Patents

Literature

188 results about "Nickel chromium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

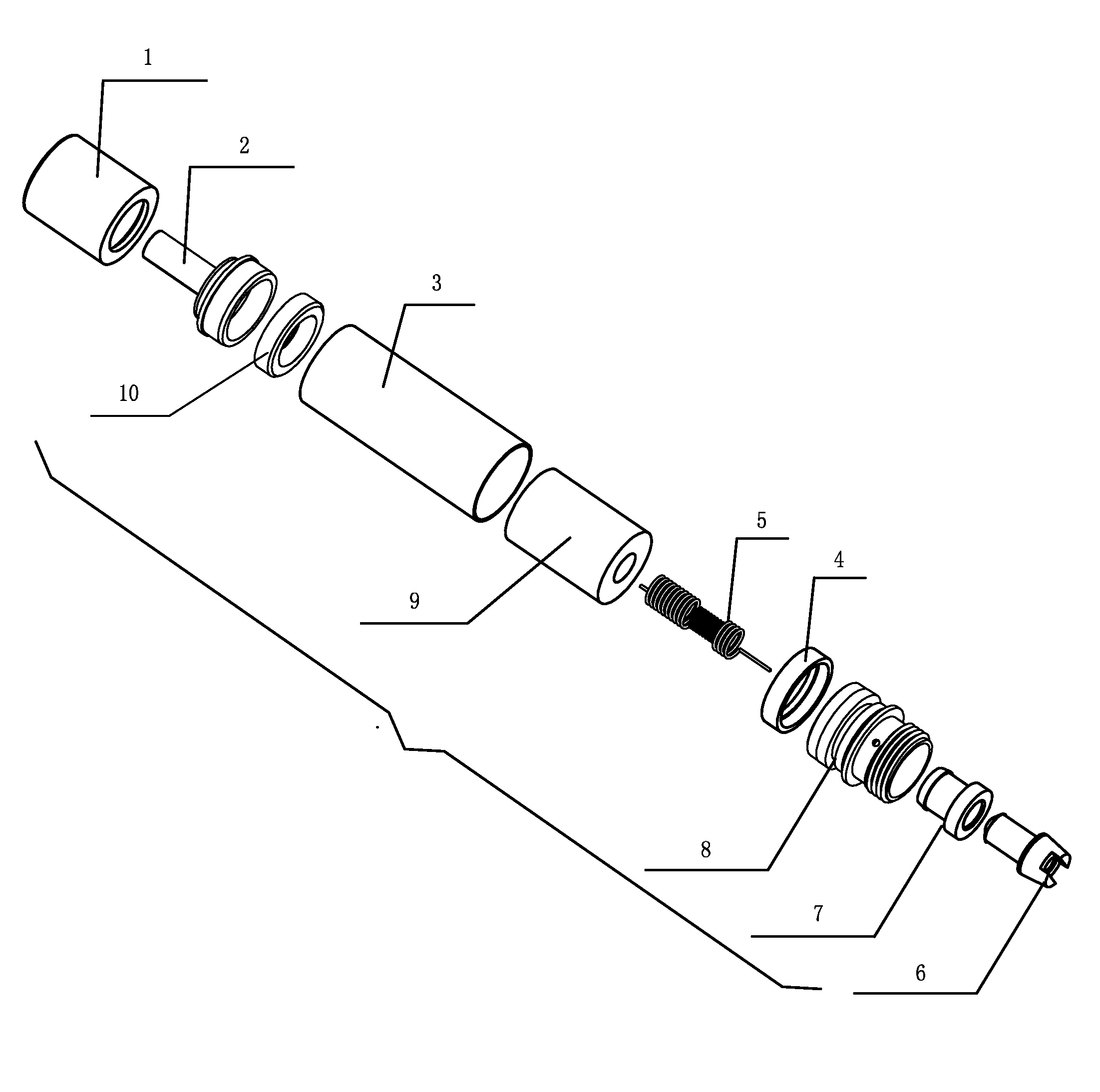

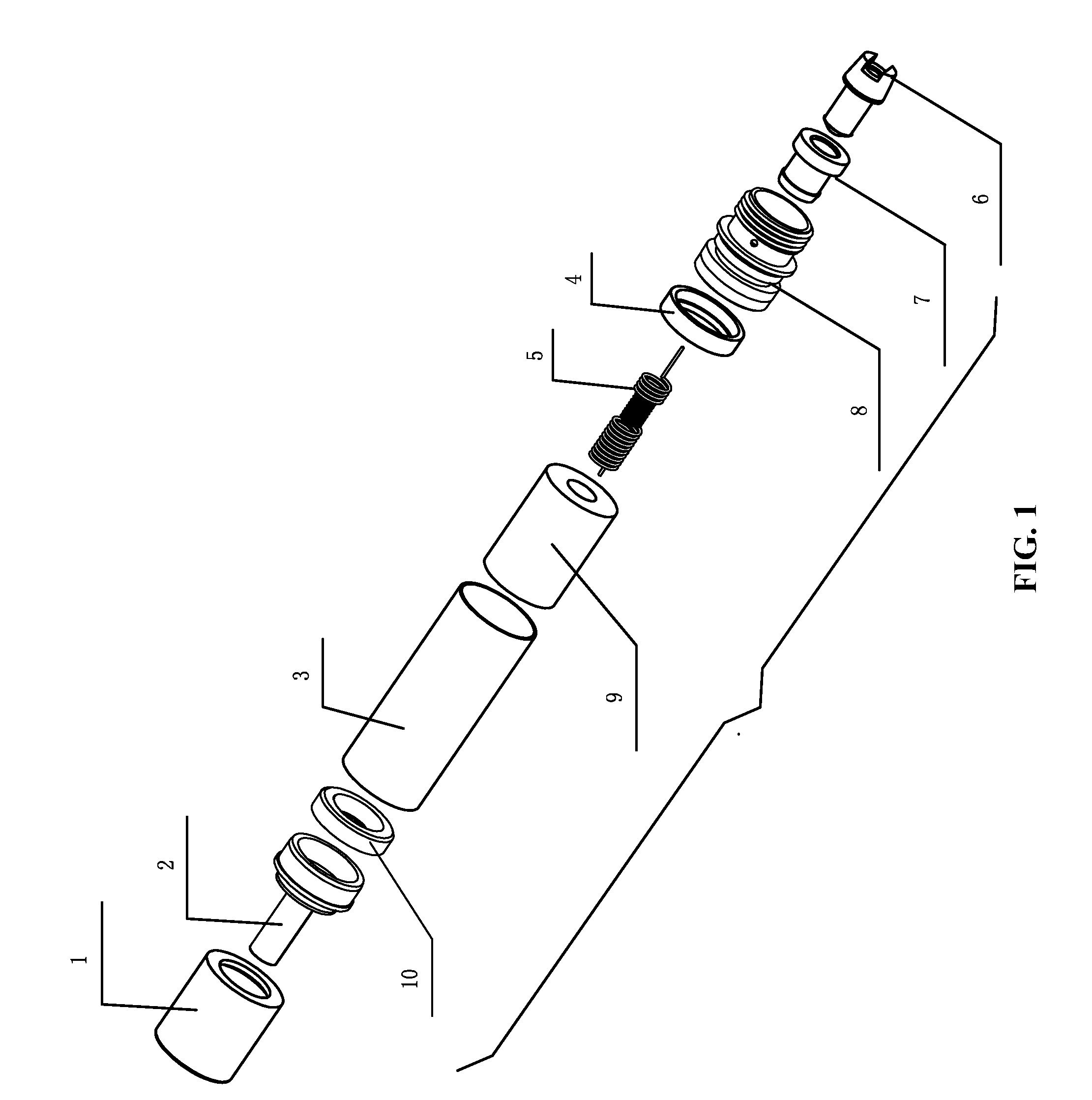

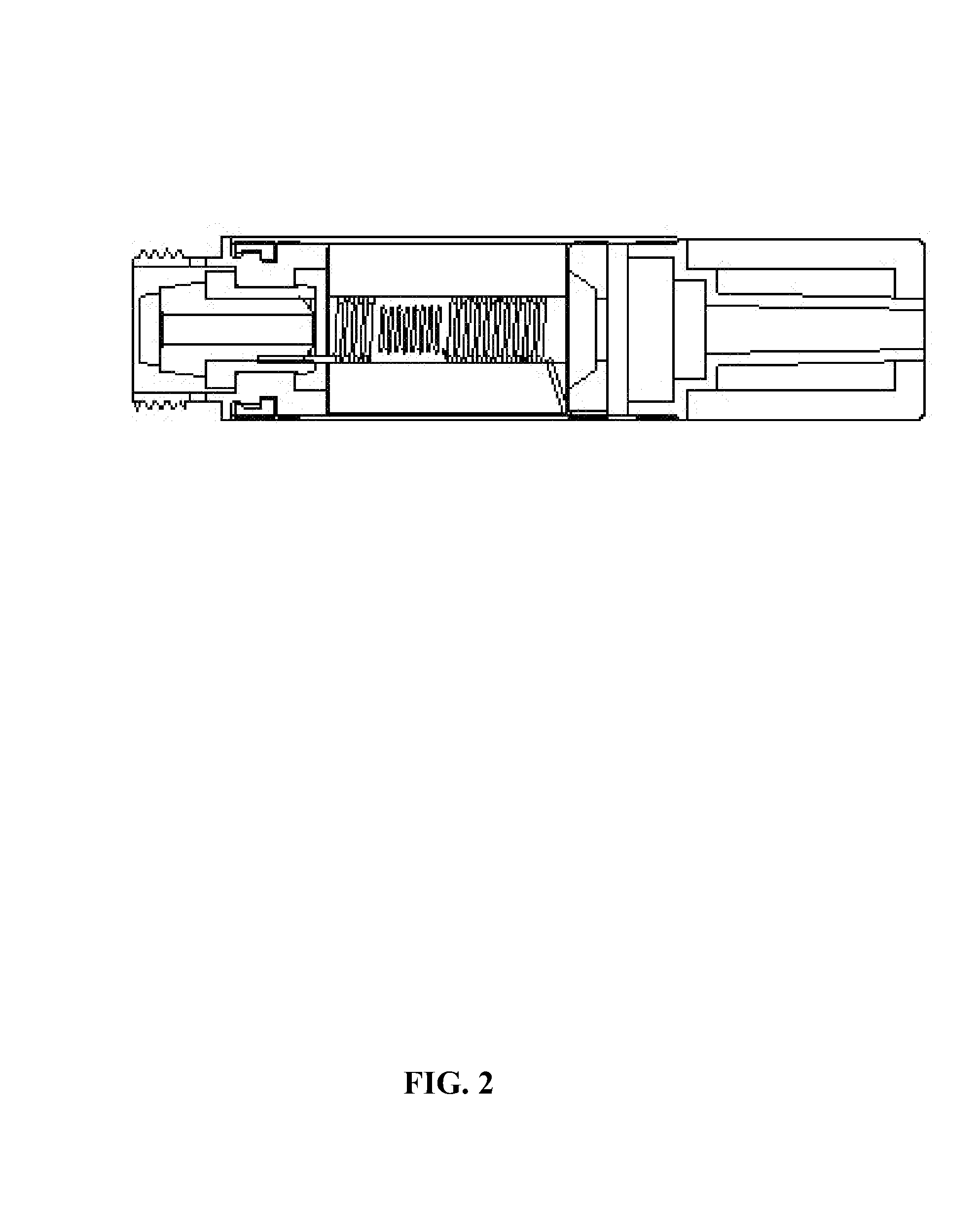

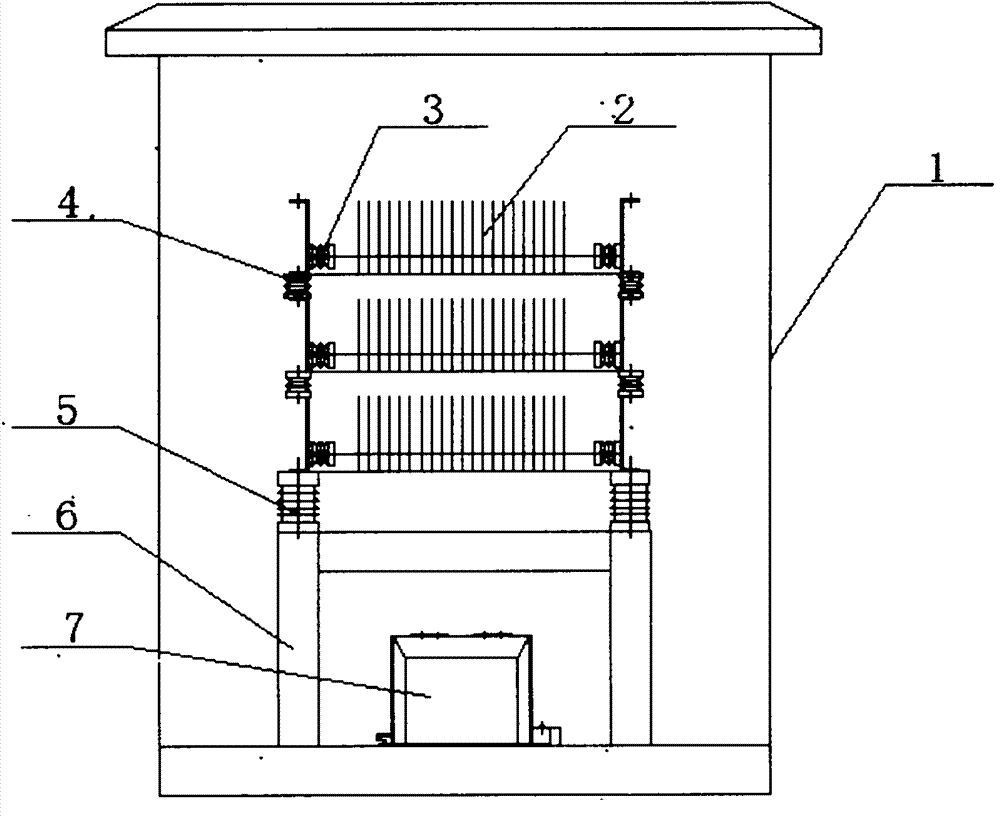

Electronic cigarette

ActiveUS20150013700A1Improve cooling effectEasy to useTobacco pipesTobacco devicesEngineeringElectronic cigarette

An electronic cigarette including a mouthpiece, a bracket for the mouthpiece, an atomization pole including a threaded copper ring, a silicate ring, a heating wire, a joint, an insulating ring, a filter cotton, and a fluid stop ring. The mouthpiece is made of silica gel and is connected with the atomization pole via the bracket. The heating wire is electrically welded using nickel-chrome as a material. The heating wire is spiral. One end of the threaded copper ring is connected with the joint. The insulating ring is disposed between the thread ring and the joint. The silicate ring is disposed between the filter cotton and the threaded copper ring. The fluid stop ring is disposed between the bracket and the heating wire for preventing the leakage of fluid.

