Patents

Literature

36 results about "Manufactured nanoparticles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

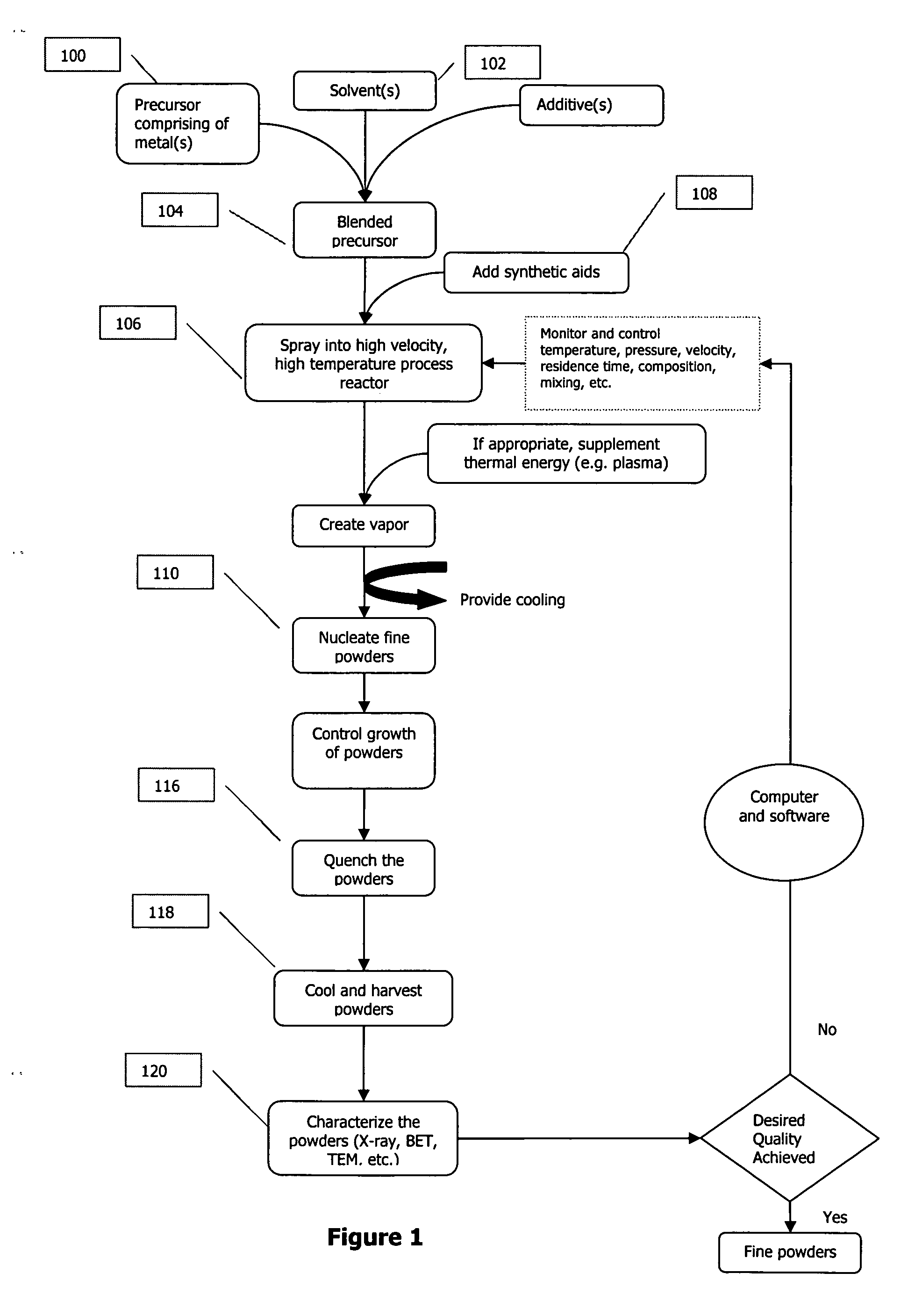

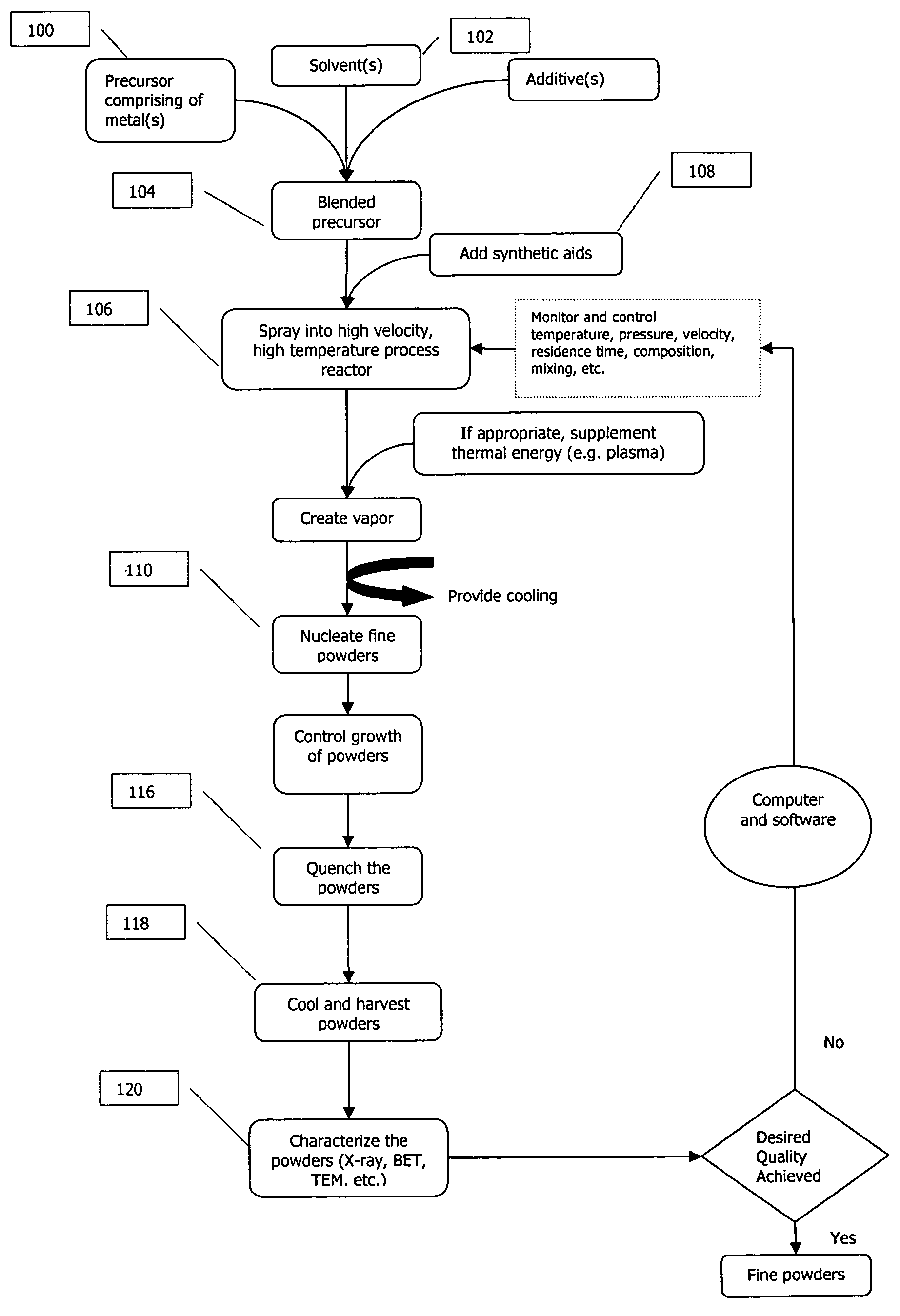

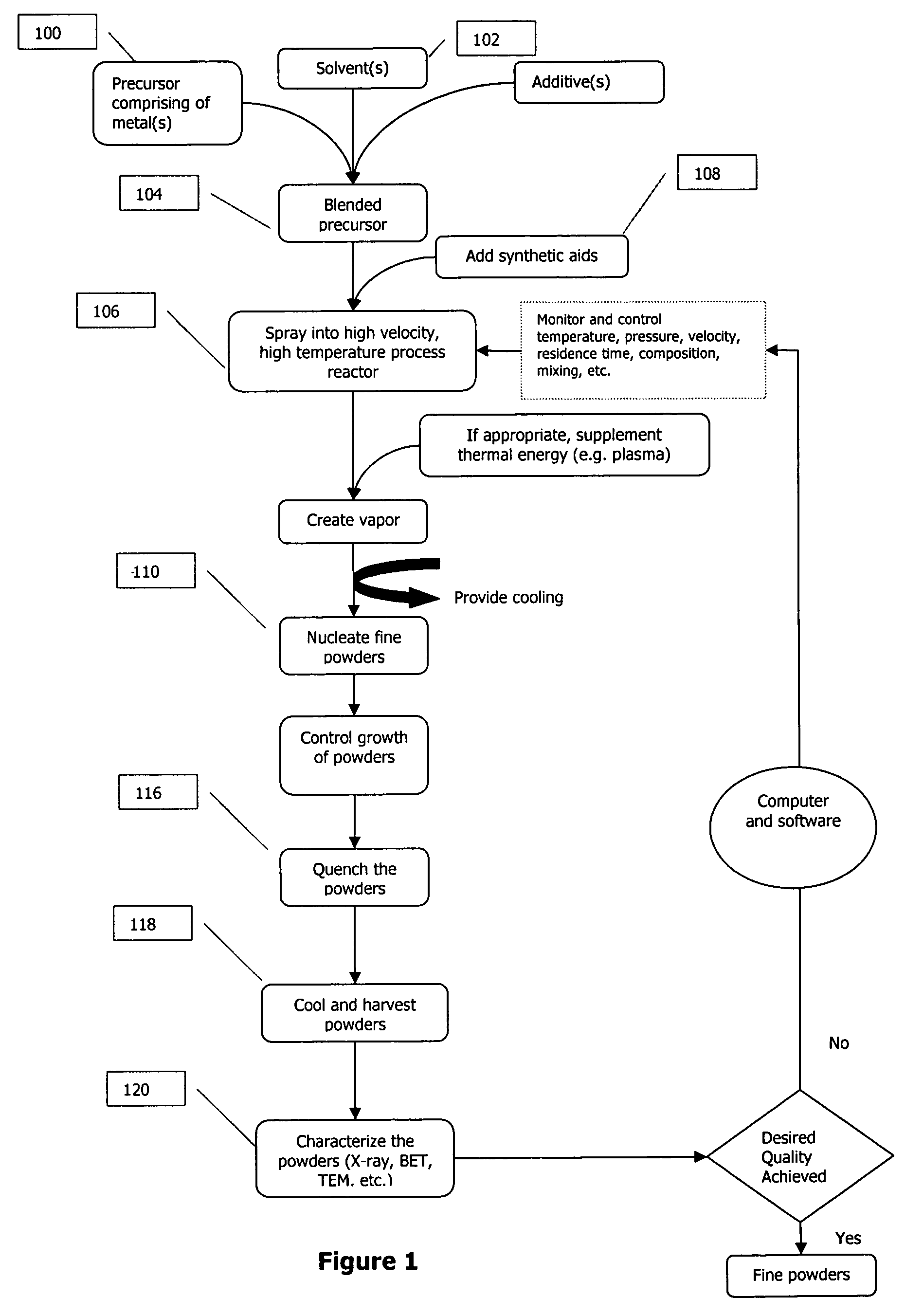

Zinc comprising nanoparticles and related nanotechnology

InactiveUS20050126338A1Increase volumeLow costPigmenting treatmentMaterial nanotechnologyZincPigment

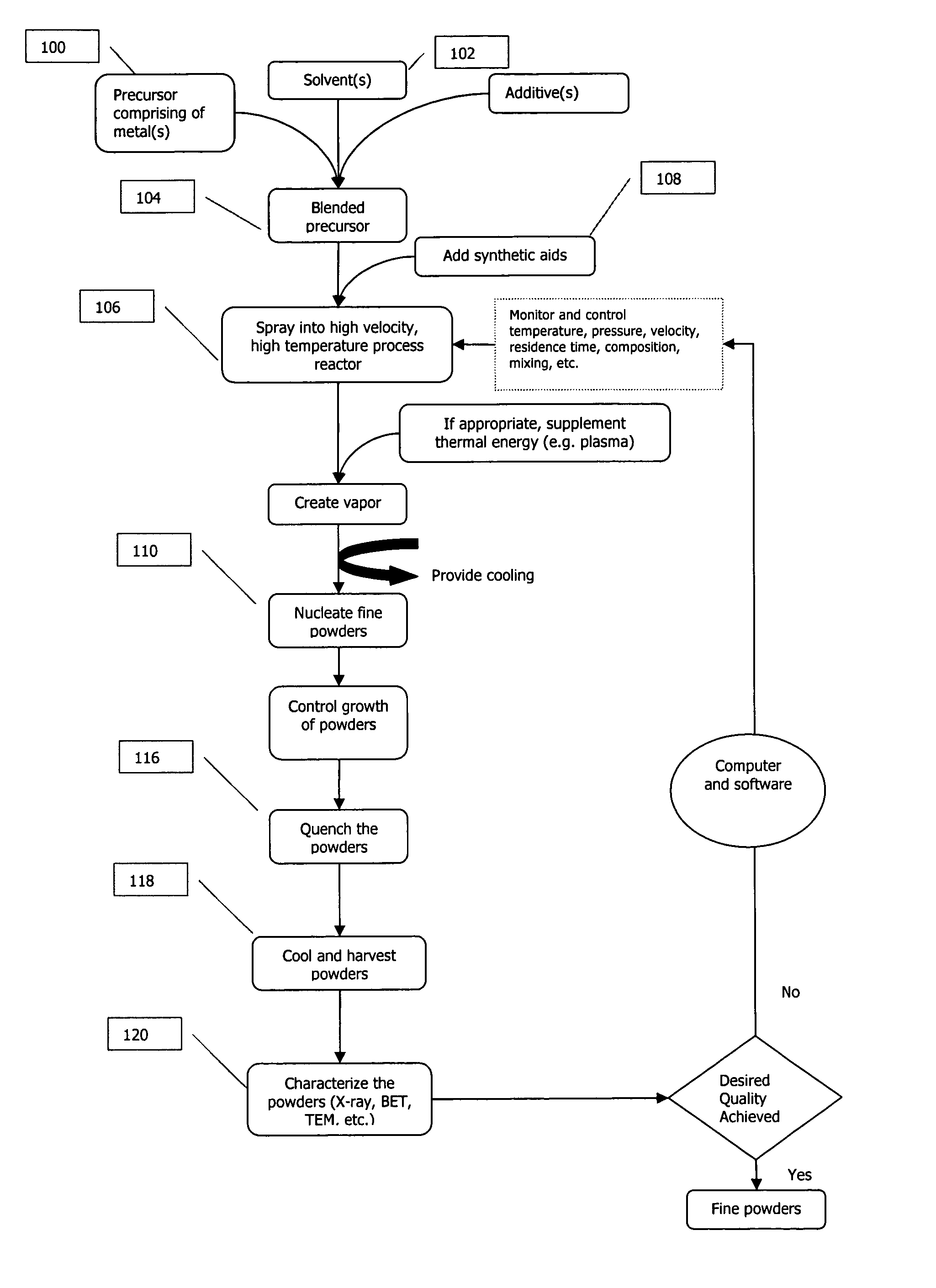

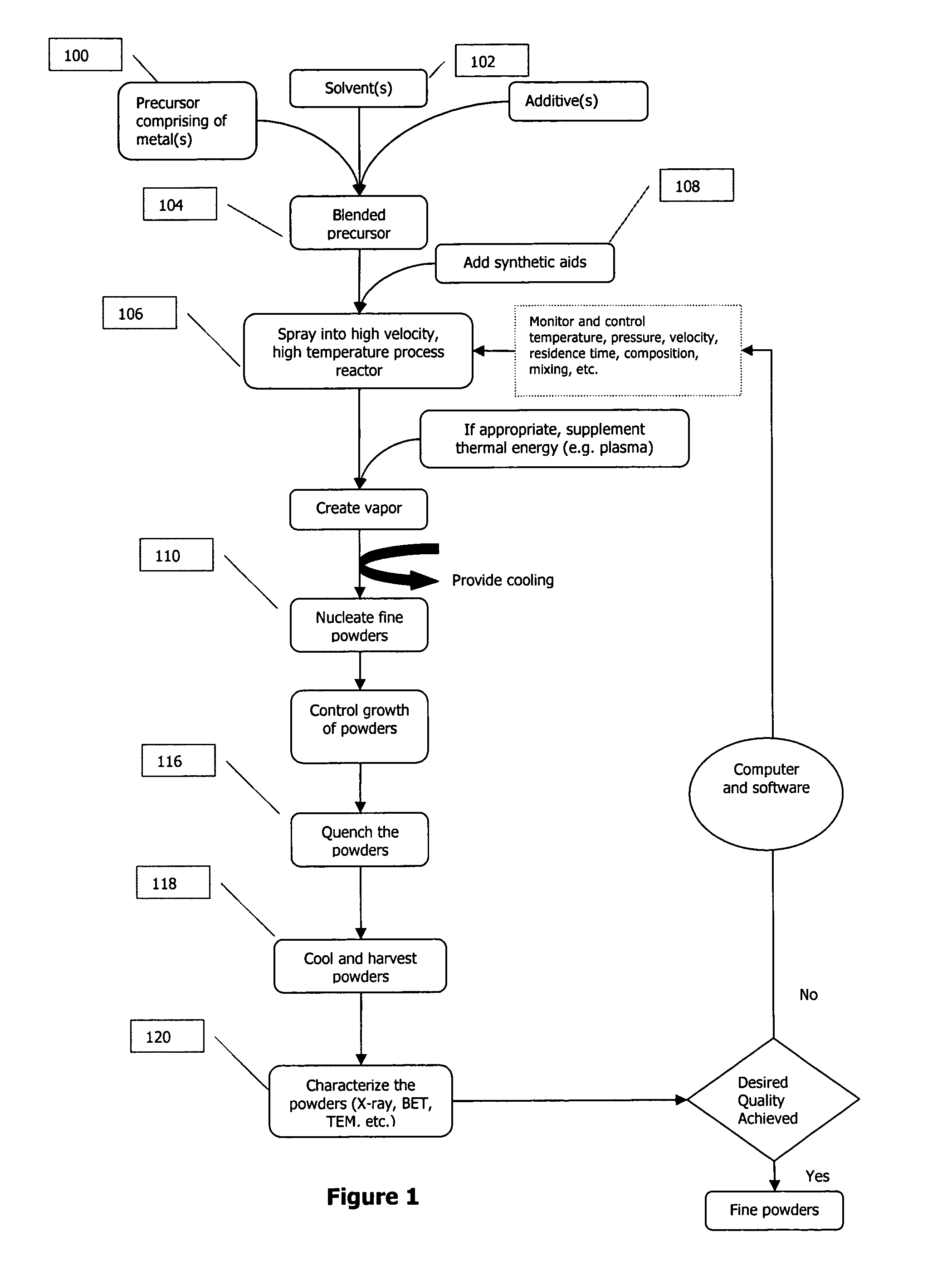

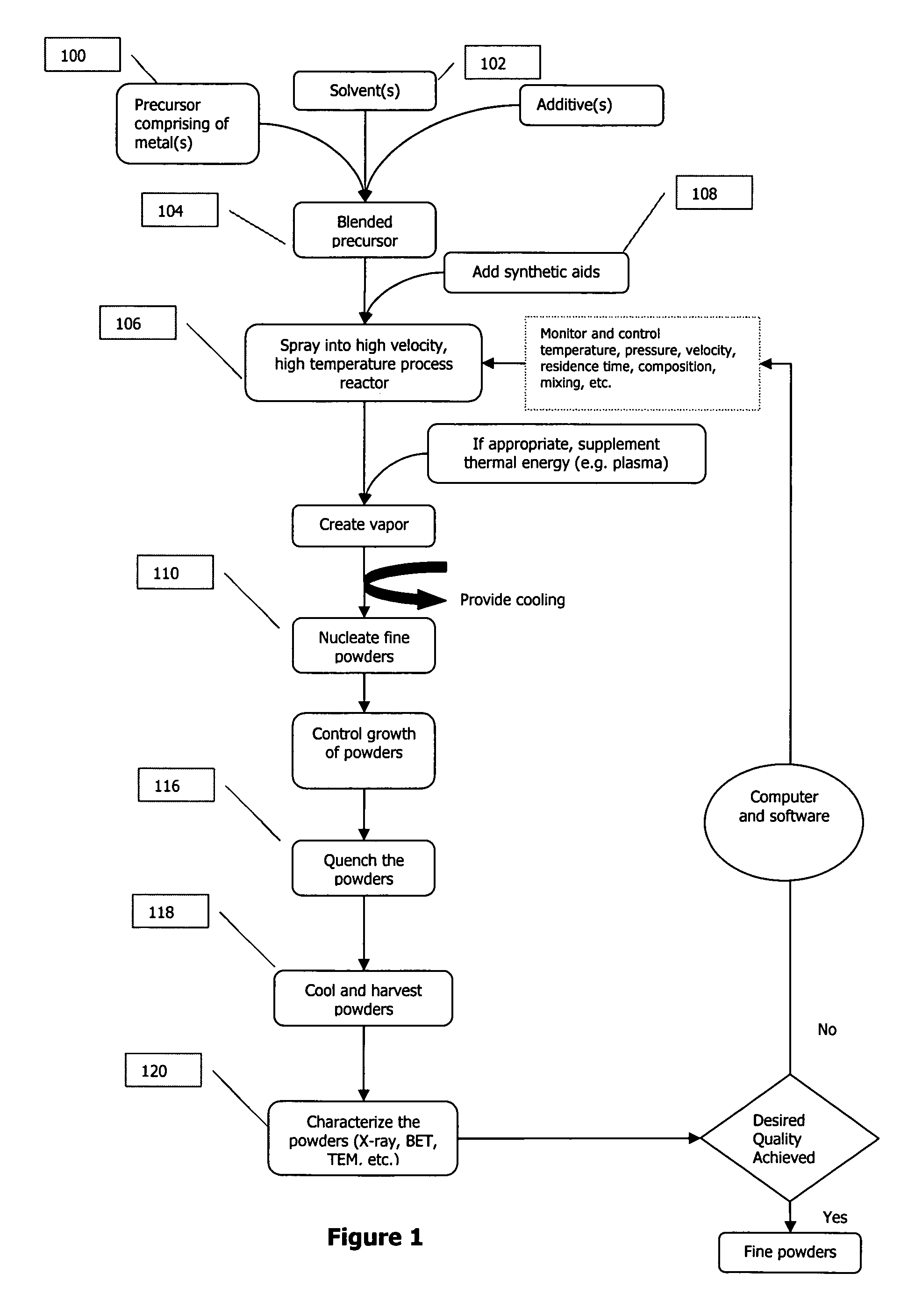

Nanoparticles comprising zinc, methods of manufacturing nanoparticles comprising zinc, and applications of nanoparticles comprising zinc, such as electrically conducting formulations, reagents for fine chemical synthesis, pigments and catalysts are provided.

Owner:PPG IND OHIO INC

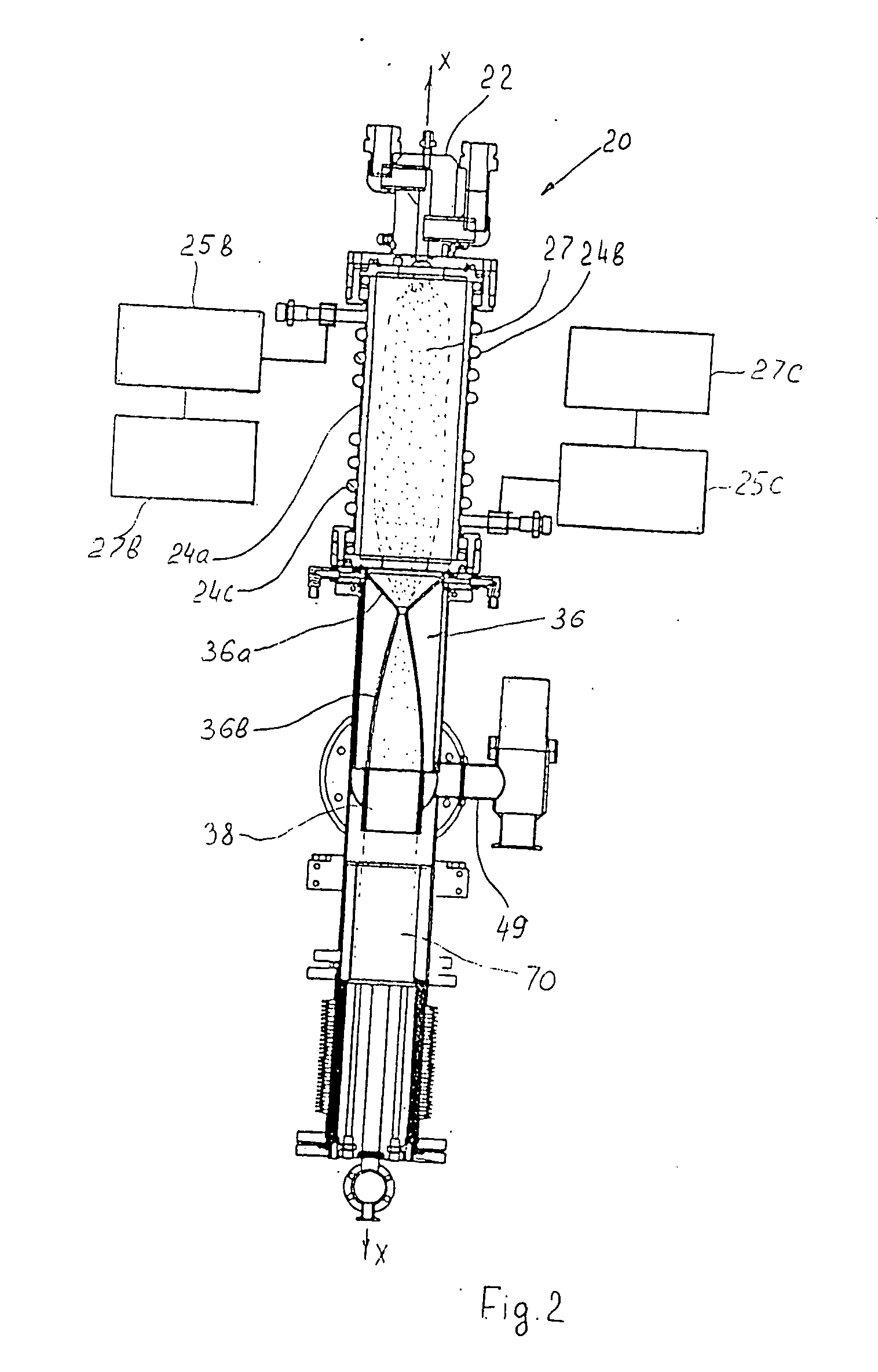

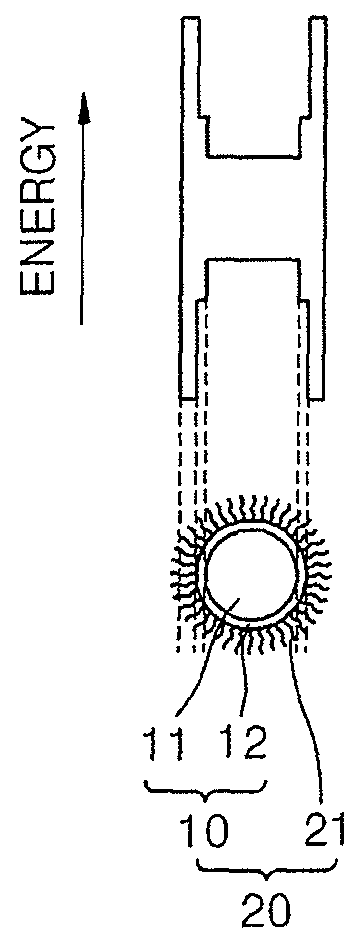

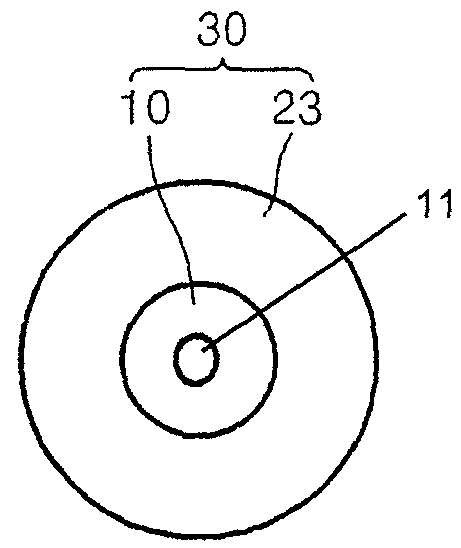

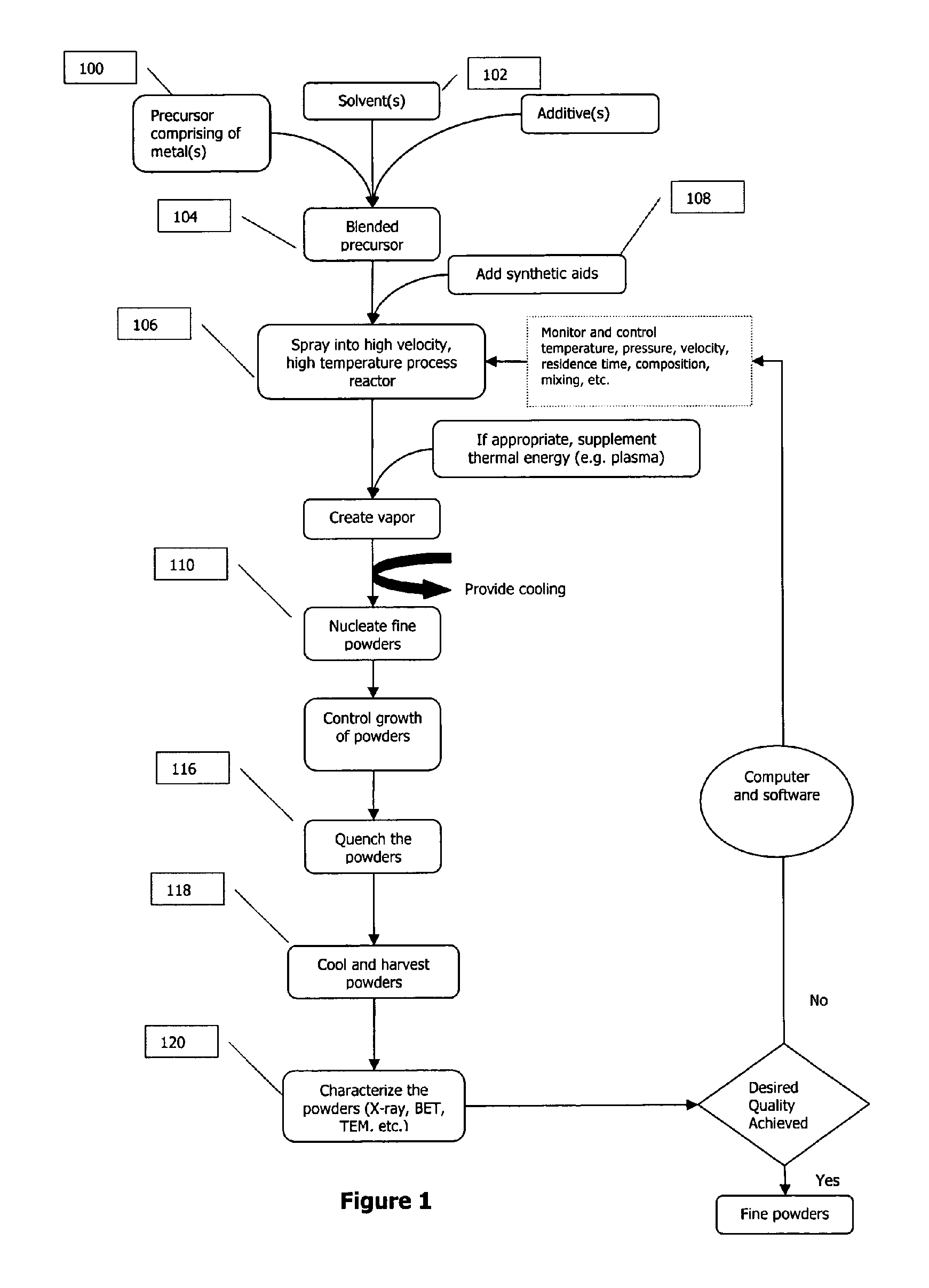

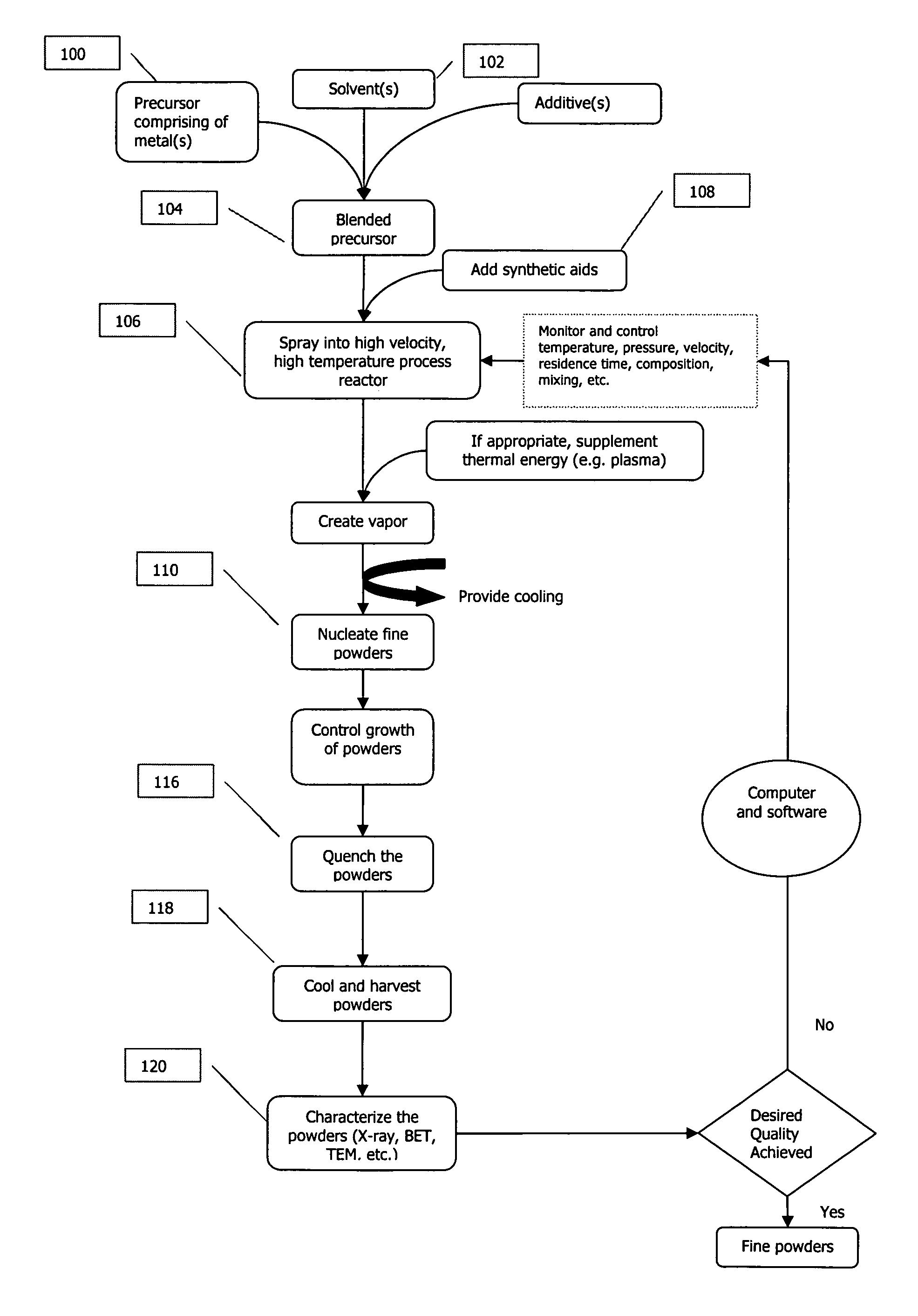

Method and apparatus for manufacture of nanoparticles

InactiveUS20050258149A1Improve production efficiencyEasy to useArc welding apparatusPlasma techniqueSemi automaticMaterials science

