the mechanical strength is high, the service life is long, the physical and chemical properties are stable, the easiness in passivating and caking is avoided, the activating and reutilization effects are realized, and the like; the electrochemistry, oxidized reduction, physical adsorption and flocculent precipitation methods can be integrated, and the biodegradability of the wastewater is improved while the wastewater is treated.

Owner:无锡市拜沃特环保科技有限公司 +1

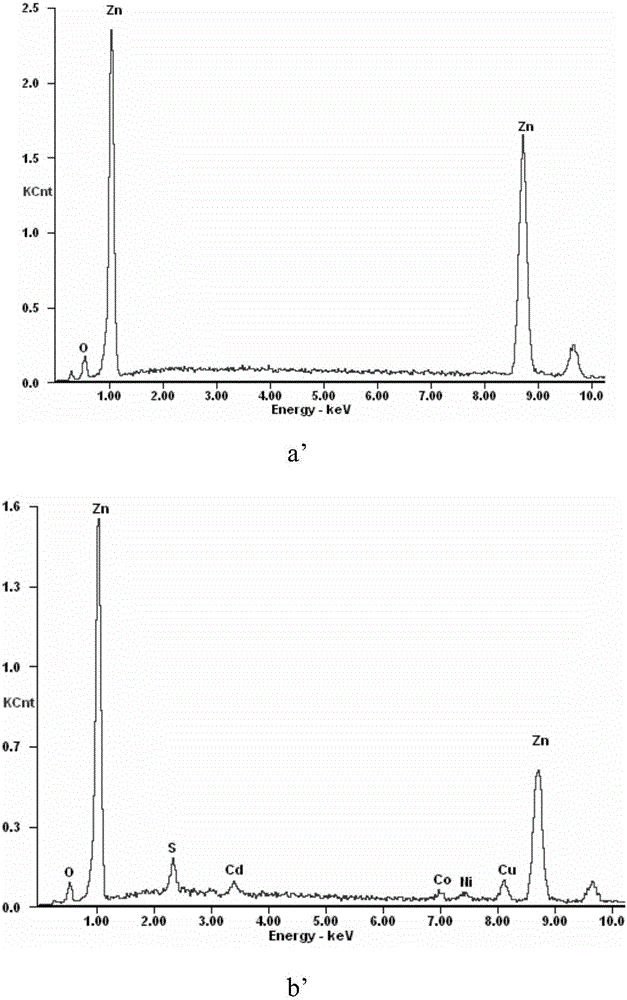

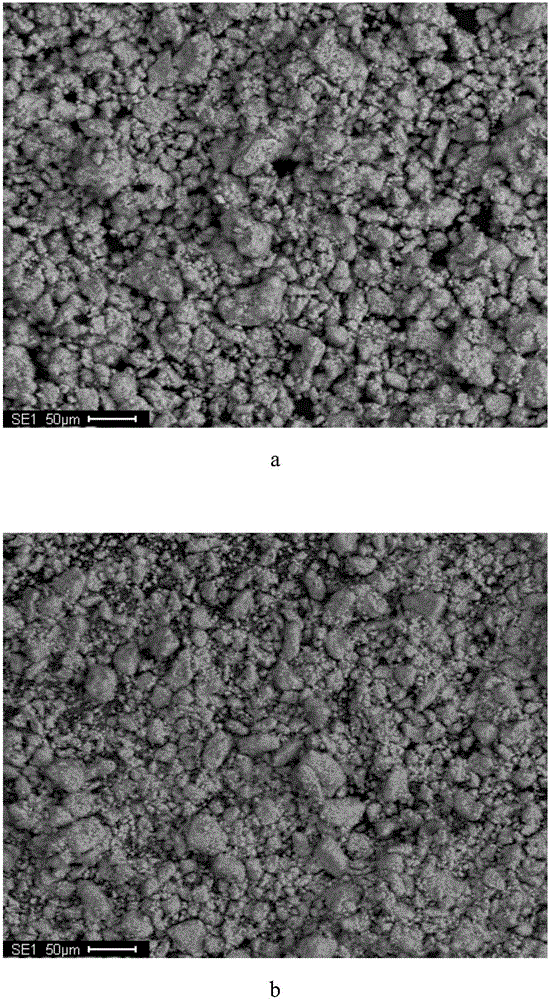

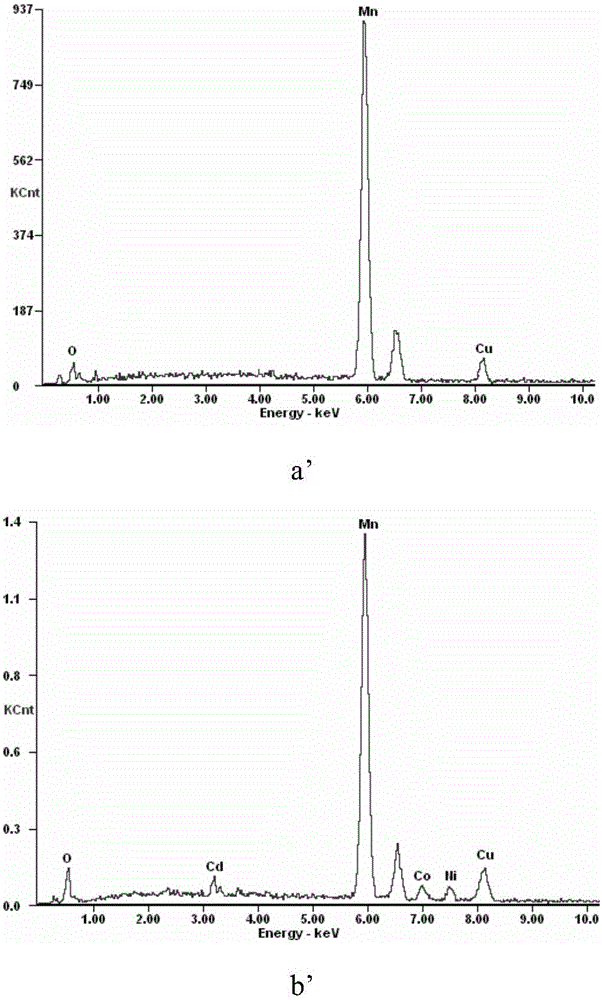

Method for removing copper, cadmium, nickel and cobalt out of zinc sulfate solution through one step

The invention discloses a method for removing copper, cadmium, nickel and cobalt out of a zinc sulfate solution through one step. The method comprises the steps that manganese metal powder and / or manganese-based alloy powder are / is added into the zinc sulfate solution containing copper, cadmium, nickel and cobalt, wherein the temperature of the zinc sulfate solution ranges from 45 DEG C to 70 DEG C, and the pH of the zinc sulfate solution is larger than 4.0; and stirring is carried out for a reaction, after the reaction is finished, filtering separation is carried out, and the zinc sulfate solution with the contents of copper, cadmium, nickel and cobalt all lower than 0.8 ppm is obtained. According to the method, copper, cadmium, nickel and cobalt can be efficiently removed out of the zinc sulfate solution through one step at the same time, no impurities endangering zinc electrolyzing are introduced, the technological process is simple and low in cost, no complex and special equipment is needed, and good industrial application prospects are achieved.

Owner:CENT SOUTH UNIV

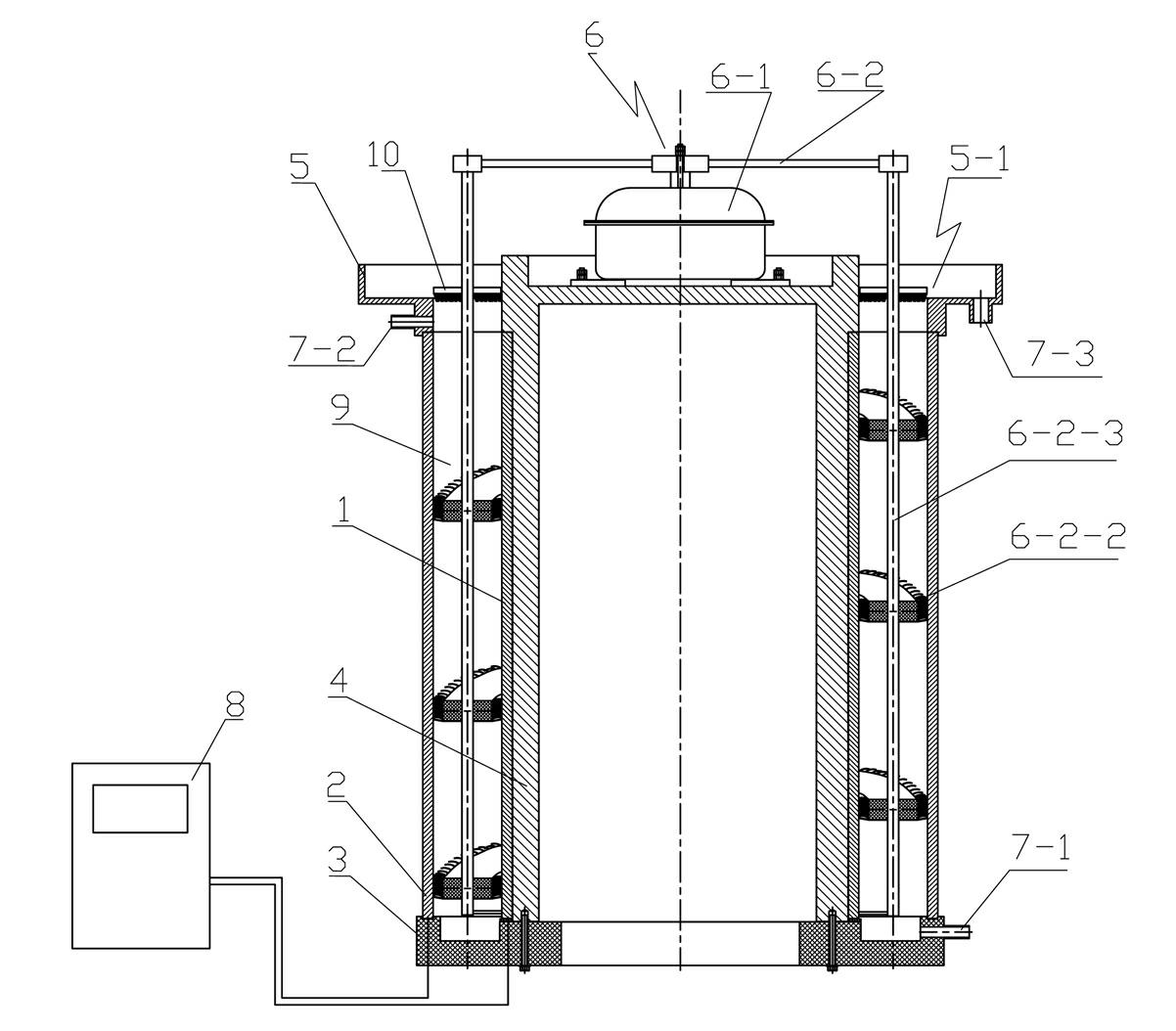

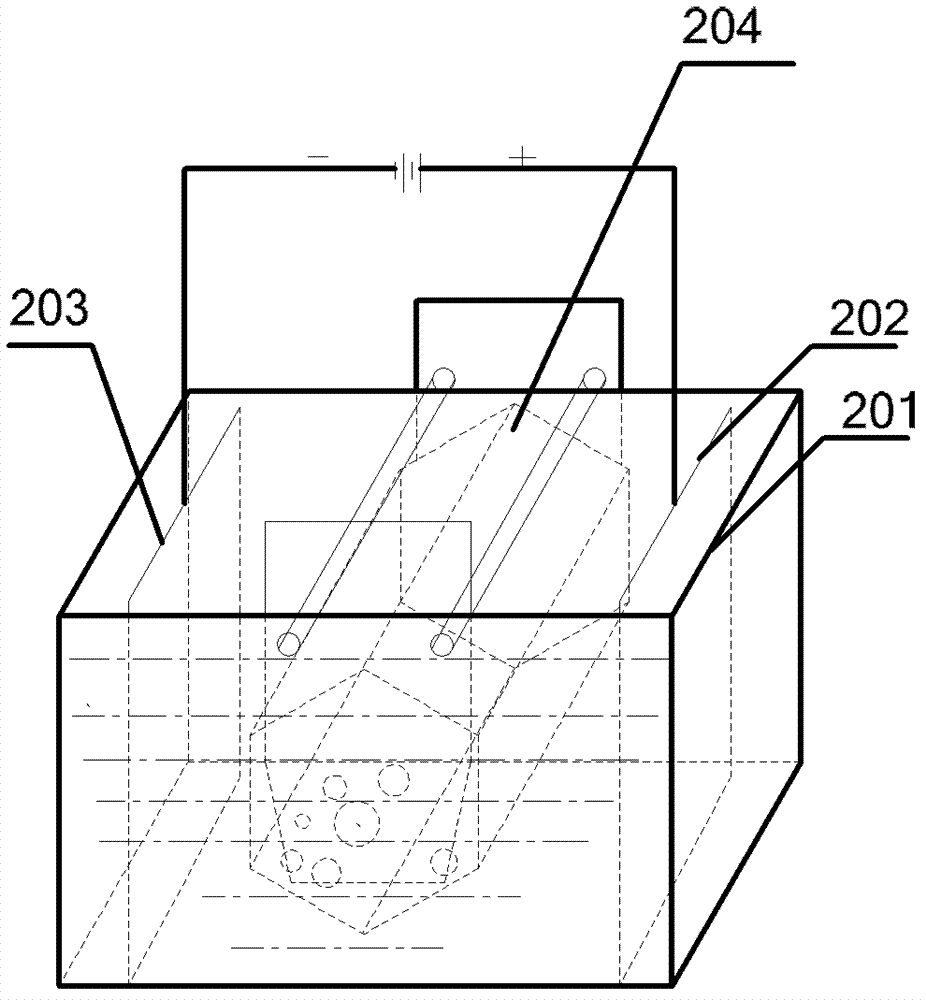

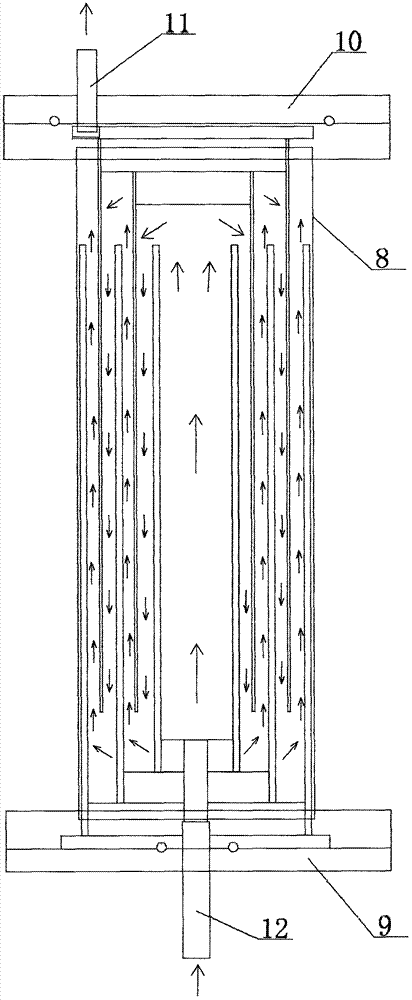

Wastewater electrochemical treatment device

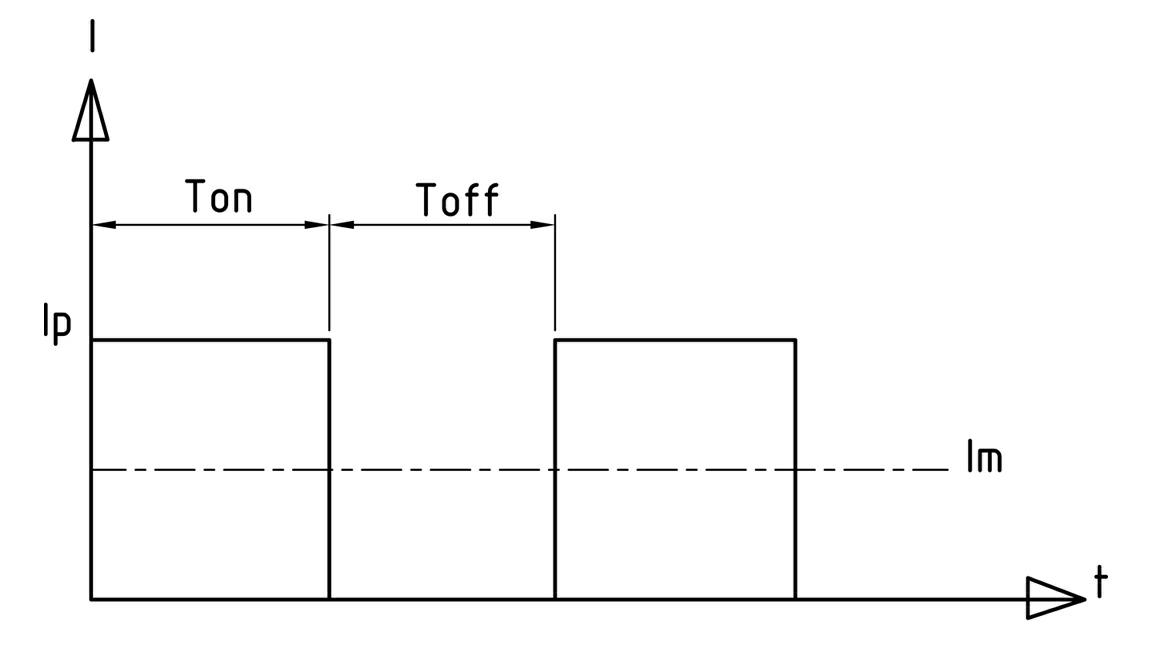

InactiveCN102173483AReduce the amount of dissolutionReduce lossWater/sewage treatment by electrochemical methodsAutomatic controlProgrammable logic controller

The invention discloses a wastewater electrochemical treatment device. The device is mainly characterized in that two pole plates are cylindric and one pole plate is sleeved outside the other pole plate; a drifter collector plate is arranged at the upper ends of wastewater electrochemical treatment cavities formed by the two pole plates oppositely; and electric brush assemblies are arranged in the electrochemical treatment cavities. The device is also characterized in that an electric controller with a PLC (programmable logic controller) is used for realizing automatic control of the technological parameters and the working process. The device has the characteristics of reasonable structure, small volume, difficulty in passivation of pole plates, quick electrochemical reaction, good water treatment effect, high efficiency, low operation cost and the like, is widely applicable to industrial wastewater and domestic wastewater treatment and can be used for purification of blue-green algae bloom.

