Patents

Literature

49results about How to "High volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silver comprising nanoparticles and related nanotechnology

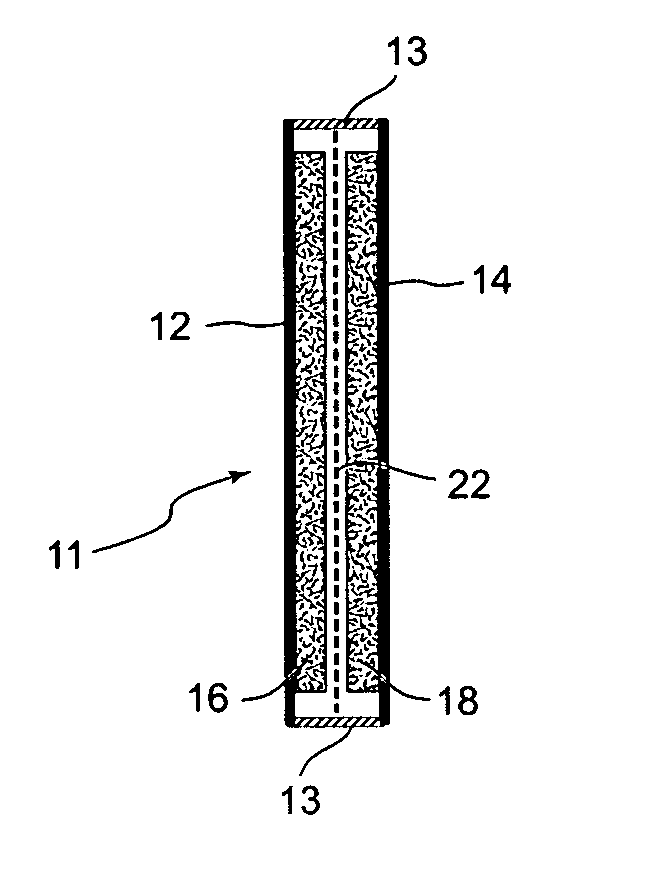

InactiveUS20050008861A1High volumeLow-costSynthetic resin layered productsCellulosic plastic layered productsOxideApplications of nanotechnology

Nanoparticles comprising silver and their nanotechnology-enabled applications are disclosed; doped metal oxides, silver comprising complex nanoparticle compositions, silver nanoparticles, methods of manufacture, and methods of preparation of products from silver comprising nanoparticles are presented; And anti-microbial formulations are discussed. Color photochromaticity and related applications are disclosed.

Owner:NANO PRODS

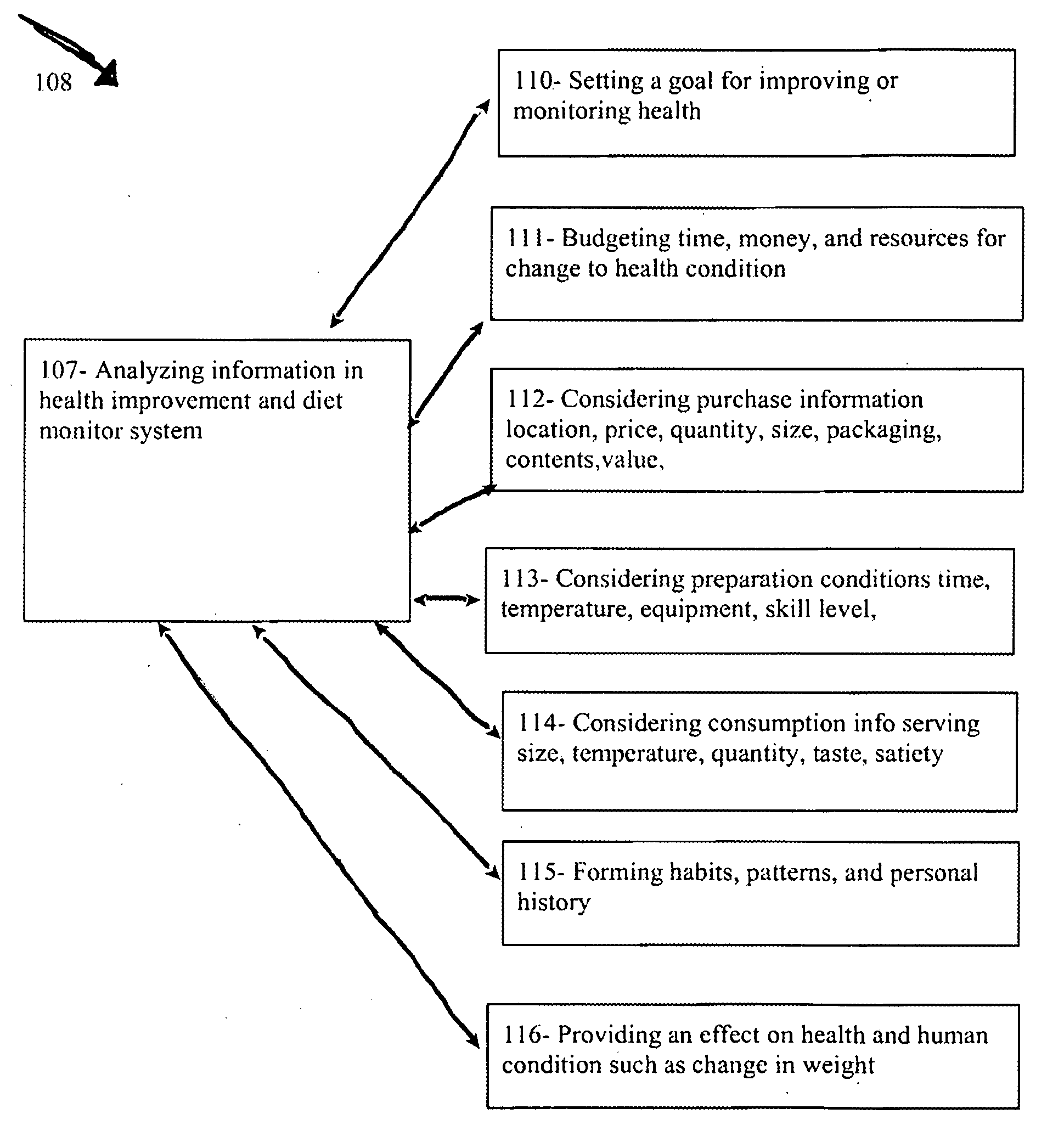

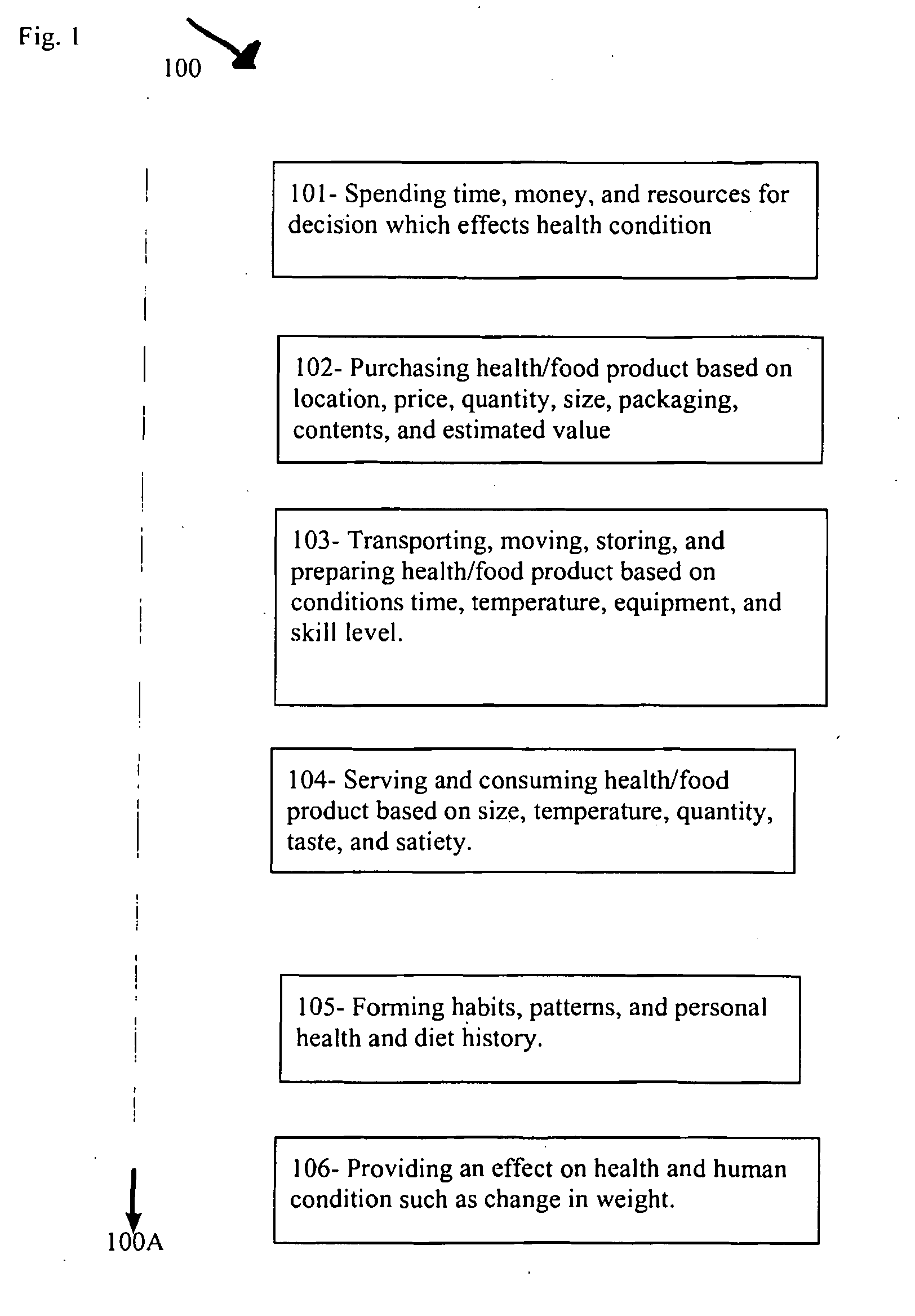

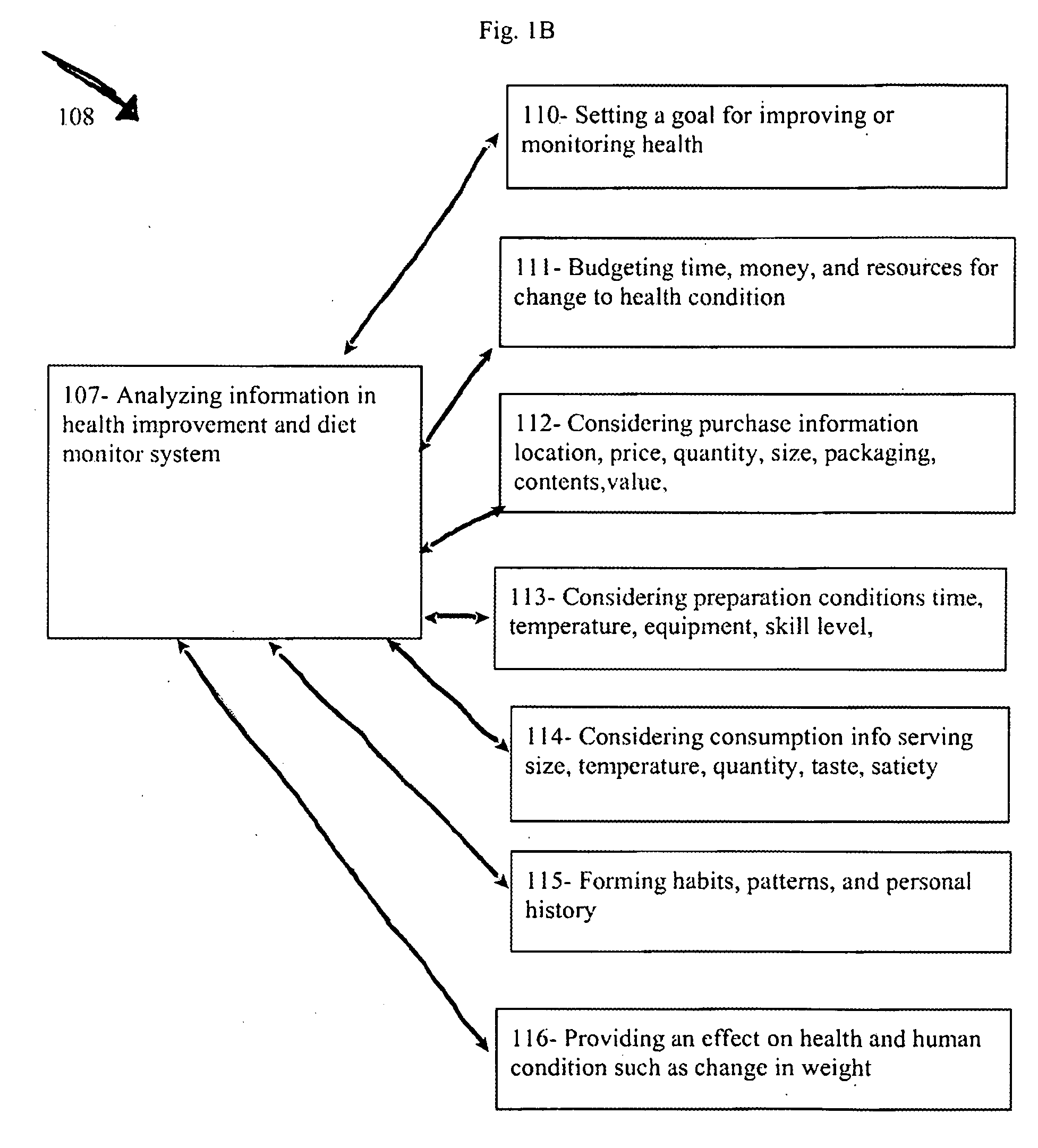

Method and Apparatus for Monitoring Calorie, Nutritent, and Expense of Food Consumption and Effect on Long Term and Short Term State

InactiveUS20090099873A1High volumeEasily monitorData processing applicationsNutrition controlNutritionPurchasing decision

A system for improving health and monitoring diet has been developed which enables a consumer before making important decisions which effect health to consider health, nutrition, dietary, budget, and time information resources more easily before decisions are made. The system has a variety of user inputs that enable the user to access information easily and enter information easily, so that the personal profile and health history and diet information is up-to-date. This system is adjustable to contain additional modules of information such as dietary restrictions which can be used to regularly recommend or restrict purchase decisions at the point of sale, storage, preparation, or consumption.

Owner:KURPLE KURT R D P +2

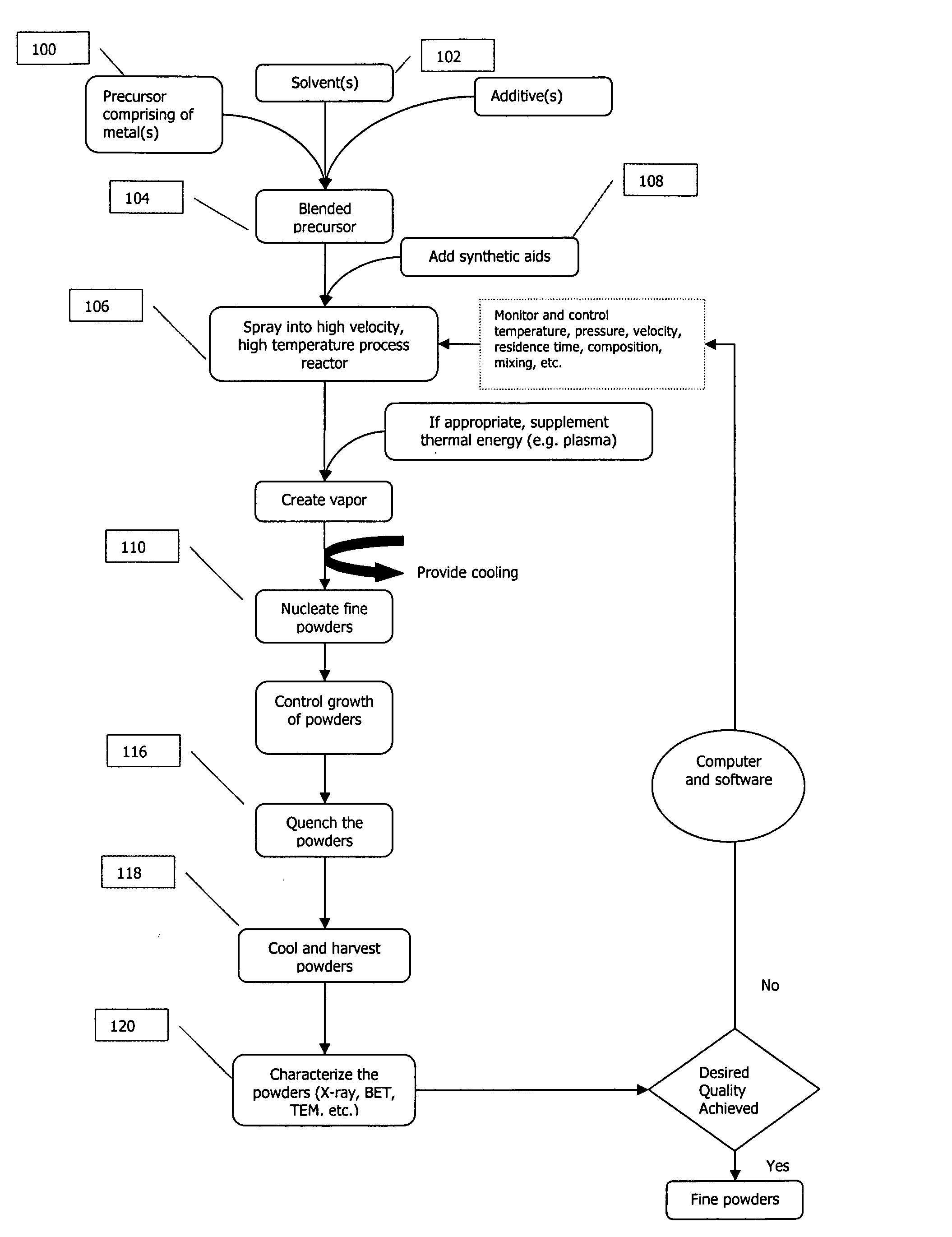

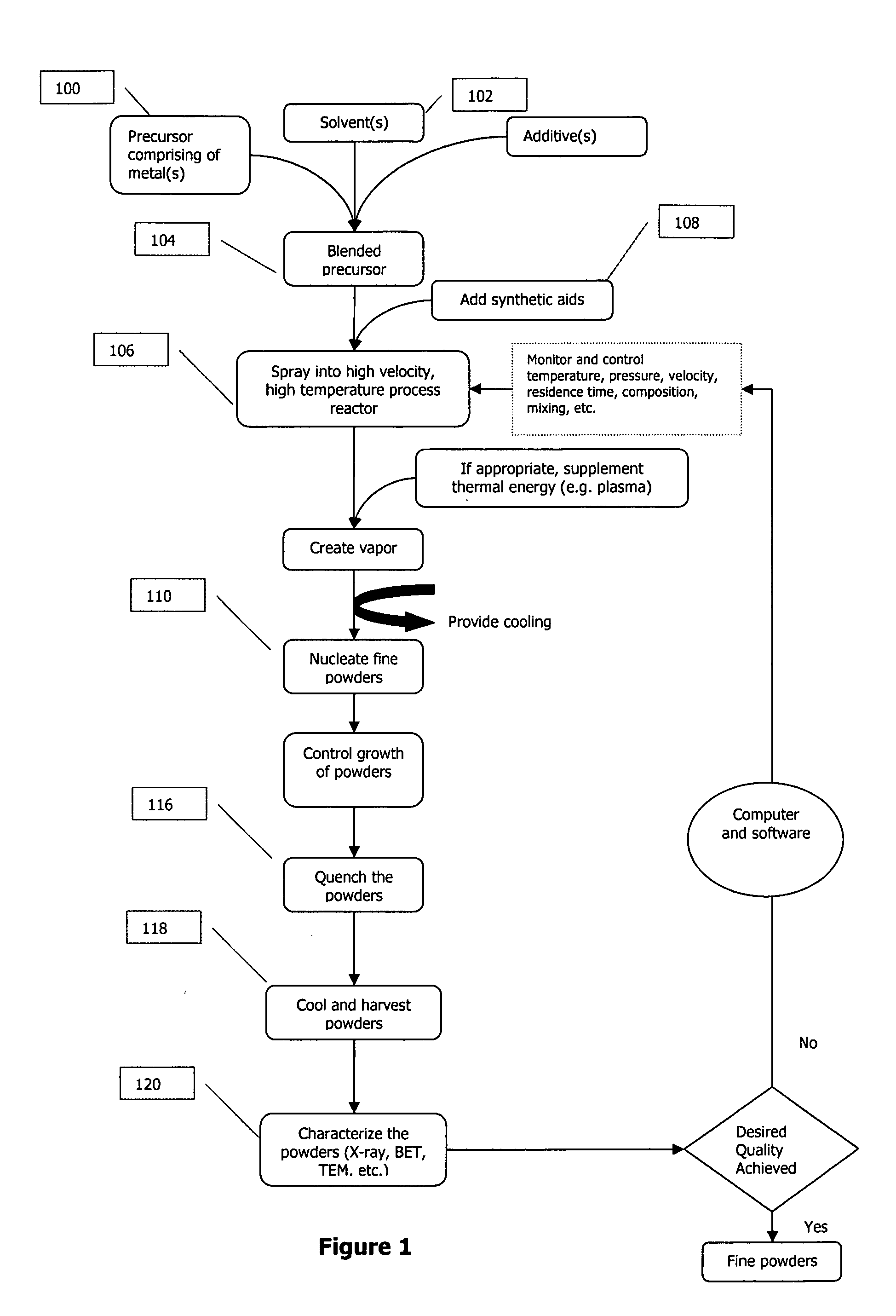

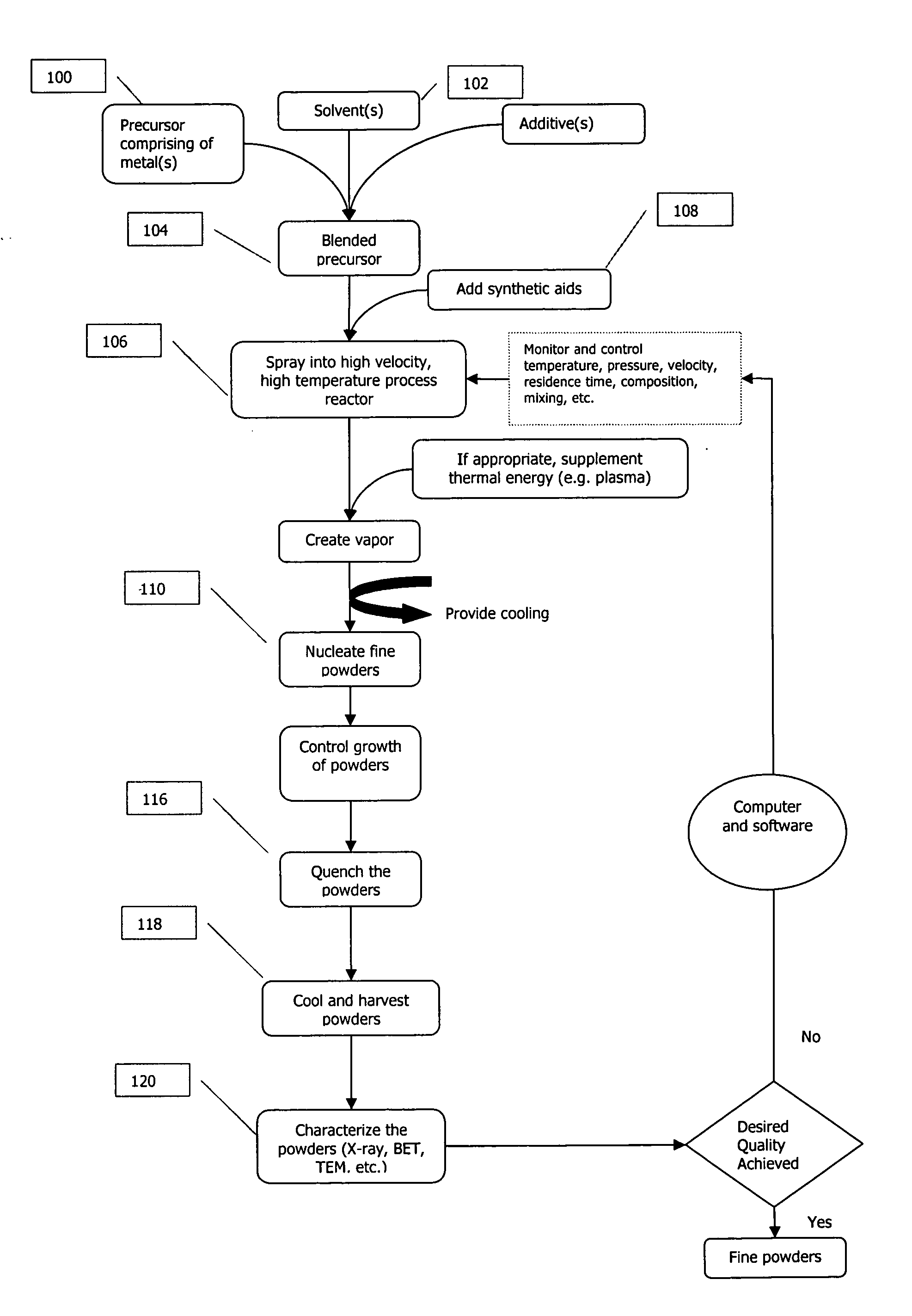

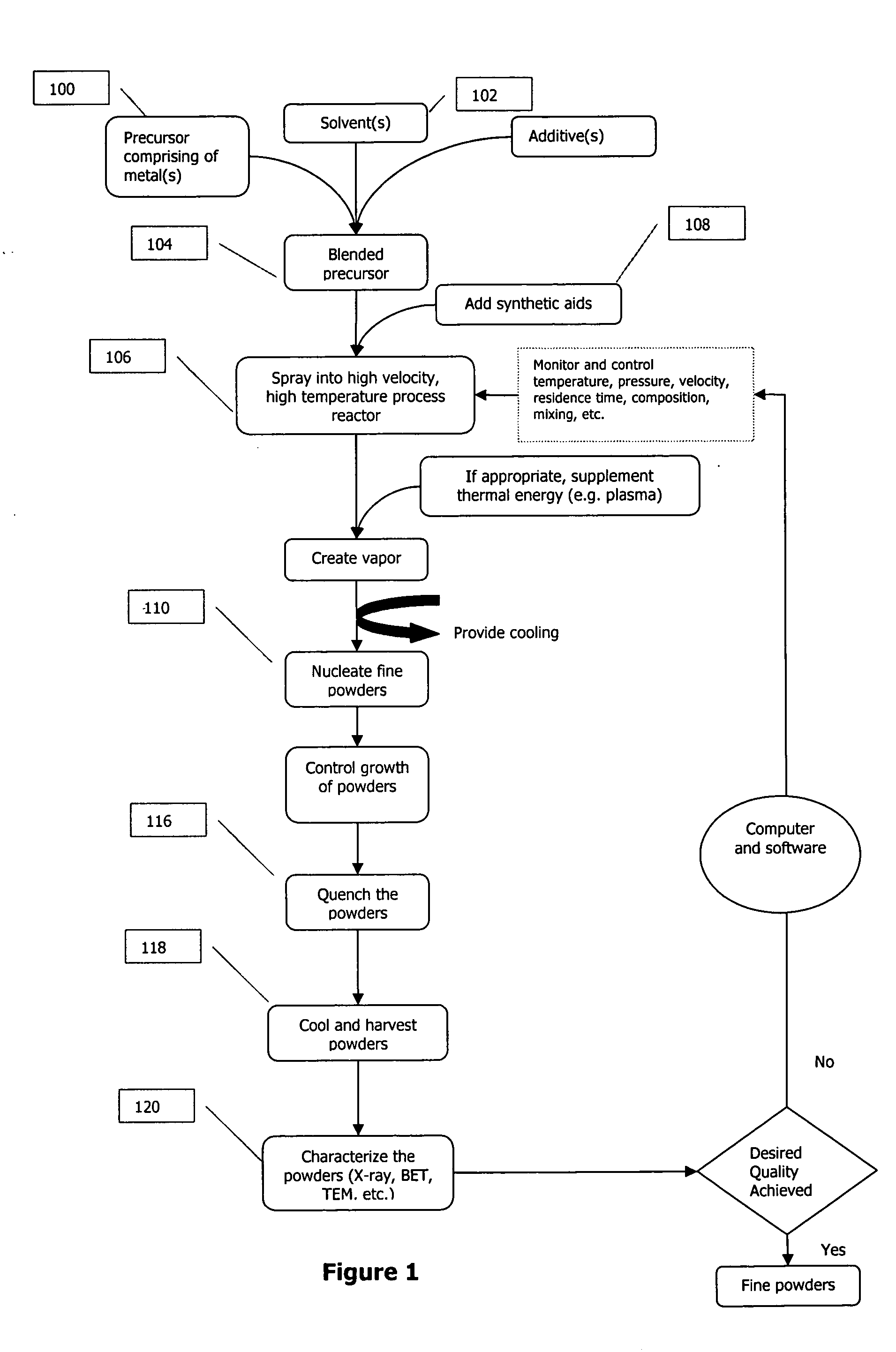

Tungsten comprising nanomaterials and related nanotechnology

InactiveUS20050271566A1High volumeIncrease volumeNanostructure manufactureCell electrodesManufactured nanoparticlesTungsten

Nanoparticles comprising tungsten, methods of manufacturing nanoparticles comprising tungsten, and applications of nanoparticles comprising tungsten, such as electronics, optical devices, photonics, reagents for fine chemical synthesis, pigments, and catalysts are provided.