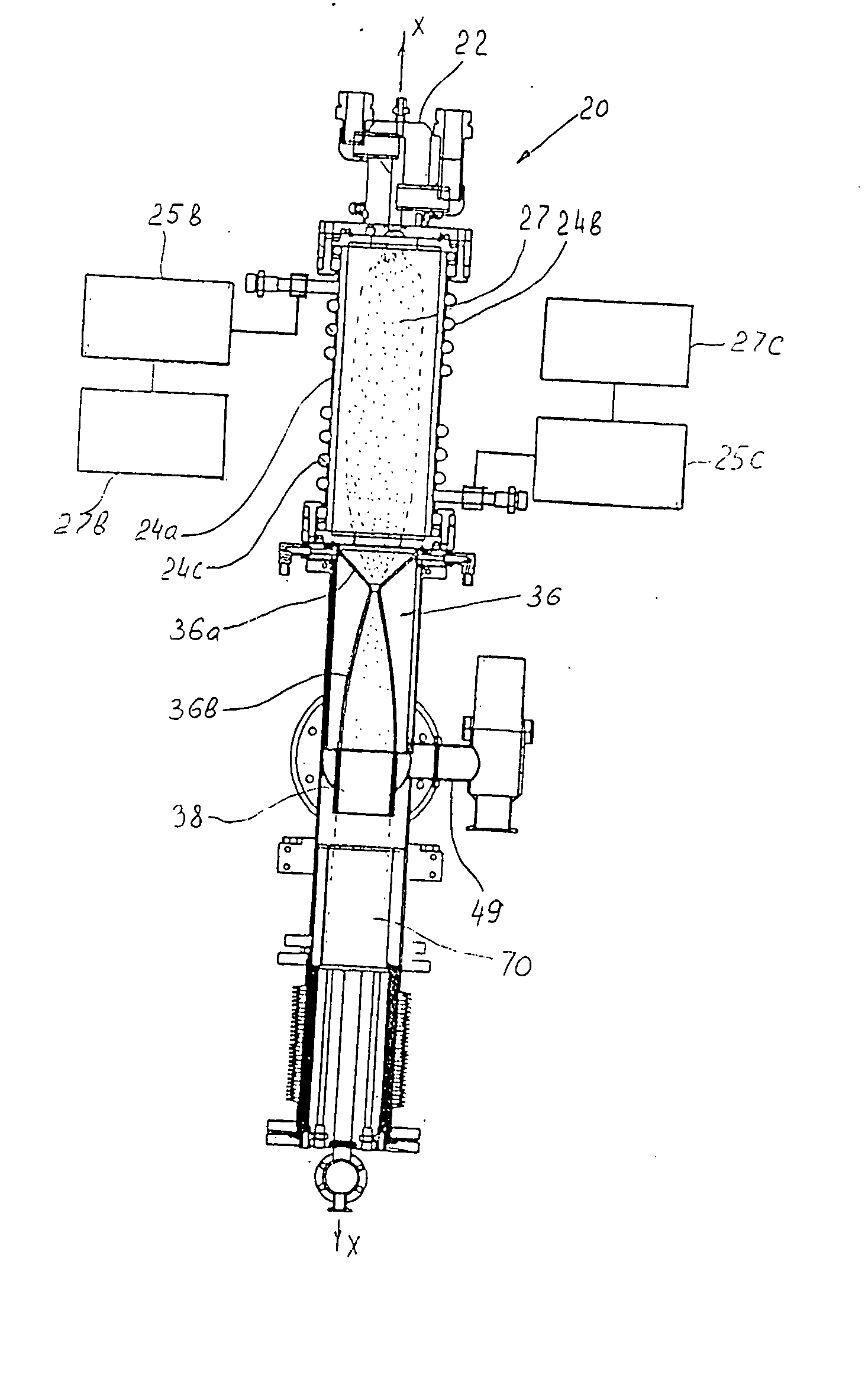

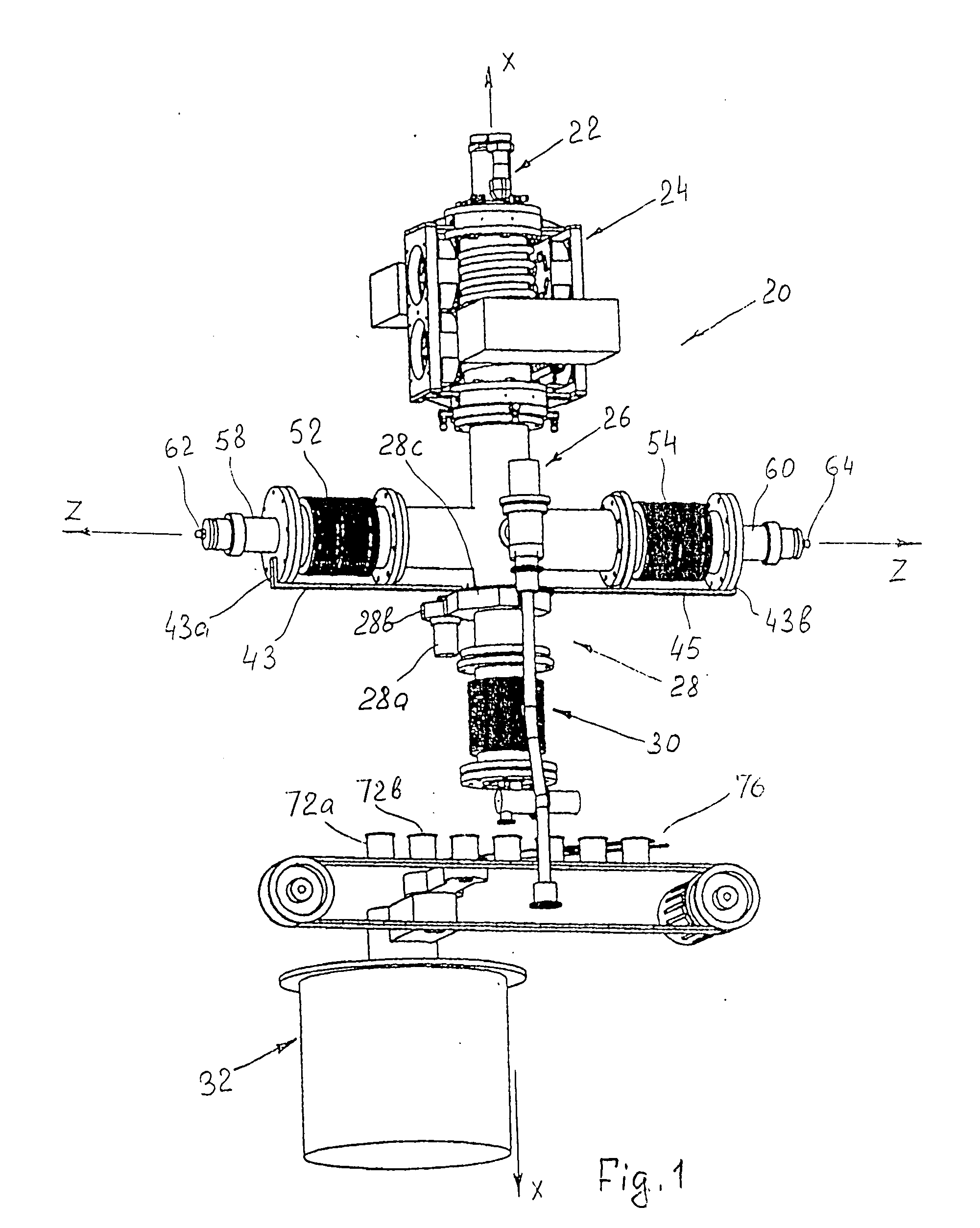

A method and apparatus for manufacturing nanoparticles by passing a carrying fluid with a nanoparticle precursor through an RF plasma volume for heating the fluid with a nanoparticle precursor to a high temperature sufficient to synthesizing the nanoparticles. The suspension of the fluid with nanoparticles is passed to the thermalization zone in a diverging portion of the Laval nozzle for subjecting the fluid with nanoparticles to jumpwise adiabatic expansion at the exit from the converging portion of the Laval nozzle to the thermalization zone. At least the diverging portion has a curvilinear profile optimized with respect to conditions of said thermalization. In the thermalization zone, the flow of fluid with nanoparticles is surrounded by a cylindrical oil shower composed of discrete drops of oil. The oil shower is emitted from a shower ring that performs twisting motions. The particles are entrapped in the oil drops while the fluid is allows to pass in the radial outward direction from a portion of the thermalization zone. The oil drops with entrapped nanoparticles are collected and loaded into cups with the use semi-automatic or automatic mechanism.

Owner:NANOMAT +1

Molybdenum comprising nanomaterials and related nanotechnology

InactiveUS20060079410A1Increase volumeLow cost productionTransportation and packagingMetal-working apparatusPhotonicsNanometre

Nanoparticles comprising molybdenum, methods of manufacturing nanoparticles comprising molybdenum, and nanotechnology applications of nanoparticles comprising molybdenum, such as electronics, optical devices, photonics, reagents for fine chemical synthesis, pigments and catalysts, are provided.

Owner:PPG IND OHIO INC

Tungsten comprising nanomaterials and related nanotechnology

InactiveUS7708974B2Increase volumeLow cost productionNanostructure manufactureCell electrodesPhotonicsNanotechnology Techniques

Nanoparticles comprising tungsten, methods of manufacturing nanoparticles comprising tungsten, and applications of nanoparticles comprising tungsten, such as electronics, optical devices, photonics, reagents for fine chemical synthesis, pigments, and catalysts are provided.

Owner:PPG IND OHIO INC

Nanoparticles and methods of manufacturing the same

InactiveUS20130092885A1Improve electrical performanceLess securityMaterial nanotechnologyNanostructure manufactureHydrazine compoundSulfur

A method of manufacturing nanoparticles including: providing a metal chalcogenide complexes (MCC) hydrazine hydrate solution; providing a first organic solution of nanoparticles with first organic ligands; forming a mixed solution by mixing the MCC hydrazine hydrate solution and the first organic solution of nanoparticles capped with the first organic ligands; and replacing the first organic ligands of the nanoparticles with ligands of the MCC hydrazine hydrate.