Owner:常州宇众机电科技有限公司

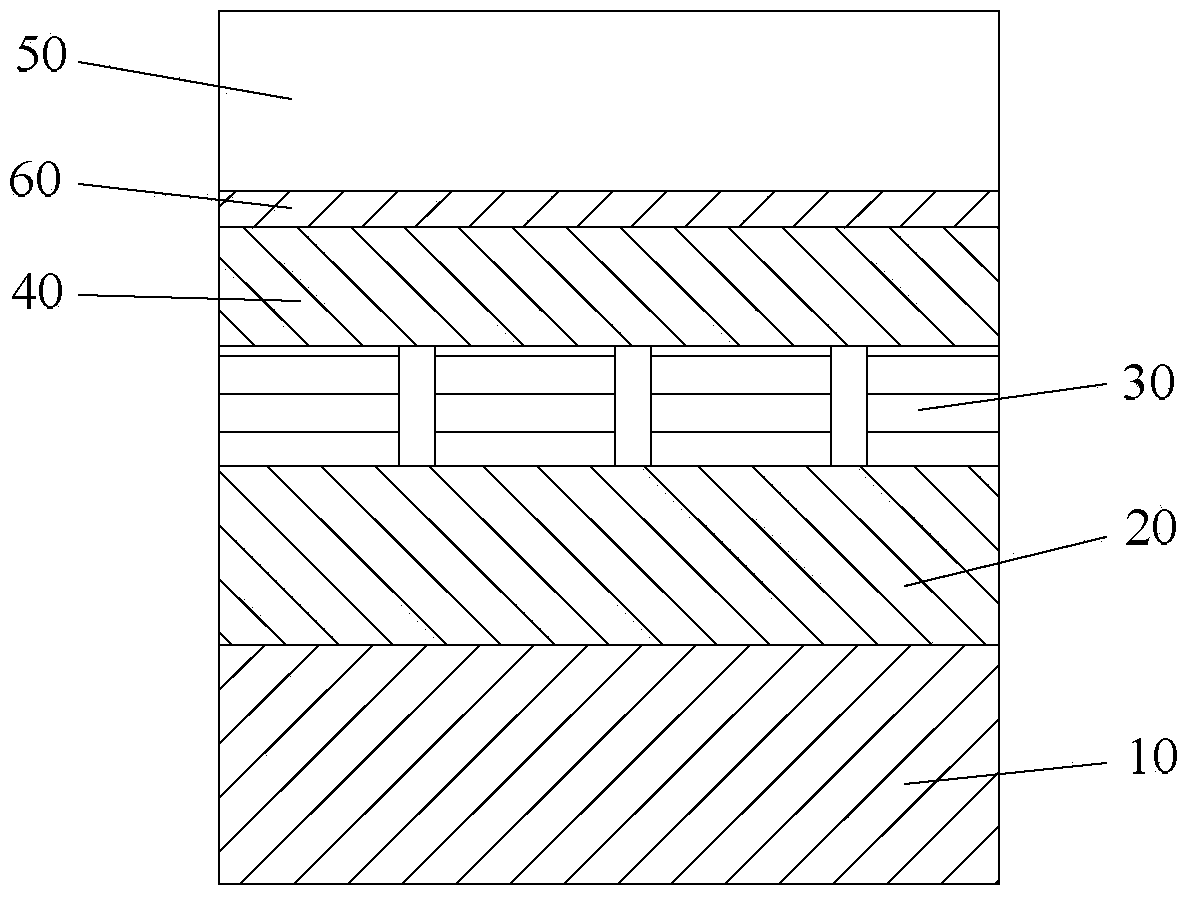

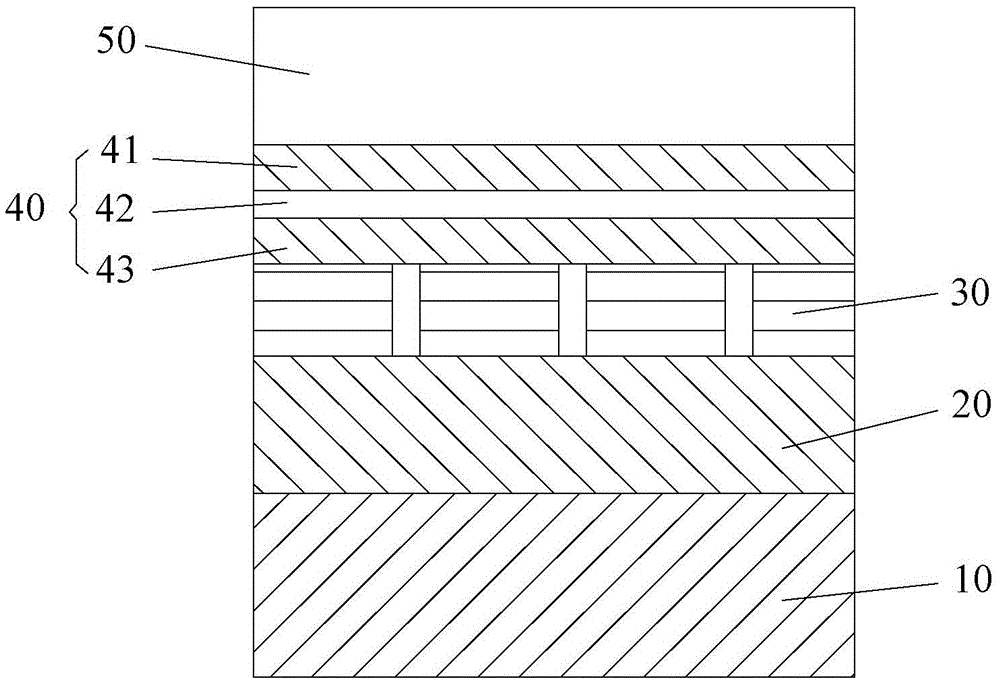

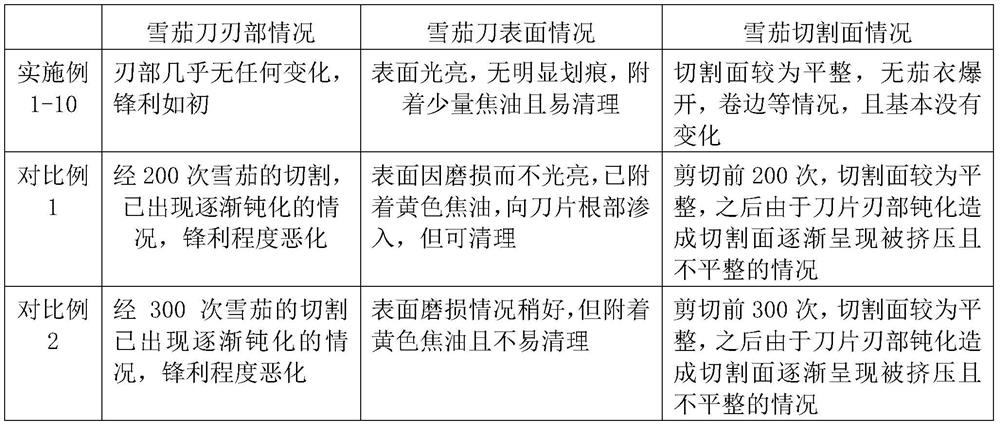

Solar cell module

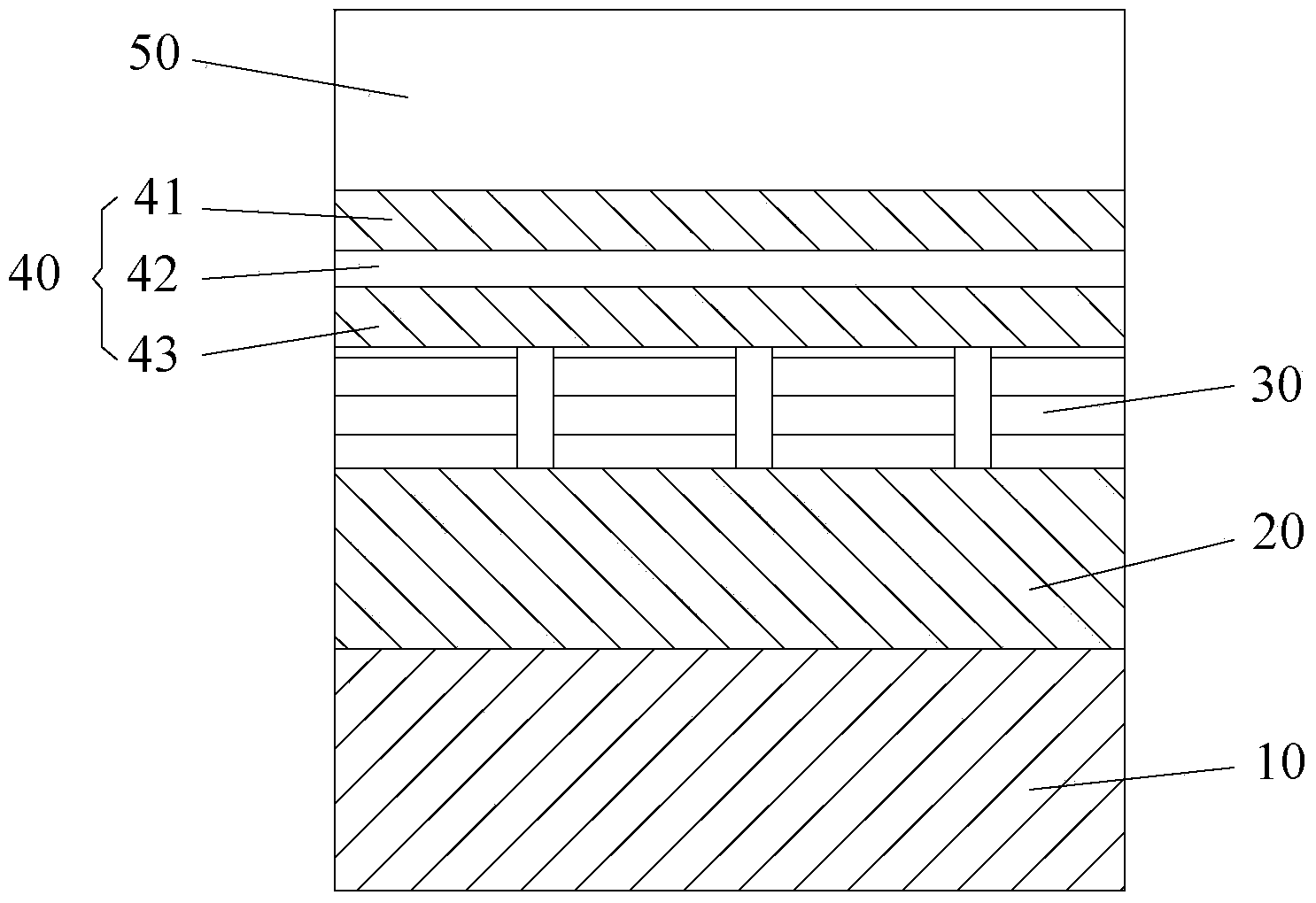

ActiveCN103646977AAvoid gatheringNot easy to passivatePhotovoltaic energy generationSemiconductor devicesSolar cellCell sheet

he invention provides a solar cell module. The solar cell module comprises a backboard layer (10), a first packaging material layer (20), a cell sheet layer (30), a second packaging material layer (40) and a glass layer (50) which are successively superposed. The solar cell module also comprises a barrier layer (60) used for preventing metal cations of the glass layer (50) from entering into the cell sheet layer (30). The barrier layer (60) is arranged between the glass layer (50) and a second packaging material layer (40). By using the solar cell module of the invention, a problem of a PID phenomenon existing in the solar cell module in the prior art is effectively solved.

Owner:YINGLI ENERGY CHINA

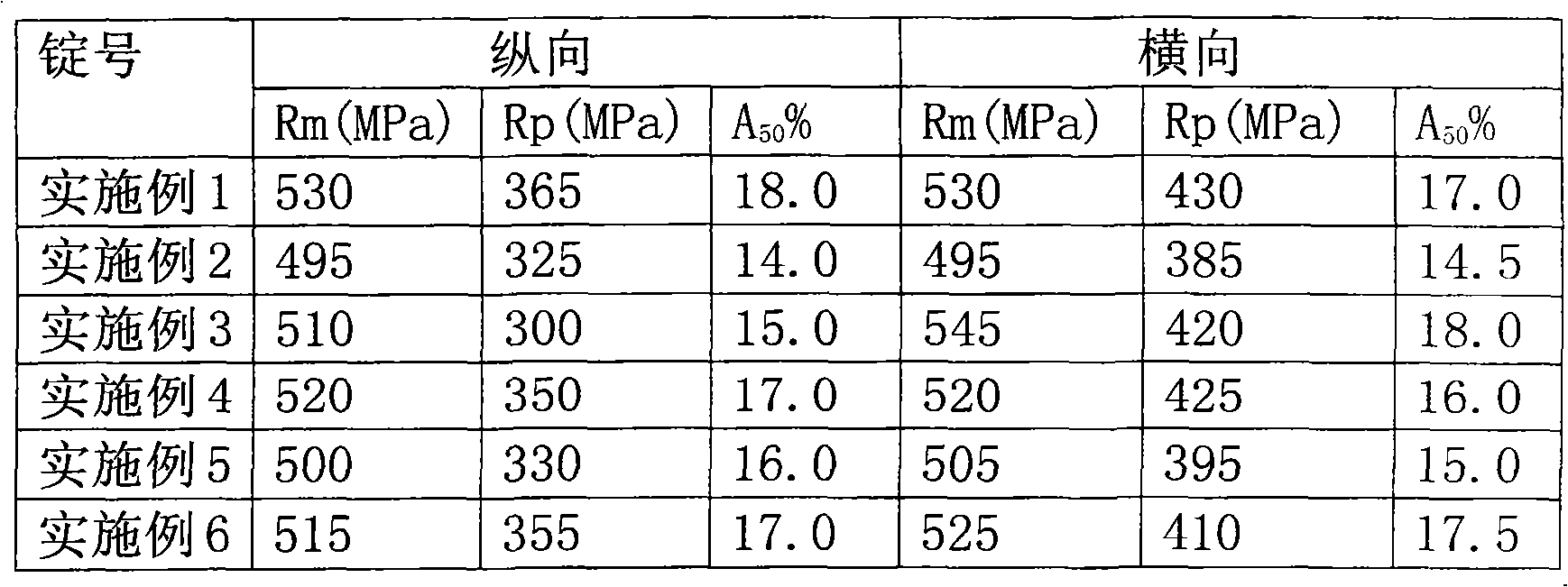

Preparation method of nanocrystal iron-nickel-chromium alloy foil by electrodeposition

InactiveCN102839399ALow priceFine and dense grainElectroforming processesElectrodesElectromechanicsNickel chromium alloy

The invention discloses a preparation method of a nanocrystal iron-nickel-chromium alloy foil by electrodeposition, belonging to the field of electrodeposition alloys. The electrochemical deposition method is implemented by carrying out electrodeposition in a sulfate-chloride-trivalent chromium water solution system to continuously prepare the nanocrystal iron-nickel-chromiumalloy foil. The technique for preparing the alloy foil is simple, the electrolyte is environment-friendly and stable, and the waste liquor is easy to treat. The alloy foil has the advantages of high chromium content, easily controlled components and thickness, smooth surface, excellent mechanical, electrical and magnetic properties, and excellent corrosion resistance, can partially substitute the stainless steel foil belt and the like to be widely used in the industrial fields of electronics, communication, electromechanics and the like, and can be used as an excellent magnetic material, battery framework material and electromagnetic shielding material.

Owner:CENT SOUTH UNIV

Solar cell module

ActiveCN103646978AAvoid gatheringNot easy to passivatePhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The invention provides a solar cell module. The solar cell module comprises a backboard layer (10), a first packaging material layer (20), a cell sheet layer (30), a second packaging material layer (40) and a glass layer (50) which are successively superposed. The second packaging material layer (40) comprises an upper packaging material layer (41), a lower packaging material layer (43) and a barrier layer (42) used for preventing metal cations of the glass layer (50) from entering into the cell sheet layer (30). The barrier layer (42) is arranged between the upper packaging material layer (41) and the lower packaging material layer (43). By using the technical scheme of the invention, a problem of a PID phenomenon existing in the solar cell module in the prior art is effectively solved.

Owner:YINGLI ENERGY CHINA

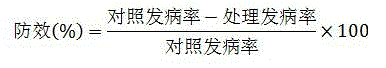

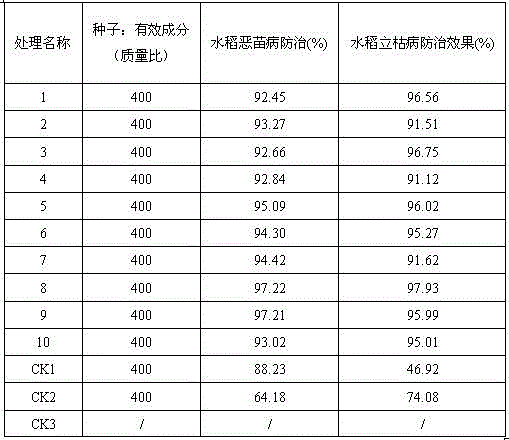

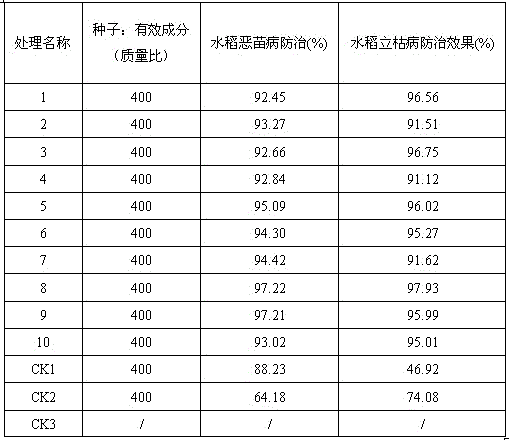

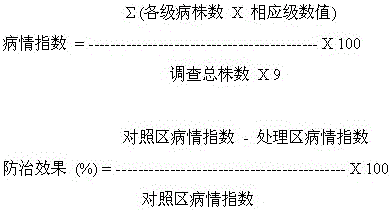

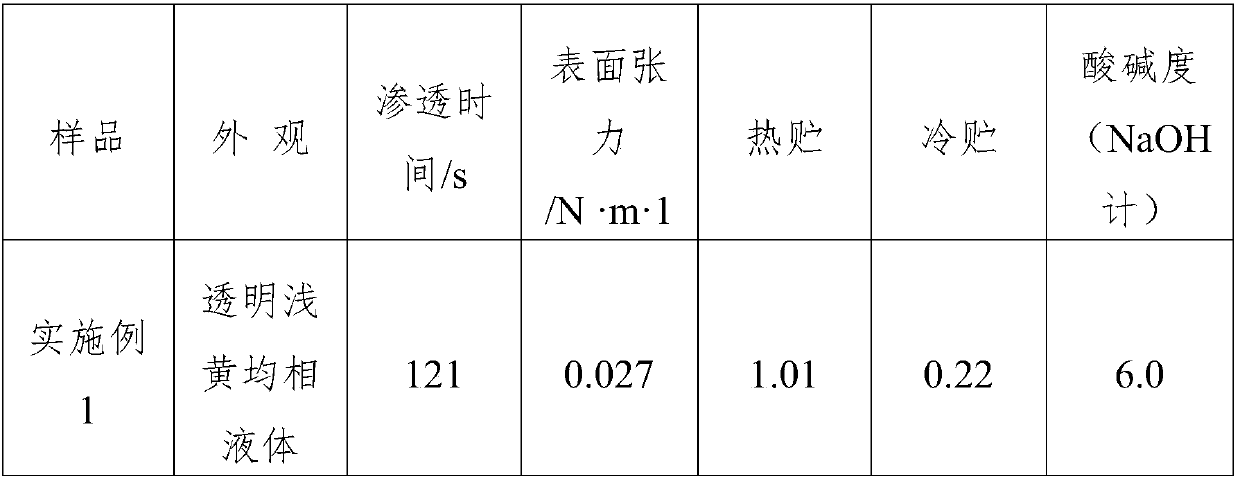

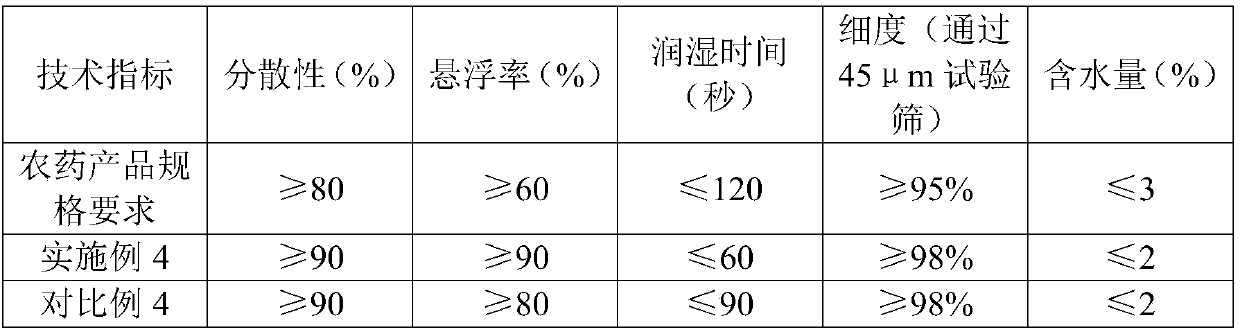

Pesticide composition containing 2-cyano-3-amino-3-phenylacrylic acetate and hymexazol

A pesticide composition containing 2-cyano-3-amino-3-phenylacrylic acetate and hymexazol belongs to the technical field of pesticide compounds. The pesticide composition contains the 2-cyano-3-amino-3-phenylacrylic acetate and the hymexazol, which are at a weight ratio of (1:90)-(90:1). According to the pesticide composition containing the 2-cyano-3-amino-3-phenylacrylic acetate and the hymexazol, the 2-cyano-3-amino-3-phenylacrylic acetate and the hymexazol are reasonably and effectively compouned, as a result, the defects that the broad-spectrum performance of the 2-cyano-3-amino-3-phenylacrylic acetate is poor and the hymexazol has a poor effect on fusarium can be overcome, the pesticide efficacy can be remarkably improved, risks caused by pesticide resistance can be lowered, and a remarkable synergy effect is realized.

