Air-conditioning apparatus

A technology of air conditioning and oil recovery, applied in space heating and ventilation, heating methods, lighting and heating equipment, etc., can solve the problems of insufficient recovery of lubricating oil, no direct disclosure or hint of lubricating oil recovery, etc., to achieve the elimination of lubricating oil The effect of insufficient oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

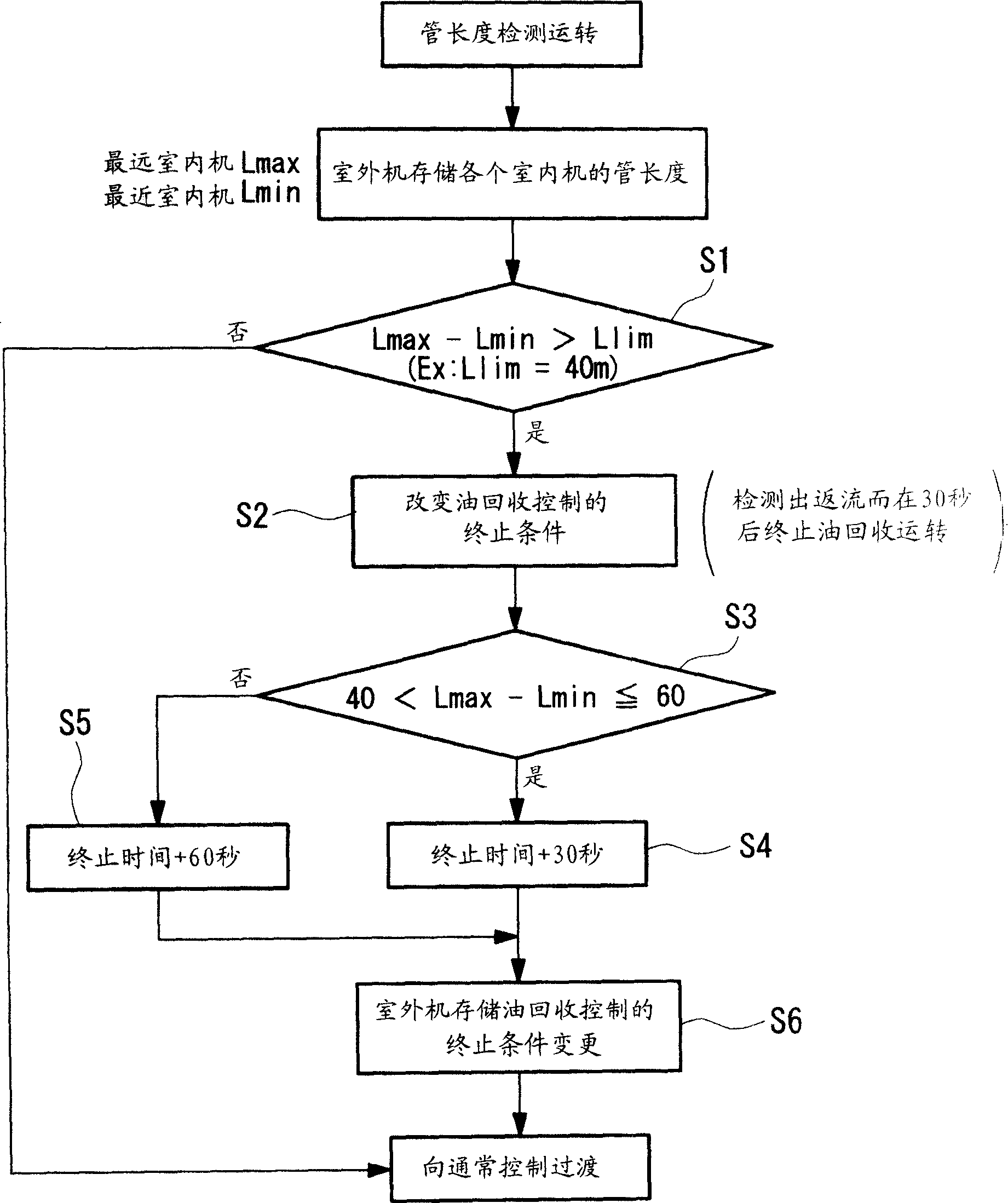

no. 1 approach

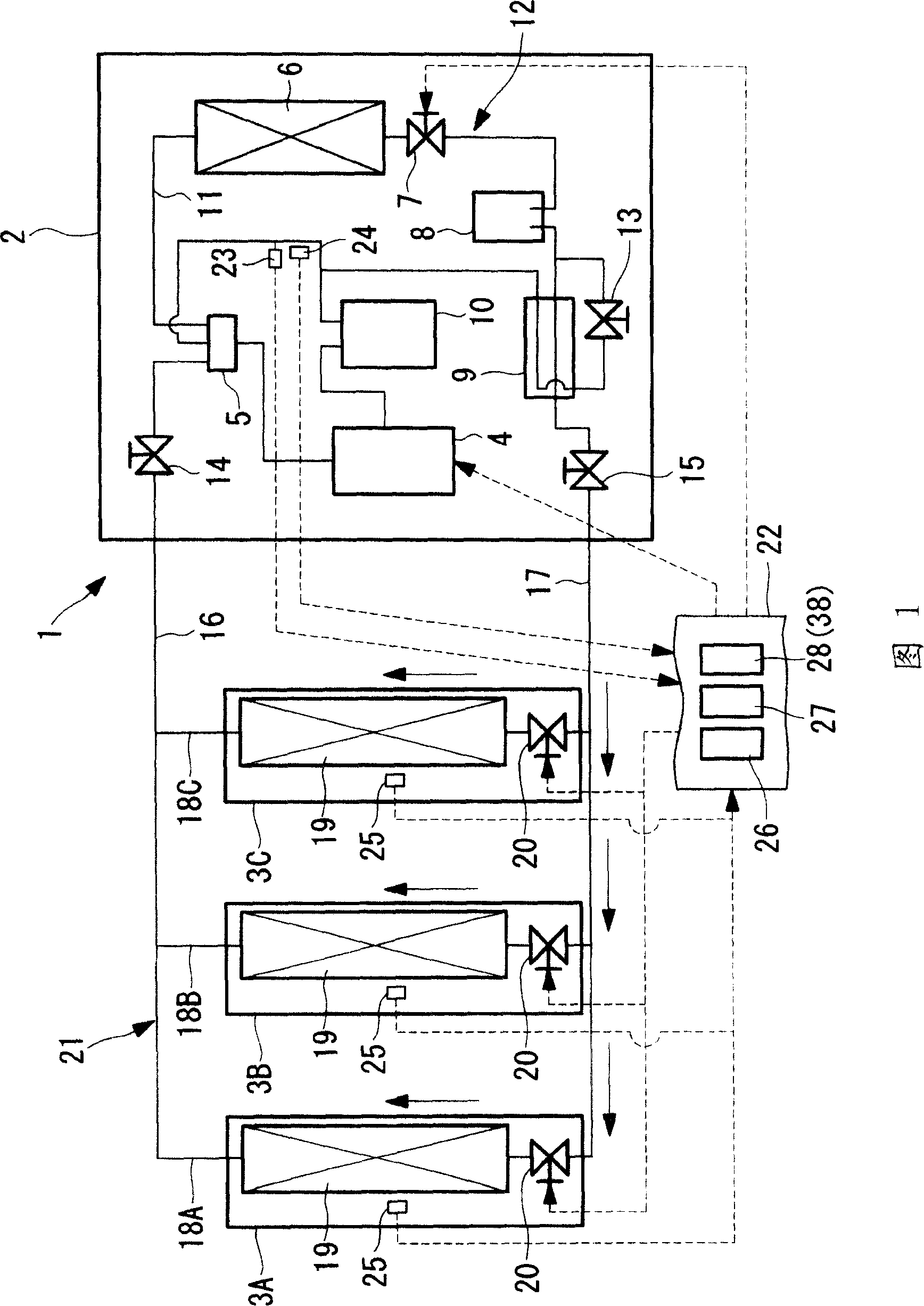

[0032] Fig. 1 shows a refrigerant circuit diagram of a combination air conditioner 1 according to a first embodiment of the present invention. The air conditioner 1 is composed of one outdoor unit 2 and a plurality of indoor units 3A, 3B, and 3C connected in parallel to the outdoor unit 2 . In addition, in this embodiment, the case where three indoor units 3A, 3B, and 3C are connected is exemplified, but the number of connected indoor units 3A, 3B, and 3C is not limited.

[0033] The outdoor unit 2 includes: a reverse-phase-driven compressor 4 for compressing refrigerant; a four-way switch valve 5 for switching the direction of refrigerant circulation; an outdoor heat exchanger 6 for exchanging heat between refrigerant and outside air; expansion valve 7; storage tank 8 for storing liquid refrigerant; subcooling heat exchanger 9 for subcooling liquid refrigerant; The accumulator 10 and the components are connected by known refrigerant pipes 11 to form a refrigerant circuit 12 ...

no. 2 approach 〕

[0061] Next use Figure 1 and Figure 3A , FIG. 3B to illustrate the second embodiment of the present invention.