Owner:SAMSUNG ELECTRONICS CO LTD

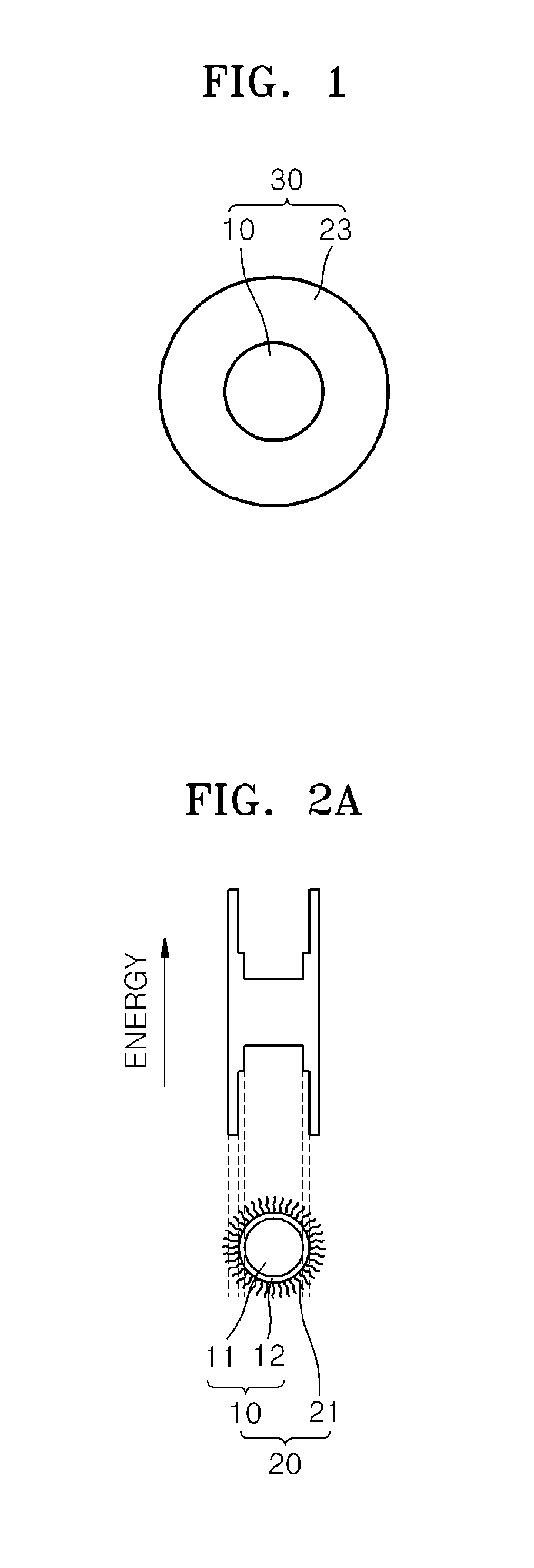

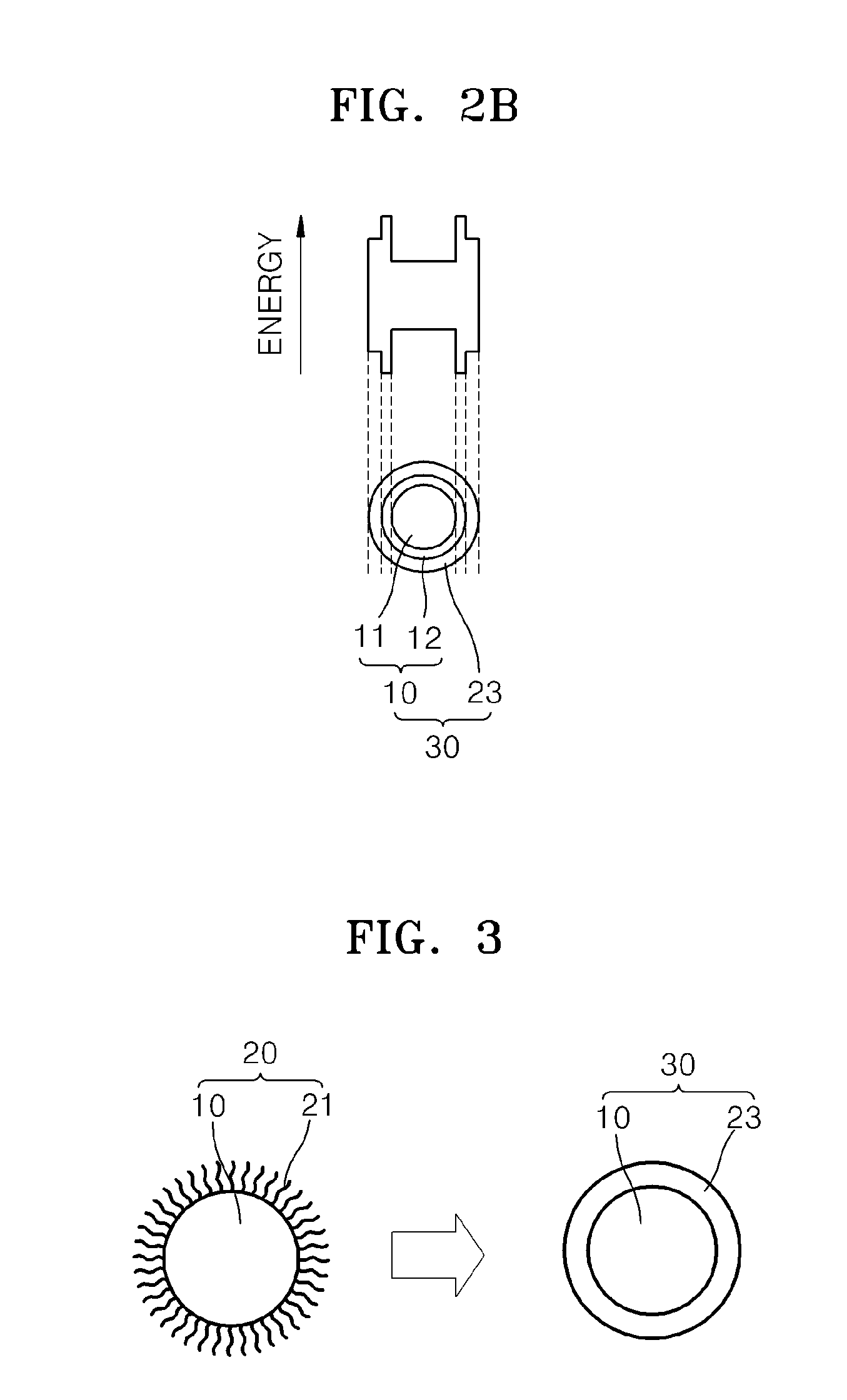

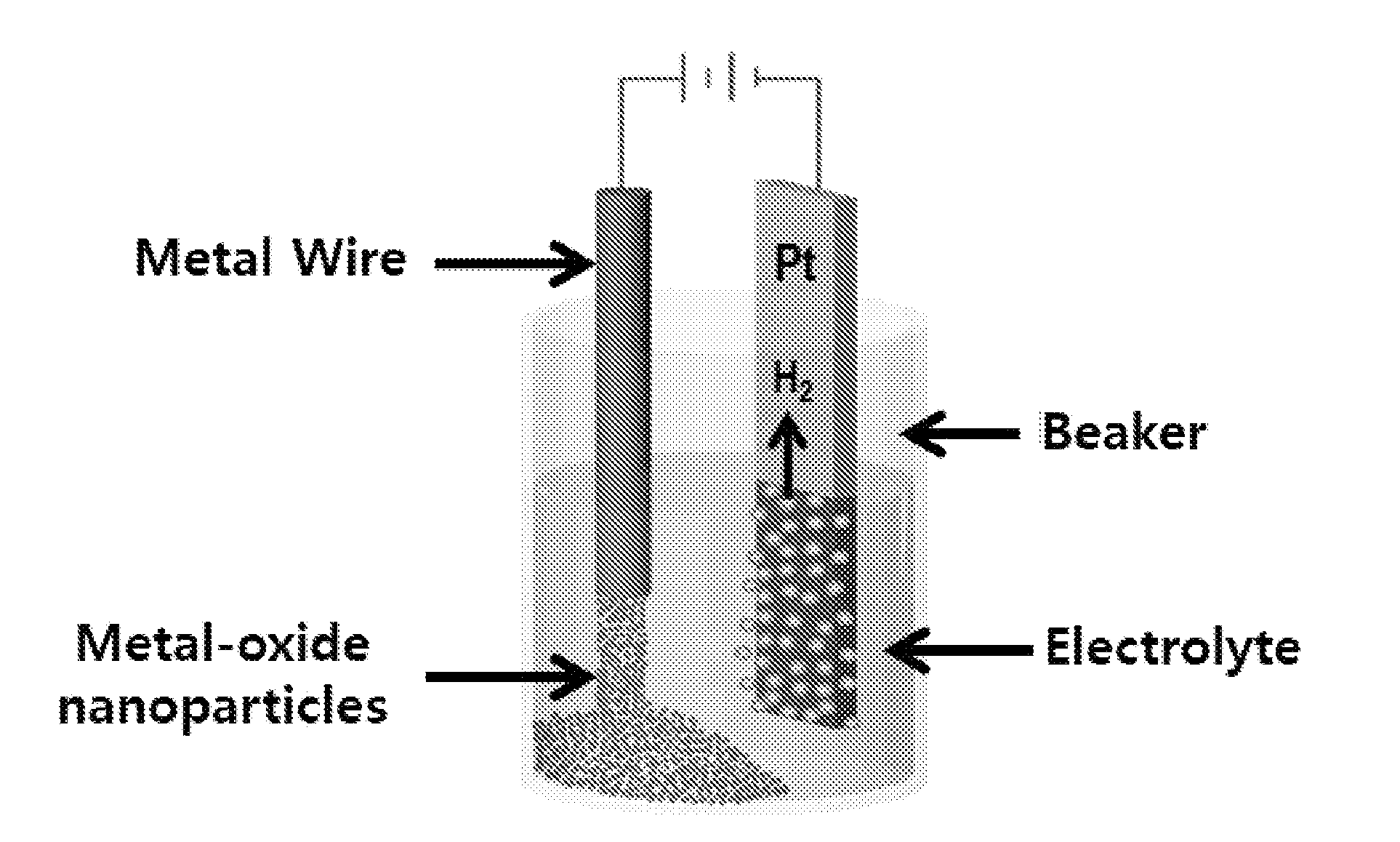

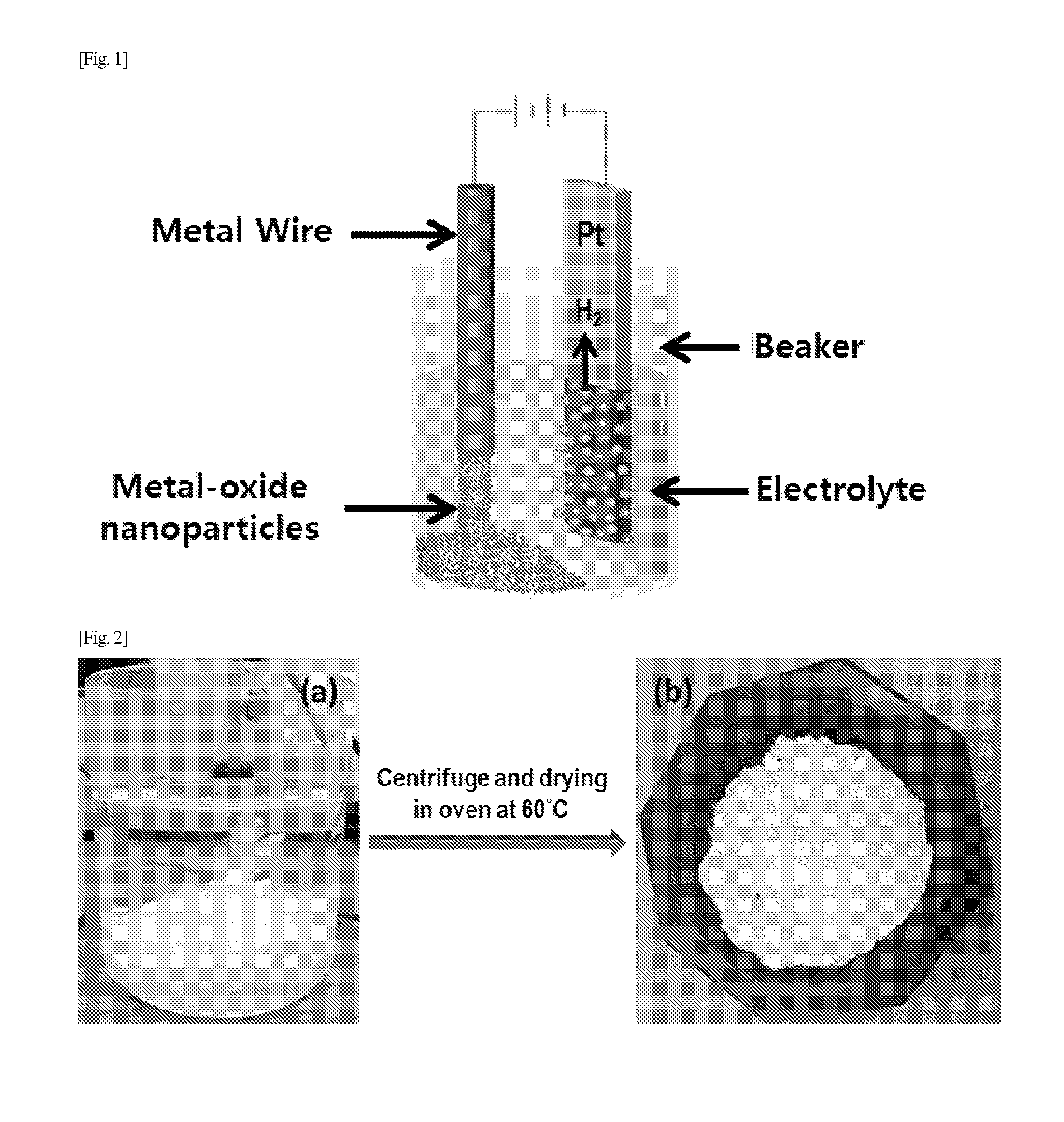

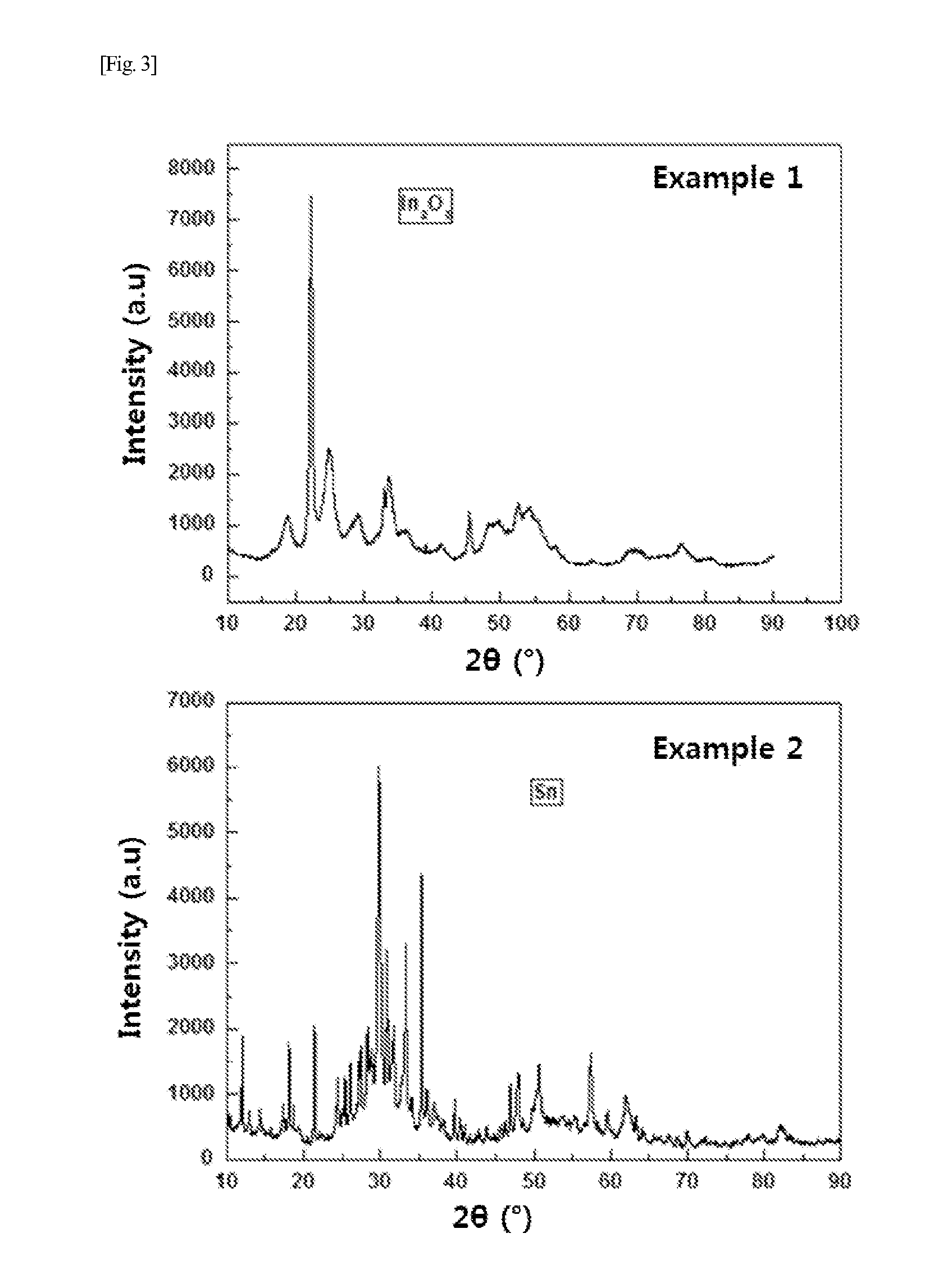

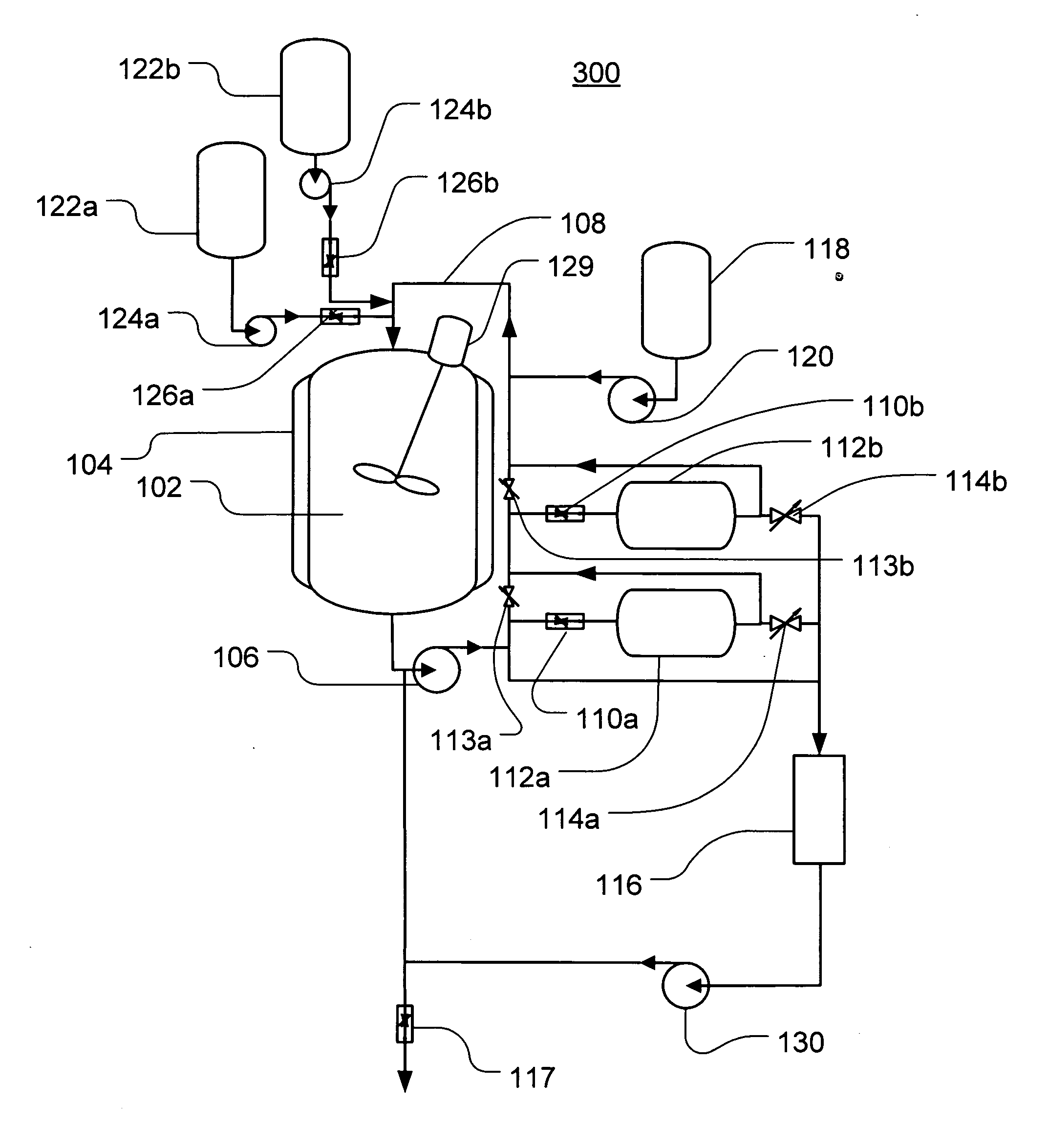

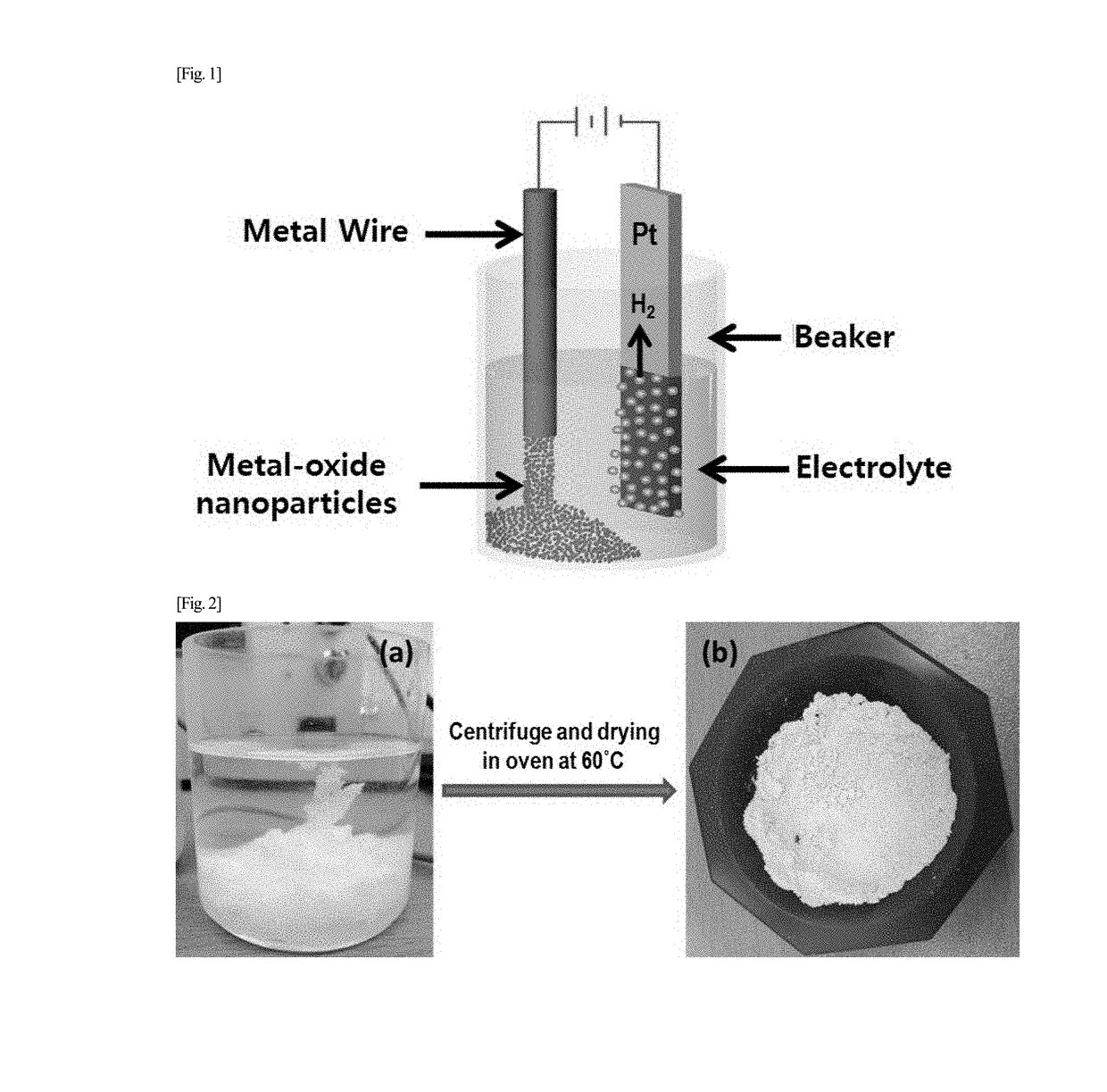

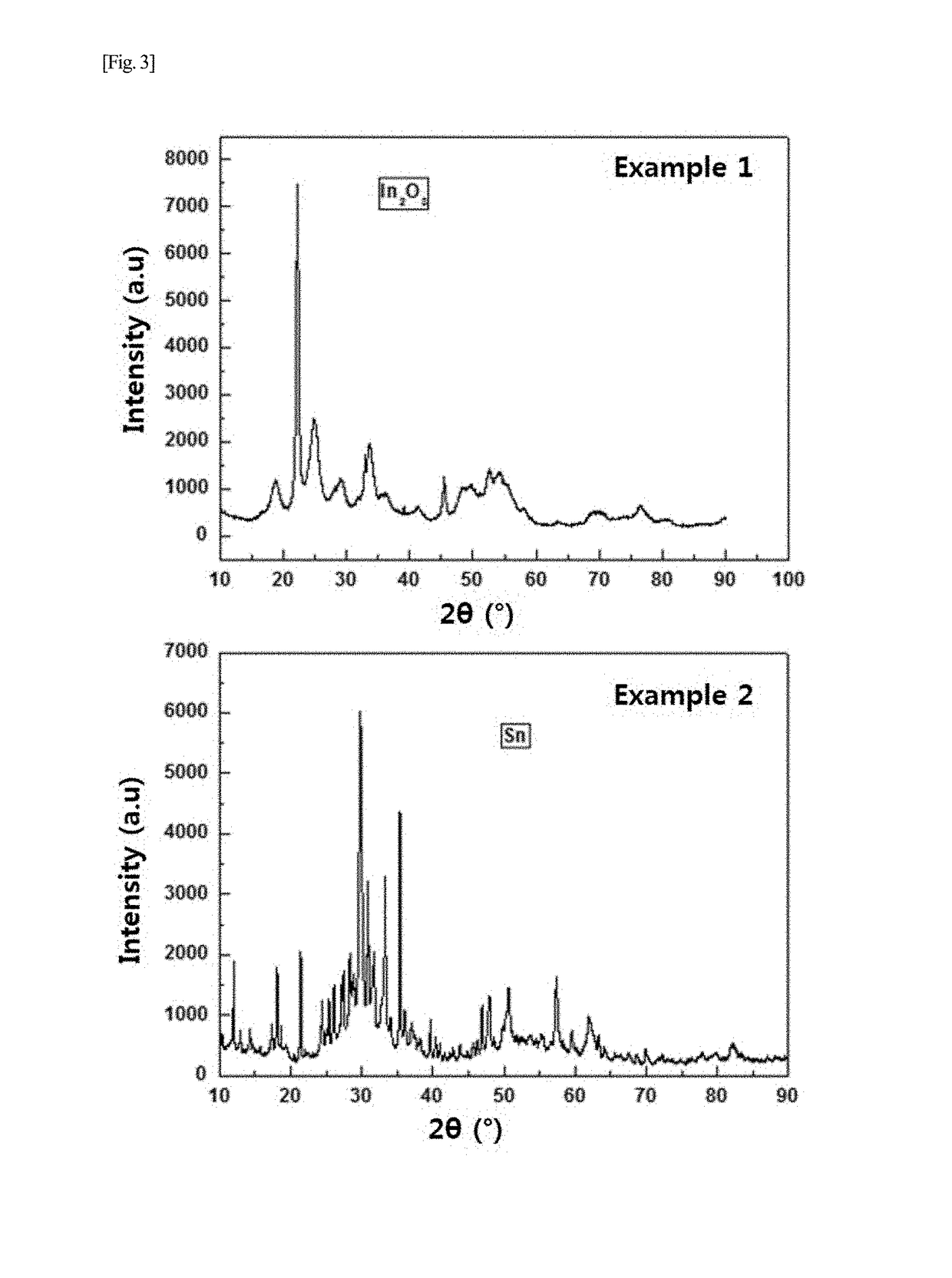

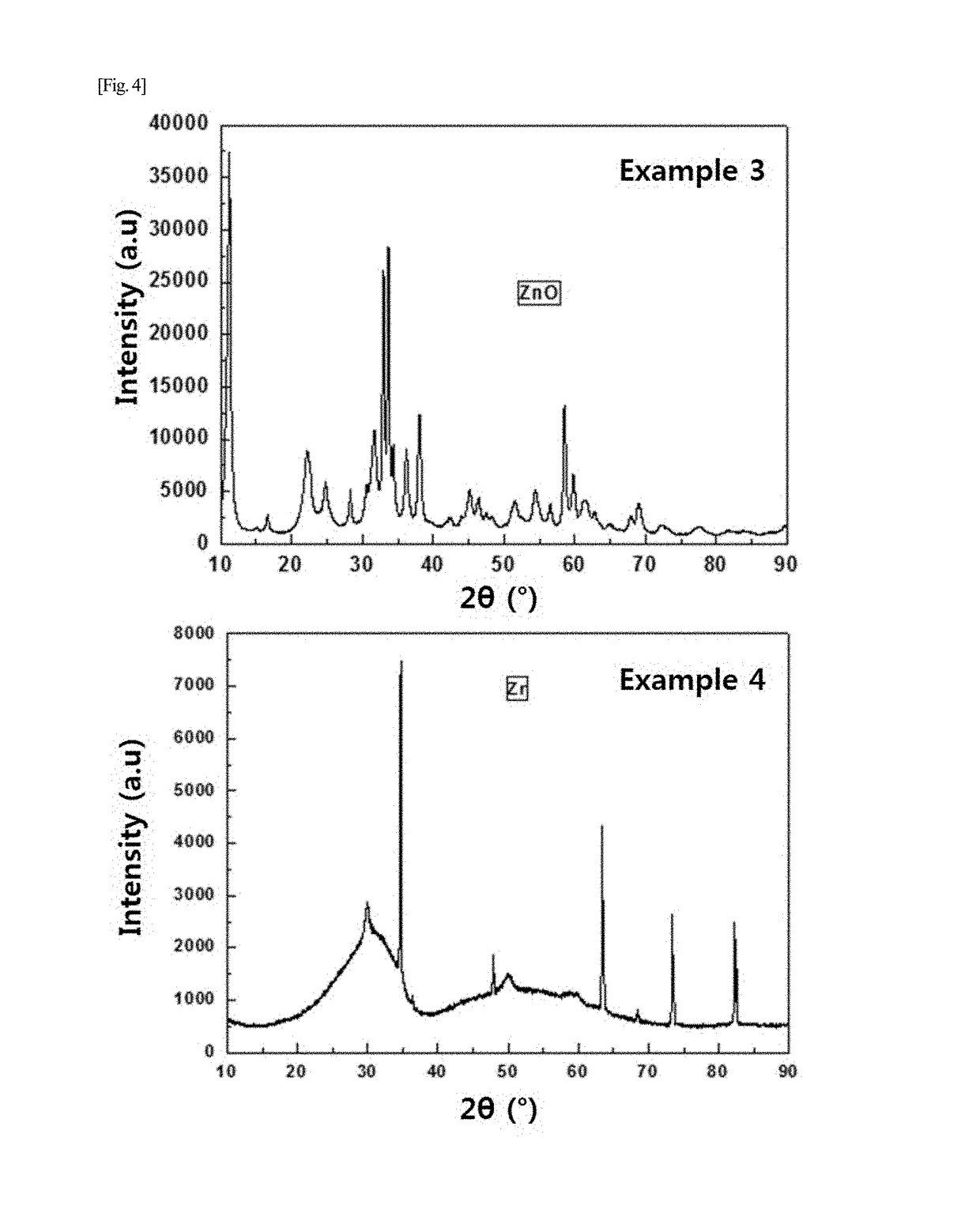

Method for manufacturing of metal oxide nanoparticles and metal oxide nanoparticles thereby

ActiveUS20150303449A1High crystallinityFast formingNanostructure manufactureCell electrodesMetal oxide nanoparticlesSingle process

The present invention relates to a method for preparing metal oxide nanoparticles and metal oxide nanoparticles prepared thereby, and more particularly, to an method for preparing metal oxide nanoparticles, the method including: dipping a cathode and an anode formed of a metal for forming oxide, in an inorganic electrolyte solution containing halogen salt (step 1); and applying voltage to the anode and the cathode to form, on the anode, metal oxide forming an anode surface (step 2). According to a method for preparing metal oxide nanoparticles of the present invention, disadvantages of typical nanoparticle synthesizing methods may be solved to cheaply and rapidly manufacture nanoparticles having various structures through a simple and single process without using a surfactant. Since an anodizing method requires only a power supply device having a low voltage of 30 V or less and an electrolyte, and is performed at room temperature, the anodizing method does not require an additional device or installation. Also, from just after the power supply device is turned on, metal oxide nanoparticles may be rapidly formed, nanoparticles having excellent crystallinity may be produced, and factors of the anodizing method, such as voltage, temperature, an electrolyte, and an electrolyte concentration may be changed to simply adjust a shape of the nanoparticles. Therefore, the present technology is expected to improve economical efficiency of the metal oxide nanoparticles to also contribute to the mass production of the metal oxide nanoparticles.

Owner:KOREA ADVANCED INST OF SCI & TECH

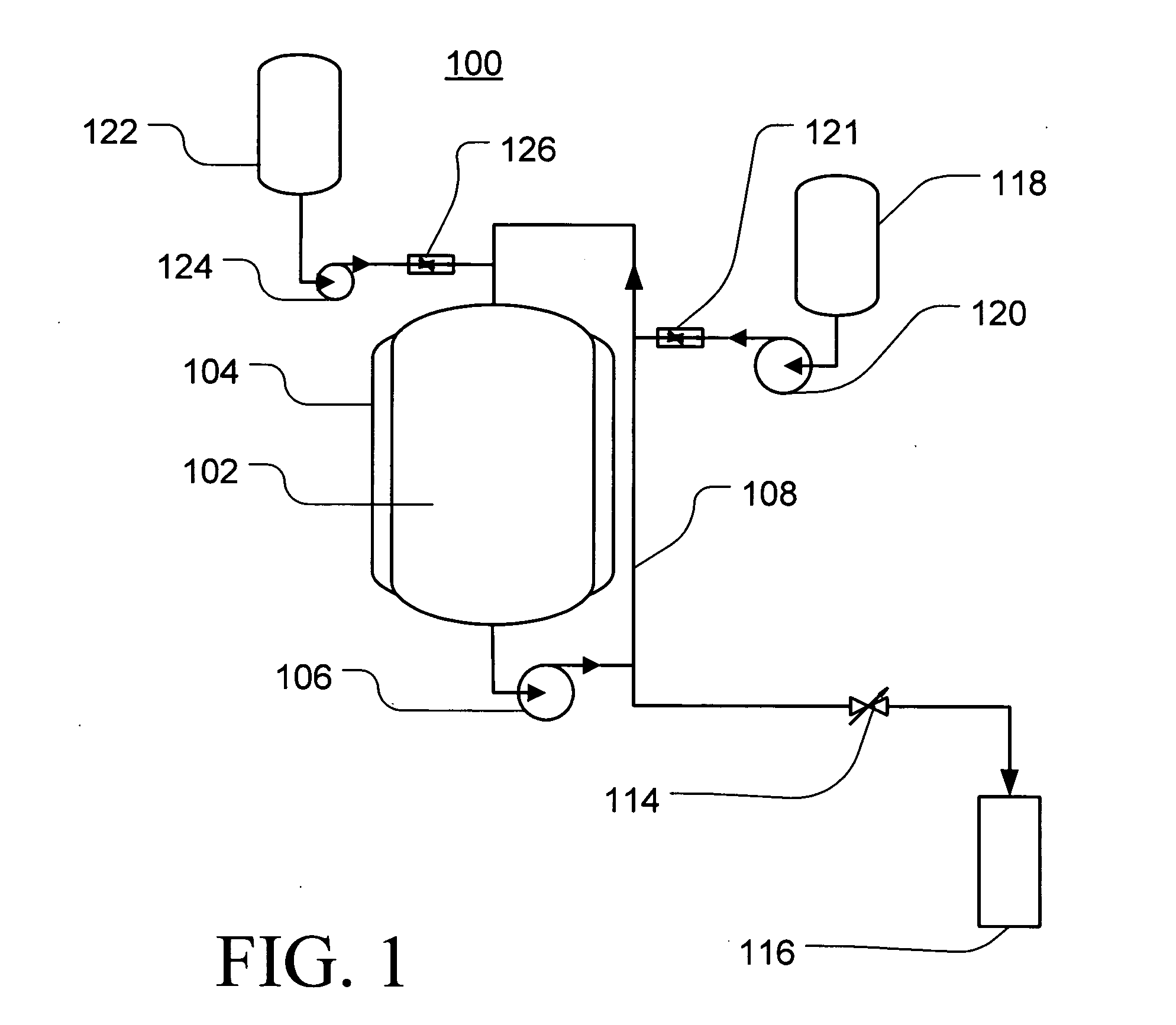

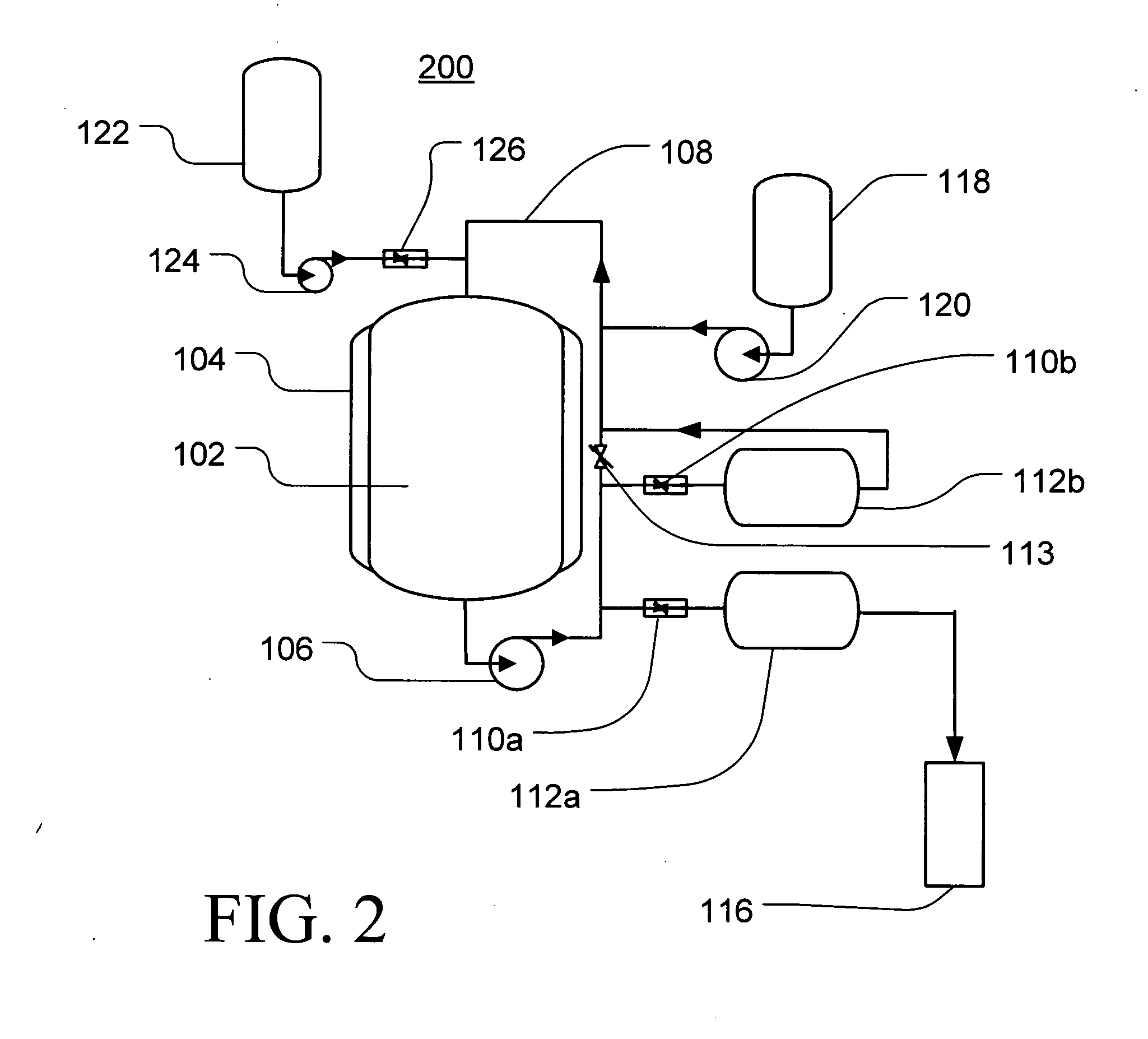

Method of manufacturing nanoparticles

ActiveUS20070151418A1Less-expensive to practiceImprove securityMaterial nanotechnologyTransportation and packagingModal particleReaction temperature

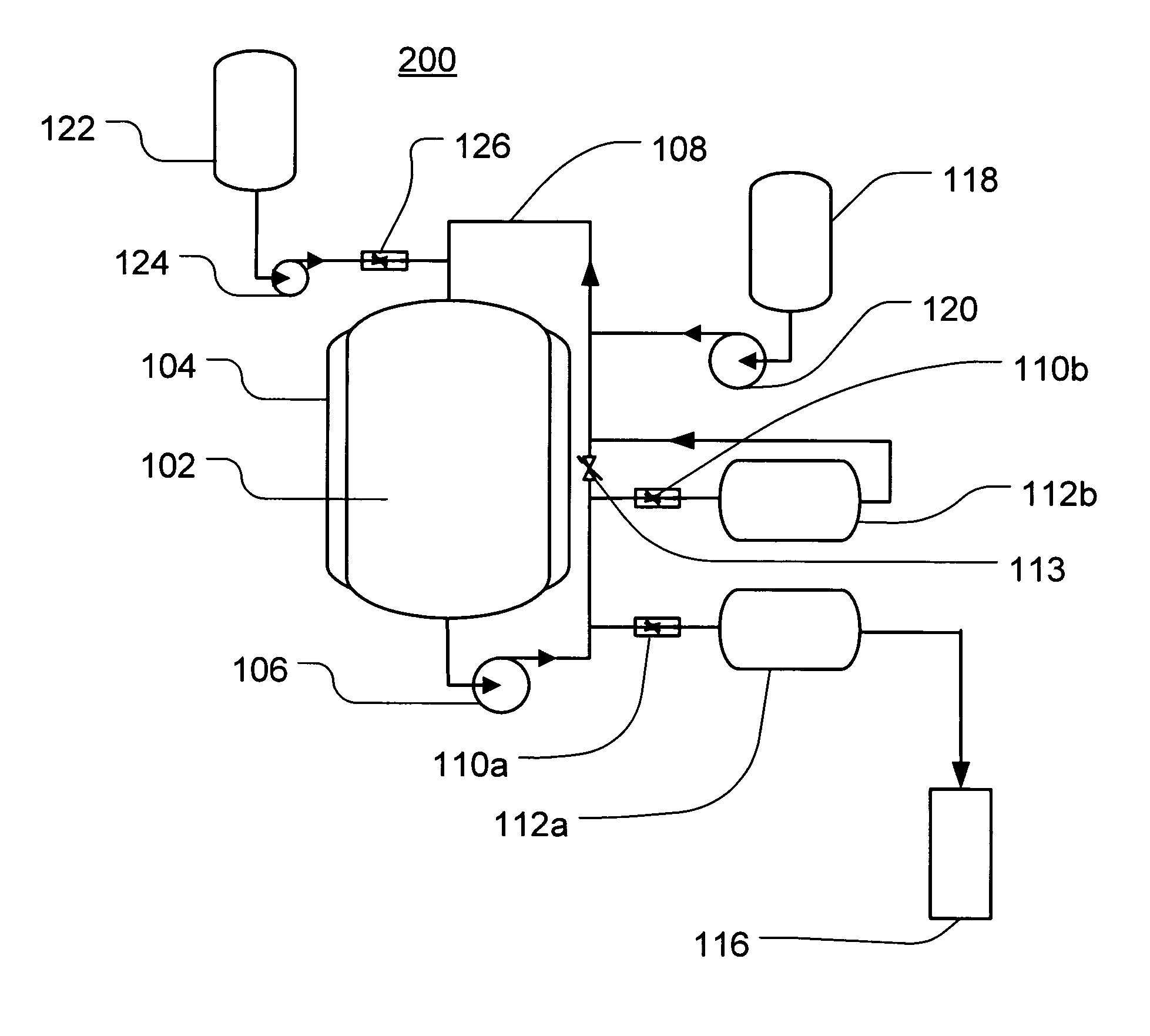

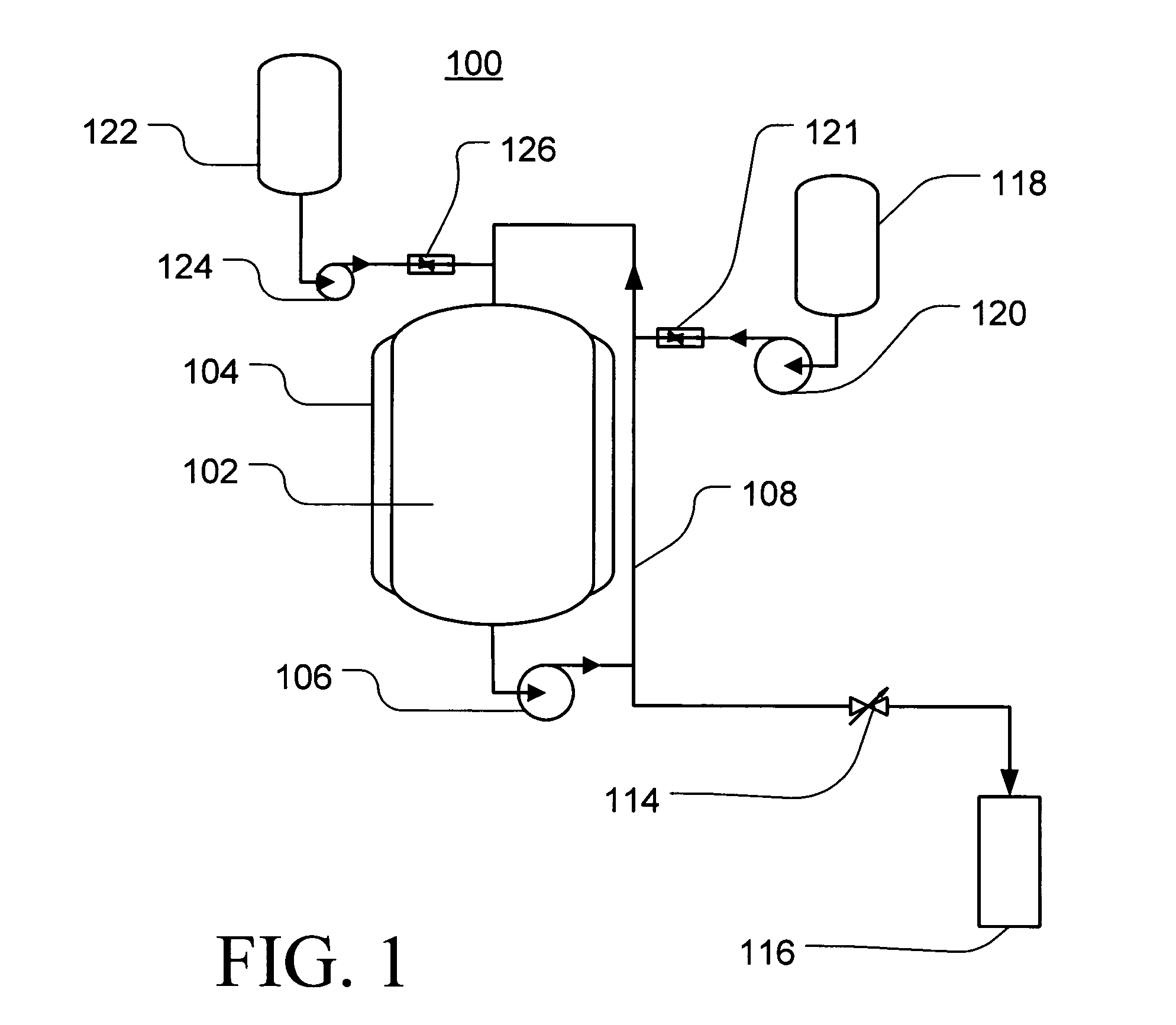

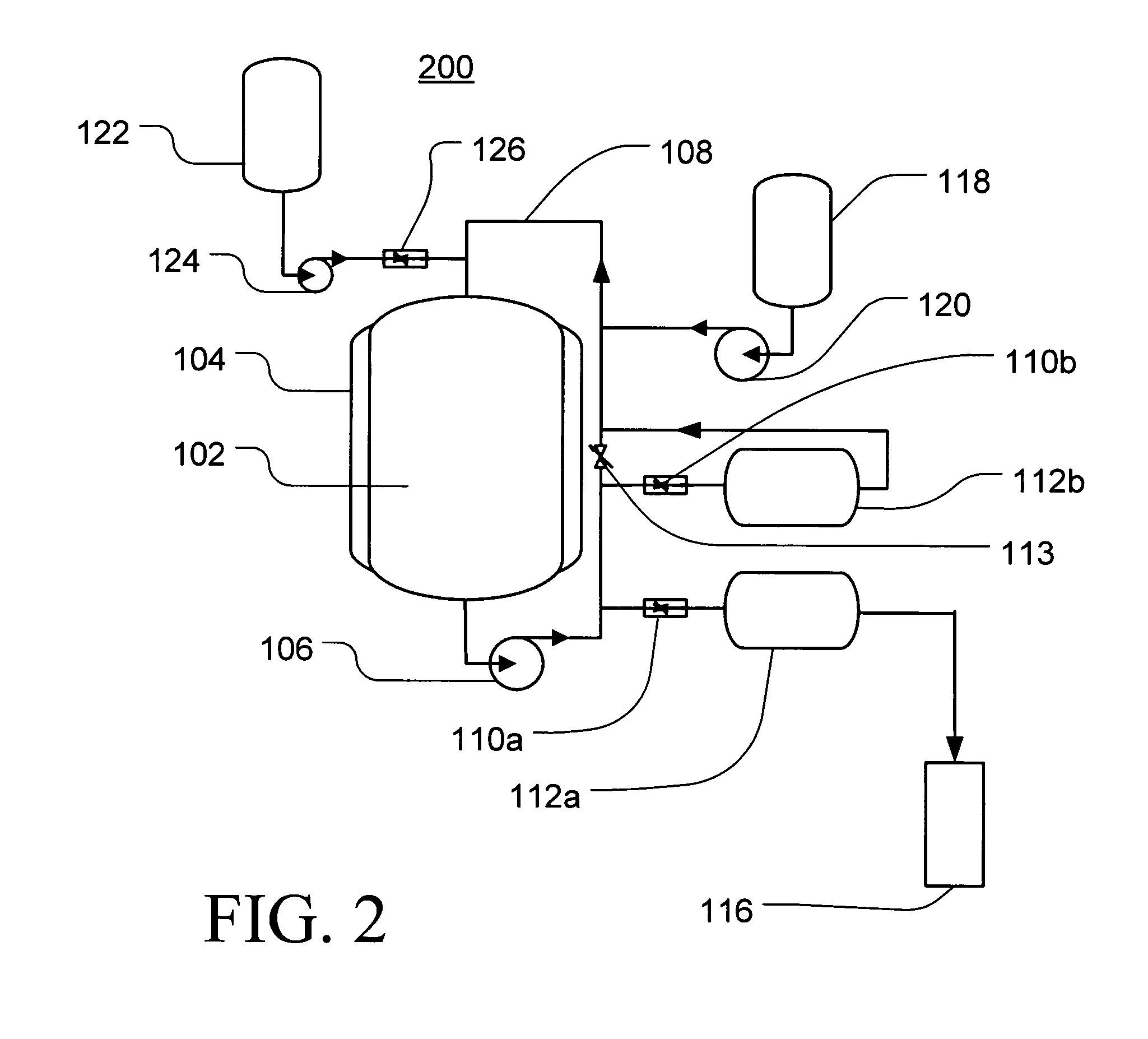

Provided are methods and systems for generating nanoparticles from an inorganic precursor compound using a hydrothermal process within at least one CSTR or PFR maintained at an elevated temperature and an elevated pressure and a treatment vessel in which this reaction solution can be applied to one or more catalyst substrates. In operation, the reaction solution may be maintained within the CSTR at a substantially constant concentration and within a reaction temperature range for a reaction period sufficient to obtain nanoparticles having a desired average particle size of, for example, less than 10 nm formation and / or deposition. Variations of the basic method and system can provide, for example, the generation of complex particle size distribution profiles, the selective deposition of a multi-modal particle size distribution on a single substrate.