Owner:CHINA NAT RICE RES INST

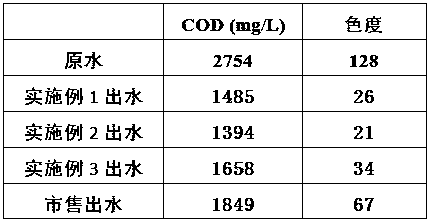

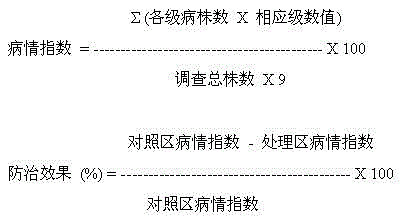

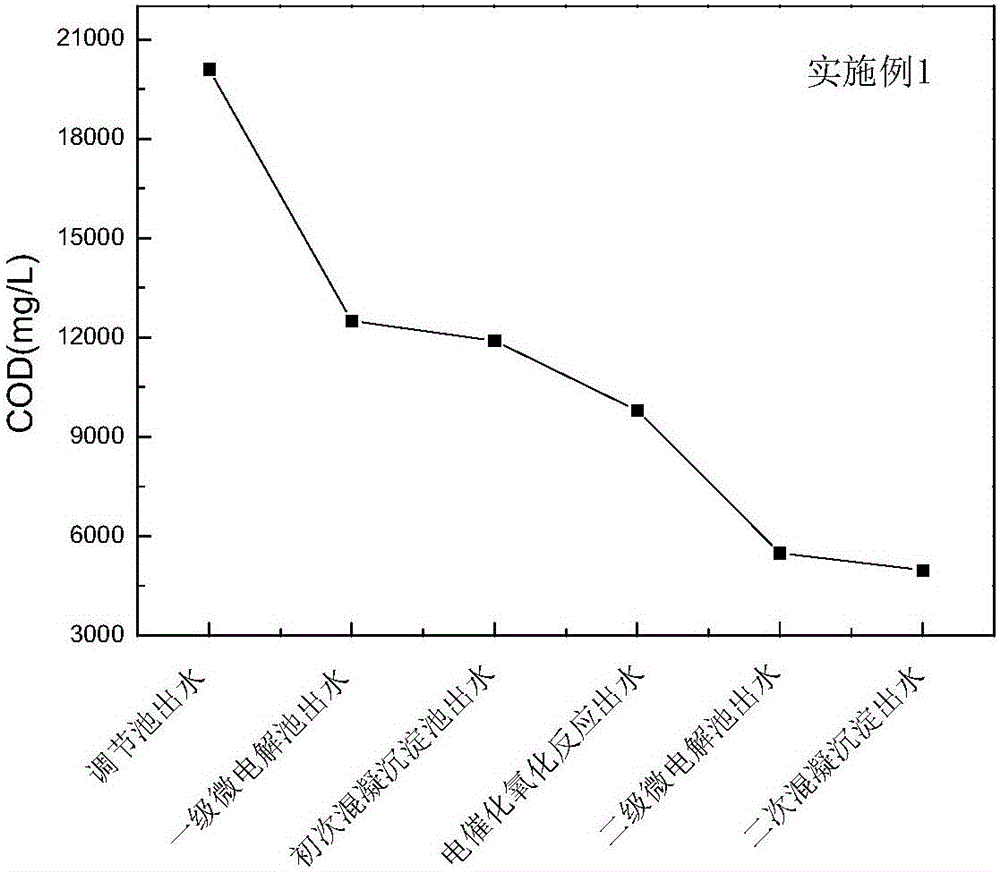

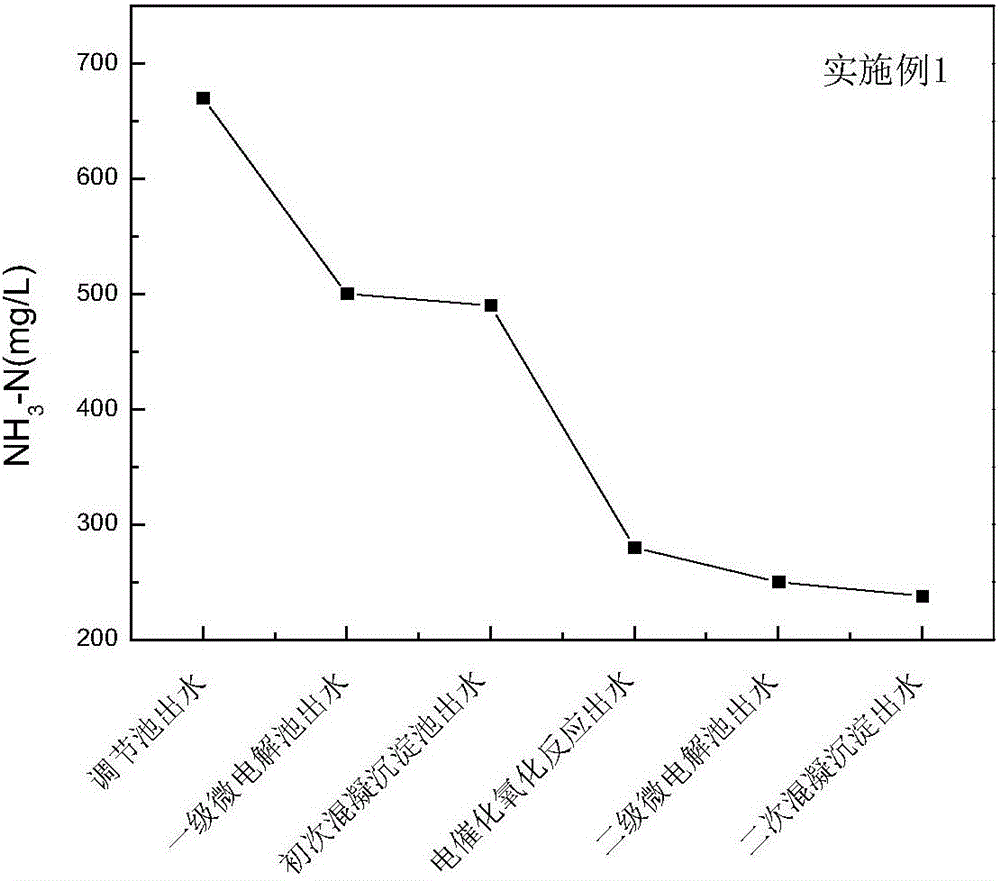

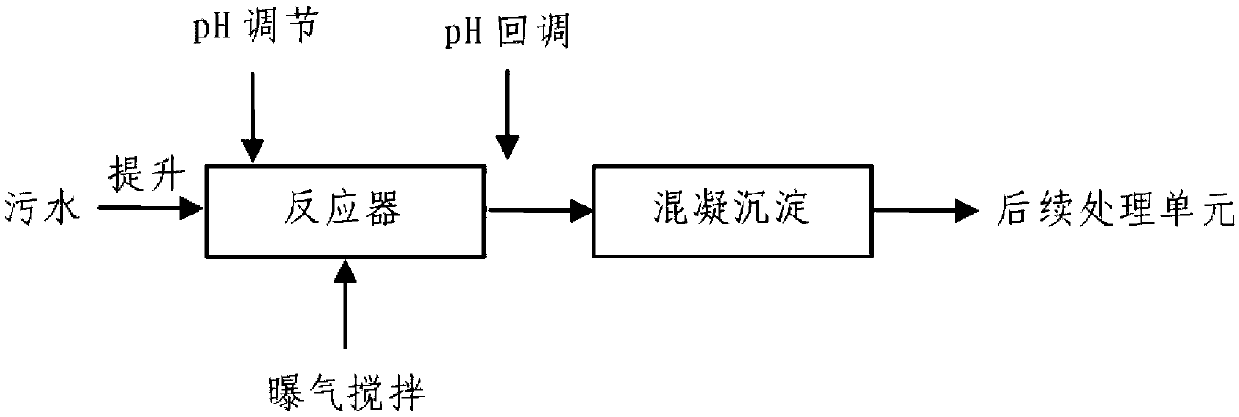

Pretreatment method of antibiotic production waste water

ActiveCN106587445AReduce chromaReduce the pressure of subsequent biochemical treatmentMultistage water/sewage treatmentWater/sewage treatment by neutralisationPretreatment methodElectrolysis

The invention provides a pretreatment method of antibiotic production waste water. The method is characterized in that the method comprises the following steps: (1) first level micro-electrolysis; (2) primary coagulating sedimentation; (3) advanced electrocatalytic oxidation; (4) second level micro-electrolysis; (5) secondary coagulating sedimentation. The method mainly aims at deficiency in the prior waste water pretreatment method in the antibiotic production process, and has the advantages of high treatment efficiency and low treatment cost; COD and chromaticity of antibiotic production waste water treated by the process reach the standard.

Owner:SHENYANG POLYTECHNIC UNIV +1

Titanium alloy anode material for electrolyzing manganese dioxide and titanium alloy anode made of same

InactiveCN102094137AImprove corrosion resistanceGood chemical stabilityElectrode shape/formsElectrolysisTitanium alloy

The invention relates to a titanium alloy anode material for electrolyzing manganese dioxide, which comprises the following components in percentage by weight: 0.5-5.0% of Ni, 0.2-1.0% of Fe, less than 0.01% of N, less than 0.001% of H, less than 0.06% of O, and the balance of Ti and inevitable impurities. The titanium alloy anode made of the titanium alloy anode material is composed of a titanium alloy anode plate and a conductive beam, wherein the conductive beam is composed of a conductive beam casing, a titanium copper conductive beam and a weighting beam; both the titanium copper conductive beam and the weighting beam are positioned in the conductive beam casing, and the titanium copper conductive beam is positioned below the weighting beam; a hoop and lifting hooks are sheathed outside the conductive beam casing; the upper ends of lifting rods are fixedly connected with the inferior parts of the hoop and the lifting hooks respectively; the lower ends of the lifting rods are fixedly connected with the upper end of the titanium alloy anode plate respectively; and the hoop is positioned between the two lifting hooks. The anode material provided by the invention has the advantages of favorable corrosion resistance, high chemical stability, favorable passivation resistance, high conductivity, high mechanical strength, easy forming and low cost. The titanium alloy anode plate provided by the invention can not be easily passivated, and can effectively lower the bath voltage and increase the current density during electrolysis.

