Titanium alloy anode material for electrolyzing manganese dioxide and titanium alloy anode made of same

A technology of electrolytic manganese dioxide and anode materials, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems that the electrolysis process cannot continue, cannot be processed into plates, and has low practical value, so as to improve the anti-passivation performance, Resistant to passivation phenomenon and the effect of improving passivation resistance

Inactive Publication Date: 2011-06-15

宝钛特种金属有限公司

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the corrosion resistance of pure titanium in the electrolysis of manganese dioxide, titanium anodes made of pure titanium have been widely used in the production of electrolytic manganese dioxide, but pure titanium anodes are prone to passivation, and passivation The film continues to thicken, the conductivity drops rapidly, and the electrolysis process cannot continue

In order to overcome the defect that pure titanium anodes are prone to passivation, some people propose to spray precious metals on the surface of pure titanium metal to improve its anti-passivation effect, but the coating is easy to fall off, the service life is short, the processing cost is high, and the practical value is not high.

Although the anode made of titanium-manganese alloy improves the anti-passivation effect and reduces power consumption, due to the poor plasticity of the material, it cannot be processed into plates, and because the electrolytic manganese dioxide production process requires a certain intensity of knocking, even if it is processed into The bar is also extremely brittle, so it is difficult to get a large number of applications in the production of electrolytic manganese dioxide