Owner:LIU TUANFANG

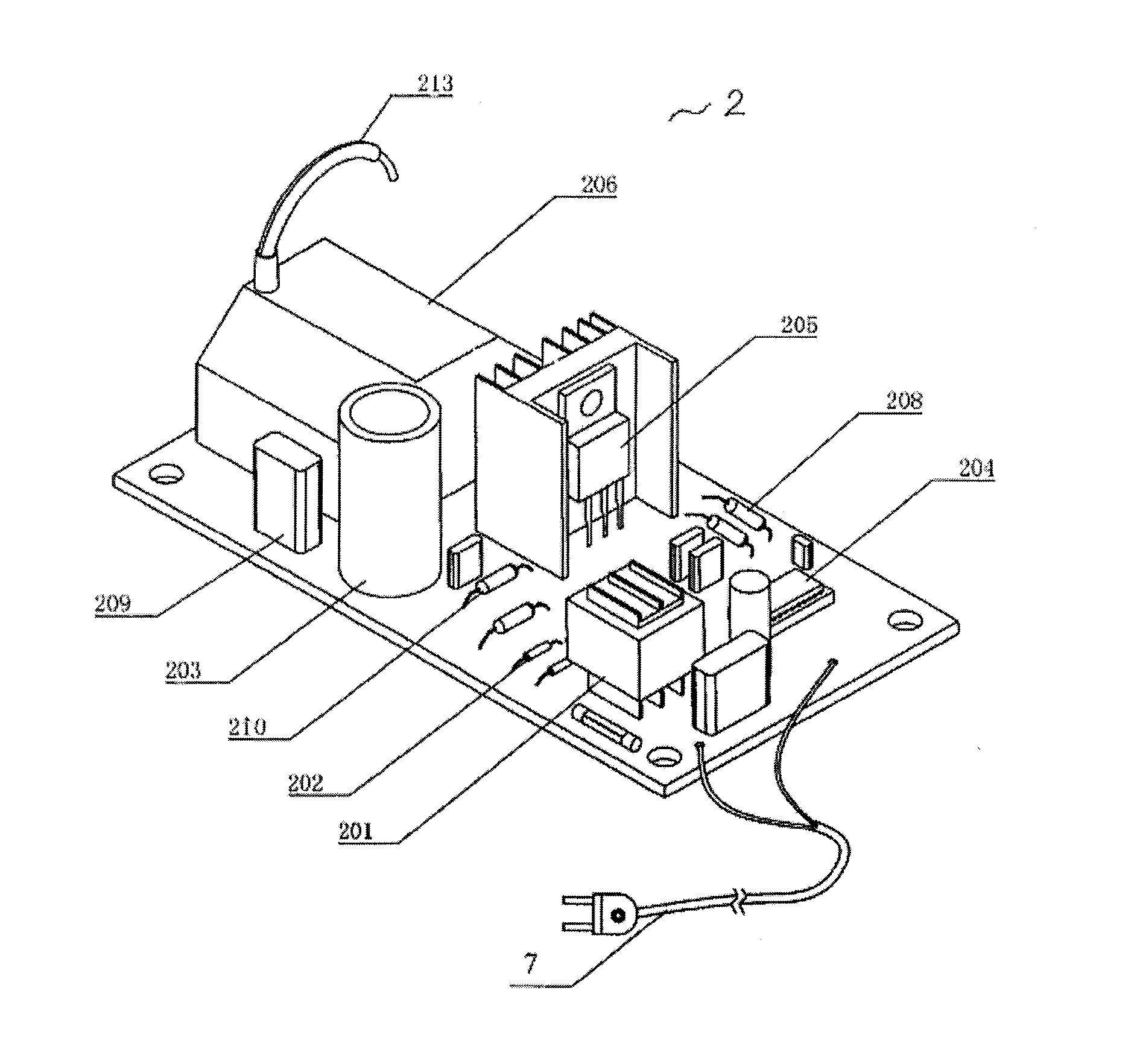

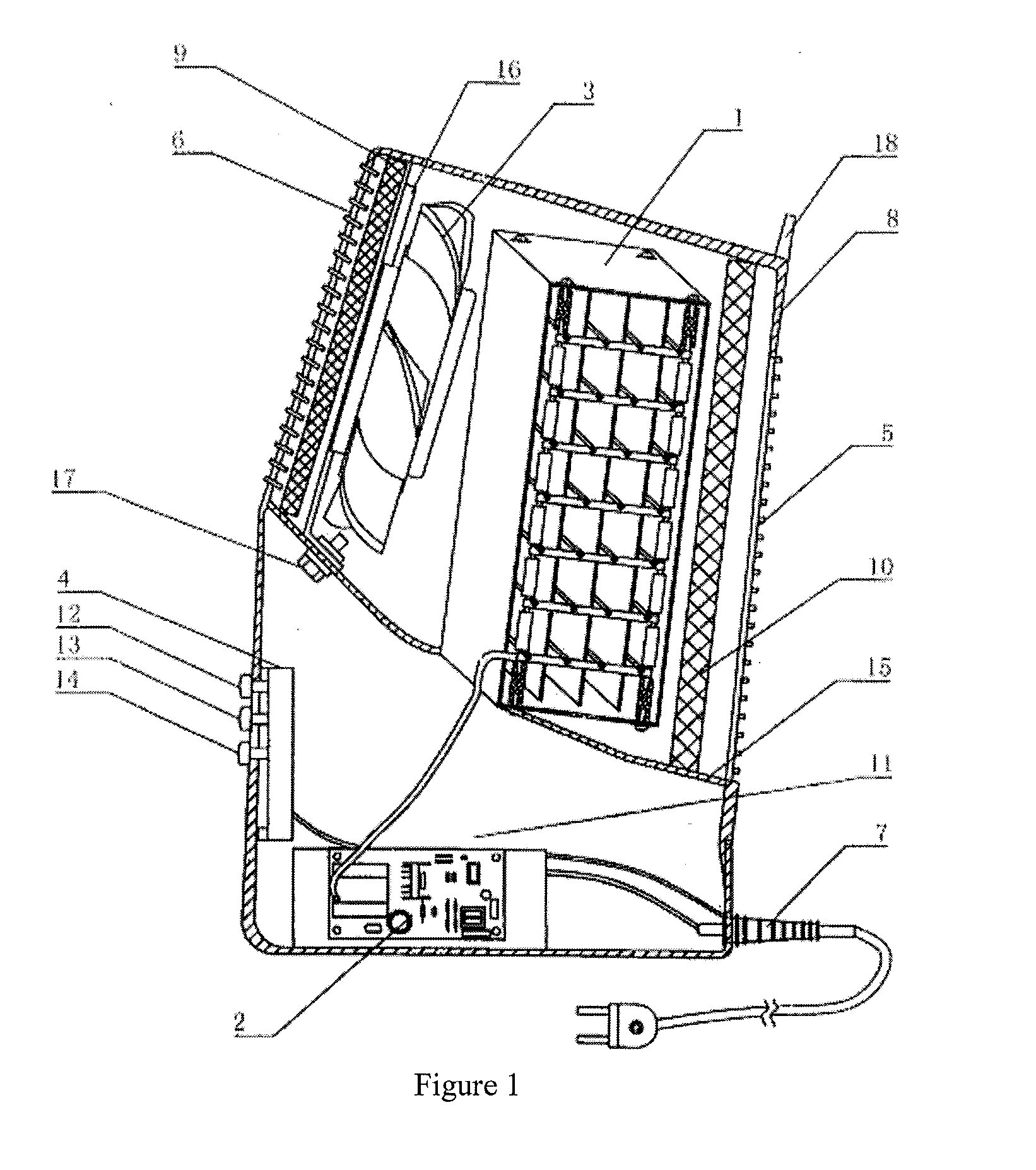

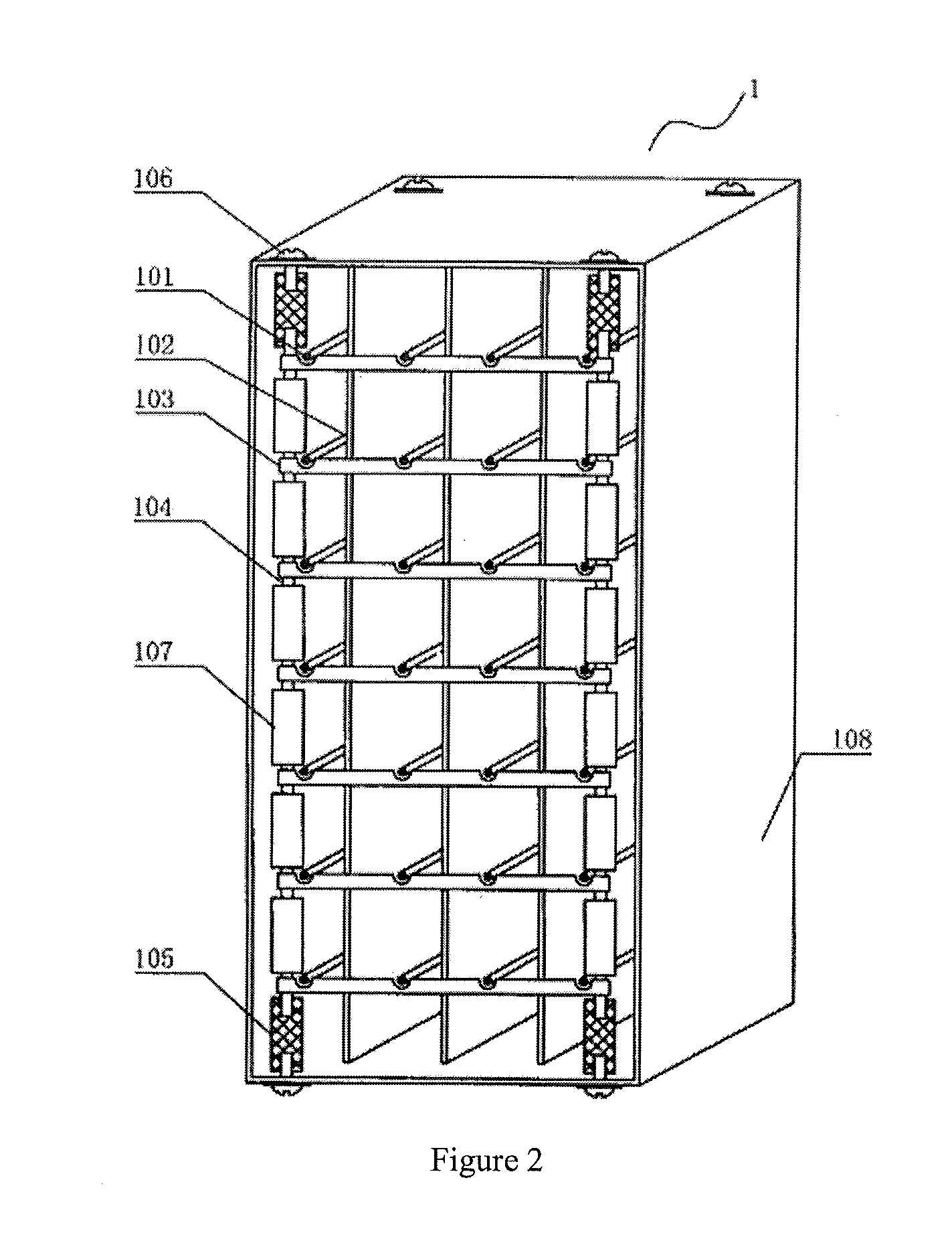

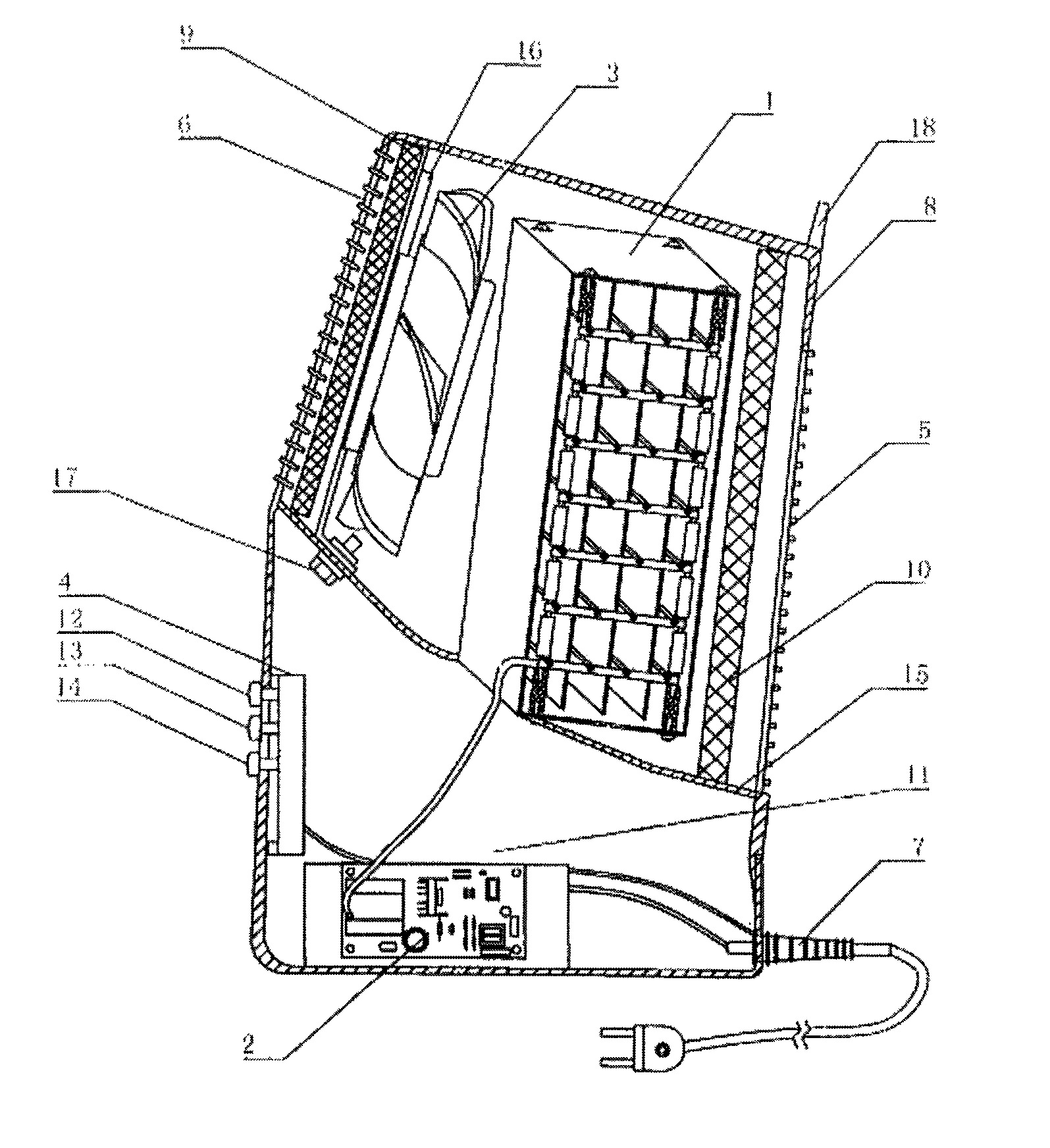

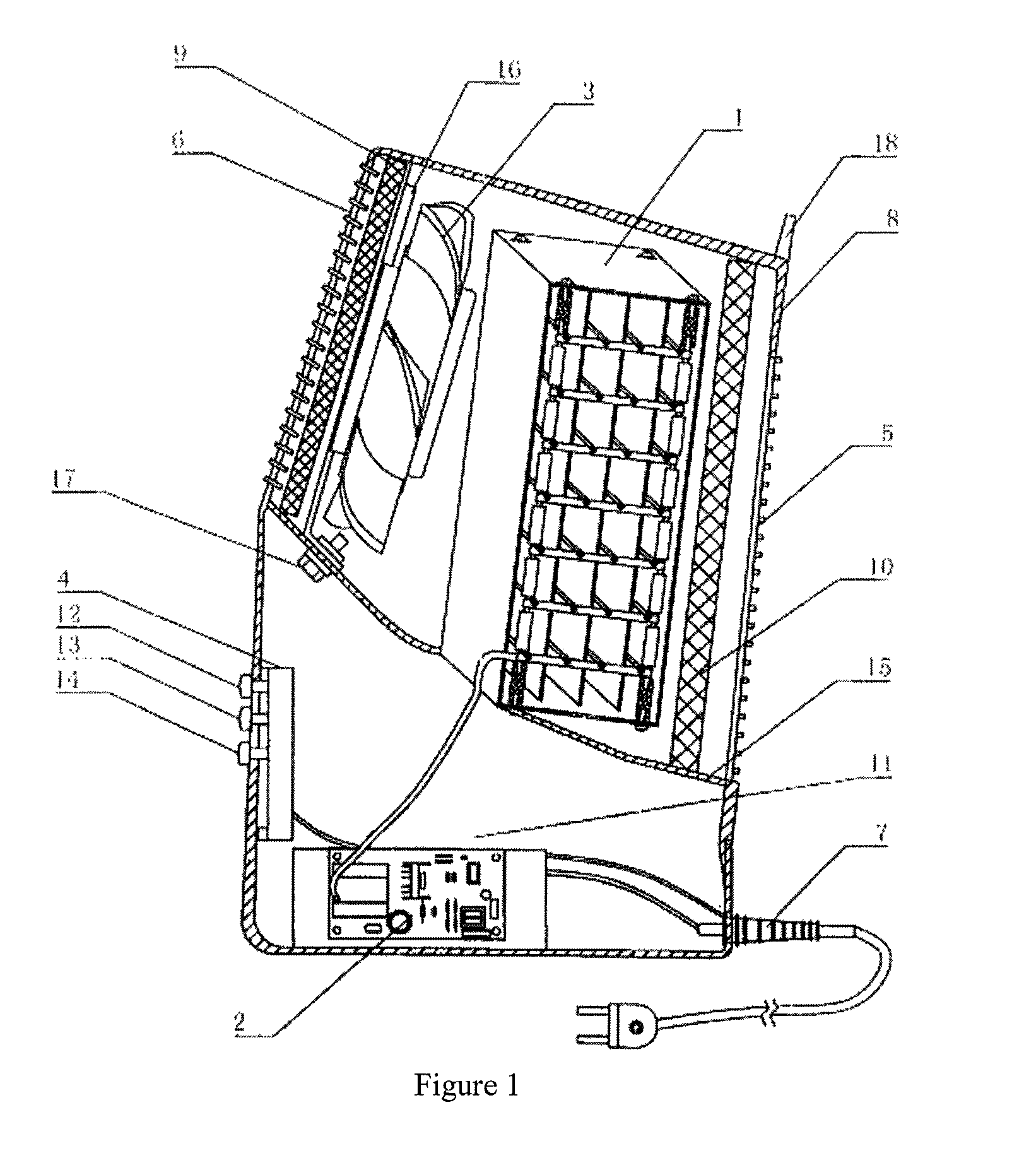

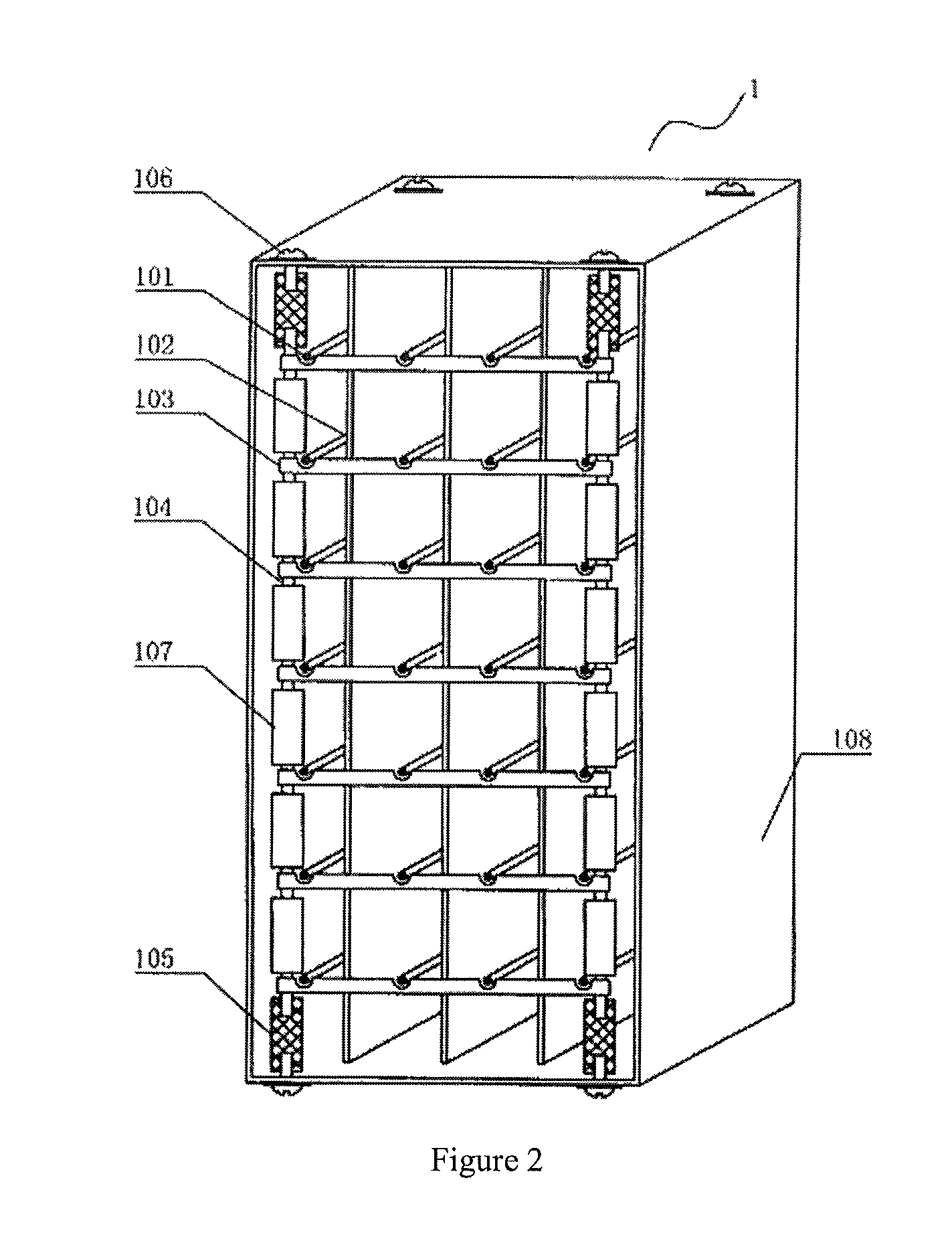

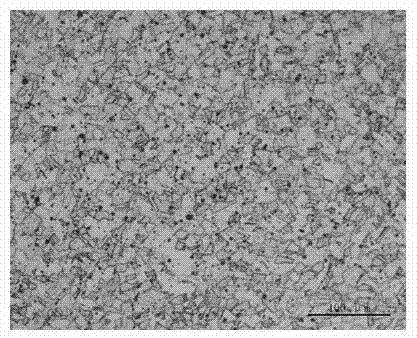

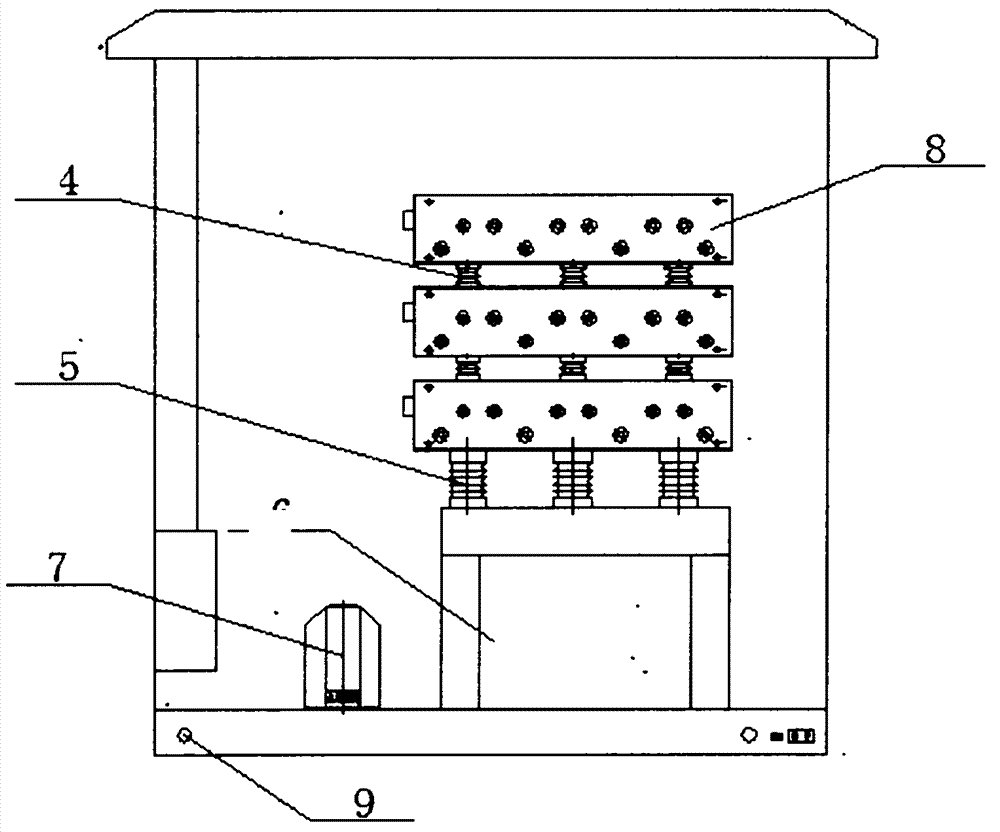

Plasma sterilizing-purifying device and method for air sterilizing and purifying

ActiveUS20120269677A1Improve reliabilityEasy to useMechanical apparatusLighting and heating apparatusVoltage pulseNickel chromium alloy

The present invention belongs to the technical field of air sterilizing and purification and in particular relates to a plasma air sterilizing and purifying device and an air sterilizing and purifying method. The plasma air sterilizing and purifying device comprises a plasma reactor, a pulse power supply, a fan component, a control device, a power adaptor, and a housing case, wherein the reactor is provided with positive electrodes formed by several nickel-chromium alloy wires or nickel-chromium alloy belts, and the two ends of each positive electrodes are fixed in the corresponding grooves on the micro-discharge preventive conductor rail; and a pulse power supply has a digital control circuit with an oscillator, an error amplifier and a PWM comparator inside which converts signals into a digital control current to control the width of the high-voltage pulse.

Owner:ZHEJIANG TIANQING ENVIRONMENTAL PROTECTION TECH CO LTD

Plasma sterilizing-purifying device and method for air sterilizing and purifying

ActiveUS8529830B2Improve reliabilityEasy to useMechanical apparatusLighting and heating apparatusPower flowNickel chromium alloy

The present invention belongs to the technical field of air sterilizing and purification and in particular relates to a plasma air sterilizing and purifying device and an air sterilizing and purifying method. The plasma air sterilizing and purifying device comprises a plasma reactor, a pulse power supply, a fan component, a control device, a power adaptor, and a housing case, wherein the reactor is provided with positive electrodes formed by several nickel-chromium alloy wires or nickel-chromium alloy belts, and the two ends of each positive electrodes are fixed in the corresponding grooves on the micro-discharge preventive conductor rail; and a pulse power supply has a digital control circuit with an oscillator, an error amplifier and a PWM comparator inside which converts signals into a digital control current to control the width of the high-voltage pulse.

Owner:ZHEJIANG TIANQING ENVIRONMENTAL PROTECTION TECH CO LTD

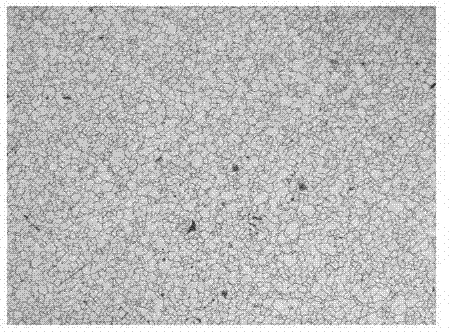

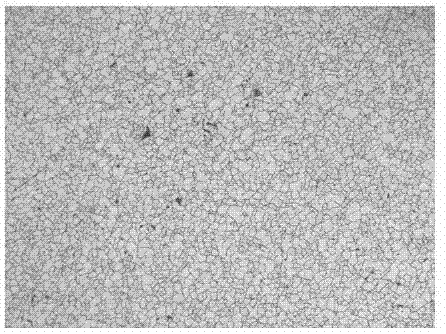

Nickel-chromium alloy metallographic corrosion solution and corrosion method

InactiveCN104513985AGrain contrast is obviousFast corrosionPreparing sample for investigationAcetic acidAlcohol

The invention relates to a nickel-chromium alloy metallographic corrosion solution and a corrosion method. The corrosion solution is a mixed solution of concentrated nitric acid, concentrated hydrochloric acid, glacial acetic acid and water in a volume ratio of 1:1:1:1. The concrete steps include: (1) preparing the corrosion solution, firstly adding water into a container, then adding concentrated nitric acid, concentrated hydrochloric acid and glacial acetic acid respectively, conducting stirring and then performing standing for 10-20min; (2) dripping the corrosion solution on the corrosion surface of a ground and polished nickel-chromium alloy metallographic sample, immersing the sample into the corrosion solution to a depth of 1-2mm, and controlling the corrosion time at 10s-10min; (3) flushing the sample surface with distilled water for more than 2min; and (4) flushing the sample surface with alcohol, and then wiping the sample surface with alcohol-carrying absorbent cotton. According to the invention, the corroded metallographic sample has obvious grain contrast and clear grain boundary line, and at the same time, the defects of under-corrosion and over-corrosion can be avoided. The corrosion solution can rapidly and efficiently corrode the metallographic structure of the sample.