Owner:宝钛特种金属有限公司

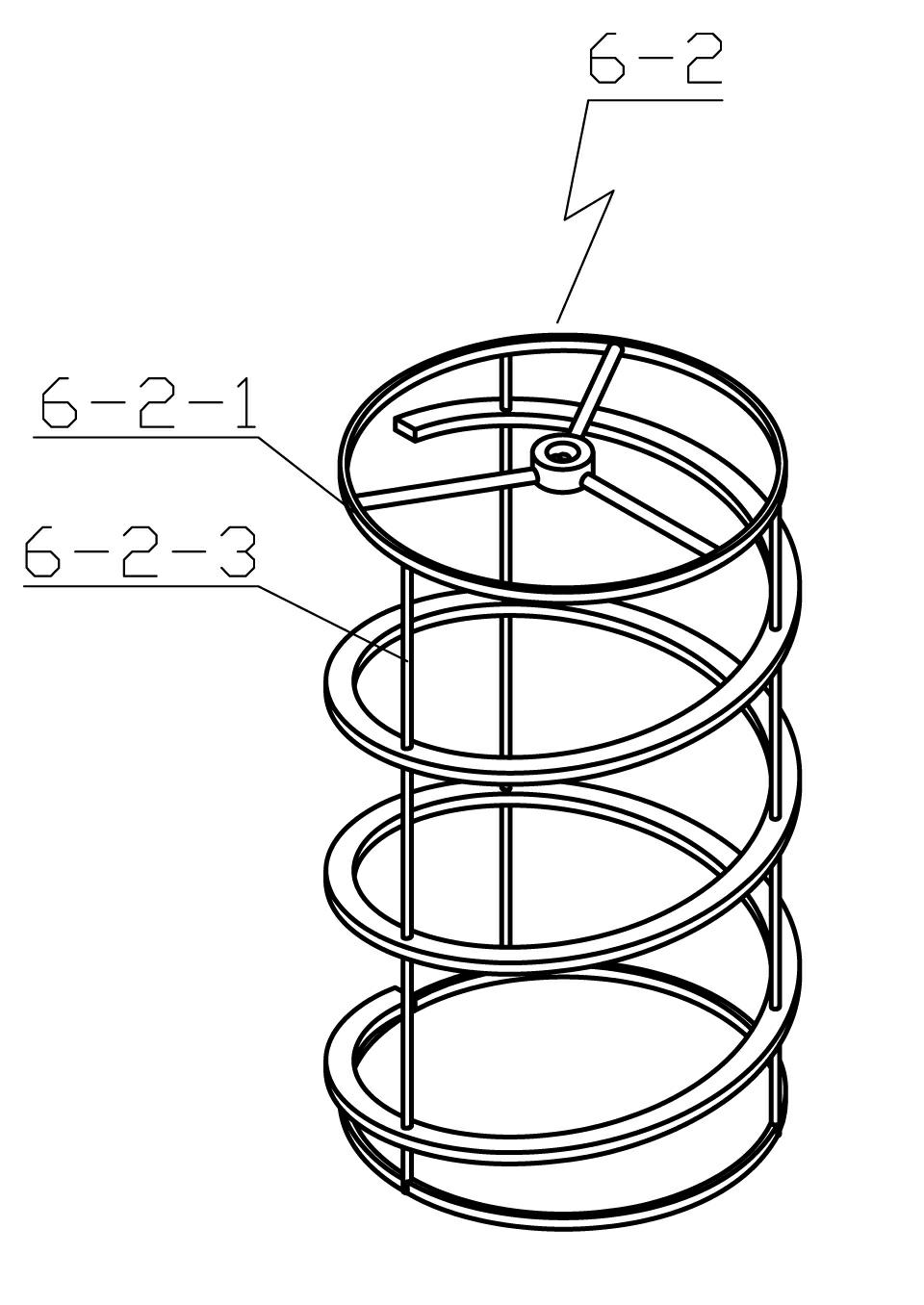

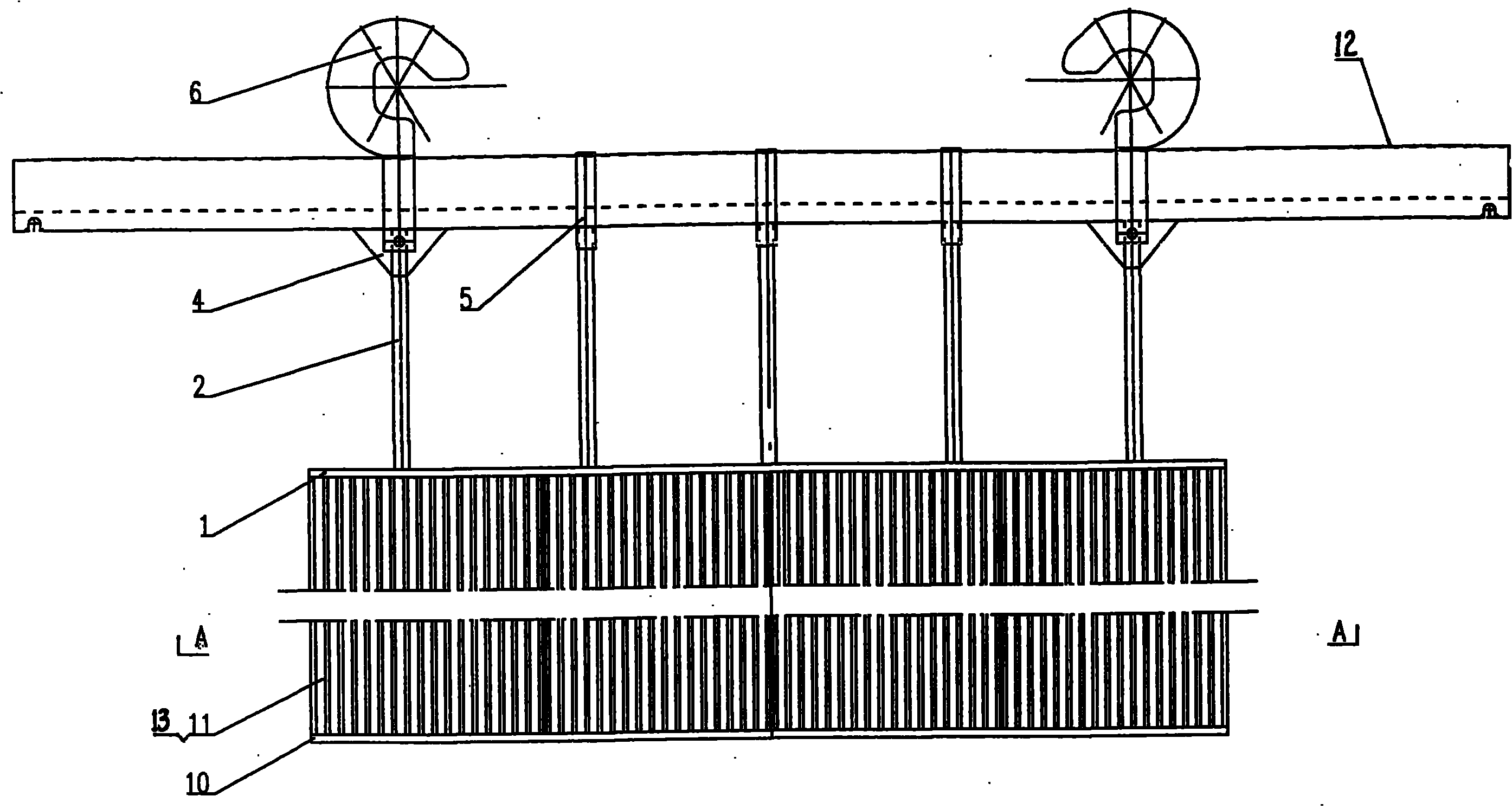

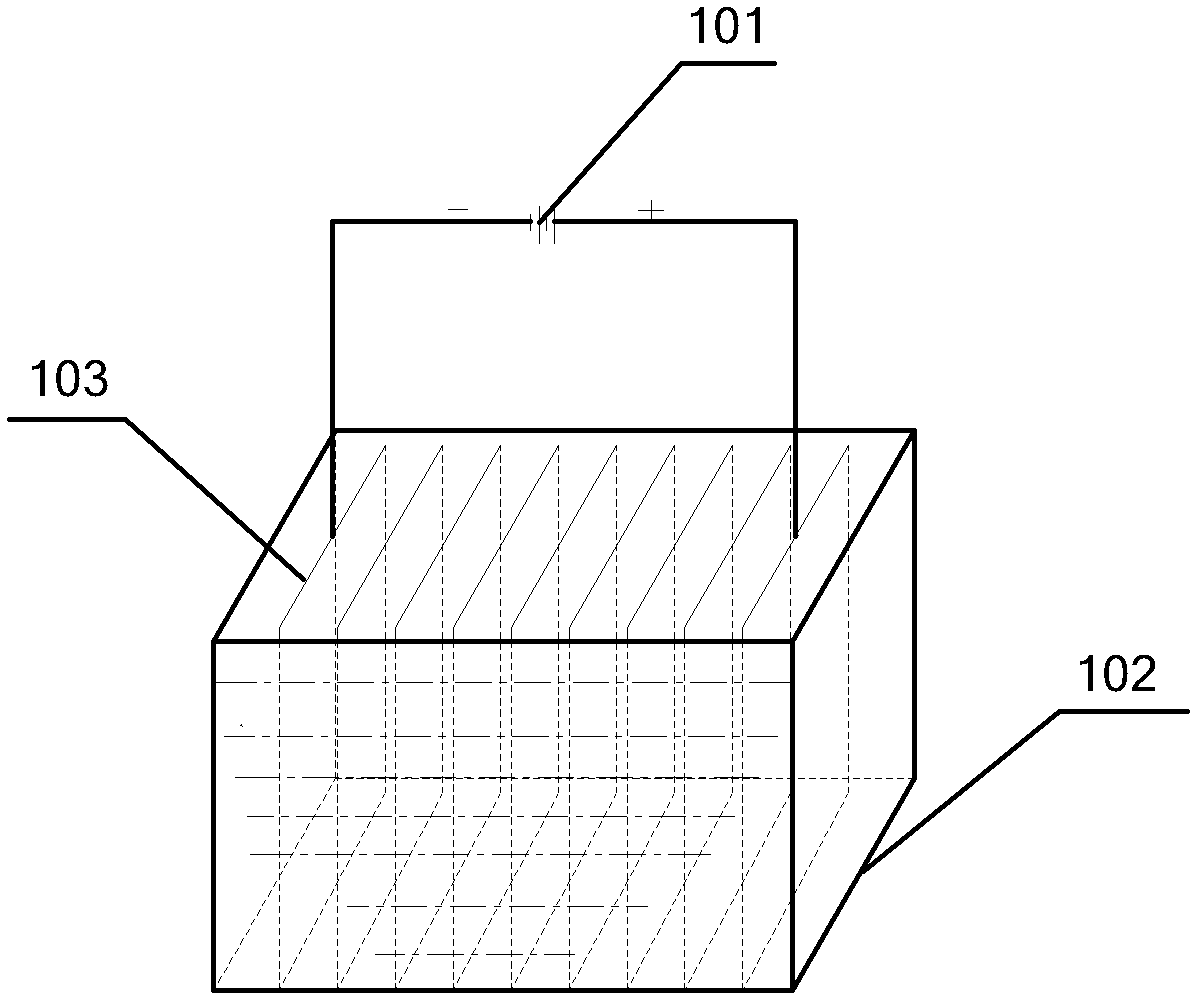

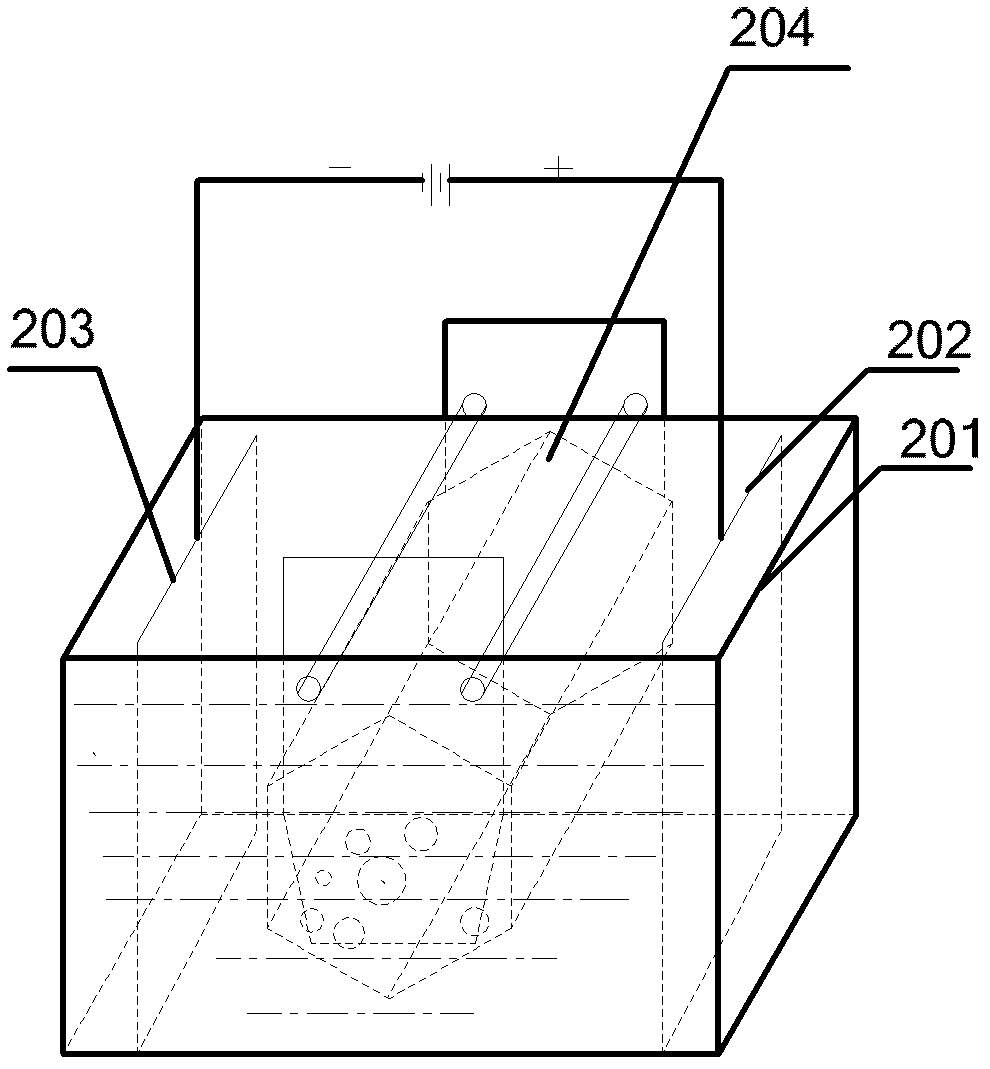

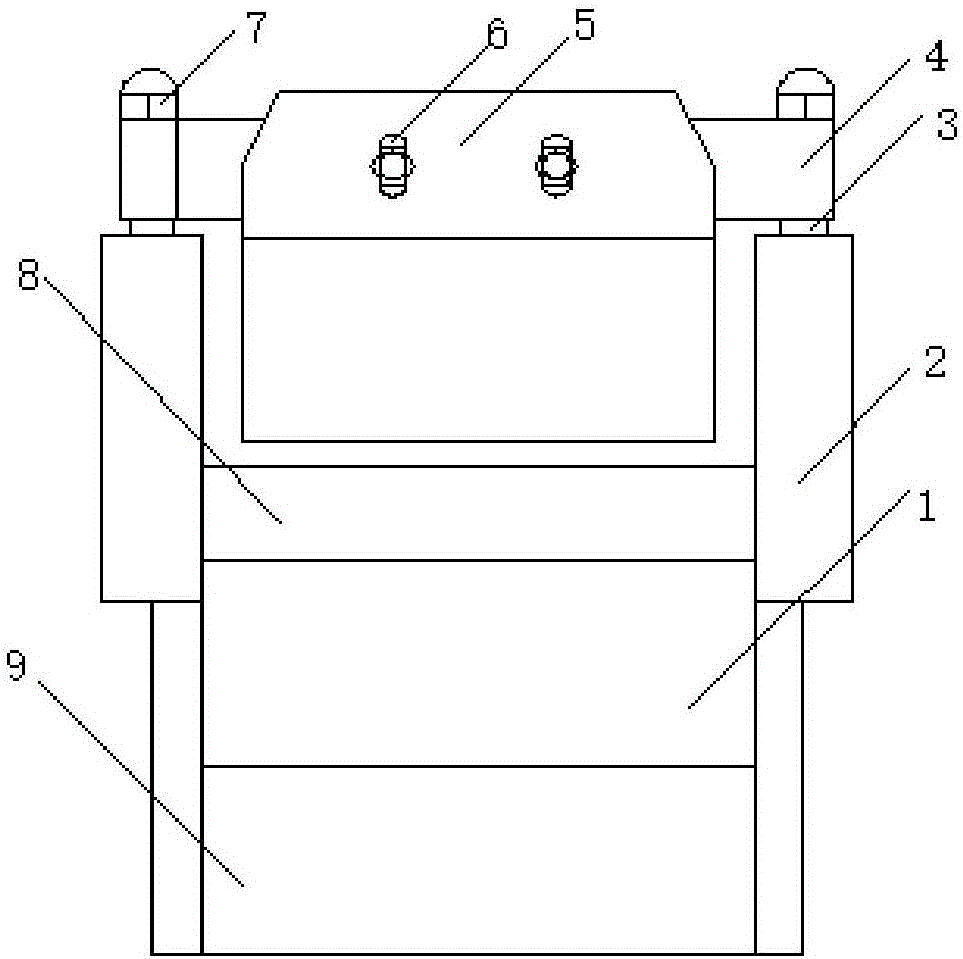

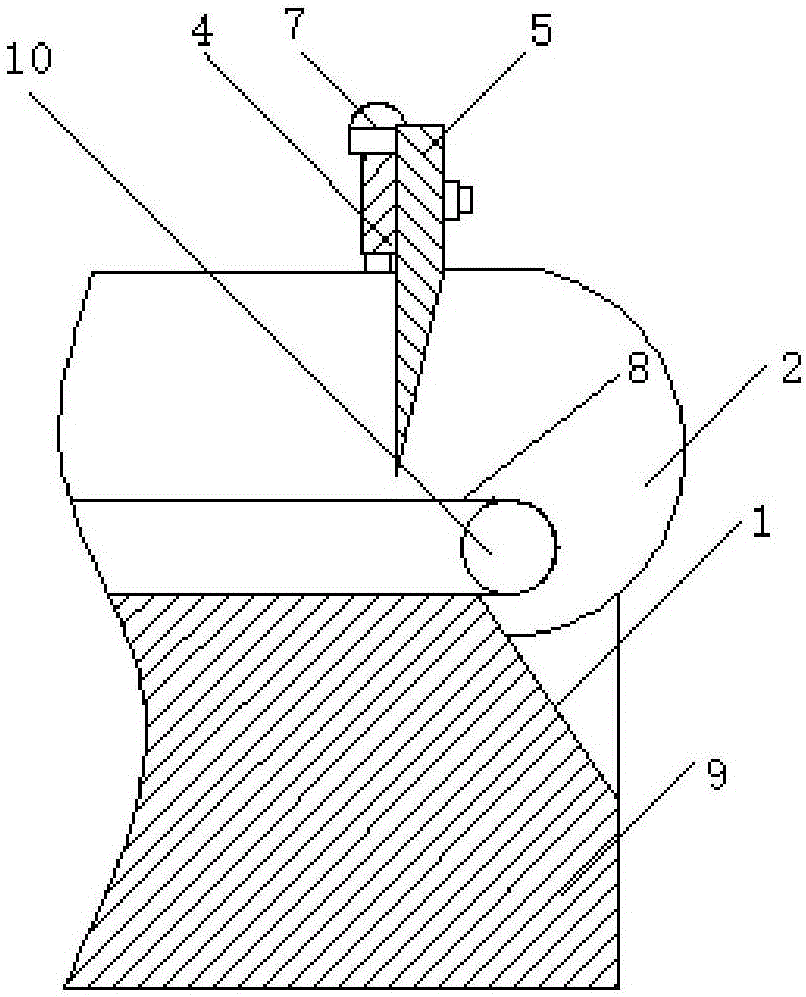

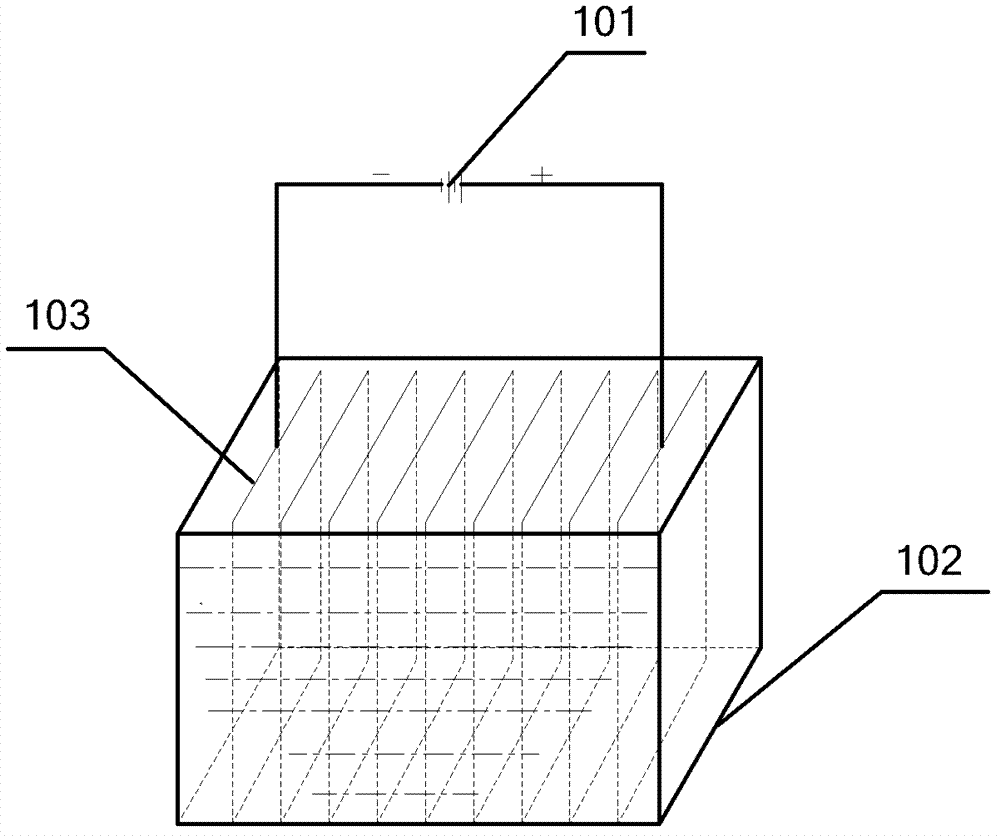

Electric flocculation device

InactiveCN102616897AIncrease electrode surface areaNot easy to passivateWater/sewage treatmentElectricityFlocculation

The embodiment of the invention discloses an electric flocculation device. The electric flocculation device comprises an electrolytic tank, wherein the electrolytic tank is internally provided with a cathode plate and an anode plate, and at least one bipolar electrode is also arranged between the anode plate and the cathode plate; and the electric flocculation device is characterized in that the bipolar electrode is a bulk metal electrode, the bulk metal electrode is placed in a load bearing component, and the load bearing component is provided with a through hole. Through the using of the bulk metal electrode, the surface areas of the electrodes are greatly increased, and thus the electrodes are not easy to passivate.

