GST high strength toughness seawater corrosion resistant iron casting and its production method

A high-strength toughness, production method technology, applied in the field of corrosion-resistant engineering material production and manufacturing, can solve the problems of high corrosion rate, shrinkage porosity, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

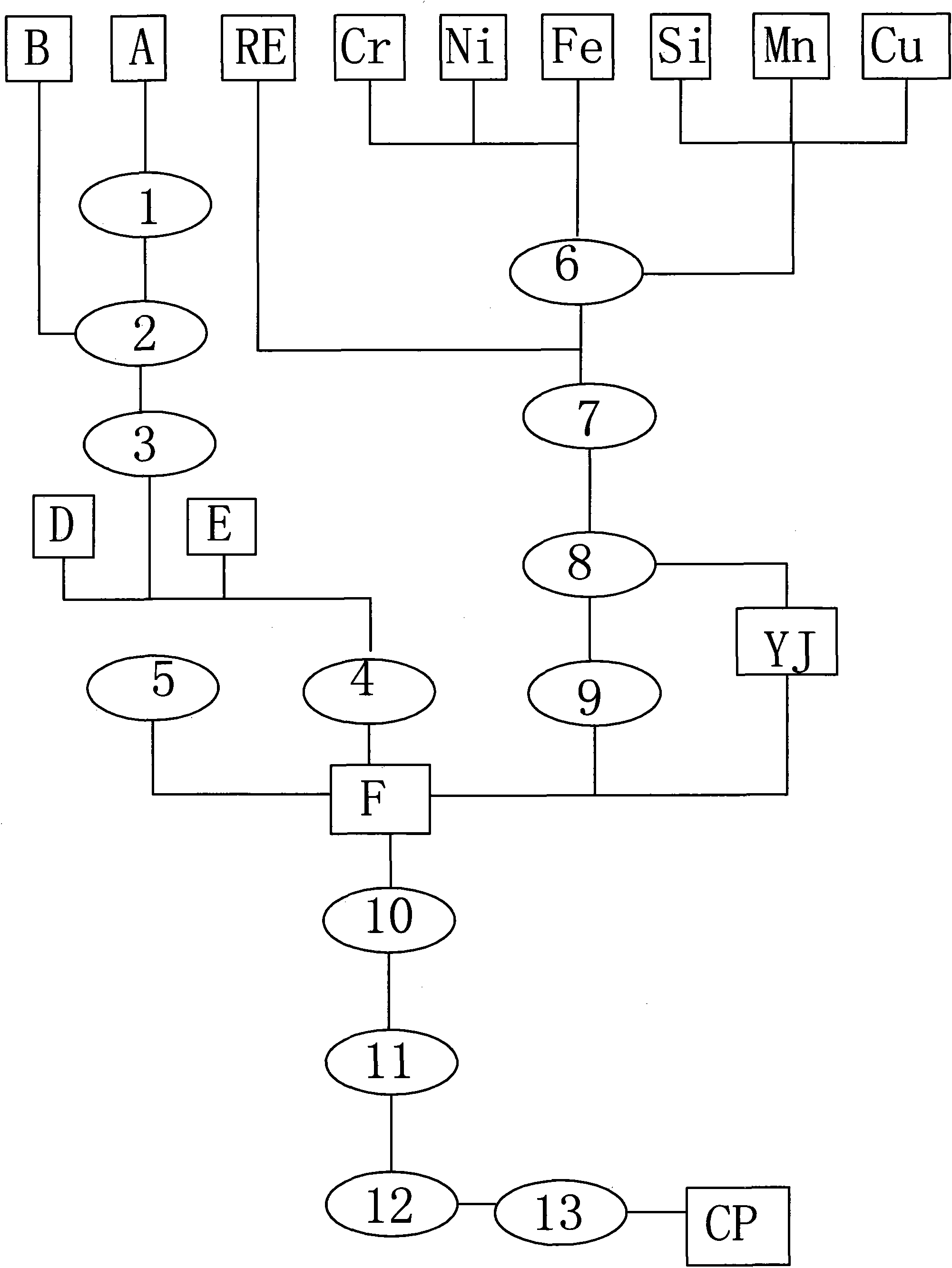

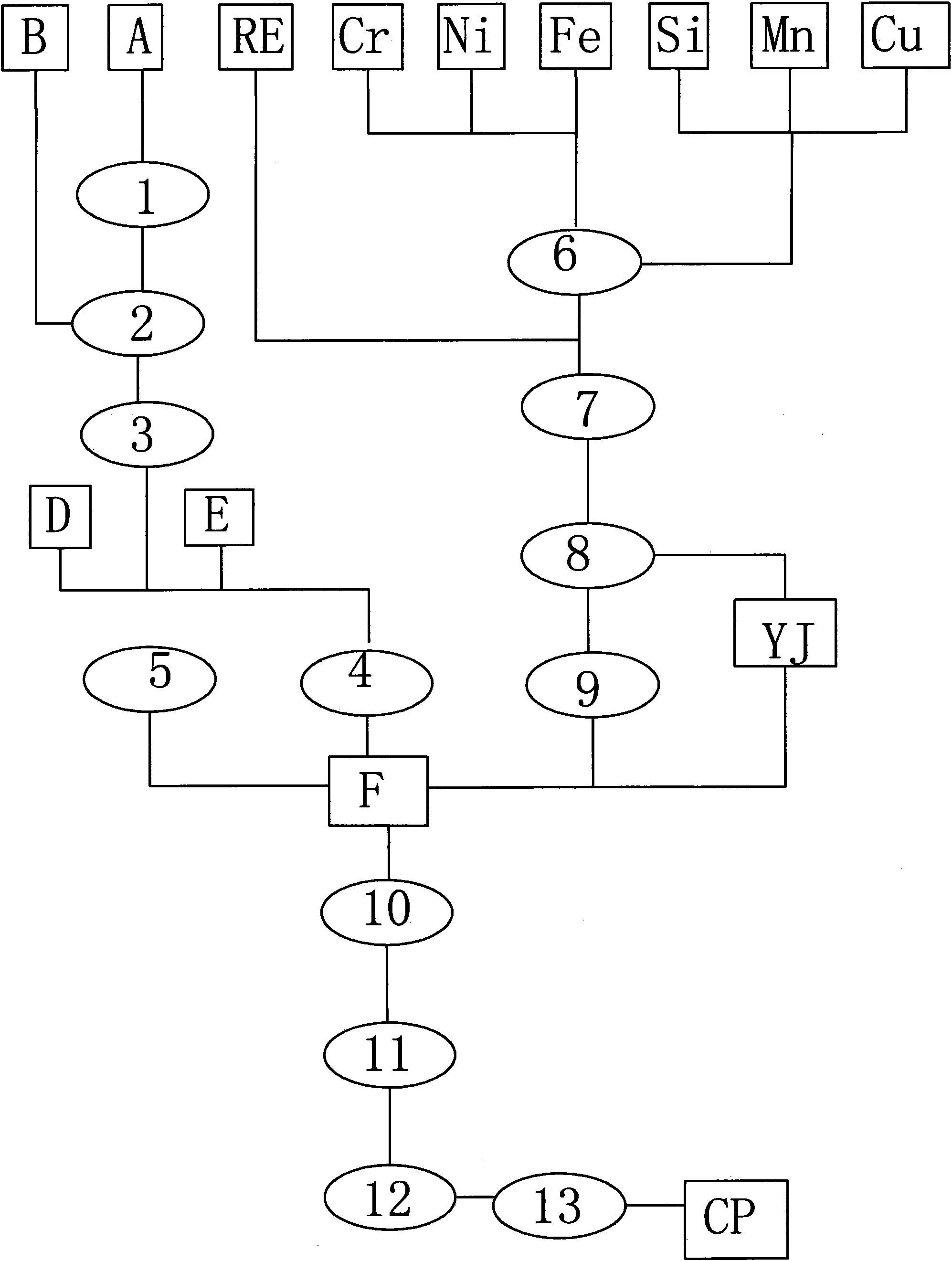

[0009] Use polystyrene foam to process and produce a polystyrene foam model that meets the requirements of the product drawing, complete process 1 to make the white mold, and enter process 2 to paint the lost foam paint on the surface of the white mold. After process 3 is dried and qualified, enter process 4 Packing: Put the dried model into the sand box E, configure the pouring system, add the molding sand D to shake it, and get the mold box F for standby. After that, nickel (Ni) and chromium (Cr) are added, and the smelting temperature is controlled at 1400-1550°C. Manganese (Mn), silicon (Si), and copper (Cu) are added in the later stage of smelting, and rare earth alloys (RE) are added before the furnace is released; enter the process 7 out of the furnace, the temperature of the out of the furnace is controlled at 1400-1460 ℃, inoculated with a strong inoculant (YJ) when out of the furnace, in the inoculation process 8, the mass percentage of the alloy elements of the GST h...

Embodiment 2

[0011] Foam the polystyrene foam beads to make a polystyrene foam model that meets the requirements of the product drawings, assemble the pouring system, complete the white mold production in process 1, enter process 2, and paint the lost foam coating B on the surface of the white mold, and pass