Probe machining equipment

A processing equipment and technology to be processed, applied in the electrolysis process, electrolysis components, etc., can solve the problems of difficult probe high-precision processing, uneven probe surface morphology, affecting probe surface quality, etc. The effect of controllability and morphological standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

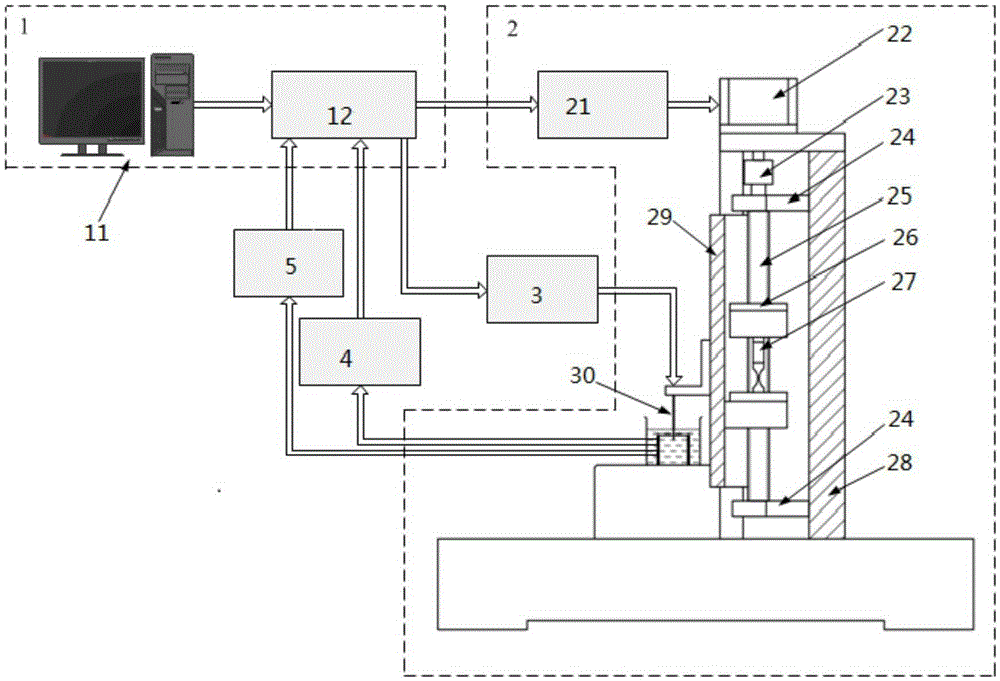

[0034] Such as figure 1 As shown, the probe processing equipment in the present invention includes an industrial computer 1, a mechanical device 2 and a control circuit; wherein, the industrial computer 1 includes a host computer 11 and a controller 12, and the controller 12 is connected to the mechanical device 2 and is used to control the mechanical device move; the mechanical device 2 is used to fix the probe and drive the probe to move up and down; the control circuit includes a preparation corrosion circuit 3 connected to the controller 12, a preparation stop circuit 4 and a judgment circuit 5, wherein: the preparation corrosion circuit 3 is used to receive the controller The corrosion voltage signal instruction issued by 12, and output the preset corrosion voltage according to the instruction and keep the corrosion voltage constant; the preparation stop circuit 4 collects the current change signal of the preparation corrosion circuit 3, and transmits the change signal to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com