Owner:PPG IND OHIO INC

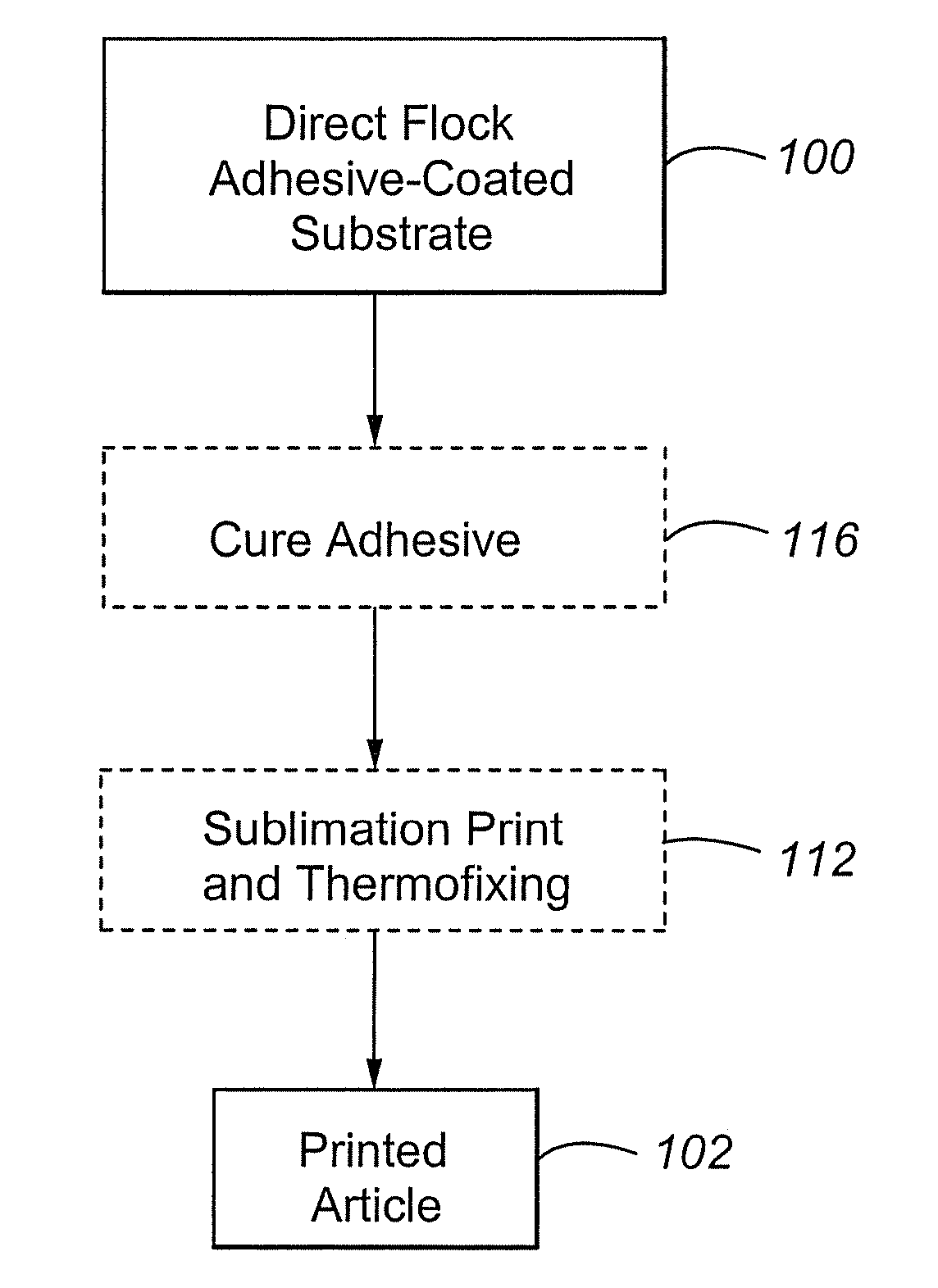

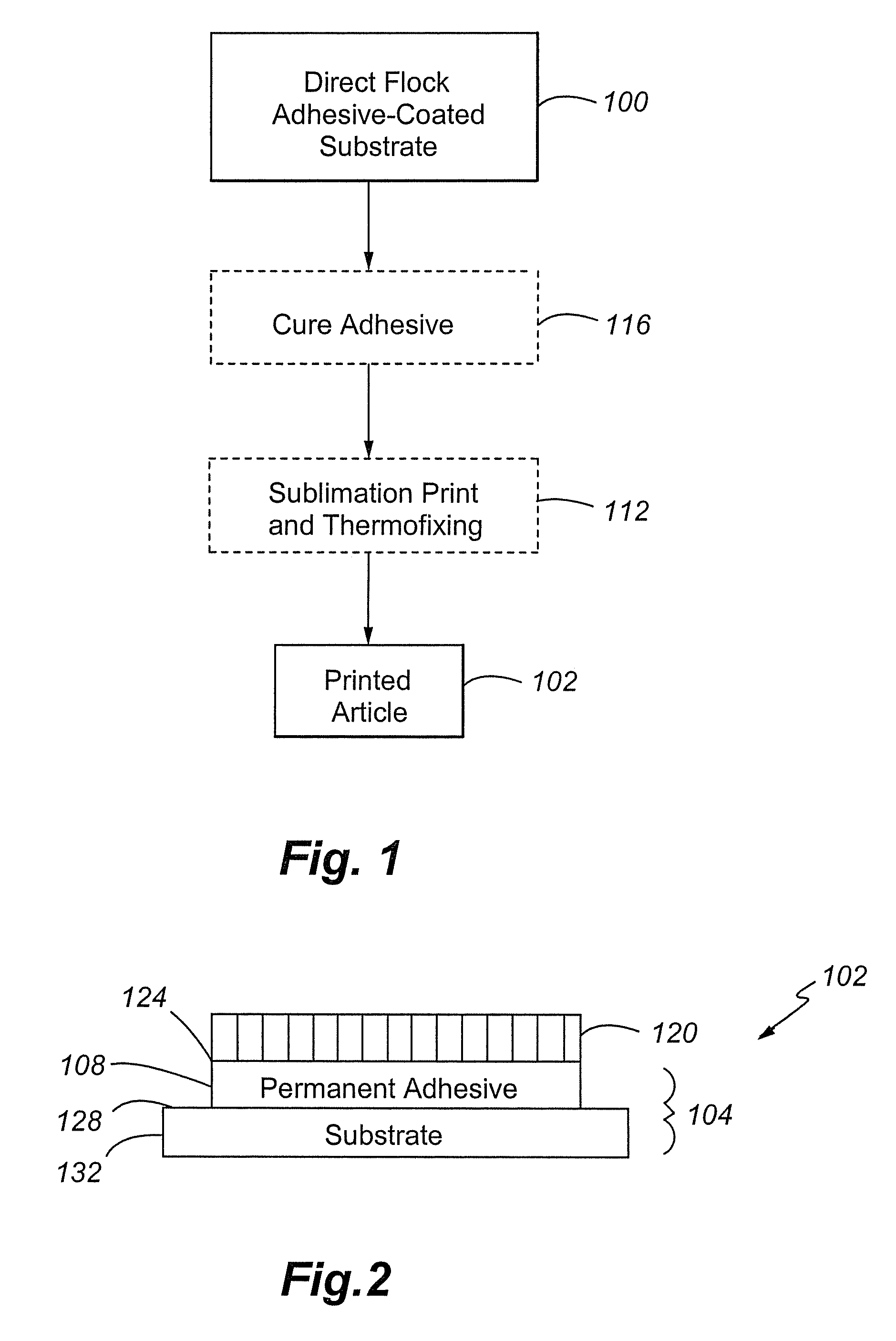

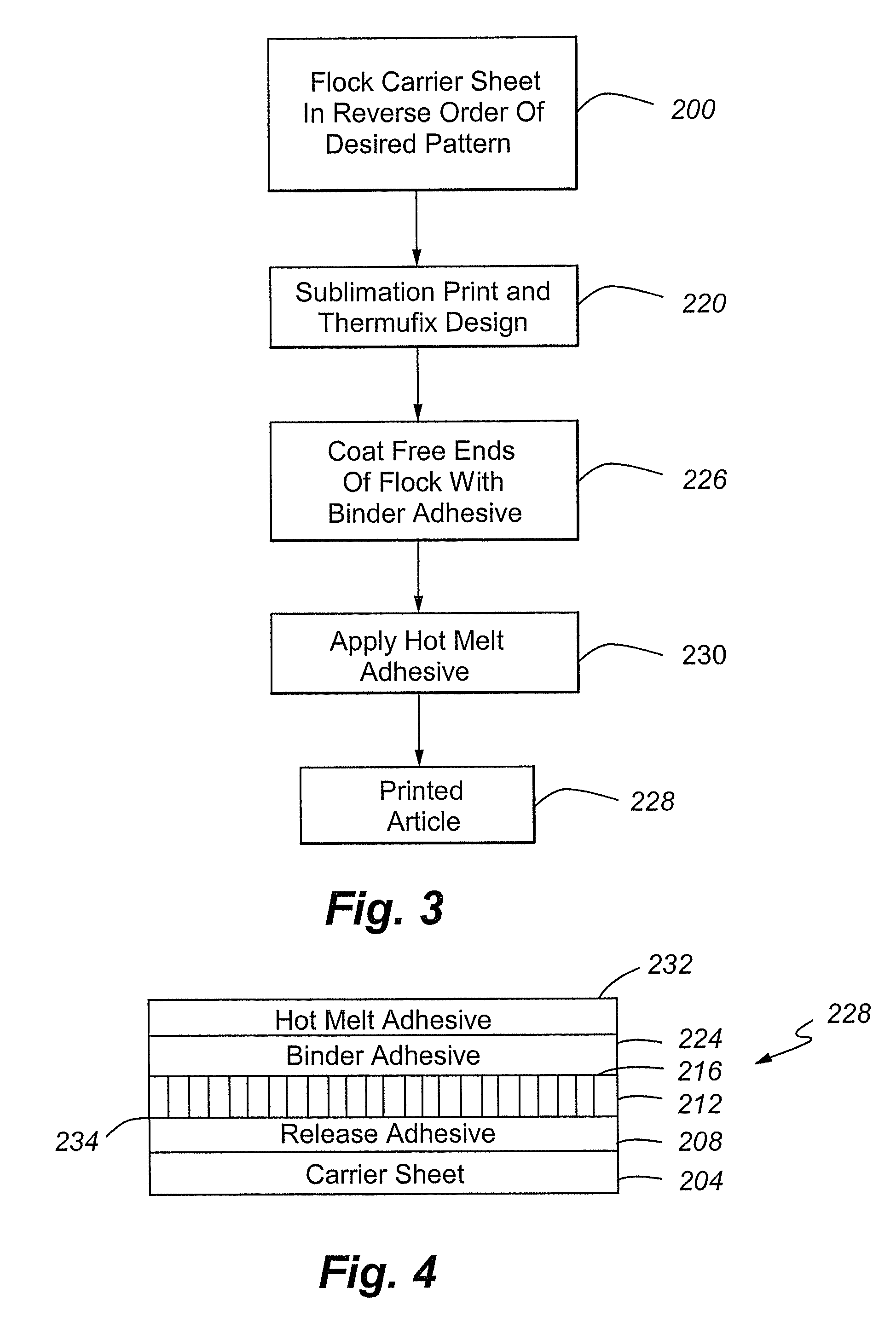

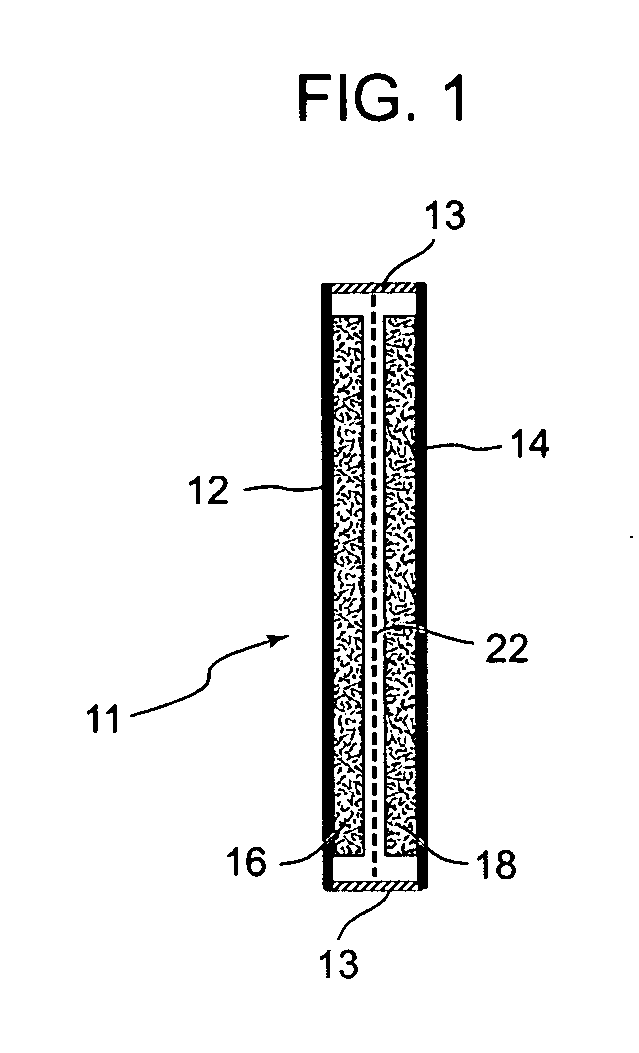

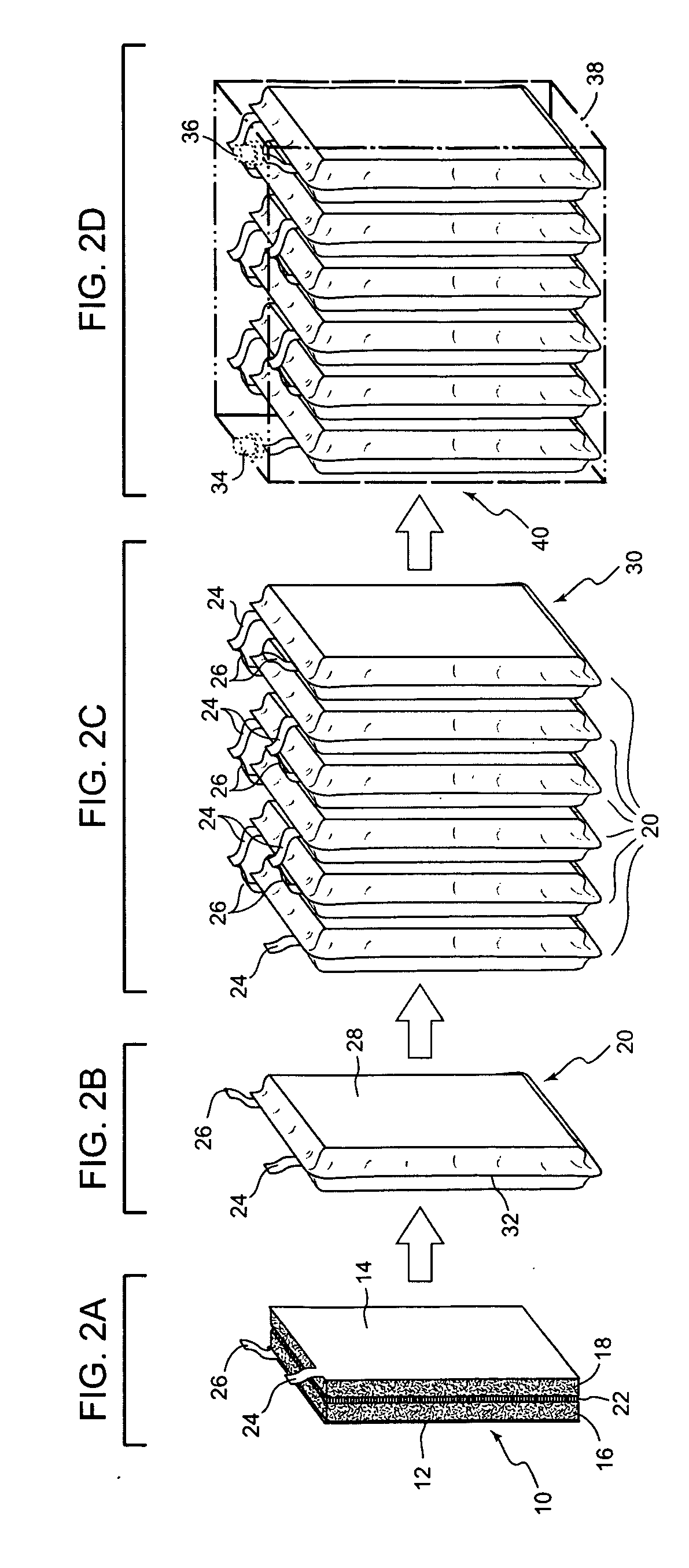

Process for heat setting polyester fibers for sublimation printing

InactiveUS20070022548A1High volumeInexpensive designTransfer printing processDyeing processPolyesterPolymer

The processes and articles of the present invention use thermally stable and loft retentive polymers in sublimation printed flock fibers, which are particularly attractive for forming molded and heat laminated articles. The process and articles use high, medium and low energy dyes on the fibers. A preferred polymer for use in the fibers is poly(cyclohexylene-dimethylene terephthalate). The fibers are heat set before sublimation printing.

Owner:HIGH VOLTAGE GRAPHICS

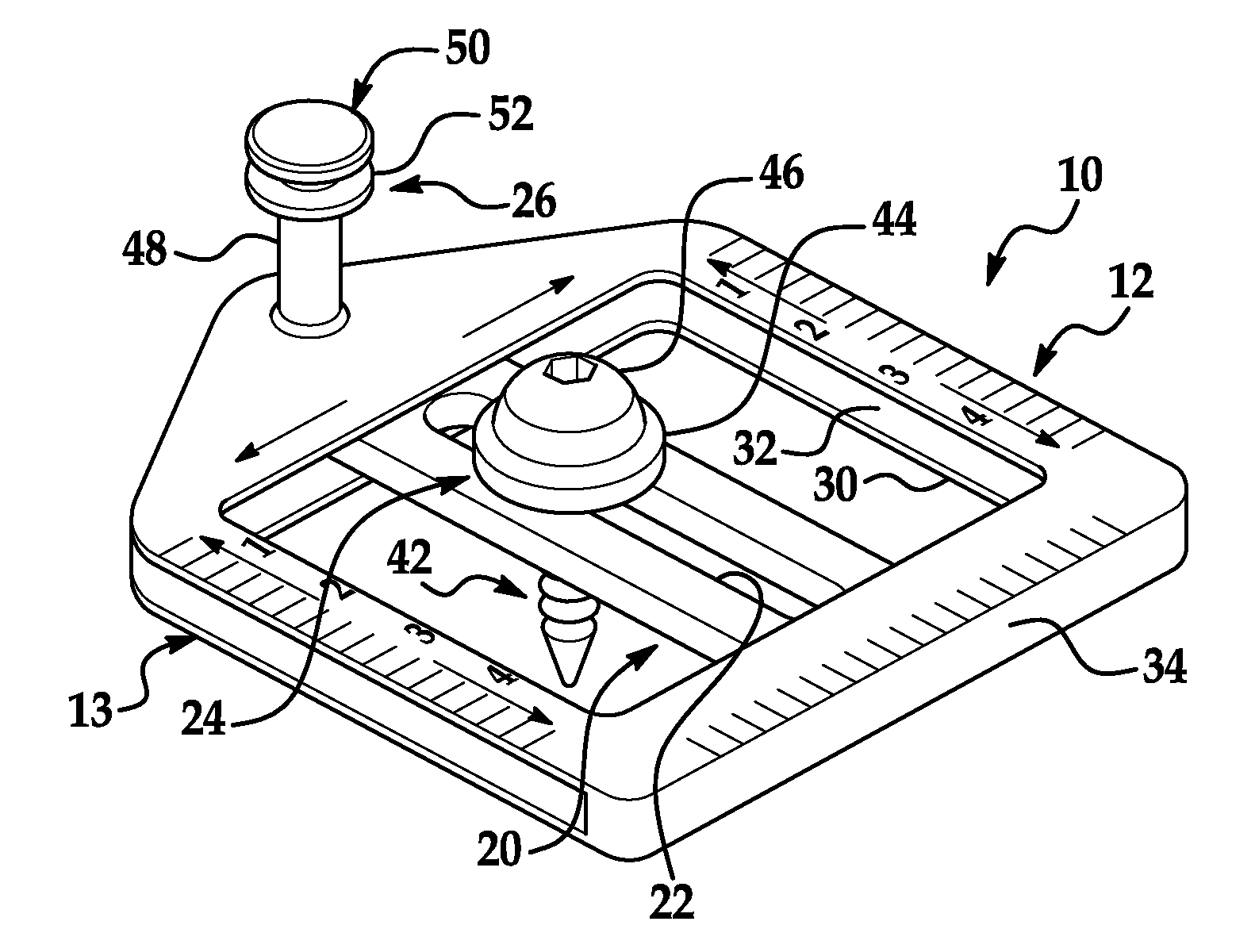

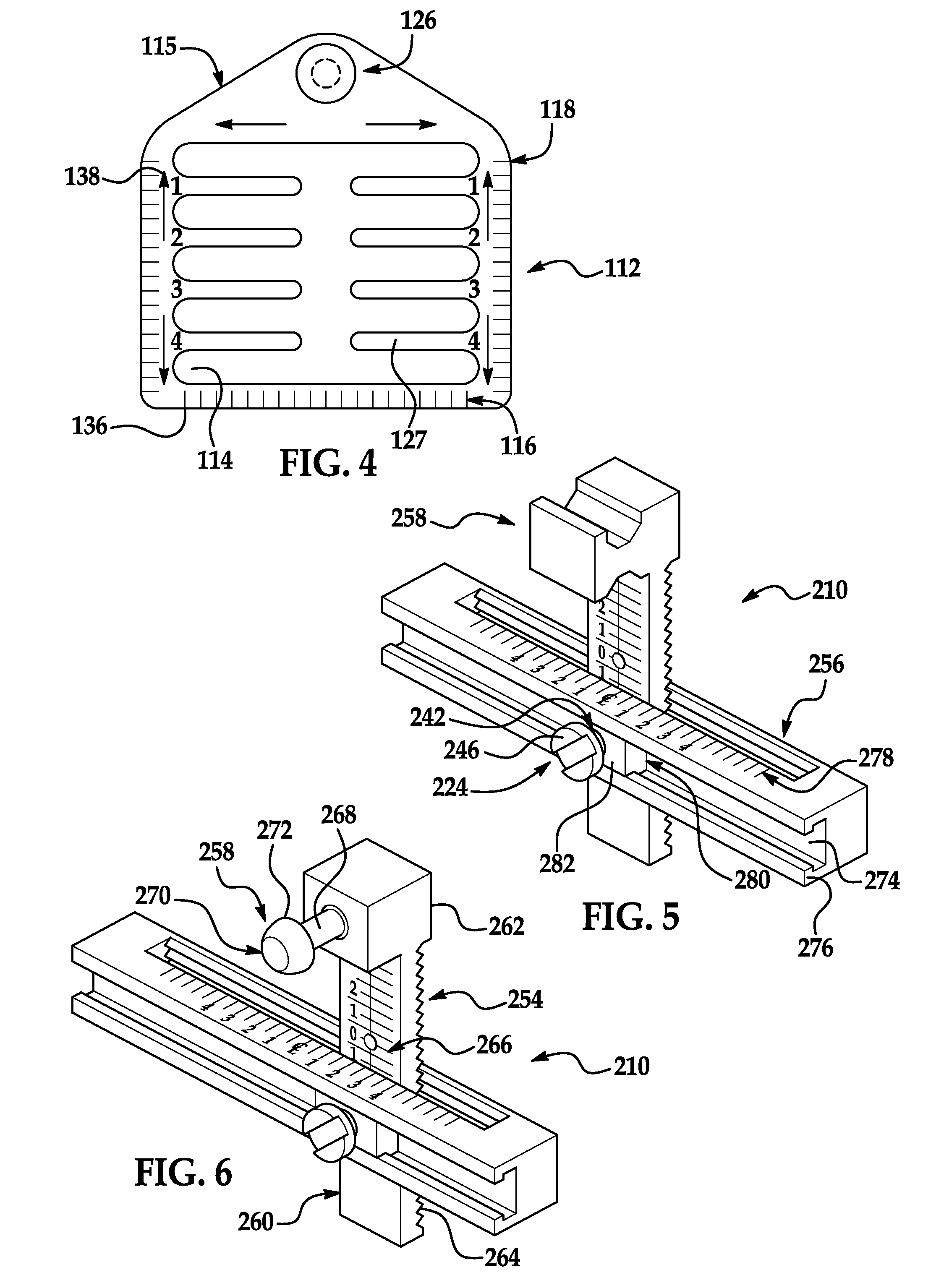

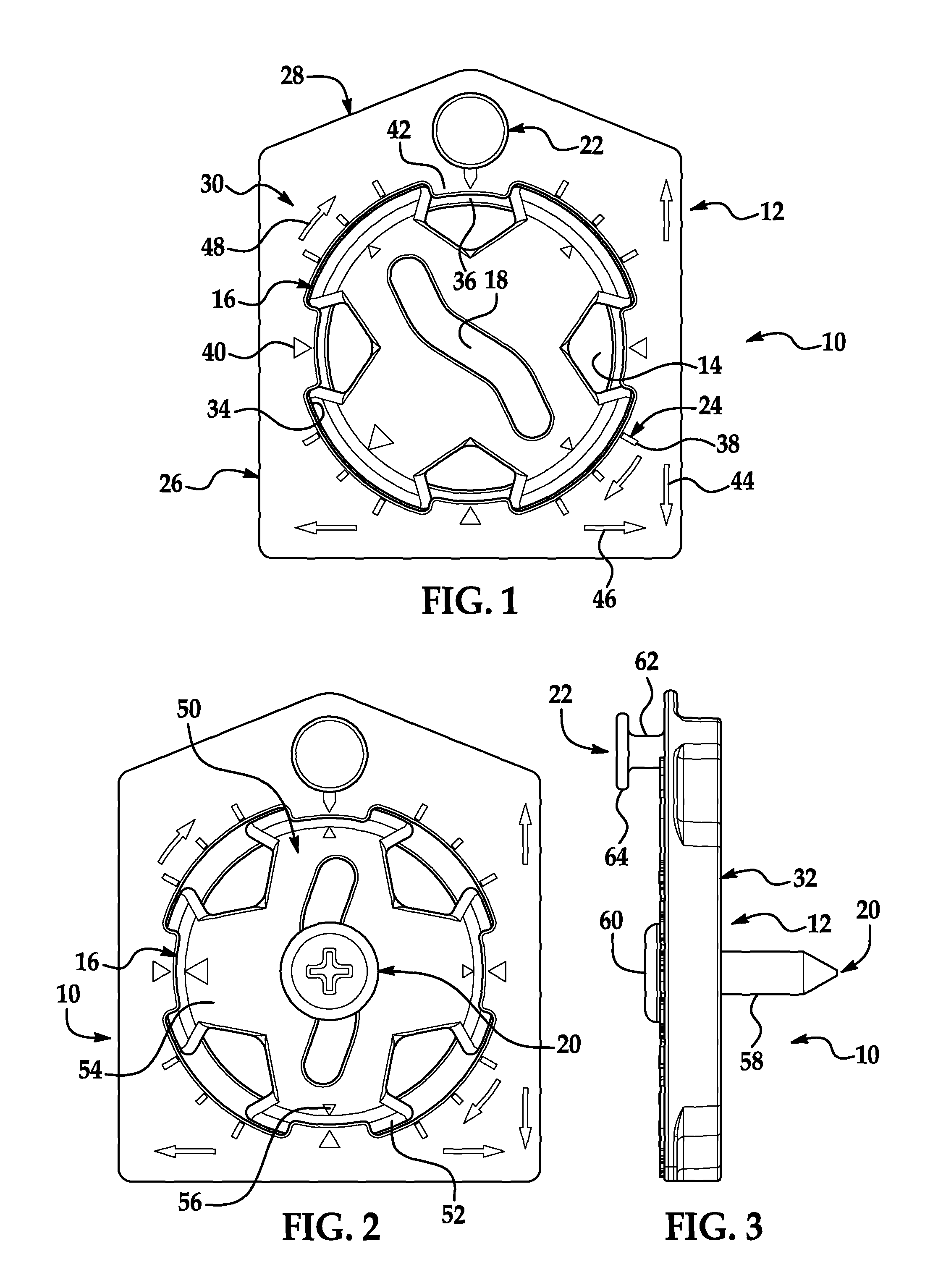

Adjustable wall-hanger assembly

InactiveUS20100116964A1Simply and inexpensively manufacturingHigh volumeCandle holdersPicture framesFastenerEngineering

An adjustable wall-hanger assembly comprises a hanger adapted to be secured to a wall and defining an opening of an interior of the hanger. A hanger slide is mounted to the hanger, is adapted to slide continuously substantially horizontally or vertically in the opening of the hanger, and defines a slot of an interior of the hanger slide extending substantially the other of horizontally or vertically with respect to the hanger slide. A mounting fastener is received through the slot of the hanger slide and adapted to slide continuously along the slot and be fastened to the wall to mount the assembly to the wall. A combination of the continuous substantially horizontal and vertical sliding of the hanger slide and mounting fastener allows for substantially infinite placement of the mounting fastener in the opening of the hanger. A hanger hook is fixedly connected to and extends outwardly from the hanger and substantially overlies the opening of the hanger for supporting an object hung on the hanger hook.

Owner:ALEO DINO D

Composite building products bound with cellulose nanofibers

ActiveUS20150033983A1High volumeLong lifespanWood working apparatusGlass/slag layered productsNanofiberConstruction aggregate

Building materials are generated by the simple mixing of cellulose nanofiber (CNF) slurry with typical wood-derived material such as wood meal, optionally with mineral particulate materials, and dried. Particle boards are made with wood meal particulates; wallboards are made with wood particulates and mineral particulates; paints are made with pigment particulates; and cement is made with aggregate particulates. The particle board samples were tested for fracture toughness. The fracture toughness was found to be from 20% higher up to ten times higher than the typical value for similar board, depending on the formulation. For cases of 20% by weight cellulose nanofibers and 80% wood, the fracture toughness was more than double that of typical particle board. The process sequesters carbon and oxygen into the building product for its lifespan—typically decades—and avoid releasing CO2 into the atmosphere.

Owner:UNIVERSITY OF MAINE

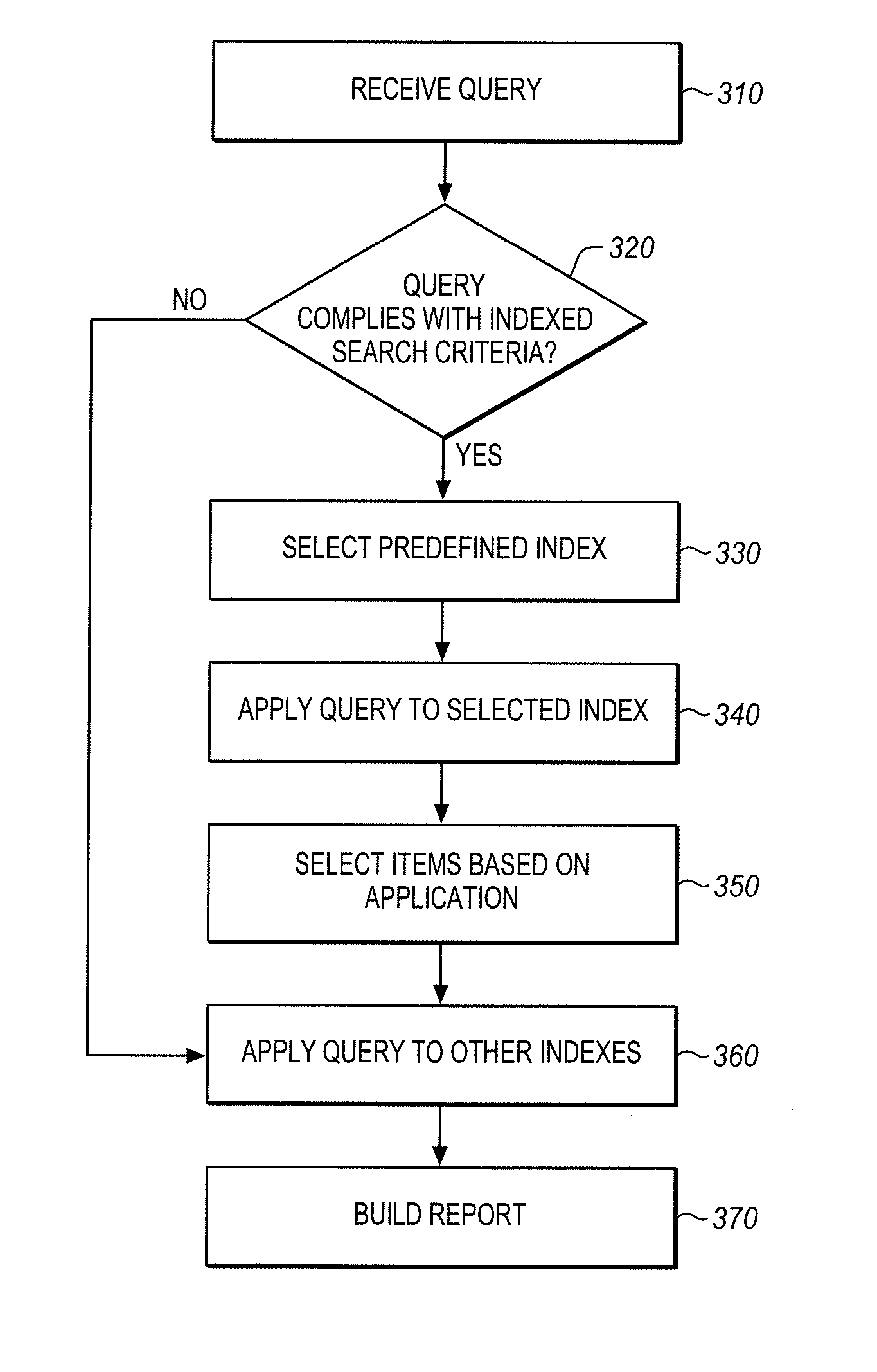

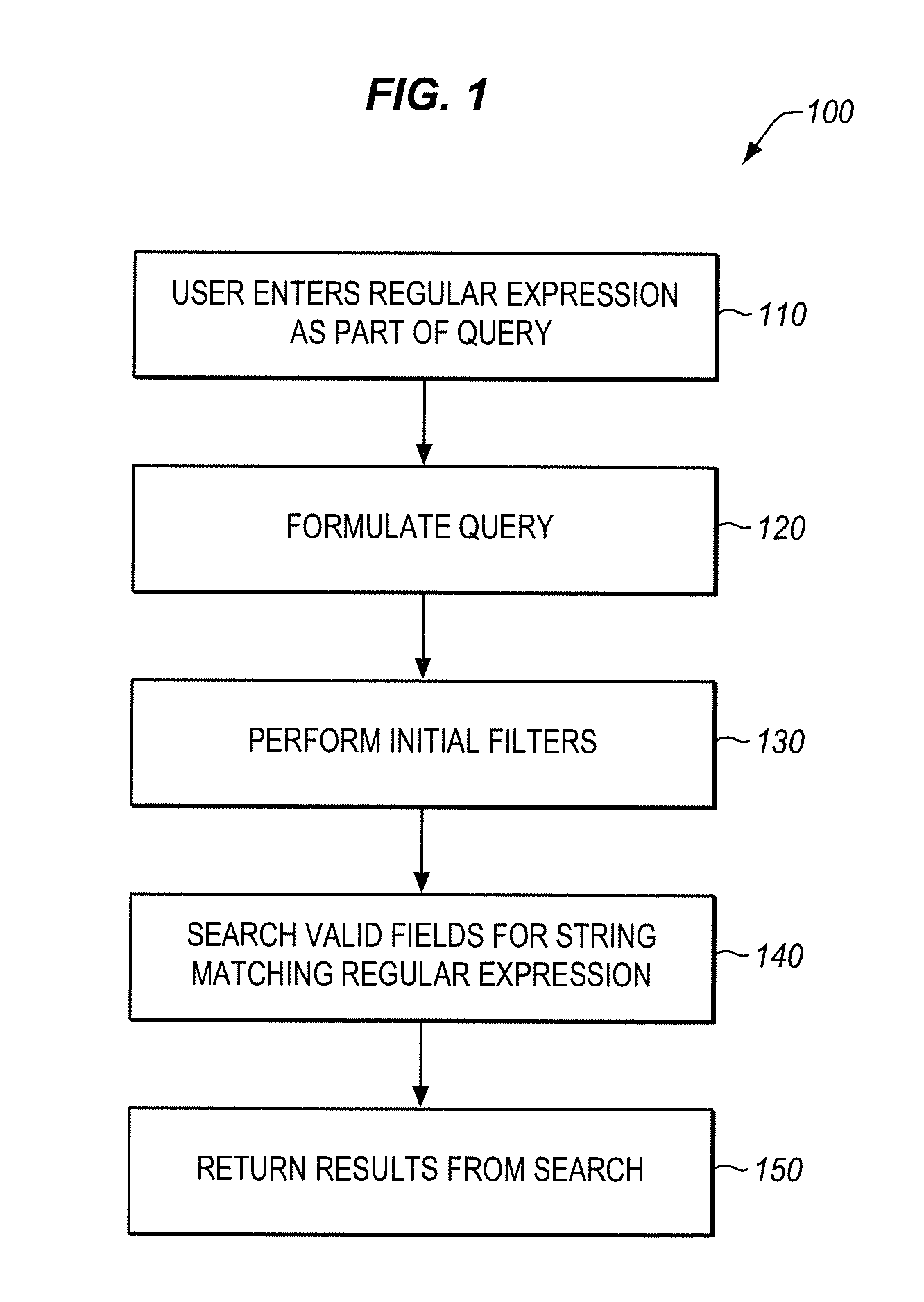

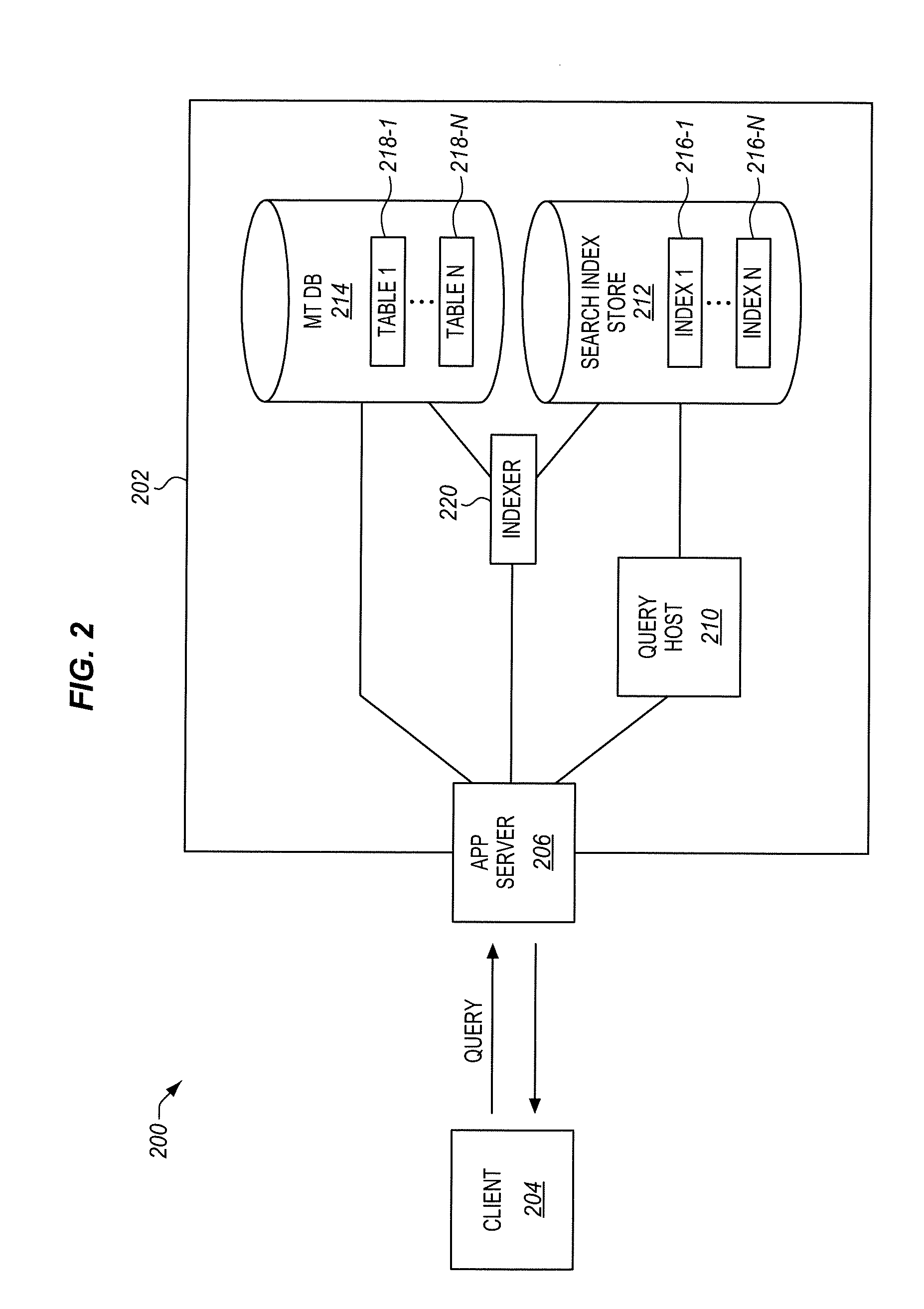

Methods and systems for performing high volume searches in a multi-tenant store

ActiveUS20110258199A1High volumeNot addressDigital data information retrievalDigital data processing detailsDatabase

Method and systems for performing high volume searches are described. In one example a method includes receiving a query directed to a database, the database including a plurality of items, determining whether the query complies with one of a plurality of search criteria, each of the plurality of search criteria corresponding to a predefined index of the database, selecting a predefined index of the database corresponding to one of the plurality of search criteria if the query complies with said search criterion, the index containing entries that comply with the corresponding search criterion, applying the query to the selected index to find database items referenced in the index, selecting items based on applying the query to the selected index, building a report for the query, the report including only items of the selected index.