Owner:JINCHUAN GROUP LIMITED

High-temperature alloy base self-lubricating composite material and surface pattern treatment method thereof

InactiveCN101078072AExtended service lifeReduce coefficient of frictionBearing componentsLaser beam welding apparatusSurface patternSuperalloy

A kind of high temperature alloy group self-lubricating compound material and the method to pattern surface of it. The components and the mass percent of them are as following: Ni: 28.8-56.8%, Fe: 10.0-30.0%, Cr: 7.2-14.2%, W: 5.0- 15.0%, C: 3.0-6.0%, Si: 0.8%-1.2%, MoS2: 5.0%-15.0%. The method to pattern it' s surface contains the following steps: The surface of the nickel chromium alloy group self-lubricating compound material sample after being hot pressed and mould will be polished. A gammaray laser will be used to corrase micropore on the surface, the focus of the focusing lens will be adjusted to 40-60mm, the facula diameter at the focus is 0.15- 0.20mm, the impulse duration will be adjusted to 450-500ns, the laser bean will process micropore according to ring shape from outside to inside. The surface after being corrased and polished will be lubricated by daubing the fat of solid layered dry lubricant. The alloy group material not only owns high mechanical strength but also owns high temperature self-lubricating ability. The coefficient of friction can be decreased, the application life can be prolonged, and low attrition abrasion in wide temperature range can also be realized by patterning the surface.

Owner:NANJING UNIV OF SCI & TECH

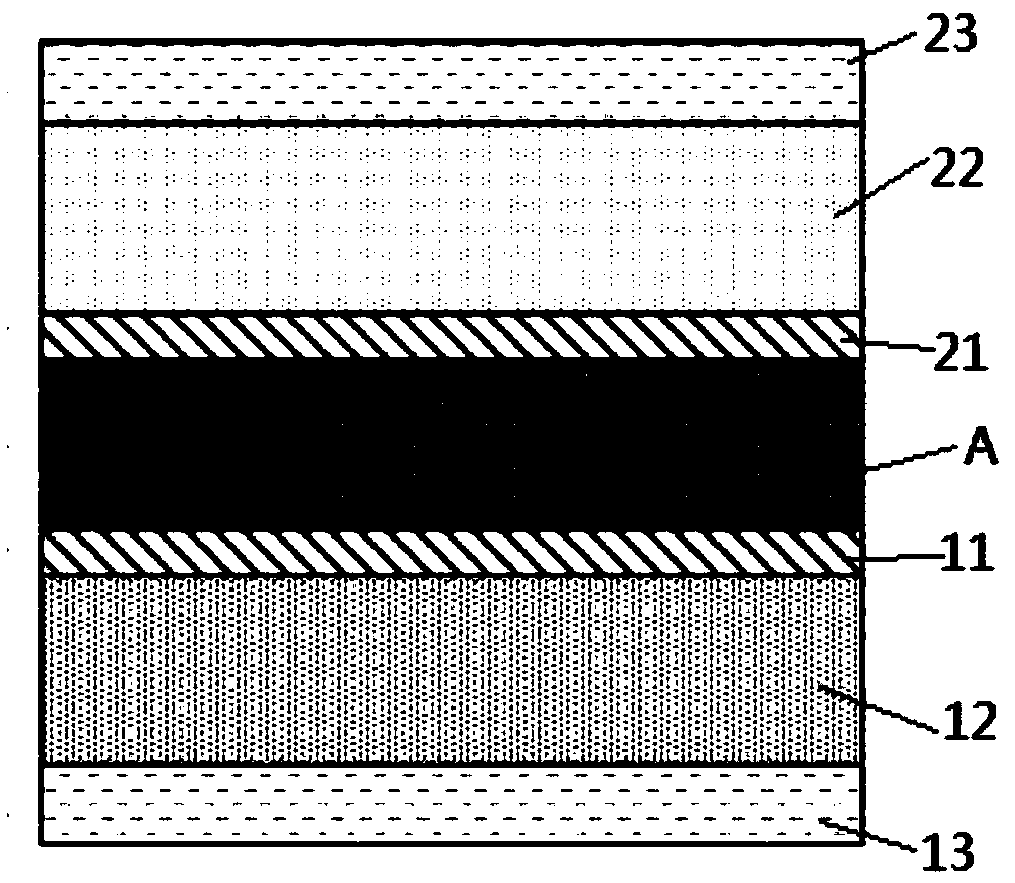

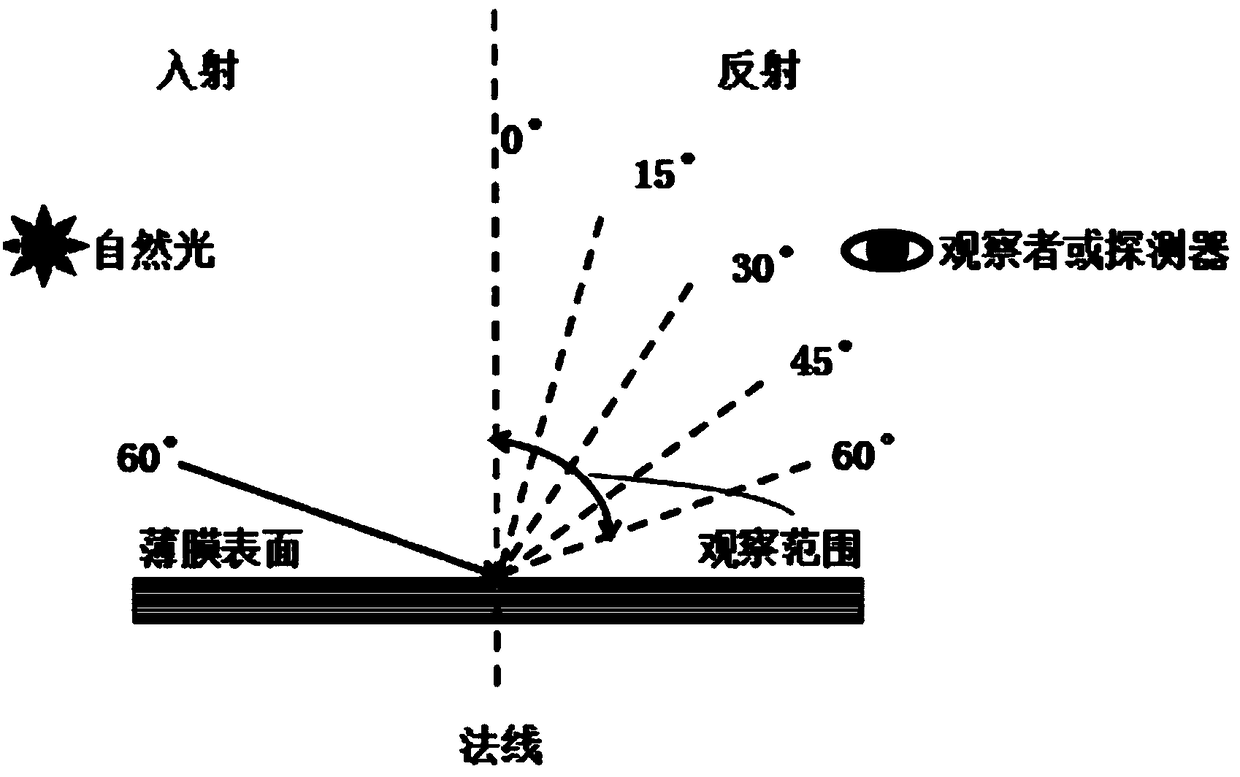

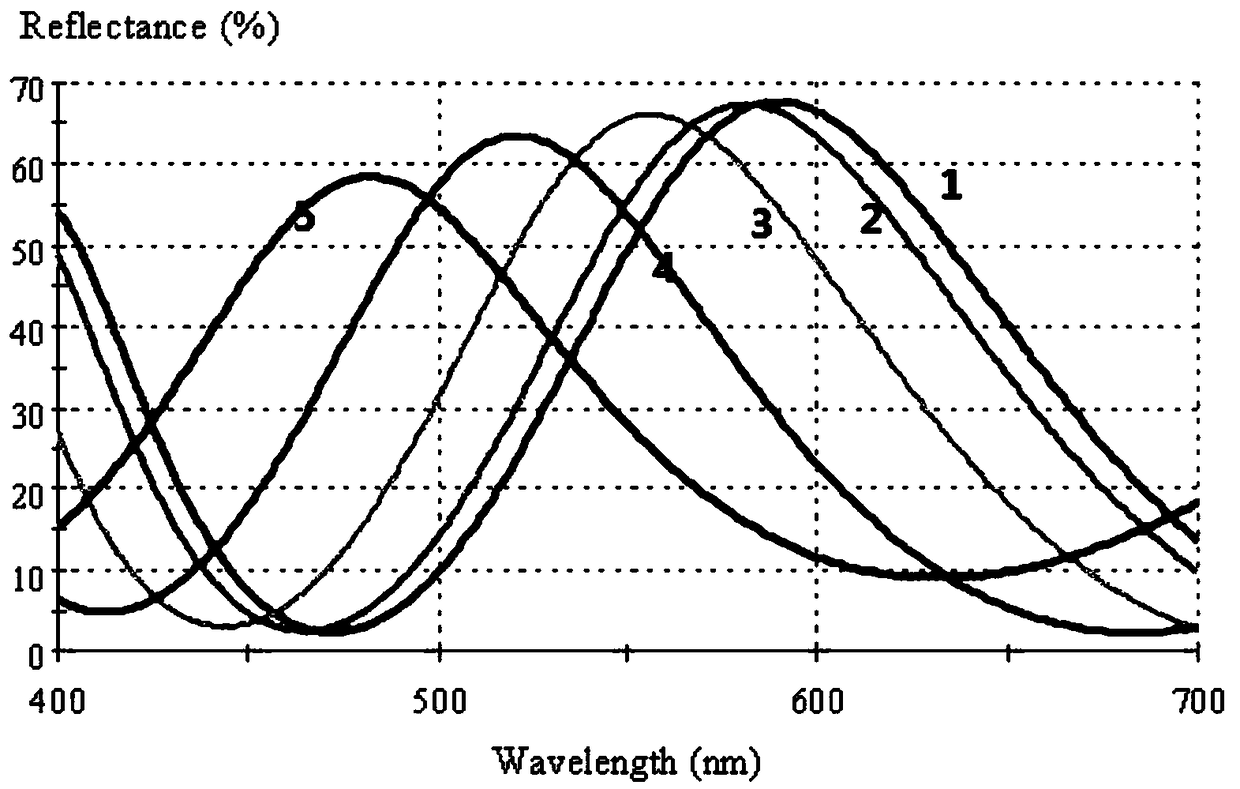

Multi-layered magnetic thin film pigment chip and preparation method thereof

InactiveCN108922776AImprove compactnessFast formingConductive/insulating/magnetic material on magnetic film applicationMagnetic film to substrate applicationNickel chromium alloyCobalt nickel alloy

The invention relates to a multi-layered magnetic thin film and pigment chips thereof, in particular to a multi-layered magnetic thin film pigment chip. The multi-layered magnetic thin film pigment chip comprises a magnetic reflection layer, one side of the magnetic reflection layer sequentially comprises a first adhesion layer, a first medium layer and a first absorption layer; the other side ofthe magnetic reflection layer sequentially comprises a second adhesion layer, a second medium layer and a second absorption layer; the first adhesion layer and the second adhesion layer are located onthe end faces of the two sides of the magnetic reflection layer respectively; the thin film pigment chip is of a symmetrical structure; and the first adhesion layer and the second adhesion layer areboth made of an elemental chromium metal material. The invention further provides a method used for preparing the multi-layered magnetic thin film pigment chip. The multi-layered magnetic thin film pigment chip adopts nickel monomer as the magnetic reflection layer, the reflection rate is higher than nickel-chromium alloys and cobalt-nickel alloys, the film layer stability is improved greatly, andthe optical effect is not affected.