Owner:JIAXING JINHAO ENVIRONMENTAL PROTECTION TECH

Optical polishing material

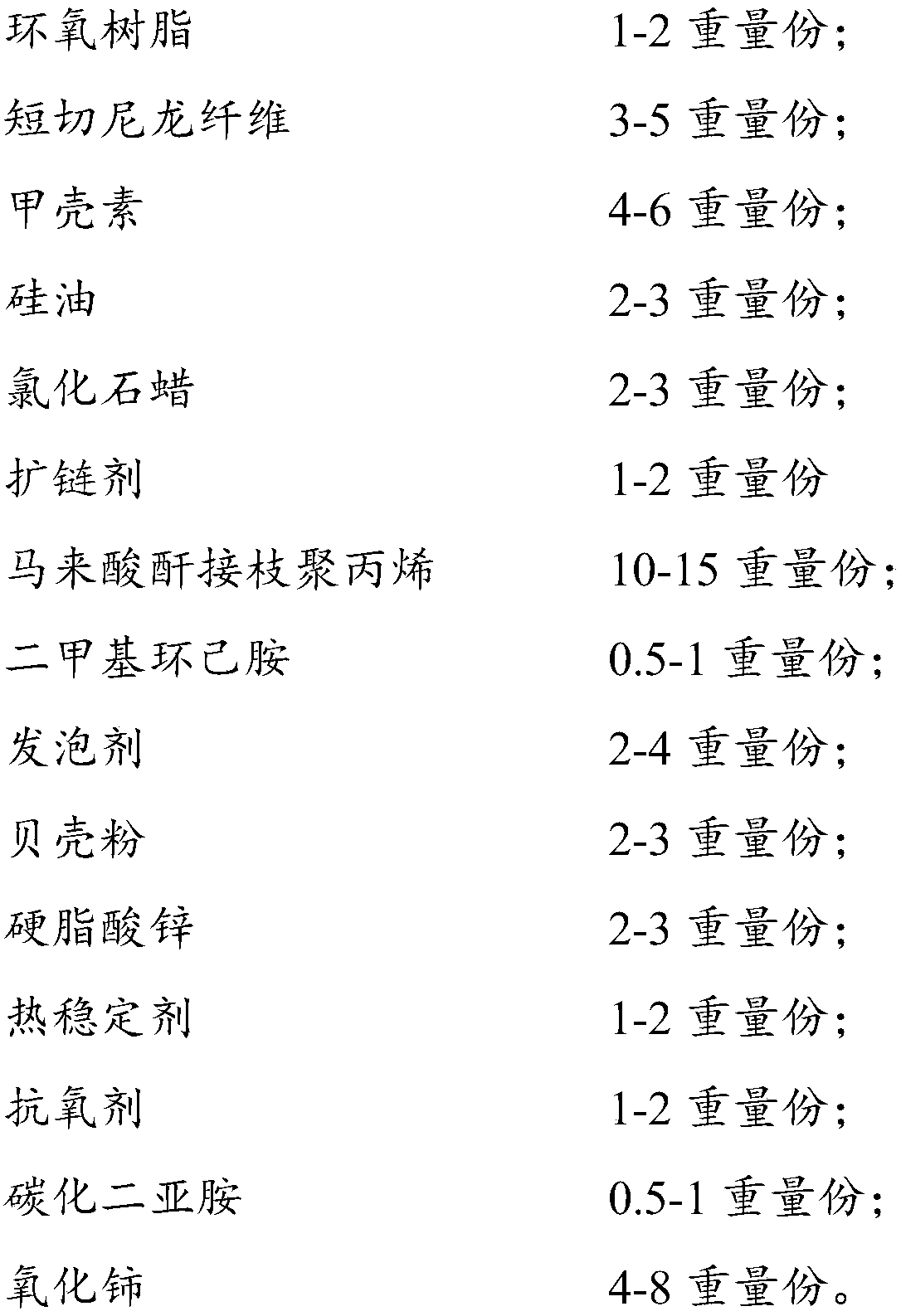

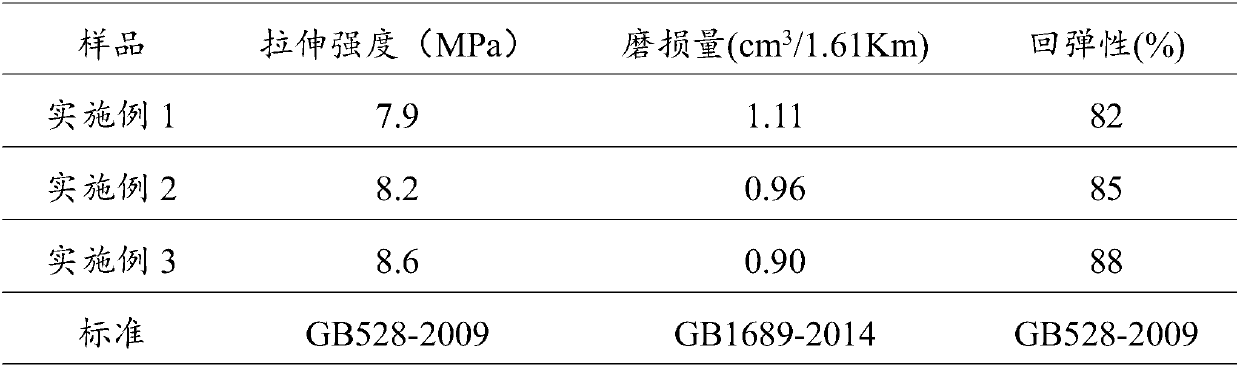

The invention relates to an optical polishing material, belongs to the technical field of polishing materials and solves the technical problem that a polyurethane polishing pad is hard and brittle andis lack of toughness and elasticity in the prior art. The optical polishing material is prepared from components in parts by weight as follows: 100 parts of polyether polyol, 100 parts of diisocyanate, 1-2 parts of bisphenol A epoxy resin, 3-5 parts of chopped nylon fiber, 4-6 parts of chitin, 2-3 parts of silicone oil, -3 parts of chlorinated paraffin, 1-2 parts of ethylene glycol, 10-15 parts of maleic anhydride grafted polypropylene, 0.5-1 part of dimethylcyclohexylamine, 2-4 parts of acetone, 2-3 parts of shell powder, 2-3 parts of zinc stearate, 1-2 parts of tris(2,4-ditert-butylphenyl)phosphite, 1-2 parts of antioxidant 1010, 0.5-1 part of carbodiimide and 4-8 parts of cerium oxide. The optical polishing material has high tensile strength and good rebound resilience, wear resistance and die assembly performance, and is not prone to passivation.

Owner:CHANGCHUN A&Z SCI CO LTD

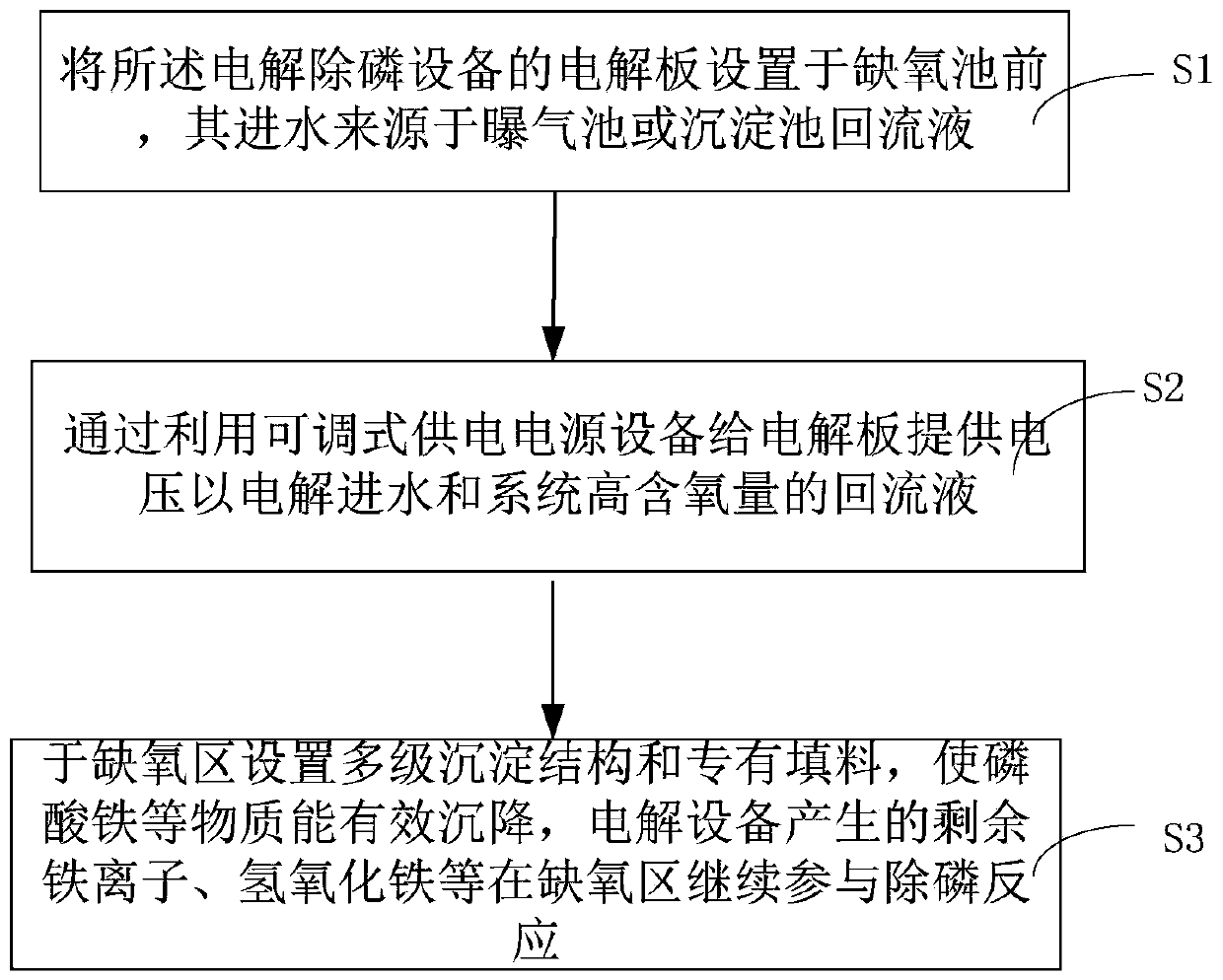

Device and method for electrolysis dephosphorization of small/medium-size sewage treatment equipment

PendingCN109734245APhosphorus removal is not easyPhosphorus removal stabilityWater contaminantsMultistage water/sewage treatmentAluminum IonElectrolysis

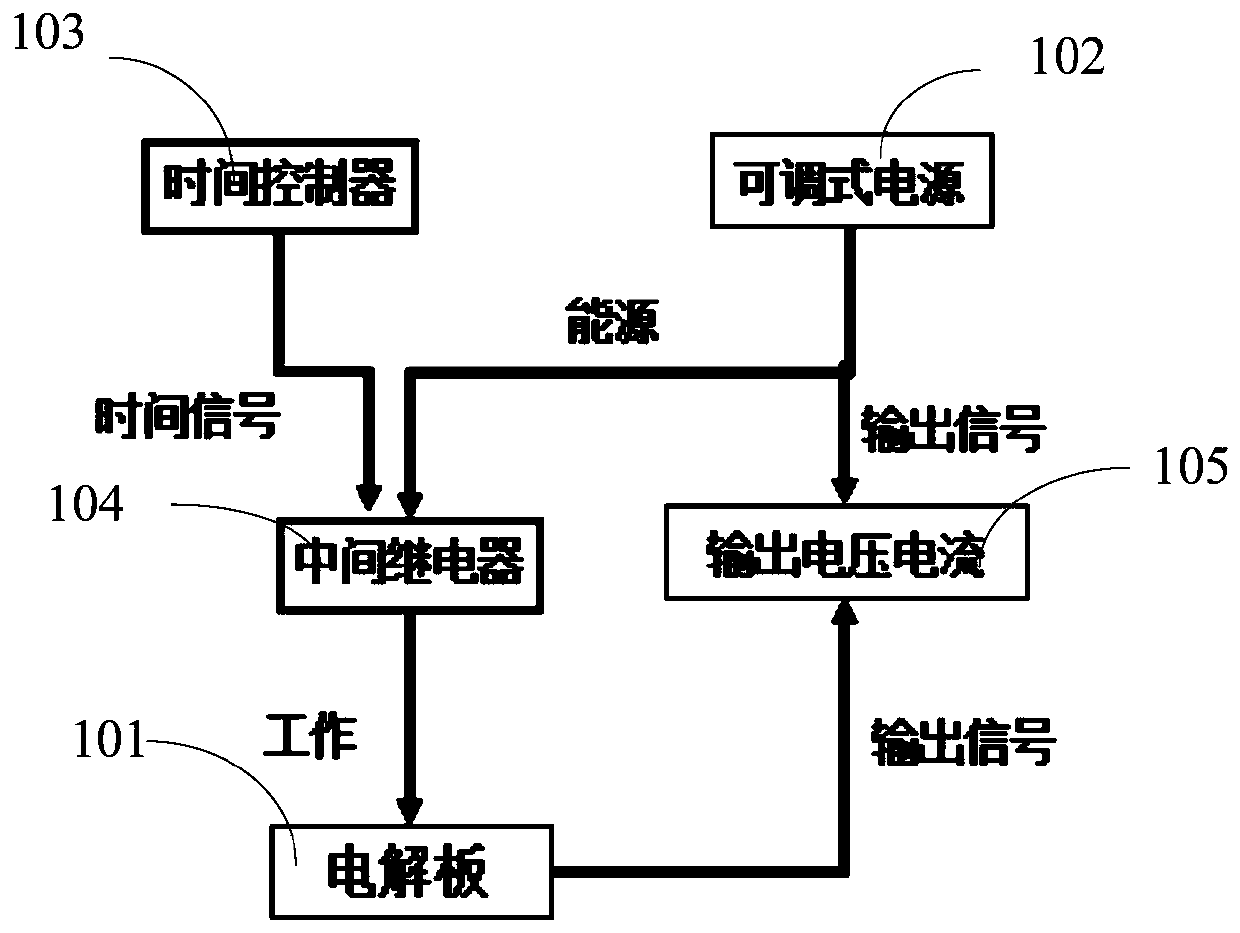

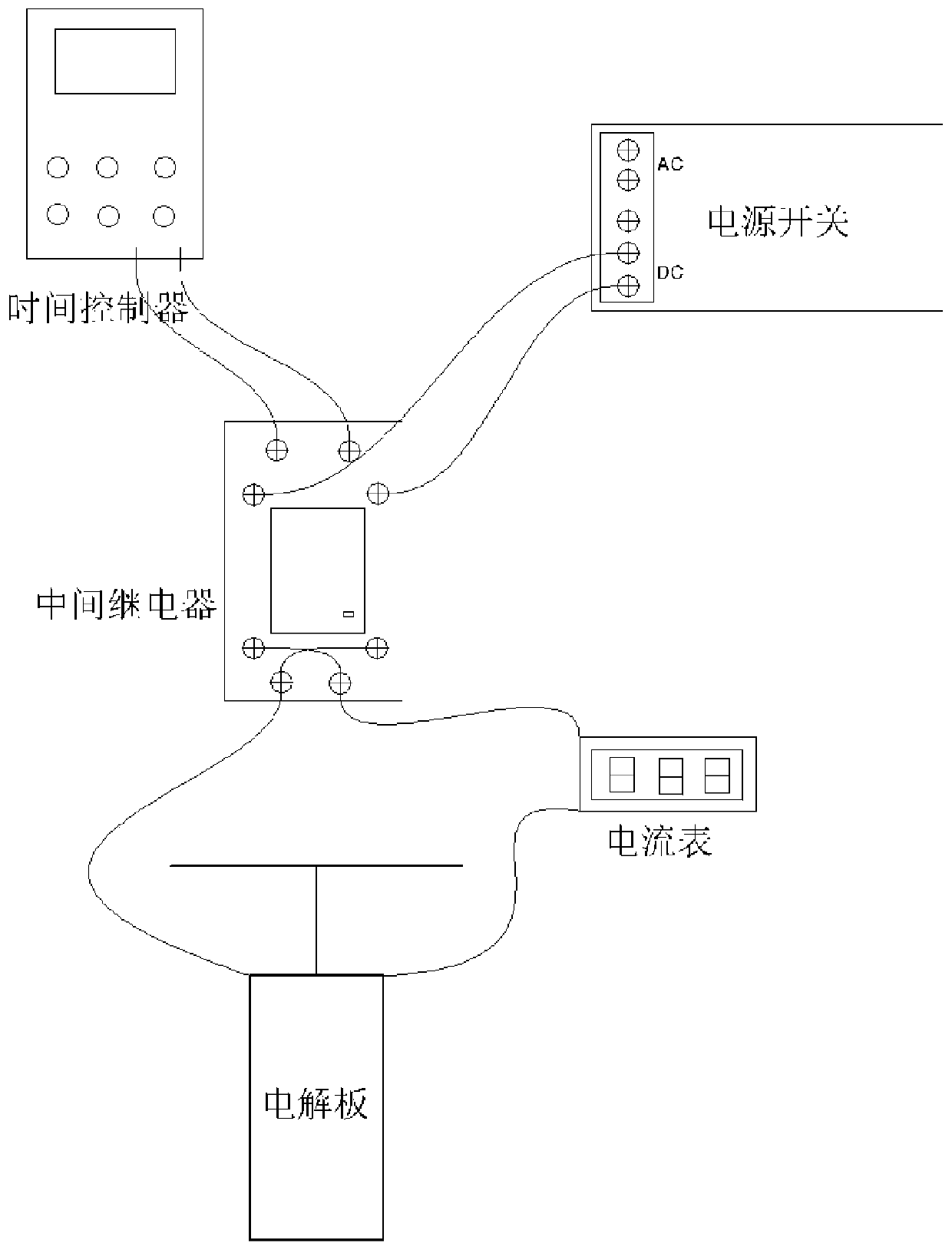

The invention discloses a device and a method for electrolysis dephosphorization of small / medium-size sewage treatment equipment. The device comprises an electrolysis plate, an adjustable power supplydevice, a time controller, an intermediate relay and a volt-ammeter; the adjustable power supply device is used for supplying variable power voltage to the electrolysis plate and controlling volume of electrolyzed iron ions or aluminum ions; the time controller is used for supplying a time signal to the electrolysis plate and is used for automatically changing anode and cathode of the electrolysis plate through the adjustable power supply device; the intermediate relay is used for sending the time signal and a power signal outputted by the adjustable power supply device to the electrolysis plate; the volt-ammeter is used for sampling real-time voltage and current of the electrolysis plate in real time. According to the invention, total phosphorus can be effectively removed by placing thedevice for electrolysis dephosphorization on the front side of an anoxic zone, electrolyzing feeding water and reflux liquid in high oxygen content of system and adopting a multi-level precipitating structure and a special filler arranged in the anoxic zone and a multi-level baffling manner. Energy consumption can be effectively saved and maintenance period can be prolonged in the manner of adjusting voltage and current and automatically switching anode and cathode.

Owner:YUNNAN HEXUN ENVIRONMENTAL TECH CO LTD

Method for separating and recovering tin coating of PCB by two-segment method

InactiveCN110938837AHigh recovery rateHigh purityPhotography auxillary processesProcess efficiency improvementElectrolytic agentAcetic acid

The invention discloses a method for separating and recovering a tin coating of a PCB by a two-segment method. The method comprises the following steps: 1) a first segment: an anode plate and a cathode plate are placed in an electrolytic bath filled with electrolyte and introduce direct current for electrolysis, and partial tin coating on the surface of the PCB is removed, wherein the anode plateis formed by combining the PCB and a conductive hard metal mesh, and the electrolyte comprises tin salt, acetic acid, acetate, a complexing agent and an additive; 2) a second segment: the PCB treatedin the step 1) is placed in an HNO3-Fe(NO3)3 system, the residual tin coating on the PCB is removed, and the qualified PCB is obtained. According to the method, the tin coating of the PCB can be efficiently, cleaned, safely and conveniently separated, most of tin can be recovered in the form of metal, the metal substrate feature, thickness and performance of the obtained PCB are good, and the PCBcan meet factory requirements.