Owner:SALESFORCE COM INC

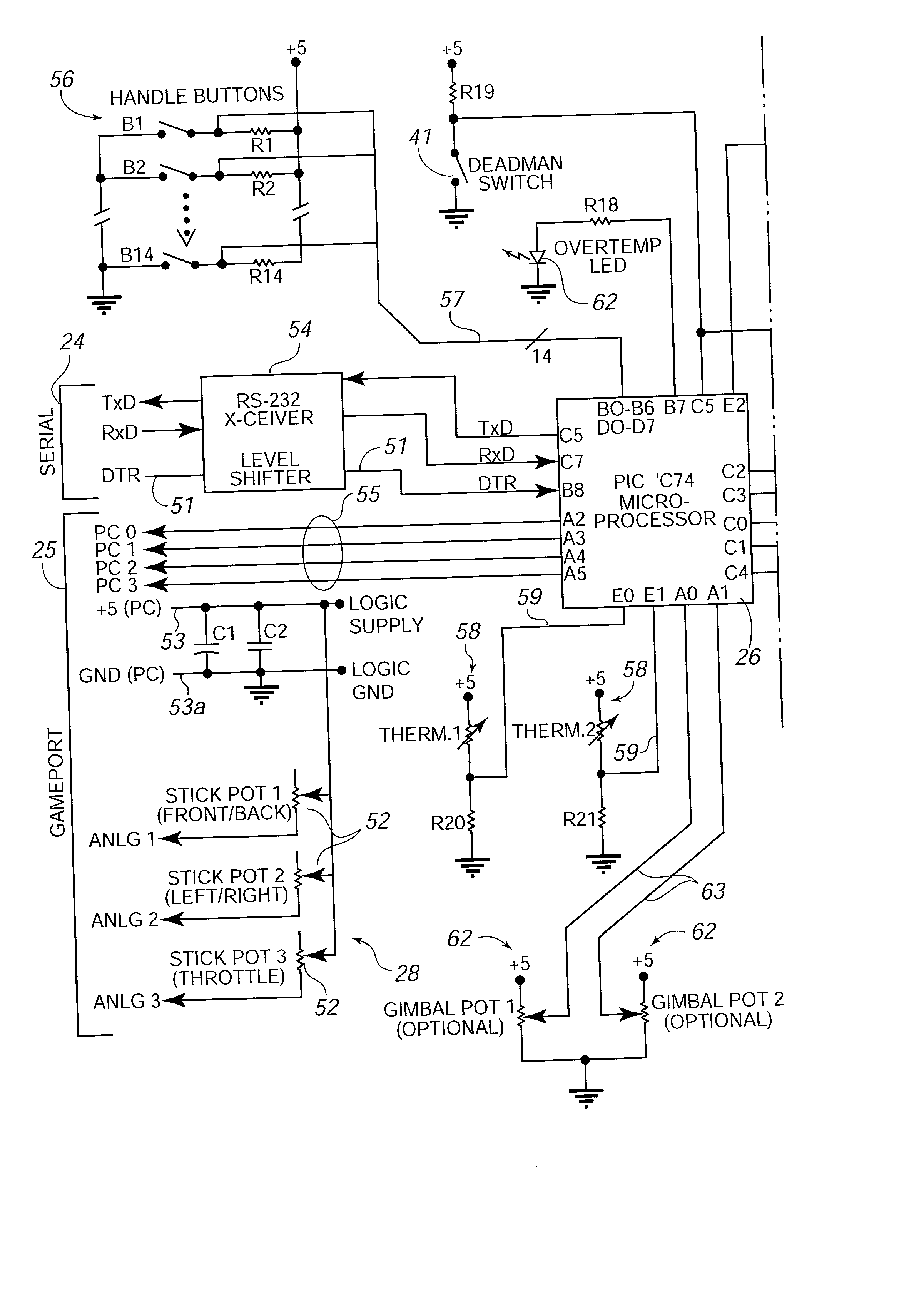

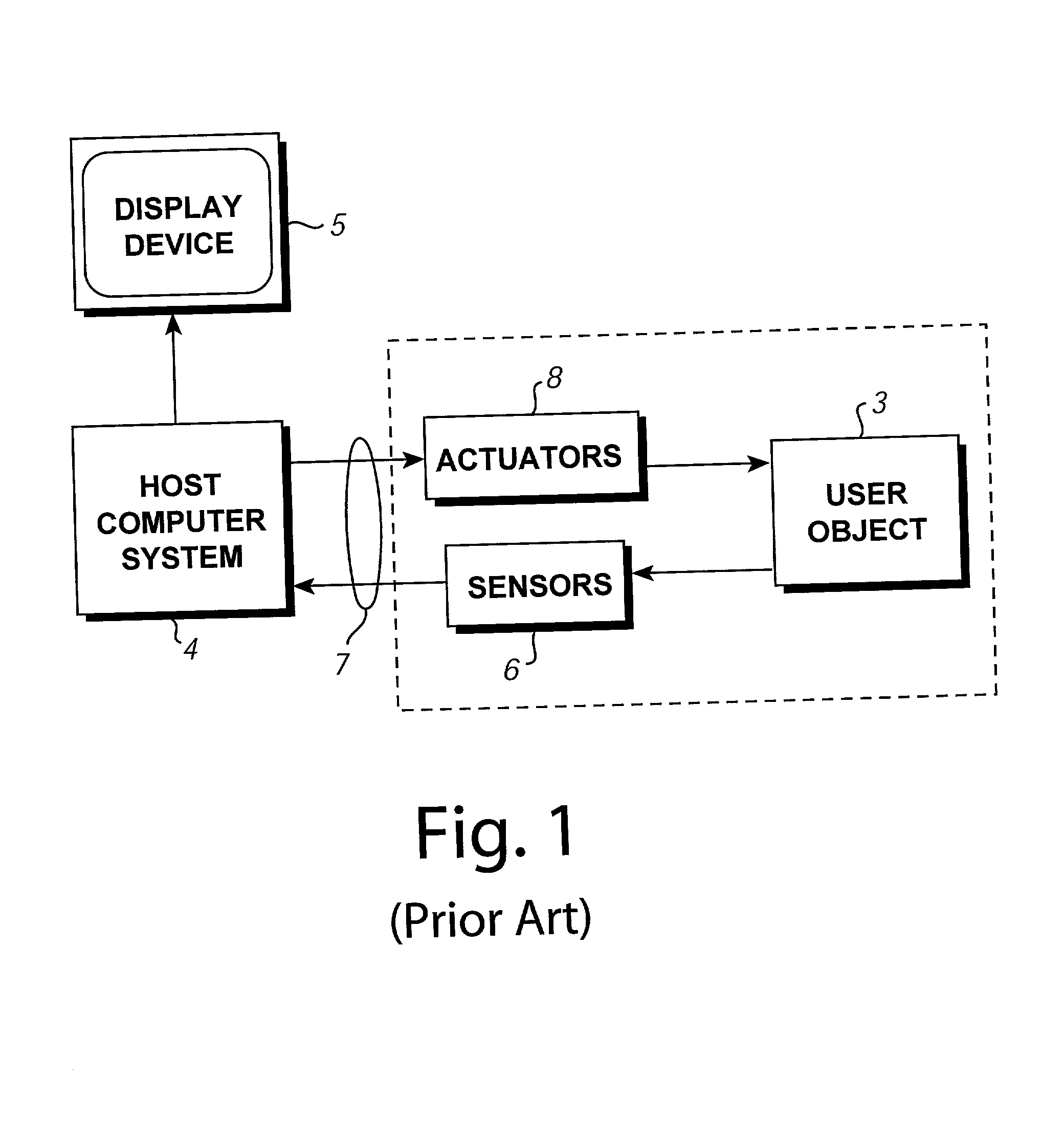

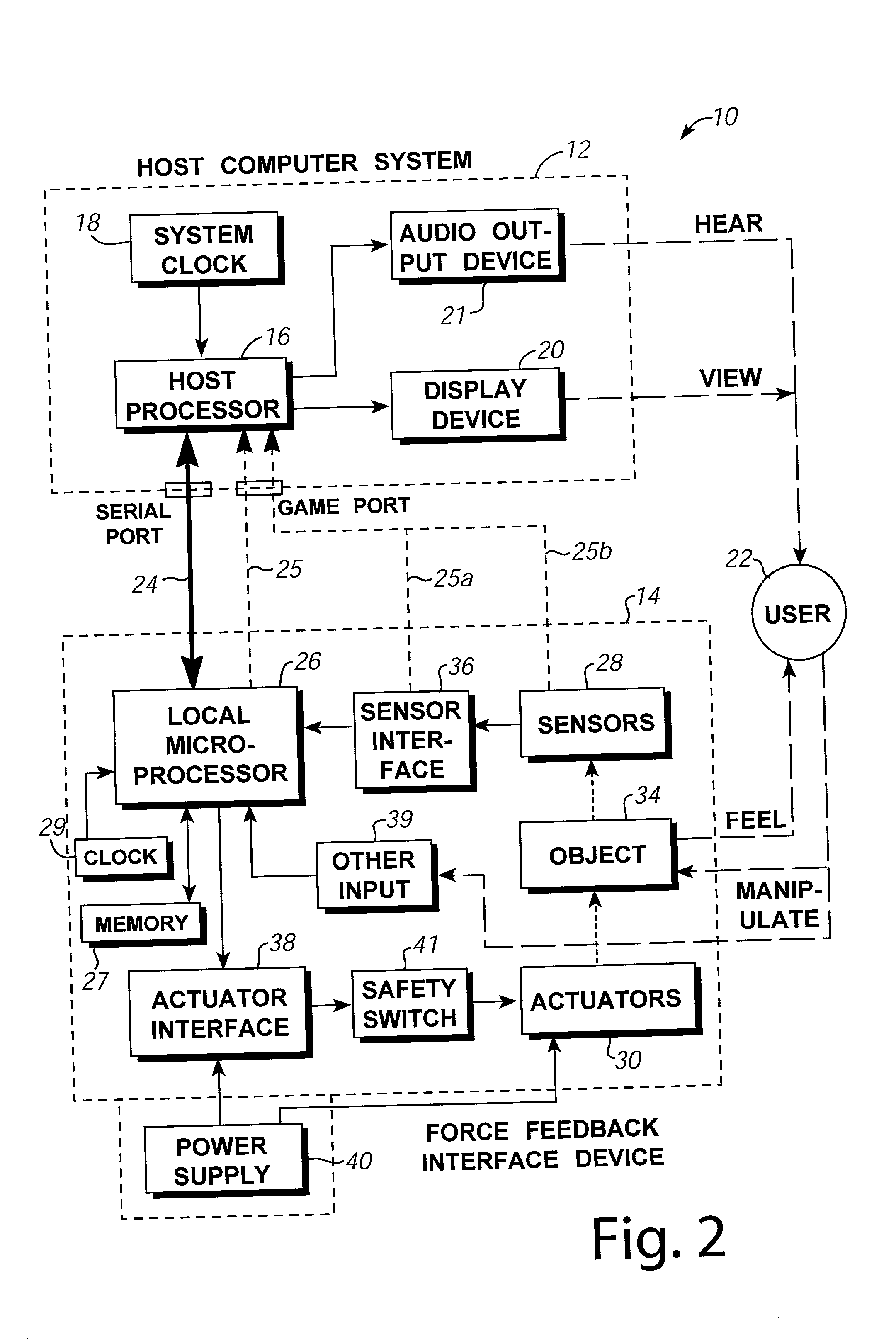

Power management for interface devices applying forces

InactiveUS20020126091A1Decrease costHigh volumeInput/output for user-computer interactionManual control with multiple controlled membersJoystickPeripheral

A method and apparatus for providing safe and low-cost force feedback peripherals for consumer applications. A device microprocessor local to an interface device is coupled to the host by a first interface bus. The microprocessor receives host commands from the host computer on the first interface bus, such as an RS-232 interface, and commands an actuator to apply a force to a user object, such as a joystick, in response to host commands. A sensor detects positions of the user object and outputs signals to the host on a second interface bus, such as a PC game port bus, separate from the first bus. In a "recoil" embodiment, a user initiates force feedback by pressing a button on the joystick, which sends an activation signal to the actuator. In other recoil embodiments, the host computer can transmit one or more enable signals and / or activation signals to the actuator to enable or command forces. A safety switch of the present invention disables the actuator when the interface device is not in use and enables the actuator when an amount of weight over a predetermined amount is placed on the joystick created by a user grasping the joystick. A circuit of the present invention includes a capacitor for storing power provided by an input signal and supplied to the actuator when forces are to be output.

Owner:IMMERSION CORPORATION

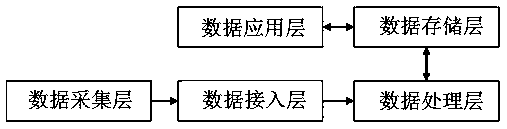

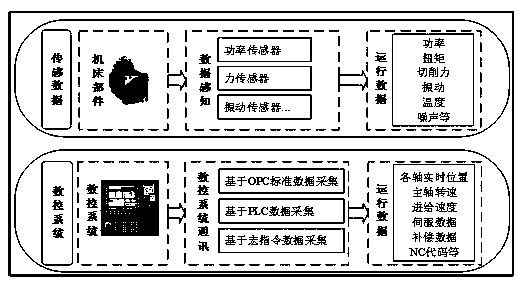

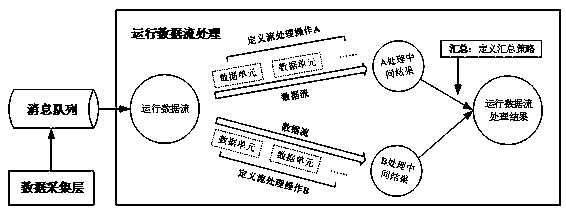

Machine tool state monitoring system and method based on running data flow

ActiveCN110347116AImprove timelinessIncrease transfer rateProgramme controlComputer controlMessage queueBatch processing

The invention discloses a machine tool state monitoring system based on a running data flow. The machine tool state monitoring system based on the running data flow comprises a data acquisition layerused for acquiring running data of a machine tool; the data acquisition layer is connected to a data processing layer through a data access layer; the data processing layer is connected to a data storage layer; the data processing layer comprises a flow processing layer used for performing flow processing on the running data of the machine tool; distributed cluster architecture is adopted in the data processing layer; the data access layer distributes the running data of the machine tool into the data processing layer through a distributed message queue; the data processing layer further comprises a batch processing layer used for performing batch processing on the running data of the machine tool; and the flowing processing layer and the batch processing layer are integrated through the shared data storage layer. The invention further discloses a monitoring method of the machine tool state monitoring system based on the running data flow. The machine tool state monitoring system basedon the running data flow in the invention is adopted. The machine tool state monitoring system and method based on the running data flow in the invention can be suitable for performing acquisition, processing, storage, analysis and visualization on the running data flow having high data characteristics.

Owner:CHONGQING UNIV +1

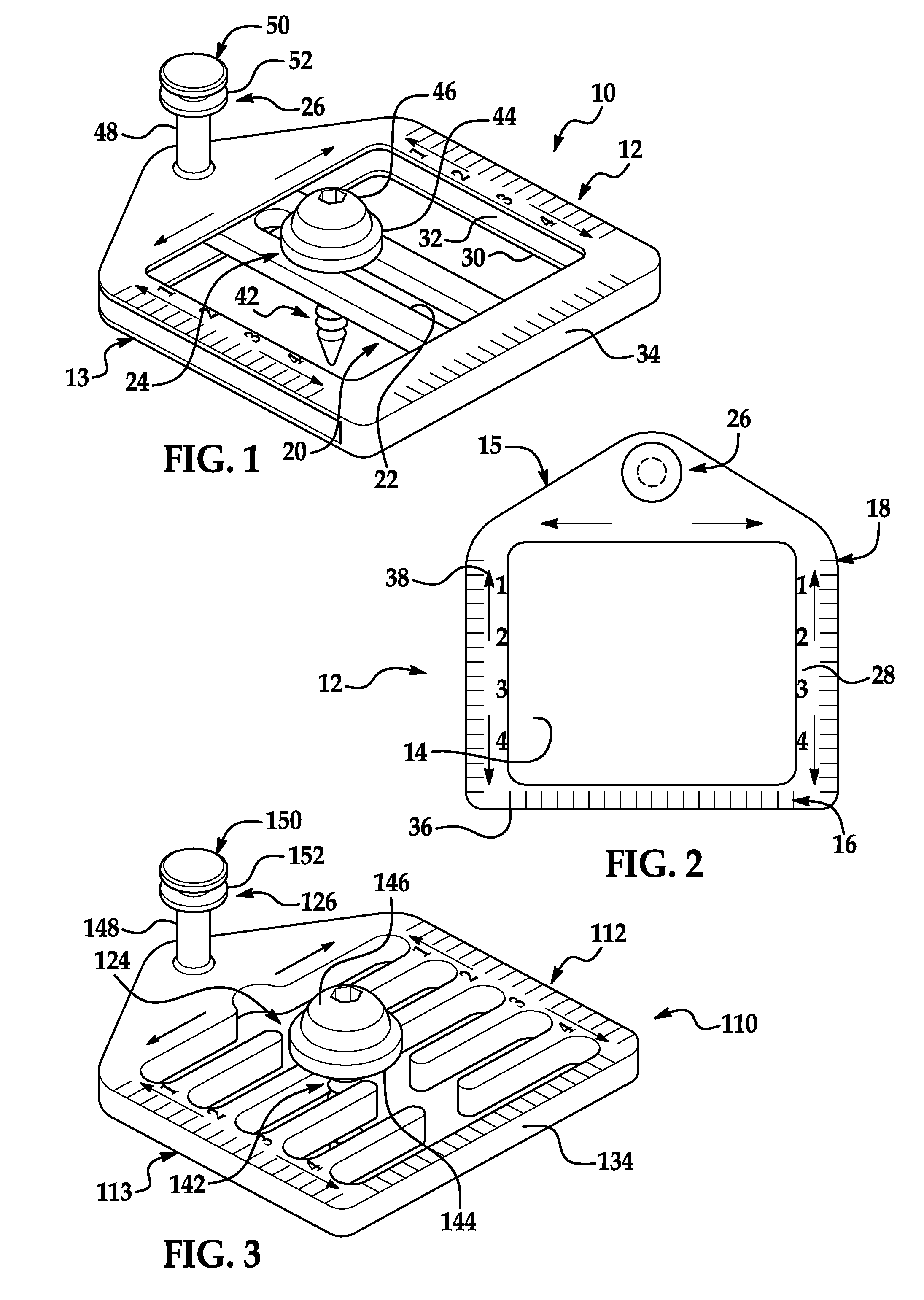

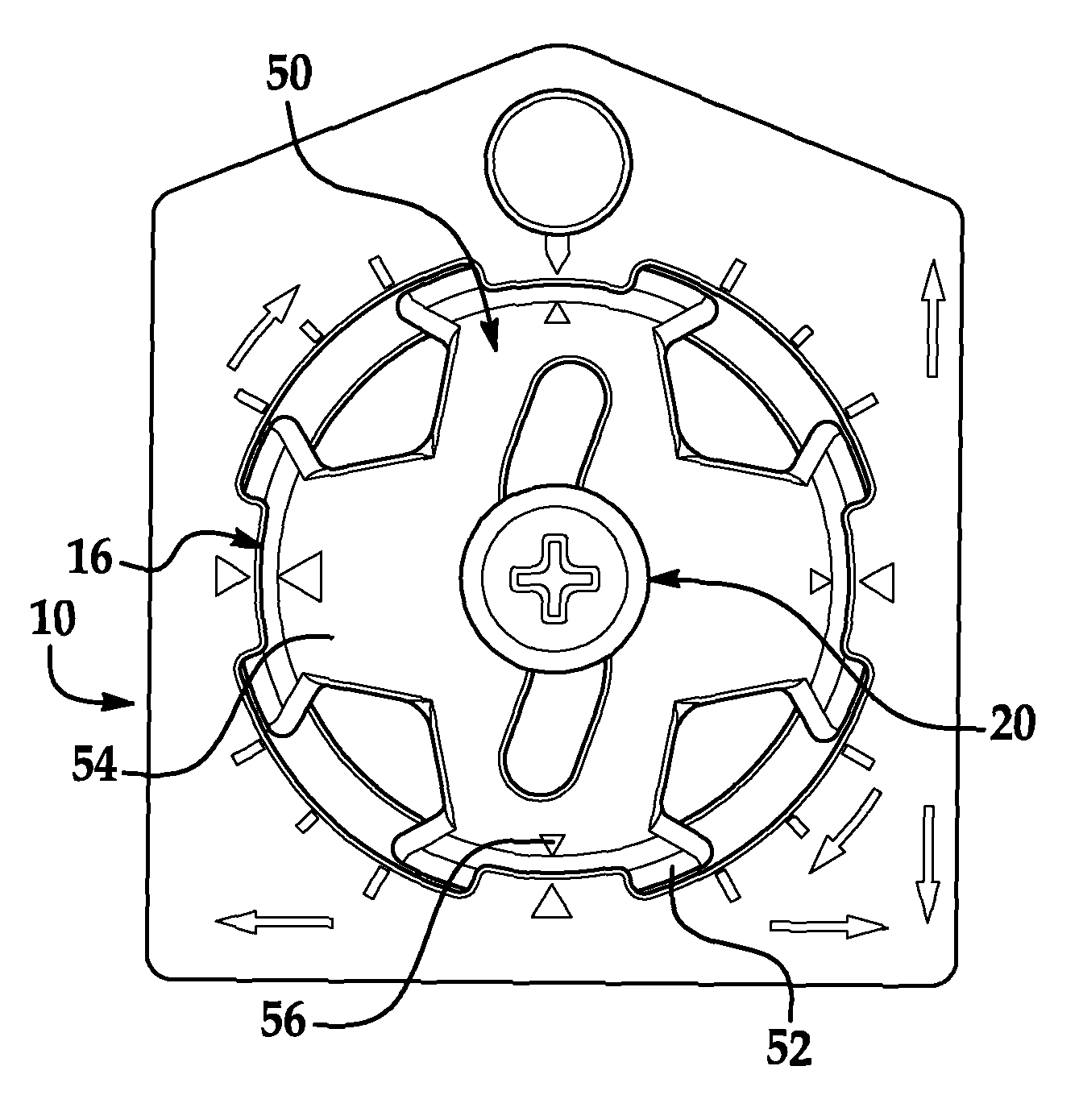

Adjustable picture-hanger assembly

InactiveUS7913967B1Manufacture simply and inexpensivelyHigh volumePicture framesDomestic mirrorsFastenerEngineering

An adjustable picture-hanger assembly comprises a hanger adapted to be secured to a wall and defining a substantially central opening of an interior of the hanger. A hanger slide is movably mounted to the hanger, is adapted to slide continuously substantially rotationally in the opening of the hanger, and defines a slot of an interior of the hanger slide. A mounting fastener is received through the slot of the hanger slide and adapted to slide continuously along the slot and be fastened to the wall to mount the assembly to the wall. A combination of the continuous substantially rotational sliding of the hanger slide and continuous sliding of the mounting fastener allows for substantially infinite placement of the mounting fastener in the opening of the hanger. A hanger hook is fixedly connected to and extends outwardly from the hanger and overlies the opening of the hanger for supporting an object hung on the hanger hook.

