Electrochemical sulfide removal reactor and sewage treatment method using reactor

A sulfide and electrochemical technology, applied in electrochemical water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. Fewer reactions, simple operation, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

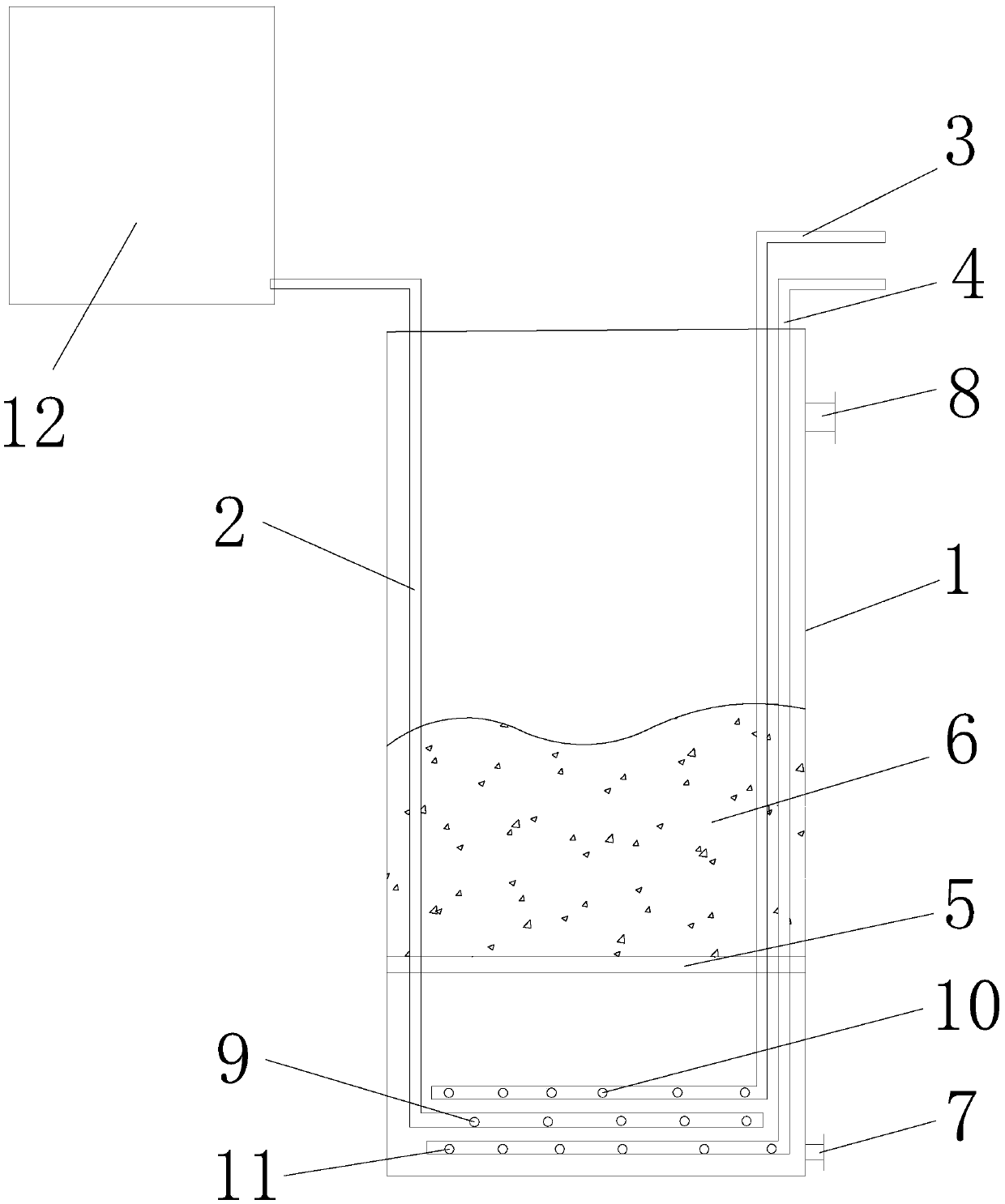

[0038] Such as figure 1 As shown, the electrochemical sulfide removal reactor in this embodiment includes a reaction tank 1 , a sewage inlet pipe 2 , an aeration stirring air pipe 3 and a backwash air pipe 4 .