Owner:CENT SOUTH UNIV

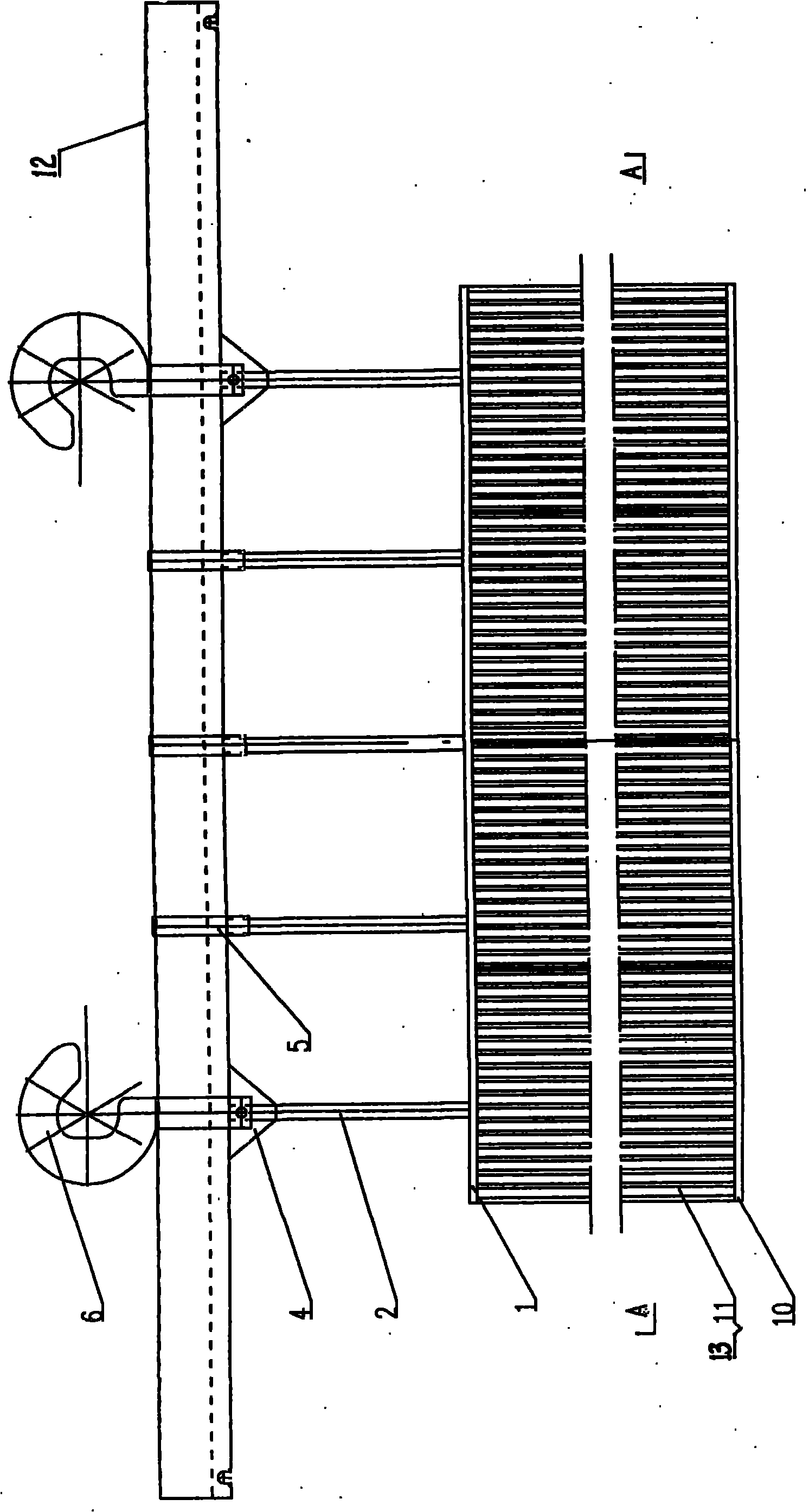

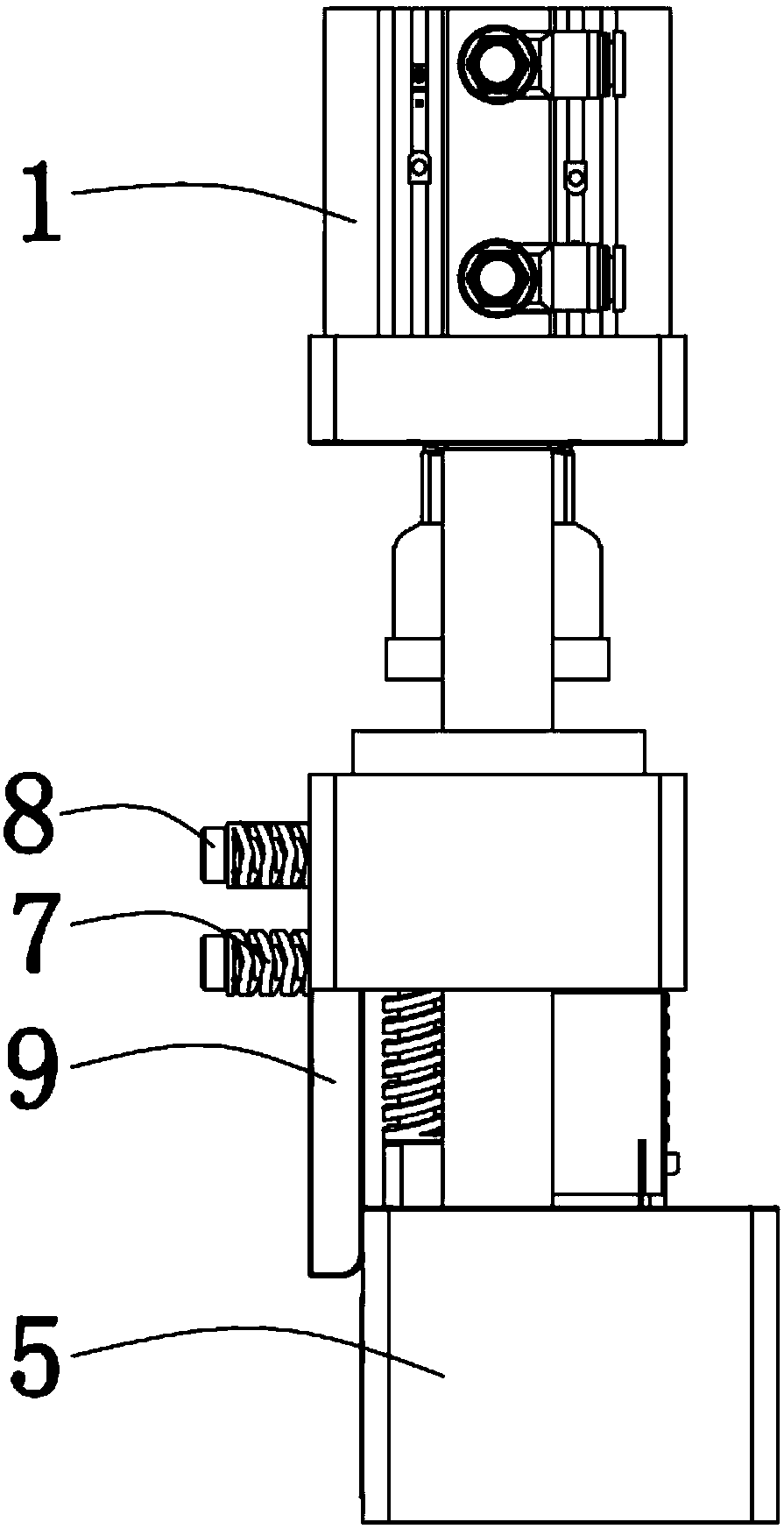

Filament cutting machine

InactiveCN106737932ANot easy to passivateExtended service lifeMetal working apparatusAgricultural engineeringEngineering

The invention discloses a filament cutting machine and belongs to the technical field of product machining device design. The filament cutting machine comprises transmission cases, a blade, pin shafts, a blade fixing base, nuts, a conveying belt, a coiling block shaft and a lathe bed; the transmission cases are arranged on the portions, close to the upper portion, of the left side and the right side of the lathe bed; a belt transmission device is arranged in the transmission case on the right side; the coiling block shaft is sleeved with the conveying belt; a belt pulley is installed at the right end of the coiling block shaft; movement of the belt pulley is transmitted by a motor through the belt transmission device in the corresponding transmission case; the blade is fixed to the blade fixing base through a bolt; and the blade fixing base and the pin shafts are fixed together through the nuts above the pin shafts. According to the filament cutting machine, the service life of the blade is long, the height of the blade can be adjusted, the pin shafts can move up and down, finally, the blade is driven to move up and down, cut bean filaments is very long, the conveying belt is not prone to damage or deformation in the filament cutting process, the cut bean filaments are uniform in width, and the bean filaments are convenient to collect.

Owner:安徽家佳生物科技股份有限公司

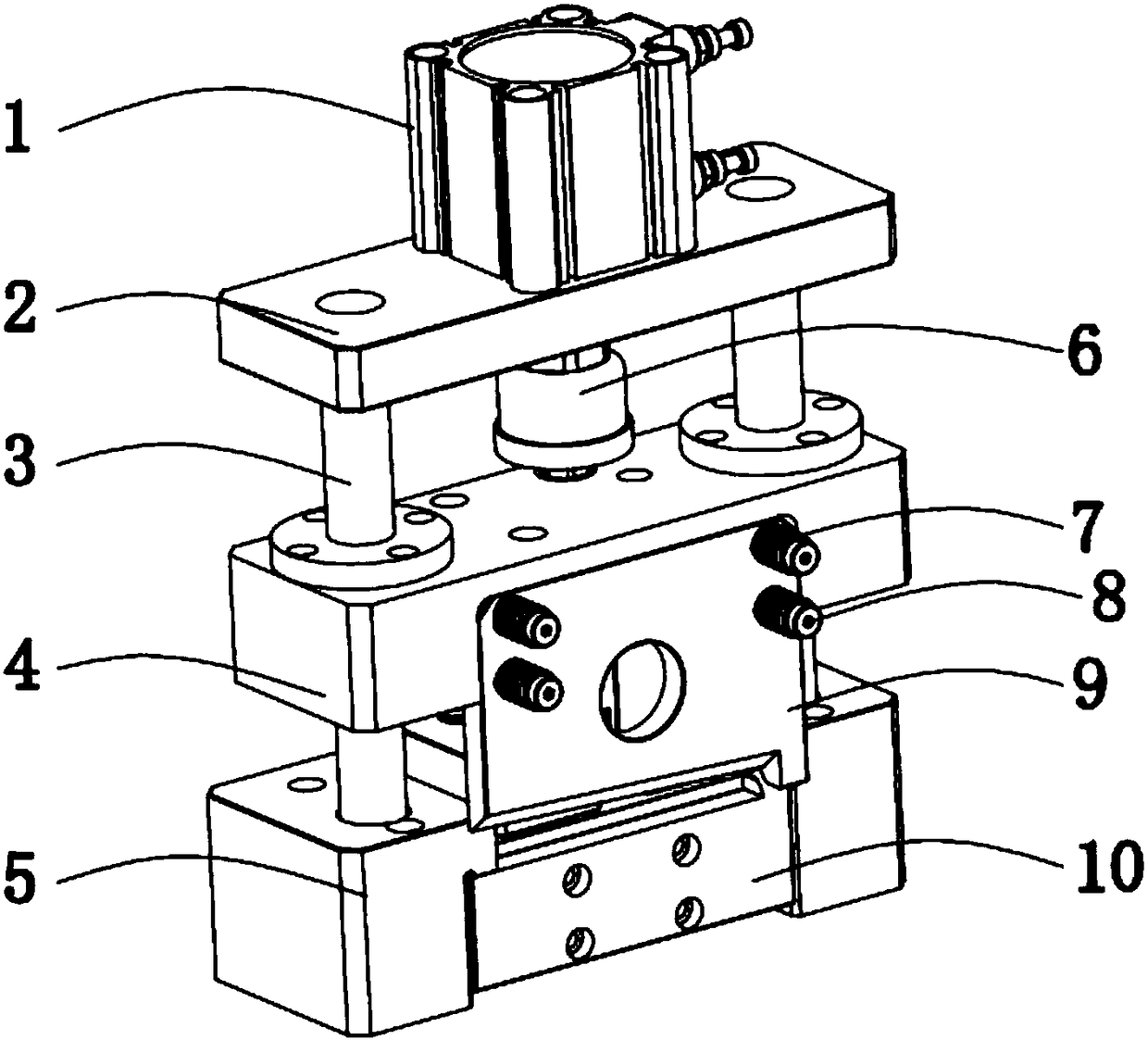

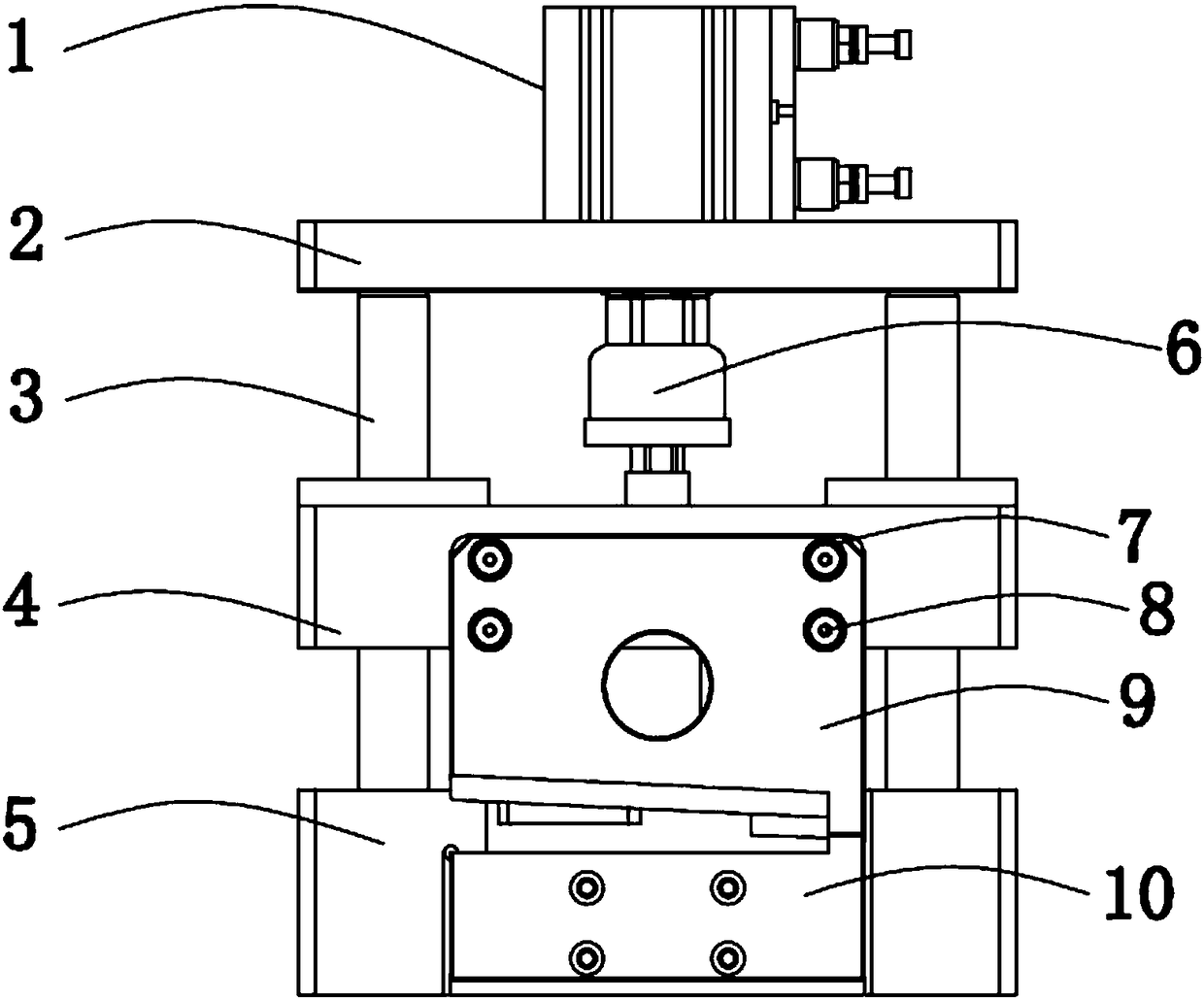

Cutting mechanism for soft materials

PendingCN108582256ANot easy to passivateShorten the timeMetal working apparatusEngineeringSoft materials

The invention discloses a cutting mechanism for soft materials. The cutting mechanism comprises an air cylinder, an upper fixed plate, cylinder rails and a lower fixed plate, the upper fixed plate andthe lower fixed plate are provided with installation holes, a sliding block is movably arranged between the upper fixed plate and the lower fixed plate through the cylinder rails, an upper cutting cutter is fixedly arranged to the front end surface of the sliding block through screw columns, abrasive tool springs are arranged between the screw columns and the sliding block, and the front end surface of the lower fixed plate is fixedly provided with a lower cutting cutter. According to the cutting mechanism for the soft materials, by means of the arrangements of the multiple abrasive tool springs and the non-parallel arrangement of an upper cutting cutter mouth and the lower cutting cutter, the upper cutting cutter is made to be close to the lower cutting cutter when moving downwards to cut, the soft materials can be cut off at one time when being cut, cut mouths are neat and have no burr, meanwhile, when the upper cutting cutter moves upwards, the upper cutter mouth can be ground on the lower cutting cutter, and then the upper cutting cutter mouth is made to be not prone to be passivated and be more sharp, time is saved, and the work efficiency is improved.

Owner:合肥瑞硕科技有限公司

Electric flocculation device

InactiveCN102616897BIncrease electrode surface areaNot easy to passivateWater/sewage treatmentElectricityFlocculation

The embodiment of the invention discloses an electric flocculation device. The electric flocculation device comprises an electrolytic tank, wherein the electrolytic tank is internally provided with a cathode plate and an anode plate, and at least one bipolar electrode is also arranged between the anode plate and the cathode plate; and the electric flocculation device is characterized in that the bipolar electrode is a bulk metal electrode, the bulk metal electrode is placed in a load bearing component, and the load bearing component is provided with a through hole. Through the using of the bulk metal electrode, the surface areas of the electrodes are greatly increased, and thus the electrodes are not easy to passivate.

Owner:JIAXING JINHAO ENVIRONMENTAL PROTECTION TECH

solar cell module

ActiveCN103646978BAvoid gatheringNot easy to passivatePhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The invention provides a solar cell module. The solar cell module comprises a backboard layer (10), a first packaging material layer (20), a cell sheet layer (30), a second packaging material layer (40) and a glass layer (50) which are successively superposed. The second packaging material layer (40) comprises an upper packaging material layer (41), a lower packaging material layer (43) and a barrier layer (42) used for preventing metal cations of the glass layer (50) from entering into the cell sheet layer (30). The barrier layer (42) is arranged between the upper packaging material layer (41) and the lower packaging material layer (43). By using the technical scheme of the invention, a problem of a PID phenomenon existing in the solar cell module in the prior art is effectively solved.