Owner:ALEO DINO D

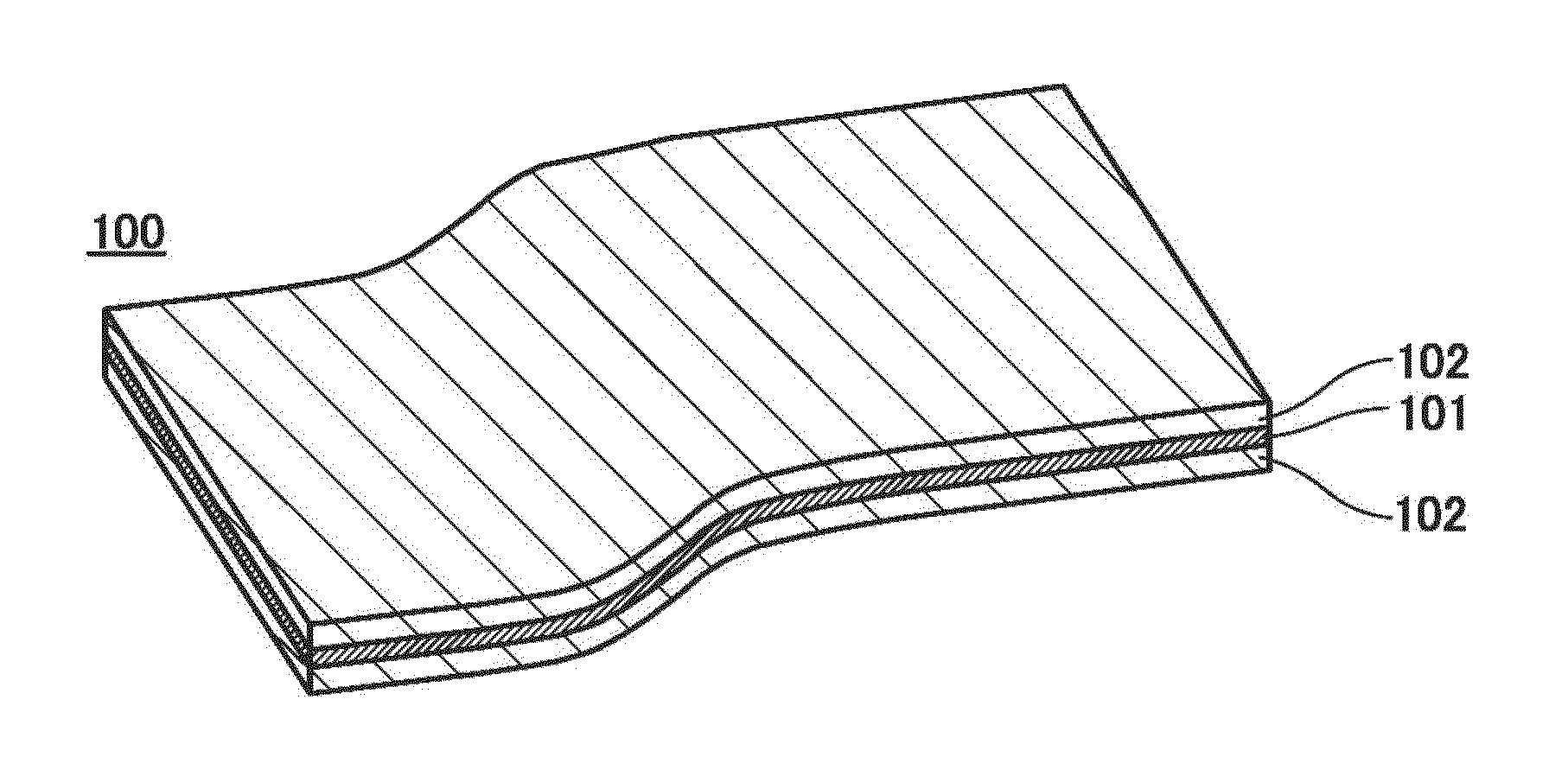

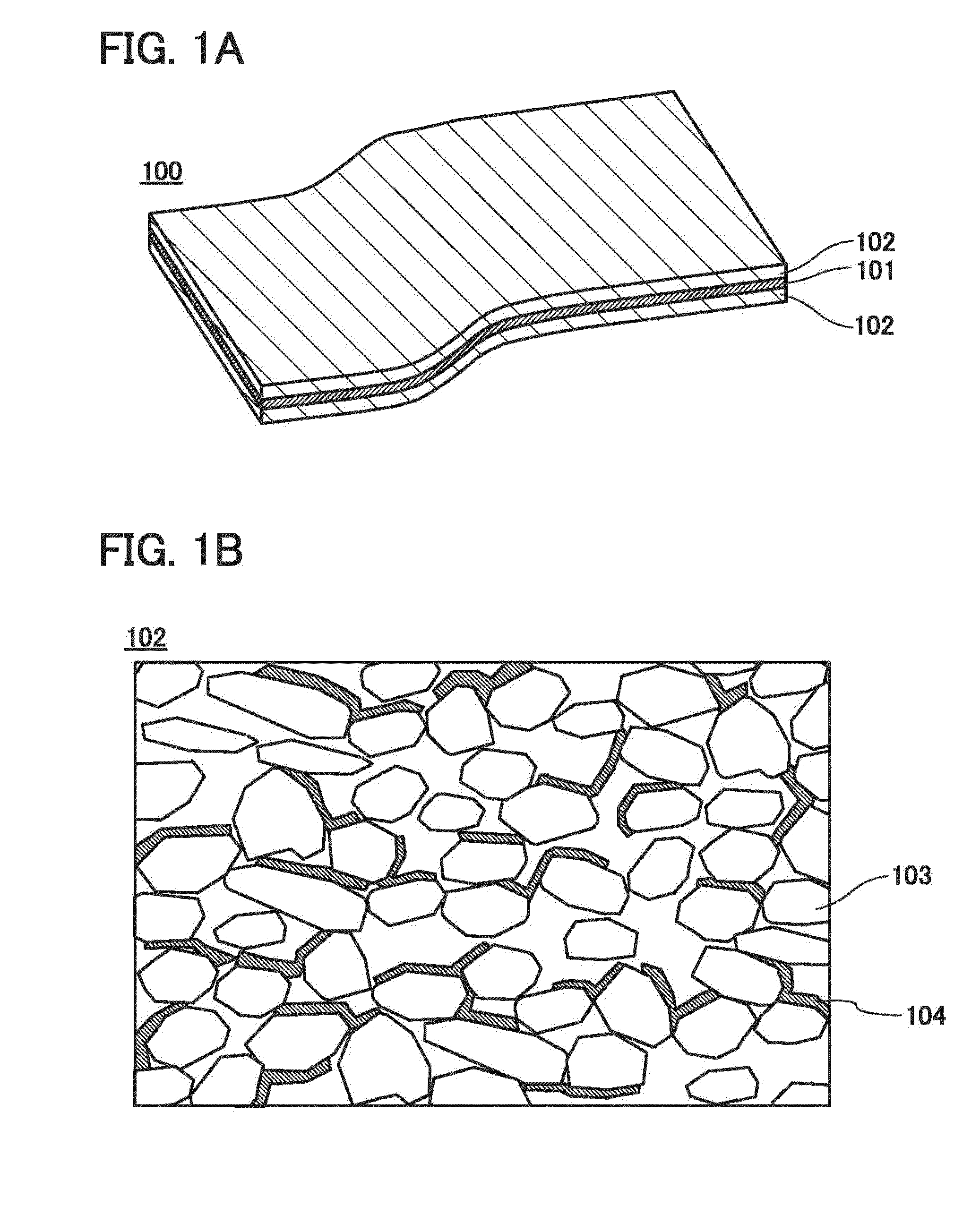

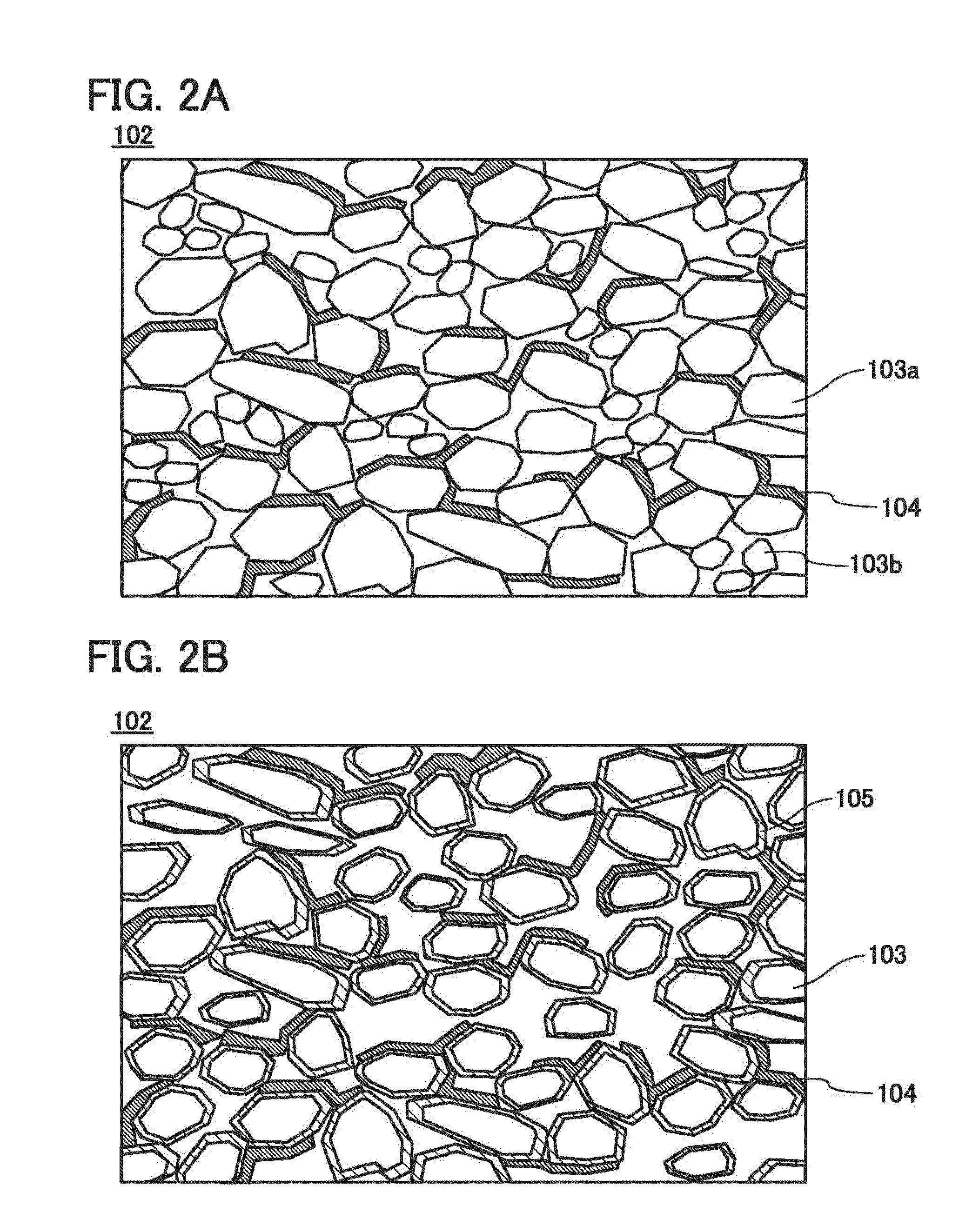

Positive electrode for nonaqueous secondary battery, method for forming the same, nonaqueous secondary battery, and electrical device

ActiveUS20140127568A1Lower discharge capacityHigh volumeConductive materialActive material electrodesEngineeringGraphene

A positive electrode for a nonaqueous secondary battery including an active material layer which has sufficient electron conductivity with a low ratio of a conductive additive is provided. A positive electrode for a nonaqueous secondary battery including an active material layer which is highly filled with an active material, id est, including the active material and a low ratio of a conductive additive. The active material layer includes a plurality of particles of an active material with a layered rock salt structure, graphene that is in surface contact with the plurality of particles of the active material, and a binder.

Owner:SEMICON ENERGY LAB CO LTD

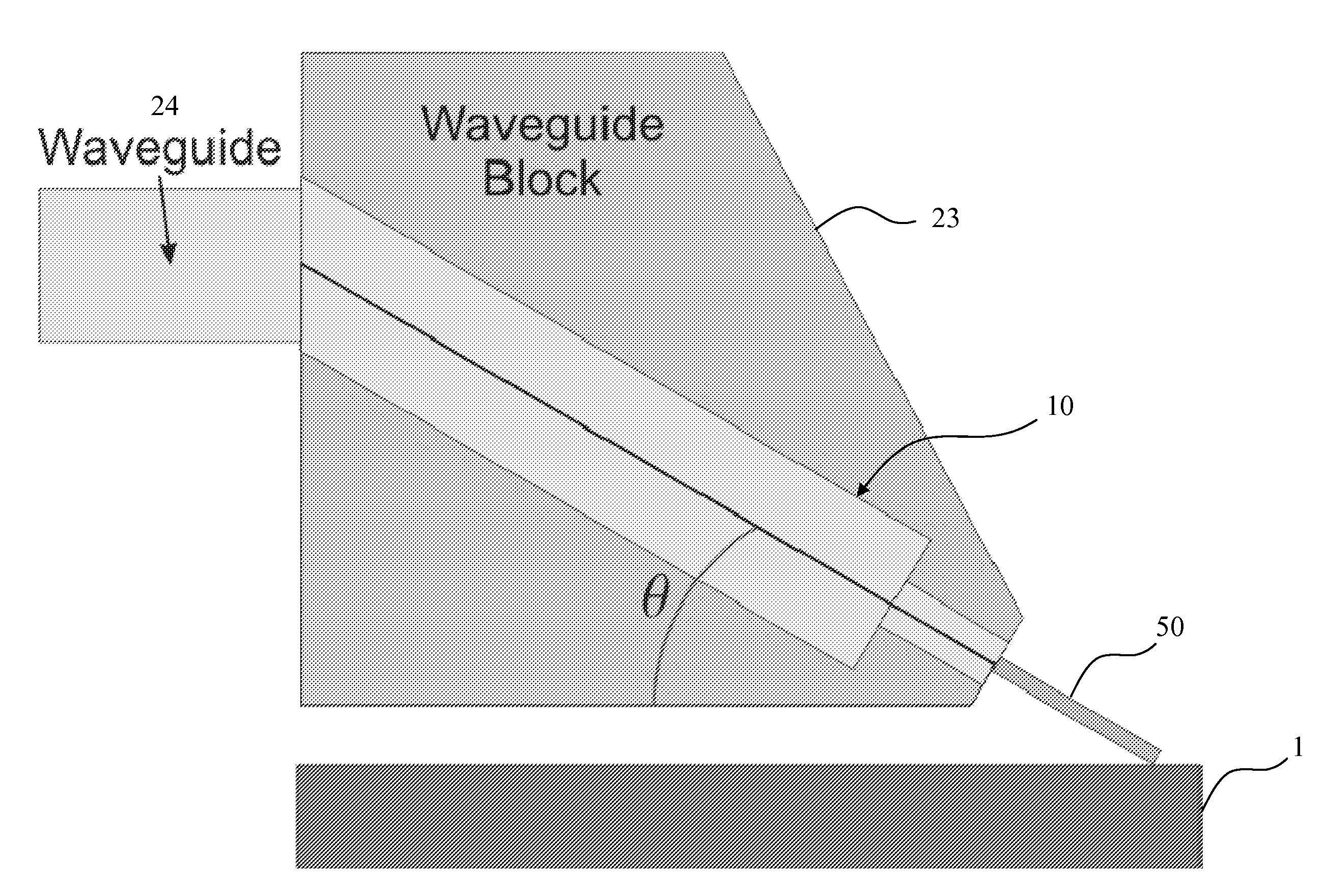

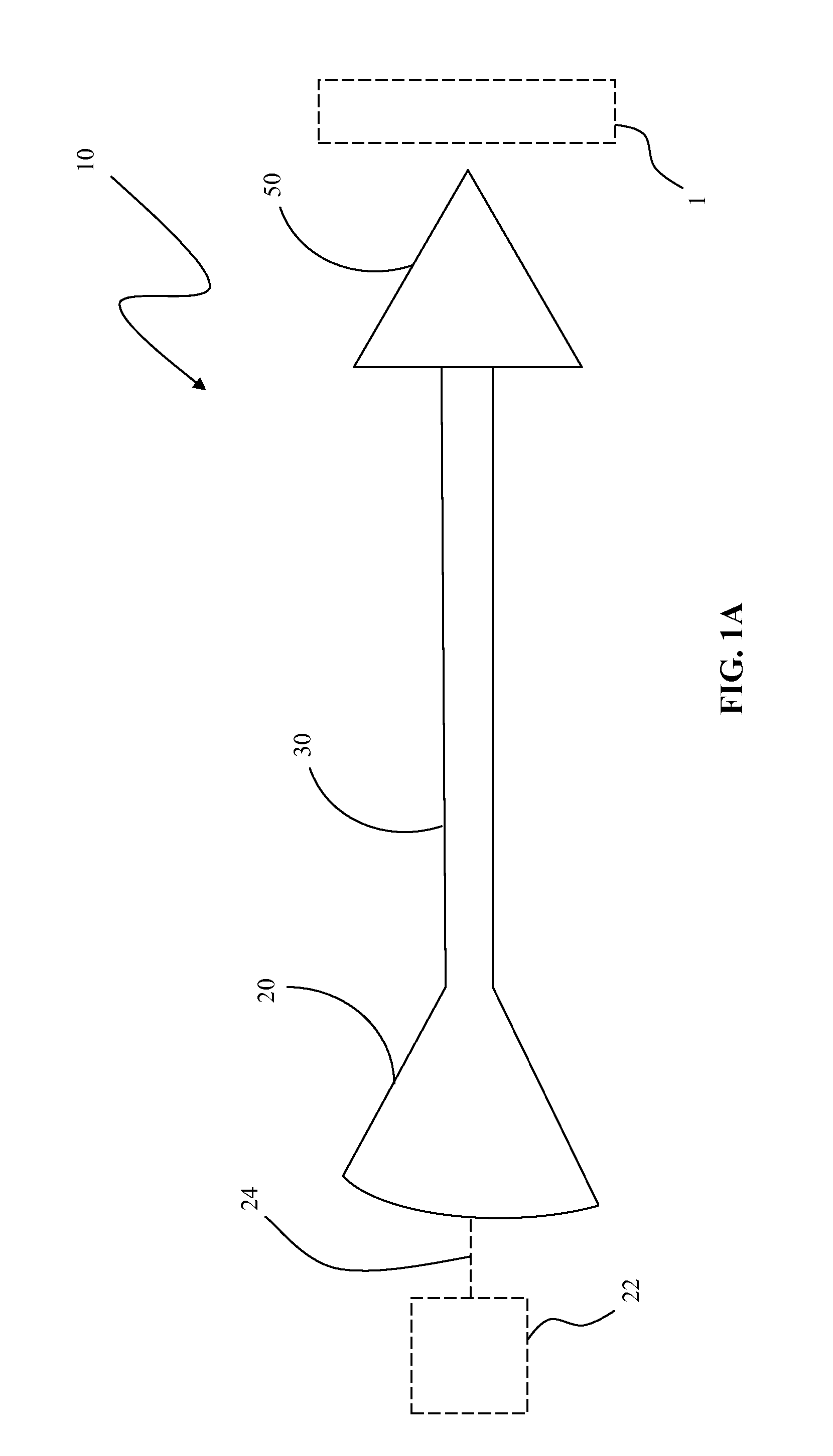

Micromachined on-wafer probes and related method

ActiveUS20130106456A1High volumeLower costElectrical testingManufacture of electrical instrumentsMechanical forceIntegrated circuit

A micromachining process to fabricate a single chip that simple drops into a supporting structure. The micromachining process provides the ability to create a probe that will interface with integrated circuits, for example, operating at frequencies in the range of about 100 GHz to about 3,000 GHz (3 THz). This approach creates a silicon structure (or other applicable choice of material) that provides mechanical force for probing while supporting the transfer of the high frequency energy between a measurement system and the integrated circuit, individual device or material.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

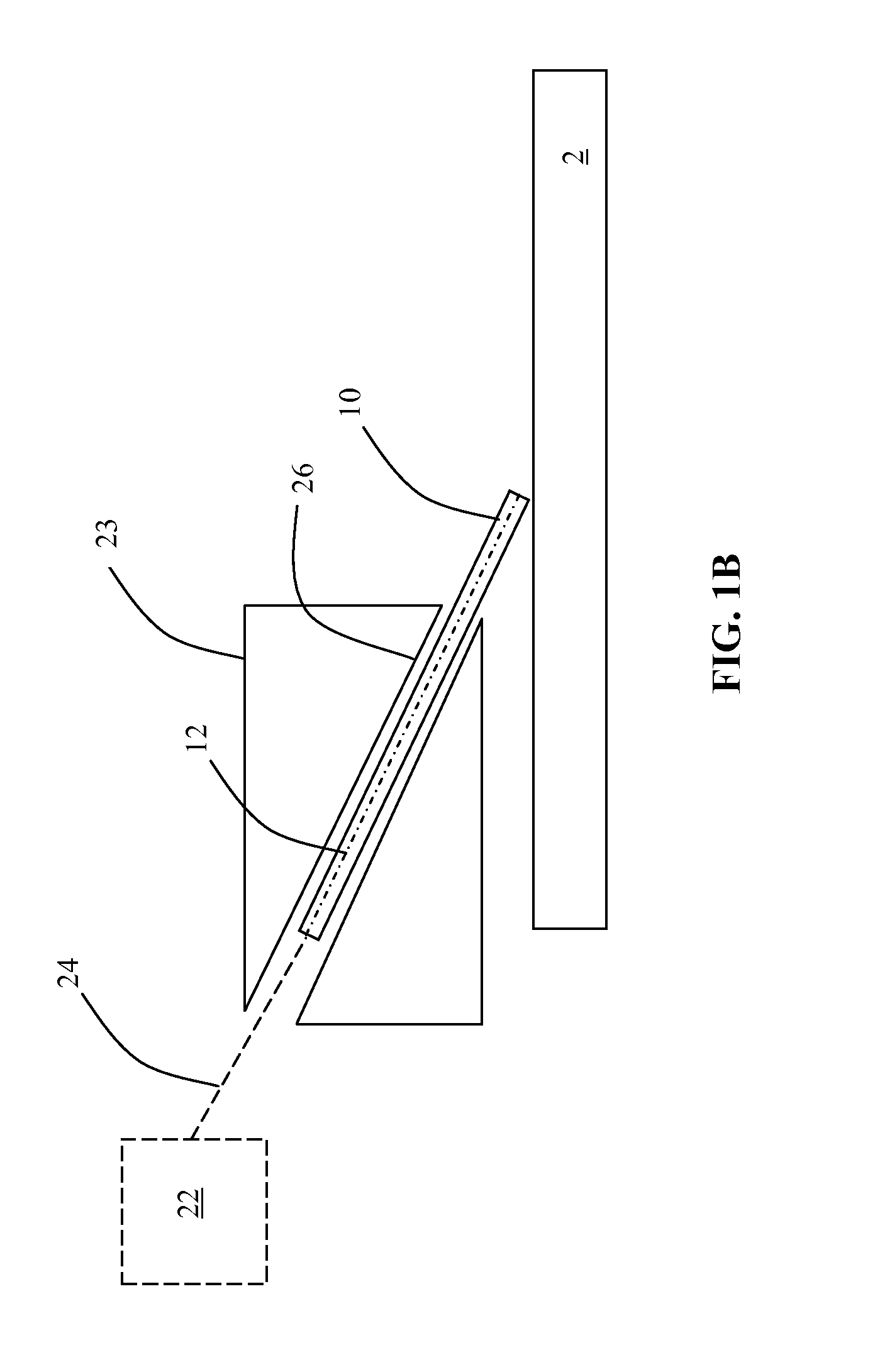

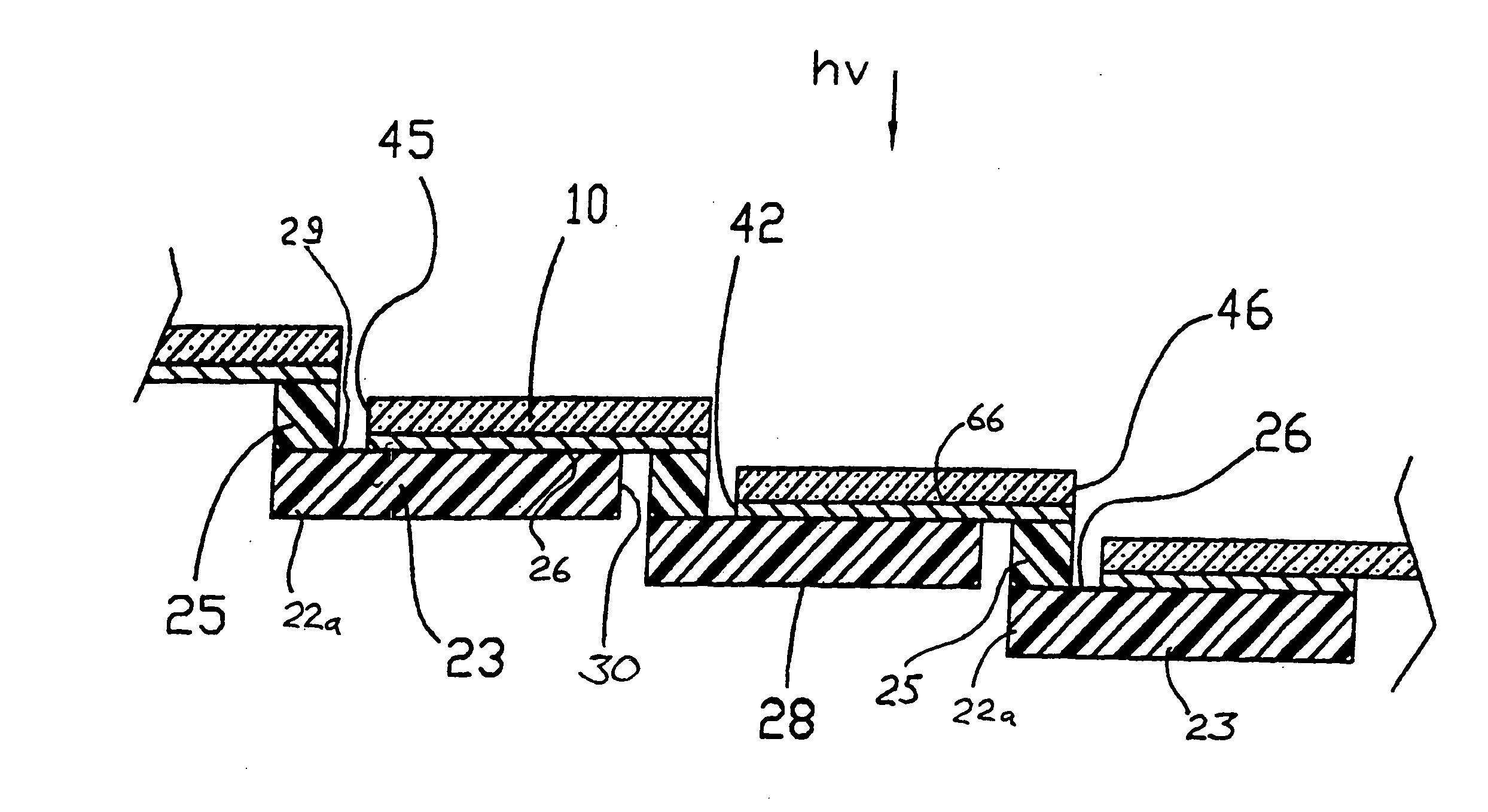

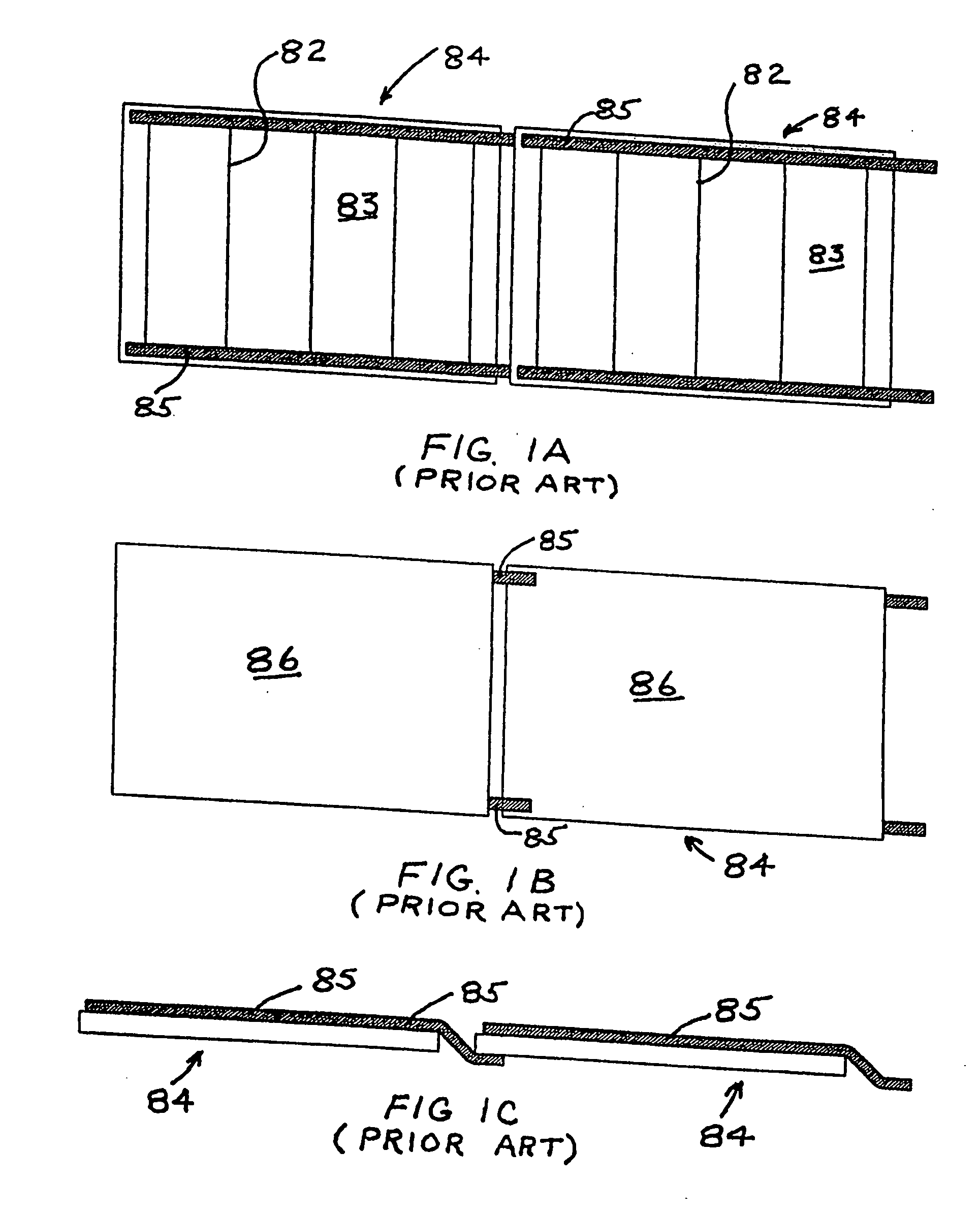

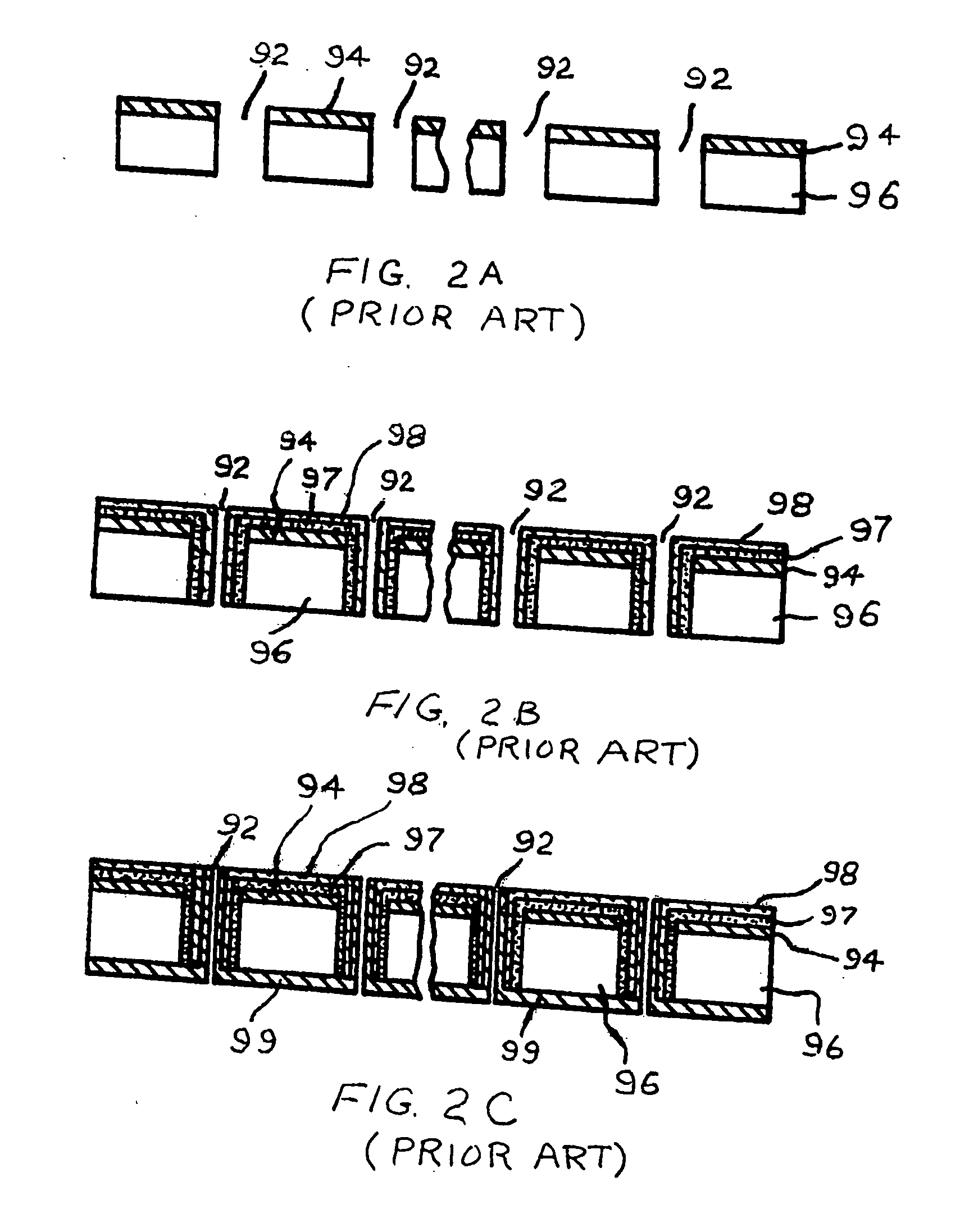

Substrate structures for integrated series connected photovoltaic arrays and process of manufacture of such arrays

InactiveUS20100229942A1Minimizing needHigh volumePV power plantsSolid-state devicesMetal foilPolymer substrate

This invention comprises manufacture of photovoltaic cells by deposition of thin film photovoltaic junctions on metal foil substrates. The photovoltaic junctions may be heat treated if appropriate following deposition in a continuous fashion without deterioration of the metal support structure. In a separate operation, an interconnection substrate structure is provided, optionally in a continuous fashion. Multiple photovoltaic cells are then laminated to the interconnection substrate structure and conductive joining methods are employed to complete the array. In this way the interconnection substrate structure can be uniquely formulated from polymer-based materials employing optimal processing unique to polymeric materials. Furthermore, the photovoltaic junction and its metal foil support can be produced in bulk without the need to use the expensive and intricate material removal operations currently taught in the art to achieve series interconnections.

Owner:SOLANNEX

High energy density electric double-layer capacitor and method for producing the same

InactiveUS20050231892A1High volumeReducing chargeHybrid capacitor electrodesDouble layer capacitorsHigh energyEngineering

An electric double layer capacitor includes polarizable electrodes immersed in an organic electrolyte, wherein the electrodes are self-binding and the electric double layer capacitor exhibits a high energy density.