Owner:广东晟铂纳新材料科技有限公司

Preparation method of high-resistance electrothermal alloy wire

InactiveCN104630564AEasy to organizeImprove plasticityFurnace typesHeat treatment process controlElectrical resistance and conductanceNickel chromium alloy

The invention discloses a preparation method of a high-resistance electrothermal alloy wire, and relates to the iron chromium aluminum alloy processing and manufacturing field. The preparation method includes five technological processes of blank preparation, annealing treatment, alkali washing, cleaning and wiredrawing treatment; in the annealing treatment process in the preparation method, through strict control of the heating temperature and the holding time of a box type resistance furnace, the internal organization of a nickel-chromium alloy wire is improved, the plasticity is increased, and the subsequent drawing technology is facilitated; in the alkali washing process, through well control of the temperature and time of alkali washing, an oxidation film of the surface of the nickel-chromium alloy wire is removed relatively thoroughly, the impurity residual amount is precious little, and the surface is smooth; and the nickel-chromium alloy wire prepared by the preparation method has high-temperature oxidation resistance greatly improved, has the advantages of high electrical resistivity, high mechanical strength under high temperature conditions, long service life, simple production process, and easy realized automation production.

Owner:DANYANG ZHISHENG ALLOY

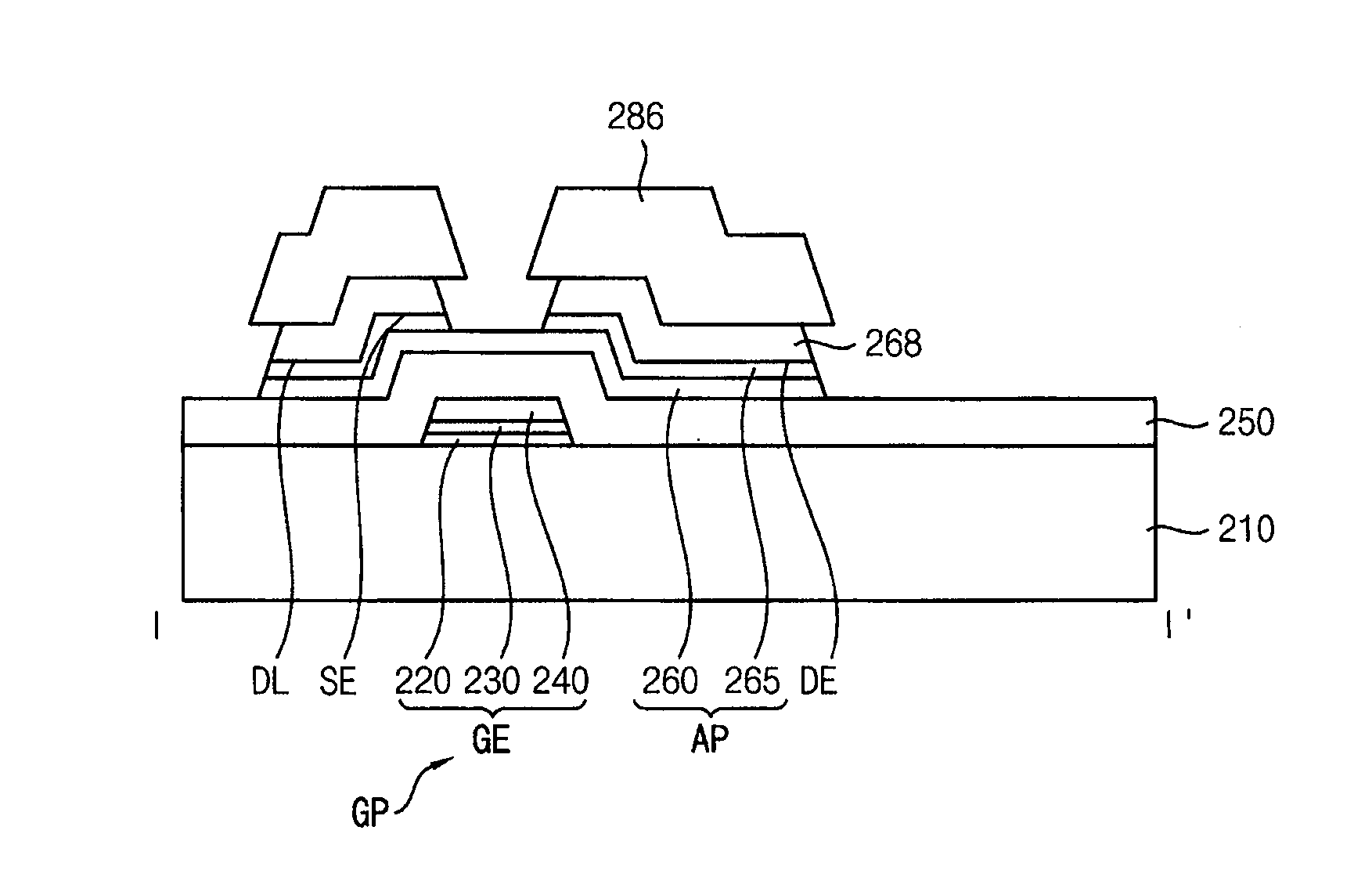

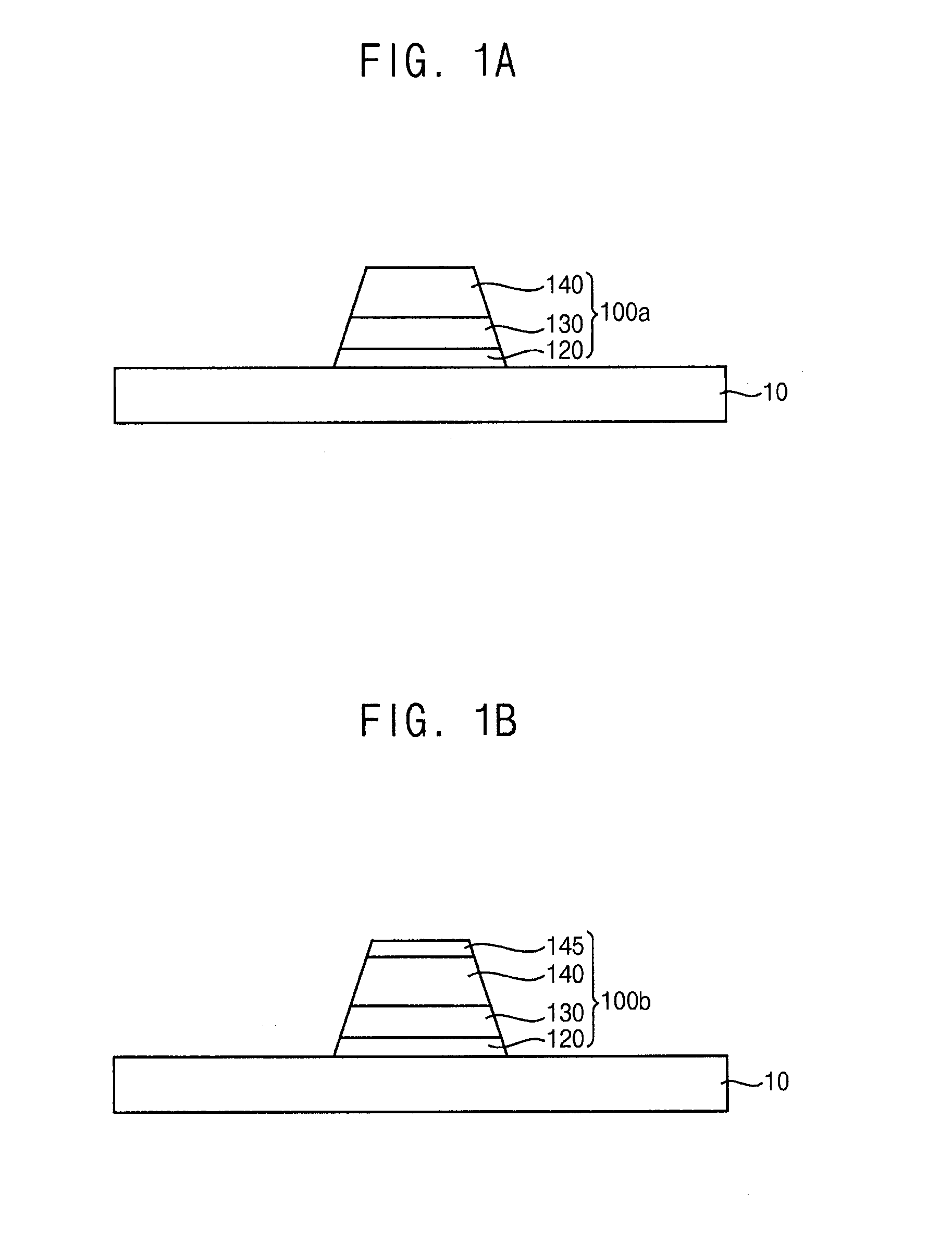

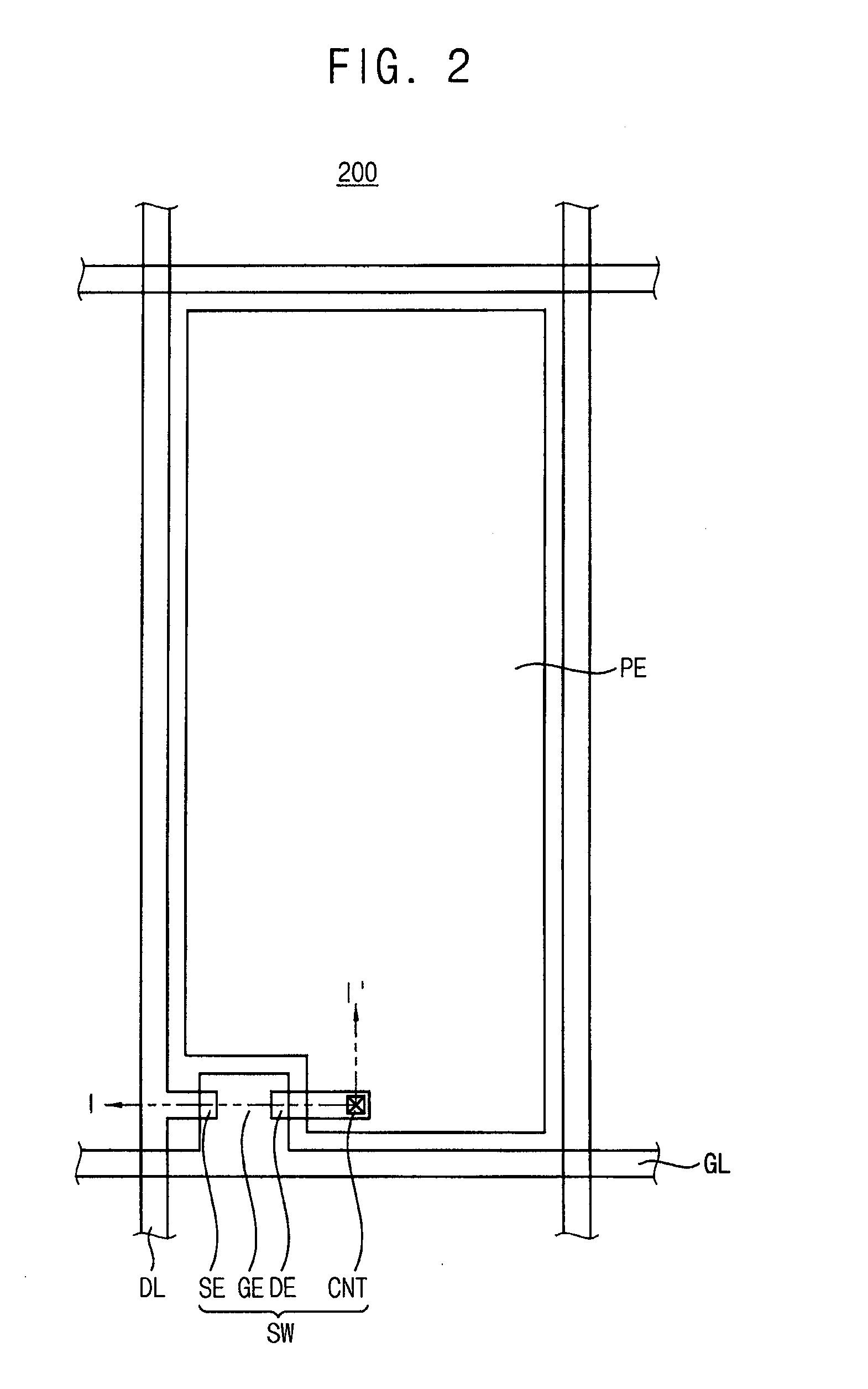

Metal wire, thin-film transistor substrate and method for manufacturing a thin-film transistor substrate

ActiveUS20150091004A1Reduce reflectivityImprove production efficiencyTransistorSolid-state devicesNickel chromium alloyDisplay device