Owner:GENERAL ELECTRIC CO

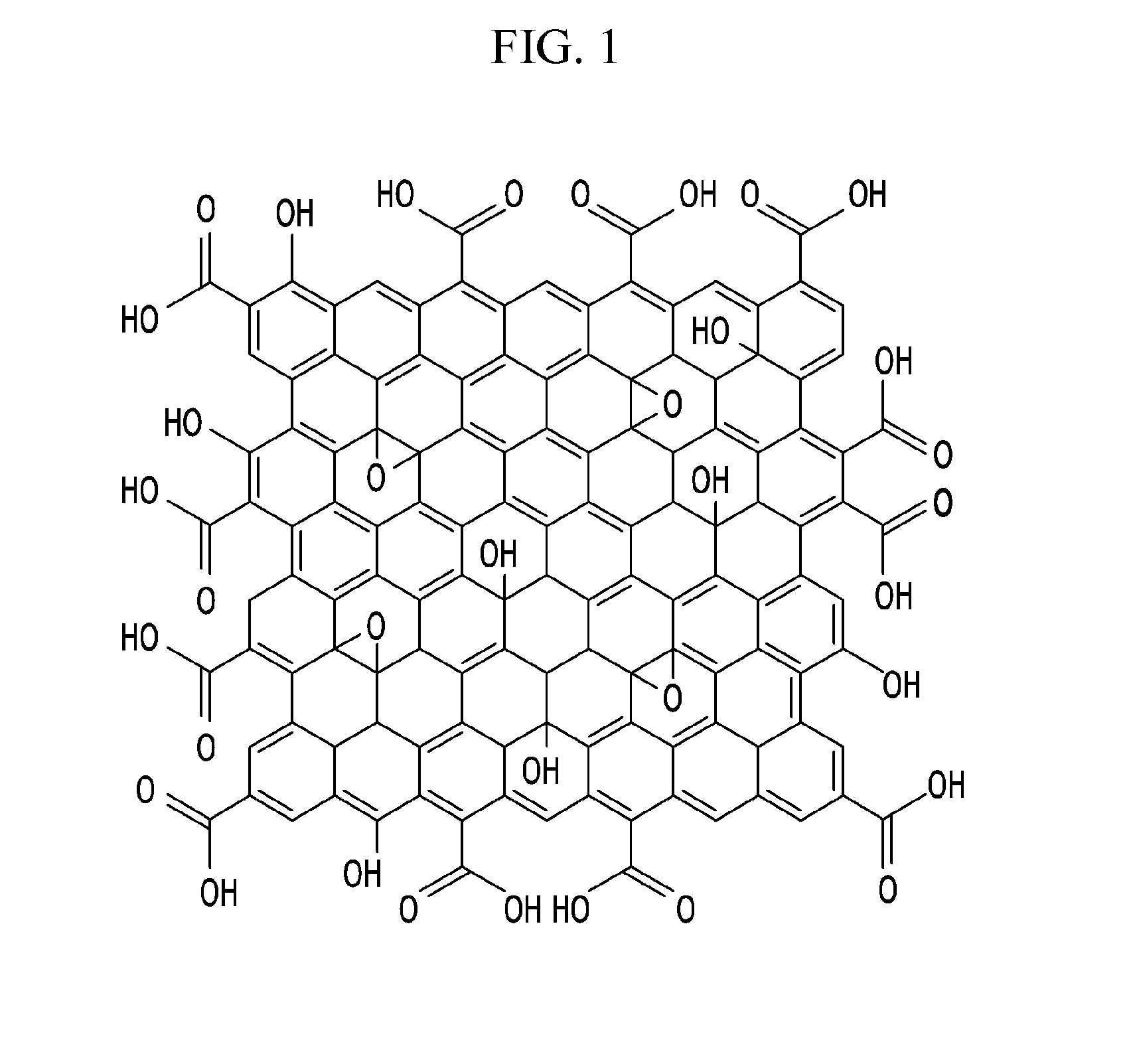

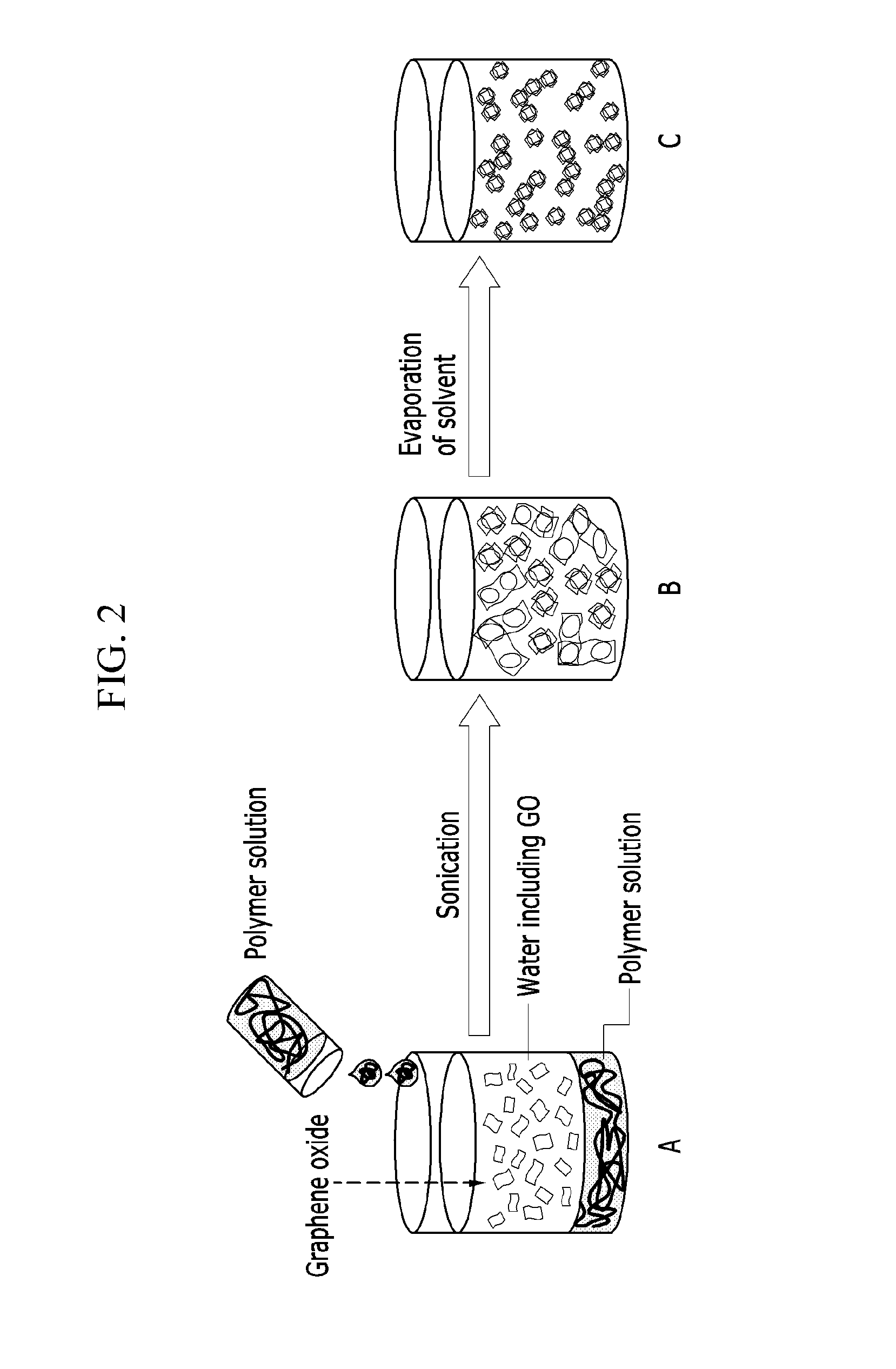

Nanoparticles, method of manufacturing nanoparticles, and electronics device including the same

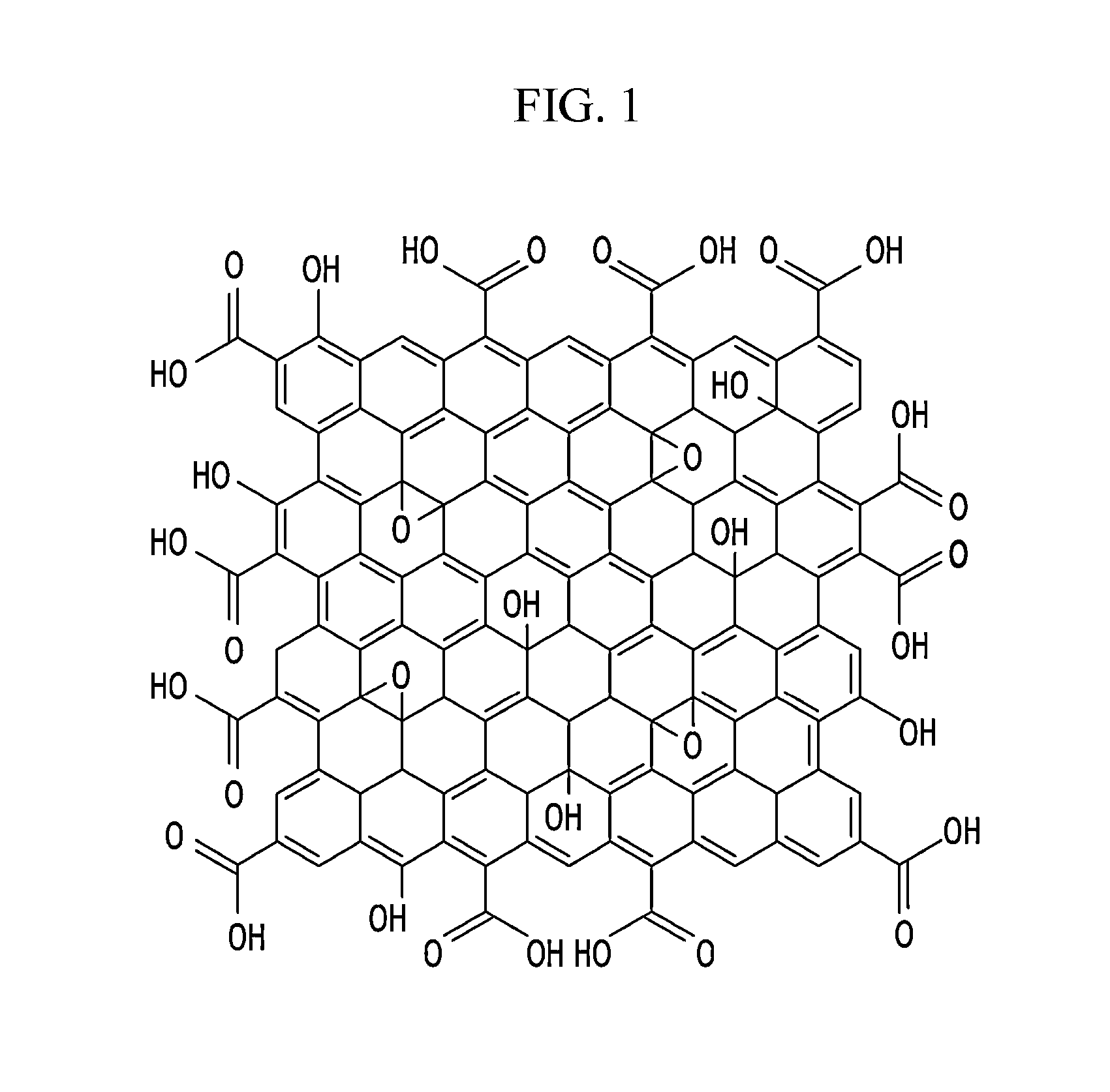

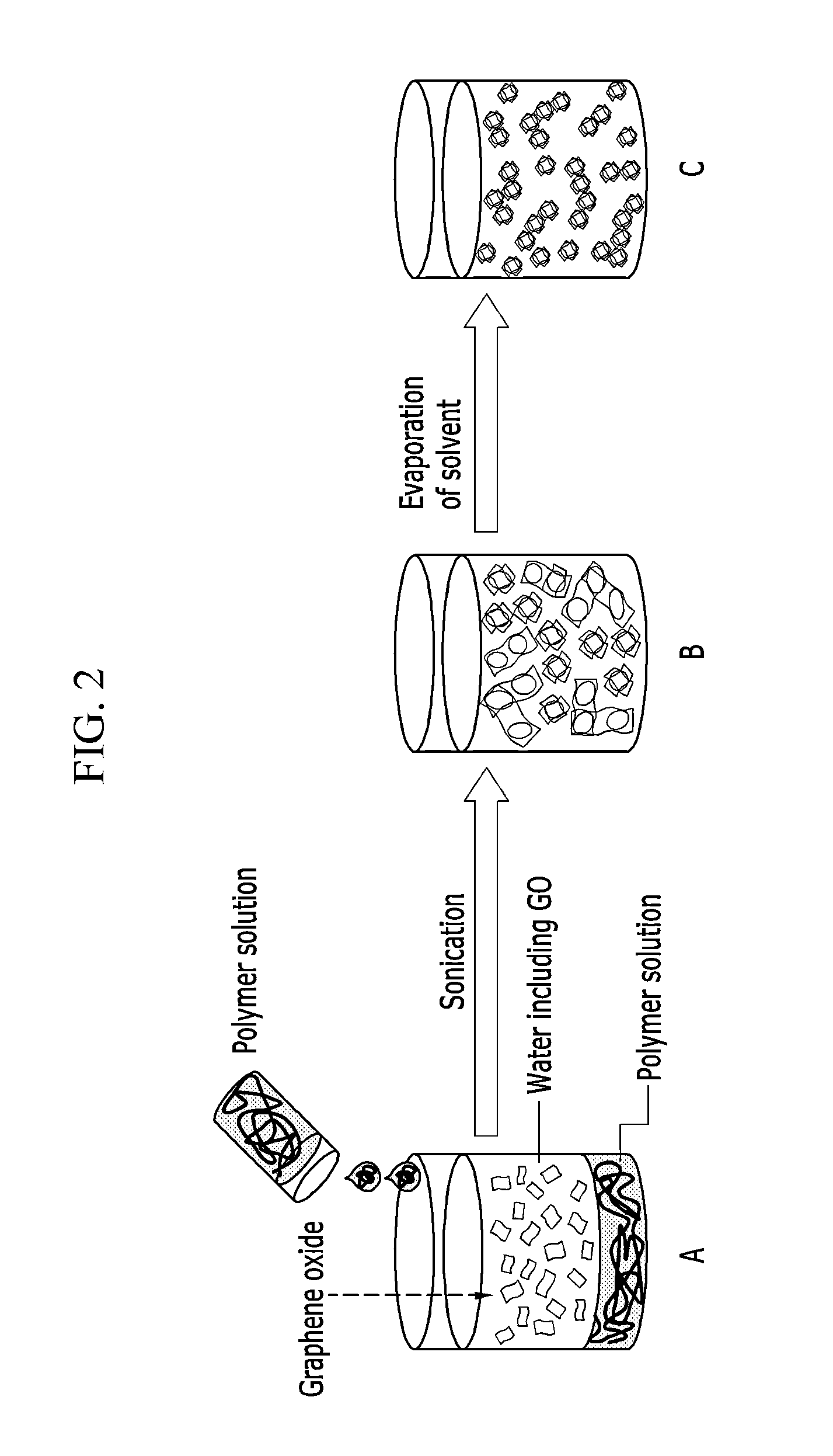

ActiveUS9331283B2Good optical performanceExcellent optical property and electrical propertySpecific nanostructure formationMaterial nanotechnologyOrganic solventGraphene

The method of manufacturing nanoparticles of a target material includes mixing graphene oxide with an aqueous solvent to prepare an aqueous solution, mixing the target material with an organic solvent to prepare an organic solution, mixing the aqueous solution with the organic solution, and preparing nanoparticles of the target material by the graphene oxide.

Owner:KOREA INST OF SCI & TECH

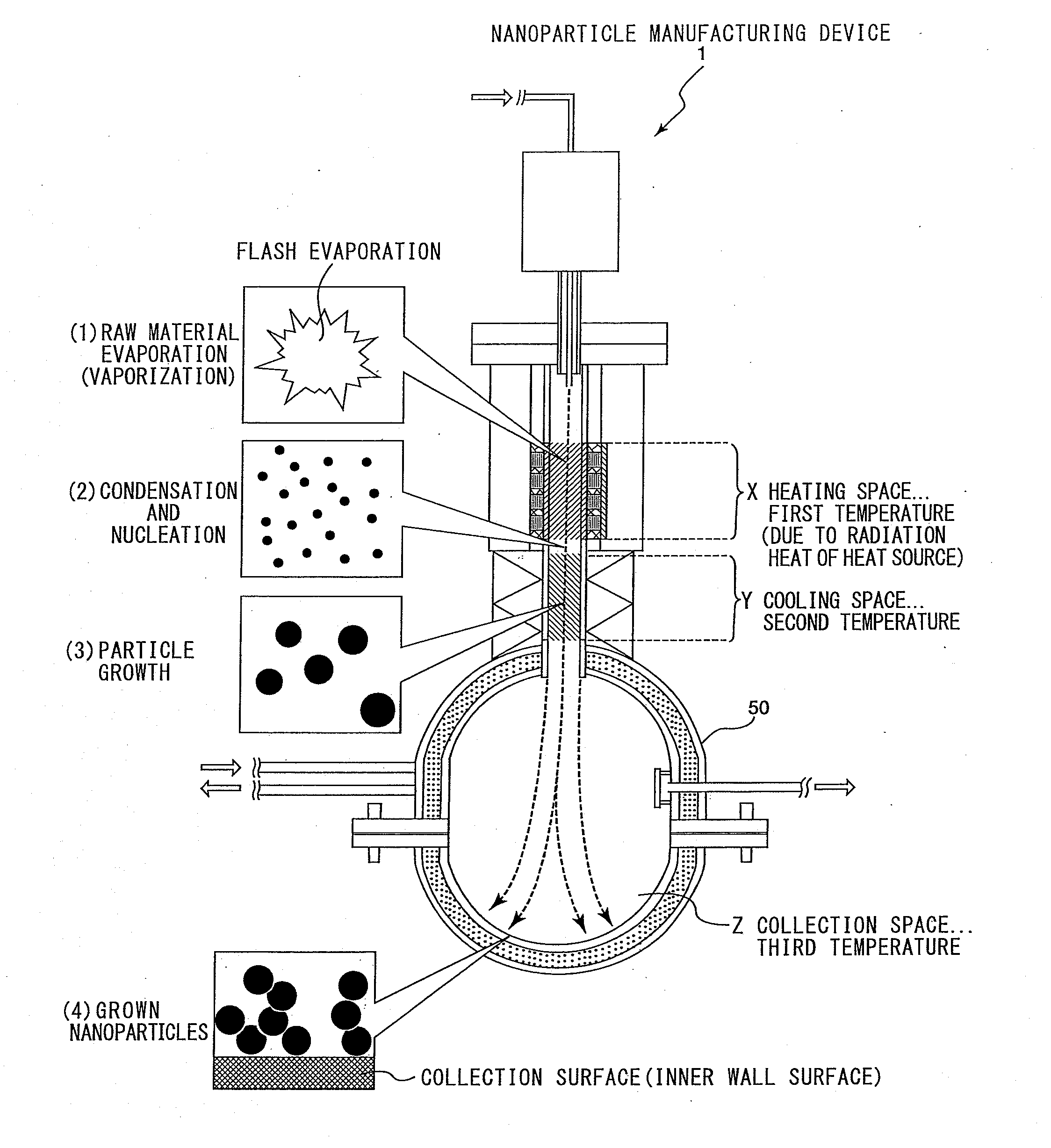

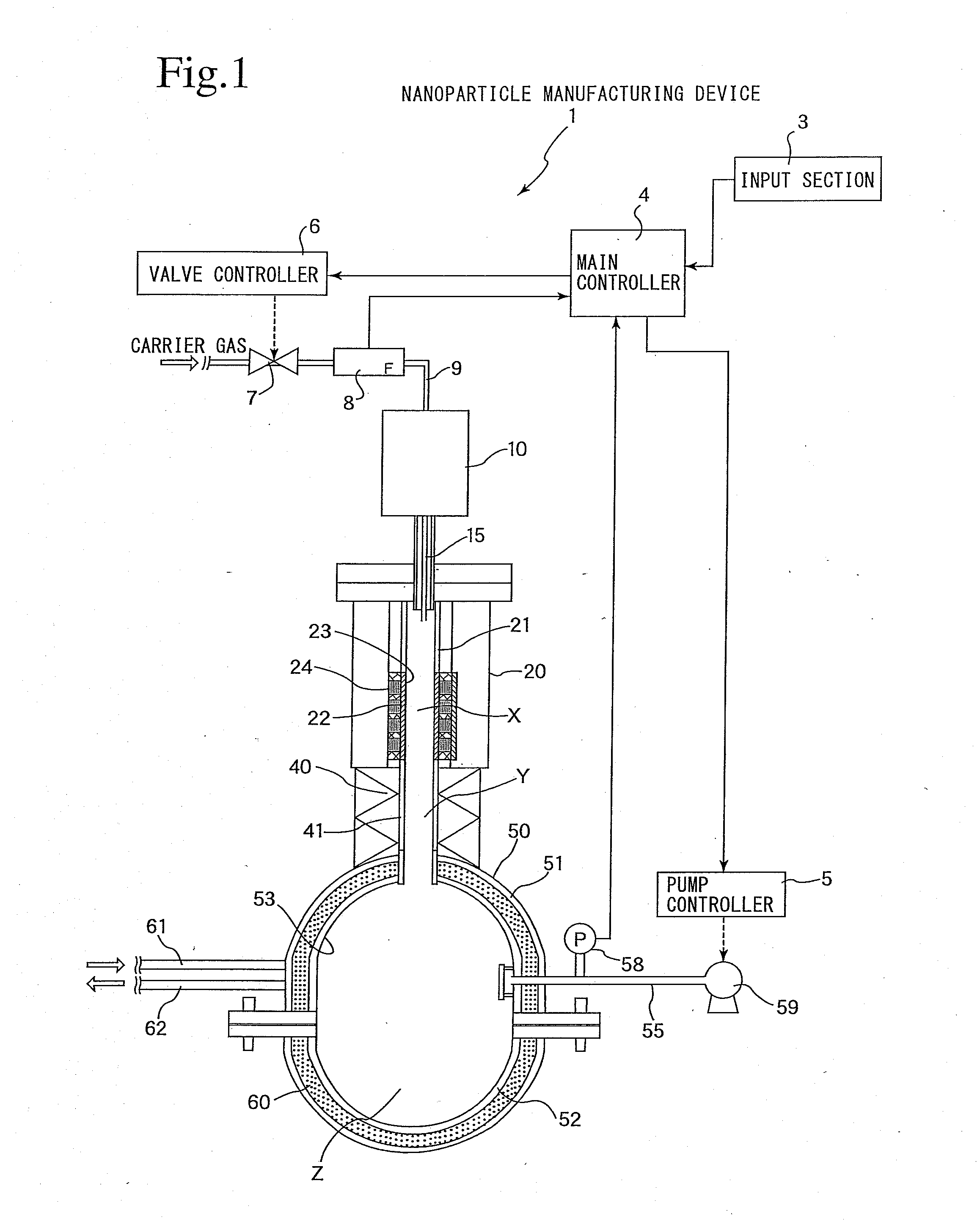

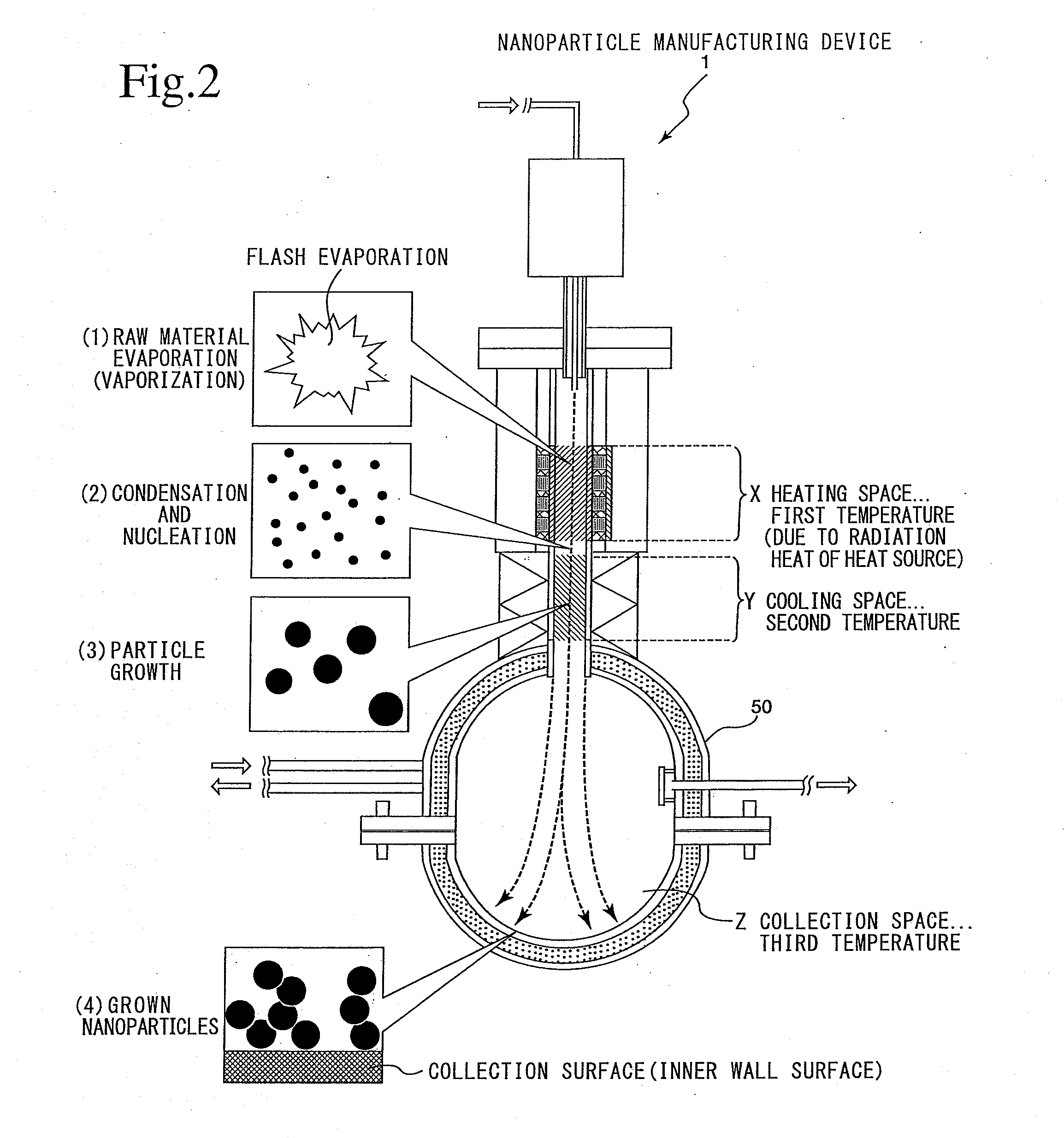

Nanoparticle manufacturing device and nanoparticle manufacturing method and method of manufacturing nanoparticle-dispersed liquid alkali metal

InactiveUS20110209578A1Good dispersionMaterial nanotechnologyTransportation and packagingNanoparticles dispersionContinuous flow

A nanoparticle manufacturing device capable of particle size control of nanoparticles made of a raw material metal powder and control of the occurrence condition of chaining of nanoparticles and of necking. The device 1 is provided for manufacturing nanoparticles by heating and melting a mixture of a raw material metal powder and a carrier gas in a heating space, cooling the mixture in a cooling space and collecting the mixture in a collection space. The heating space, the cooling space and the collection space form a continuous flow path without a back flow, and the cross-sectional area of the collection space is set at a large value compared to the cross-sectional area of the heating space and the cooling space. Further, there is provided a method of manufacturing a nanoparticle-dispersed liquid alkali metal by dispersing nanoparticles in a liquid alkali metal. A liquid alkali metal obtained by dispersing nanoparticles in the liquid alkali metal is manufactured by performing a rough dispersion step of stirring nanoparticles in the liquid alkali metal by a physical effect and a dispersion step of dispersing nanoparticles in the liquid alkali metal by irradiating the liquid alkali metal with ultrasonic waves after the rough dispersion step.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP +1

Nanoparticles, method of manufacturing nanoparticles, and electronic device including the same

ActiveUS20140061546A1Excellent optical propertiesGood electrical propertiesMaterial nanotechnologySpecific nanostructure formationPrinting inkSolar cell

A method of manufacturing nanoparticles, nanoparticles, and an organic light emitting diode, a solar cell, a printing ink, a bioimaging device, and a sensor including the same are provided.The method of manufacturing nanoparticles of a target material includes mixing graphene oxide with an aqueous solvent to prepare an aqueous solution, mixing the target material with an organic solvent to prepare an organic solution, mixing the aqueous solution with the organic solution, and preparing nanoparticles of the target material by the graphene oxide.

Owner:KOREA INST OF SCI & TECH

Nanoparticles and methods of manufacturing the same

InactiveUS9385194B2Good electrical conductivity and stabilityLess securityMaterial nanotechnologyNanostructure manufactureSulfurHydrazine compound

Owner:SAMSUNG ELECTRONICS CO LTD

Zinc Comprising Nanoparticles And Related Nanotechnology

InactiveUS20120164561A1Increase volumeLow costMaterial nanotechnologyElectrode manufacturing processesOxidation stateZinc

Nanoparticles comprising zinc, methods of manufacturing nanoparticles comprising zinc, and applications of nanoparticles comprising zinc, such as electrically conducting formulations, reagents for fine chemical synthesis, pigments and catalysts are provided, and more particularly, a coating, comprising a nanomaterial composition comprising zinc and at least one metal other than zinc, wherein the at least one metal comprises an element that (a) has an oxidation state higher than an oxidation state of zinc and that (b) dopes zinc in the nanomaterial composition, and wherein the coating has an electrical conductivity greater than 0.0001 mhos·cm.