Owner:HARVEY TROY A

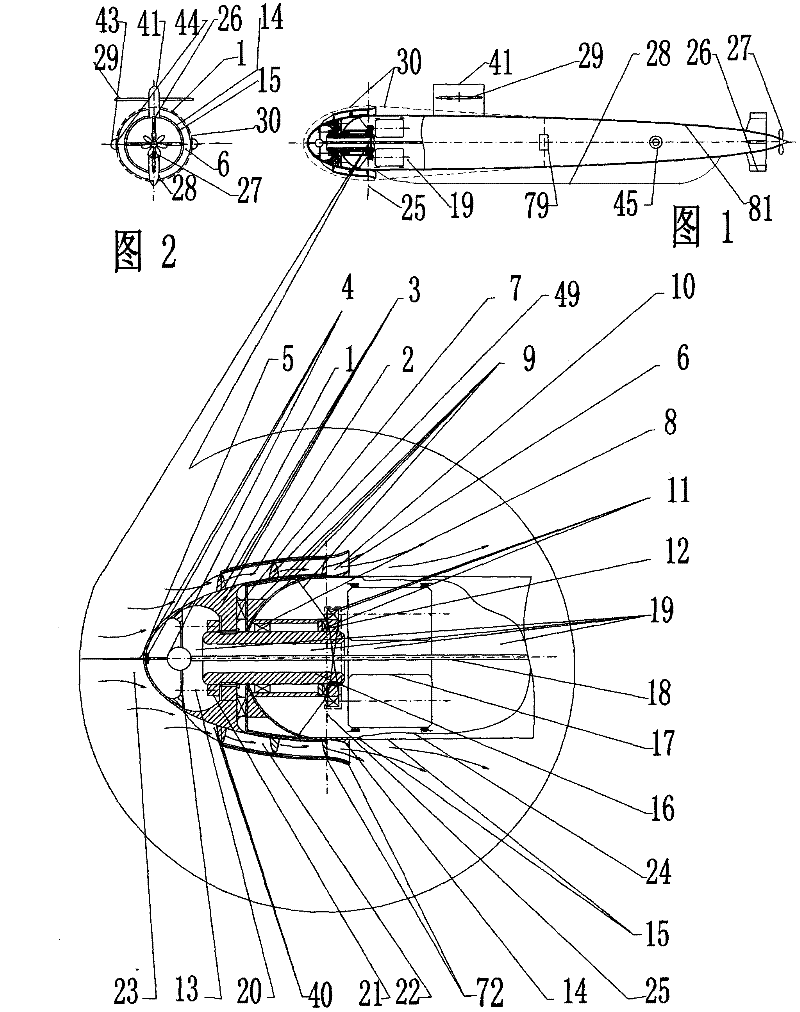

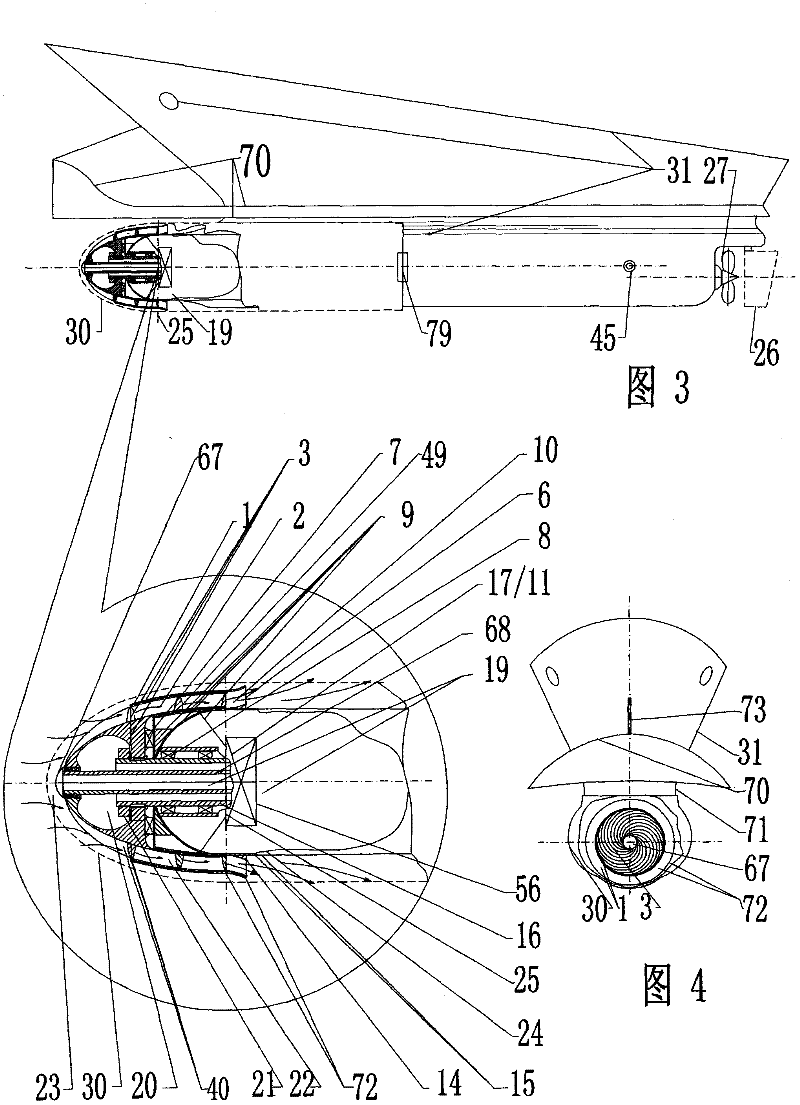

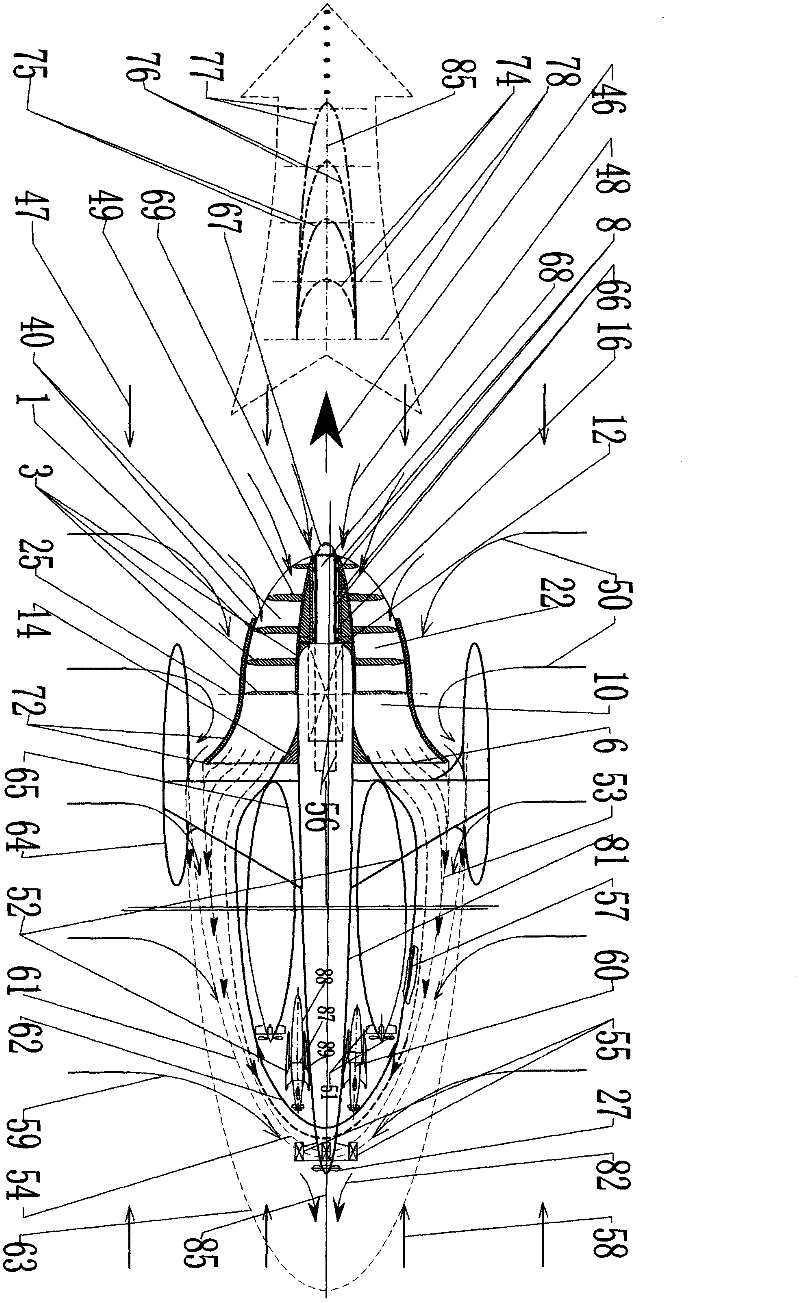

A kind of submarine ship forward tubular propeller technology

InactiveCN102285438AIncrease speedImprove concealmentRotary propellersWatercraft hull designFiberCavitation

A forward cross-flow propeller technology for submarine ships, especially the installation of a cross-flow drill propeller at the front of the submarine (ship), the three-dimensional super-side arc of the rotor blade is 30°-720° and the blade height and blade width , blade pitch gradual change through the paddle wheel mother shell and the rotor wheel body as a whole, the "ellipsoidal crown body" with super strong stress and rigid body, the rotor structure of the dynamic balance rotating outer profile, the cavitation disk arm of the stator through-flow tube is formed by umbrella-shaped injection The ultra-low (negative) pressure semi-ellipsoid super-supercavitation area around the submarine ship may be filled with rubber carbon fiber airbags to eliminate most of the wave-making resistance of conventional ships and form submarine ships (especially submarines) to sail at super speed And the energy-saving and overspeeding propeller technology and "drill bit effect" working principle of the submarine ship of energy-saving most tractive power.

Owner:管理 +2

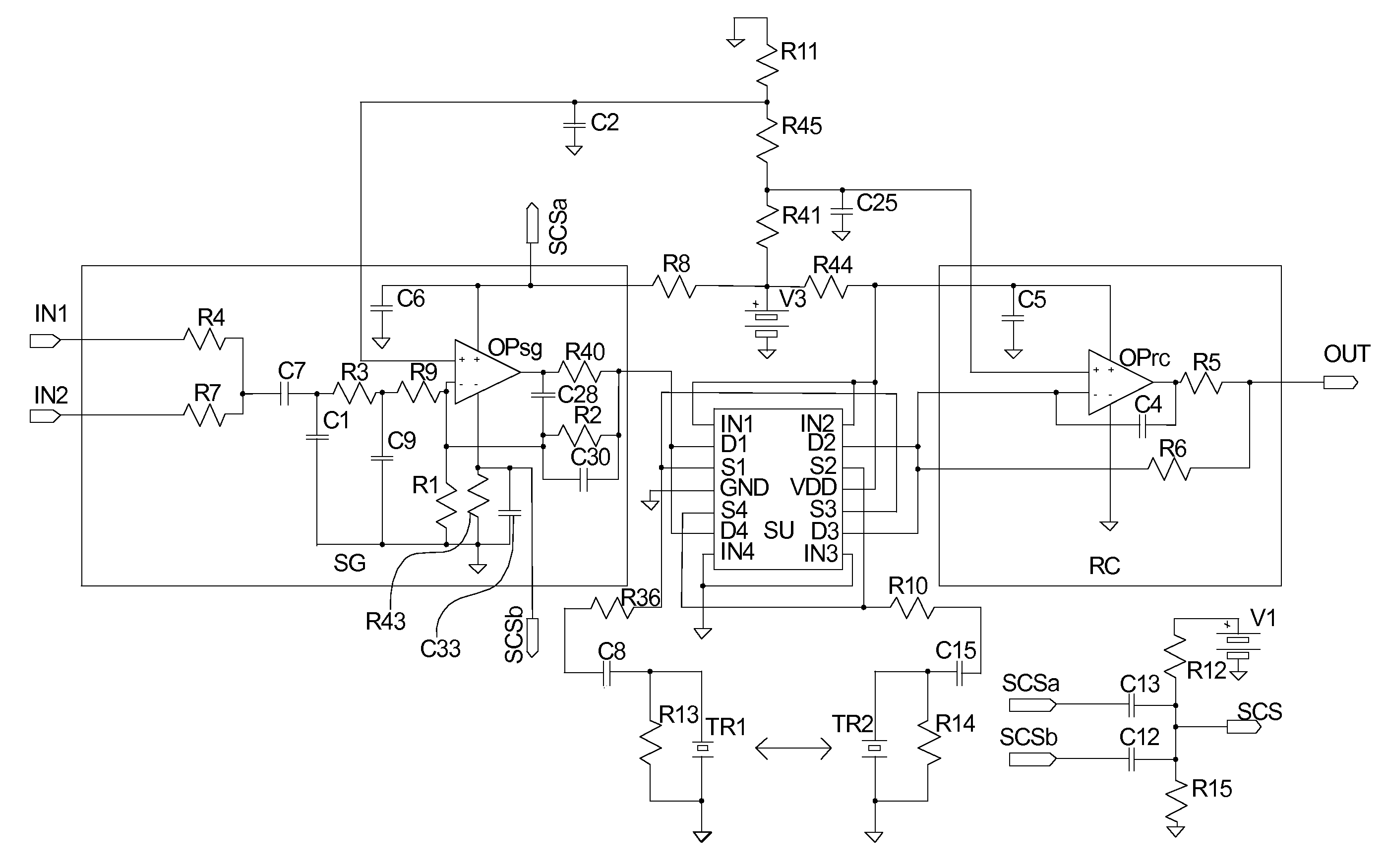

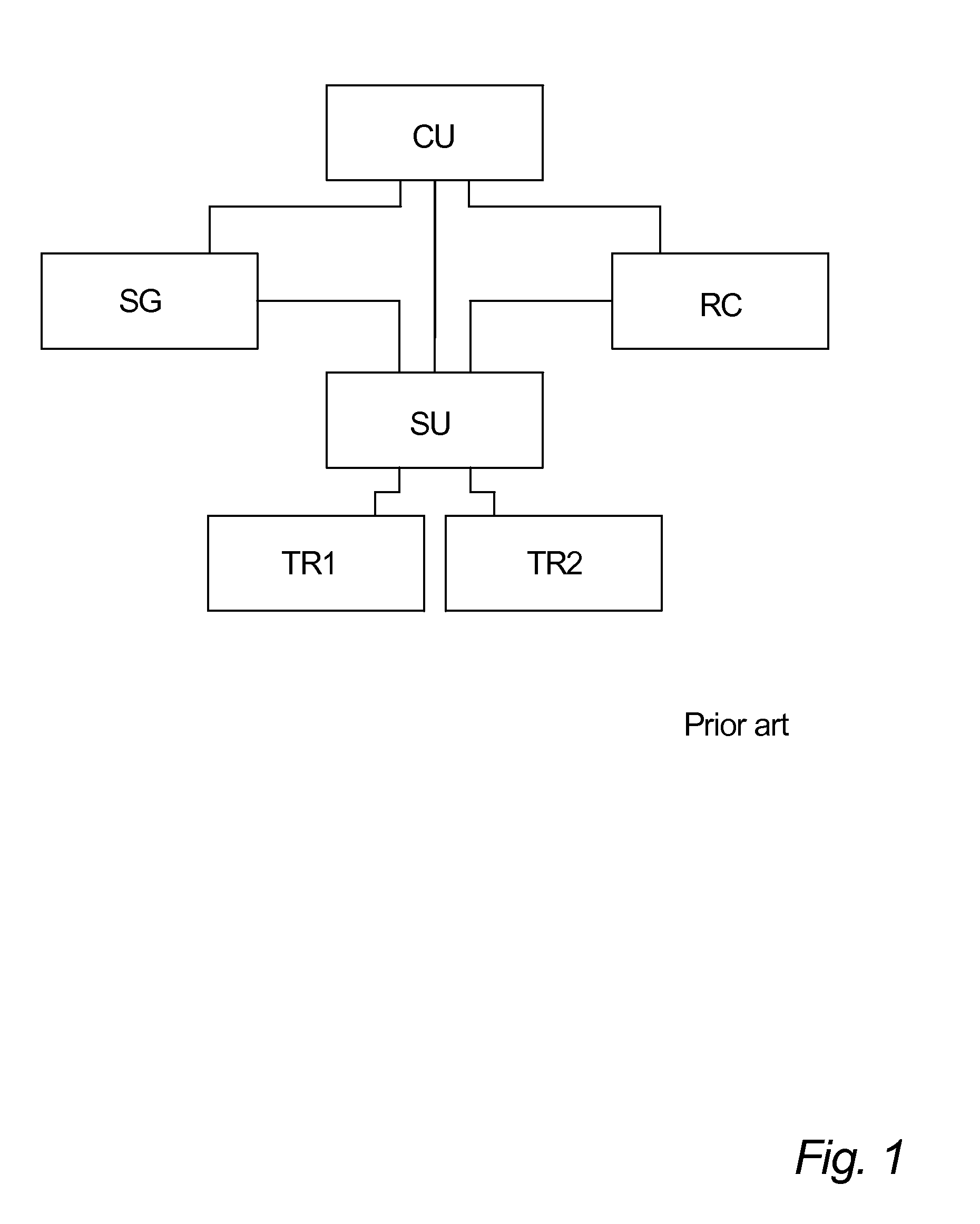

Ultrasonic Flow Meter

ActiveUS20130047695A1High accuracyHigh volumeVolume/mass flow measurementTesting/calibration of speed/acceleration/shock measurement devicesPower flowSupply current

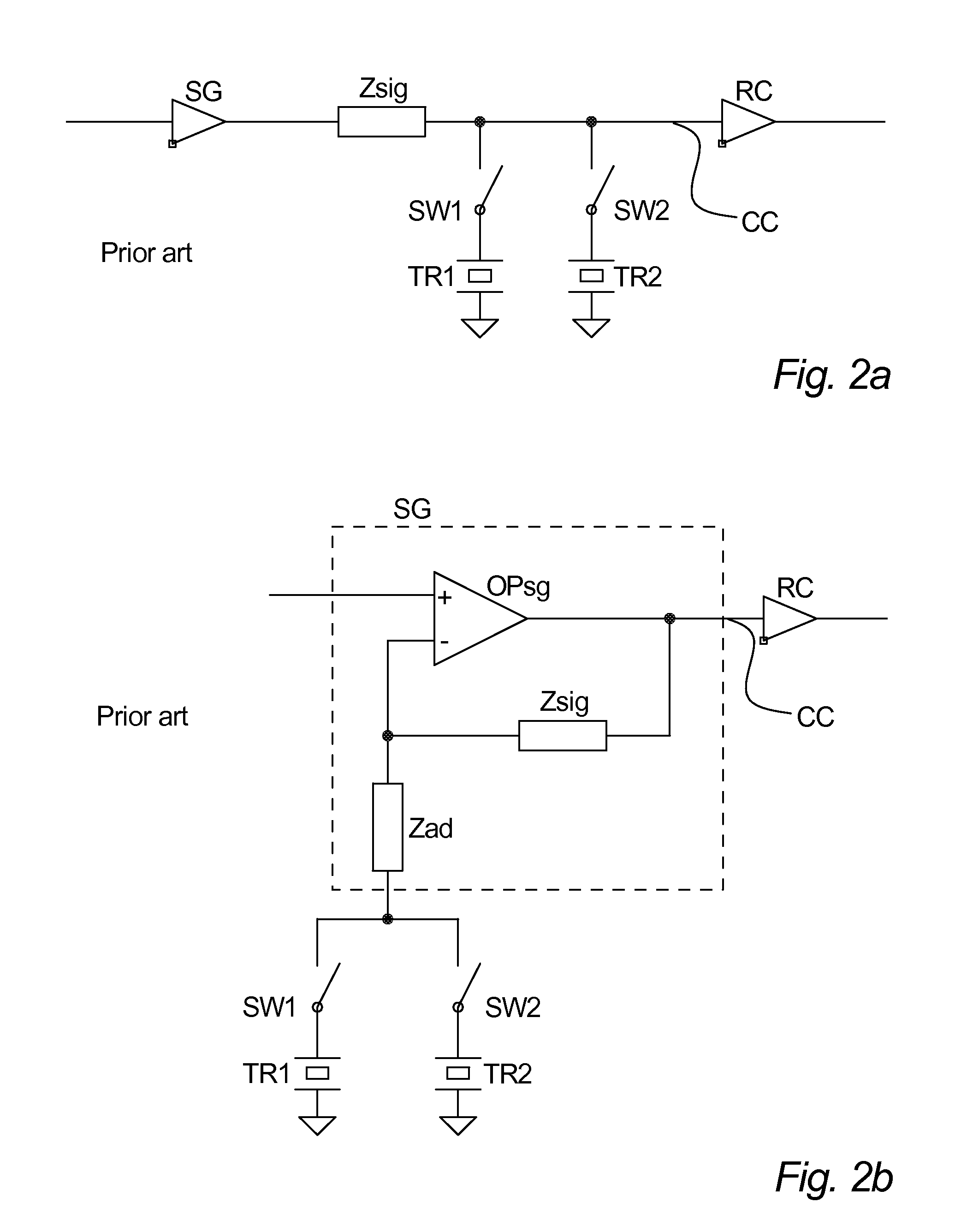

An ultrasonic flow meter is disclosed, including a switching unit for switching electrical transmission signals between a signal generator and at least two ultrasonic transducers and for switching electrical reception signal between the transducers and a receiver circuit, wherein the switching unit is coupled to an output terminal of an operational amplifier of the signal generator and to an inverting input terminal of an operational amplifier of the receiver circuit. Furthermore, a method for characterizing an ultrasonic transducer is disclosed, including the step of determining directly from one or more supply current signals for an active component of a signal generator one or more quantities useful for characterizing the transducer. Furthermore, a method for determining the time delay of an ultrasonic signal in a flow path of an ultrasonic flow meter is disclosed, including the step of comparing physically transmitted, delayed and received signals with simulated non-delayed signals.

Owner:APATOR MIITORS APS

End of arm tooling

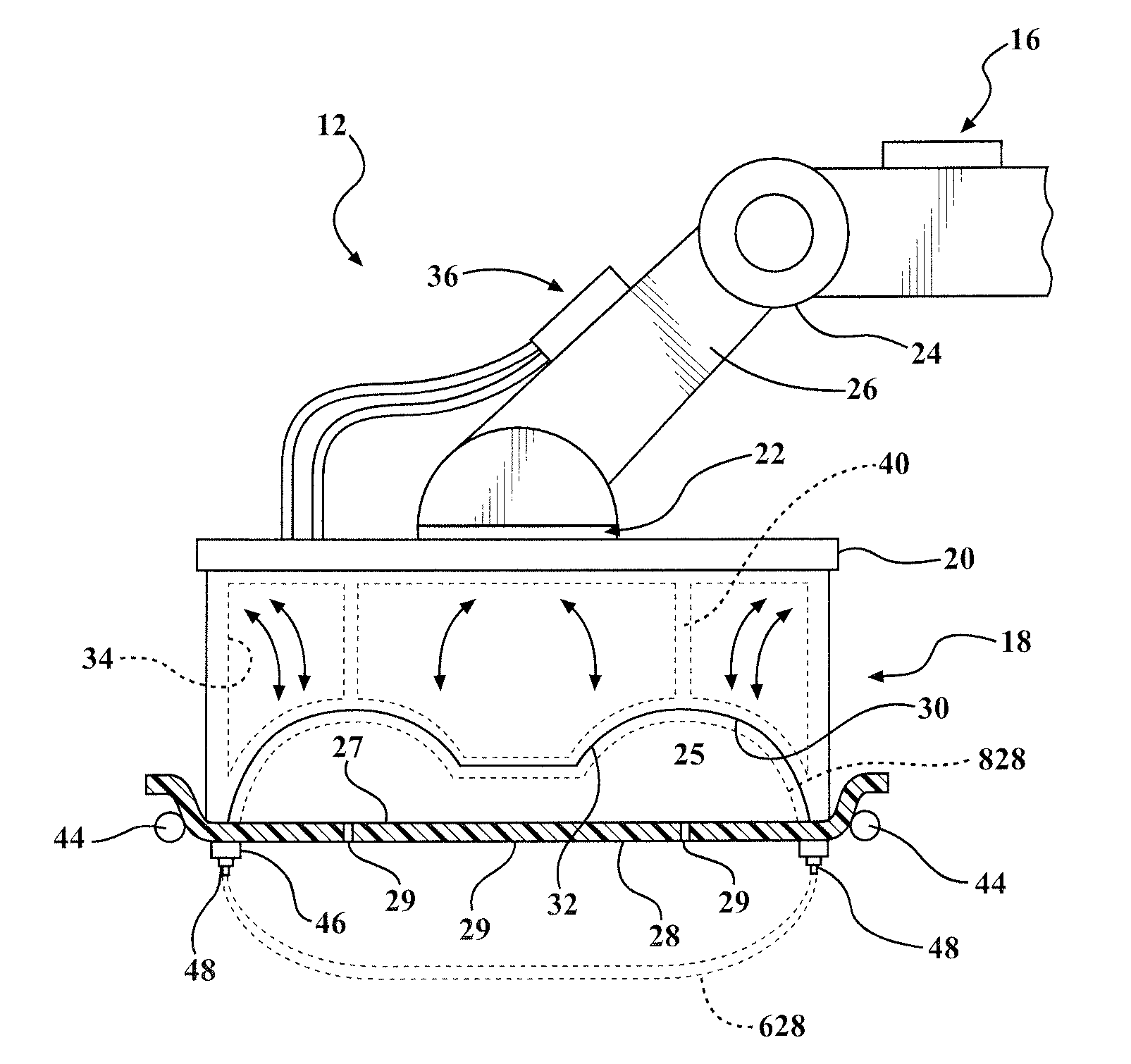

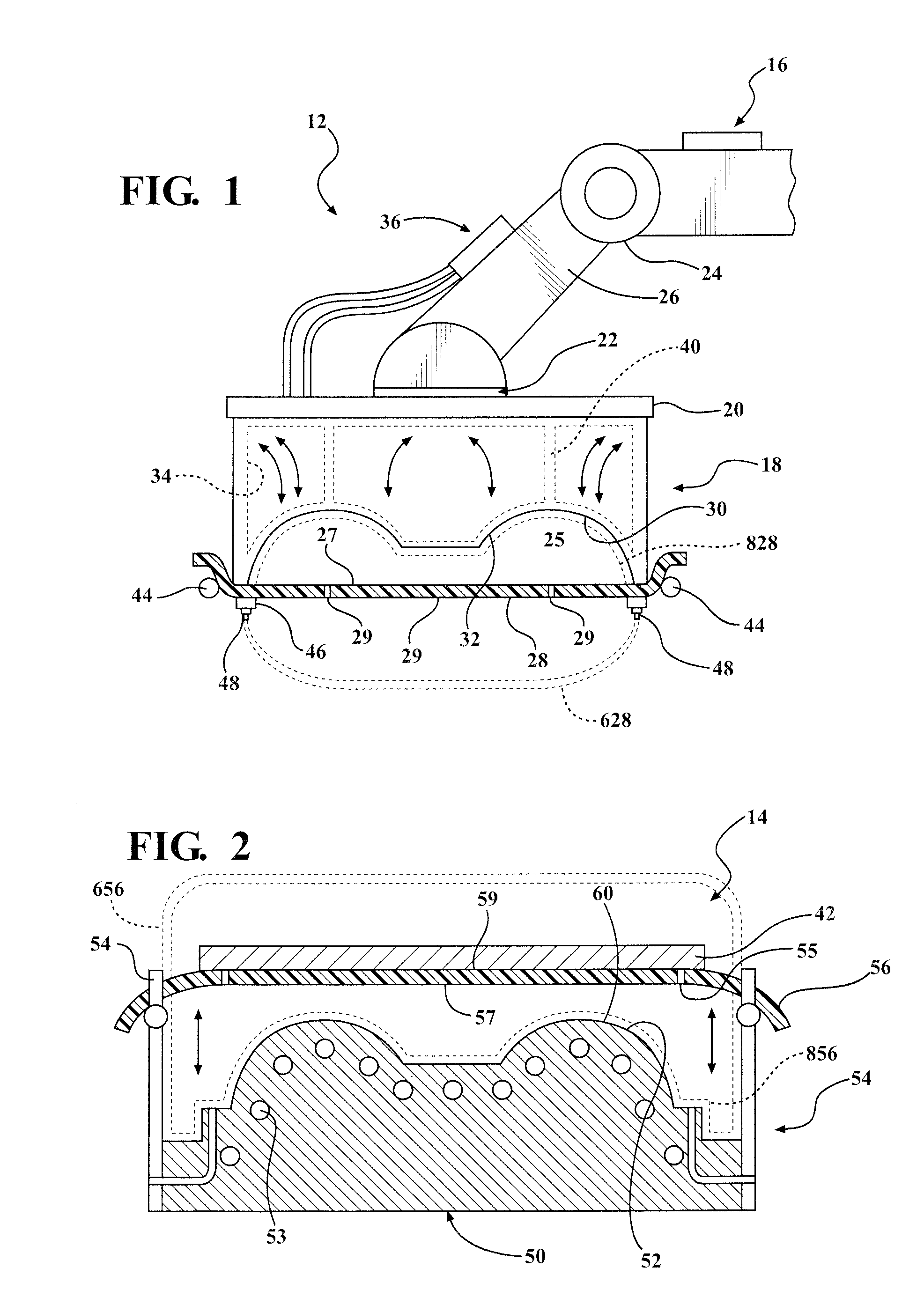

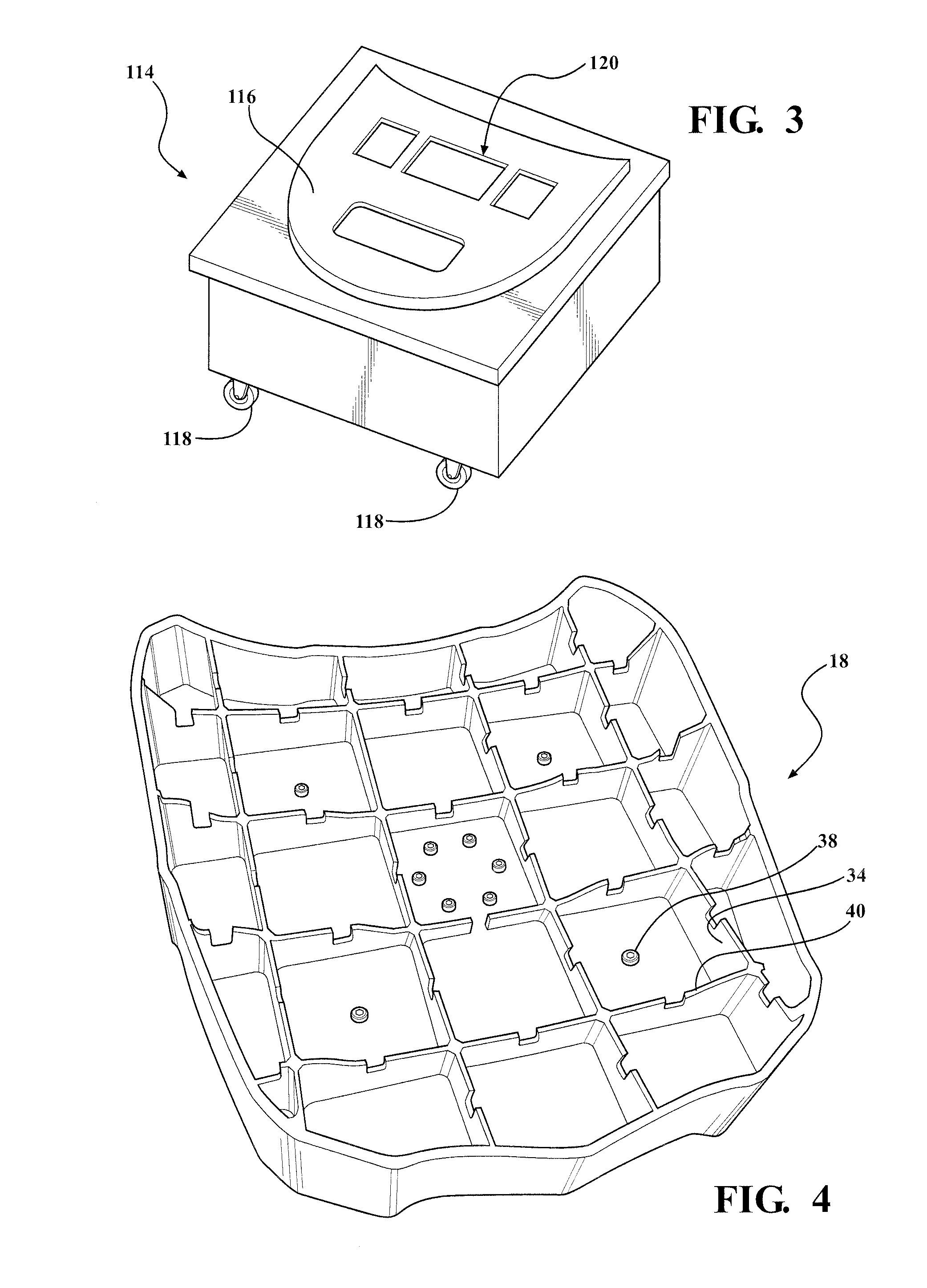

End of arm tooling system and a method for manufacture is provided. The end or arm tooling system provides automated material handling, part manipulation, pre-forming and transferring of a pre-impregnated carbon fiber material. A robot is connected to end of arm tooling for automated material handling and transfer operations from at least a lower preform tool system where light compression is applied to a molding press. The end or arm tooling system includes a cured silicone membrane as well as vacuum and air blow off, allowing for robotically preforming, picking up and dropping-off pre-impregnated carbon fiber materials which are notoriously sticky and difficult to handle.

Owner:MAGNA EXTERIORS INC

Rubber composition and tire having tread thereof

InactiveUS6160047ALow bulk densityHigh volumeSpecial tyresTyre tread bands/patternsCarbon blackElastomer

A rubber composition as a blend comprised of an elastomer(s), and particulate reinforcement provided as an intimate blend of carbon black particles and fumed silica particles, together with a coupling agent. A tire having a component of such rubber composition such as, for example, a tread, is specifically contemplated.