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

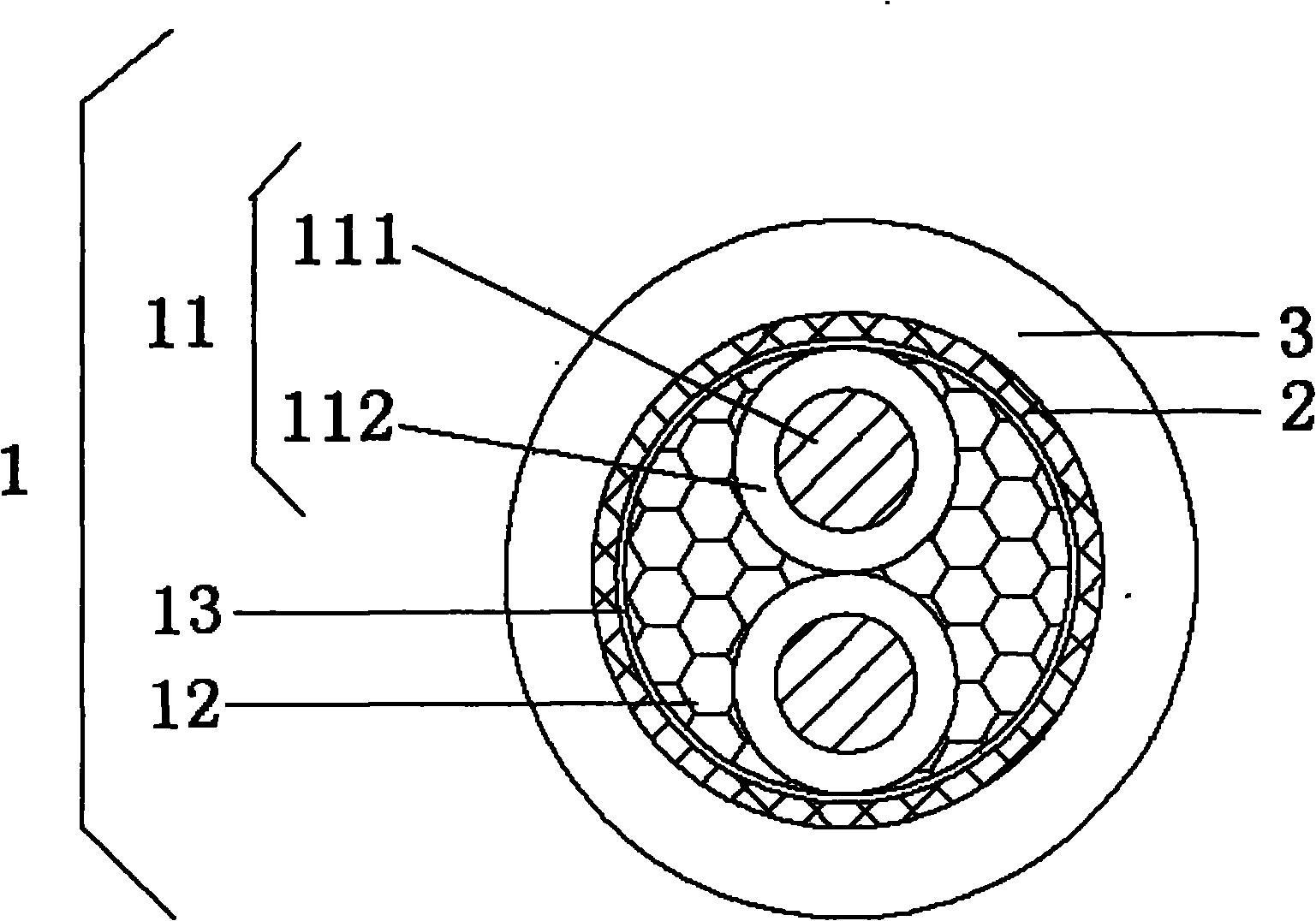

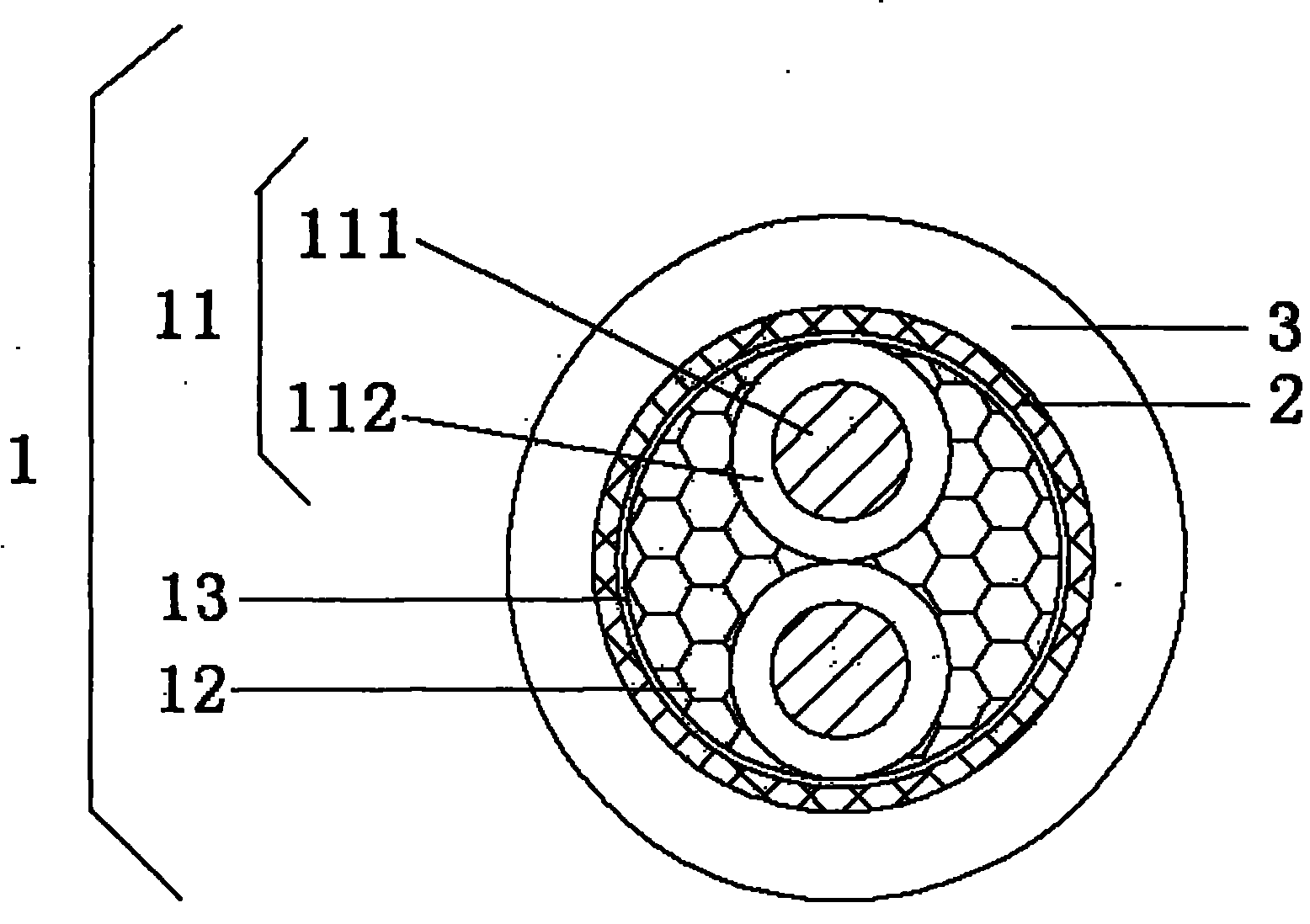

Thermotolerant corrosion-resistant flexibility-resistant cable

InactiveCN102081999AEnvironmentally friendlyImprove flex resistanceNon-insulated conductorsFlexible cablesElectrical conductorNickel chromium alloy

The invention relates to a thermotolerant corrosion-resistant flexibility-resistant cable belonging to the technical field of special cables and comprising a cable core, a shielding layer and an outer sheath, wherein the shielding layer is arranged outside the cable core, the outer sheath is arranged outside the shielding layer, the cable core comprises a lead, a filler and a wrapping layer, and the lead comprises a conductor and an outer coating layer coated outside the conductor. The thermotolerant corrosion-resistant flexibility-resistant cable is characterized in that the filler is aramid fiber and surrounds the lead; the conductor is formed by stranding nickel-chromium alloy wires or nickel-aluminum alloy wires; the outer coating layer and the wrapping layer are both Teflon; and the outer sheath is irradiation crosslinking fluorubber. The thermotolerant corrosion-resistant flexibility-resistant cable has ideal beading resistance and excellent performances of high-temperature resistance, chemical corrosion resistance and radioactive ray resistance and also has a feature of environmental protection.

Owner:SUZHOU CABLEPLUS PHOTOELECTRIC TECH

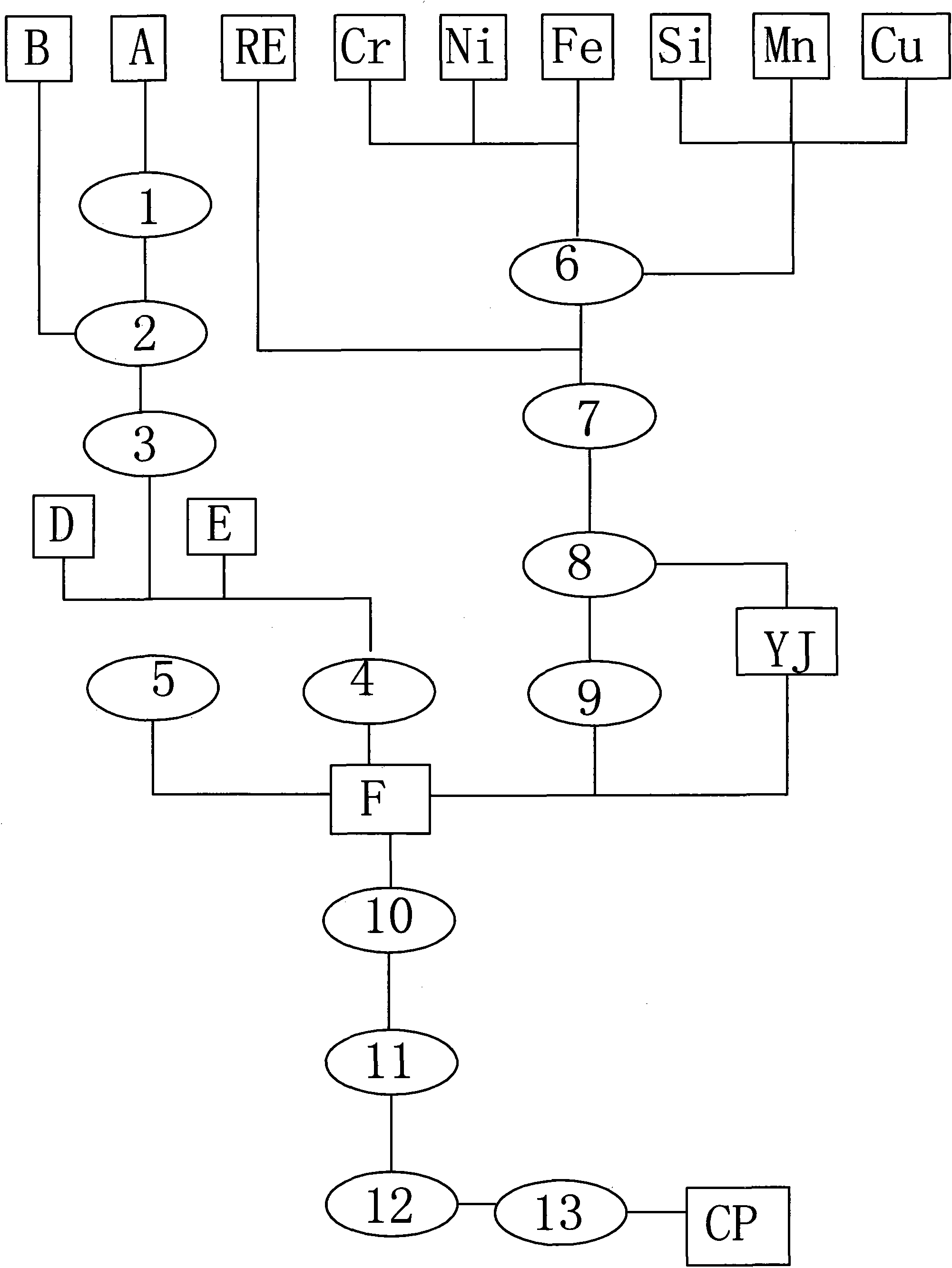

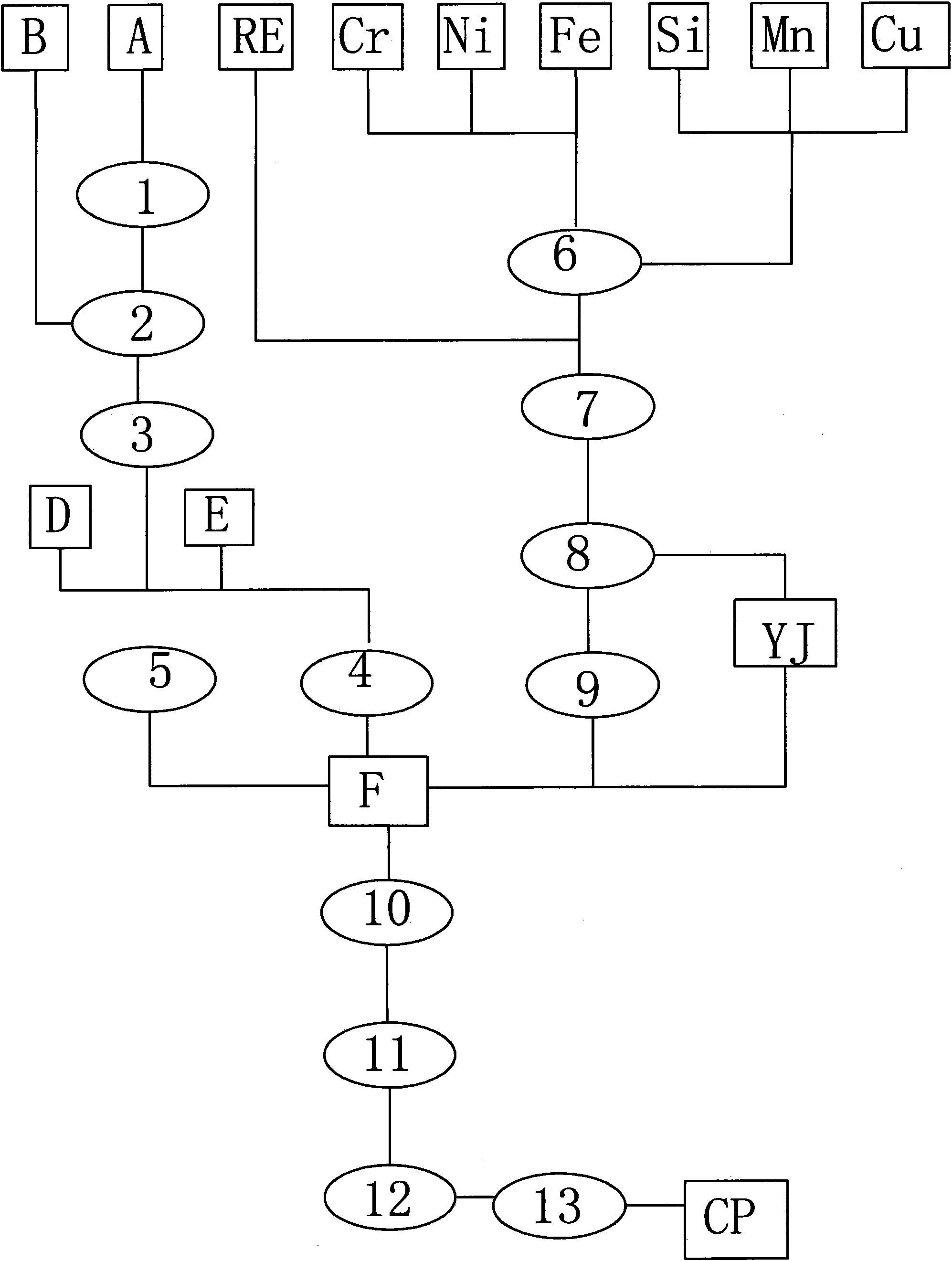

Process for wear-resistant treatment of valve core of instrument valve

ActiveCN103643194AImprove corrosion resistanceImprove wear resistanceMolten spray coatingHeat inorganic powder coatingChemical compositionNickel chromium alloy

The invention discloses a process for wear-resistant treatment of a valve core of an instrument valve. A method for coating a nickel-chromium alloy coating on the valve core comprises the steps of (1) preparing nickel-chromium alloy powder comprising the following chemical components in percentage by weight: 0-3.8% of Re, 45-50% of Ni, 20-30% of Cr, 1.6-5.6% of Si, 0.5-4% of C, 10-20% of Fe, 1.2-8.4% of Cu and 1-2.2% of composite rare earth; (2) washing the processed valve core, then drying the valve core in drying equipment, then putting the valve core into spraying equipment, uniformly spraying tiny sand grains on the surface of the valve core by using a spray gun at first, and then uniformly spraying the nickel-chromium alloy powder on the surface of the valve core by using the spray gun; (3) cooling the valve core to the room temperature in a first cooling process, and then cooling the valve core to the room temperature in a second cooling process; (4) inspecting the cooled valve core and putting the cooled valve core in storage. The process disclosed by the invention improves the wear resistance, corrosion resistance and the like of the valve core.

Owner:镇江市华阳机电制造有限公司

Nickel-chromium alloy electroplate liquid

The invention relates to nickel-chromium alloy electroplate liquid. A liter of the electroplate liquid comprises from 25g to 35g of nickel sulfate hexahydrate, from 80g to 100g of chromium trichloride hexahydrate, from 30ml to 40ml of formic acid, from 20g to 30g of boric acid, from 1g to 60g of urea, from 30g to 80g of ammonium chloride, from 40g to 60g of potassium chloride, from 30g to 60g of critic acid, from 0.1g to 0.12g of sodium dodecyl sulfate, from 1.5g to 2.5g of saccharin, from 2ml to 4ml of nickel plating brighteners and the balance water. The urea is used as a coordination additive, and the performance of the electroplate liquid is greatly improved, so that behaviors of electrodes, the covering power and the dispersing power of a cathode and the stability, the coating performance and the contamination status of the electroplate liquid are greatly improved.

Owner:LUDONG UNIVERSITY

Preparation method of electromagnetic shielding material, electromagnetic shielding material and applications thereof

InactiveCN103114457AOvercome resourcesOvercoming processingPhysical treatmentDry-cleaning apparatus for textilesChemical platingElectromagnetic shielding

The invention discloses a preparation method of an electromagnetic shielding material, an electromagnetic shielding material and applications thereof. The method comprises the following steps: carrying out pretreatment and drying treatment on a fabric, and sputtering nickel or copper or nickel chromium alloy metals with a certain thickness on the fabric subjected to pretreatment by using a magnetron sputtering device under vacuum conditions; carrying out electro-coppering on the fabric by using a copper pyrophosphate coppering process, and simultaneously carrying out multi-stage water washing, drying treatment and winding on the fabric subjected to coppering; and carrying out electro-nickelling, nickel-cobalt alloying or ferro-nickel alloying on the fabric, and then carrying out multi-stage water washing, drying treatment and winding on the fabric, thereby completing the preparation of an electromagnetic shielding material. According to the scheme, a method of combining magnetron sputtering with electroplating is adopted, so that the problems that independent chemical plating is high in production cost and wastes water and wastewater caused by chemical plating is difficult to treat are solved; the method can carry out continuous production, thereby being more suitable for mass production. An electromagnetic shielding material prepared by using the method disclosed by the invention can be widely applied to the industries such as electronics, communications, textile and garment, construction, medical equipment, military projects, aerospace and the like.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

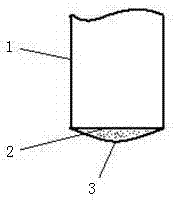

Corroding method for metallographic specimen of high nickel-chromium alloy

InactiveCN104502173ADisplay clearThe display method is clearPreparing sample for investigationNickel chromium alloyMaterials science

The invention discloses a corroding method for a metallographic specimen of a high nickel-chromium alloy. The method comprises the following steps: soaking a pretreated metallographic specimen in a corrosive liquid with a corrosive face facing downward; and slowly lifting up the specimen above the liquid level of the corrosive liquid, wherein the peak of a corrosive drop on the corrosive face is contacted with the liquid level of the corrosive liquid. The display method of the metallographic structure of the alloy specimen provided by the invention is suitable for high nickel-chromium alloy which is hard to corrode by conventional methods. By selecting a proper corrosive liquid, the high nickel-chromium alloy specimen is corroded by virtue of the method disclosed by the invention, so that surface passivation of the corrosive face of the specimen can be eliminated. The corrosive degree can be controlled, the metallographic structure is clearly displayed and the operating method is simple and convenient.

Owner:JINCHUAN GROUP LIMITED

Technology for depositing titanium nitride film on surface of 4Cr13 stainless steel vernier caliper

InactiveCN103628024AHigh strengthHigh hardnessVacuum evaporation coatingSputtering coatingNickel chromium alloyTitanium nitride

The invention discloses a technology for depositing a titanium nitride film on the surface of a 4Cr13 stainless steel vernier caliper. The technology comprises the steps of cleaning the surface of the 4Cr13 stainless steel vernier caliper in a physical way and a chemical way; then, depositing pure metal or an alloy with the thickness of 0.1-0.5 micron on the surface of the 4Cr13 martensitic stainless steel vernier caliper as a transition layer by an arc ion plating, ion sputtering plating or radio frequency (RF) sputtering plating technology, wherein the transition layer can be made of pure titanium, pure nickel, pure copper, pure molybdenum, pure chromium or the like, and the alloy can be an iron-carbon alloy, a tungsten-molybdenum alloy, a nickel-chromium alloy or the like; and filling reactant gases including nitrogen and argon in a certain ratio to obtain the hard titanium nitride film with the deposition thickness of 0.5-1 micron. The titanium nitride film deposited on the surface of a tool such as the vernier caliper is high in strength and hardness, and has corrosion-resistant and wear-resistant properties and a good visual effect.