[0039] Wherein, the reaction pool 1 is an open type, resistant to acid and alkali corrosion, and can be designed in shapes such as circles and squares; a supporting plate 5 with holes is arranged in the reaction pool 1, and the supporting plate 5 separates the reaction pool 1 into The upper and lower areas; the desulfurization filter material 6 is placed on the supporting plate 5, that is, the desulfurization filter material 6 is located in the upper area of the reaction pool 1; the lower end of the reaction pool 1 is provided with an empty port 7 for discharging the reaction pool Residual water or impurities in 1; a water outlet 8 is provided at the upper end of the reaction tank 1 for discharging desulfurized water, and the position of the water outlet 8 is usually...

Embodiment 2

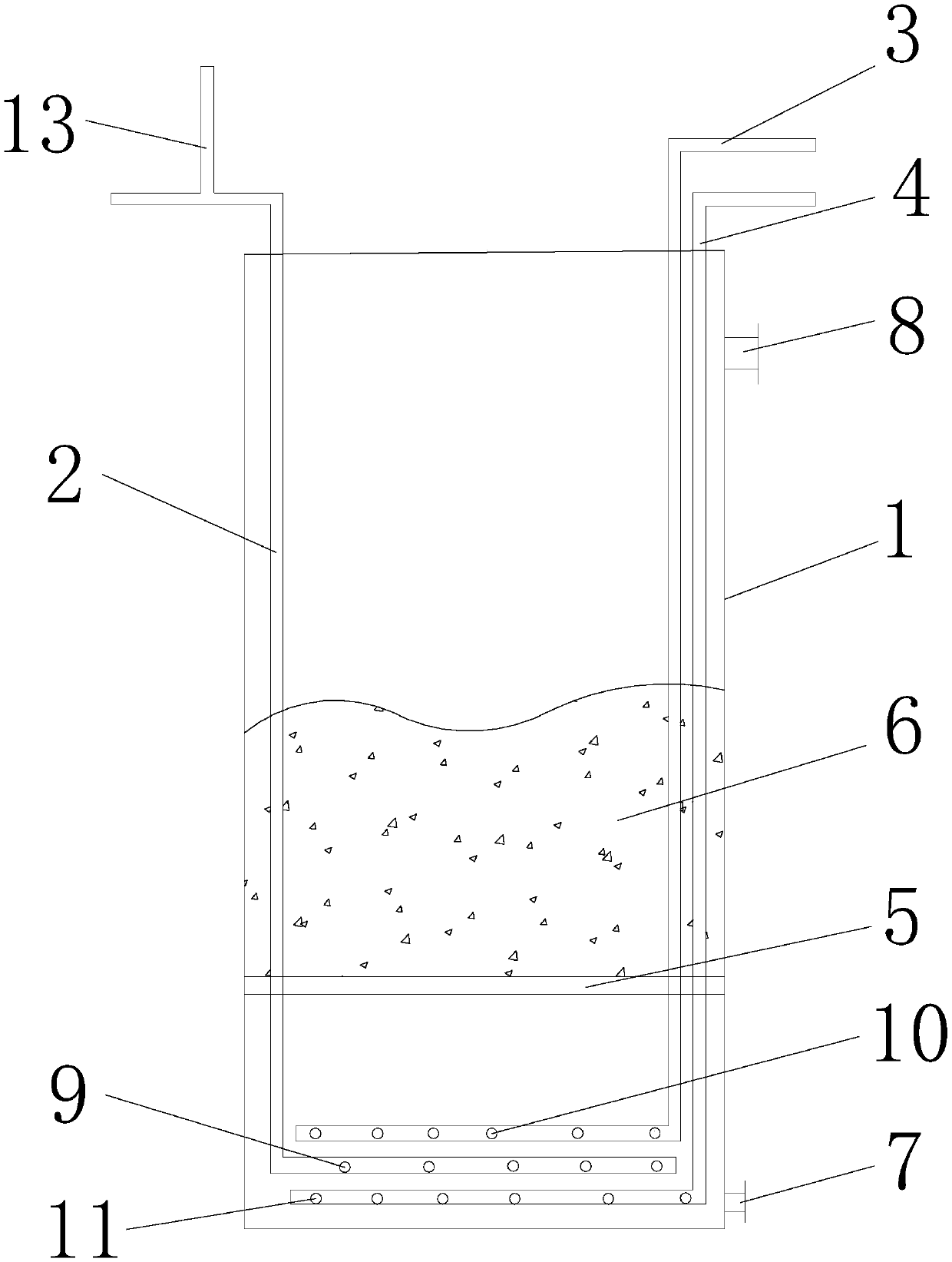

[0046] Such as figure 2 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the head end of the sewage inlet pipe 2 is not connected to the pH adjustment tank 12, but leads to an acid adding pipe 13 for adding acid to the sewage inlet pipe 2. Acid, adjust the pH value of sewage. Compared with Example 1, in this example, acid is directly added to the sewage inlet pipe 2 .