the process 3. After passing the drying, enter the process 4 packing: put the dried model into the sand box E, install the molding sand D and shake it, and get the mold box F for standby. The melting process 6 is carried out in the medium frequency induction furnace: put the metal raw material into the furnace Internal smelting, nickel (Ni) and chromium (Cr) are added after melting, the smelting temperature is controlled at 1480-1520°C, manganese (Mn), silicon (Si), and copper (Cu) are added in the later stage of smelting, and rare earth alloy RE is added before the furnace is released ; enter process 7 out of the furnace, the temperature out of the furnace is controlled at 1400-1460 ° ...

Embodiment 3

[0013] Use expandable polystyrene raw materials to make a foam model in the mold that meets the requirements of the product drawing, assemble the pouring system, complete the production of the white mold in process 1, enter the process 2 and paint the paint B on the surface of the white mold, and pass the drying process in process 3 , enter process 4 packing: put the dried model into the sand box E, add the molding sand D to shake it, and get the mold box F for standby, the melting process 5 is carried out in the intermediate frequency induction furnace: put the metal raw material into the furnace for melting, melt After that, nickel (Ni) and chromium (Cr) are added, and the smelting temperature is controlled at 1480-1520°C. Manganese (Mn), silicon (Si), and copper (Cu) are added in the later stage of smelting, and rare earth alloys (RE) are added before the furnace is released; enter the process 6 out of the furnace, the temperature of the out of the furnace is controlled at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com