Owner:YADAV TAPESH

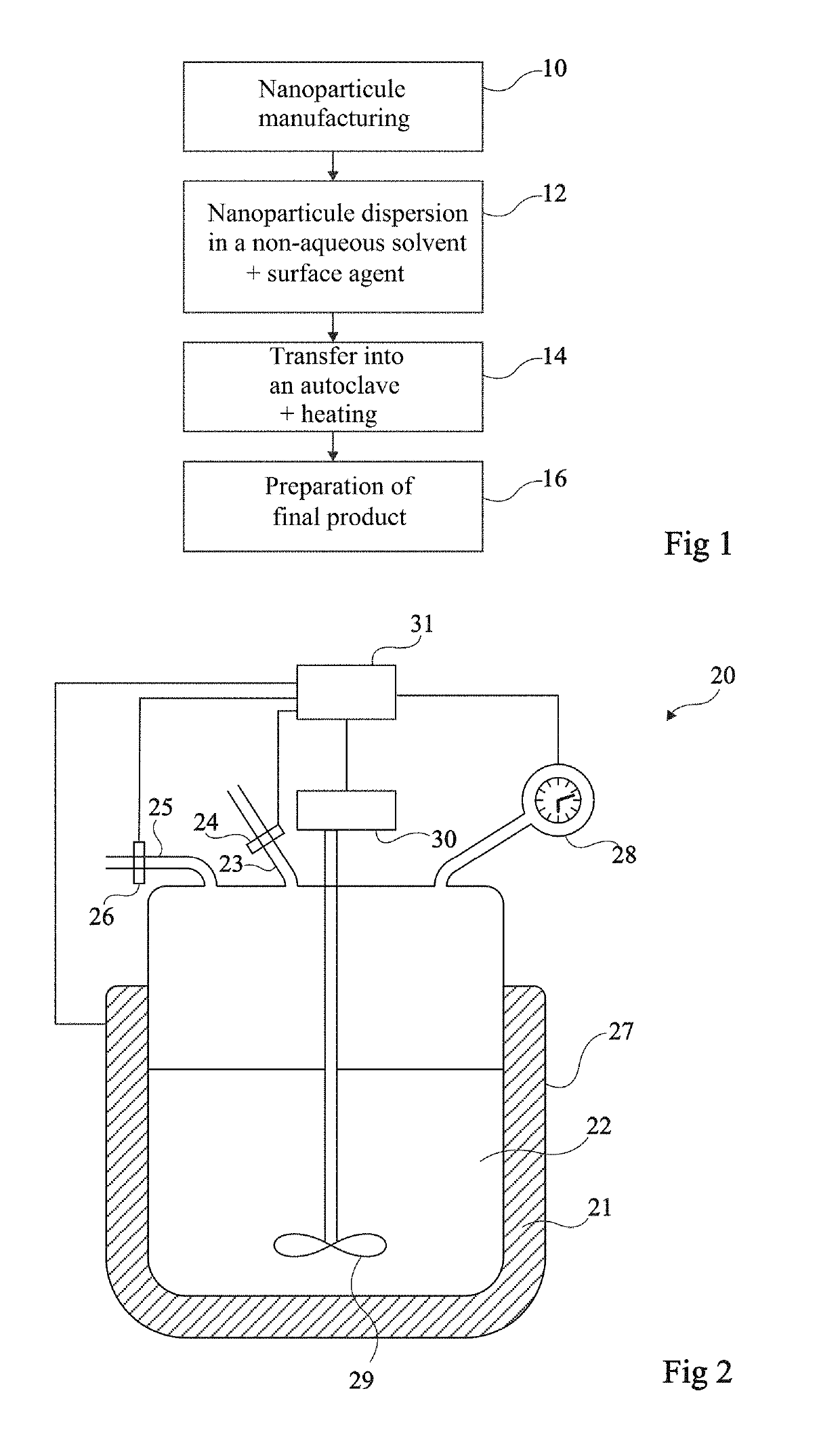

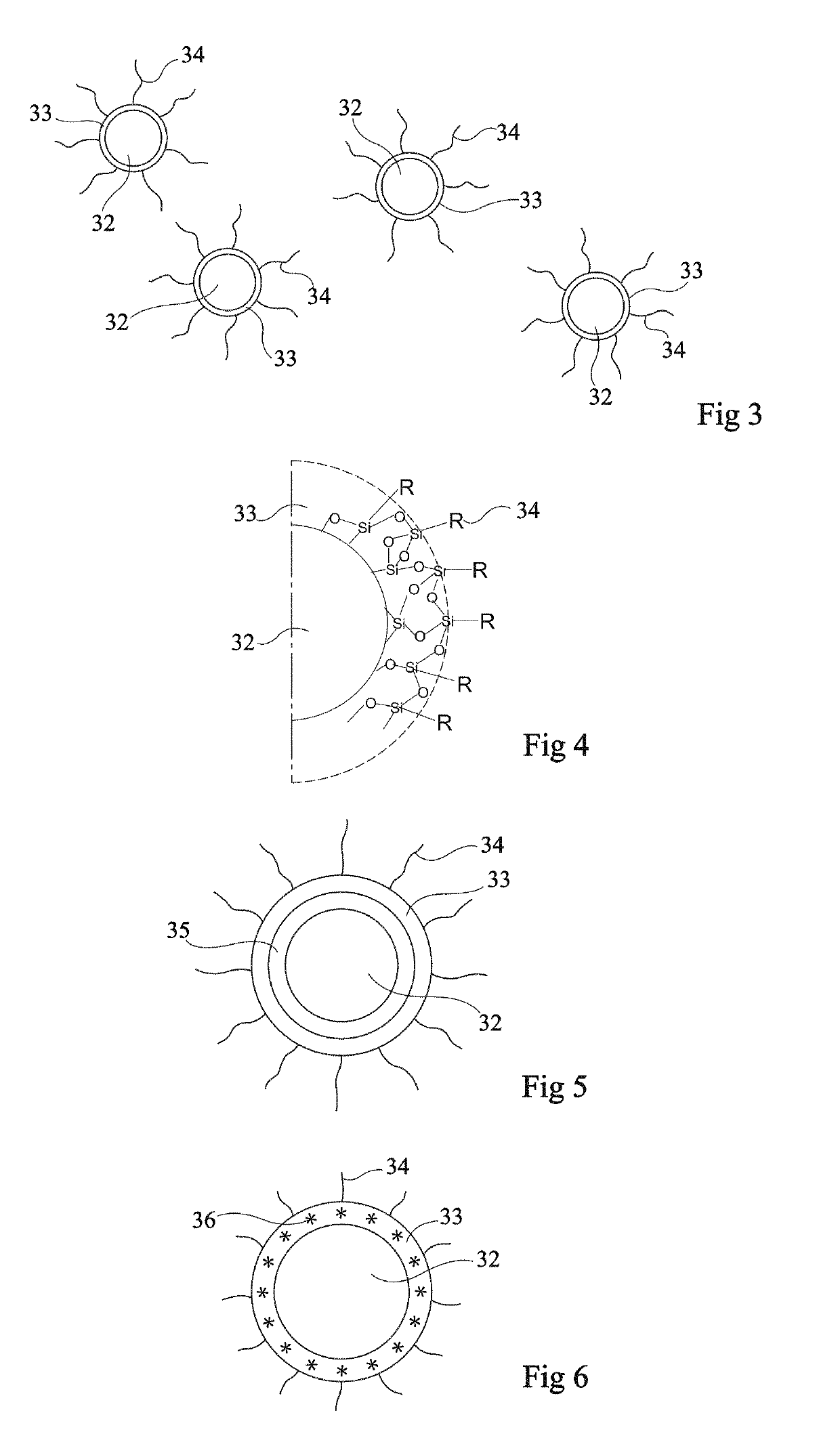

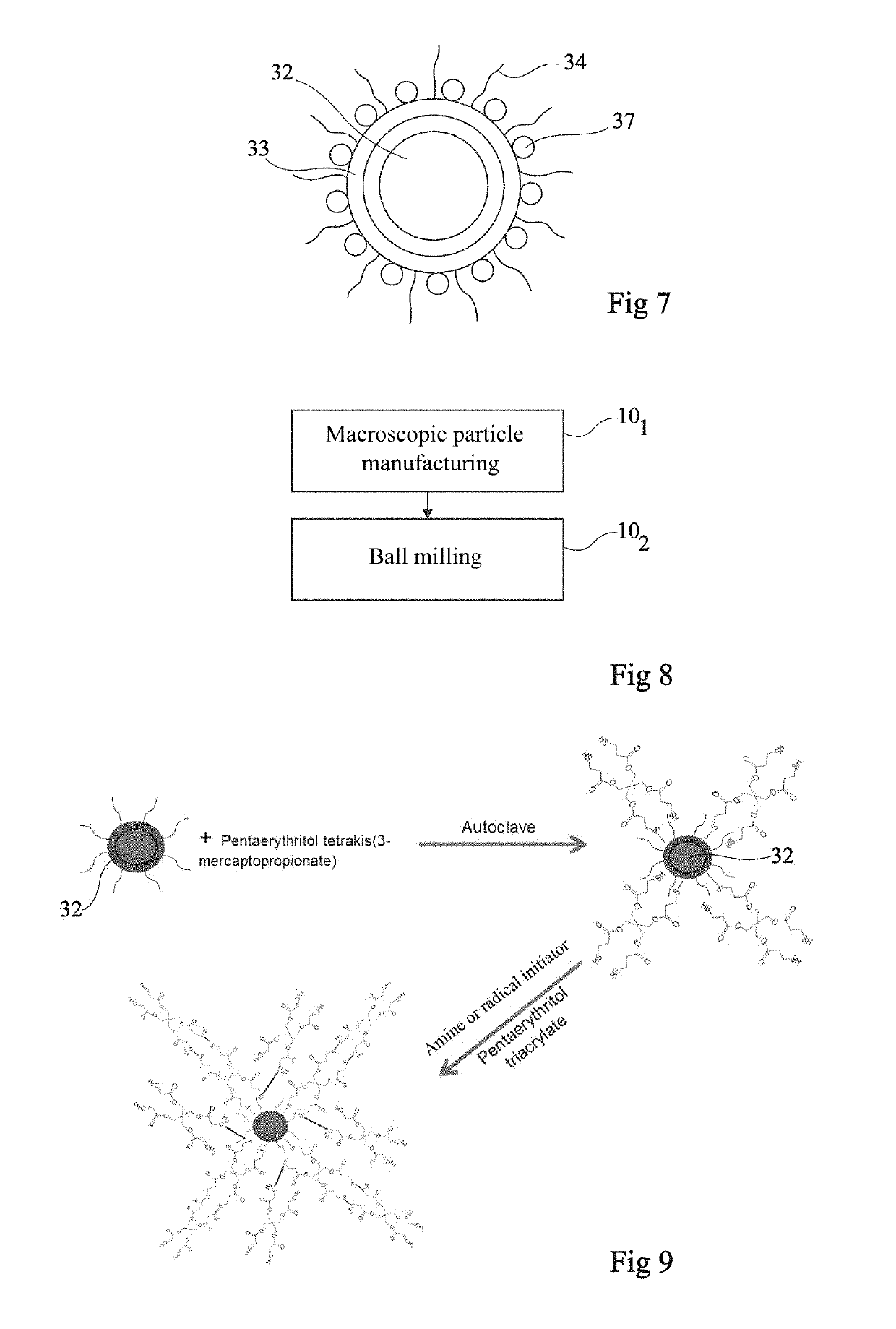

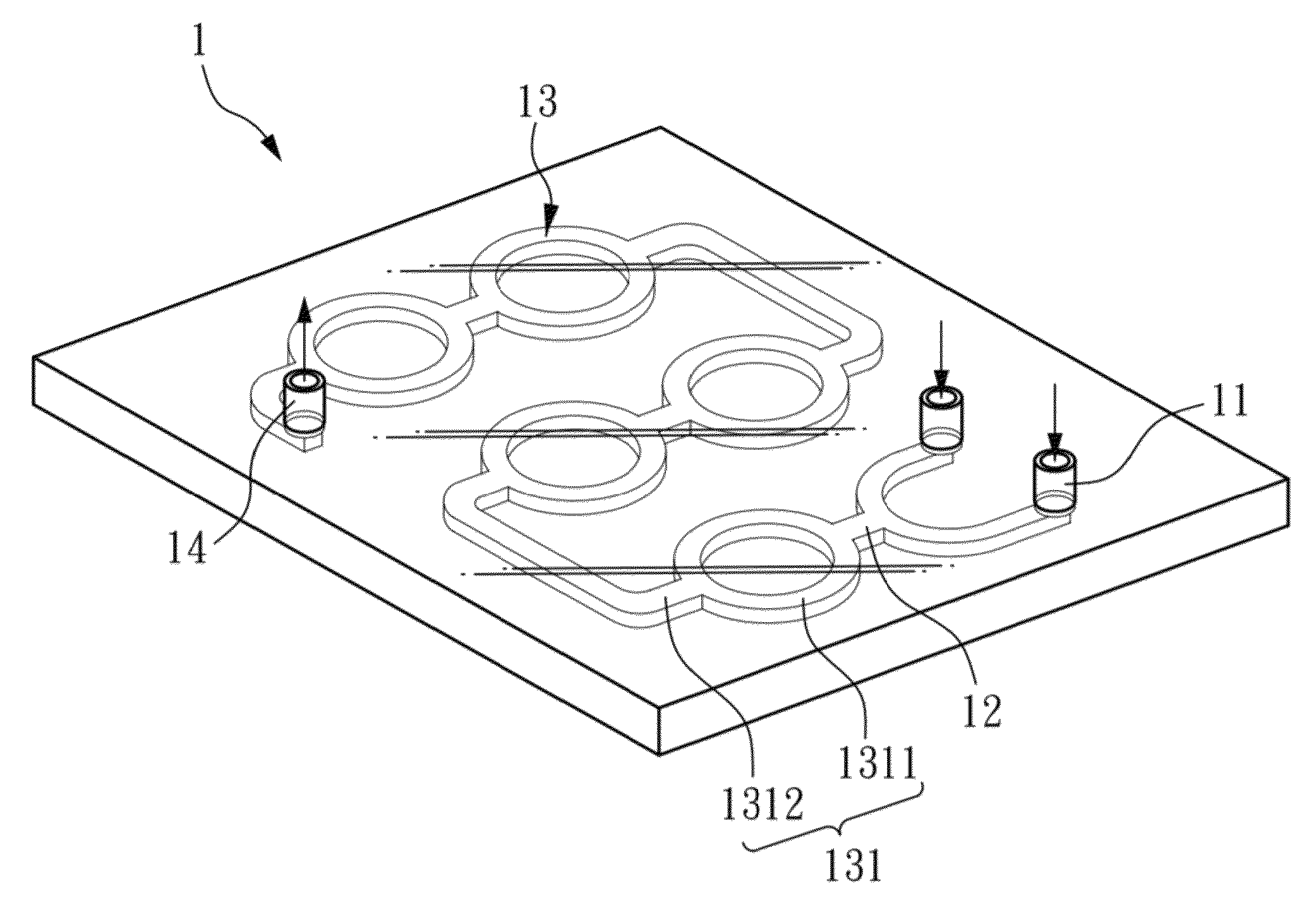

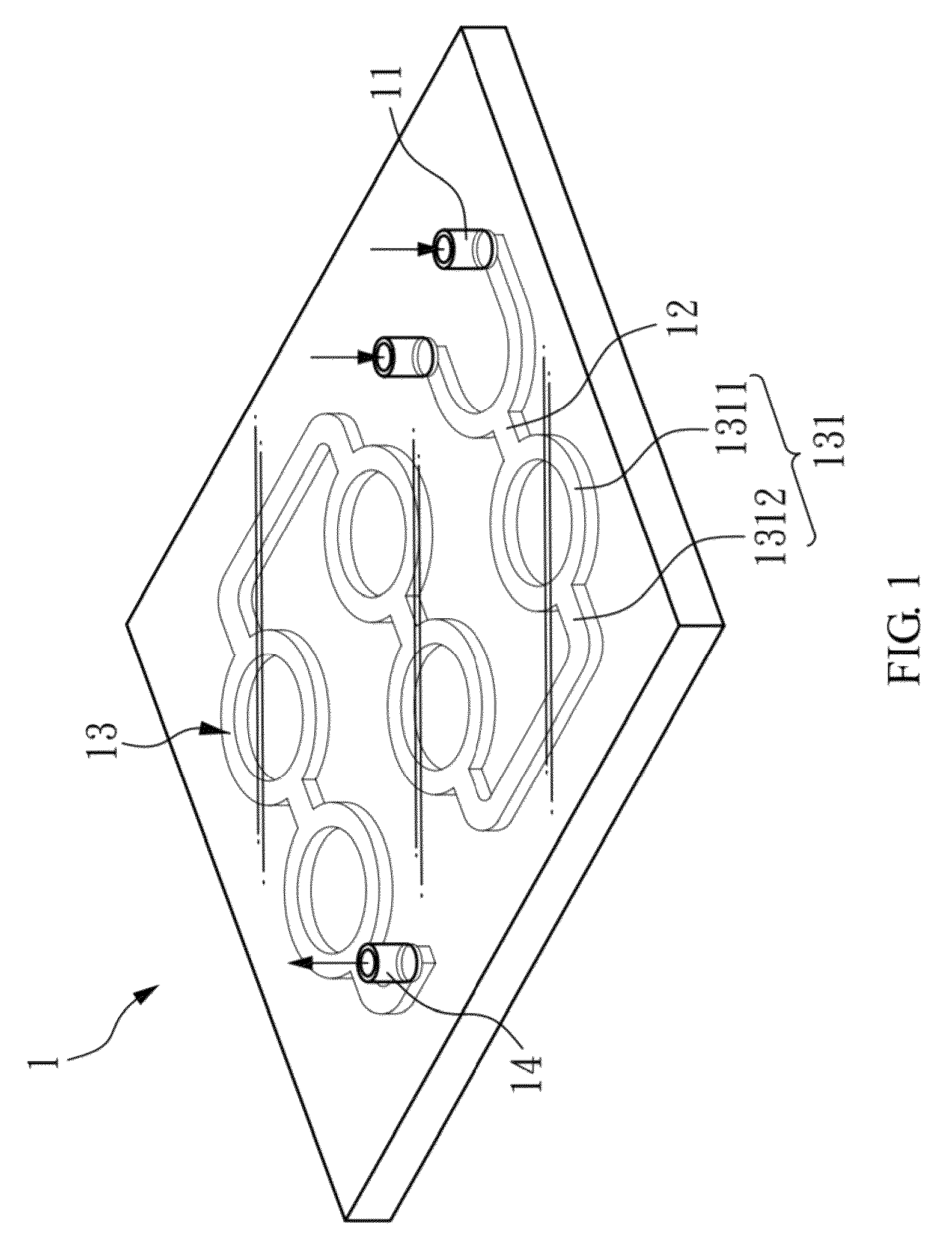

Method for producing photoluminescent particles

A method of manufacturing nanoparticles of a photoluminescent material, including the successive steps of: a) forming nanometer-range particles of said photoluminescent material; b) forming a dispersion containing the particles in a non-aqueous solvent, the dispersion further containing at least one surface agent; c) placing the dispersion in an autoclave at a pressure in the range from 2 MPa to 100 MPa; and d) recovering the particles.

Owner:ALEDIA +3

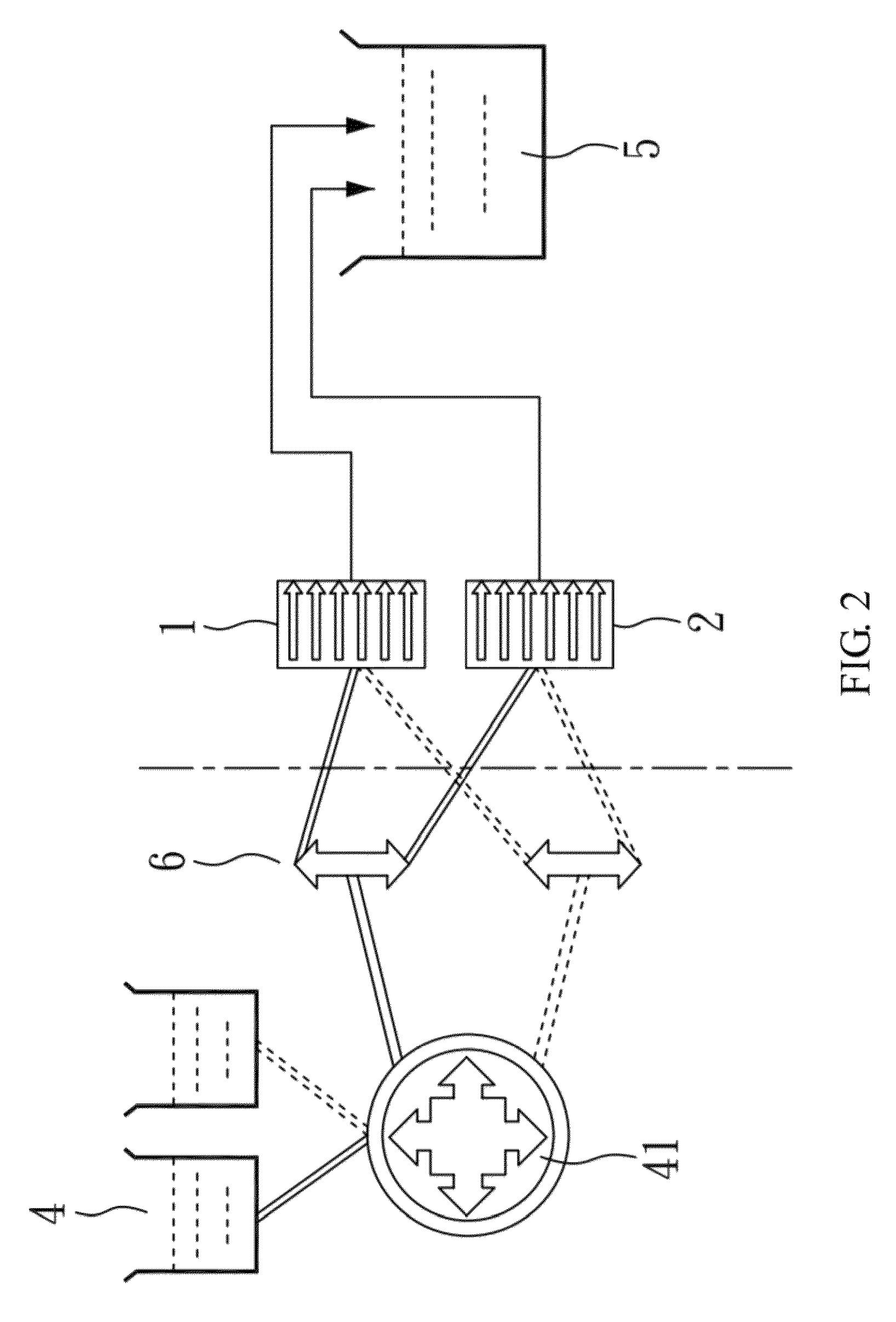

Continuous reactor and method for manufacturing nanoparticles

InactiveUS9050655B2High flow rate toleranceReduce riskMaterial nanotechnologyFrom normal temperature solutionsContinuous reactorEngineering

Owner:NATIONAL TSING HUA UNIVERSITY

Preparation method of nanoparticle reinforced resin lead core

The invention discloses a preparation method of a nanoparticle reinforced resin lead core. The method includes: dispersing graphite and a surfactant in water, conducting ultrasonic stirring, carrying out reaction for a period of time to obtain a surfactant intercalated and coated graphite; dispersing the surfactant modified graphite and a salt for preparation of corresponding nanoparticles in a solvent, conducting charge induction to enable in-situ growth of nanoparticles on the graphite surface, thus obtaining nanoparticle loaded graphite; and using nanoparticle modified graphite to replace pure graphite, performing compounding according to an existing core-making technology and preparing the nanoparticle reinforced high performance resin lead core. The manufactured nanoparticle modified resin fine lead core has excellent performance, and the quality of the nanoparticle reinforced resin lead core is proved to up to the international level A standard. The method can significantly improve the flexural strength, impact strength and writing comfort of the resin lead core without changing the existing processing technology, has the characteristics of simple operation, low cost, high product quality, low equipment investment and the like, and is suitable for large-scale industrial production.

Owner:蓬莱凯威文体制品有限公司

Method of manufacturing nanoparticle dispersion liquid

InactiveUS20130338304A1Small particle sizeMaterial nanotechnologyRare earth metal chloridesSolventViscosity

The present invention provides a method of producing a nanoparticle dispersion liquid, including: altering a surface of a nanoparticle in the presence of an ion by contacting a complex that includes the nanoparticle and a solid material present around the nanoparticle with a surface altering agent-containing liquid, that includes a surface altering agent for altering the surface of the nanoparticle and a solvent for dissolving the solid material and that has a viscosity of 1.10 mPa·s or more at 25° C.; and a dispersing step of dispersing the surface-altered nanoparticle in the solvent.