[0062] This embodiment differs from the first embodiment described above in the configuration of the oil recovery control unit 38 . Other points are the same as those of the first embodiment, and thus description thereof will be omitted.

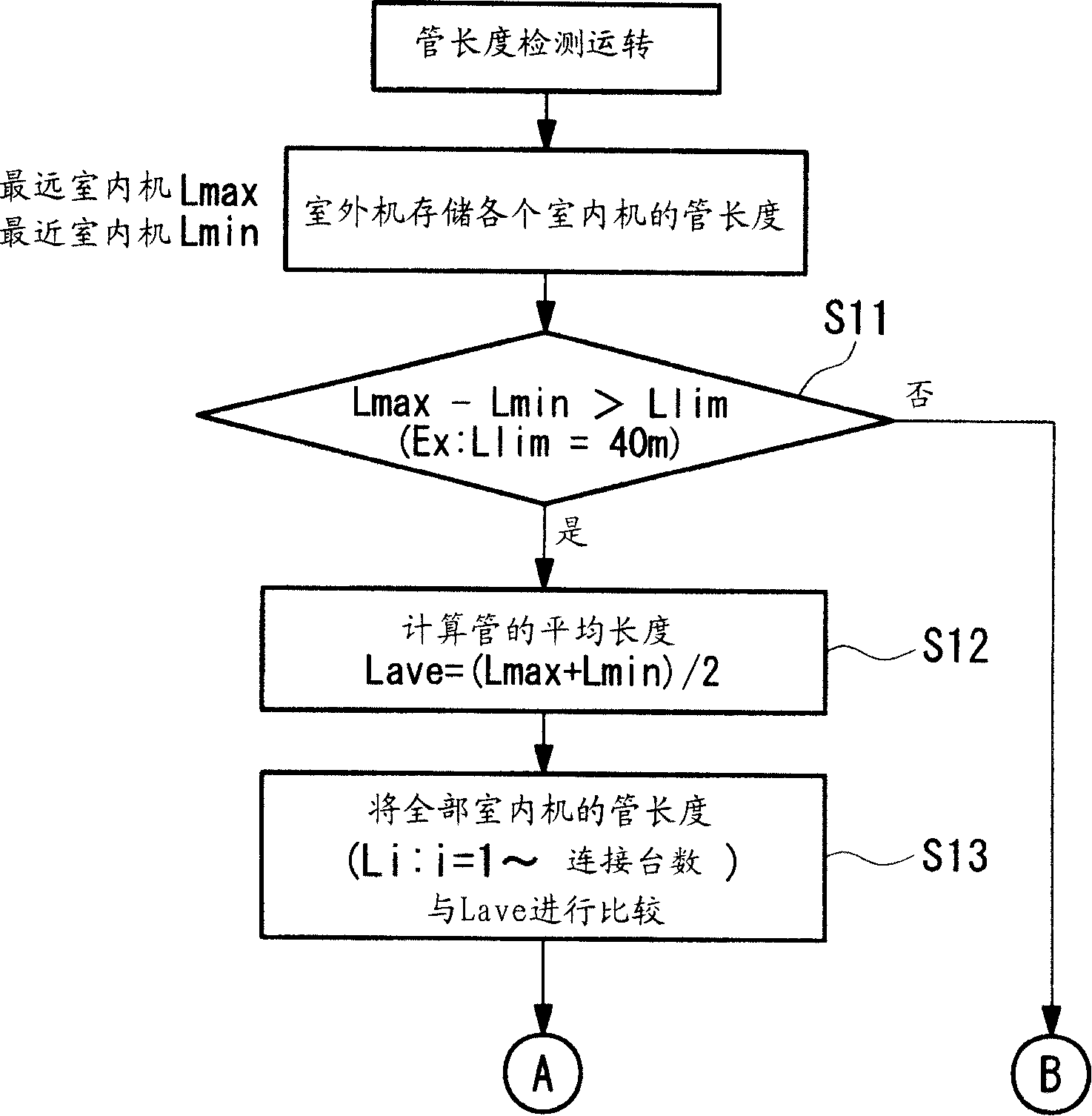

[0063] The oil recovery control unit 38 of this embodiment changes the opening degree of each indoor electronic expansion valve 20 based on the refrigerant pipe length of each indoor unit 3A, 3B, 3C instead of changing the operation time during the oil recovery operation.

[0064] The oil recovery control unit 38 is based on Figure 3A , the control flow shown in FIG. 3B controls the opening of each indoor electronic expansion valve 20 during the oil recovery operation as follows.

[0065] Such as Figure 3A , as shown in FIG. 3B, in the oil recovery control unit 38, based on the detection result of the refrigerant tube lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com