Thermotolerant corrosion-resistant flexibility-resistant cable

A corrosion-resistant and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant, corrosion-resistant, and flexure-resistant cables, can solve problems such as difficult to meet the use requirements, and the flex resistance cannot meet the use requirements, and achieve excellent high temperature resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

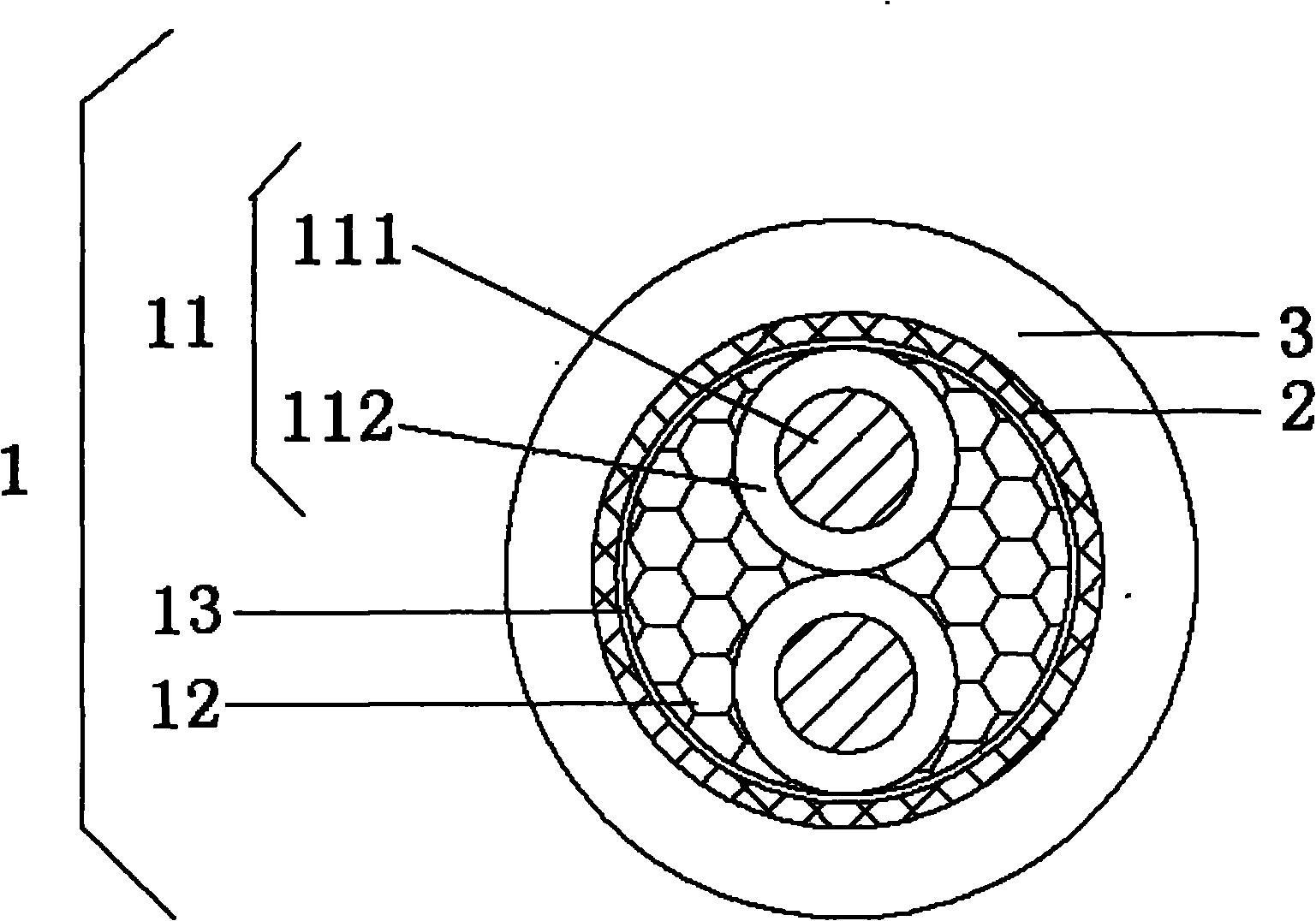

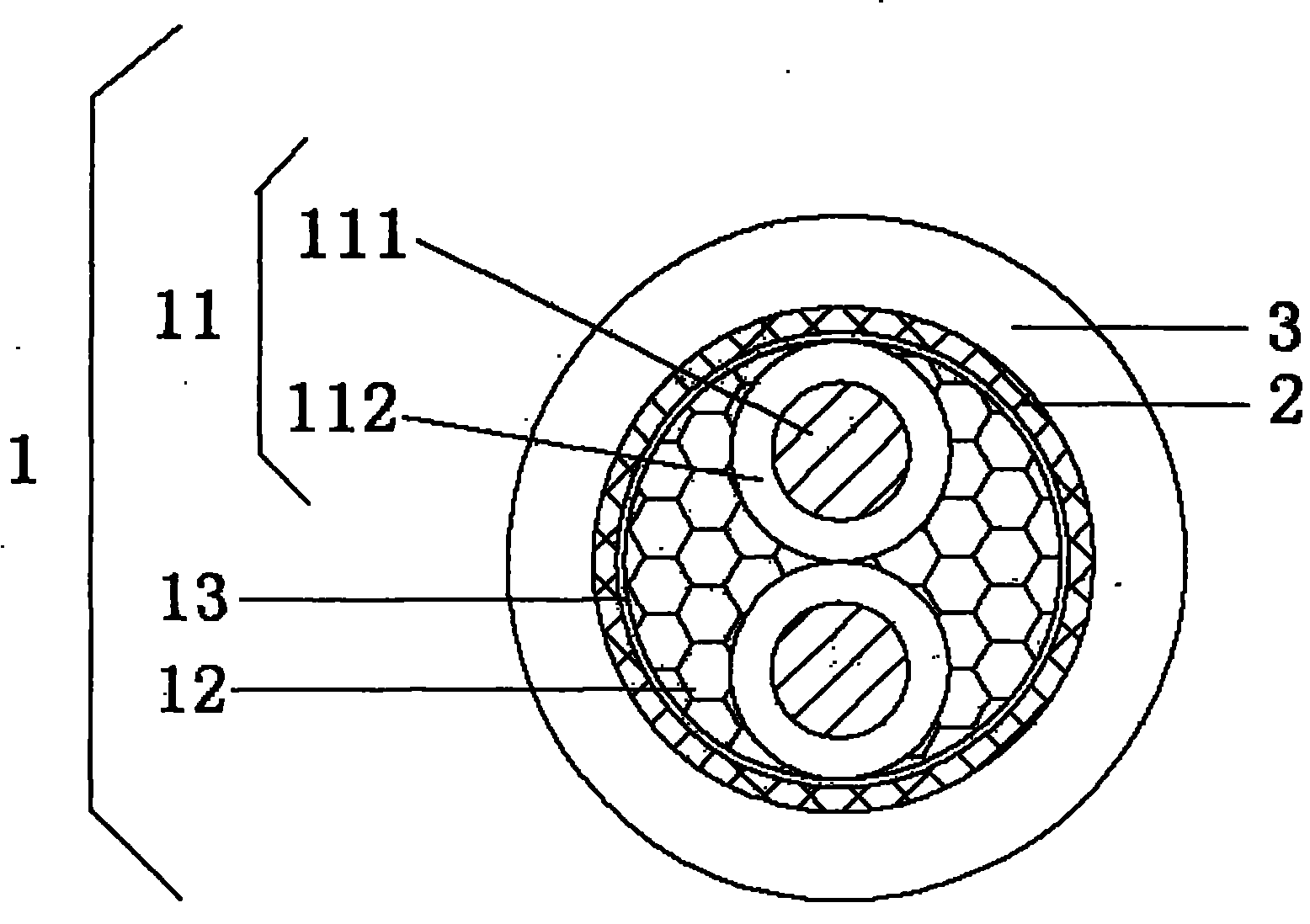

[0012] please see figure 1 , figure 1 Provided is the cross-section of the high-temperature-resistant, corrosion-resistant, and flex-resistant cable of the present invention, including a cable core 1, a shielding layer 2 arranged outside the cable core 1, and an outer sheath 3 positioned outside the shielding layer 2, and the cable core 1 includes a wire 11. The filler 12 and the wrapping layer 13, while the wire 11 is composed of a conductor 111 and an outer covering layer 112 covered outside the conductor 111 (the industry customarily calls it a wire quilt or an outer quilt), and the conductor 111 is formed by twisting nickel-chromium alloy wires. It can also be formed by twisting nickel-aluminum alloy wires, or a mixture of nickel-chromium alloy wires and nickel-aluminum alloy wires. Both the coating layer 112 and the wrapping layer 13 are preferably made of PTFE (i.e. polytetrafluoroethylene). The filler 12 adopts aramid fiber and surrounds the wire 11 . Before being cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com