Owner:THE GOODYEAR TIRE & RUBBER CO

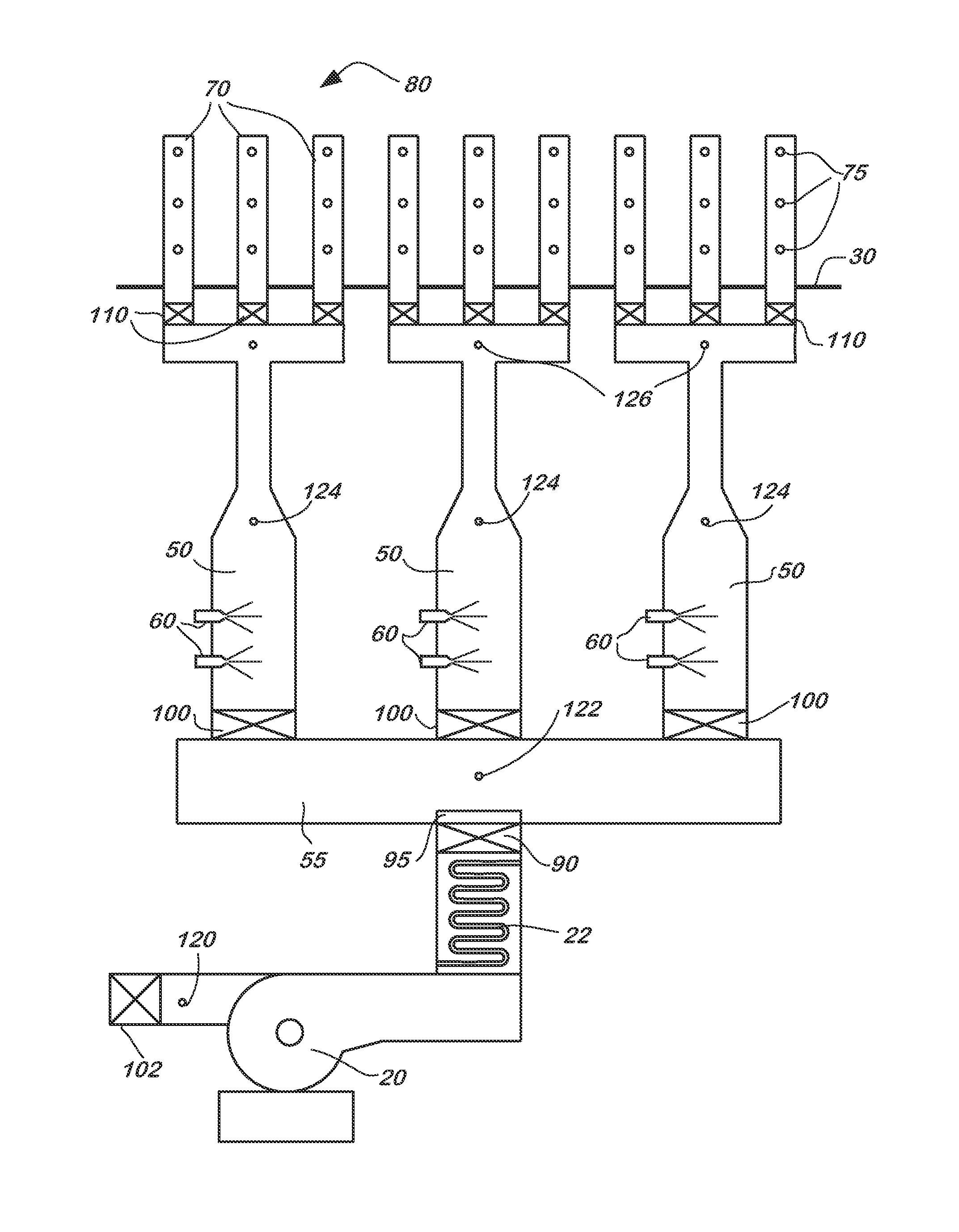

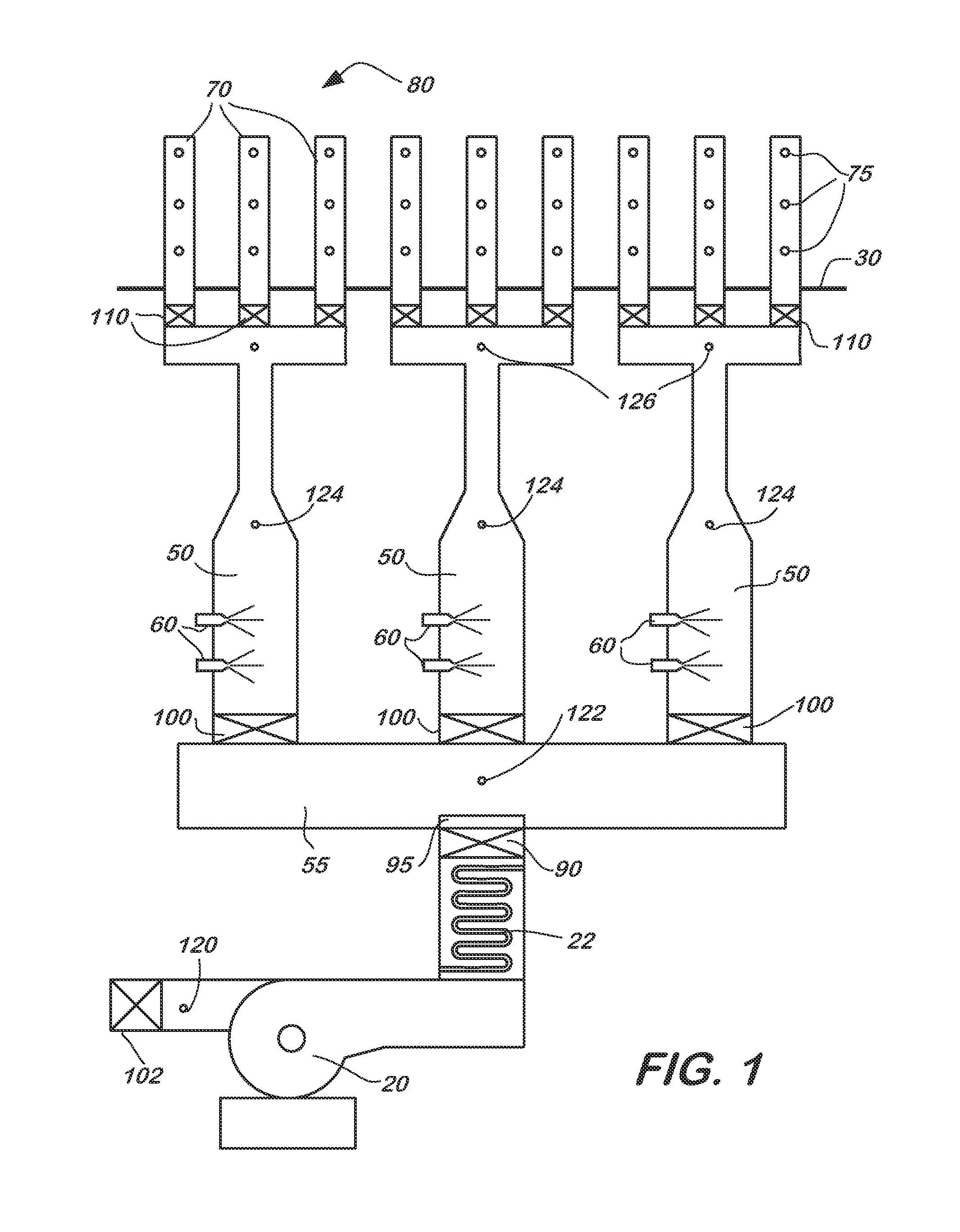

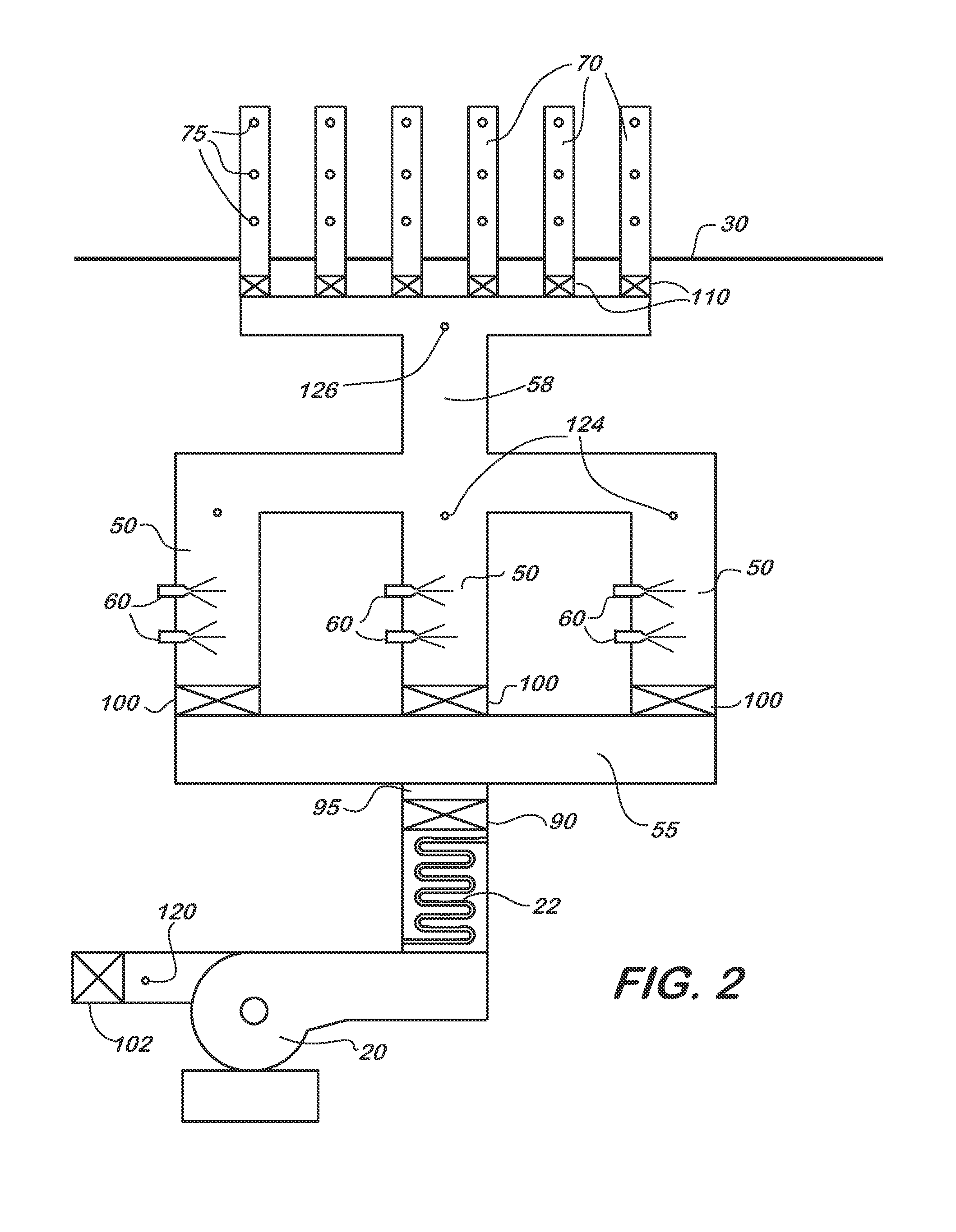

Tunable AIG for Improved SCR Performance

InactiveUS20150093315A1High volumeIncrease volumeNitrogen compoundsInternal combustion piston enginesDecompositionMesh grid

A system for controlling reagent flow to an exhaust of a lean burn combustion source includes a plurality of decomposition ducts each being connected to at least one injection lance of a reagent injection grid and supplying reagent and hot carrier gas to the injection lance, and at least one metering valve in communication with each of the plurality of decomposition ducts that controls reagent injection rate to the injection lance. A method of controlling a reagent flow to an exhaust of a lean burn combustion source includes providing a reagent injection grid having at least one injection lance, supplying the reagent and hot carrier gas to the reagent injection grid from a plurality of decomposition ducts coupled to the injection grid, and controlling reagent injection rate to the injection grid via at least one metering valve in communication with each of the plurality of decomposition ducts.

Owner:PEERLESS MFG CO

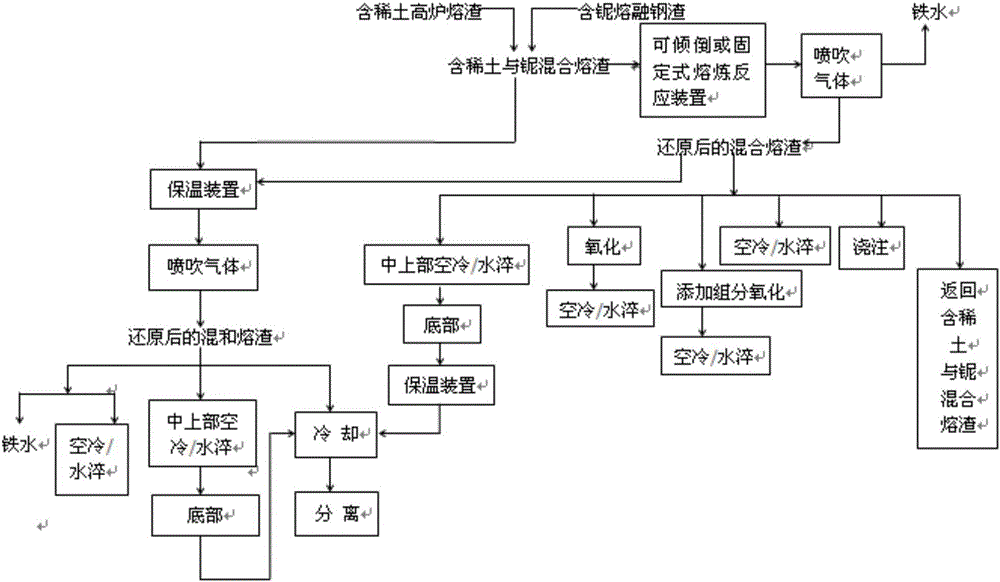

Smelting reduction recovery and thermal refining method for rare-earth-niobium-containing slag mixture

ActiveCN106048106AEasy to removeTake advantage ofRecycling and recovery technologiesProcess efficiency improvementNiobiumSlag

The invention relates to a smelting reduction recovery and thermal refining method for a rare-earth-niobium-containing slag mixture and belongs to the field of non-blast furnace ironmaking and resource comprehensive utilization. The smelting reduction recovery and thermal refining method for the rare-earth-niobium-containing slag mixture comprises the following steps of (1) mixing rare-earth-containing blast furnace slag and niobium-containing molten steel slag to form the rare-earth-niobium-containing slag mixture and controlling the temperature of the rare-earth-niobium-containing slag mixture within a set temperature range; (2) injecting oxidative gas and conducting smelting reduction to reduce iron oxide into metallic iron fully; and (3) conducting separation and recovery according to different reaction devices. According to the method, the rare earth, the calcium component, the niobium component and the phosphorus component in the slag mixture can be efficiently recycled; cold-state niobium-rare-earth-iron-containing materials can be processed and at the same time thermal refining of the slag can be realized, so that the efficient resource comprehensive utilization can be achieved. The method is short in reaction time, high in metal recovery rate, low in production cost, strong in raw material adaptability, large in processing capacity, friendly with environment, high in economic income and capable of solving the problems of efficient recovery and utilization of metallurgical resources and heat energy effectively.

Owner:NORTHEASTERN UNIV

Polytetrafluoroethylene hexaferrite composites

ActiveUS20190264005A1High permeability valueHigh volumeInorganic material magnetismInductances/transformers/magnets manufacturePolytetrafluoroethylenePermittivity

Disclosed herein is a hexaferrite composite comprising polytetrafluoroethylene; and greater than or equal to 40 vol %, or 40 to 90 vol % a plurality of Co2Z hexaferrite particles based on the total volume of the polytetrafluoroethylene and the plurality of Co2Z hexaferrite particles on a void-free basis; wherein the hexaferrite composite has a porosity of greater than or equal to 10 vol % based on the total volume of the hexaferrite composite; wherein the hexaferrite composite has a permeability of greater than or equal to 2.5 and a ratio of the permeability to the permittivity of greater than or equal to 0.4, both determined at 500 MHz.

Owner:ROGERS CORP

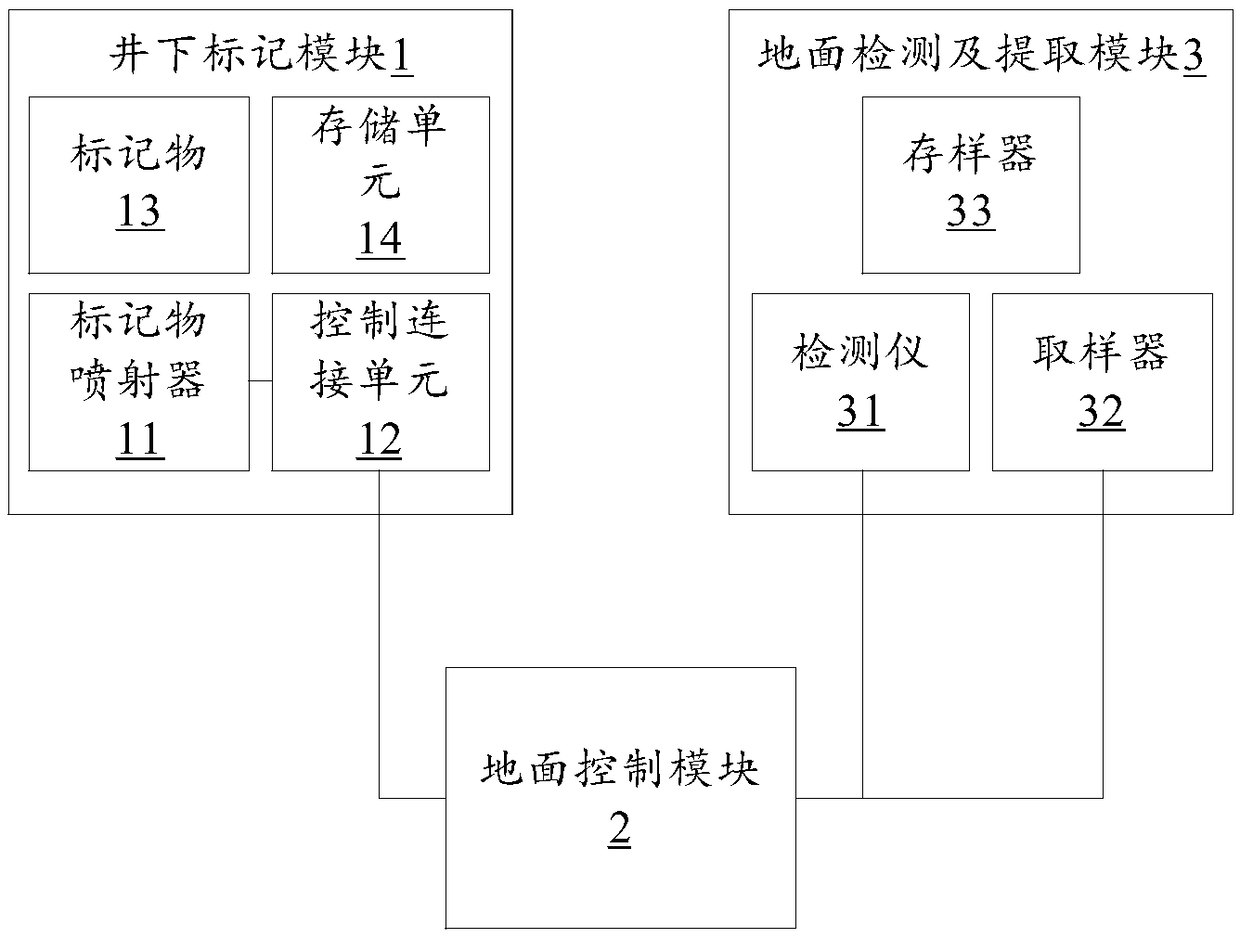

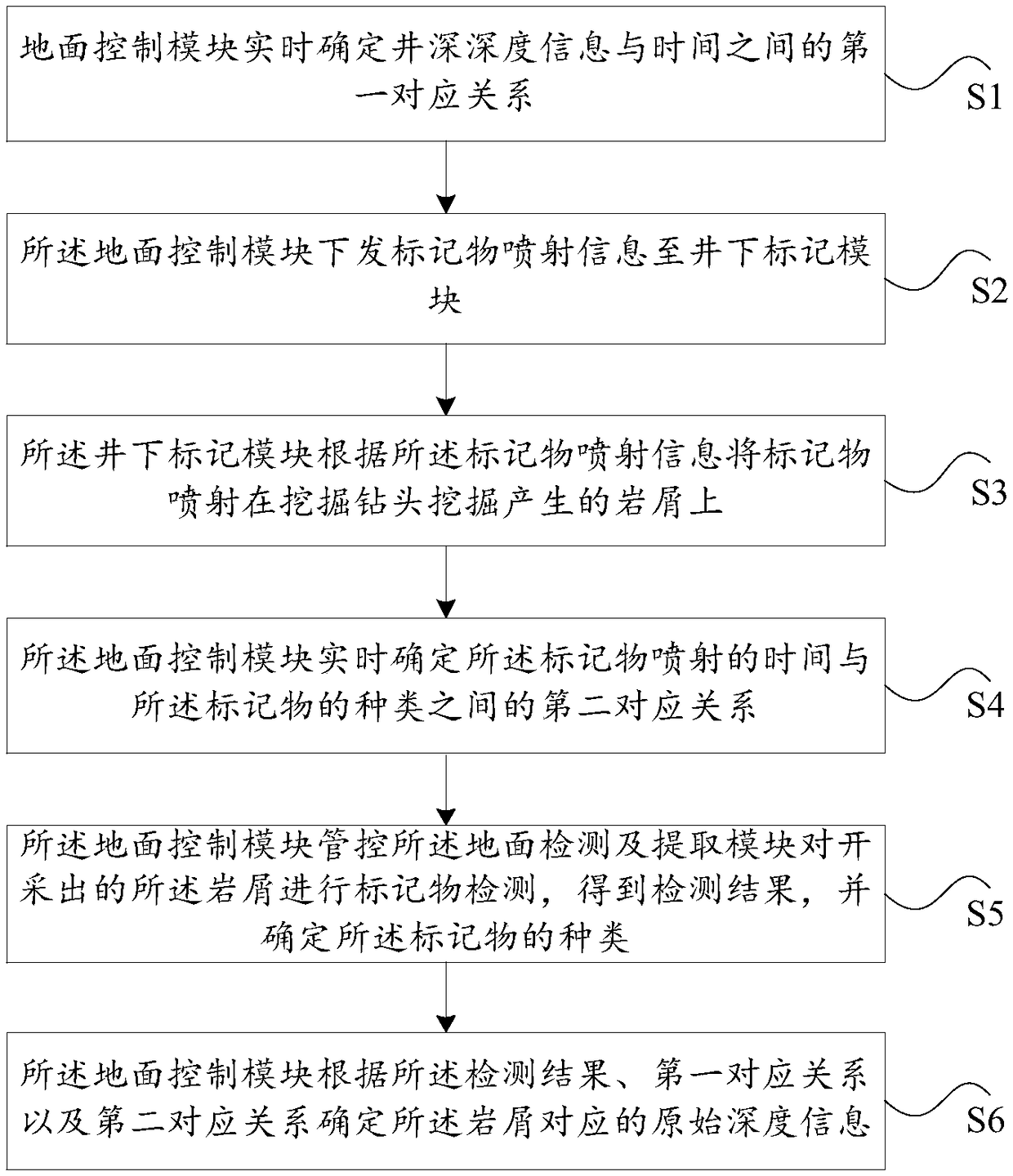

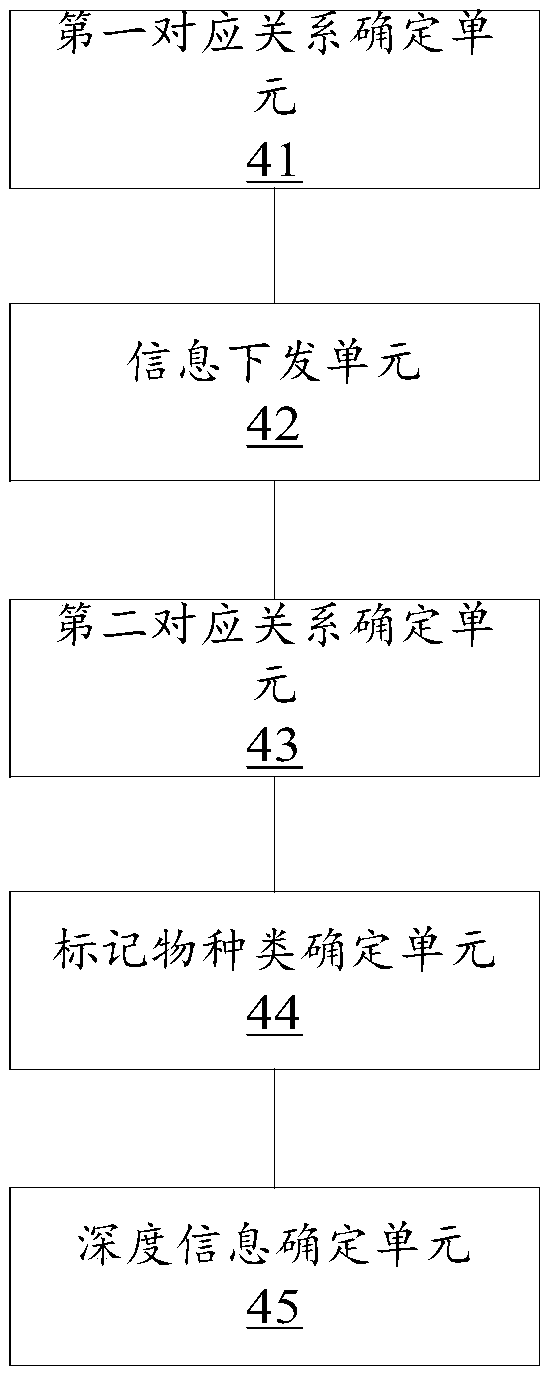

Downhole rock debris extraction system and control method thereof

PendingCN108930535AImprove detection timelinessImprove sampling accuracySurveyConstructionsDrill bitPetrology

The invention discloses a downhole rock debris extraction system and a control method thereof. The control method comprises the steps that a ground control module determines a first corresponding relation between depth information of the well depth and time in real time, and then marker jet information is sent down to a downhole marker module; according to the marker jet information, the downholemarker module sprays markers onto rock debris produced by excavation through an excavation bit; the ground control module determines a second corresponding relation between marker jet time and the types of the markers in real time, a ground detection and extraction module is controlled to carry out marker detection on the extracted rock debris, and the types of the markers are determined; the ground control module determines original depth information corresponding to the rock debris according to detection results, the first corresponding relation and the second corresponding relation; and therequirements of high detection ageing and simple and easy operation for downhole rock debris extraction can be effectively met, and meanwhile, the control method can achieve the purpose of accurate sampling, low sampling cost and high completed amount.

Owner:CNPS PETRO EQUIP CO LTD

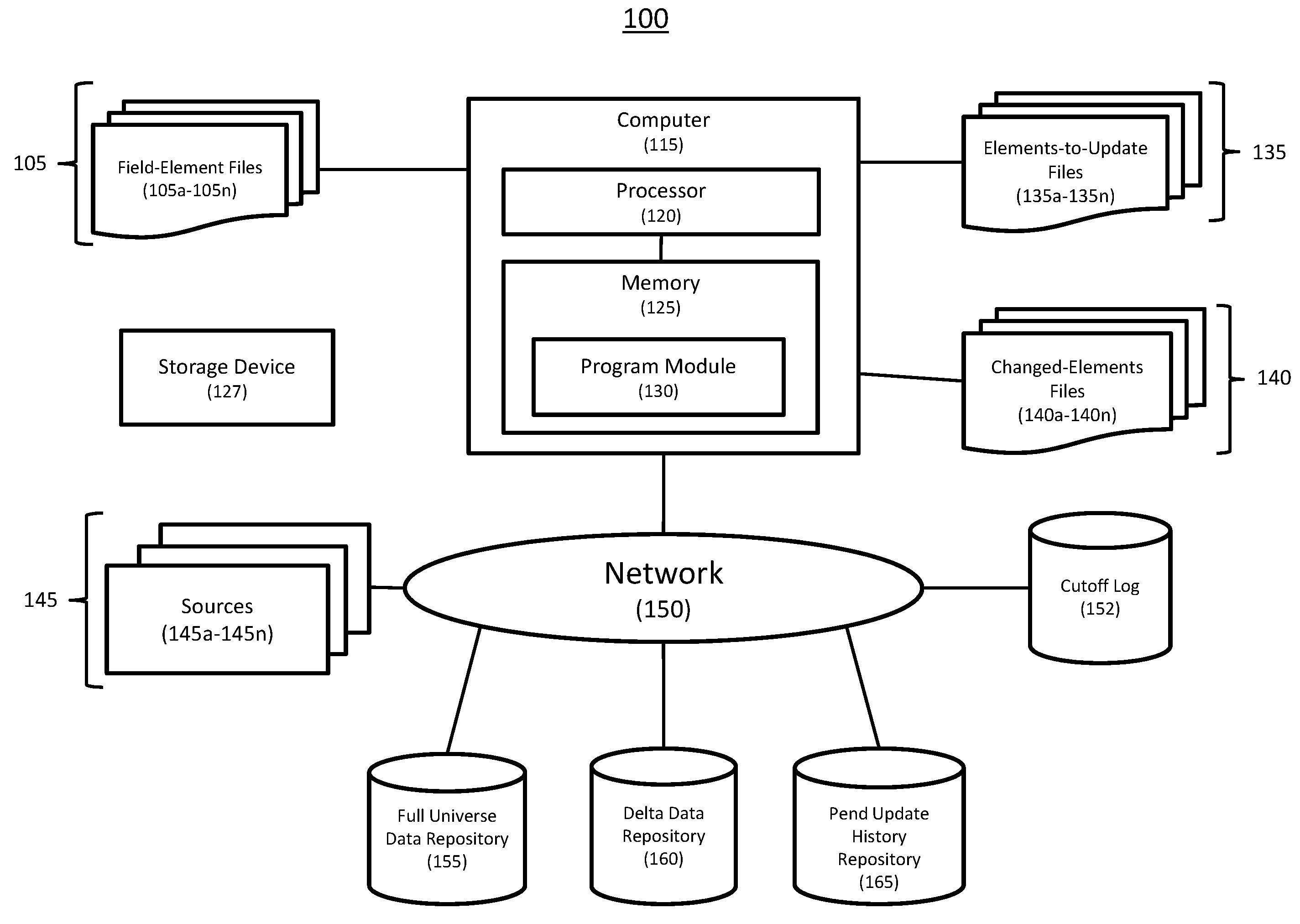

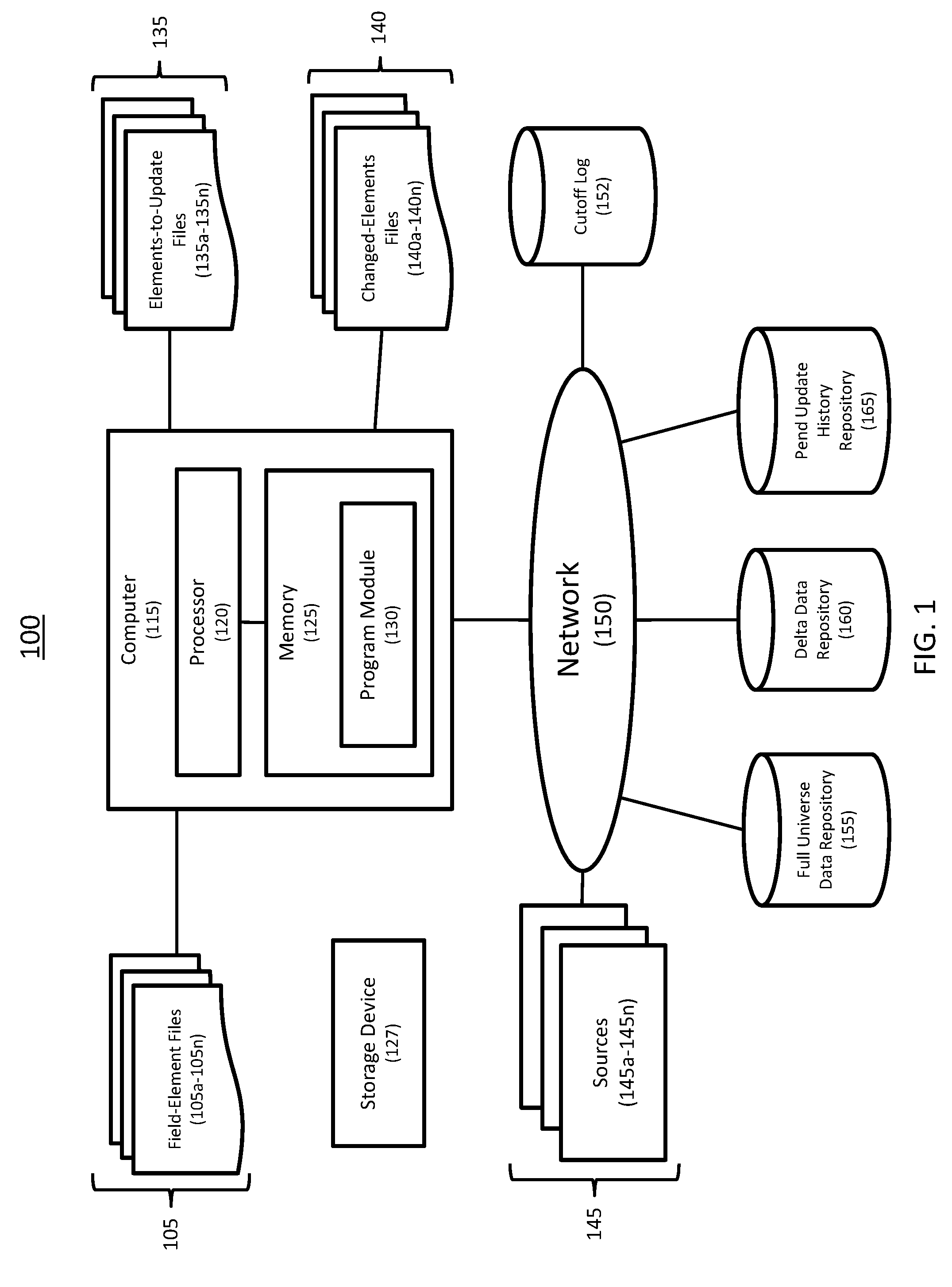

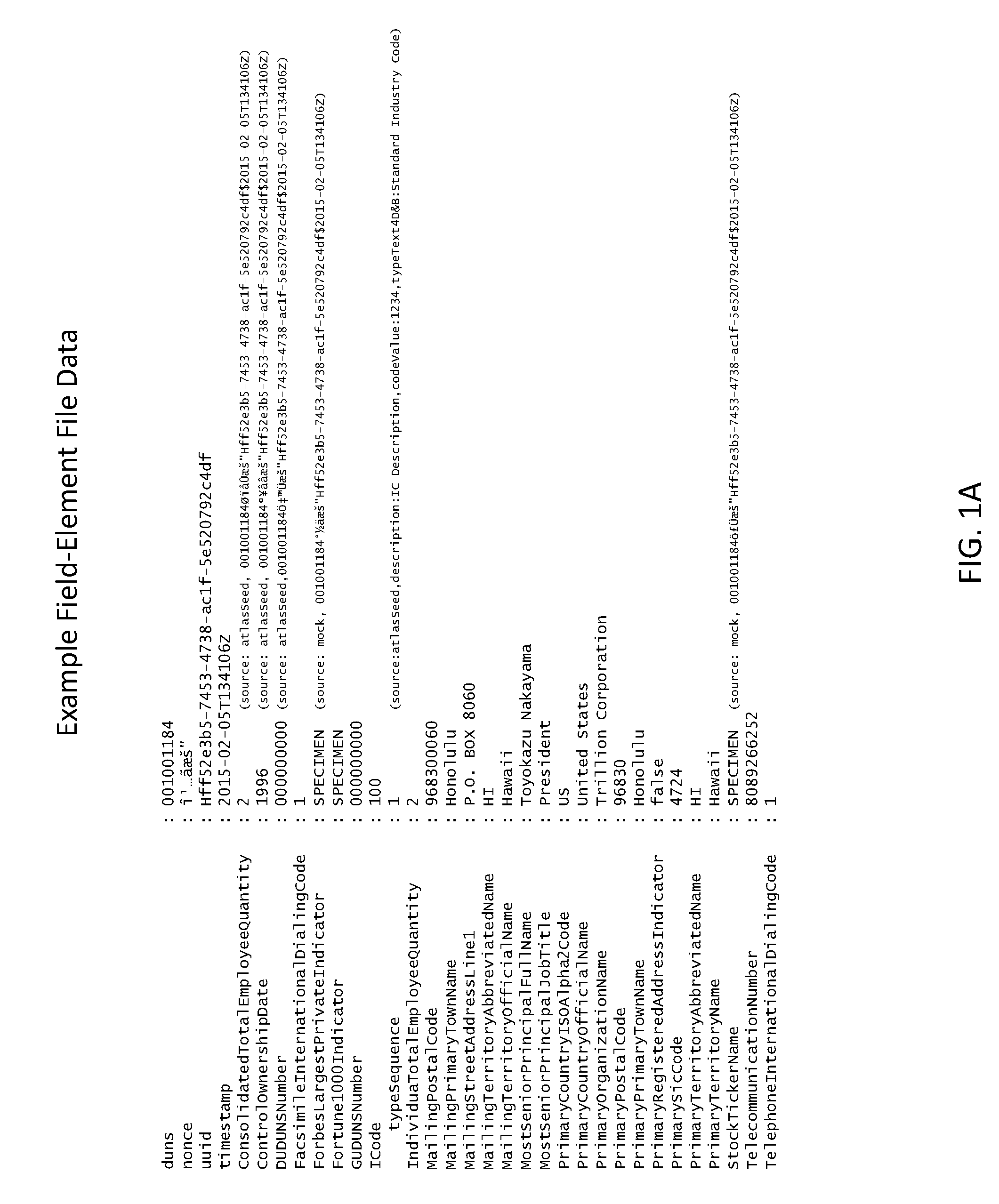

Aggregating high volumes of temporal data from multiple overlapping sources

ActiveUS20160275130A1Faster accessHigh volumeDatabase updatingSpecial data processing applicationsTime rangeData mining