Owner:GUILIN GUANGLU MEASURING INSTR

Nickel-chrome alloy coating for ceramic and preparation method thereof

The invention discloses a nickel-chrome alloy coating for ceramic and a preparation method thereof. The nickel-chrome alloy coating for ceramic comprises the following components in percentage by mass: 12.2% to 12.5% of dravite, 7.2% to 7.5% of phyllite, 3.5% to 3.8% of calcium oxide, 0.2% to 0.5% of quartz, 6.5% to 6.8% of zinc oxide, 1.5% to 1.8% of manganese dioxide, 3.6% to 3.8% of rutile, 3.2% to 3.8% of kaolinite, 5.5% to 5.8% of chromium powder, 3.6% to 4.2% of nickel powder, 0.8% to 1.2% of copper powder, 7.2% to 7.5% of additive, 1.7% to 1.9% of barium carbonate and the balance of clay.

Owner:SUZHOU TONGMING MACHINERY

Aluminium alloy and aluminium alloy profile

InactiveCN103290269AHigh strengthAdapt to high-strength welding requirementsLiquid surface applicatorsCoatingsNickel chromium alloyNichrome

Owner:广东兴裕铝业有限公司

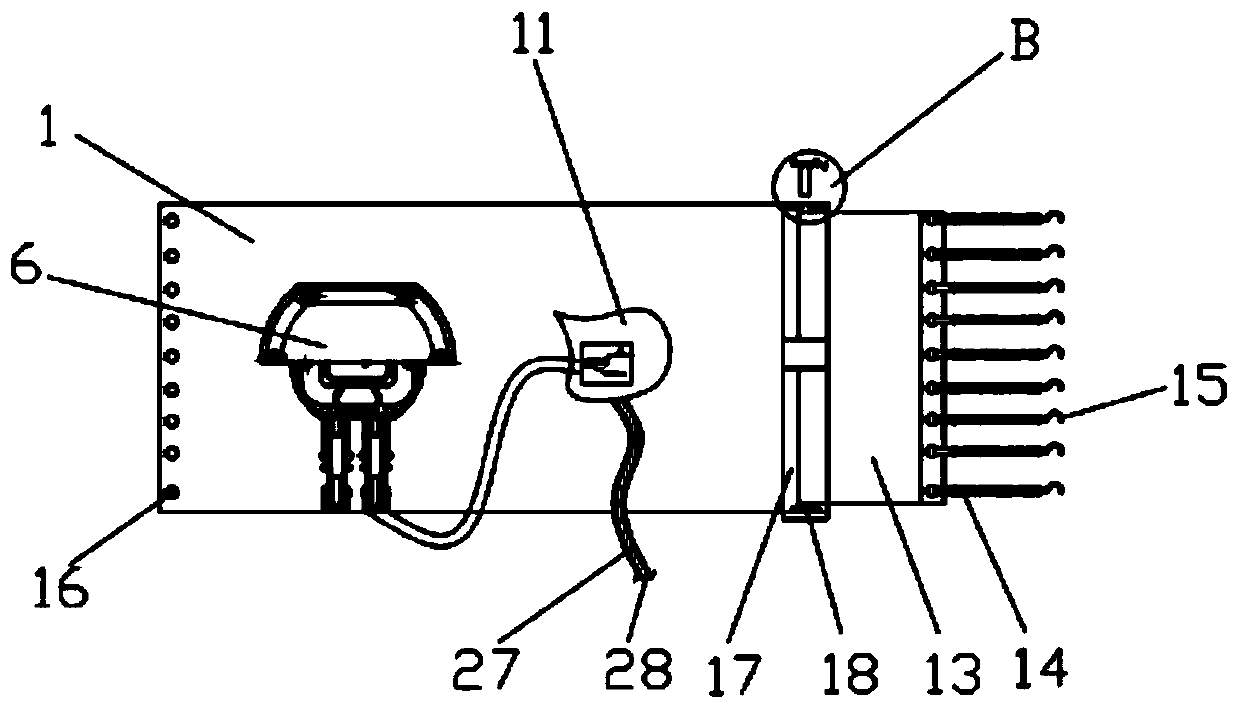

Neutral-point grounding resistance cabinet

InactiveCN104124677APlay the role of current limiting and stepping downSuppression of resonance overvoltageEmergency protective arrangements for limiting excess voltage/currentCurrent limitingNickel chromium alloy

The invention discloses a neutral-point grounding resistance cabinet, and relates to a resistance cabinet. The neutral-point grounding resistance cabinet comprises a cabinet body, nickel-chromium alloy resistors, horizontal insulators, vertical insulators, support insulators, a support and a voltage transformer, wherein the support is arranged in the cabinet body; a grounding connection hole is formed in a cabinet bottom below the support; three rows of the nickel-chromium alloy resistors are arranged on the support through the support insulators; the both ends of each of the nickel-chromium alloy resistors are fixed on side plates through the horizontal insulators; the adjacent nickel-chromium alloy resistors are insulated and fixed through a plurality of the vertical insulators; the nickel-chromium alloy resistors are further connected with the voltage transformer. The neutral-point grounding resistance cabinet disclosed by the invention is good in insulativity, high in safety, capable of avoiding the occurrences of accidents, and capable of playing current-limiting and voltage-dropping roles in case of a grounding fault.

Owner:安徽恒凯电力保护设备有限公司

Treatment process for improving corrosion resistance of bearing

ActiveCN104195570AHigh strengthHigh hardnessMolten spray coatingFurnace typesNickel chromium alloyNichrome

The invention discloses a treatment process for improving corrosion resistance of a bearing. The treatment process comprises the following steps: (1) preparing a nickel-chromium alloy coating; (2) feeding the bearing into a heating furnace, heating to 1100-1200 DEG C, rapidly cooling the bearing to be 520-550 DEG C through a first cooling procedure, spraying the nickel-chromium alloy coating on the surface of the bearing under the condition that the thickness is 0.06-0.09mm, putting the bearing into the hearting furnace, rapidly heating to be 1000-1050 DEG C, keeping the temperature for 30-35 minutes, and finally cooling to the room temperature through a second cooling procedure; (3) tempering the bearing; (4) performing normalization once, tempering once and surface high-frequency quenching once on the bearing; and (5) detecting the flaws by using ultrasonic waves, and washing and packaging after the bearing is qualified. By adopting the treatment process, the corrosion resistance of the bearing is improved, the oxidation resistance and wearing resistance of the bearing are also improved, and thus the service life of the bearing is prolonged.

Owner:南京创贝高速传动机械有限公司

Flexible alloy and preparation method thereof

The invention discloses a flexible alloy. The flexible alloy is made by melting the following ingredients in parts by weight: 20-30 parts of cobalt-chromium alloy, 4-6 parts of gold alloy, 30-35 parts of aluminum-manganese alloy, 40-50 parts of nickel-chrome alloy, 12-18 parts of PVC / ABS blend resin. A preparation method of the flexible alloy is also provided. The invention has the benefits that: according to the flexible alloy and preparation method thereof provided by the invention, the impact of ambient temperature changes on the alloy body of the prepared flexible alloy can be effectively reduced, the toughness of the alloy is increased, and the flexible alloy is applicable to the aerospace field. The factory experiments show that the rate of toughness change of the flexible alloy is less than or equal to 5% under high- / low-temperature conditions.

Owner:WUXI YANGGONG MACHINERY MFG

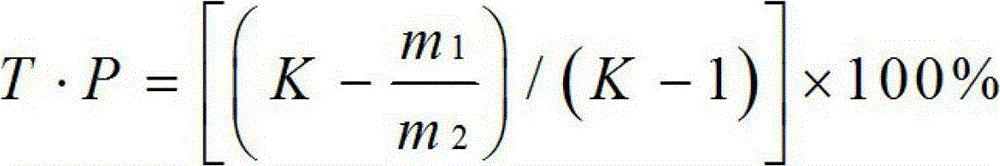

GST high strength toughness seawater corrosion resistant iron casting and its production method

The invention relates to a GST high strength toughness sea water corrosion resistant iron casting which is a low nickel chromium alloy iron casting, comprising a seawater or sewage waterborne engineering gate, a gate slot embedded part, parts such as trash screens, a seawater or sewage pump housing, an impeller, conveying pipelines, a pipe fitting, a valve and the like. The tensile strength of the iron casting is greater than or equal to 450MPa, its elongation percentage is greater than or equal to 5% and its corrosion speed in seawater is less than or equal to 0.10mm / a; The mass percent of iron casting alloy elements is as follows: 2.80-3.60 of C, 1.60-2.60% of Si, 0.40-1.2% of Mn, 0.80-1.8% of Cr, 0.8-3.2% of Ni, 0.6-1.5% of Cu and the balance being Fe. According to the invention, technologies of intermediate frequency induction furnace melting, compound reinforced inoculation and lost foam casting are adopted to obtain the GST high strength toughness seawater corrosion resistant iron casting with uniform chemical component and microstructure as well as excellent mechanical properties.

Owner:周传禄

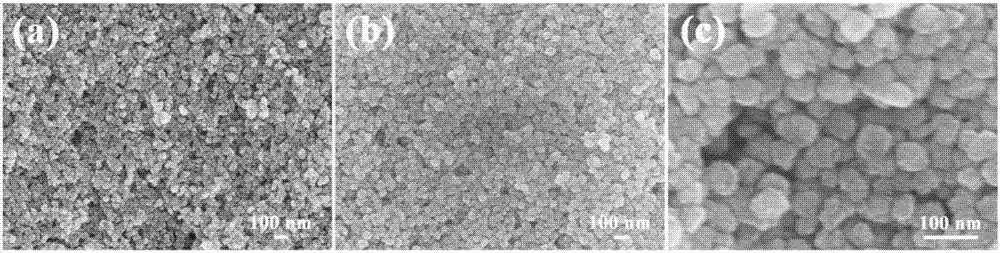

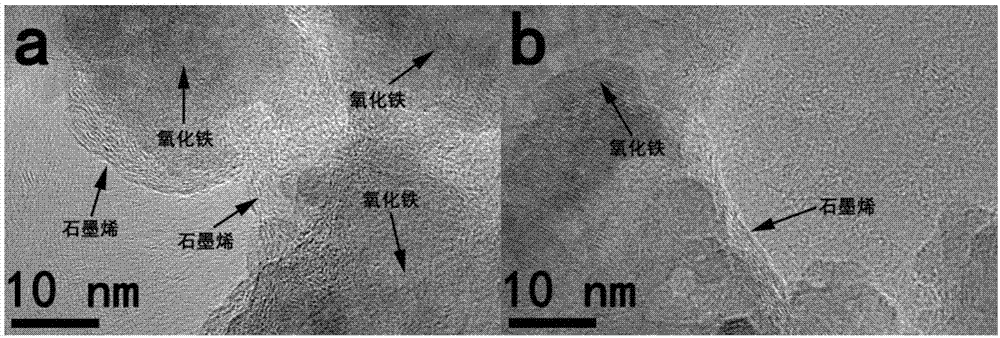

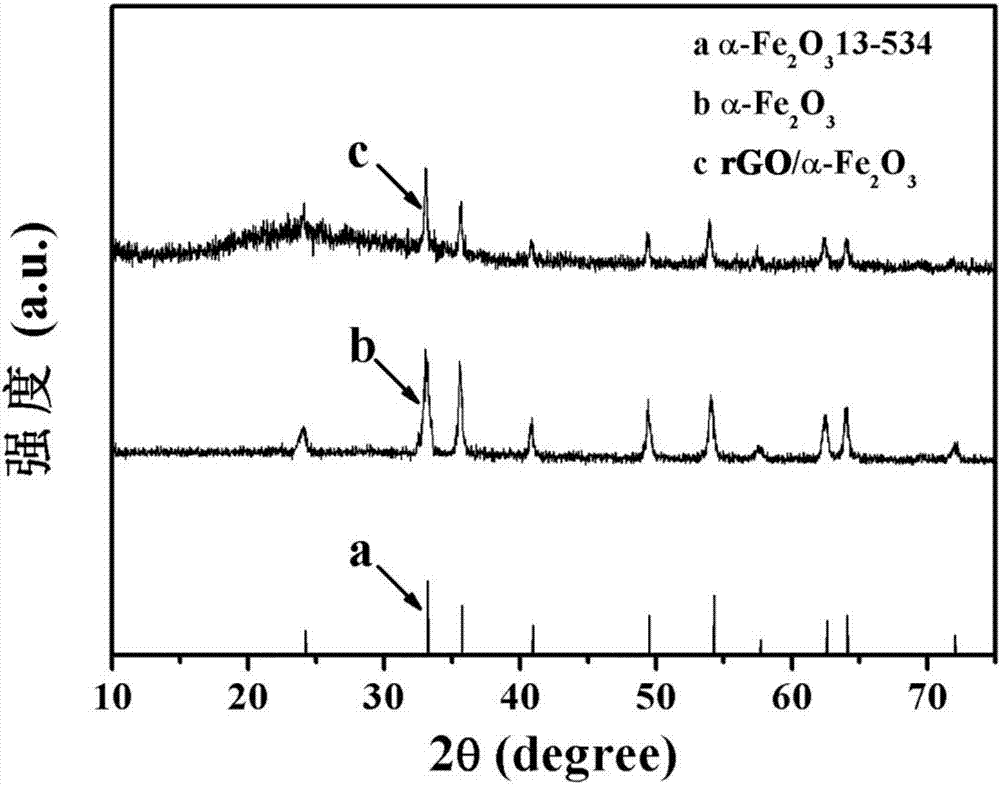

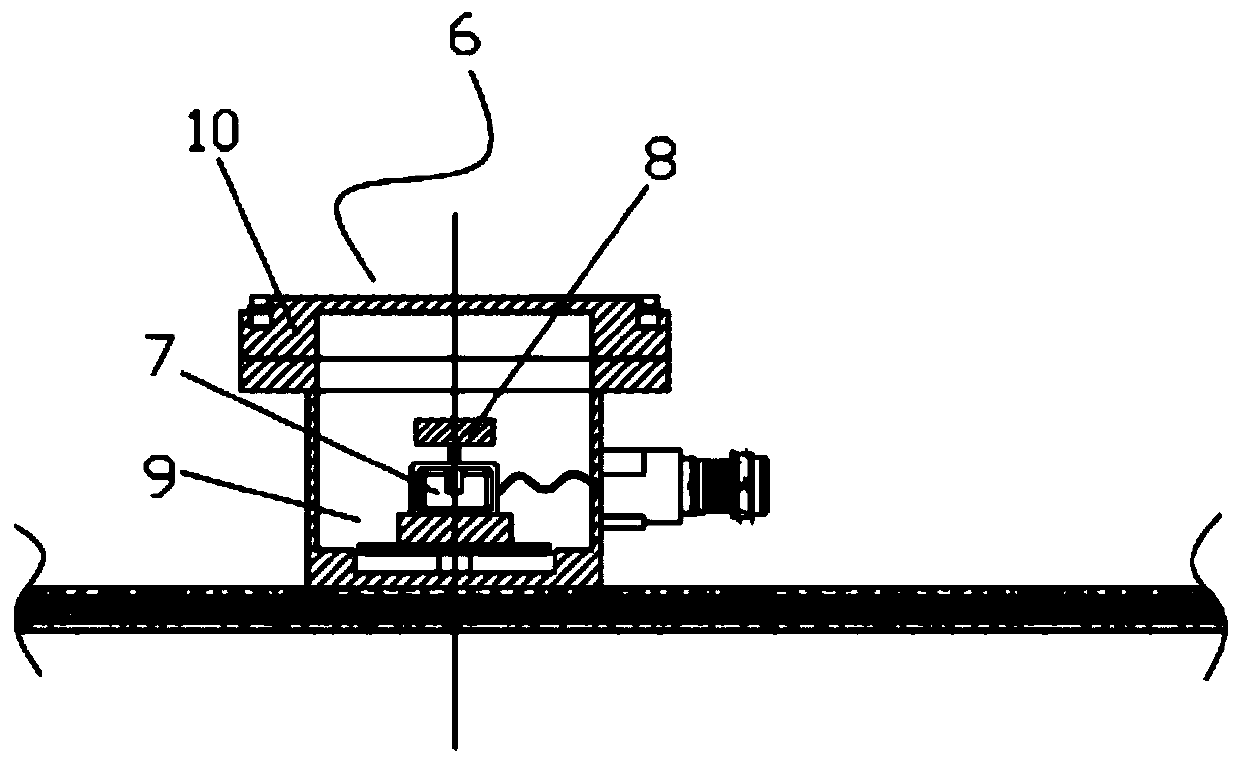

Room-temperature NO2 sensor based on graphene-coated alpha-Fe2O3 compound and preparation method thereof

InactiveCN107966480AThe synthesis method is simpleLow costMaterial resistanceHeterojunctionChemical reaction

The relates to a room-temperature NO2 sensor based on graphene-coated alpha-Fe2O3 compound and a preparation method thereof, which belong to the technical field a semiconductor metal oxide gas sensor.The sensor comprises a sold Al2O3 insulation ceramic tube having two annular gold electrodes, a semiconductor sensitive material coating the annular gold electrode and the Al2O3 insulation ceramic tube, and a nickel-chromium alloy heating coil passing through the Al2O3 insulation ceramic tube. The graphene-coated alpha-Fe2O3 compound sensitive material is obtained by water bath and a hydrothermalmethod, a high specific surface area of graphene, gas adsorption capability, a fast carrier migration rate and good conductivity, and heterojunction formed between graphene and the alpha-Fe2O3 are used, so that a chemical reaction of the surface of detected gas is increased, charge transfer between rGO and alpha-Fe2O3 is formed, sensitive characteristic of the sensor on NO2 is effectively increased, work temperature of the sensor is reduced to room temperature, and the sensor has a wide application prospect on the NO2 content aspect in detection microenvironment.