Embodiment 3

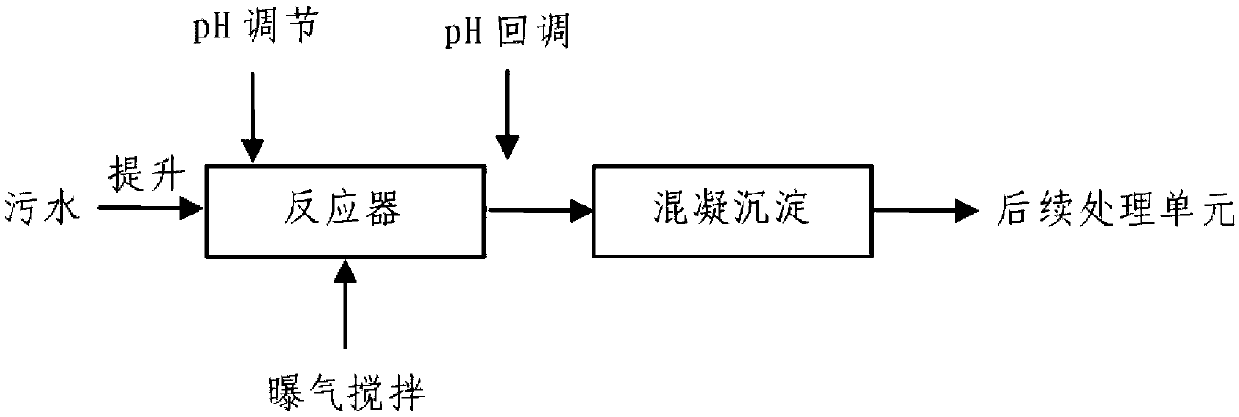

[0048] Such as image 3 As shown, in the present embodiment, the sewage treatment method using the aforementioned electrochemical sulfide removal reactor comprises the following steps:

[0049] 1) Add acid to sewage, adjust the pH value of sewage to 2-5, make it reach suitable reaction conditions; The adjustment tank 12 is used for adjustment; when the electrochemical sulfide removal reactor in Example 2 is used, the acid is added from the acid adding pipe 13 into the sewage inlet pipe 2 and mixed with the sewage for adjustment.

[0050] 2) Desulfurize the sewage after adjusting the pH value through the electrochemical sulfide removal reactor; the sewage enters the bottom of the electrochemical sulfide removal reactor through the sewage water inlet pipe 2 and distributes water evenly; the sewage passes through the supporting plate 5 passes through the desulfurization filter material 6, and an electrochemical reaction occurs in the desulfurization filter material 6, and the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com