Owner:D&B BUSINESS INFORMATION SOLUTIONS

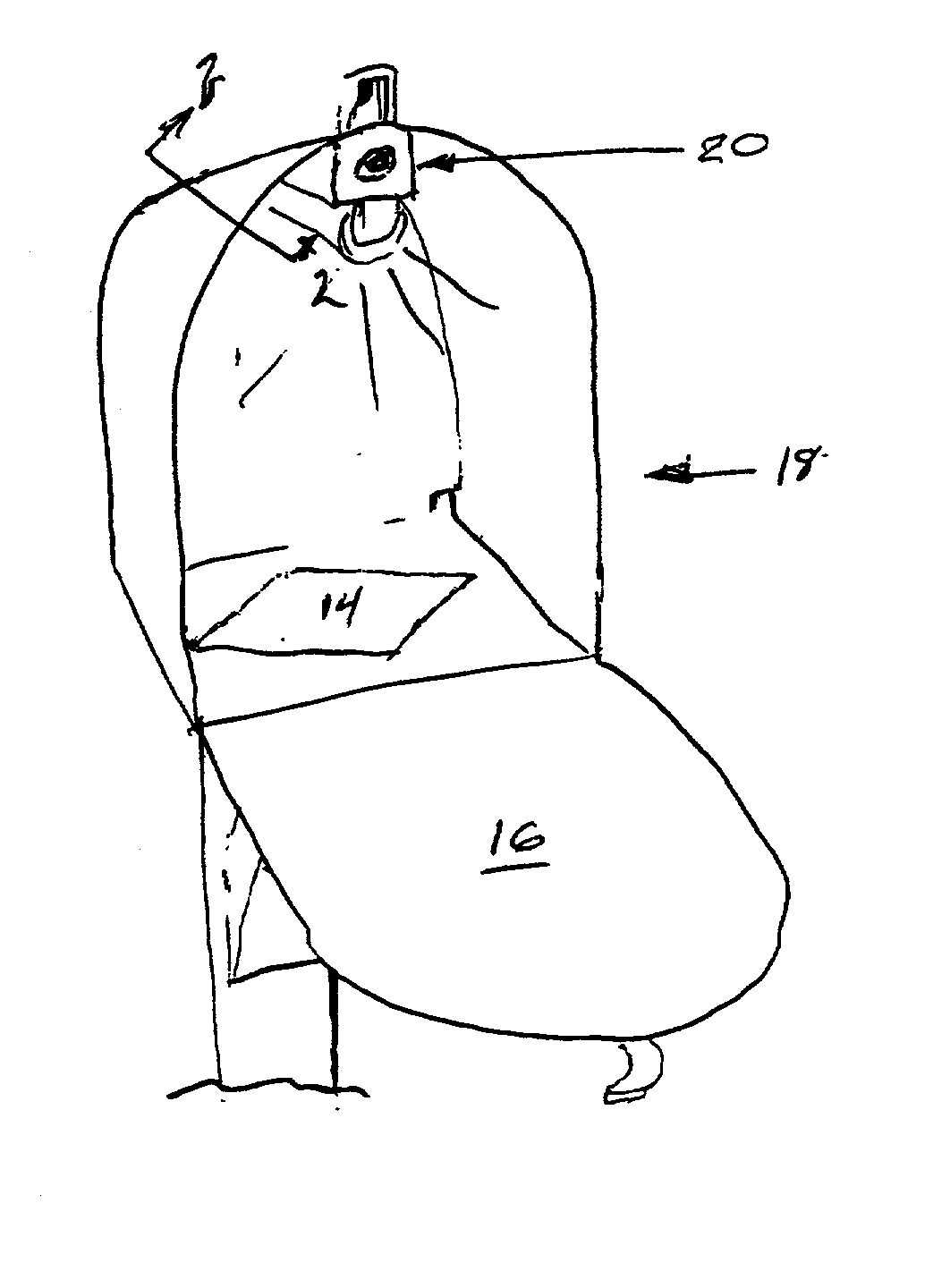

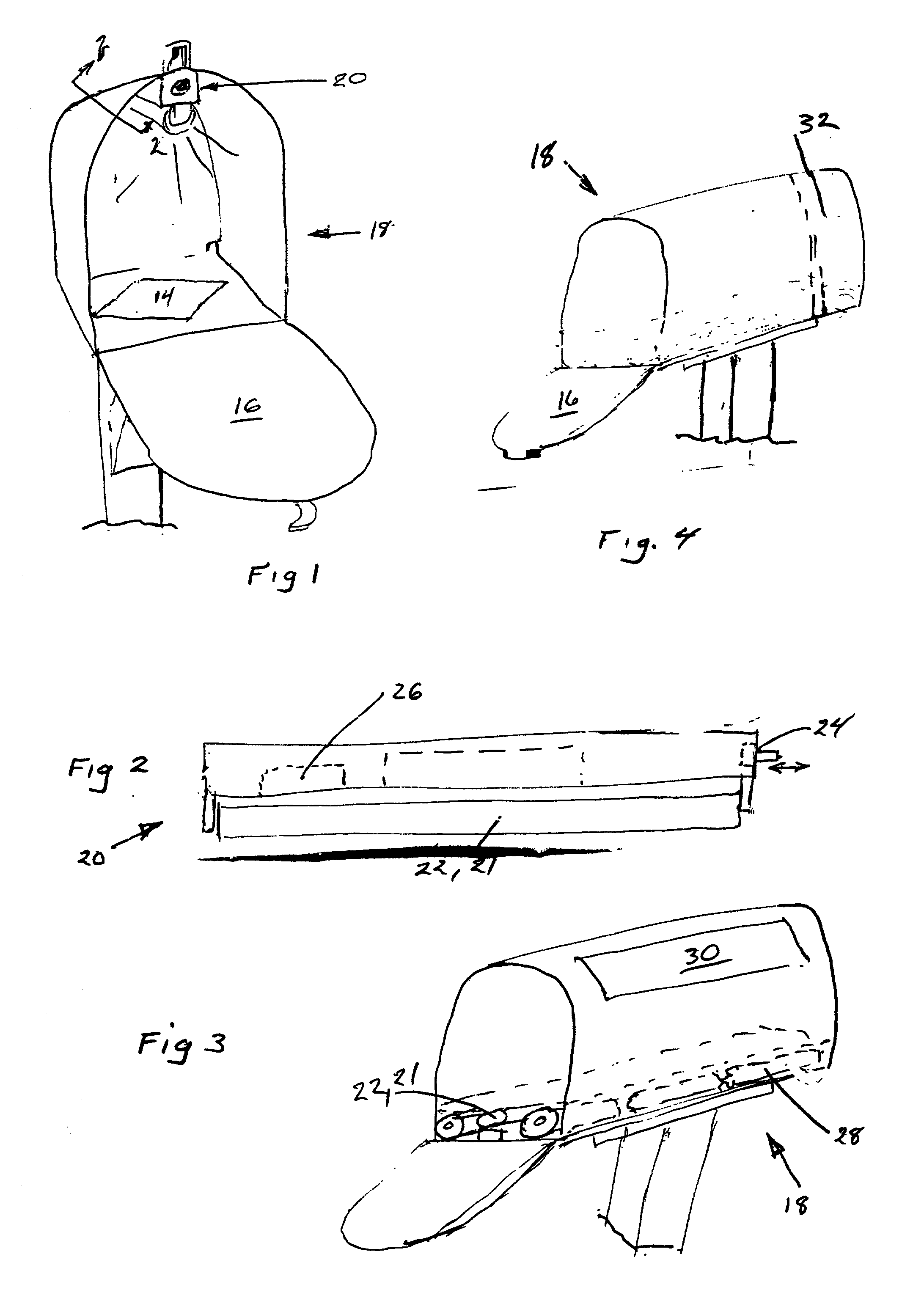

Method of sterilizing mail

InactiveUS20030161757A1High volumeMaterial analysis using wave/particle radiationElectric discharge tubesSufficient timeEngineering

A method of automatically sterilizing mail all mail received provides assurance to the recipients of the mail and facilitates efficient processing of the mail. The method comprises the steps of: providing an internal electromagnetic radiation source to sterilize mail deposited in the mail box; providing an electric door switch serially connected to the electromagnetic radiation source adapted to close only when the mail box door is closed so that the electromagnetic radiation radiates from the source only when the front door is closed; and, providing a sterilization timer activated when the mail box door is closed, said timer configured to maintain the electromagnetic source on for a sufficient period after the mail box door is closed to radiate and thereby sterilize any mail deposited therein. One aspect of the invention comprises a method of retrofitting a mail box with an assembly containing all of the components listed above.

Owner:EVANS CHARLES E

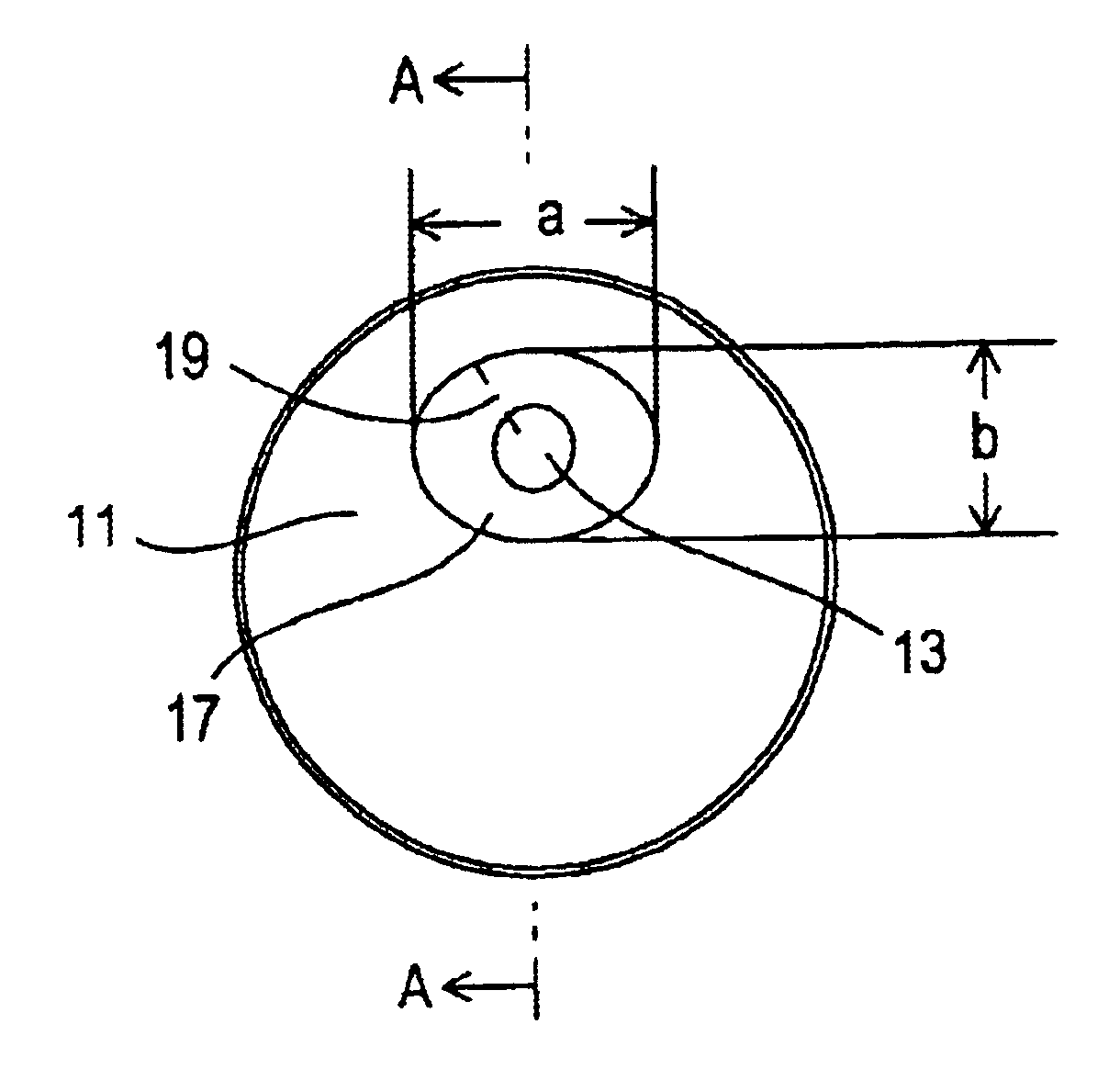

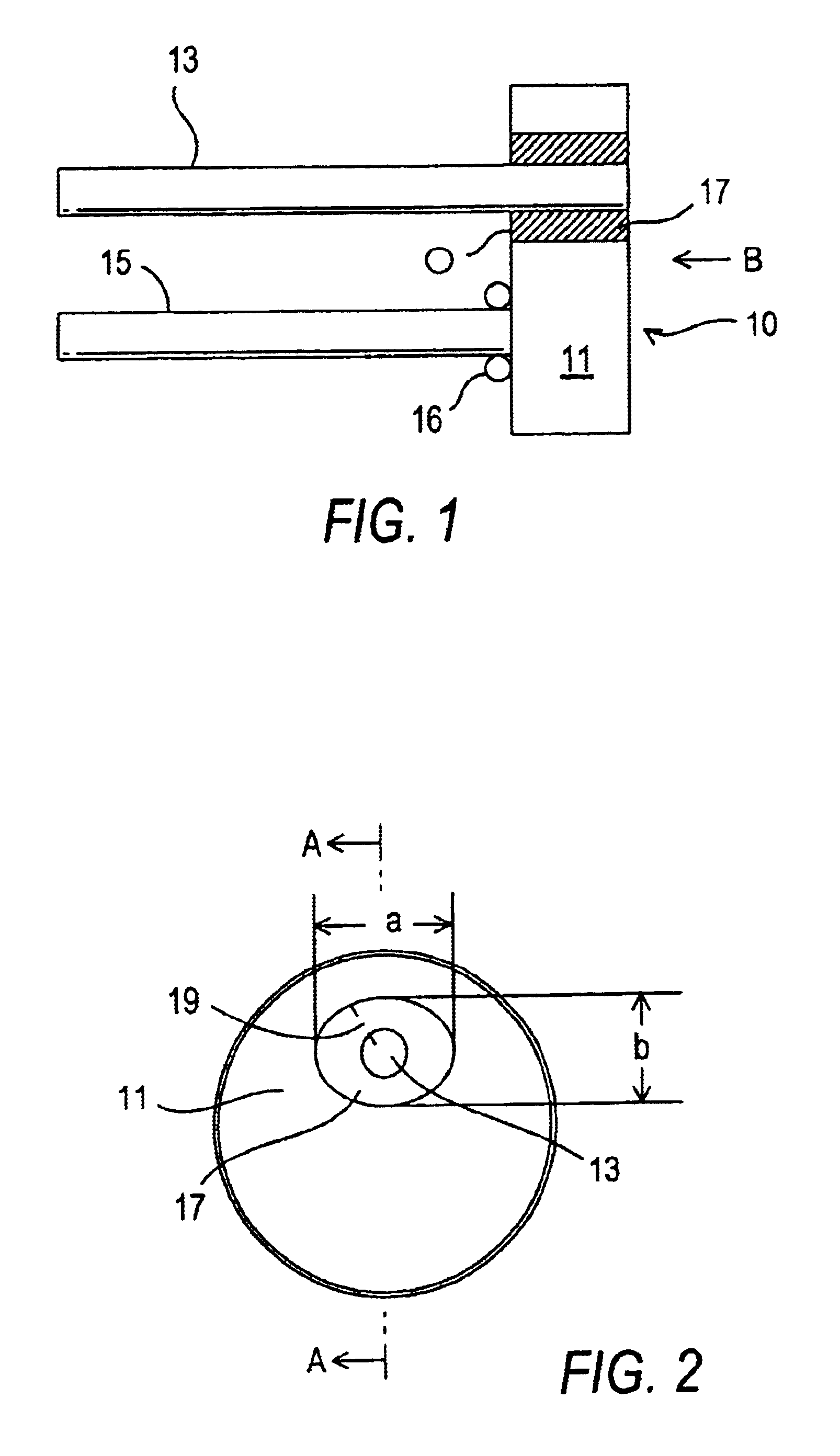

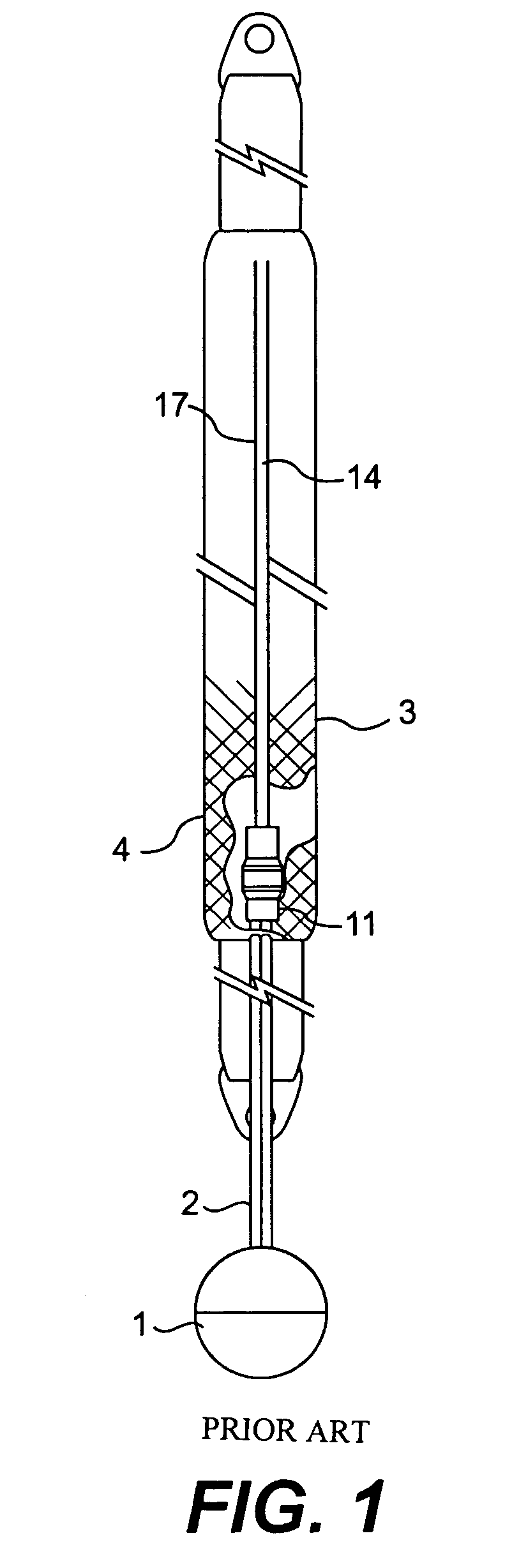

Hermetically sealed electrical feed-through device with a straight isolated pin in an offset oval glass seal

InactiveUS6874423B2High volumeLow pricingIncandescent ignitionPedestrian/occupant safety arrangementEngineeringElectrical and Electronics engineering

The hermetically sealed electrical feed-through device has a circular metal disk (11) with a conductive straight isolated pin (13) hermetically sealed in an oval or elliptical through-going opening (O) positioned offset from the center of the circular metal disk. The straight isolated pin (13) is sealed in the opening (O) by means of a glass-to-metal seal (17). A conductive straight ground pin (15) is connected to the rear side of the circular metal disk (11) adjacent to the opening (O) and extends approximately parallel to the straight isolated pin (13). Because the through-going opening (O) has an elliptical or oval cross-section, a wider range of different bridge wires of different lengths, which are connectable on the front side of the metal disk (11) between the front surface of the metal disk (11) and the straight isolated pin (13), is possible. The straight isolated and ground pins have circular transverse cross-sections.

Owner:SCHOTT AG

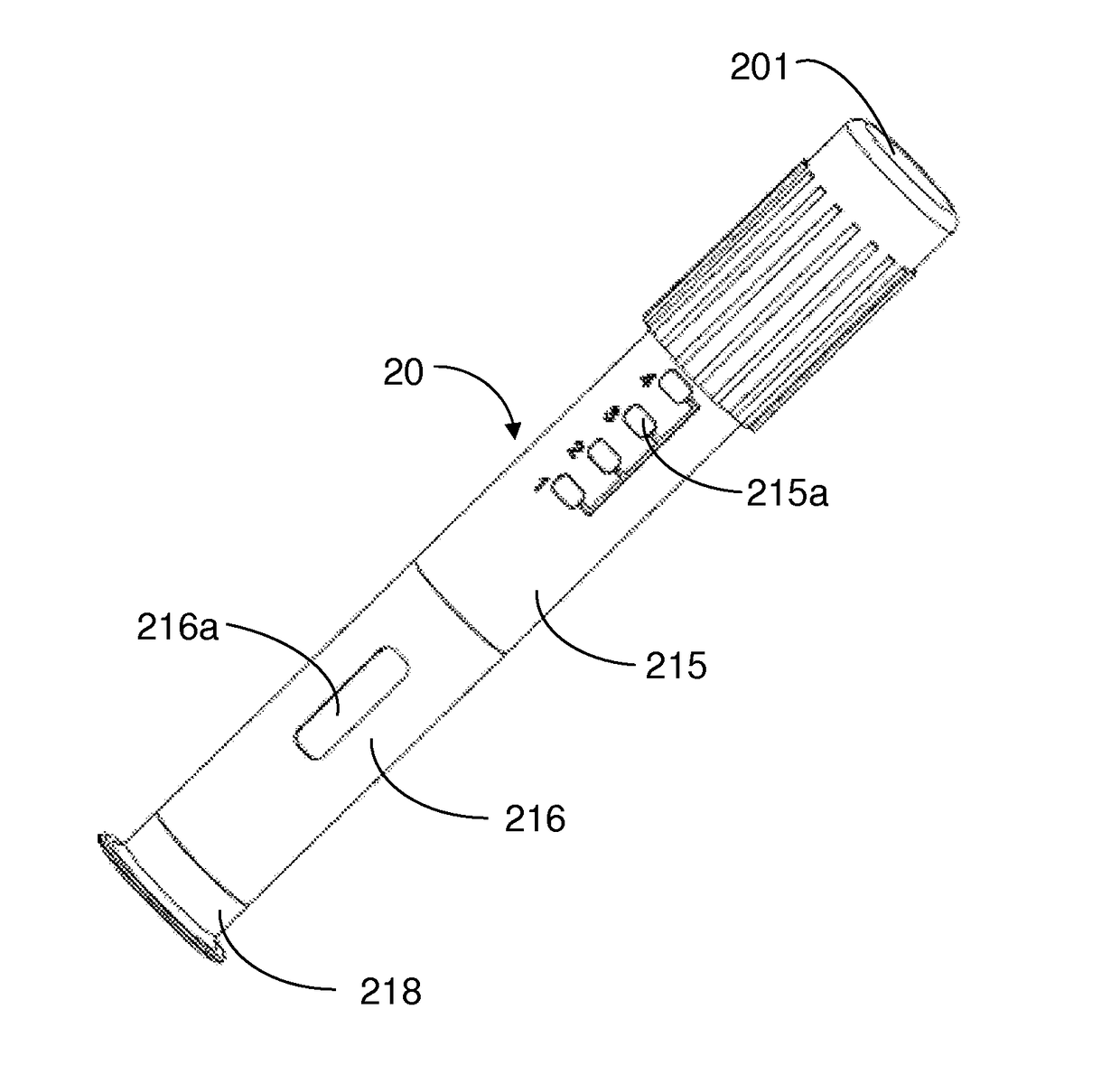

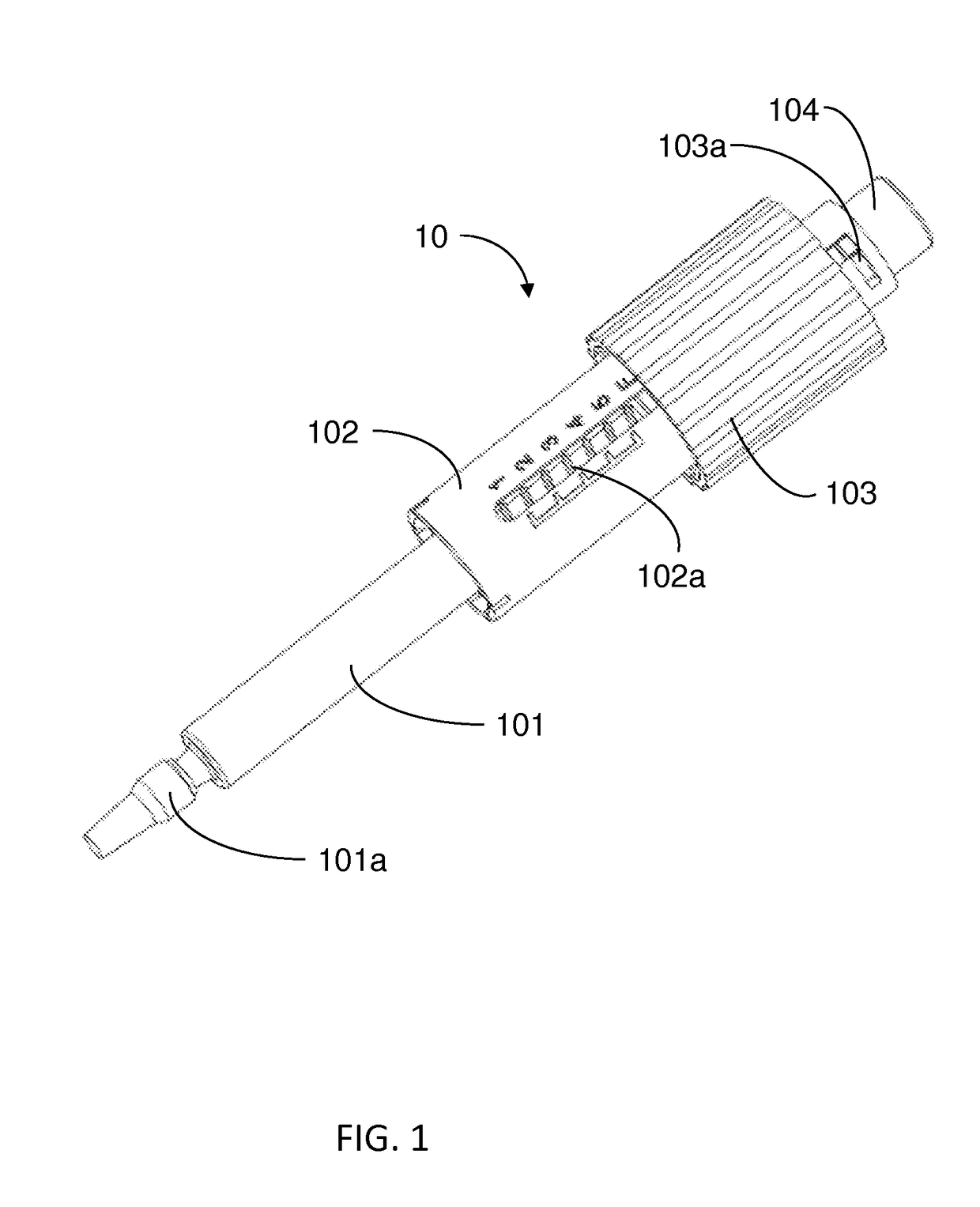

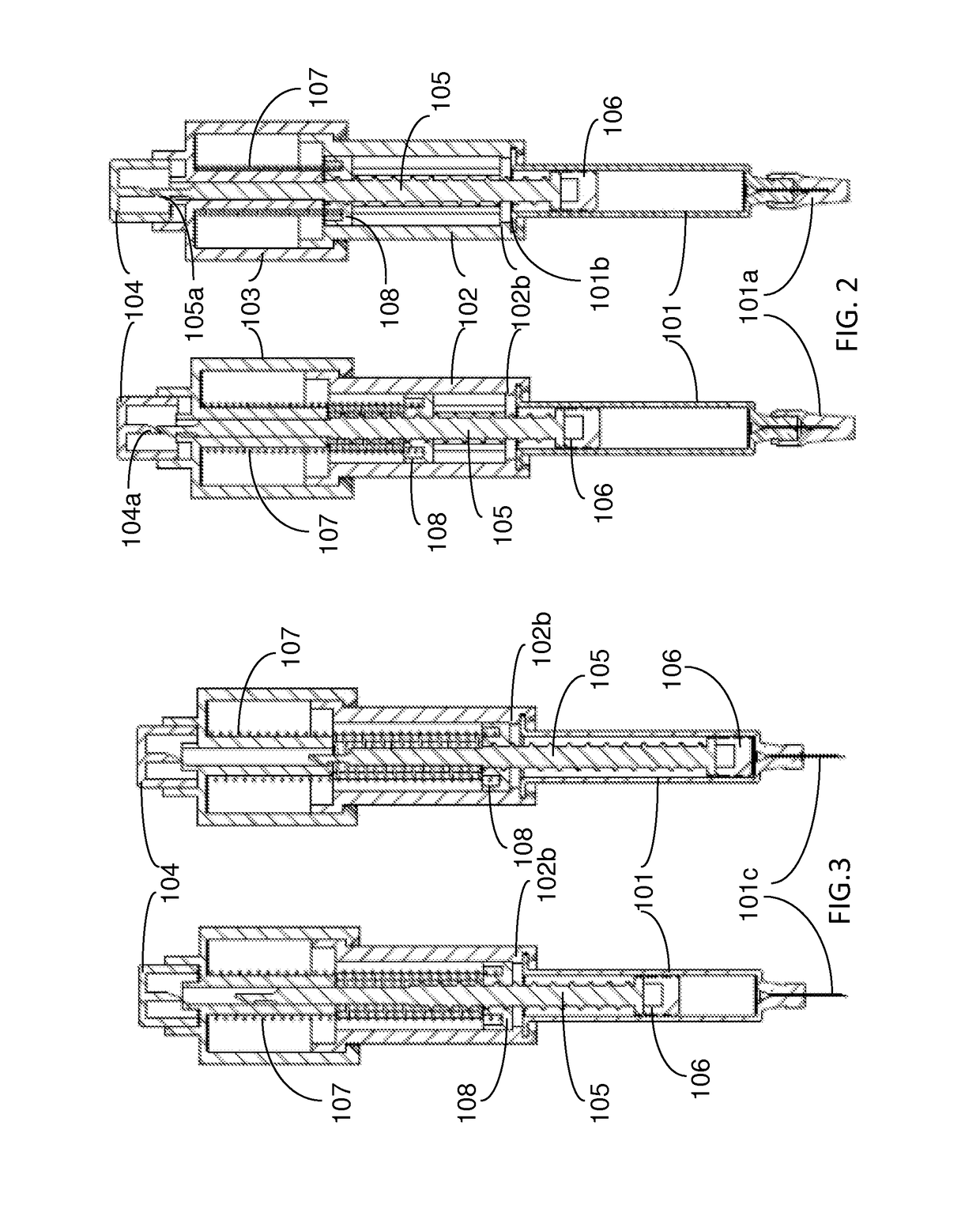

Automatic Injection Device With Variable Dosing

ActiveUS20170239424A1High volumeHighly viscousAutomatic syringesInfusion needlesBiomedical engineeringBiological activation