Owner:YINGLI ENERGY CHINA

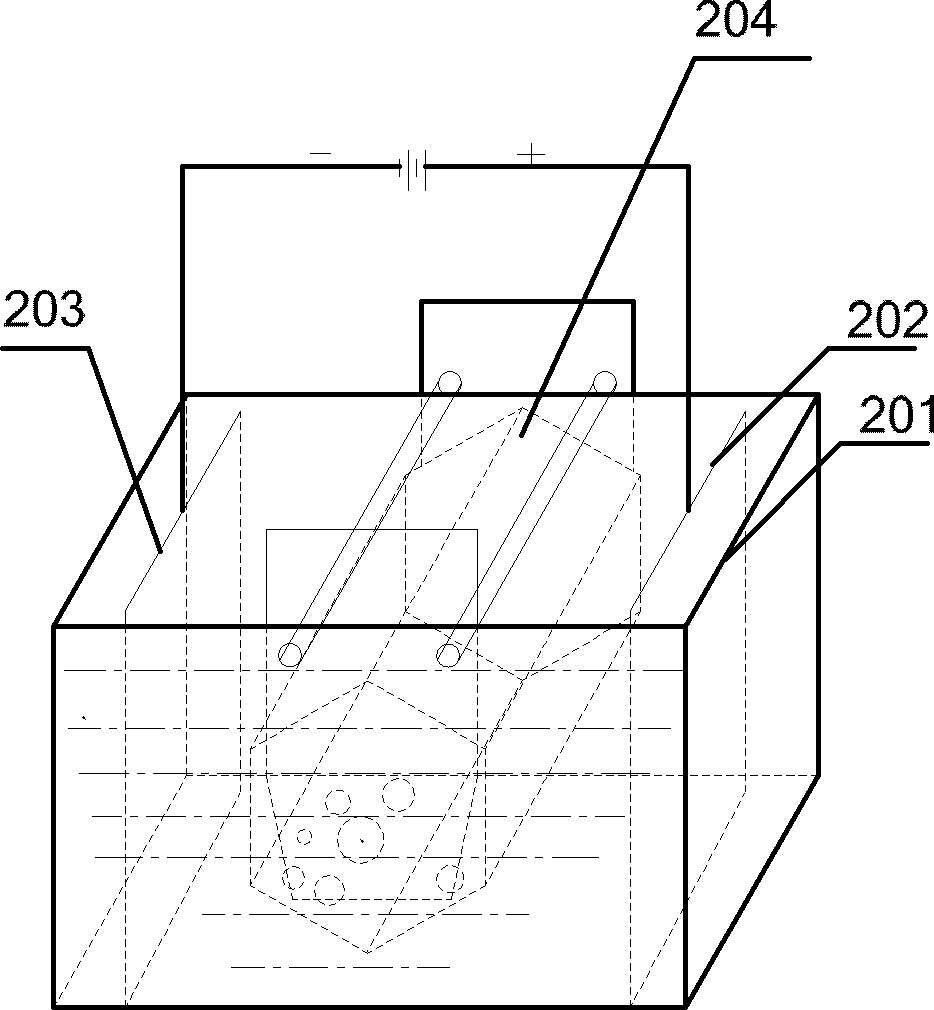

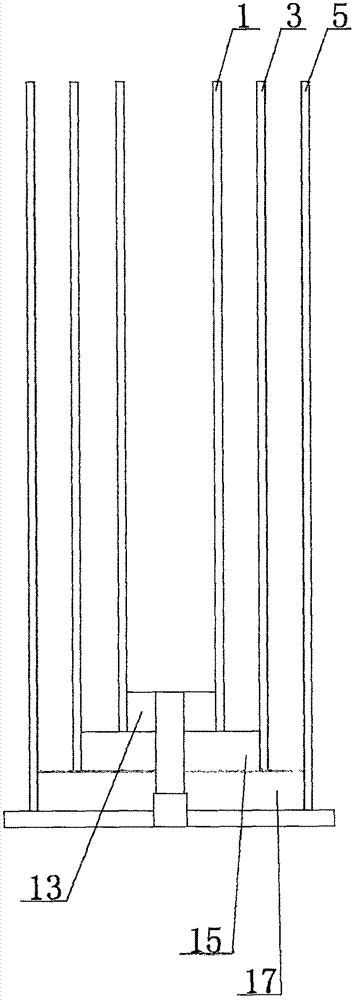

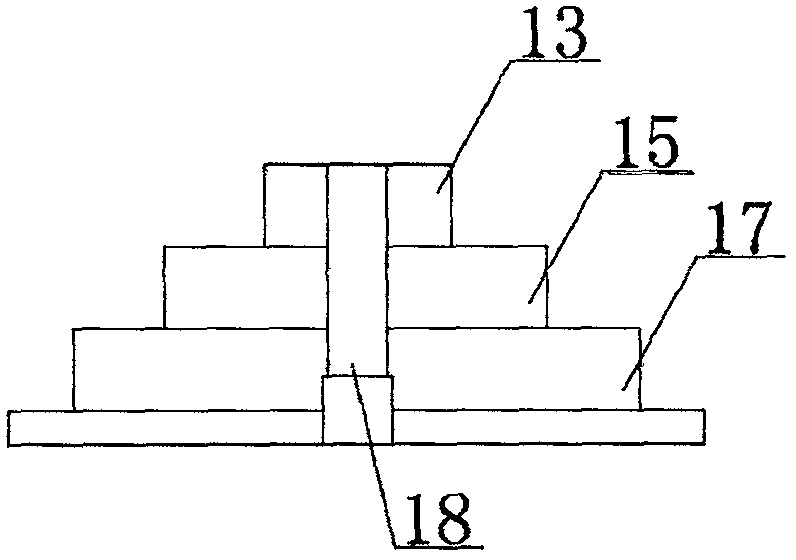

Small-sized efficient energy-saving over-current type equipment for electric flocculation process

InactiveCN107572636AEasy and quick electrode replacementEasy to operateWater/sewage treatmentElectricityFlocculation

The invention relates to small-sized efficient energy-saving over-current type equipment for an electric flocculation process. The small-sized efficient energy-saving over-current type equipment is characterized in that a tubular type electrode A, a tubular type electrode C and a tubular type electrode E are arranged on an electrode fixed tray A, and a tubular type electrode B and a tubular type electrode D are arranged on an electrode fixed tray B, wherein the electrode fixed tray A and the electrode fixed tray B are combined up and down to form a body; a sleeve barrel is arranged outside theelectrode fixed tray A and the electrode fixed tray B; a sleeve cover A is mounted on the bottom of the electrode fixed tray A; a sleeve cover B is mounted on the top of the electrode fixed tray B; awater inlet is formed in the central position of the electrode fixed tray A; a water outlet is formed in one side of the electrode fixed tray B; a wiring end A is arranged in the water inlet; and a wiring end B is arranged in the water outlet. The small-sized efficient energy-saving over-current type equipment has the beneficial effects that: the whole set of process equipment has the characteristics and the advantages of a small size, high efficiency, energy conservation, not-liable-to-passivate electrodes, automatic flushing and stirring, adjustable current amount and wastewater (fluid) flow ratio, high efficiency, stability and the like.

Owner:云南腾雅环境科技有限公司

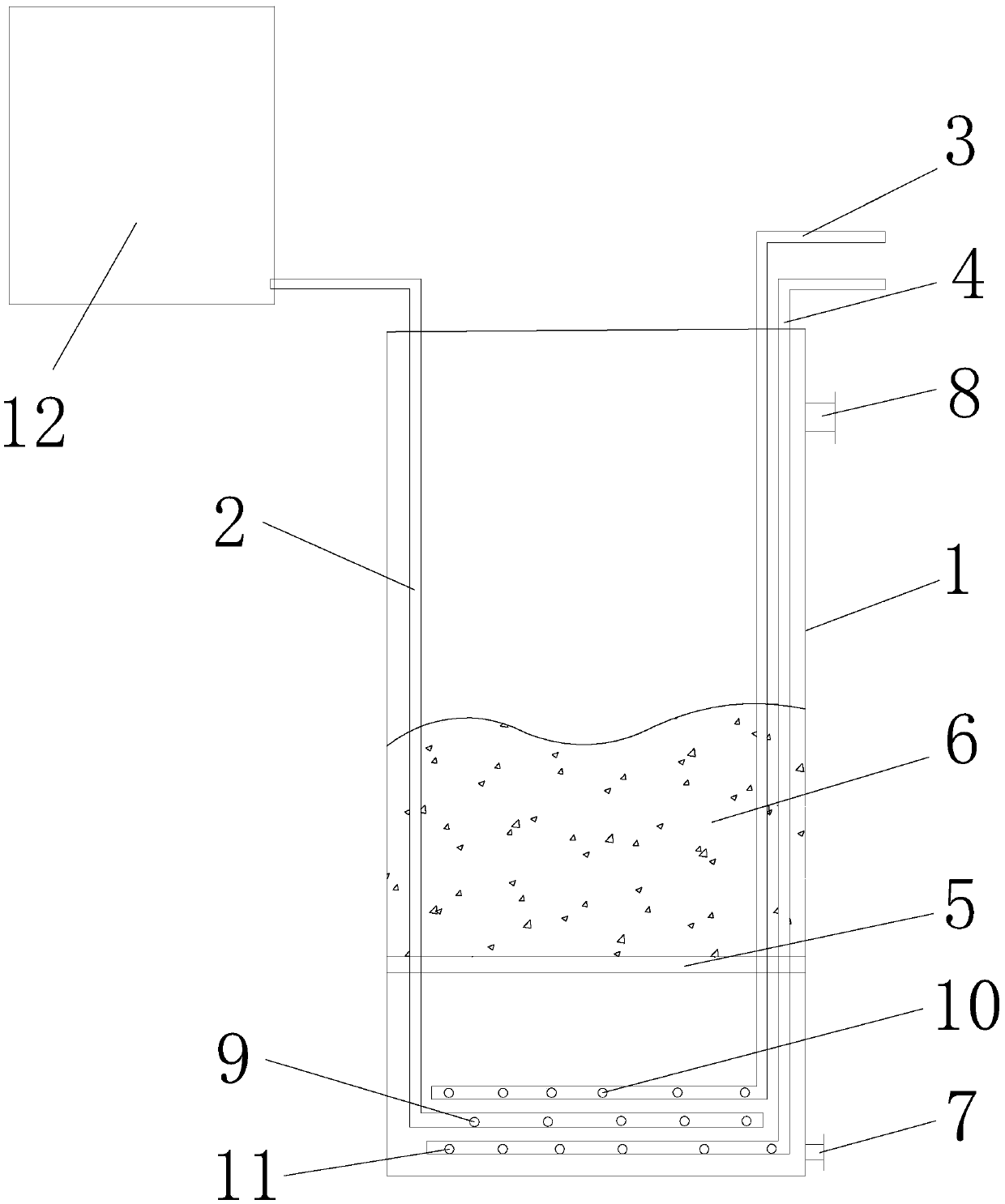

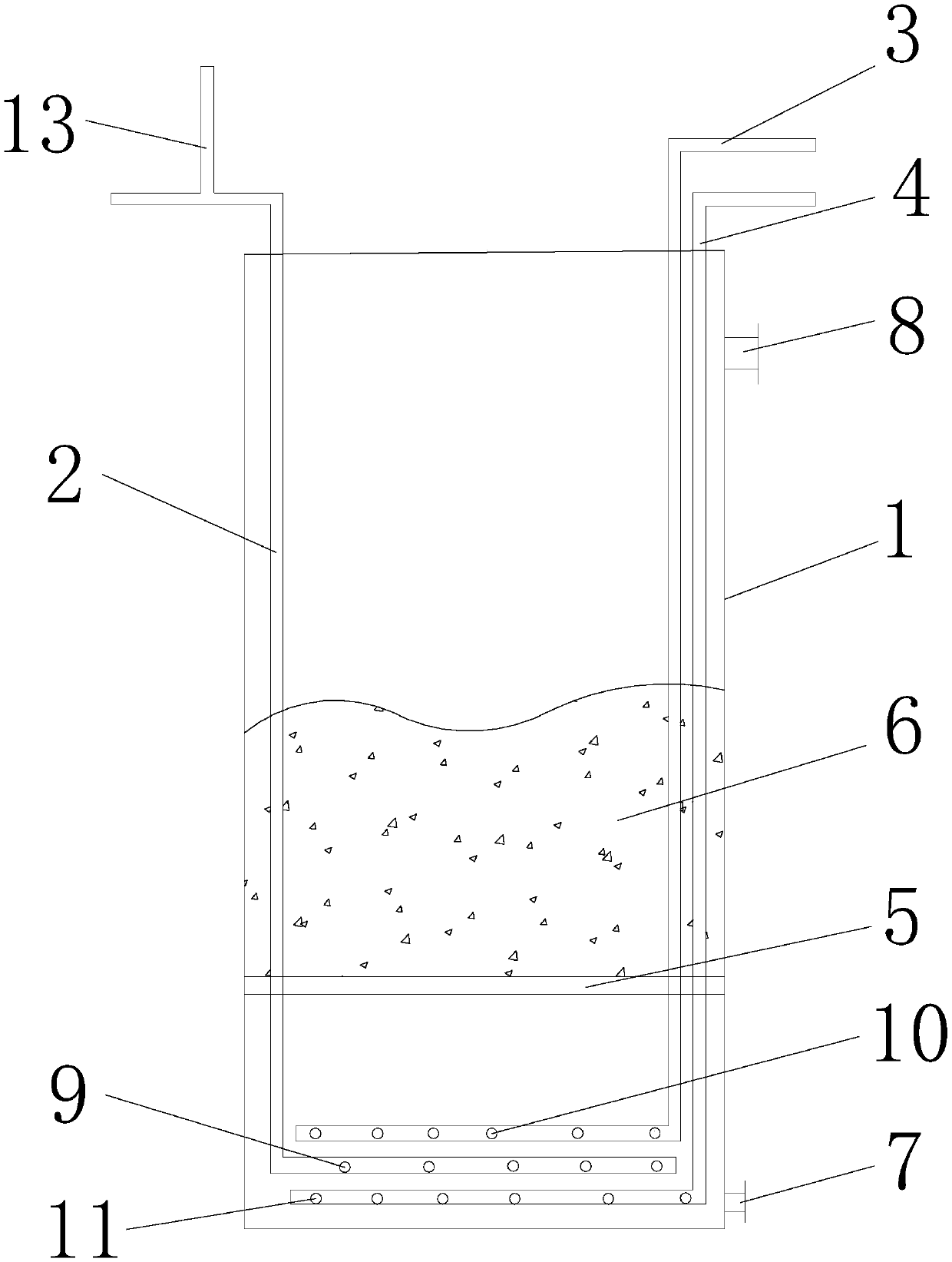

Electrochemical sulfide removal reactor and sewage treatment method using reactor

InactiveCN106698595AEfficient removalLess chemical side reactionsWater contaminantsWater/sewage treatment by electrochemical methodsSmall footprintSulfide

The invention puts forward an electrochemical sulfide removal reactor, which comprises a reaction tank, a sewage inlet tube, an aeration stirring air-tube and a backwashing air-tube. A bearing plate and a desulfuration filter material are arranged inside the reaction tank. A head end of the sewage inlet tube is positioned outside the reaction tank, and a tail end of the sewage inlet tube extends to the bottom of the reaction tank. The tail end of the sewage inlet tube is provided with a water distributor hole. A head end of the aeration stirring air-tube is positioned outside the reaction tank, and a tail end of the aeration stirring air-tube extends to the bottom of the reaction tank. The tail end of the aeration stirring air-tube is provided with an aerator pipe hole. A head end of the backwashing air-tube is positioned outside the reaction tank, and a tail end of the backwashing air-tube extends to the bottom of the reaction tank. The tail end of the backwashing air-tube is provided with a backwashing pipe hole. The invention also discloses a sewage treatment method using the electrochemical sulfide removal reactor. By the use of the electrochemical sulfide removal reactor, sulfides in sewage are effectively removed; there is less chemical side reaction; no toxins are generated; action time is short; floor area is small; operating expenses are low; and repairing and maintenance are convenient.

Owner:河北润港环保科技有限公司

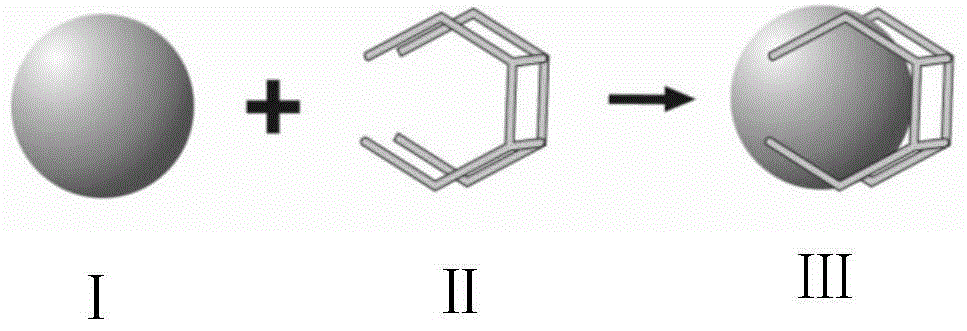

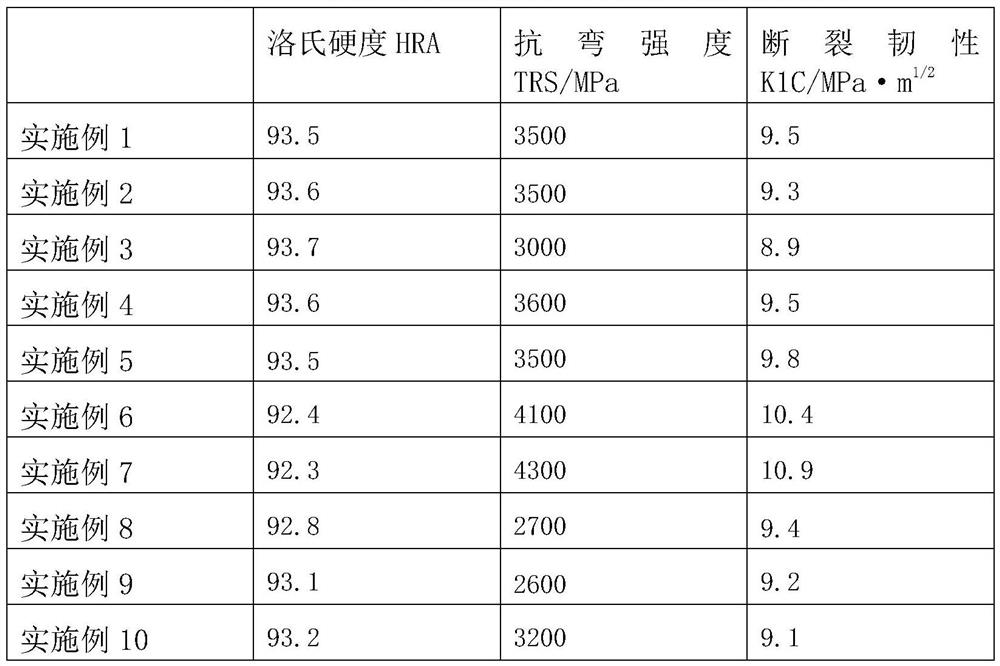

Preparation method of special blade for cigar scissors or cigar knife and blade

ActiveCN114227147AGrinding surface with high surface finishHigh strengthTobacco pipesFiberKnife blades

The invention discloses a preparation method of a blade special for cigar scissors or cigar knives and the blade. The blade is made of hard alloy or metal ceramic; when the blade is made of hard alloy, the thickness of the blade is larger than or equal to 0.5 mm and smaller than or equal to 0.8 mm or larger than 0.8 mm and smaller than or equal to 1.5 mm. When the blade is made of metal ceramic, the thickness of the blade is larger than or equal to 0.5 mm and smaller than or equal to 1 mm or larger than 1 mm and smaller than or equal to 1.5 mm. The special blade for the cigar scissors or the cigar knife has the advantages that the surface smoothness of a grinding surface is high, the strength, the hardness, the wear resistance and the toughness are excellent, and enough cutting edge sharpness can be kept while high-fiber tobacco shreds are cut; the surface of the notch is smooth, so that the service life, the attractiveness and the use satisfaction degree of a user of the cigar knife or the cigar scissors can be remarkably improved.