Owner:JILIN UNIV

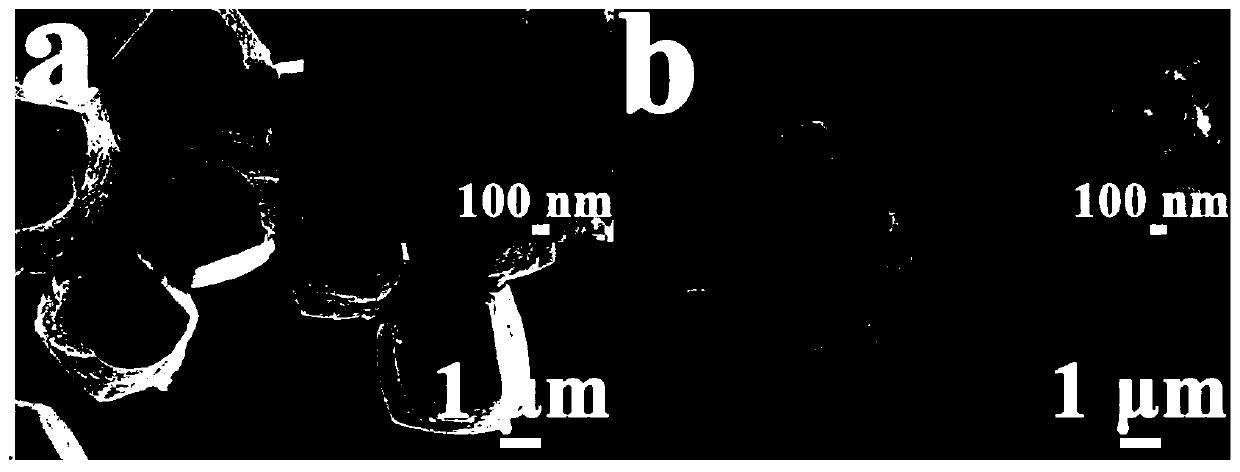

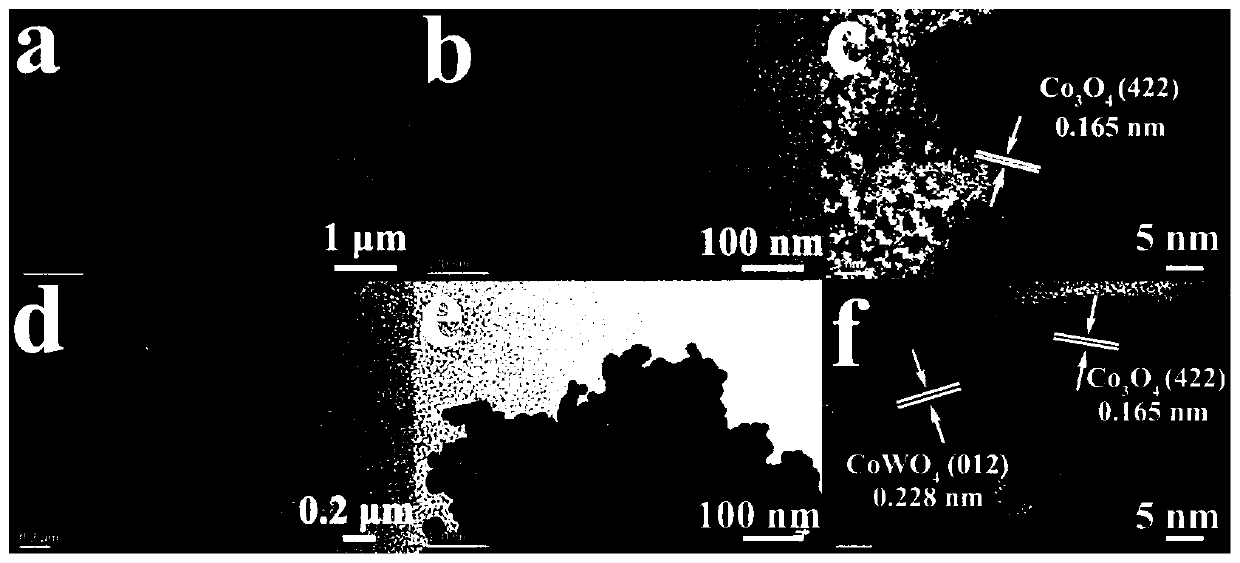

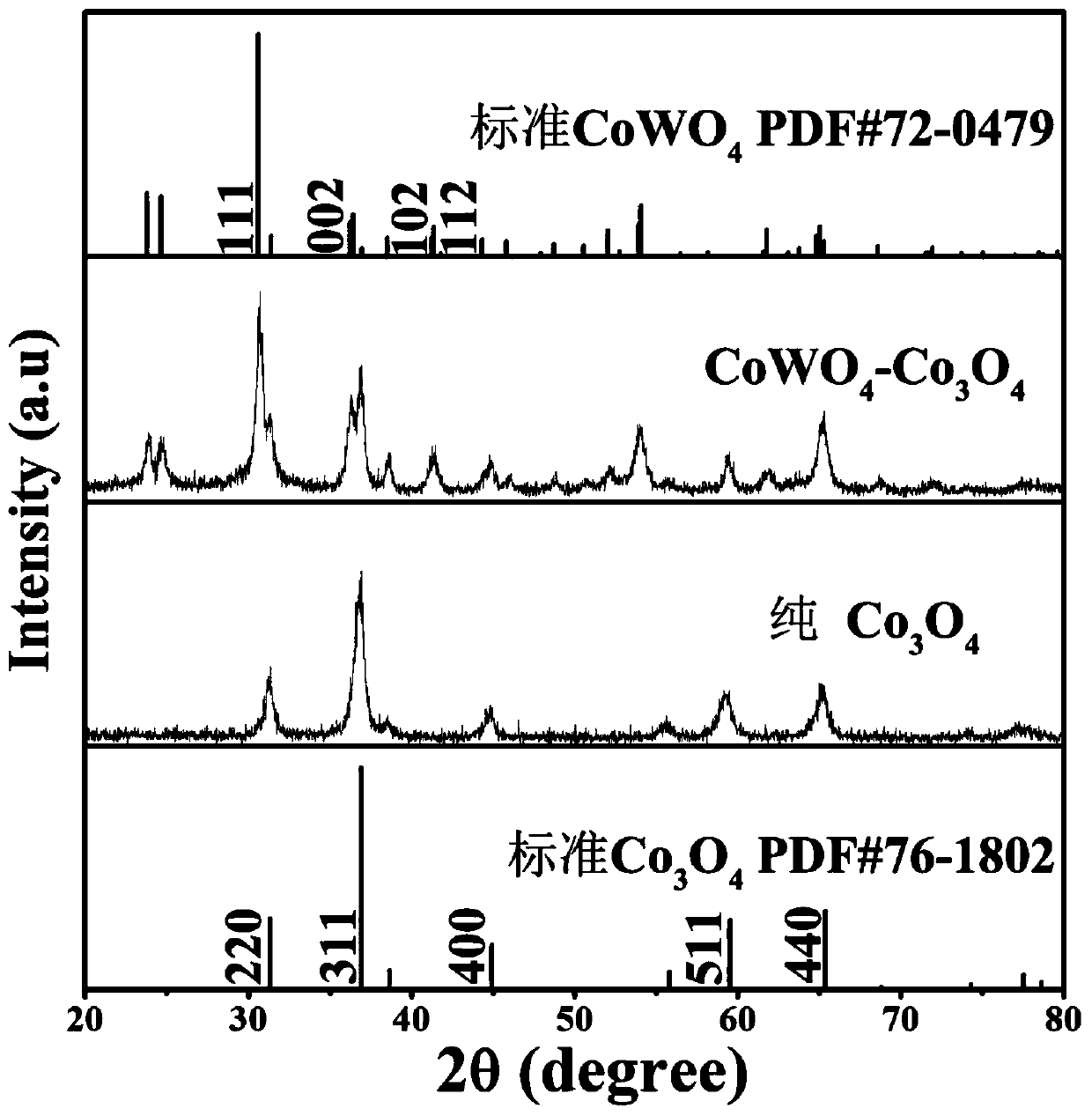

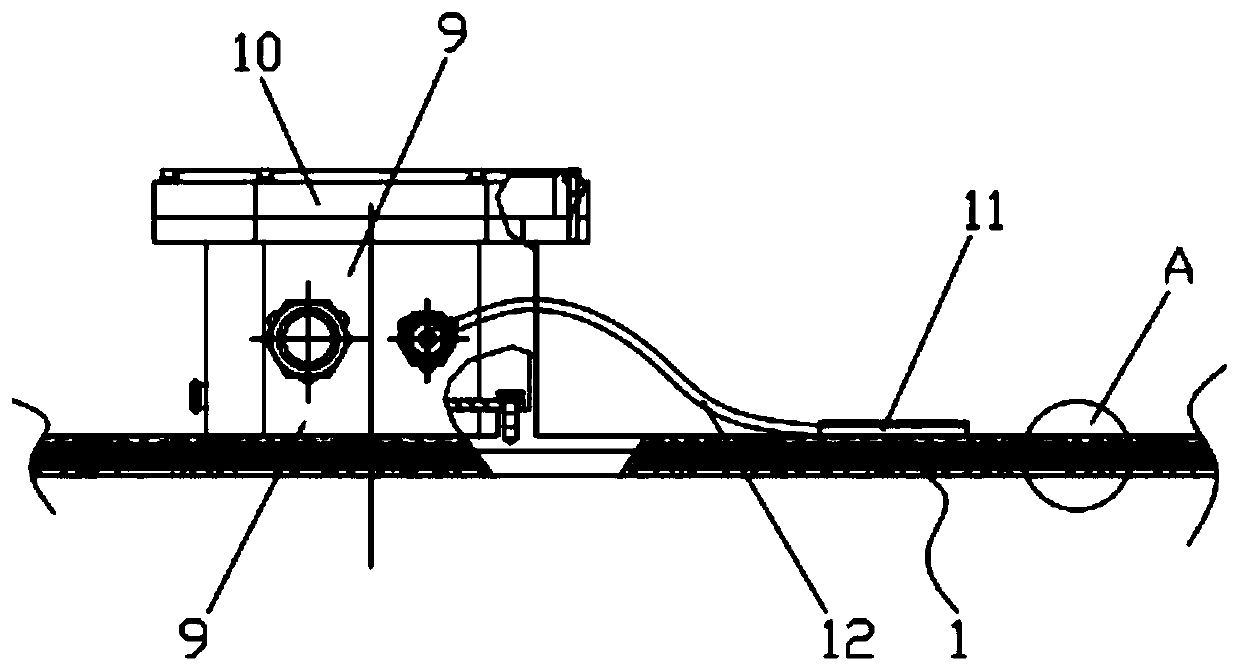

Xylene gas sensor based on CoWO4-Co3O4 heterojunction nanostructure sensitive material, and preparation method thereof

ActiveCN110455891ASignificant change in resistanceHigh catalytic oxidation activityMaterial electrochemical variablesHeterojunctionLower limit

The invention discloses a xylene gas sensor based on a CoWO4-Co3O4 heterojunction nanostructure sensitive material, and a preparation method thereof, belonging to the technical field of semiconductoroxide gas sensors. The xylene gas sensor is composed of an Al2O3 insulating ceramic tube with two ring-shaped gold electrodes, a semiconductor sensitive material spread on the ring-shaped gold electrodes and the ceramic tube and a nickel-chromium alloy heating coil passing through the ceramic tube. The CoWO4-Co3O4 heterojunction nanostructure sensitive material used for the xylene gas sensor provided by the invention is prepared through a simple hydrothermal method, a P type Co3O4 semiconductor sensitive material is modified through formation of a heterojunction, and thus, greater leap of gassensitivity is realized. The sensor has excellent sensitivity (51.6-100ppm) and lower detection lower limit (0.3ppm) to the xylene. The xylene gas sensor can be prepared through simple technologies, is small in size and suitable for being produced in large batches, and has wide application prospect in the aspect of detection of xylene pollutant in a microenvironment.

Owner:JILIN UNIV

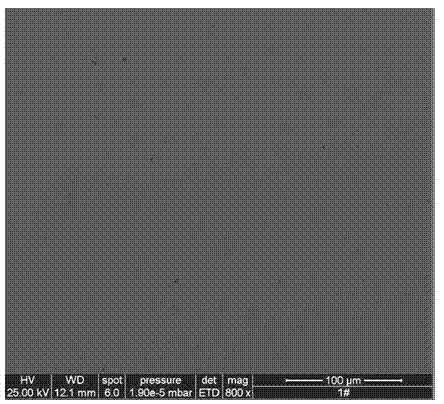

Preparation method of nanocrystal iron-nickel-chromium alloy foil by electrodeposition

InactiveCN102839399ALow priceFine and dense grainElectroforming processesElectrodesElectromechanicsNickel chromium alloy

The invention discloses a preparation method of a nanocrystal iron-nickel-chromium alloy foil by electrodeposition, belonging to the field of electrodeposition alloys. The electrochemical deposition method is implemented by carrying out electrodeposition in a sulfate-chloride-trivalent chromium water solution system to continuously prepare the nanocrystal iron-nickel-chromiumalloy foil. The technique for preparing the alloy foil is simple, the electrolyte is environment-friendly and stable, and the waste liquor is easy to treat. The alloy foil has the advantages of high chromium content, easily controlled components and thickness, smooth surface, excellent mechanical, electrical and magnetic properties, and excellent corrosion resistance, can partially substitute the stainless steel foil belt and the like to be widely used in the industrial fields of electronics, communication, electromechanics and the like, and can be used as an excellent magnetic material, battery framework material and electromagnetic shielding material.

Owner:CENT SOUTH UNIV

Method for smelting chromel alloy by stainless steel dedusting ash and laterite-nickel ore

ActiveCN103526030AEliminate pollutionHigh recovery rateProcess efficiency improvementSteelmakingNickel chromium alloy

The invention discloses a method for smelting chromel alloy by stainless steel dedusting ash and laterite-nickel ore. The method comprises the steps as follows: a stainless steel dedusting ash briquette is manufactured; the stainless steel dedusting ash briquette is added into the laterite-nickel ore, the laterite-nickel ore is placed in an electric plasma furnace to be molten into a mother liquid, the temperature of the molten mother liquid ranges from1,650 DEG C-1,750 DEG C; coke is added for smelting after the mother liquid is molten completely, the smelting temperature is controlled in a range from 1,650 DEG C to 1,750 DEG C simultaneously, and an additive is simultaneously added for an early reduction reaction for 1-2 hours; after the early reduction reaction is finished, a fluxing agent and calcium carbonate are added for continuous reduction reaction for 1-2 hours, so that a metal liquid is obtained; the temperature of the metal liquid is adjusted in a range from 1,650 DEG C to 1,750 DEG C, dregs are removed, and the metal liquid is remained; and pouring is performed to form ingots. With the adoption of the method, waste is reused, so that pollution of the waste on the environment is reduced; and further, steel-making dedusting ash and the laterite-nickel ore are sufficiently combined for smelting, and the chromel alloy with high recovery rate and high content is obtained through addition of an NCP-2 additive.

Owner:TAIZHOU YONGXING ALLOY MATERIAL TECH

High-resistance electric heating alloy wire for electric heating element

InactiveCN106280630AExcellent abrasion resistanceAntioxidant is goodAnti-corrosive paintsHigh resistancePhenyl Ethers