Owner:TOKYO UNIVERSITY OF SCIENCE

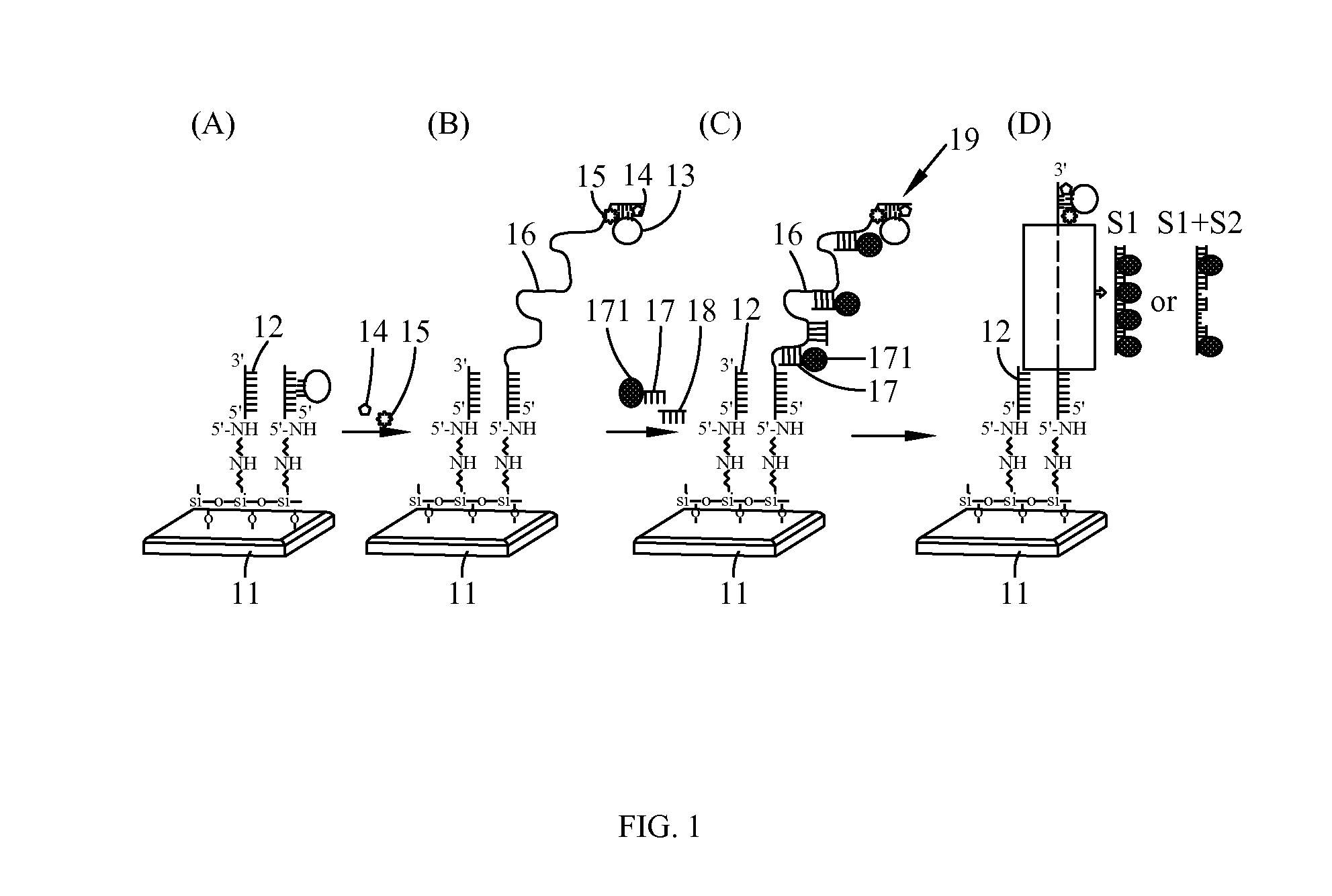

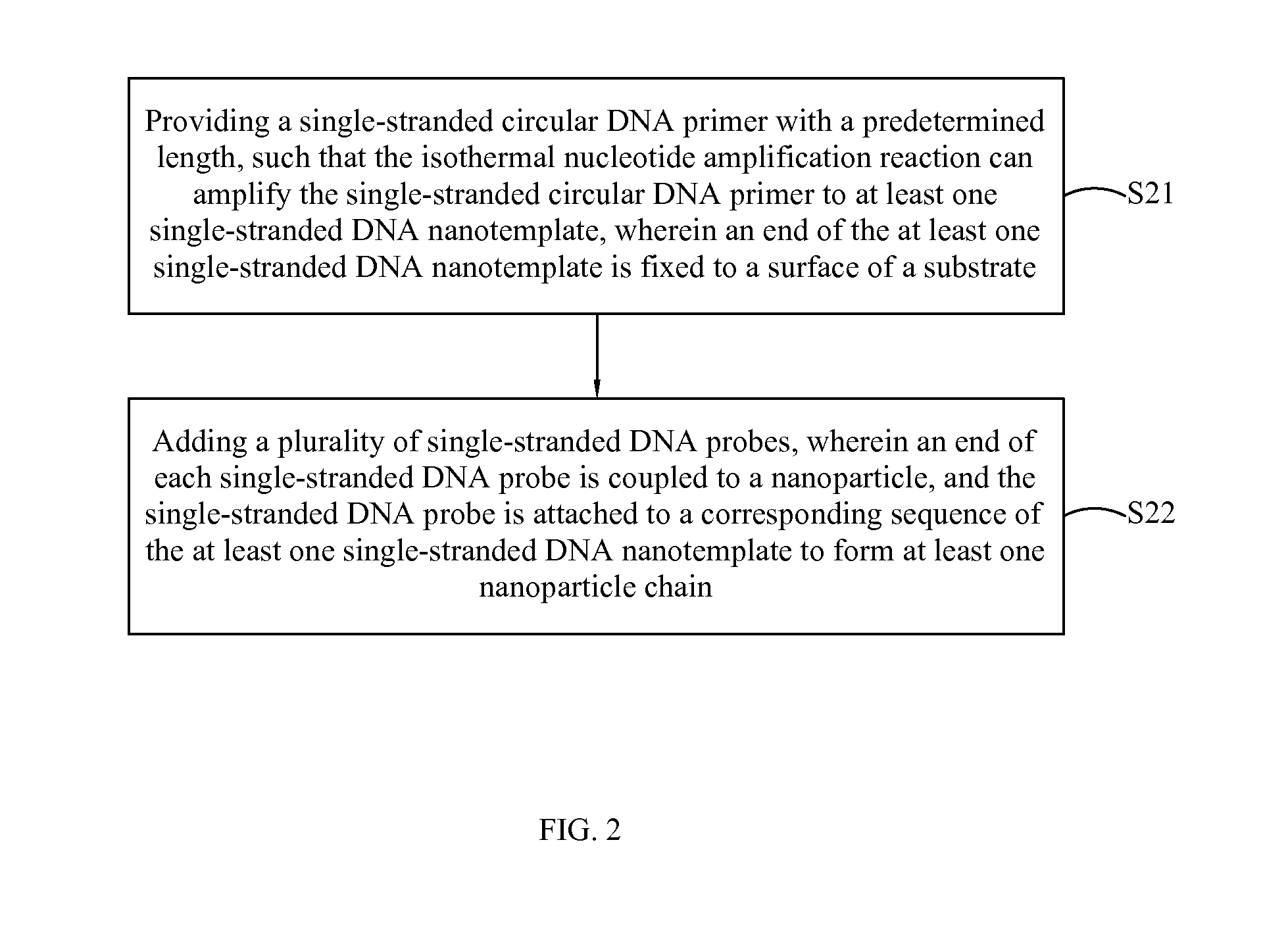

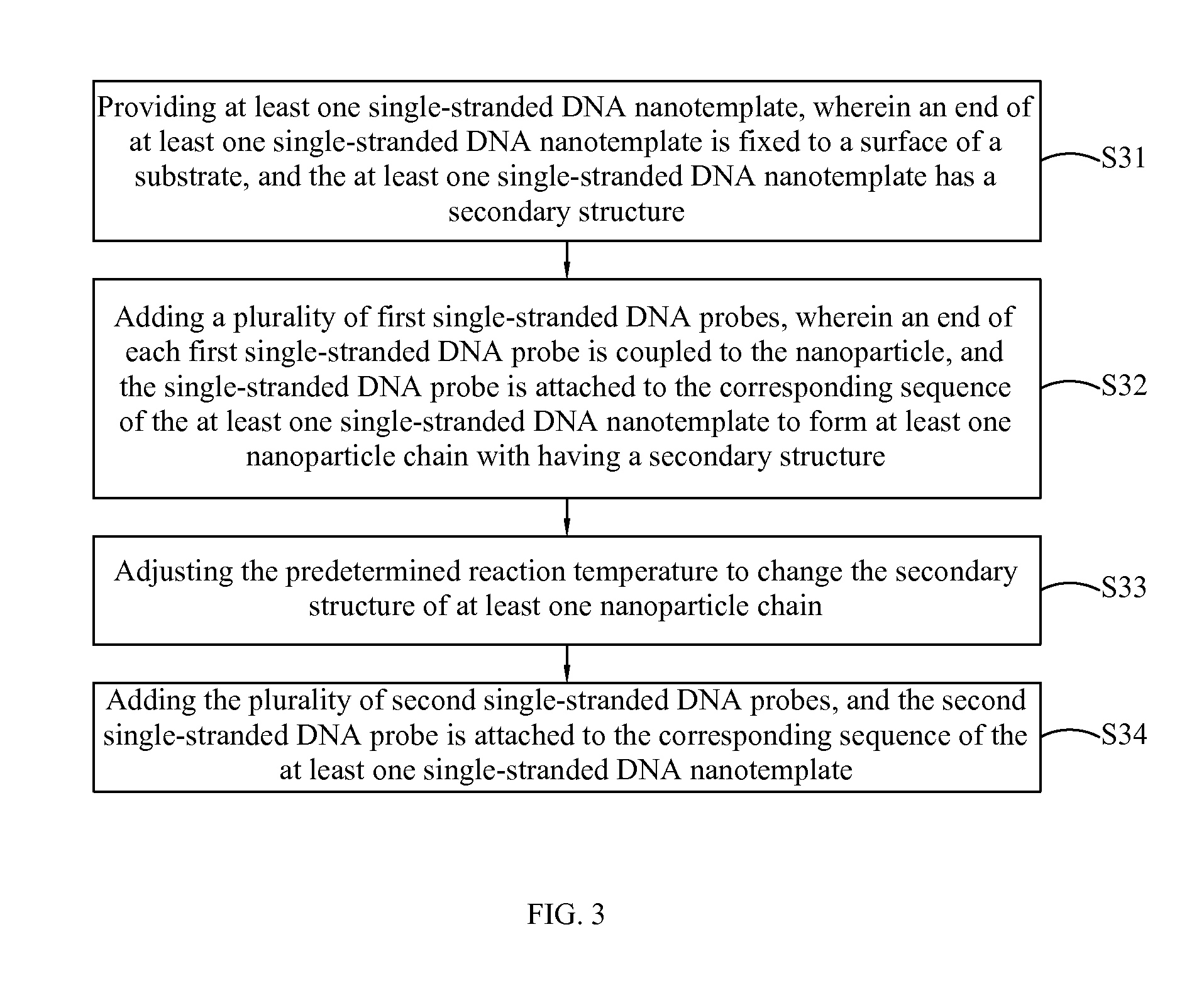

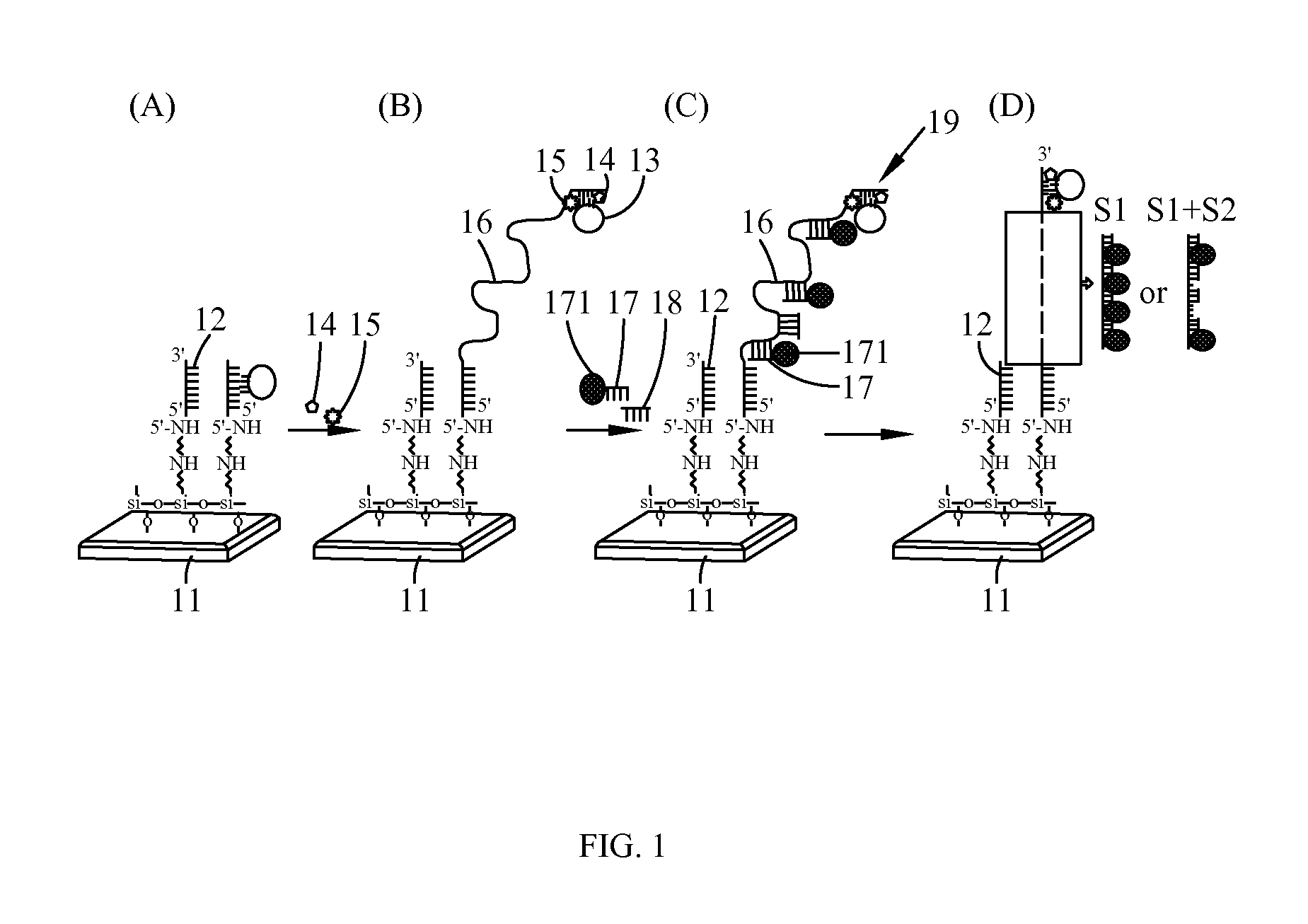

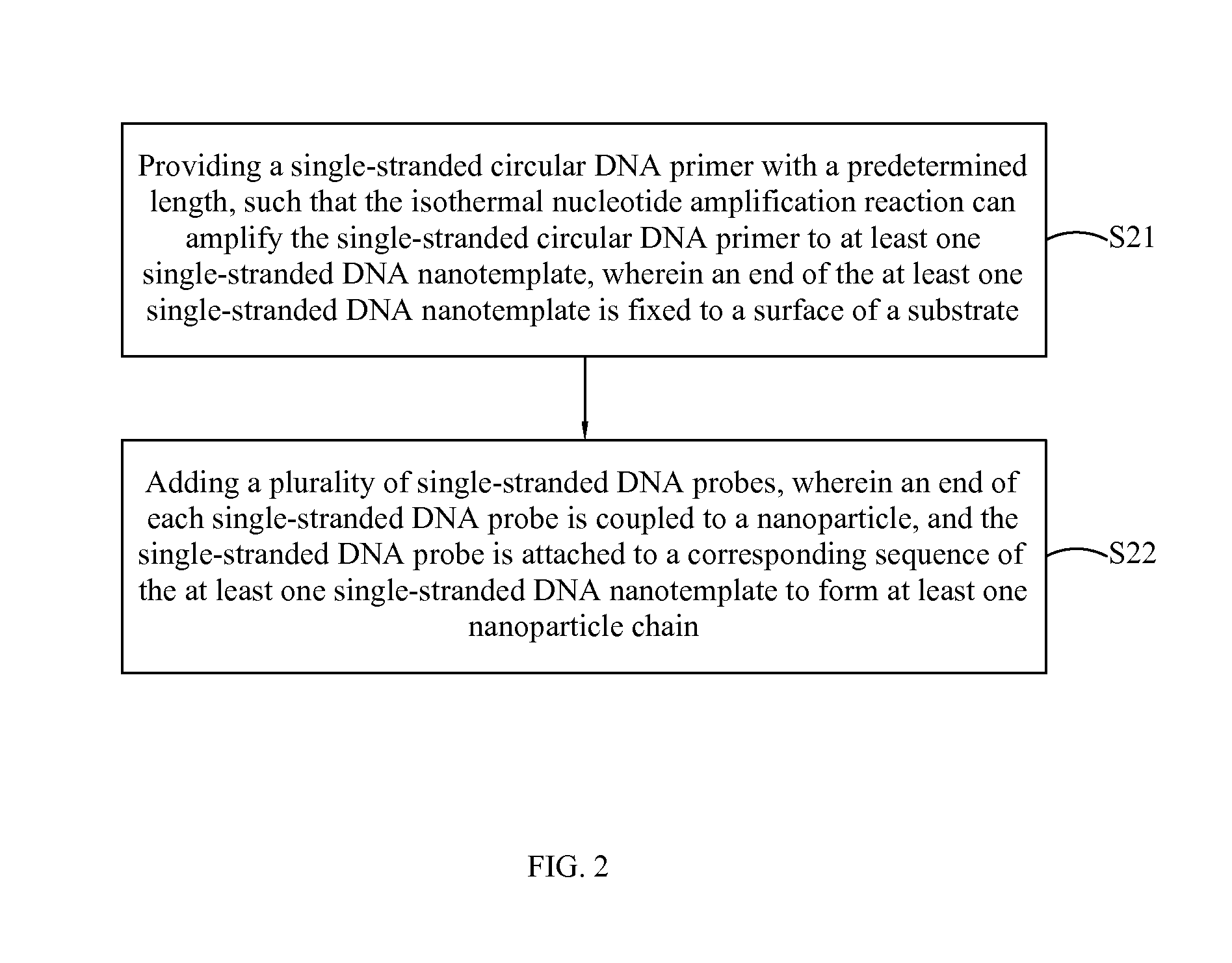

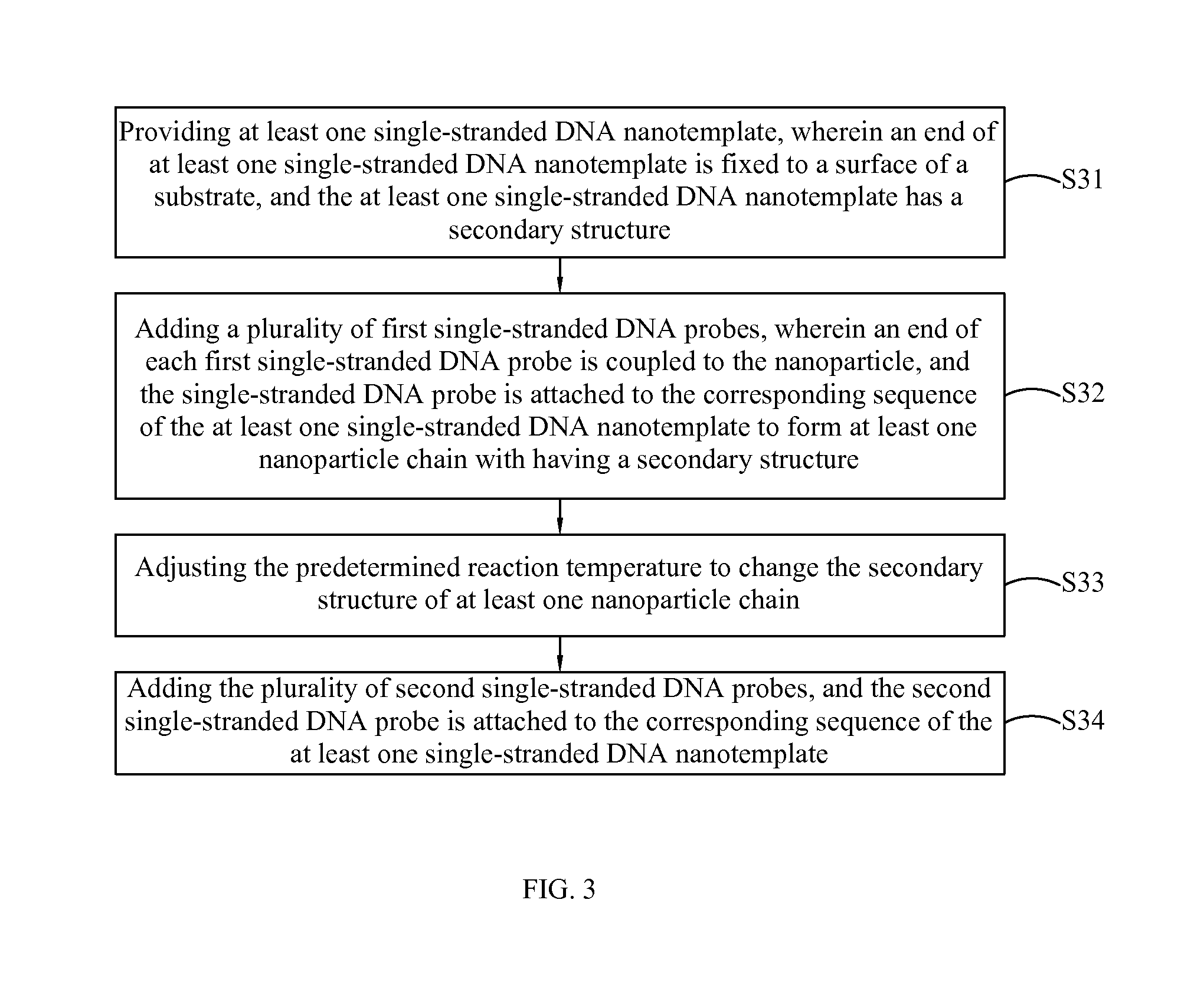

Method of Manufacturing Nanoparticle Chain

InactiveUS20130273610A1Increase distanceLow costMicrobiological testing/measurementFermentationFluid controlReaction temperature

A method of manufacturing a nanoparticle chain is disclosed. The method comprises the steps of: providing a single-stranded circular primer with a determined length, and amplifying the single-stranded circular primer into single-stranded DNA nanotemplate by an isothermal nucleotide amplification reaction such that an end of the single-stranded DNA nanotemplate is fixed to a surface of a substrate; and adding a single-stranded DNA probe conjugated with nanoparticle at one end of which, and attaching the single-stranded DNA probe to the corresponding sequence on the single-stranded DNA nanotemplate to form a nanoparticles chain. The method of manufacturing a nanoparticle chain further comprises providing a fluid, and the flowing direction of the fluid controls the aligning direction of the nanoparticle chain. Wherein, the inter-nanoparticle distance of the nanoparticle chain can be adjusted by adjusting a reaction temperature or adding the single-stranded DNA probe without conjugating with nanoparticles.

Owner:NAT APPLIED RES LAB

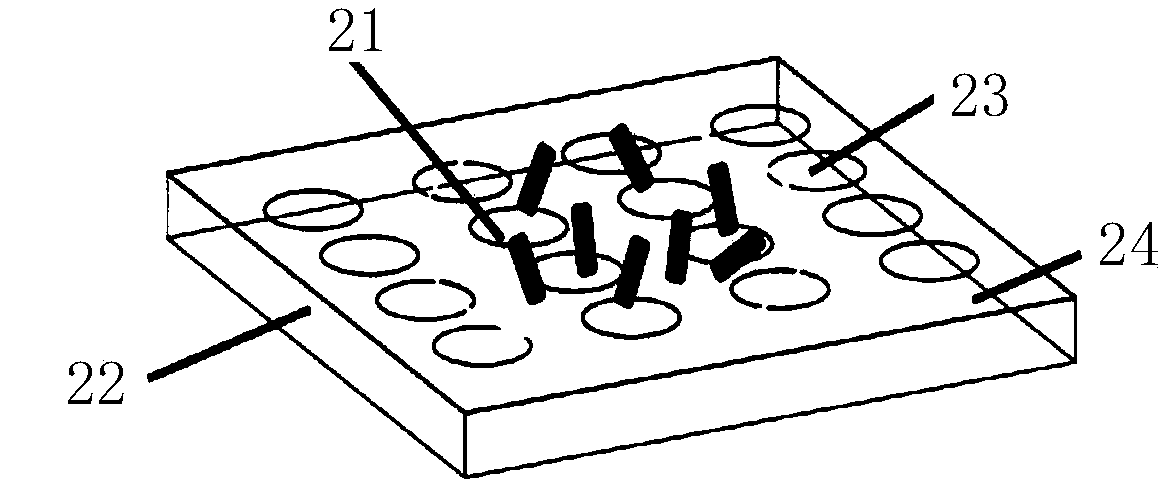

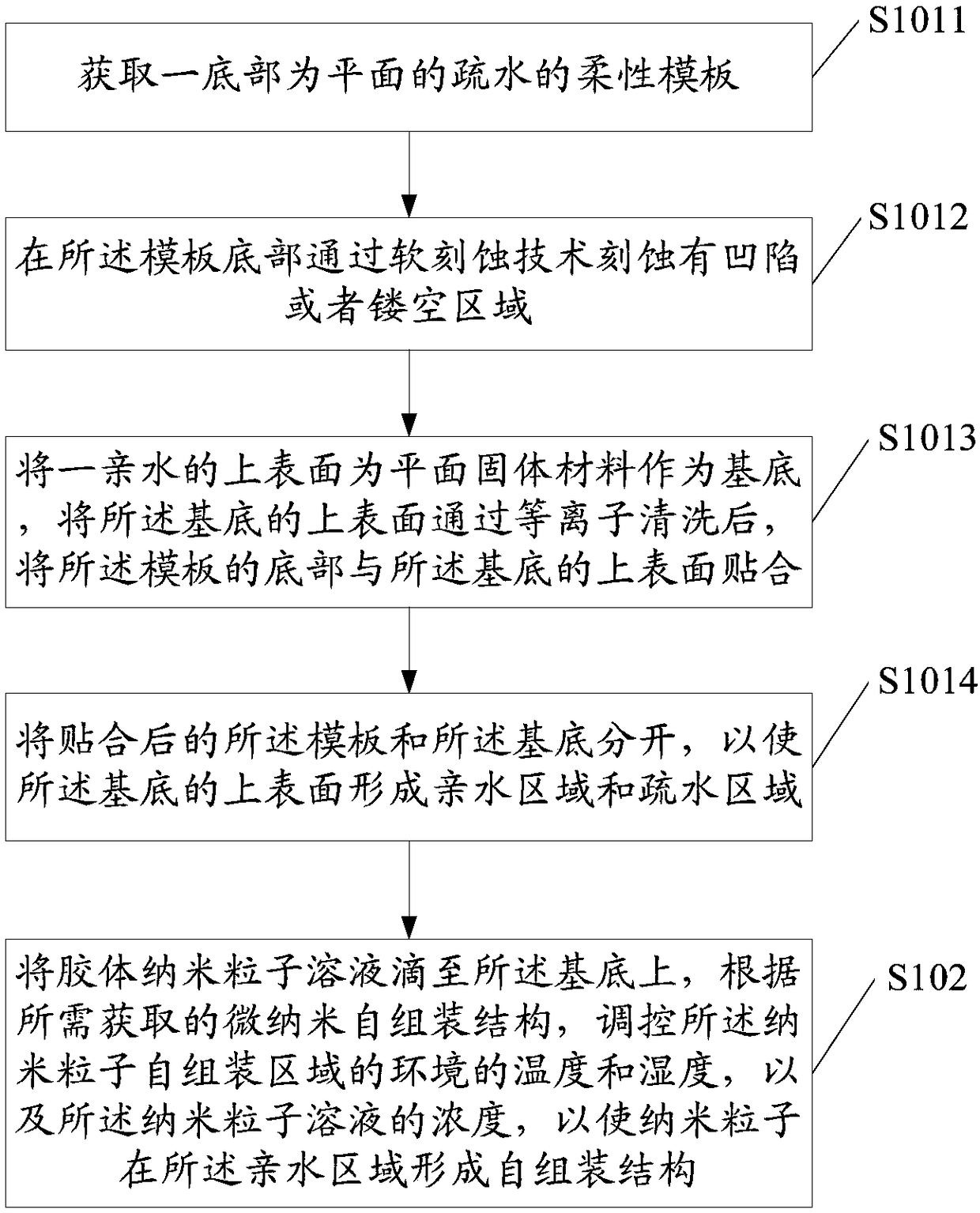

Method and device for manufacturing nanoparticle self-assembled structure

The embodiment of the invention discloses a method and a device for manufacturing a nanoparticle self-assembled structure. The manufacturing method comprising the following steps: A, obtaining a substrate provided with a hydrophilic region and a hydrophobic region; B, dropping a colloidal nanoparticle solution onto the substrate, so that the nanoparticles form a self-assembled structure in the hydrophilic region. From the above, the method and the device for manufacturing nanoparticle self-assembled structure can precisely control the self-assembly position of the nanoparticles, and is simpleand easy to operate.

Owner:TIANJIN UNIV

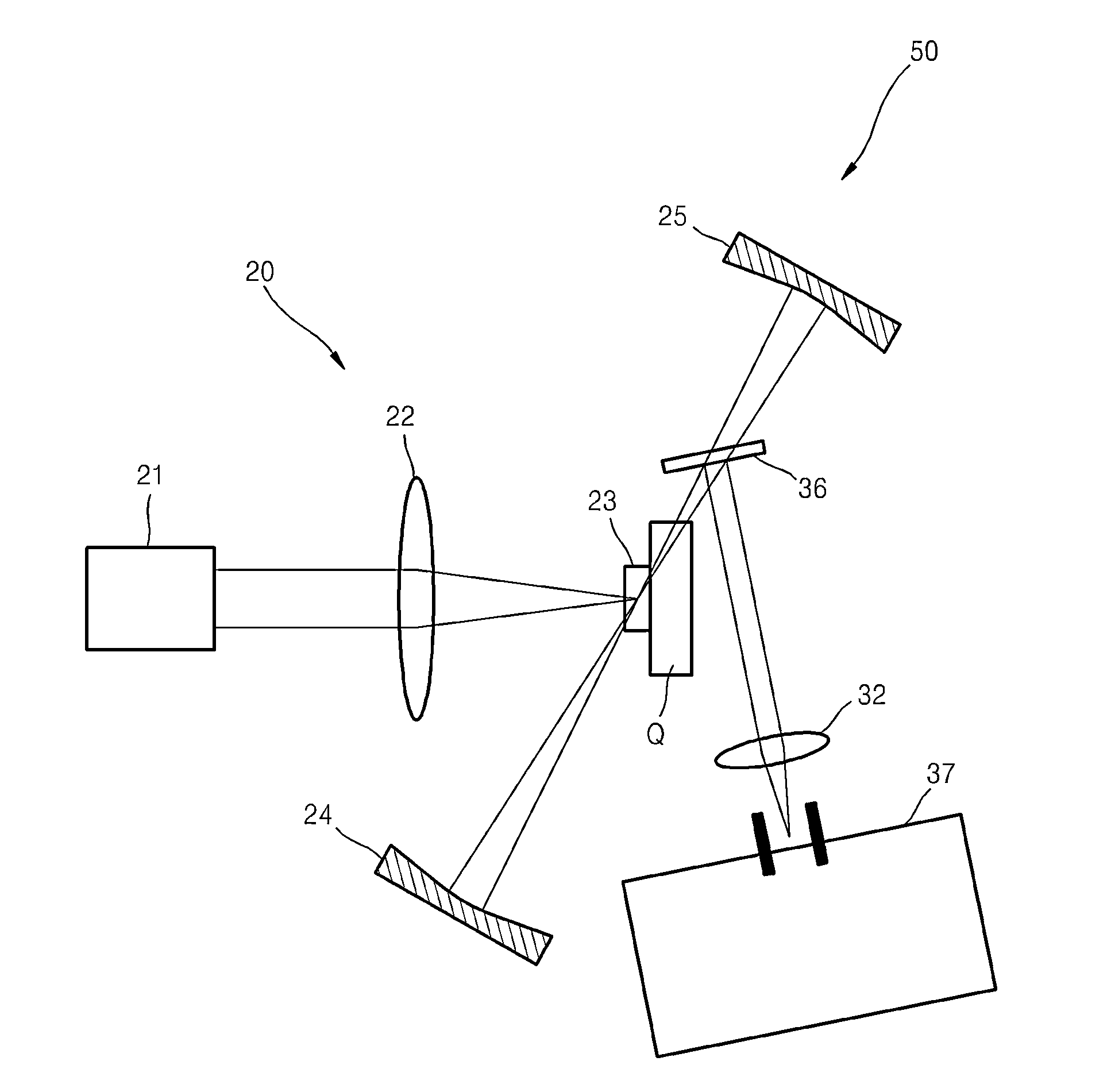

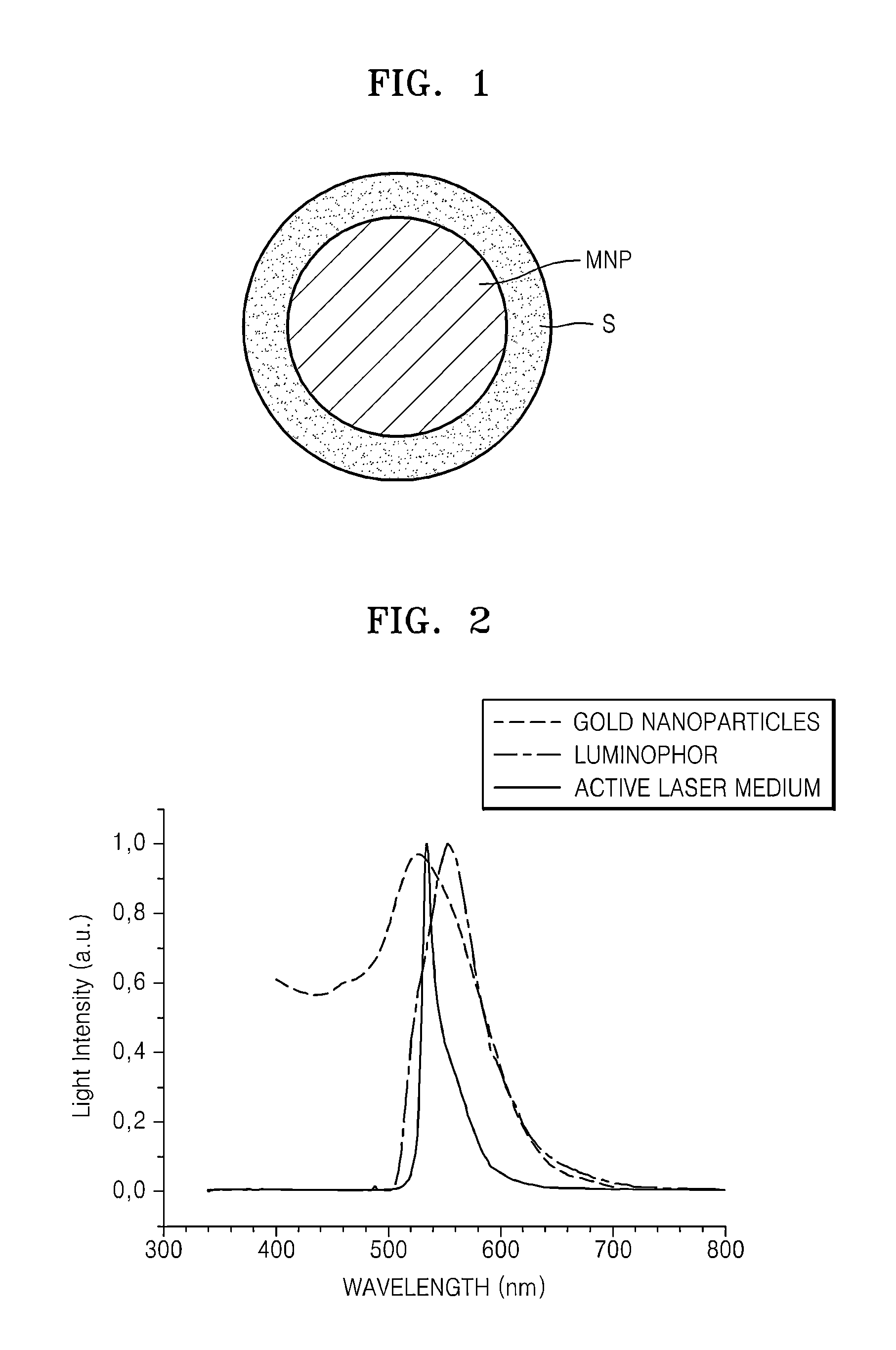

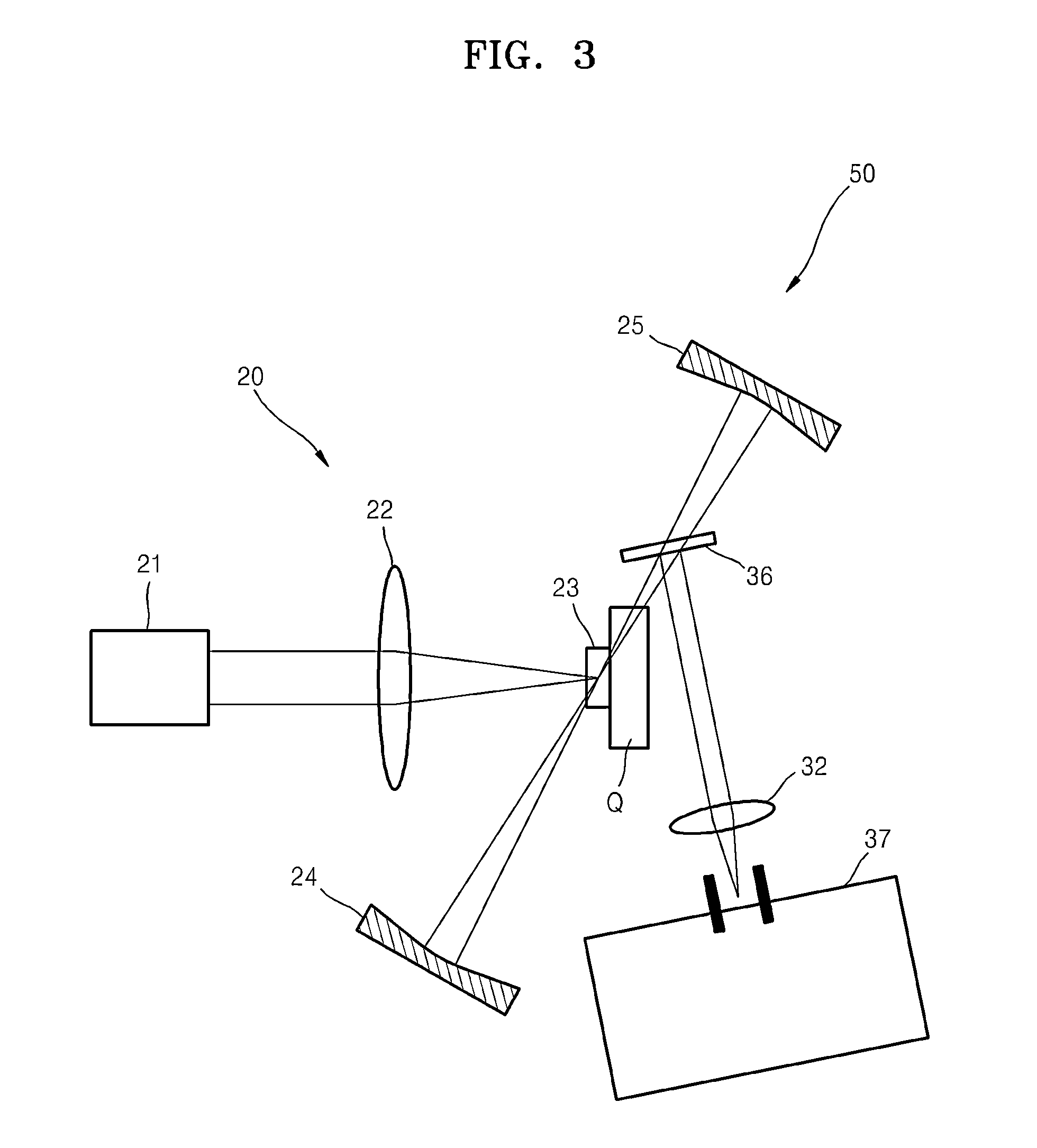

Active laser medium including nanoparticles, laser apparatus including the active laser medium, and method of manufacturing nanoparticles

An active laser medium includes a metal nanoparticle and a shell surrounding the metal nanoparticle, the shell including a luminophor, wherein a luminescence spectrum of the luminophor overlaps with a peak of surface plasmon resonance of the metal nanoparticle.