Owner:CHENGDU MET CERAMIC ADVANCED MATERIALS

Silicon carbide material polishing method

InactiveCN113695989AReduce surface roughnessImprove the finishEdge grinding machinesPolishing machinesCarbide siliconSlurry

The invention relates to a silicon carbide material polishing method. The silicon carbide material polishing method comprises the following steps that S1, 800-mesh silicon carbide micro powder, 1200-mesh silicon carbide micro powder and 1500-mesh silicon carbide micro powder are evenly stirred with a non-aqueous solvent mixed solution, and silicon carbide polishing slurry of different specifications is obtained; S2, a silicon carbide component needing to be polished is filled with silicon carbide particle slurry prepared from 800-mesh silicon carbide powder, the internal silicon carbide slurry is subjected to high-speed rotary grinding through a stirrer to be subjected to rough polishing, and surface impurities and attachments are ground to be flat; S3, silicon carbide slurry prepared from 1200-mesh silicon carbide powder is poured into the polished component, high-speed rotary grinding is conducted, and medium polishing is conducted; S4, silicon carbide slurry prepared from 1500-mesh silicon carbide powder is poured into the polished component, high-speed rotary grinding is conducted, and fine polishing is conducted; and S5, diamond powder is used for repairing polished flaws. According to the polishing method, the surface roughness of the ultra-fine chemical component can be reduced, and the polished surface smoothness is improved.

Owner:常州容导精密装备有限公司

Amino acid-containing water-soluble fertilizer added with sugar alcohol and preparation method thereof

The invention provides an amino acid-containing water-soluble fertilizer added with sugar alcohol and a preparation method thereof. The raw material composition includes amino acid, calcium salt and water, and the raw material composition also includes 5% to 10% of sugar alcohol by weight percentage. The amino acid-containing water-soluble fertilizer of the present invention is a calcium element type, and sugar alcohol is added as a chelating agent for calcium element. Through the reasonable proportioning relationship of sugar alcohol, amino acid and calcium salt, the sugar alcohol and calcium element are chelated to form a stable small Molecular chelates, combined with the penetration and wetting functions of sugar alcohols themselves, increase the absorption and transportation efficiency of the chelated calcium elements; at the same time, amino acids can also help calcium absorption, and can also promote photosynthesis and increase chlorophyll content. Therefore, the amino acid-containing water-soluble fertilizer added with sugar alcohol of the present invention has a high utilization rate under the combined action of sugar alcohol and amino acid, can increase the transportation speed of plant nutrients, increase the absorption of plant calcium and the sugar content of plants.

Owner:BEYONDCHEM LIFE TECH

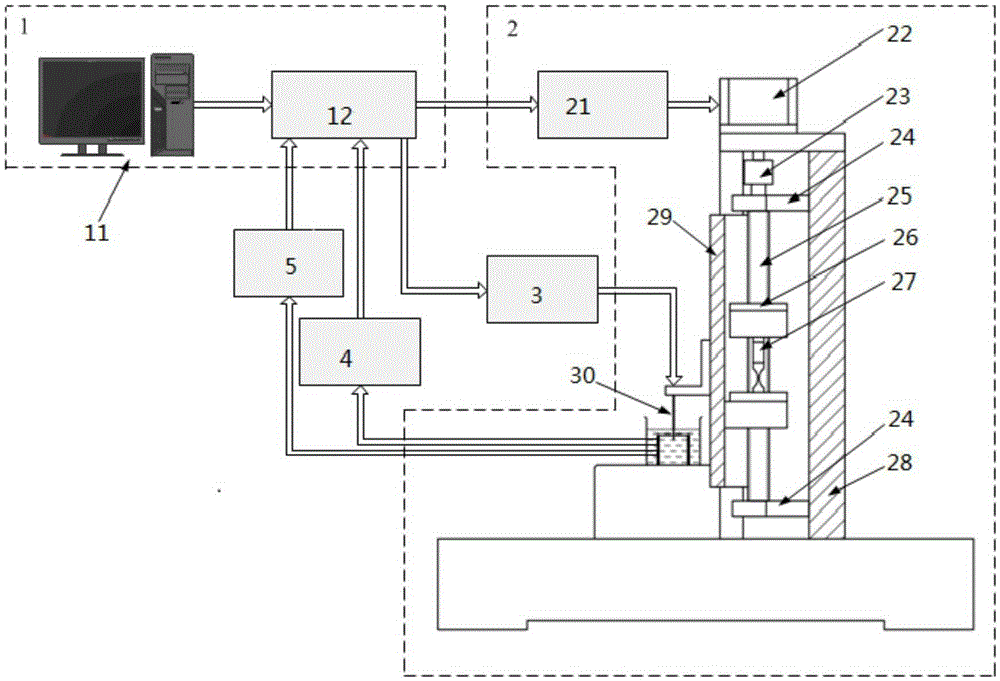

Probe machining equipment

InactiveCN105239148AReduce use costAchieve precision controllabilityElectrolysis componentsPower flowControl circuit

The invention discloses probe machining equipment. The probe machining equipment comprises a controller, a control circuit, a mechanical device and a corrosive liquid device, wherein the controller is connected with the mechanical device; the corrosive liquid device comprises an electrode and corrosive liquid; the mechanical device is used for fixing a probe to be machined and drives the probe to be machined to move; the control circuit comprises a preparation corrosive circuit, a preparation stopping circuit and a judgment circuit; the preparation corrosive circuit is used for outputting corrosive voltage to the electrode; the preparation stopping circuit collects a current change signal of the preparation corrosive circuit; the judgment circuit is used for detecting whether the probe is immersed in the corrosive liquid or not. According to the probe machining equipment, the structure and connection mode of the control circuit are improved, and other components of the mechanical device and the like are matched, so that important parameters like corrosive voltage, probe immersing depth and probe lifting speed in the probe corrosion process are accurately controlled, and the nano probe high in precision, resistant to abrasion, recyclable and low in cost can be obtained through machining.

Owner:XIANGYANG HONGWEI AIRCRAFT

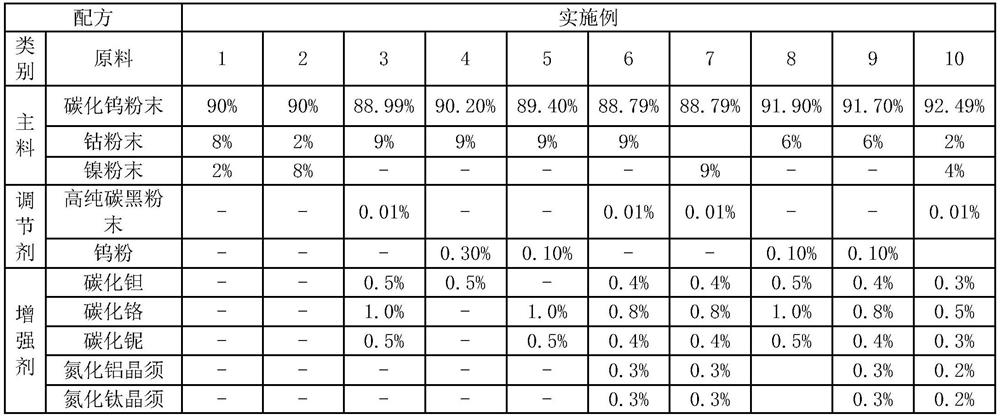

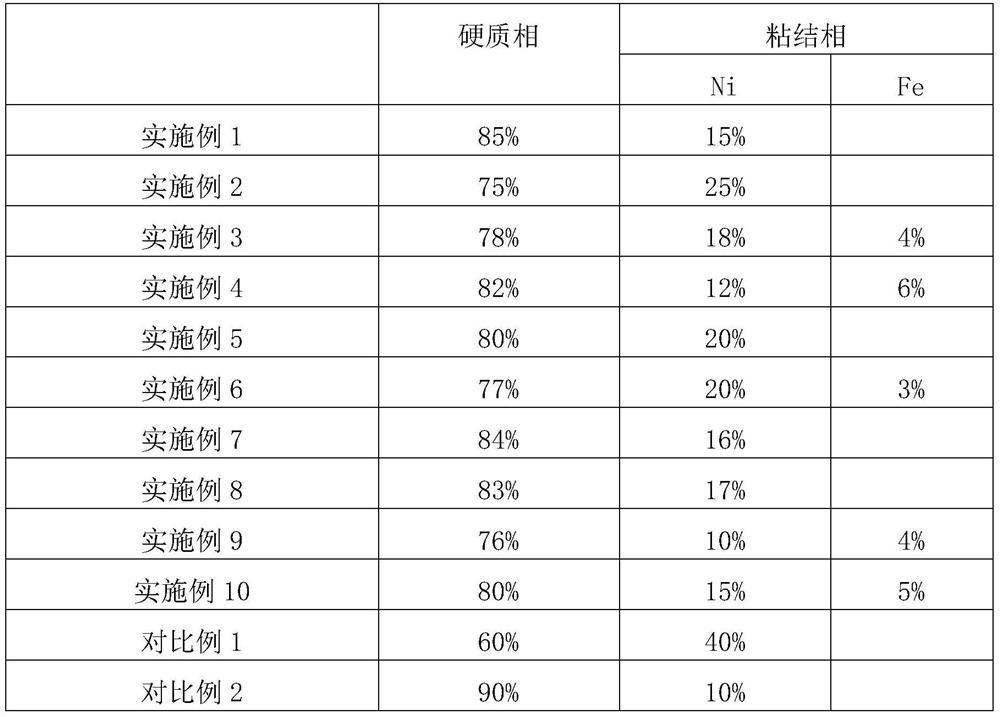

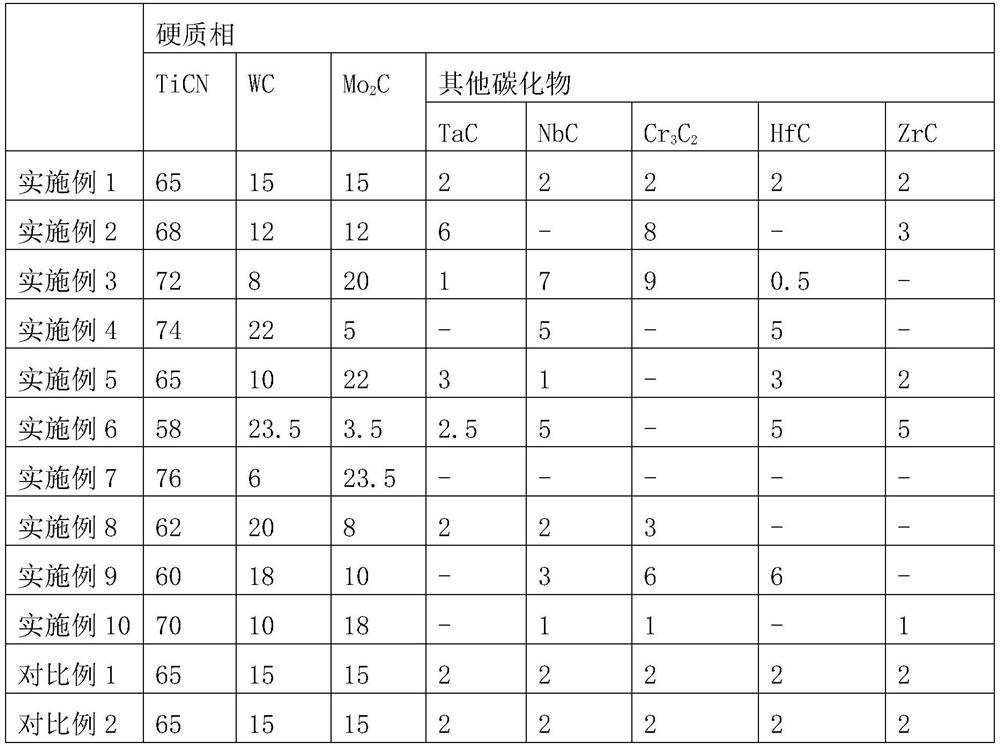

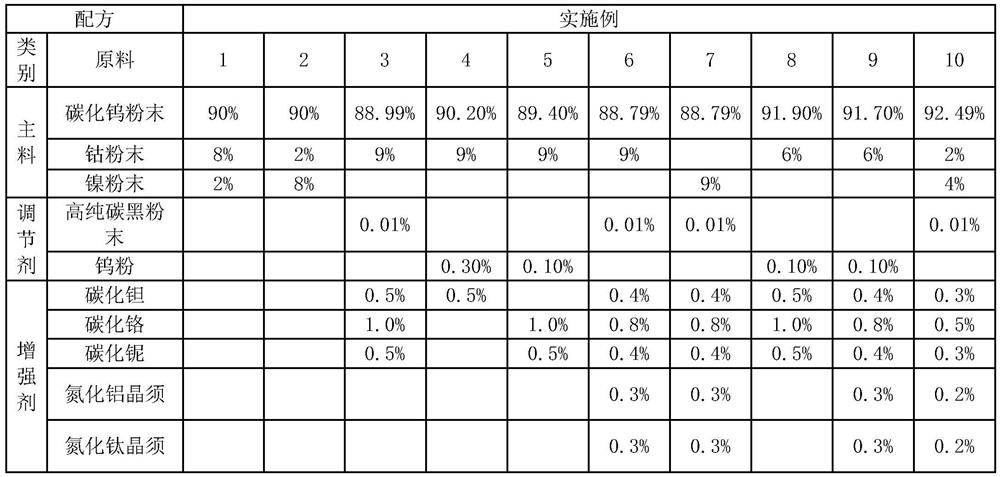

Hard alloy material for cigar knife and preparation method of hard alloy material

The invention discloses a hard alloy material for cigar knives and a preparation method of the hard alloy material. The hard alloy material for the cigar knife is prepared from the following raw materials in percentage by weight: 88-95% of tungsten carbide powder; 0-10% of cobalt powder; 0-10% of nickel powder; 0-0.02% of high-purity carbon black powder; 0-0.3% of tungsten powder; 0-0.5% of tantalum carbide; 0-1% of chromium carbide; 0-0.5% of niobium carbide; 0-0.5% of aluminum nitride whisker; 0-0.5% of titanium nitride whiskers; the sum of the weight percentages of the raw materials is 100%. The hard alloy material has good hardness, wear resistance, toughness and strength and can be used for preparing the cigar knife blade, during use, the cutting edge is not prone to passivation or edge curling, tar is not prone to adhering to the blade, the blade replacement frequency is low, the overall quality of a cigar knife and the use experience of a user are greatly improved, and the cigar knife is suitable for popularization and application. And the use cost is reduced.

Owner:CHENGDU MET CERAMIC ADVANCED MATERIALS +1

solar cell module

ActiveCN103646977BAvoid gatheringNot easy to passivatePhotovoltaic energy generationSemiconductor devicesSolar cellBattery cell

The invention provides a solar cell assembly, which comprises a backsheet layer (10), a first encapsulation material layer (20), a cell sheet layer (30), and a second encapsulation material layer (40) stacked in sequence As well as the glass layer (50), the solar cell module also includes a barrier layer (60) for blocking the metal cations of the glass layer (50) from entering the cell layer (30), and the barrier layer (60) is arranged between the glass layer (50) and Between the second packaging material layer (40). The invention effectively solves the problem of the PID phenomenon in the solar battery module in the prior art.

Owner:YINGLI ENERGY CHINA

A kind of pesticide composition containing cyprostrobin and hymexazol

A pesticide composition containing 2-cyano-3-amino-3-phenylacrylic acetate and hymexazol belongs to the technical field of pesticide compounds. The pesticide composition contains the 2-cyano-3-amino-3-phenylacrylic acetate and the hymexazol, which are at a weight ratio of (1:90)-(90:1). According to the pesticide composition containing the 2-cyano-3-amino-3-phenylacrylic acetate and the hymexazol, the 2-cyano-3-amino-3-phenylacrylic acetate and the hymexazol are reasonably and effectively compouned, as a result, the defects that the broad-spectrum performance of the 2-cyano-3-amino-3-phenylacrylic acetate is poor and the hymexazol has a poor effect on fusarium can be overcome, the pesticide efficacy can be remarkably improved, risks caused by pesticide resistance can be lowered, and a remarkable synergy effect is realized.

Owner:CHINA NAT RICE RES INST

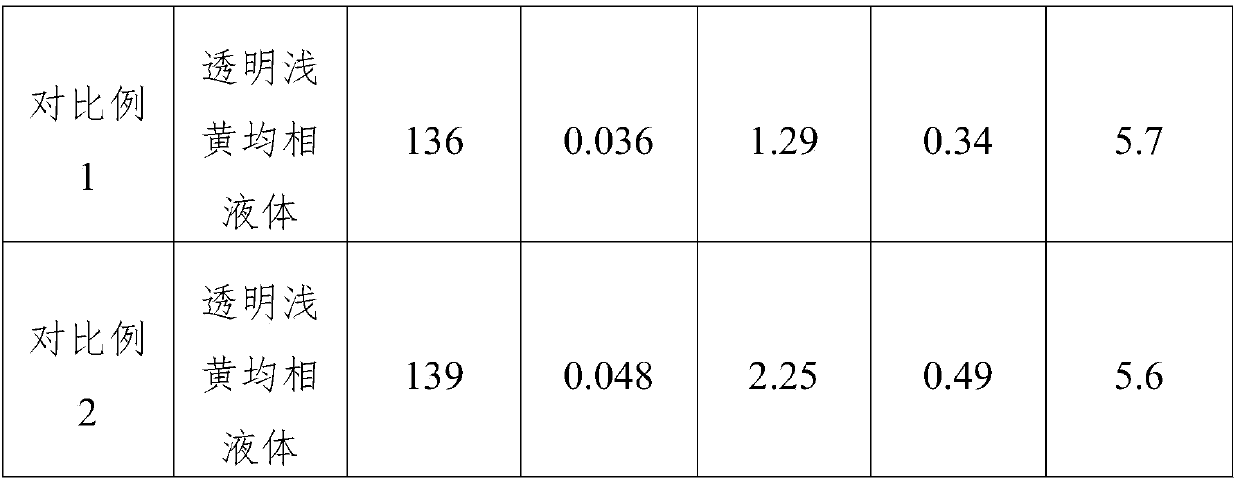

Weeding composition

InactiveCN110839632AGood resistance to hard waterIncrease speed and volumeBiocideAnimal repellantsPesticideActive agent

The invention relates to a weeding composition, which comprises, by mass, 1-60% of triclopyr raw pesticide, 1-20% of a salt forming agent, 1-30% of a surfactant and the balance of a filler. Accordingto the invention, the composition can obviously improve the deposition and penetration effects of the drug on the surface of plants, and enhance the ability of the drug to penetrate through organellemembrane structures, so that the composition has higher weeding activity than the existing triclopyr and butoxyethyl triclopyr.

Owner:LIER CROPSCIENCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com