Owner:WEI MIN

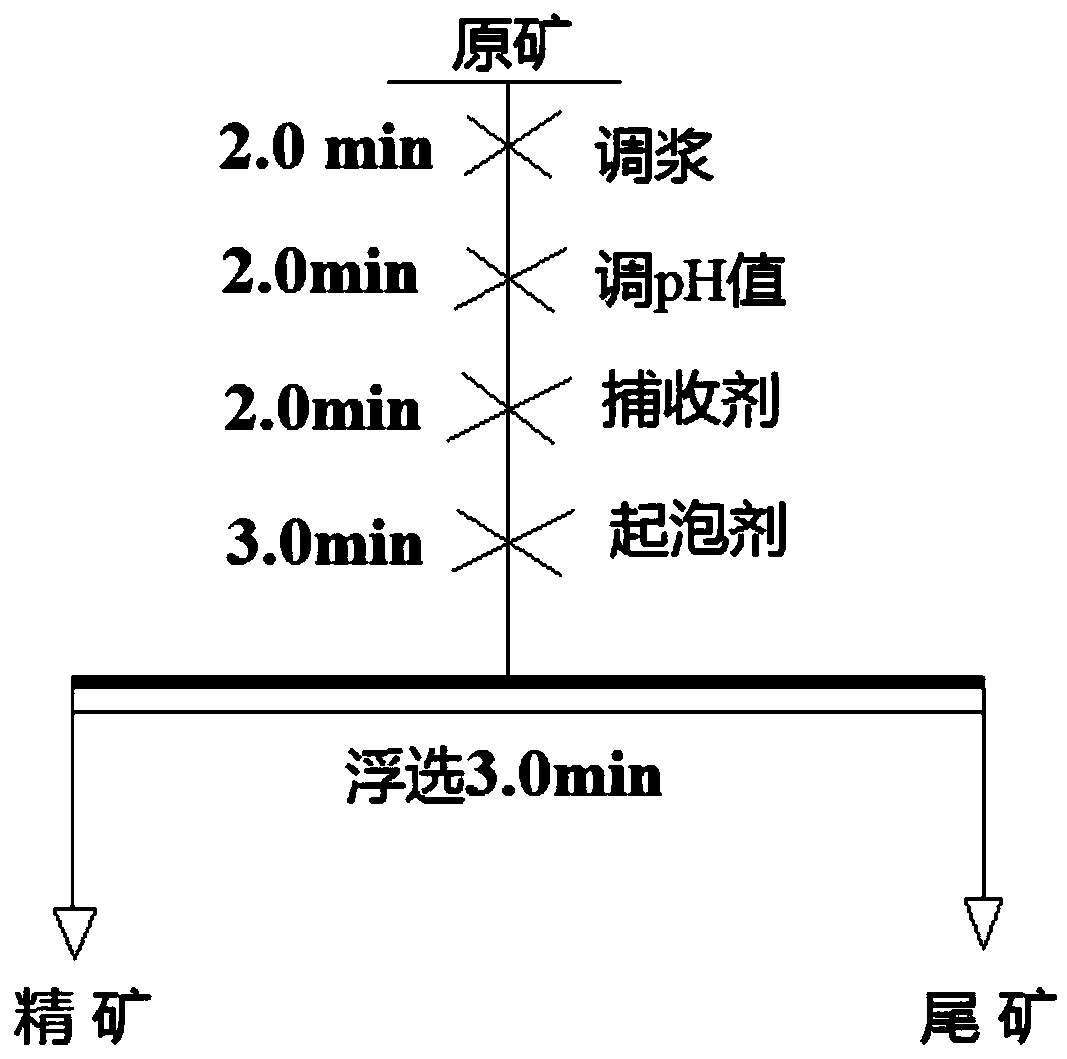

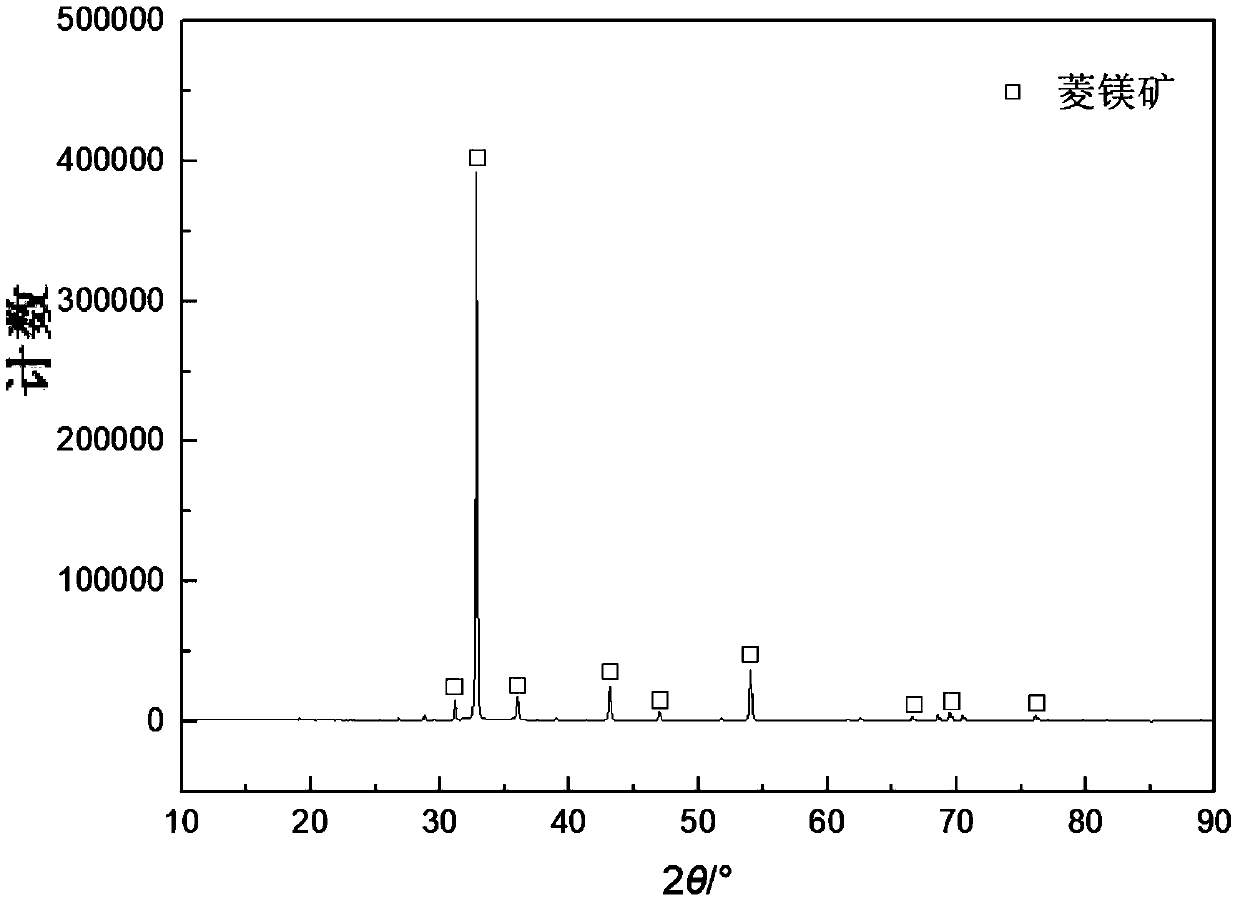

Method for temperature-control flotation and decalcification of magnesite

The invention relates to a method for temperature-control flotation and decalcification of magnesite, and belongs to the technical field of magnesite ore dressing and purification processes. The method comprises the steps of crushing and sieving high-calcium low-grade magnesite to obtain magnesite powder with the particle size of 38-74 microns; adding deionized water for mixing and slurry blendingto obtain magnesite slurry with the mass concentration of 10-40%, wherein the temperature of the magnesite slurry is 5-20 DEG C; adding NaOH to the magnesite slurry to adjust the pH value to 10-12, firstly adding an aqueous solution of a collecting agent sodium oleate for uniform stirring, and then conducting direct flotation roughing to obtain low-calcium magnesite concentrate. By means of the method, according to the difference in floatability of magnesite and impurity minerals dolomite in magnesite at different slurry temperatures, calcium minerals in magnesite are removed, the quality ofmagnesite is improved, and a new technology is provided for ore dressing and decalcification of high-calcium low-grade magnesite.

Owner:NORTHEASTERN UNIV

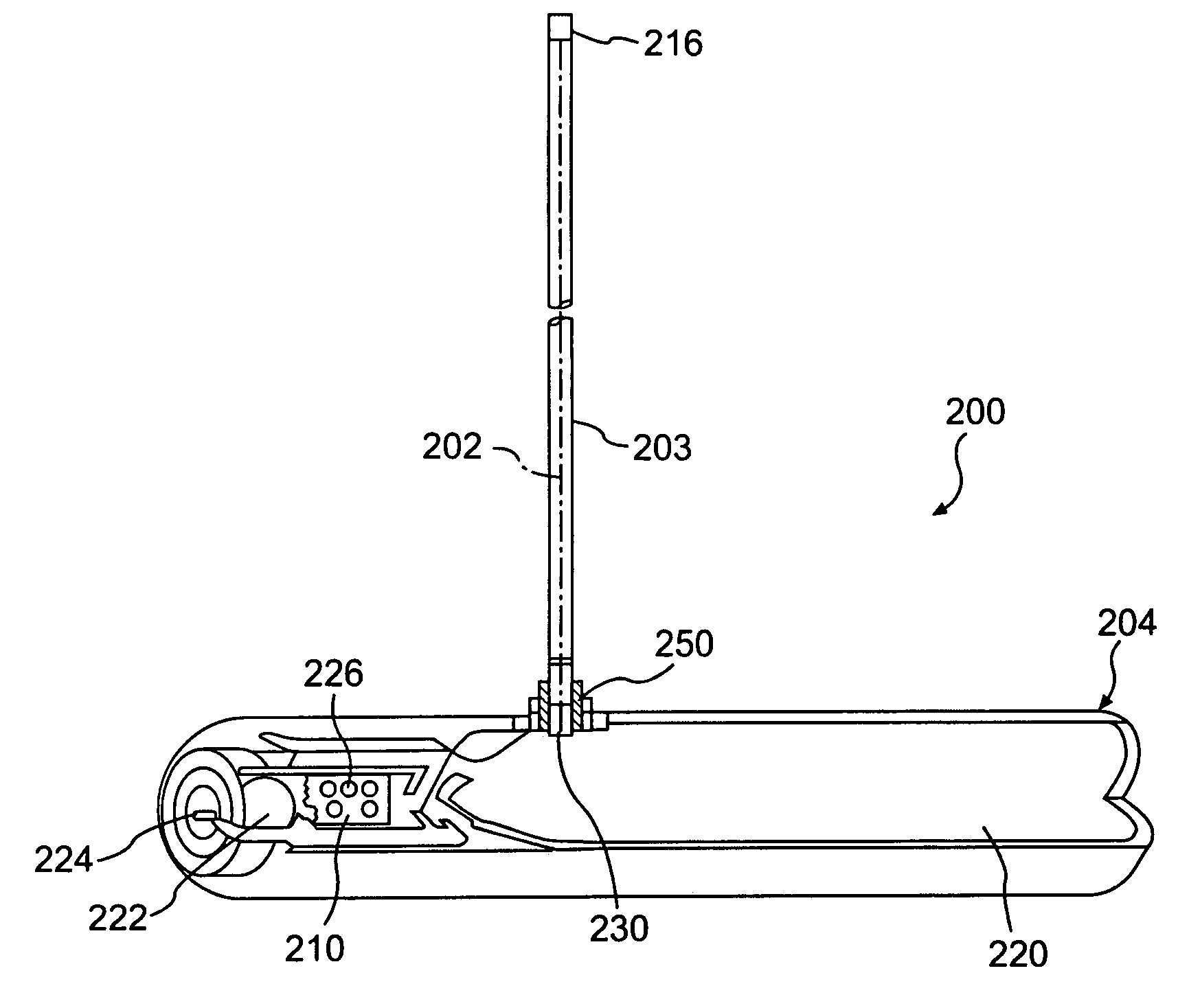

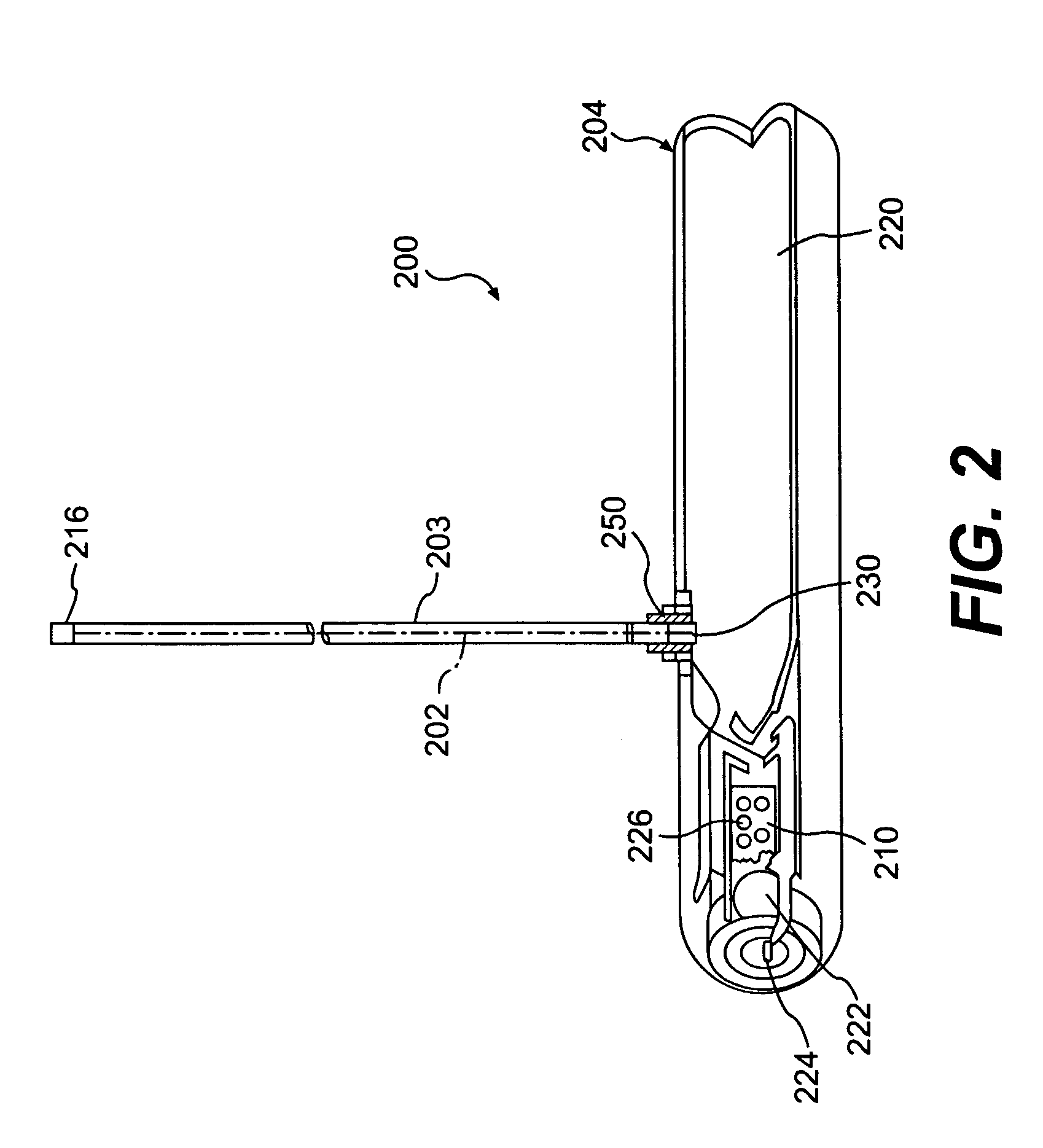

Distributed charge inflator system

InactiveUS7162958B2High volumePedestrian/occupant safety arrangementPressure gas generationNuclear engineeringCombustion chamber

An inflator includes a distributed charge to be distributed within an inflatable component of an inflatable system and a housing. The housing includes a combustion chamber and a gas storage chamber. The combustion chamber includes an initiator and a gas propellant. The gas storage chamber includes an inert gas at a high pressure. The housing also includes a gas nozzle. The distributed charge is connected to the housing through the gas nozzle. The distributed charge may be mechanically joined to the housing by a ferrule. Upon receiving an electrical signal from a crash sensor or other activator, the initiator ignites the gas propellant in the combustion chamber. The hot gas and hot particles from the burning gas propellant and the initiator flow into the gas storage chamber and heat the compressed inert gas in the gas storage chamber. The heated, compressed gas in the gas storage chamber flows through the gas nozzle and ignites the distributed charge. Combustion of the distributed charge generates a high volume of gas and inflates an inflatable component of an inflatable system.

Owner:ZODIAC AUTOMOTIVE US

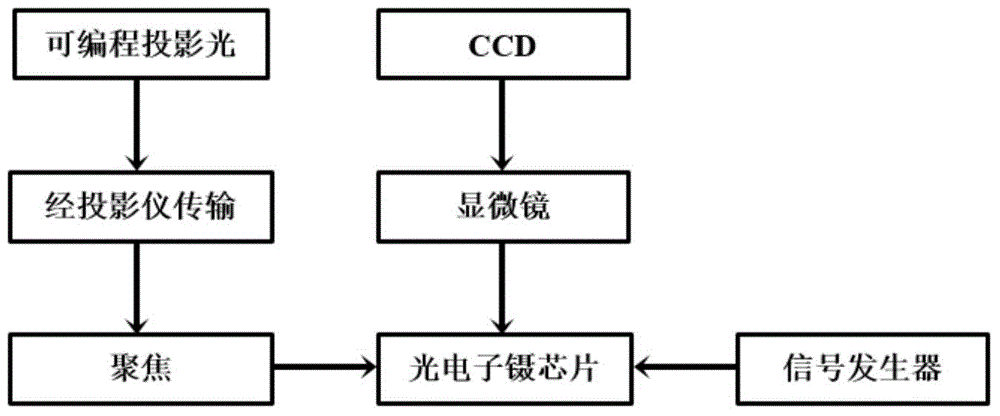

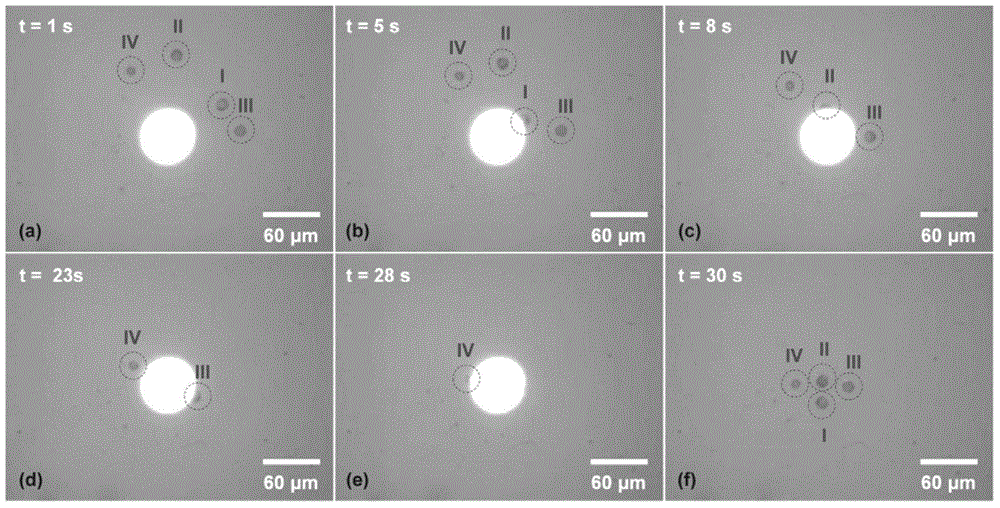

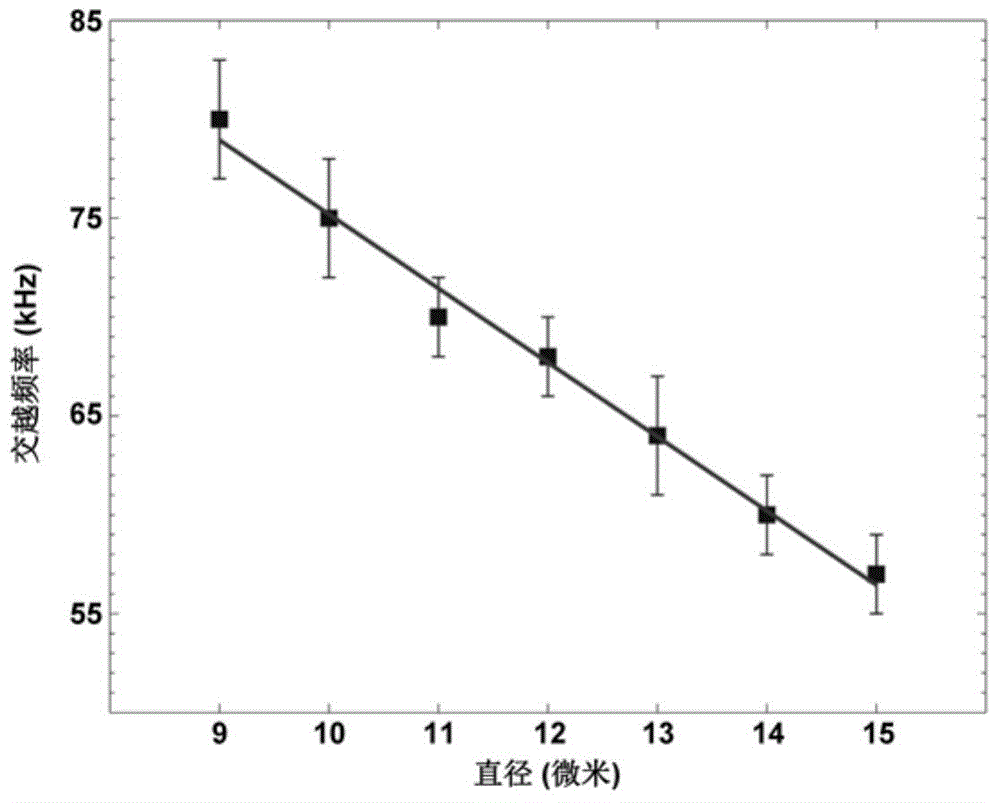

Method for acquiring label-free cells electrical characteristics based on light-induced dielectrophoresis mechanical force

The invention relates to a method for acquiring label-free cells electrical characteristics based on light-induced dielectrophoresis mechanical force. The method comprises the following steps: incident light is projected to a lower surface of a photoelectron tweezer chip; frequency of alternating voltage emitted by a signal-generator is affected on a conducting layer of the photoelectron tweezer chip; cells move far from the incident light; frequency of applied alternating voltage can be increased, when certain cell is stationary, the frequency is a cross-over frequency of the cell; frequency of the applied alternating voltage is continuously increased, the cell moves towards to the incident light; when all the cells move in an incident light scope, the incident light and the applied alternating voltage are closed; a relation between the cross-over frequency and a diameter of each cell can be obtained; and capacitance of each cell membrane can be obtained according to the relation between the cell membrane capacitance and cell diameter. The preparation of metal microelectrodes with a specific structure is not required; the electrical characteristic parameter of single cell or many cells can be obtained with real time; an antibody is not required for being used for identification of the cells, and the method has the advantages of automation, mass production and high throughput capacity.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

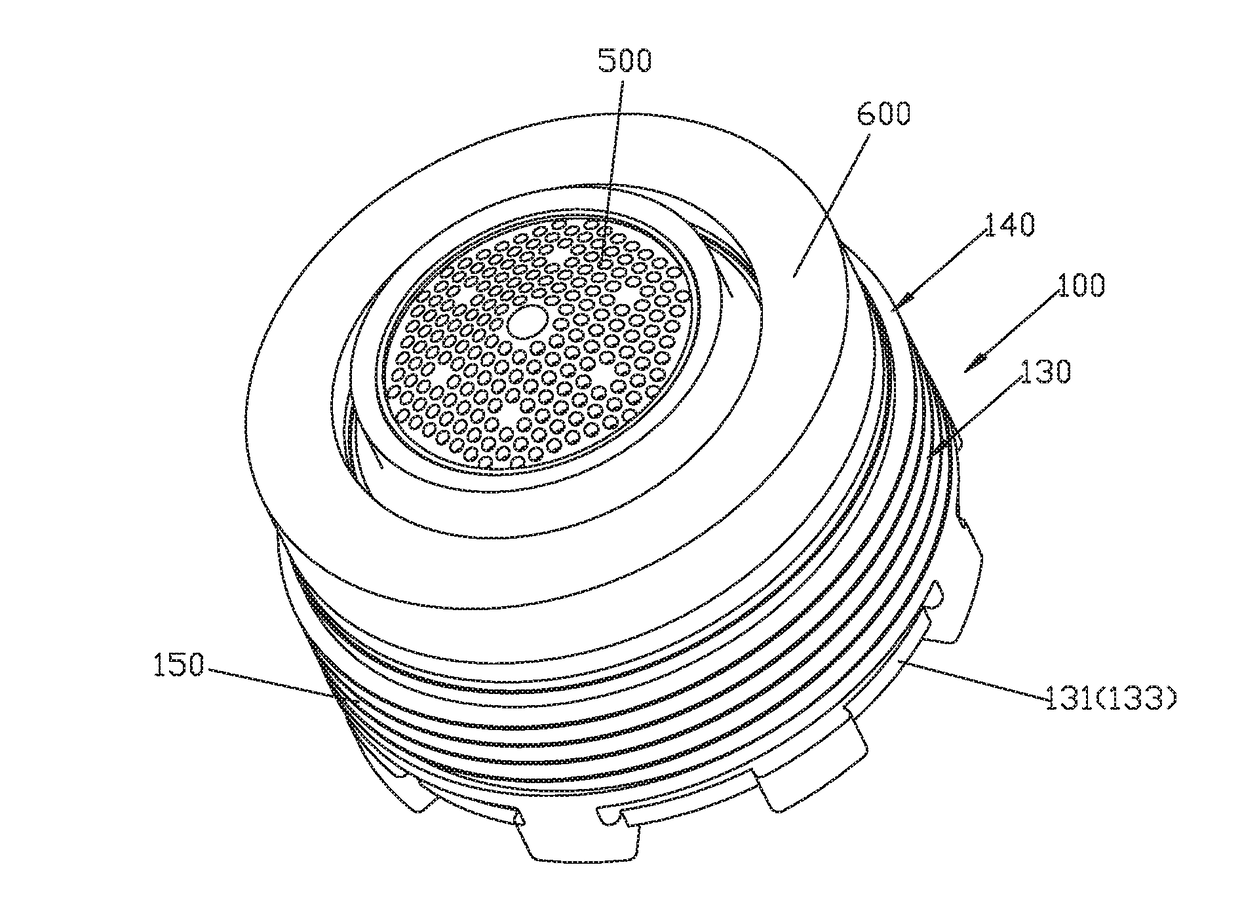

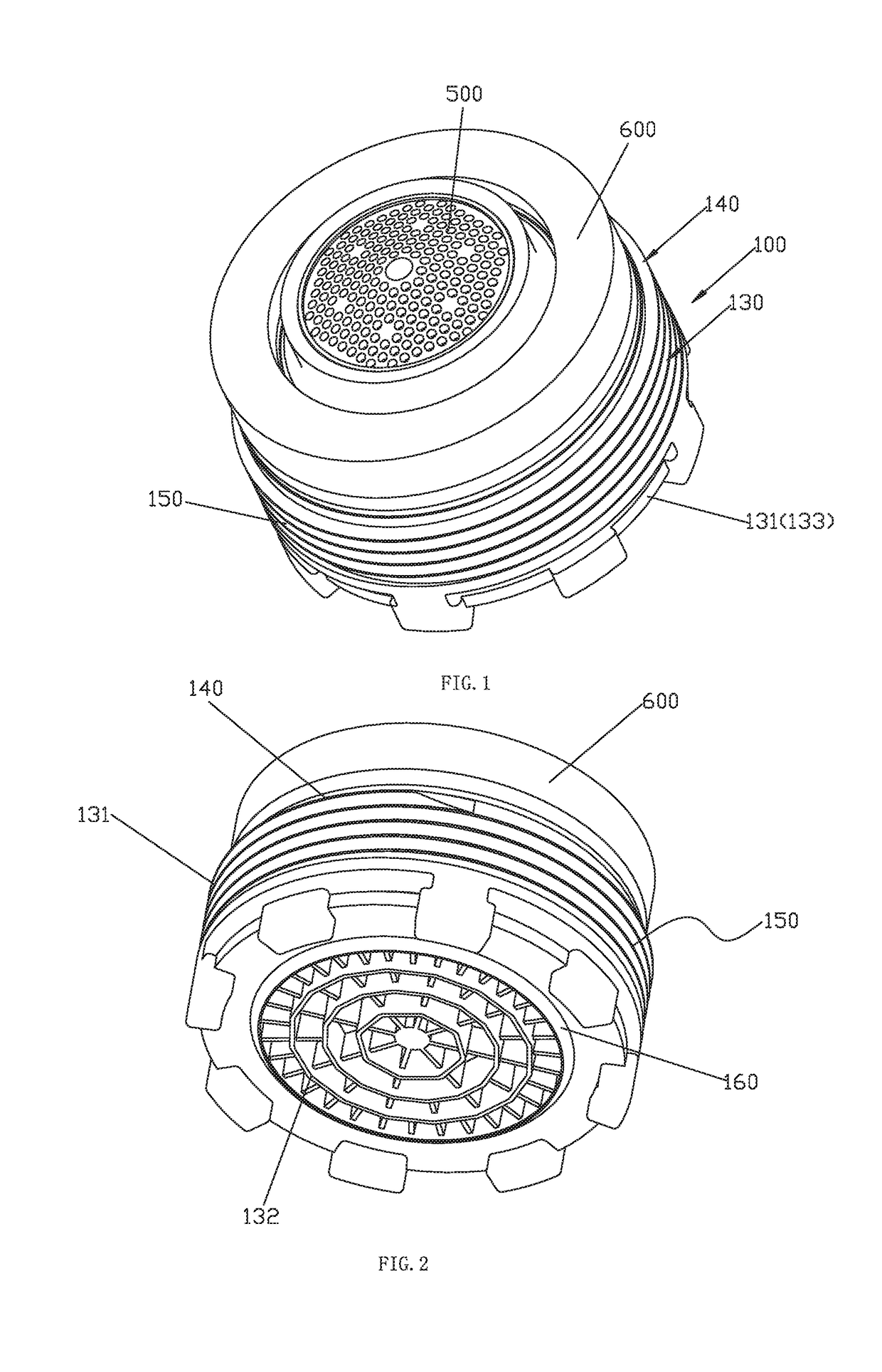

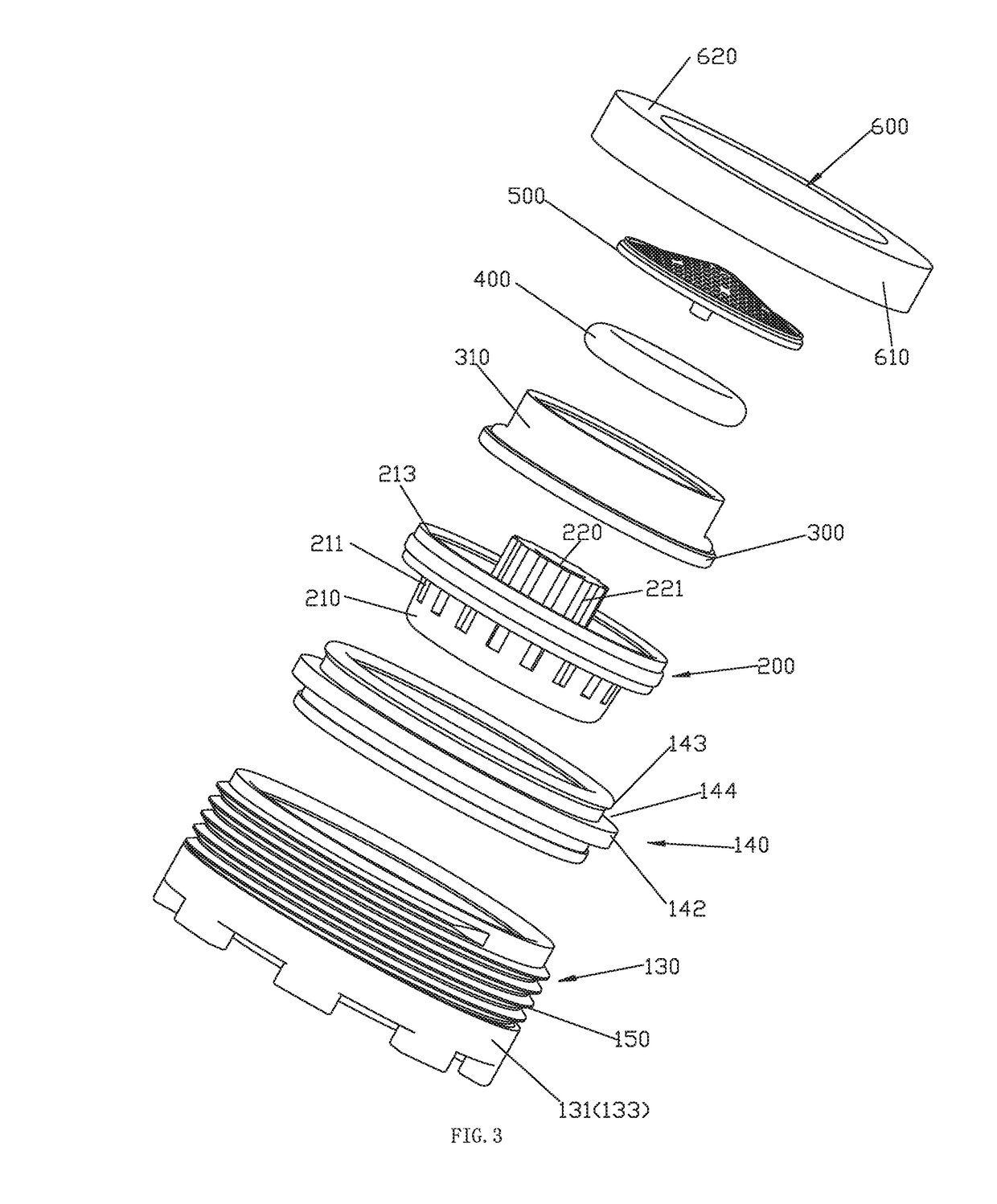

Concealed flow regulator

ActiveUS20170136476A1Reduce pressure lossHigh volumeSpray nozzlesDomestic plumbingMutationEngineering

Disclosed is a concealed flow regulator, which comprises a housing portion and a diversion device, the housing portion is disposed with a mutation cavity and a suction passage, the diversion device is used to divide the water flowing, the divided water enters the mutation cavity and negative pressure generates; the external revolution surface of the housing portion is disposed with external thread, the housing portion is threaded to the water supplying opening via the external thread; the suction passage has an internal port faced to the mutation cavity and an external port at the external revolution surface, the air flowing clearance is connected to the external port, so that air can enter the mutation cavity through the air flowing clearance, the external port and the internal port. It has advantages: the flow regulator can be assembled in the water supplying opening and be concealed.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com