Owner:SAMSUNG ELECTRONICS CO LTD

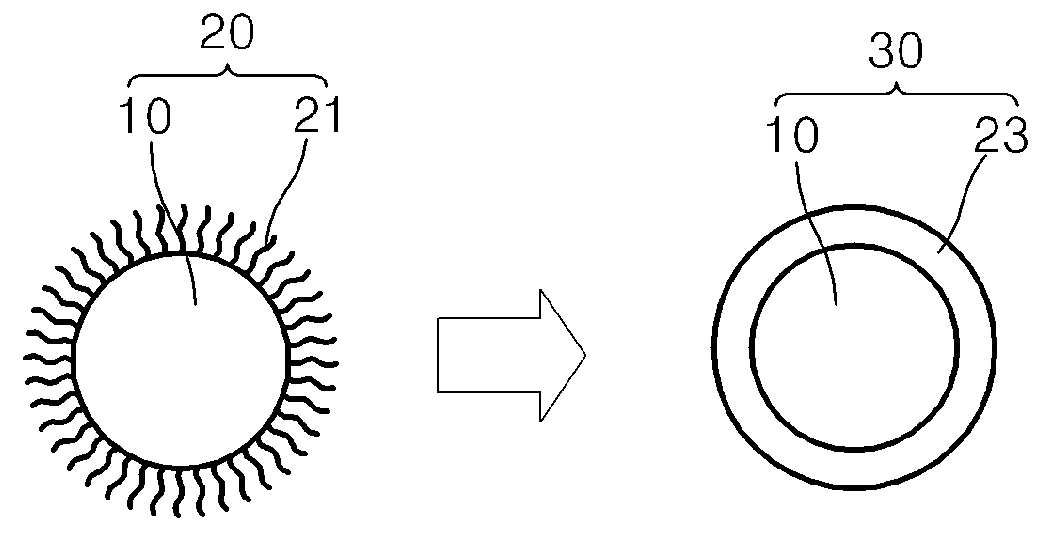

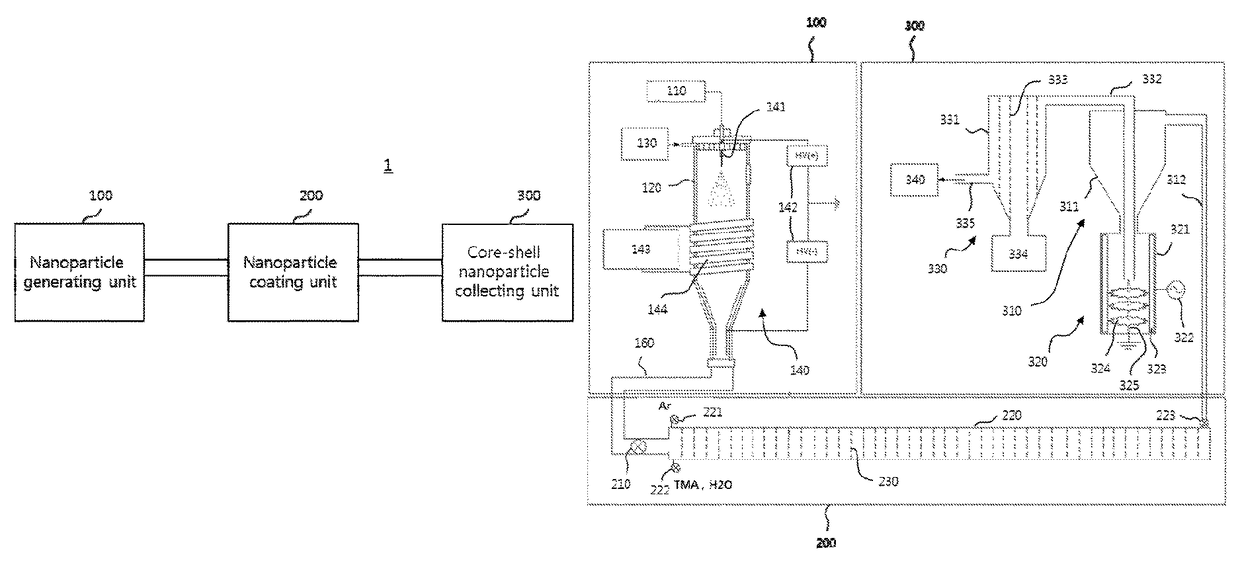

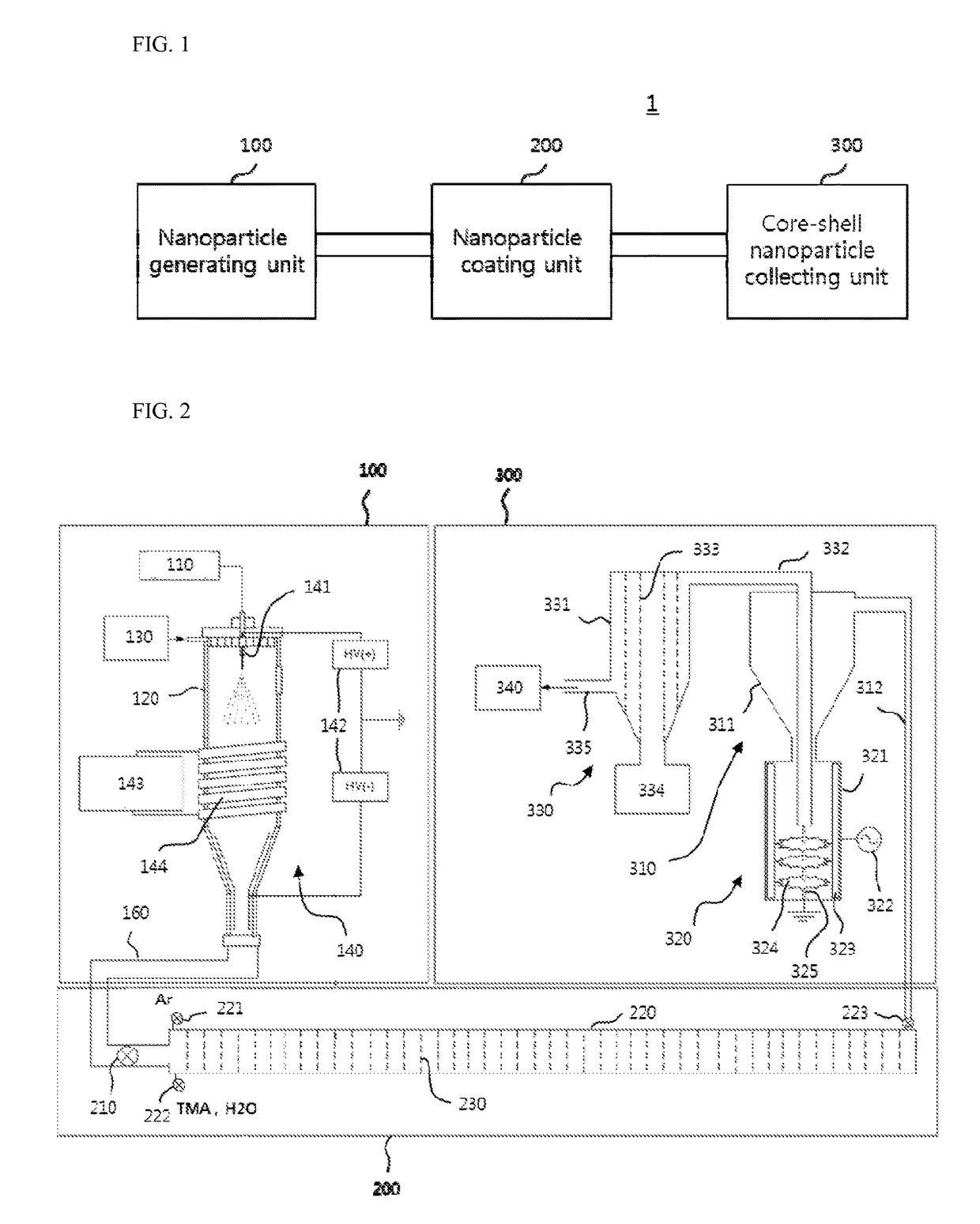

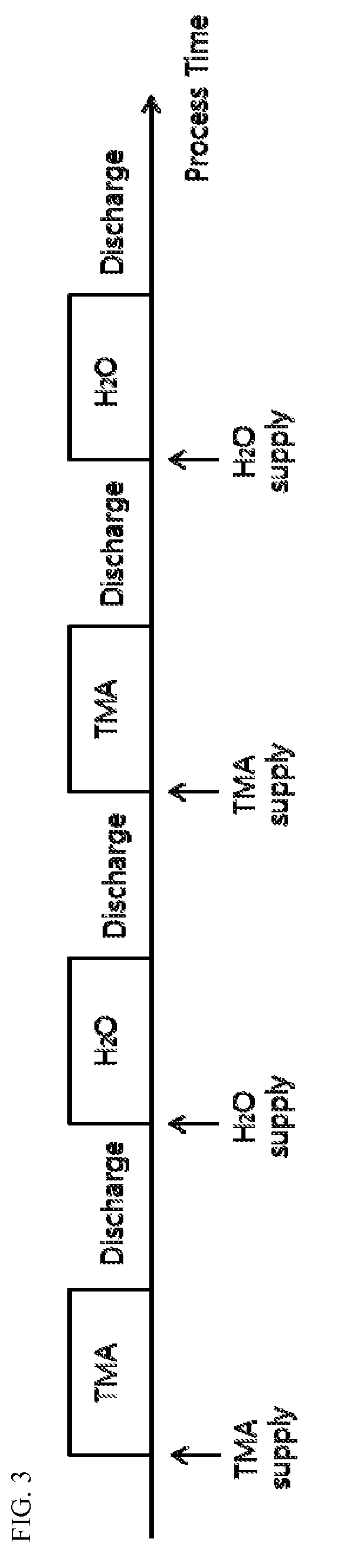

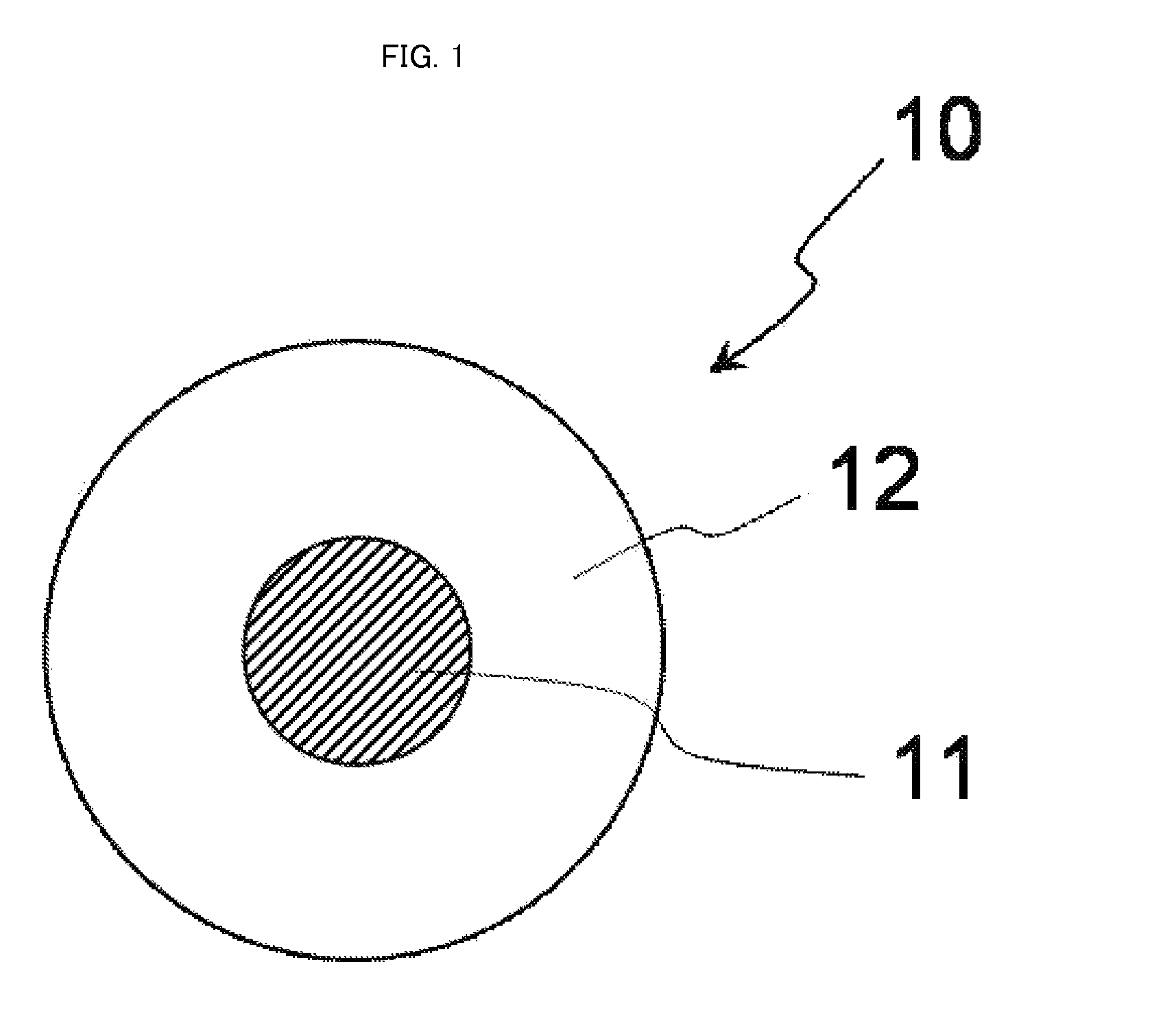

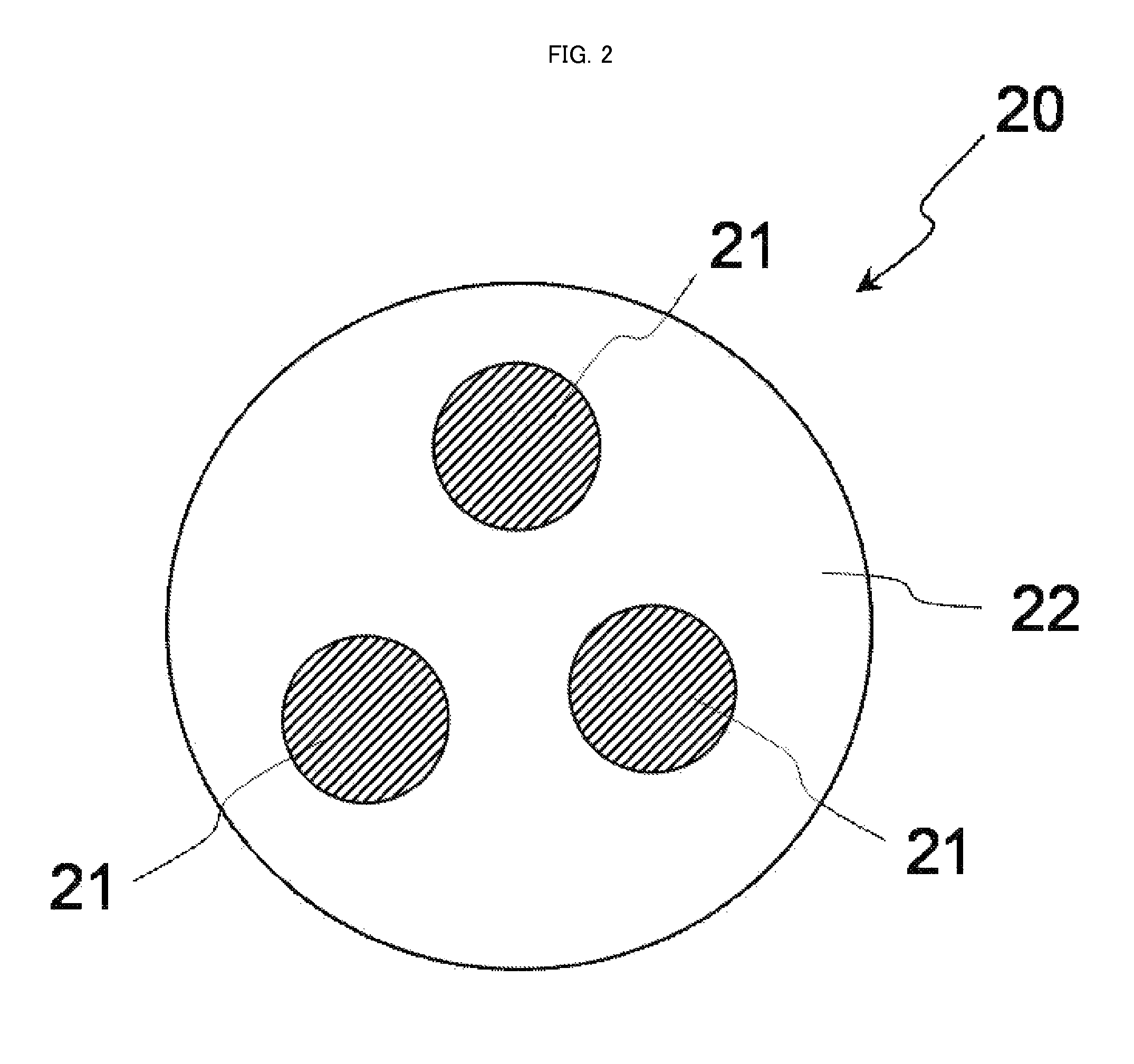

In situ system and method of manufacturing nanoparticles having core-shell structure

ActiveUS9822448B2Increasing the thicknessReduce movement speedNanostructure manufactureChemical/physical/physico-chemical processesCore shell nanoparticlesCore shell

Disclosed is a nanoparticle generating unit, a nanoparticle coating unit, and a core-shell nanoparticle collecting unit are connected to link and continuously process generation of nanoparticles and a coating and collecting process. The nanoparticle coating unit is formed of a porous material or in a grid structure and a moving speed of the nanoparticles can be decreased using a speed adjustment member installed at a process passage of a coating chamber.

Owner:DAEJIN UNIV CENT FOR EDUCATIONAL INDAL COOPERATION

Molybdenum comprising nanomaterials and related nanotechnology

InactiveUS7968503B2Increase volumeLow cost productionPigmenting treatmentTransportation and packagingPhotonicsNanometre

Nanoparticles comprising molybdenum, methods of manufacturing nanoparticles comprising molybdenum, and nanotechnology applications of nanoparticles comprising molybdenum, such as electronics, optical devices, photonics, reagents for fine chemical synthesis, pigments and catalysts, are provided.

Owner:PPG IND OHIO INC

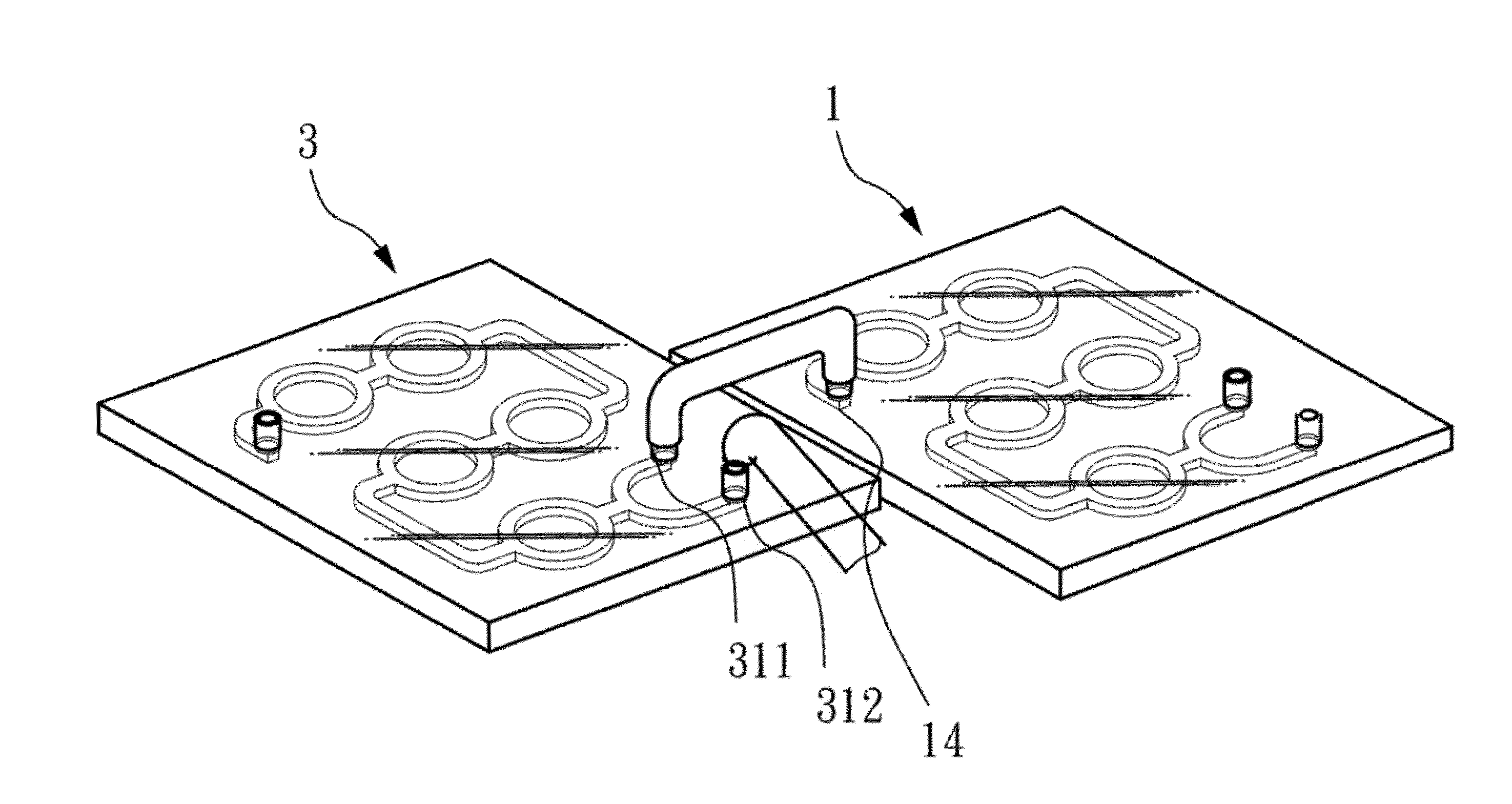

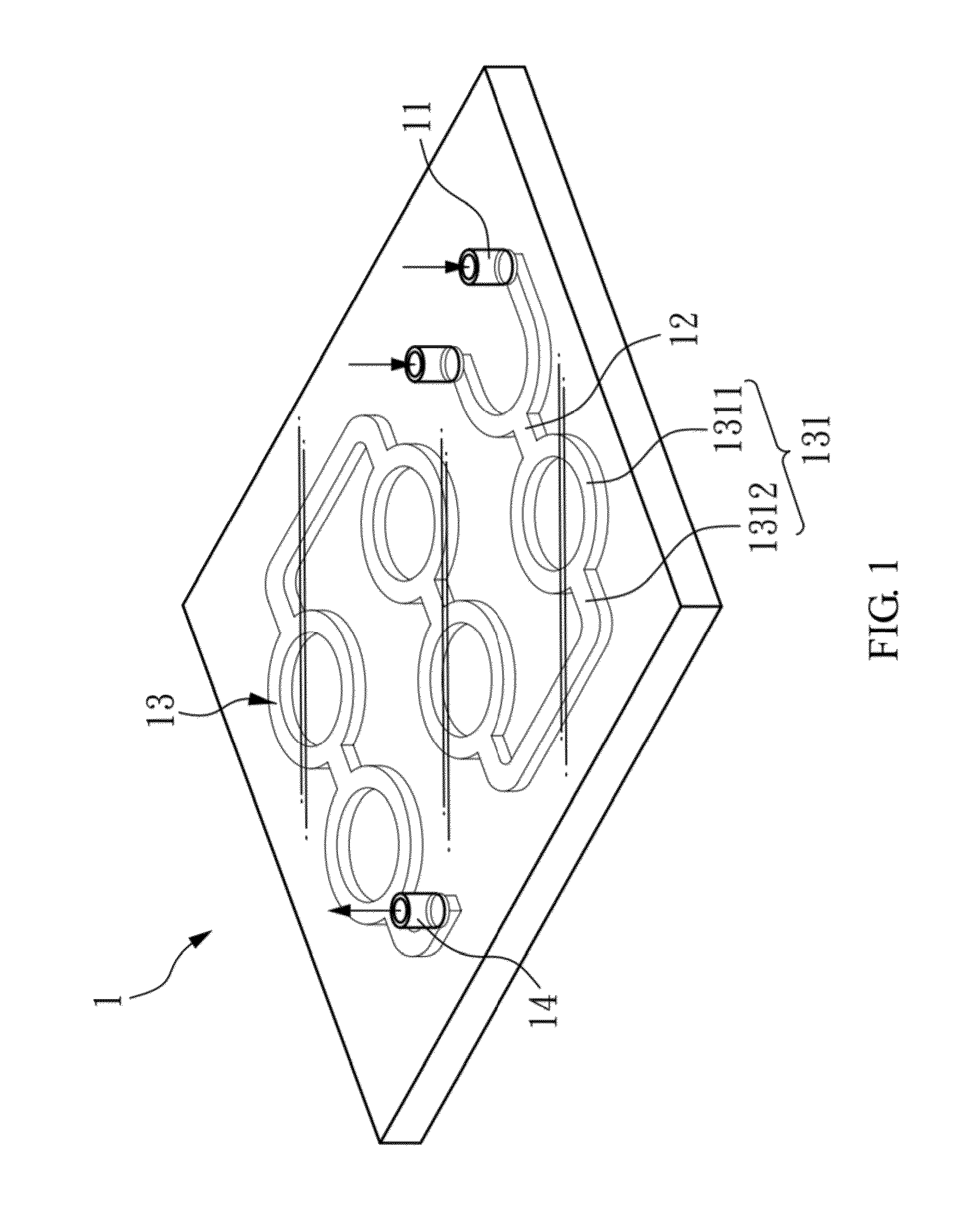

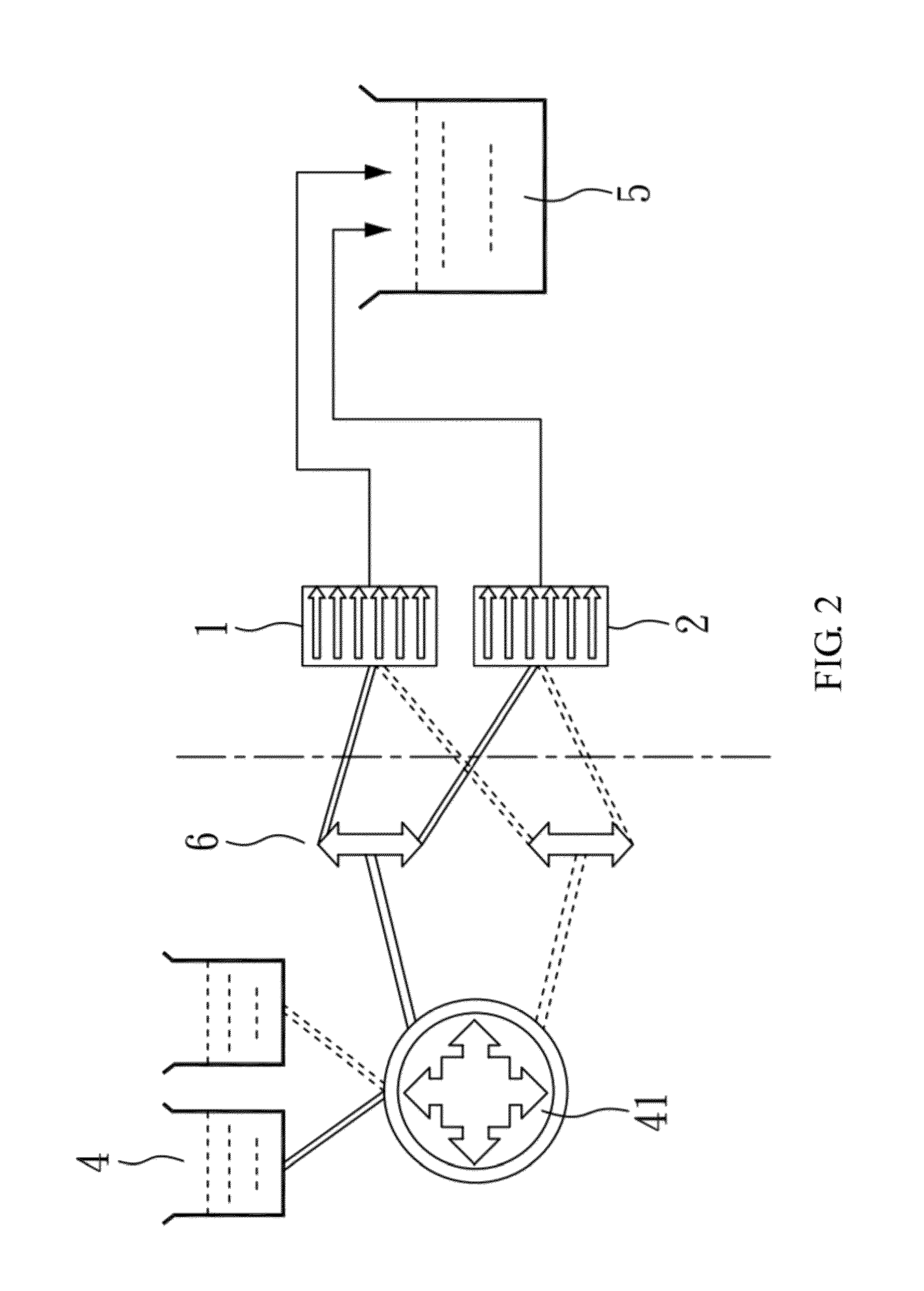

Continuous Reactor and Method for Manufacturing Nanoparticles

InactiveUS20140047950A1High flow rate toleranceReduce riskMaterial nanotechnologyTransportation and packagingContinuous reactorEngineering

The present invention relates to a continuous reactor a method for manufacturing nanoparticles. The reactor of the present invention includes: a plurality of first inputs for individually inputting a plurality of reagents; a first mixing part connected to the first inputs to mix the reagents; N number of first reaction units, each comprising a plurality of first diverging channels and a first converging channel to form a channel having the first diverging channels and the first converging channels alternately connected to one another in series for N times of diverging-converging actions, wherein N≧1, and the first diverging channels of a 1st one of the first reaction units are connected to the first mixing part; and a first output connected to the first converging channel of an Nth one of the first reaction units, so as to output a product of nanoparticles.

Owner:NATIONAL TSING HUA UNIVERSITY

Method of manufacturing nanoparticles

ActiveUS8048192B2Less-expensive to practiceImprove securityMaterial nanotechnologyLiquid surface applicatorsModal particleReaction temperature

Provided are methods and systems for generating nanoparticles from an inorganic precursor compound using a hydrothermal process within at least one CSTR or PFR maintained at an elevated temperature and an elevated pressure and a treatment vessel in which this reaction solution can be applied to one or more catalyst substrates. In operation, the reaction solution may be maintained within the CSTR at a substantially constant concentration and within a reaction temperature range for a reaction period sufficient to obtain nanoparticles having a desired average particle size of, for example, less than 10 nm formation and / or deposition. Variations of the basic method and system can provide, for example, the generation of complex particle size distribution profiles, the selective deposition of a multi-modal particle size distribution on a single substrate.