Owner:CHANGSHU MEILI ALLOY MATERIAL CO LTD

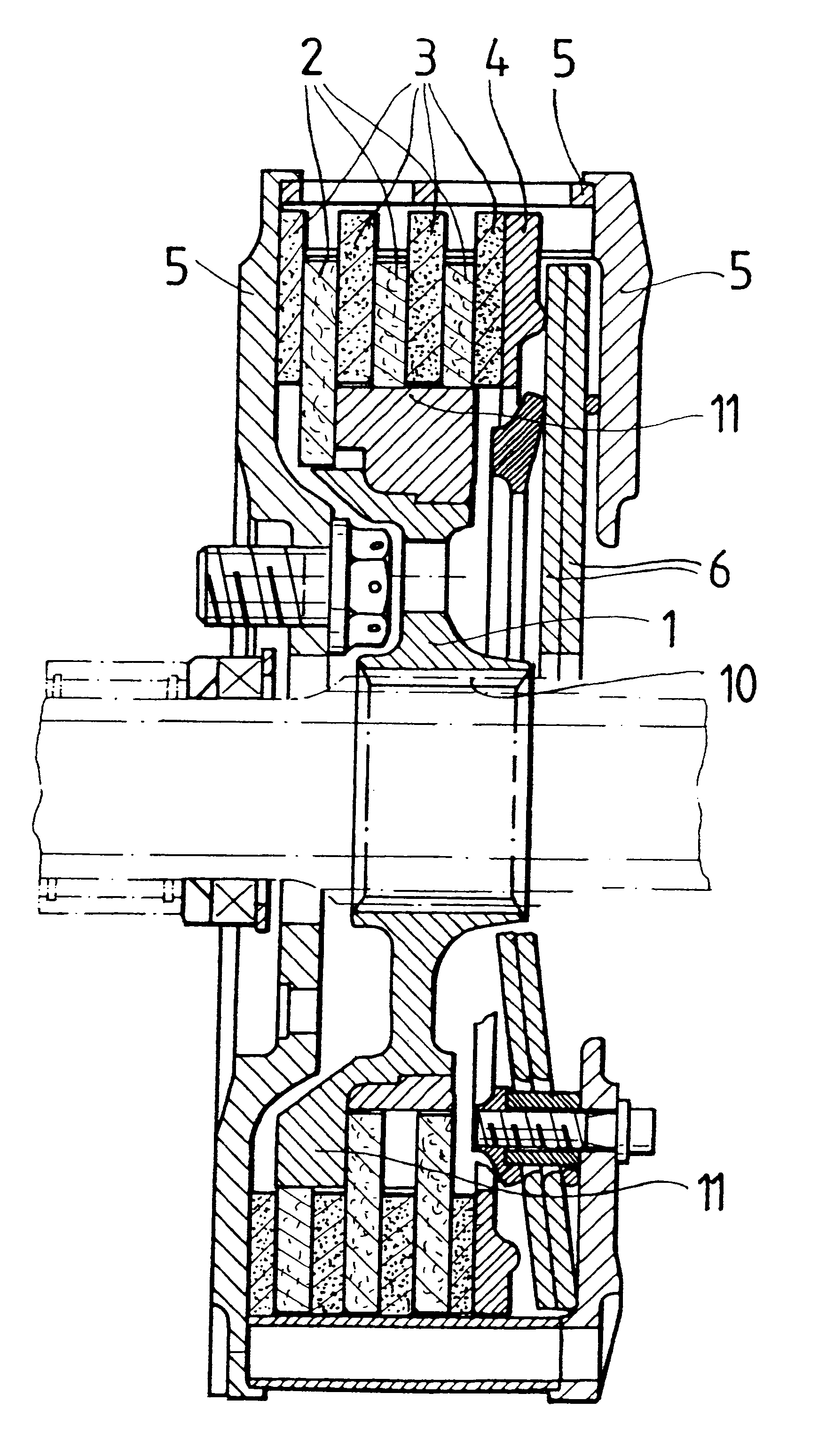

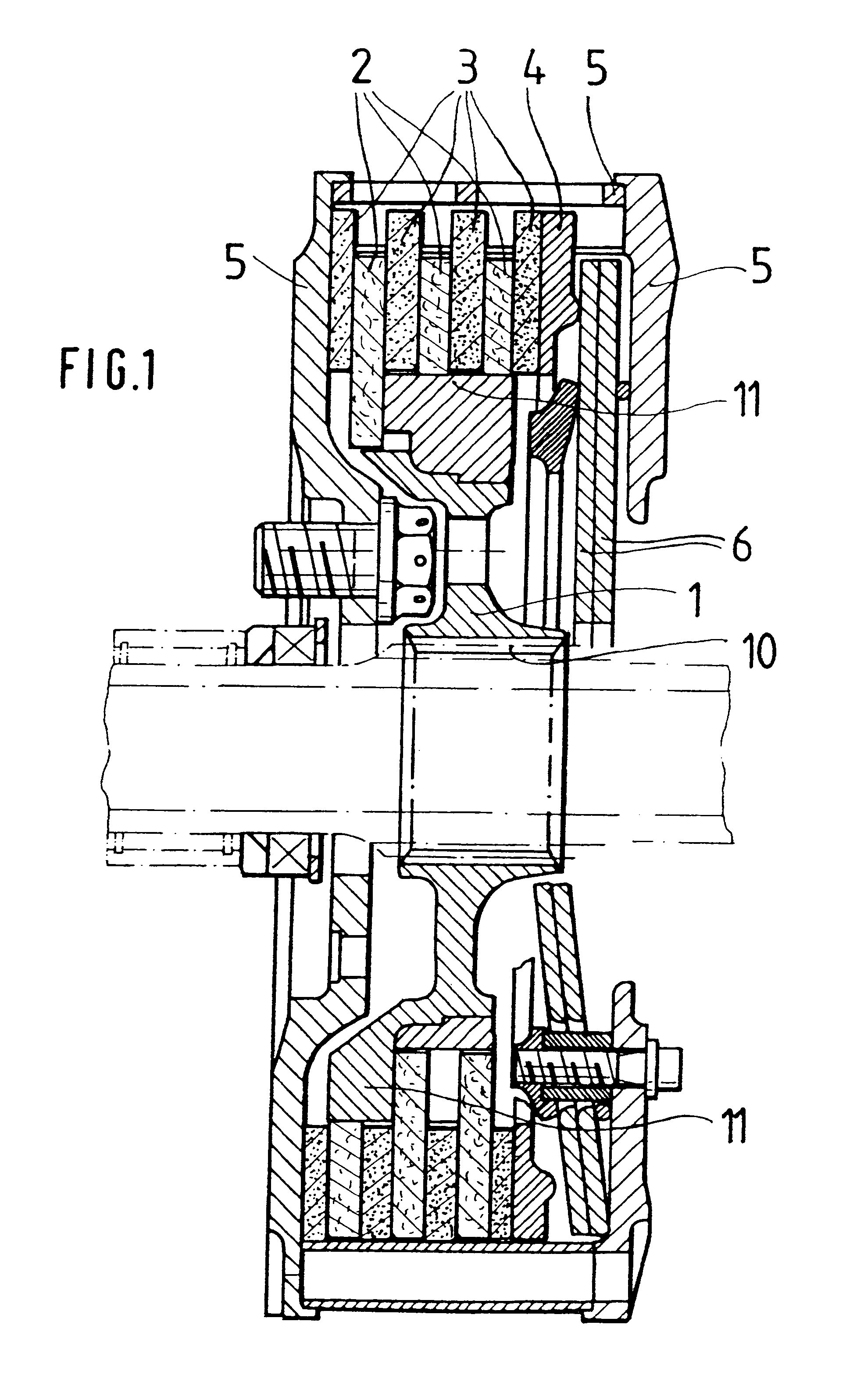

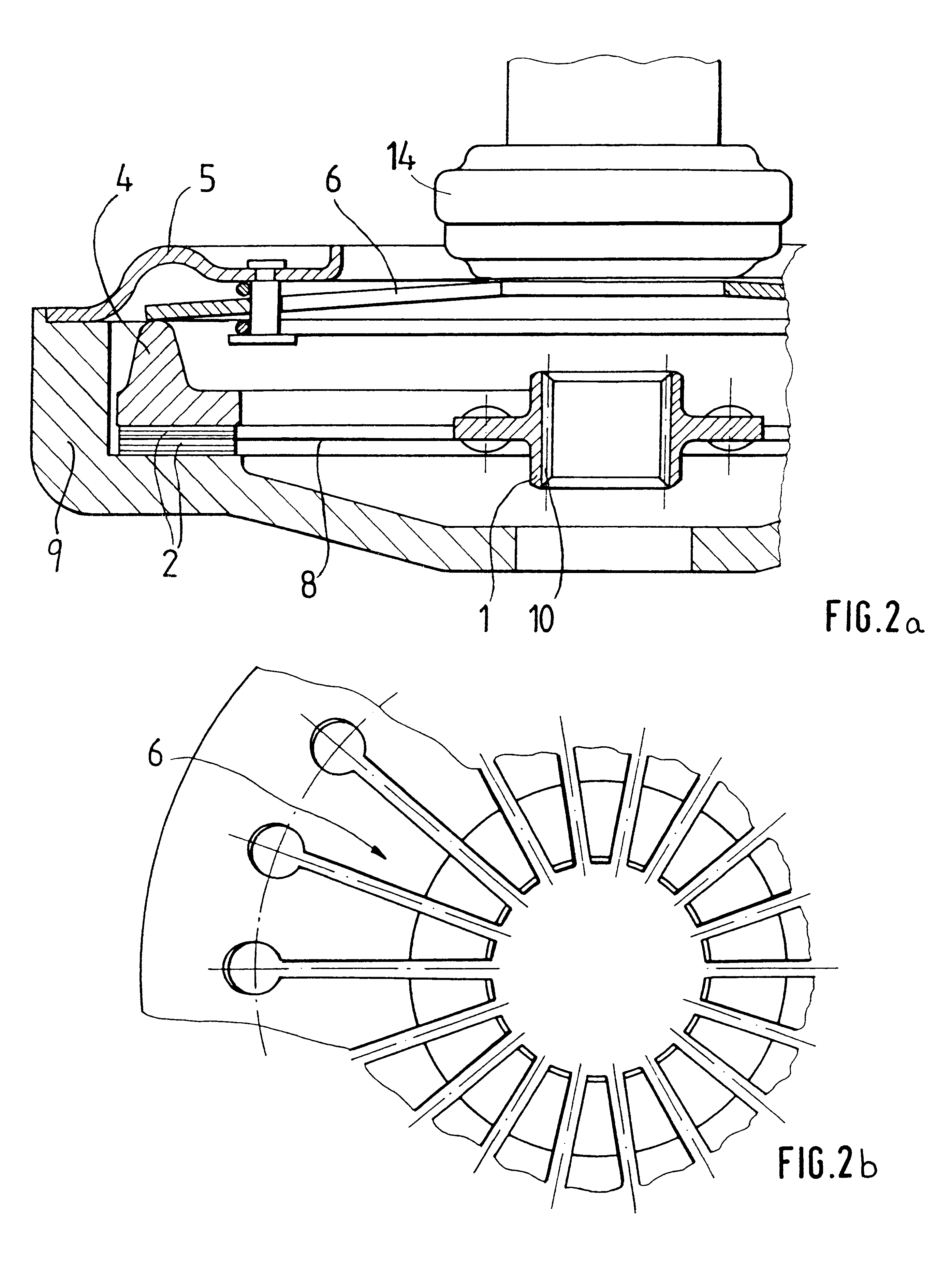

Friction clutch with nickel-chromium alloy spring elements

A friction coupling for use in particular in the drive train of a motor vehicle includes a clutch casing, a pressure plate which is guided in a rotationally fixed manner with respect to the clutch casing, at least one clutch disk and a spring device containing about 40-60% nickel. A method for coating a nickel-base material, in particular the above mentioned spring element for friction clutches, wherein at least part of the surface of the spring device contains boride, and also a method for producing such a spring device which includes a heat treatment are also disclosed.

Owner:SACHS RACE ENG

Door/window-coated nickel-chrome alloy coating and heat treatment process thereof

InactiveCN104561666AImprove corrosion resistanceImprove mechanical propertiesMetallic material coating processesNickel chromium alloyNichrome

The invention discloses a door / window-coated nickel-chrome alloy coating. The nickel-chrome alloy coating comprises the following chemical components in percentage by weight: 1.21-1.23% of C, 0.53-0.57% of Zn, 4.32-4.35% of Cu, 0.25-0.28% of Mg, 0.55-0.58% of K, 22.3-22.5% of Cr, 0.21-0.23% of Si, 1.52-1.55% of Fe, 0.23-0.25% of Co, 8.4-8.6% of Al, 4.65-4.68% of rare earth and the balance of Ni and micro-impurity. The door / window-coated nickel-chrome alloy coating has the advantages that the strength of door / window can be improved, the high temperature resistance is good, and friction and corrosion resistances are also achieved; the nickel-chrome alloy coating can be used under bad environment, and the service life is long; a provided heat treatment process not only can reduce the machining cost, but also can shorten the machining cycle.

Owner:SUZHOU SHENLONG DOORS & WINDOWS

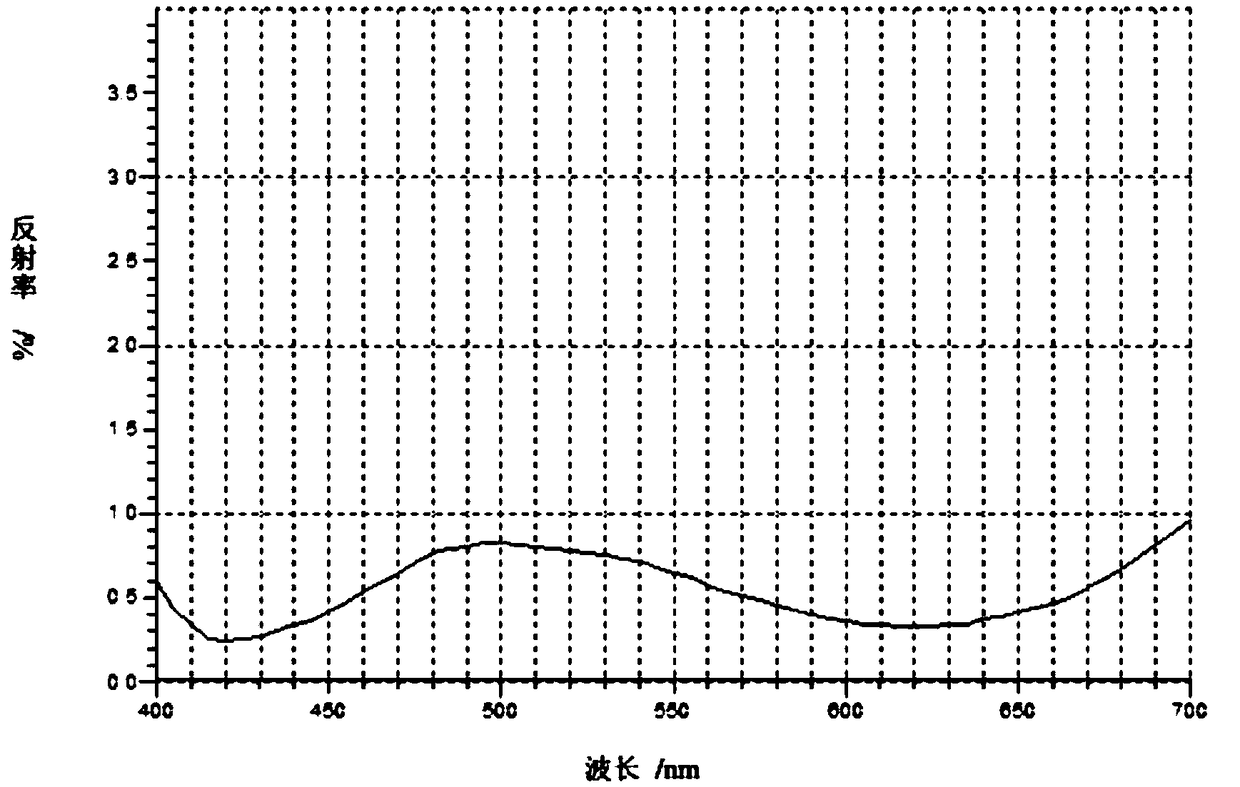

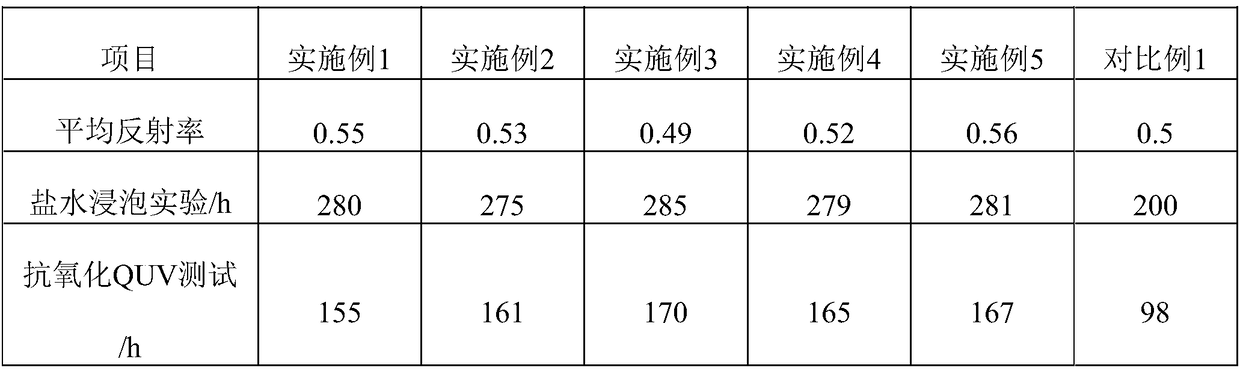

Antioxidation antireflex corrosion-resistant lens and preparation method thereof

ActiveCN108866482AHigh and stable resistivityGood surface oxidation resistanceVacuum evaporation coatingSputtering coatingOptical transmittanceOxidation resistant

The invention relates to an antioxidation antireflex corrosion-resistant lens and a preparation method thereof. The lens comprises a resin substrate and a film layer arranged at the inner surface of the resin substrate; the film layer comprises seven thin film layers which are sequentially stacked from inside to outside and respectively include a silicon-aluminum mixture, nickel-chromium alloy, titanium oxides, a silicon-aluminum mixture, nickel-chromium alloy, a silicon-aluminum mixture and a waterproof layer. The average reflectivity of the prepared antioxidation antireflex corrosion-resistant lens on the wavelength being 400 to 700nm is smaller than or equal to 0.56 percent; the reflection light intensity is effectively reduced; the generation of dazzle light can be prevented; the lighttransmittance is increased; the eyes of a wearer are effectively protected; the antioxidation and corrosion-resistant effects are achieved; the service life is long; the controllability of the preparation process is high; the process can be completed by common operators; good market prospects are realized.

Owner:厦门美澜光电科技有限公司

Novel explosion-proof oil drum heating band

InactiveCN111532602AIsolated contactAvoid explosionLarge containersTank wagonsGlass fiberTemperature control

The invention discloses a novel explosion-proof oil drum heating band. The novel explosion-proof oil drum heating band comprises a heating pad, wherein the heating pad comprises a single sided siliconrubber glass fiber cloth, a diamond copper net and a single sided silicon titanium fireproof cloth; a nickel chrome alloy electrothermal etching sheet is embedded in the silicon rubber glass fiber cloth; a liquid level temperature sensing probe and an explosion-proof box are arranged on the heating pad, a knob type temperature controller is arranged in the explosion-proof box, a temperature controlled switch is connected to the knob type temperature controller, and a silicon rubber high-temperature cable is connected between the knob type temperature controller and the liquid level temperature sensing probe; an elastic band is arranged at one end of the heating pad, a locking spring is arranged at the end of the elastic band, a locking hook is connected to the locking spring, and a locking catch cooperating with the connecting hook is arranged at the other end of the heating pad; and a tightening assembly is arranged at the connecting part of the heating pad and the elastic band. Thenovel explosion-proof oil drum heating band can effectively eliminate the potential safety hazards existing when the heating band of an oil drum is used in explosion gas environment, and casualties caused by explosion can be avoided.

Owner:东台市诚旺电热科技有限公司

High-tenacity high-hardness flux-cored wire

ActiveCN106141505AImprove wear resistanceImprove stabilityWelding/cutting media/materialsSoldering mediaRare earthManganese

The invention discloses a high-tenacity high-hardness flux-cored wire. The high-tenacity high-hardness flux-cored wire is formed by wrapping a low-carbon cold-rolled steel strip sheath around the outer side of a flux core. The flux core comprises the raw materials including, by weight, 30-40 parts of high-carbon ferrochrome, 5-15 parts of chrome, 11-25 parts of rare earth fluoride, 1-2.8 parts of calcium carbonate, 1-4 parts of ferromolybdenum, 1-4 parts of ferrovanadium, 6-10 parts of cobalt powder, 2-6 parts of electrolytic manganese, 1-1.8 parts of graphite, 6-10 parts of nickel-chromium alloy, 0.5-1.5 parts of tungsten powder, 2-8 parts of aluminum oxide, 9-14 parts of titanium diboride powder, 6-8 parts of low-silicon iron, 1-5 parts of feldspar, 1-2 parts of magnesite and 100-180 parts of iron powder. The high-tenacity high-hardness flux-cored wire is reasonable in chemical component ratio and high in tenacity and corrosion resistance, and the hardness of a welded joint is high.

Owner:天长市瑞颖焊材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com