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

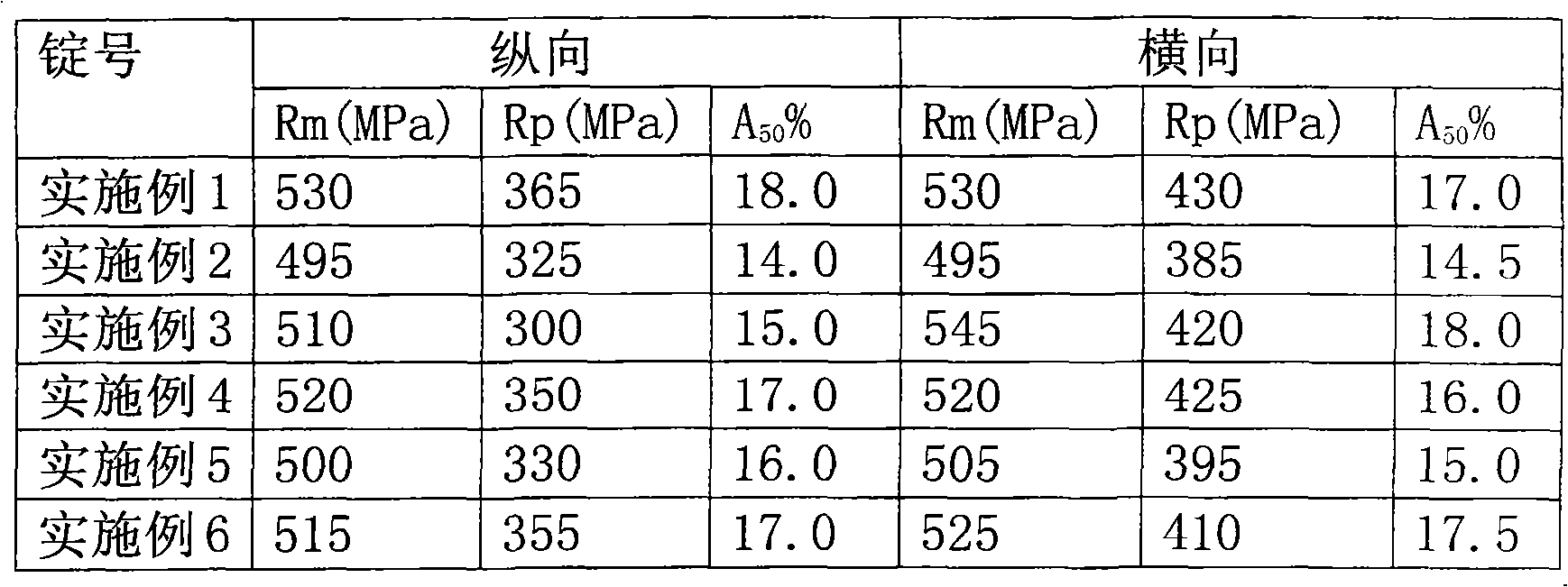

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

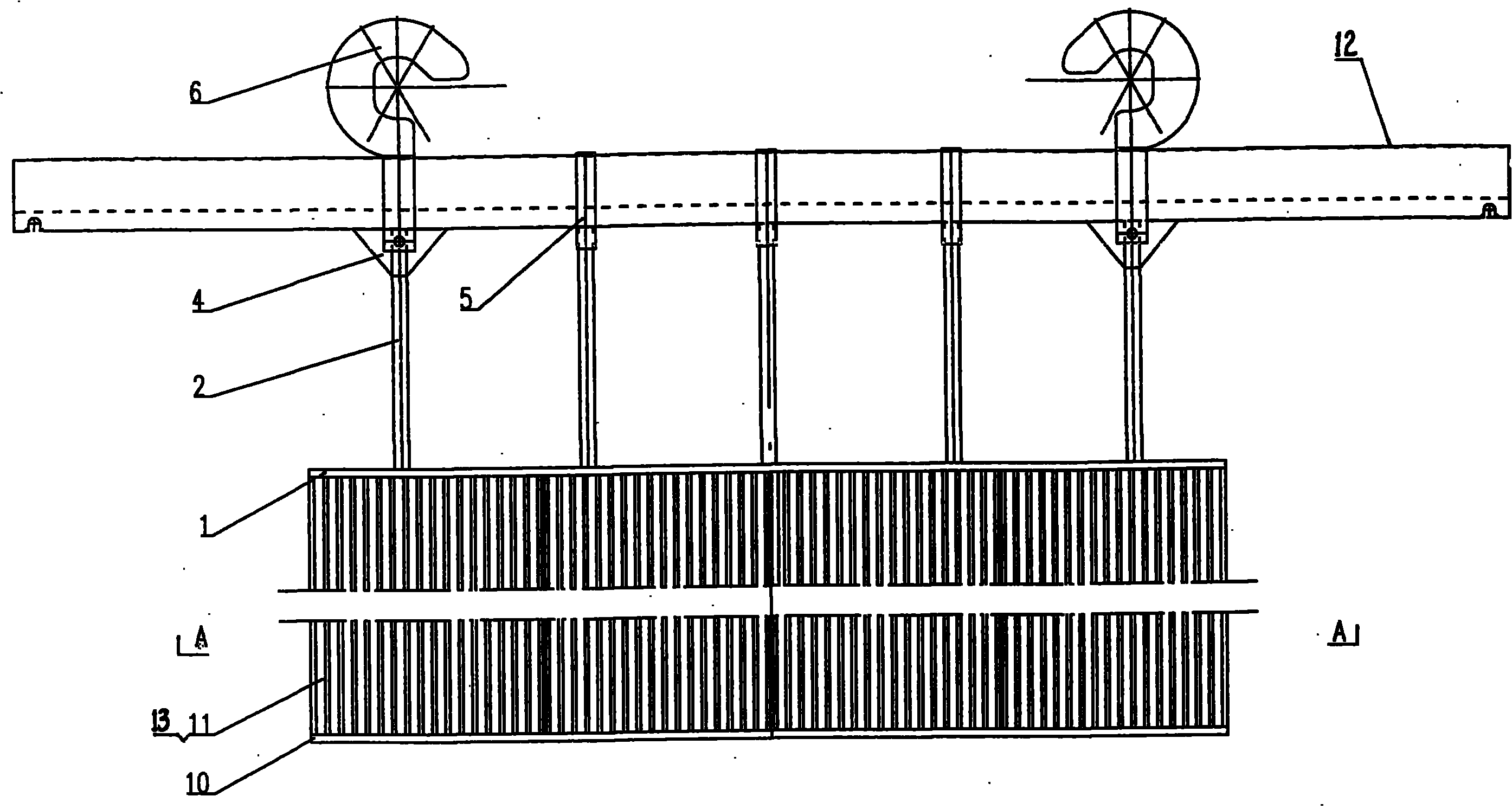

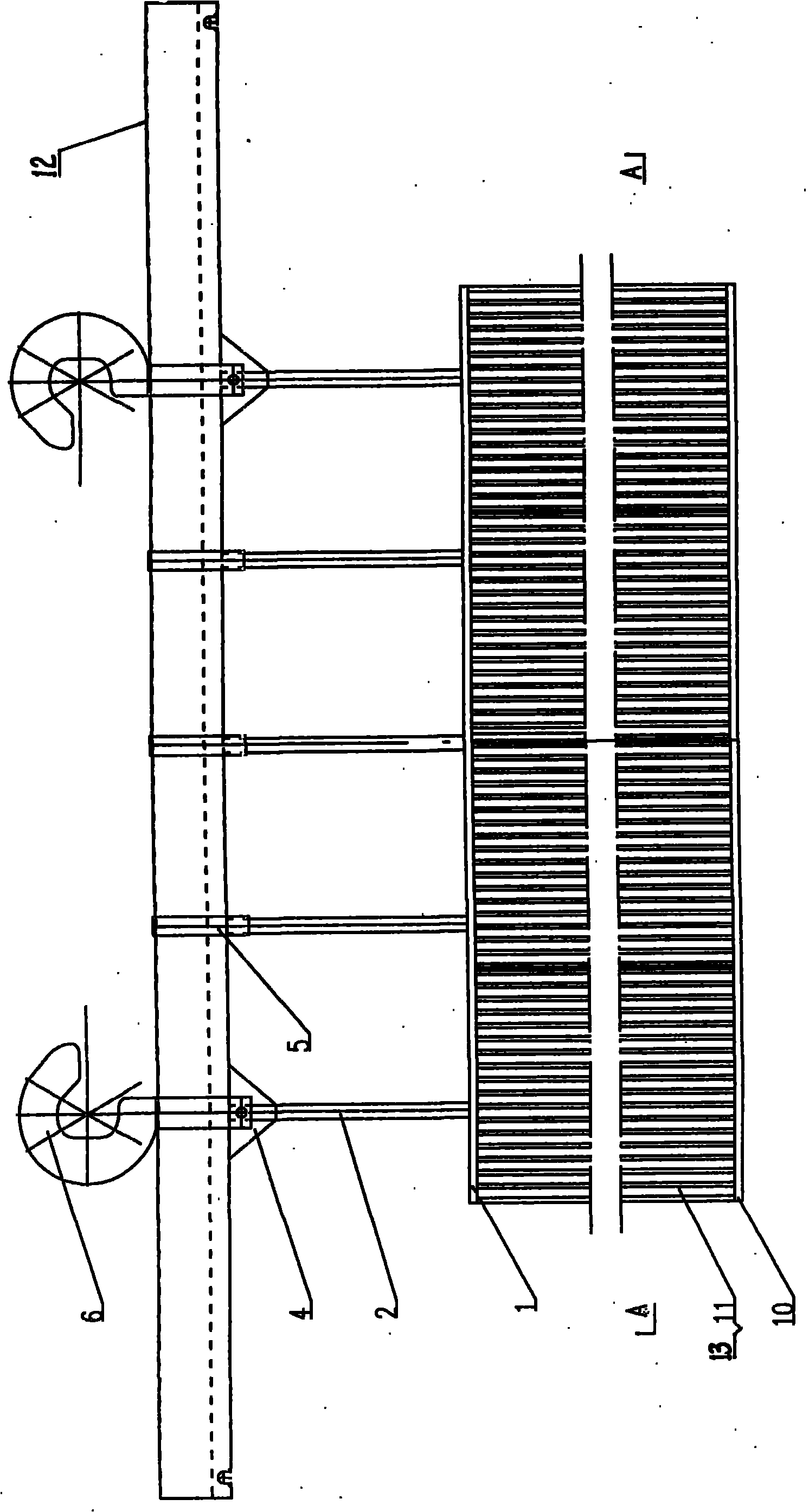

The invention relates to a titanium alloy anode material for electrolyzing manganese dioxide, which comprises the following components in percentage by weight: 0.5-5.0% of Ni, 0.2-1.0% of Fe, less than 0.01% of N, less than 0.001% of H, less than 0.06% of O, and the balance of Ti and inevitable impurities. The titanium alloy anode made of the titanium alloy anode material is composed of a titanium alloy anode plate and a conductive beam, wherein the conductive beam is composed of a conductive beam casing, a titanium copper conductive beam and a weighting beam; both the titanium copper conductive beam and the weighting beam are positioned in the conductive beam casing, and the titanium copper conductive beam is positioned below the weighting beam; a hoop and lifting hooks are sheathed outside the conductive beam casing; the upper ends of lifting rods are fixedly connected with the inferior parts of the hoop and the lifting hooks respectively; the lower ends of the lifting rods are fixedly connected with the upper end of the titanium alloy anode plate respectively; and the hoop is positioned between the two lifting hooks. The anode material provided by the invention has the advantages of favorable corrosion resistance, high chemical stability, favorable passivation resistance, high conductivity, high mechanical strength, easy forming and low cost. The titanium alloy anode plate provided by the invention can not be easily passivated, and can effectively lower the bath voltage and increase the current density during electrolysis.

Description

Titanium alloy anode material for electrolytic manganese dioxide and titanium alloy anode made of this material technical field The invention belongs to the technical field of electrolytic manganese dioxide production, and in particular relates to a titanium alloy anode material for electrolytic manganese dioxide and a titanium alloy anode made of the material. Background technique Electrolytic manganese dioxide is an indispensable and important raw material for the production of high-performance dry batteries. Due to the corrosion resistance of pure titanium in the electrolysis of manganese dioxide, titanium anodes made of pure titanium have been widely used in the production of electrolytic manganese dioxide, but pure titanium anodes are prone to passivation, and passivation The film keeps thickening, the conductivity drops rapidly, and the electrolysis process cannot continue. In order to overcome the defect that pure titanium anode is prone to passivation, some people...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C14/00C25B11/04C25B11/02C25B1/21

Inventor 和平志宋文君刘红孟觉明董长升郭建华

Owner 宝钛特种金属有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com