Owner:GE HITACHI NUCLEAR ENERGY AMERICAS

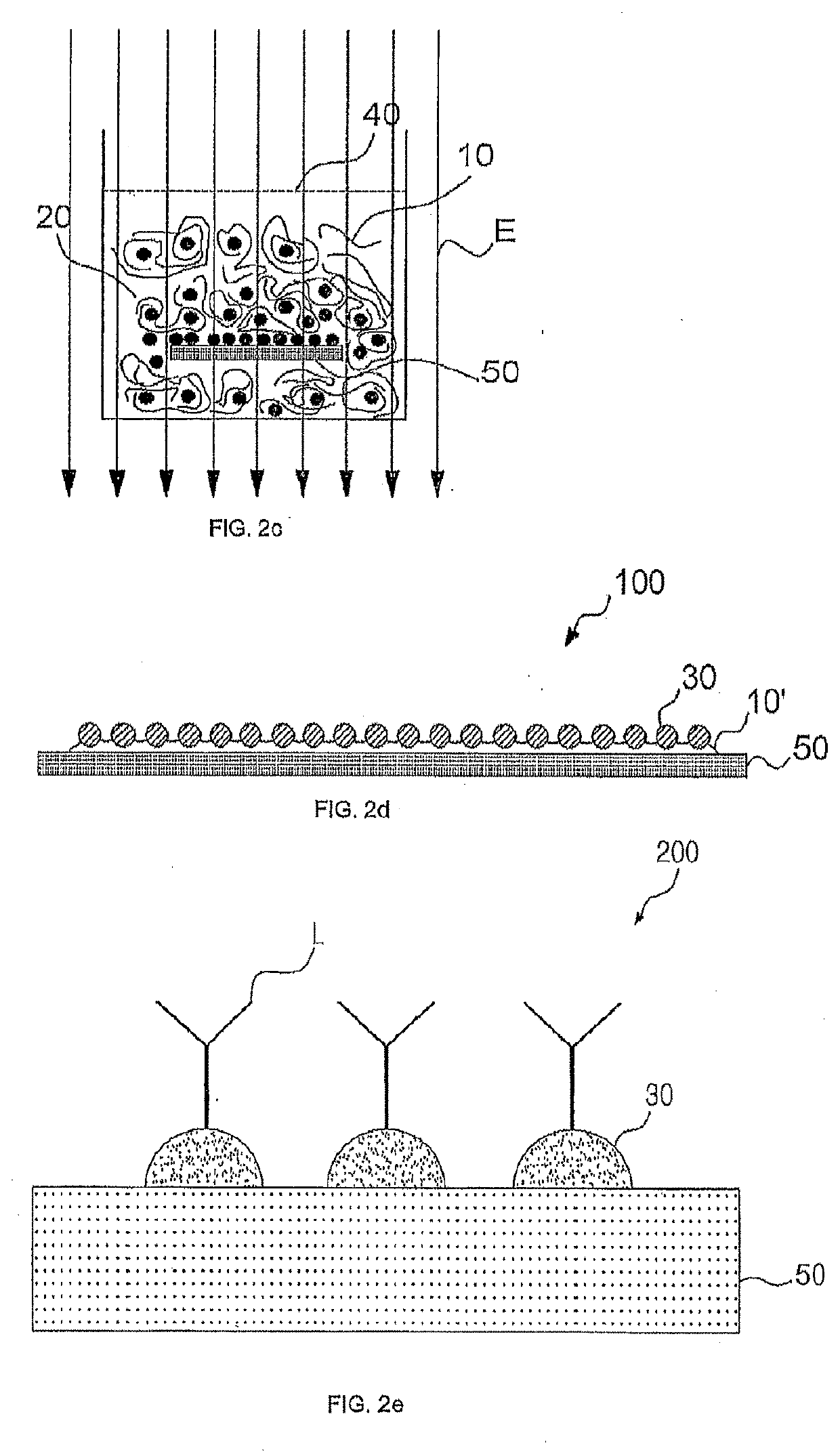

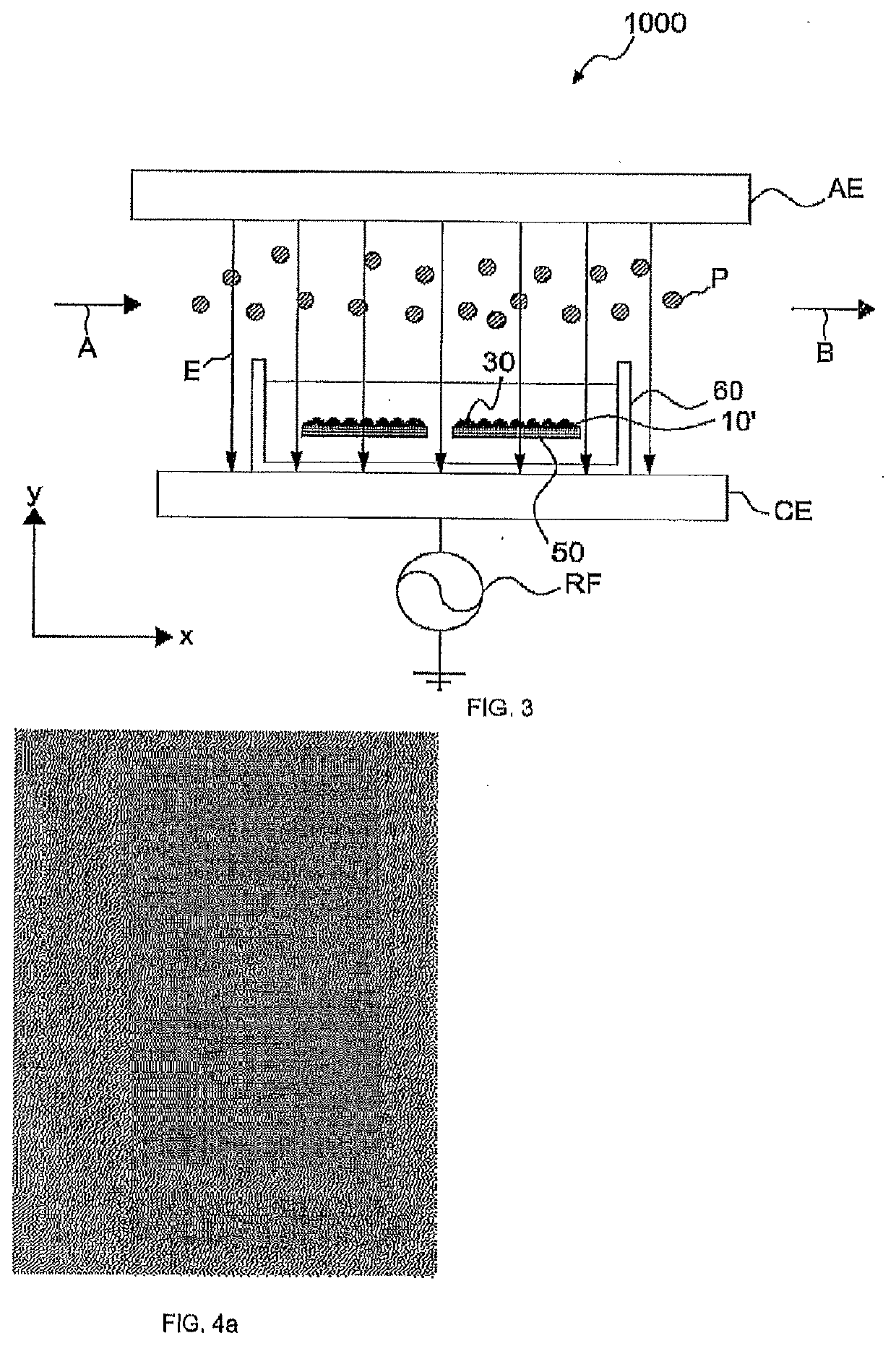

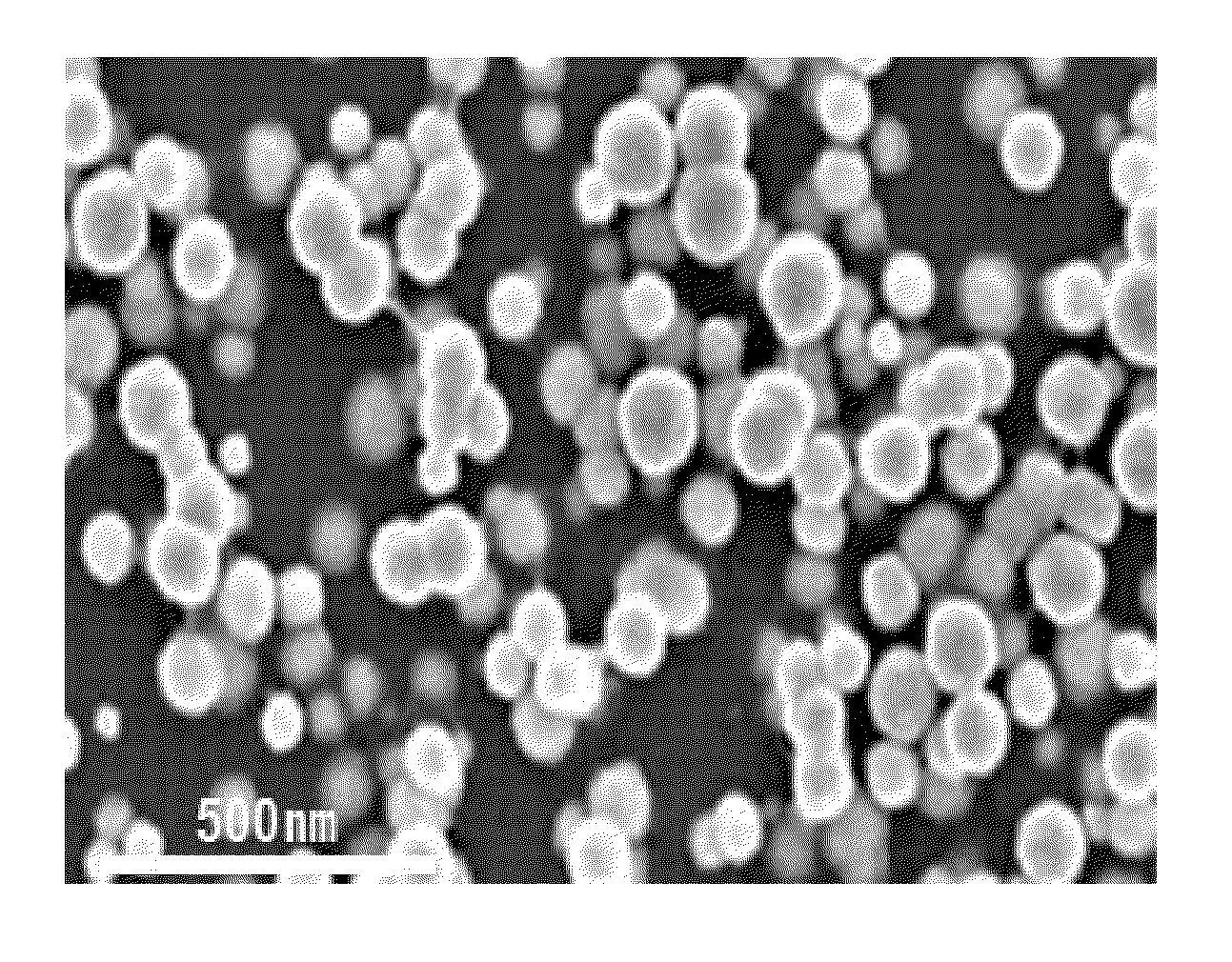

Method for manufacturing nanoparticle array, surface plasmon resonance-based sensor and method for analyzing using same

InactiveUS20190339200A1Cost-effective manufacturingHigh detection sensitivityNanostructure manufactureDecorative surface effectsHigh densitySurface plasmon

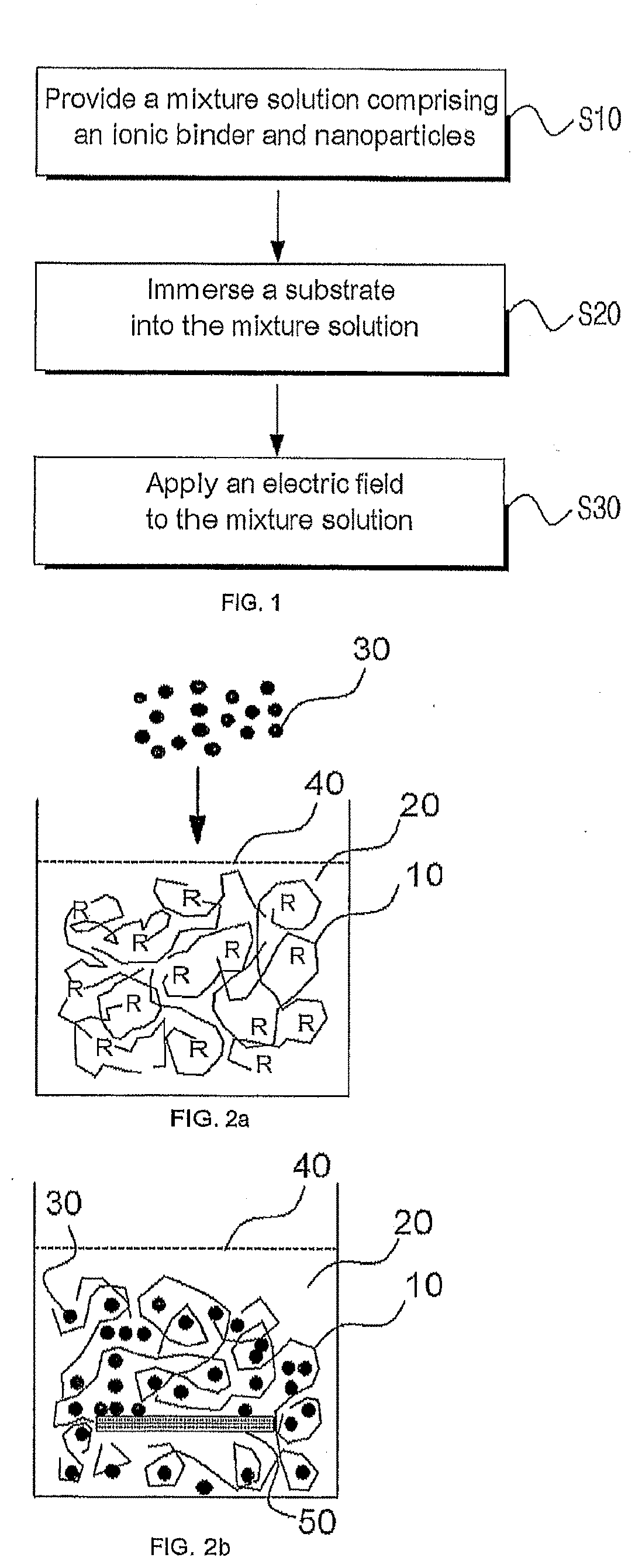

The present invention relates to a method for manufacturing a nanoparticle array, a surface plasmon resonance-based sensor, and a method for analyzing using the same. According to one embodiment of the present invention, after a mixed solution of an ionized binder and conductive nanoparticles is prepared, a substrate is dipped into the mixed solution. Thereafter, by applying an electric field to the mixed solution into which the substrate is dipped so as to induce coating of the conductive nanoparticles on the substrate, it is possible to manufacture, by a wet method, a nanoparticle array in which the conductive nanoparticles are quickly coated on the substrate with high density.

Owner:PLEXENSE

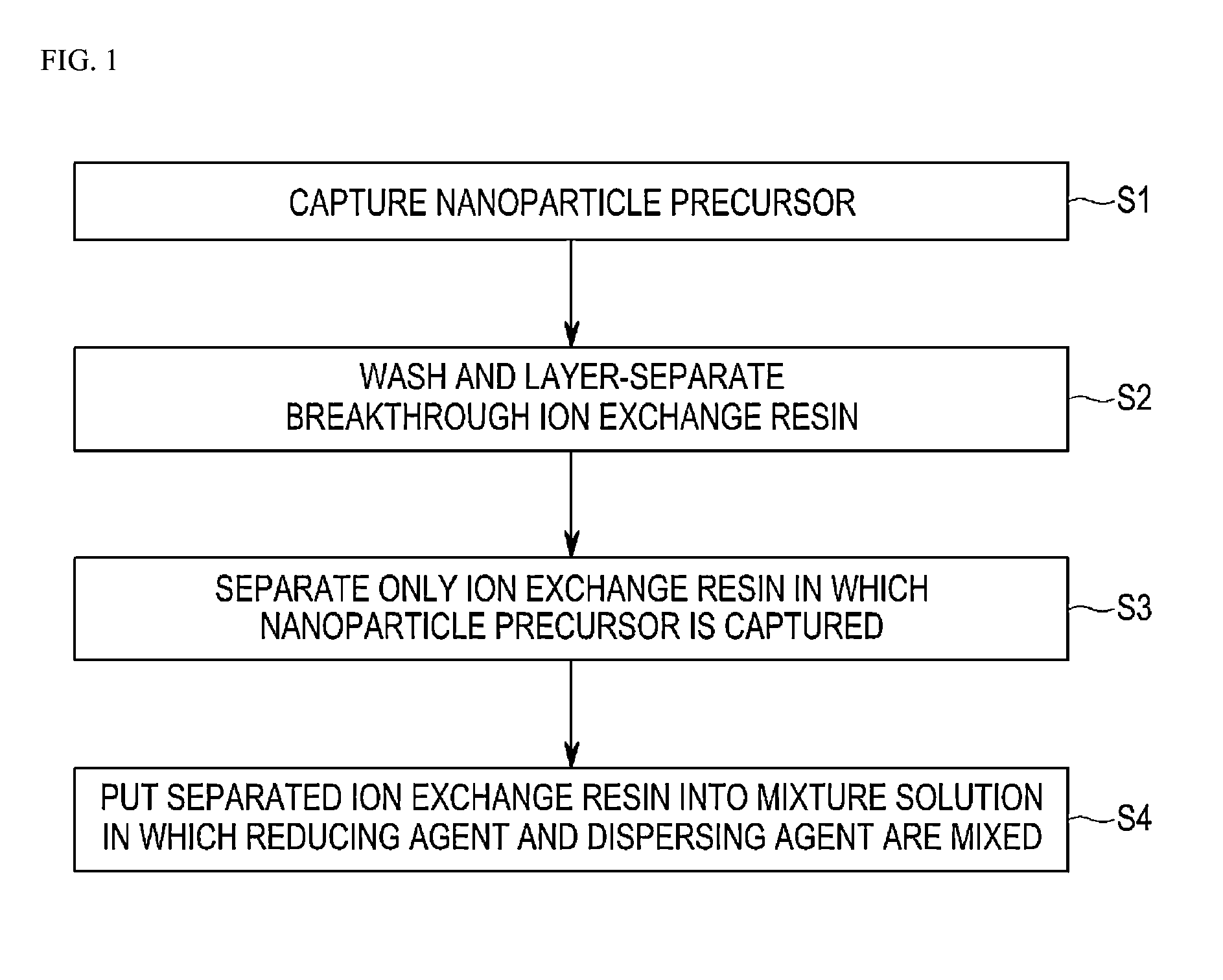

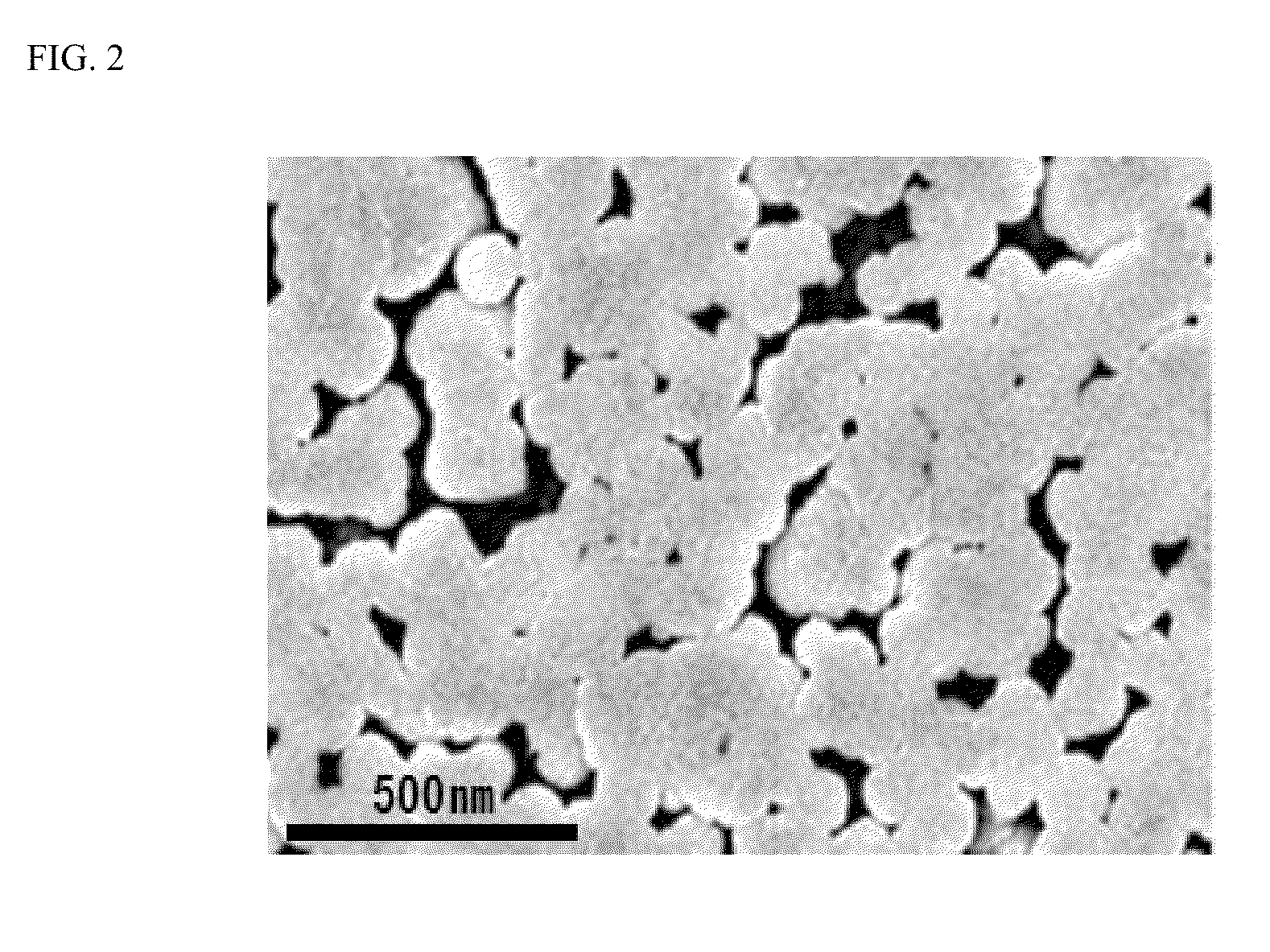

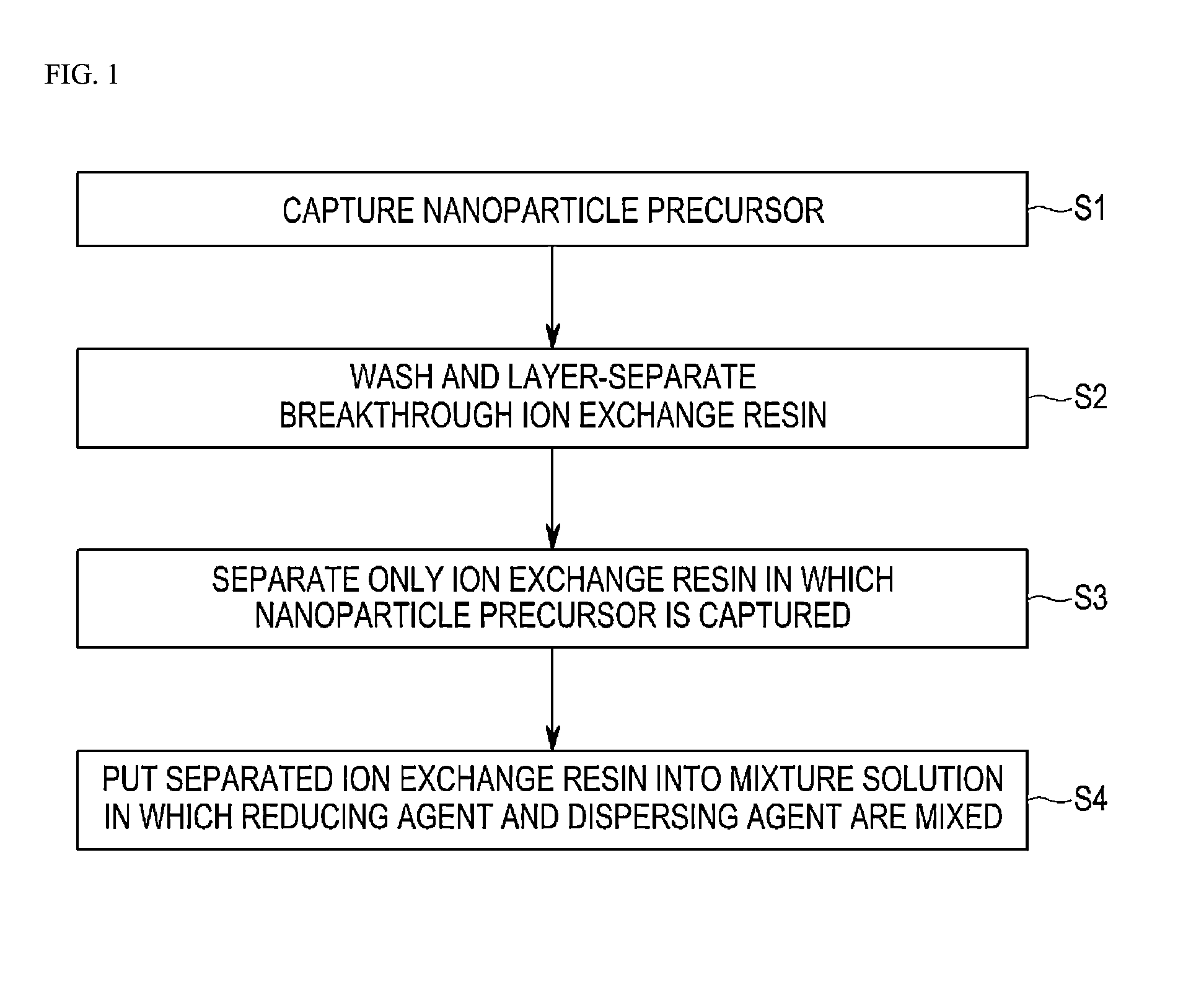

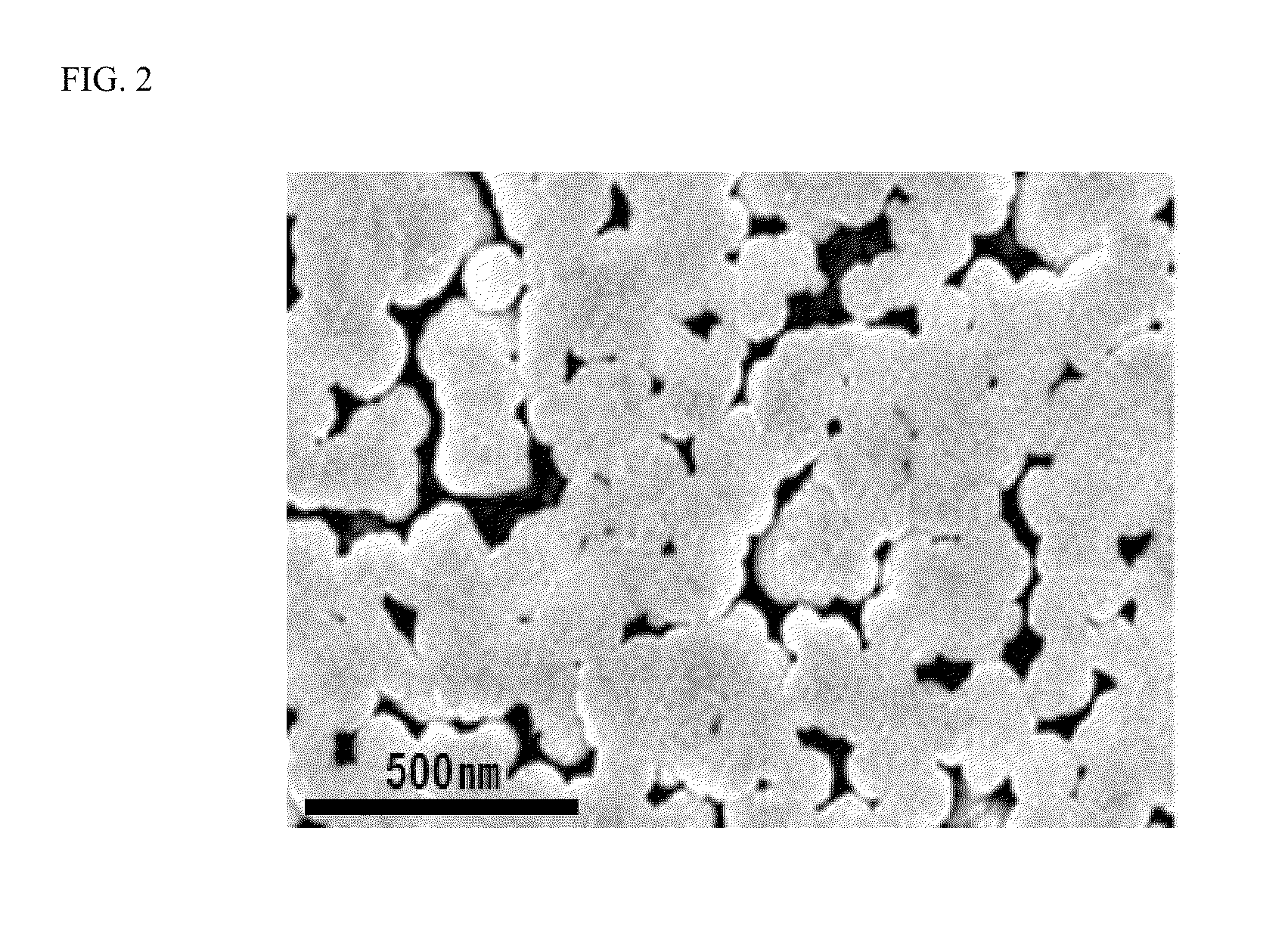

Method of manufacturing nanoparticles using ion exchange resin and liquid reducing process

ActiveUS9089897B2High yieldTransportation and packagingIndividual molecule manipulationIon exchangeIon-exchange resin

Provided is a method of manufacturing nanoparticles using an ion exchange resin and a liquid reducing process. The method includes (a) capturing a nanoparticle precursor from a solution in which impurities are mixed using an ion exchange resin, (b) washing and layer-separating the breakthrough ion exchange resin, (c) separating only the ion exchange resin in which the nanoparticle precursor is captured from the layer-separated ion exchange resin, and (d) putting the separated ion exchange resin into a mixture solution in which a reducing agent and a dispersing agent are mixed.

Owner:SOONCHUNYANG UNIV IND ACAD COOP FOUND

A kind of preparation method of nanoparticle reinforced resin lead core

The invention discloses a preparation method of a nanoparticle reinforced resin lead core. The method includes: dispersing graphite and a surfactant in water, conducting ultrasonic stirring, carrying out reaction for a period of time to obtain a surfactant intercalated and coated graphite; dispersing the surfactant modified graphite and a salt for preparation of corresponding nanoparticles in a solvent, conducting charge induction to enable in-situ growth of nanoparticles on the graphite surface, thus obtaining nanoparticle loaded graphite; and using nanoparticle modified graphite to replace pure graphite, performing compounding according to an existing core-making technology and preparing the nanoparticle reinforced high performance resin lead core. The manufactured nanoparticle modified resin fine lead core has excellent performance, and the quality of the nanoparticle reinforced resin lead core is proved to up to the international level A standard. The method can significantly improve the flexural strength, impact strength and writing comfort of the resin lead core without changing the existing processing technology, has the characteristics of simple operation, low cost, high product quality, low equipment investment and the like, and is suitable for large-scale industrial production.

Owner:蓬莱凯威文体制品有限公司

Method of manufacturing nanoparticles using ion exchange resin and liquid reducing process

ActiveUS20150082946A1High yieldGranularity adjustableTransportation and packagingIndividual molecule manipulationIon exchangeIon-exchange resin

Provided is a method of manufacturing nanoparticles using an ion exchange resin and a liquid reducing process. The method includes (a) capturing a nanoparticle precursor from a solution in which impurities are mixed using an ion exchange resin, (b) washing and layer-separating the breakthrough ion exchange resin, (c) separating only the ion exchange resin in which the nanoparticle precursor is captured from the layer-separated ion exchange resin, and (d) putting the separated ion exchange resin into a mixture solution in which a reducing agent and a dispersing agent are mixed.

Owner:SOONCHUNYANG UNIV IND ACAD COOP FOUND

Method of manufacturing nanoparticle chain

InactiveUS8921075B2Increase distanceLow costMicrobiological testing/measurementFermentationFluid controlNucleotide

A method of manufacturing a nanoparticle chain is disclosed. The method comprises the steps of: providing a single-stranded circular primer with a determined length, and amplifying the single-stranded circular primer into single-stranded DNA nanotemplate by an isothermal nucleotide amplification reaction such that an end of the single-stranded DNA nanotemplate is fixed to a surface of a substrate; and adding a single-stranded DNA probe conjugated with nanoparticle at one end of which, and attaching the single-stranded DNA probe to the corresponding sequence on the single-stranded DNA nanotemplate to form a nanoparticles chain. The method of manufacturing a nanoparticle chain further comprises providing a fluid, and the flowing direction of the fluid controls the aligning direction of the nanoparticle chain. Wherein, the inter-nanoparticle distance of the nanoparticle chain can be adjusted by adjusting a reaction temperature or adding the single-stranded DNA probe without conjugating with nanoparticles.

Owner:NAT APPLIED RES LAB

Method for manufacturing of metal oxide nanoparticles and metal oxide nanoparticles thereby

ActiveUS10193133B2Cheaply and rapidly manufactureSimple processAnodisationNanostructure manufactureAnodizingMetal oxide nanoparticles

The present invention relates to a method for preparing metal oxide nanoparticles and metal oxide nanoparticles prepared thereby. The method includes: dipping a cathode and an anode formed of a metal for forming oxide, in an inorganic electrolyte solution containing halogen salt, and applying voltage to the anode and the cathode to form, on the anode, metal oxide forming an anode surface. According to a method of the present invention, disadvantages of typical nanoparticle synthesizing methods may be solved to cheaply and rapidly manufacture nanoparticles having various structures through a single process without using a surfactant. In practicing a method of the invention, metal oxide nanoparticles may be rapidly formed, nanoparticles having excellent crystallinity may be produced, and factors of the anodizing method, such as voltage, temperature, an electrolyte, and an electrolyte concentration may be changed to simply adjust a shape of the nanoparticles.

Owner:KOREA ADVANCED INST OF SCI & TECH

Method of manufacturing nanoparticle dispersion liquid

InactiveUS8809437B2Small particle sizeMaterial nanotechnologyRare earth metal chloridesSolventViscosity

The present invention provides a method of producing a nanoparticle dispersion liquid, including: altering a surface of a nanoparticle in the presence of an ion by contacting a complex that includes the nanoparticle and a solid material present around the nanoparticle with a surface altering agent-containing liquid, that includes a surface altering agent for altering the surface of the nanoparticle and a solvent for dissolving the solid material and that has a viscosity of 1.10 mPa·s or more at 25° C.; and a dispersing step of dispersing the surface-altered nanoparticle in the solvent.

Owner:TOKYO UNIVERSITY OF SCIENCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com