Patents

Literature

166 results about "Nanotechnology Techniques" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Systematic procedures which are utilized for the manipulation of materials at the nanoscale (i.e., less than 100 nanometers).

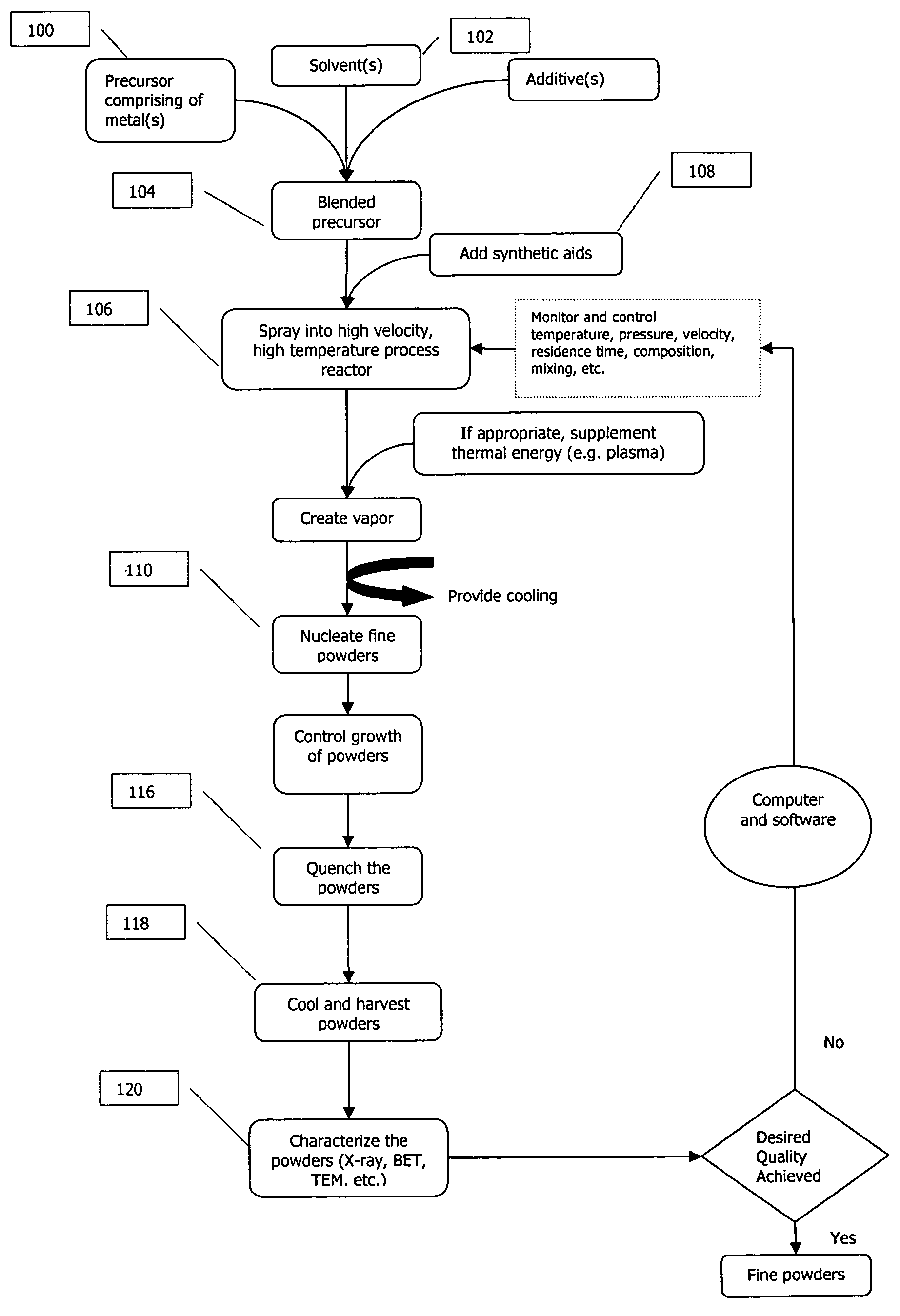

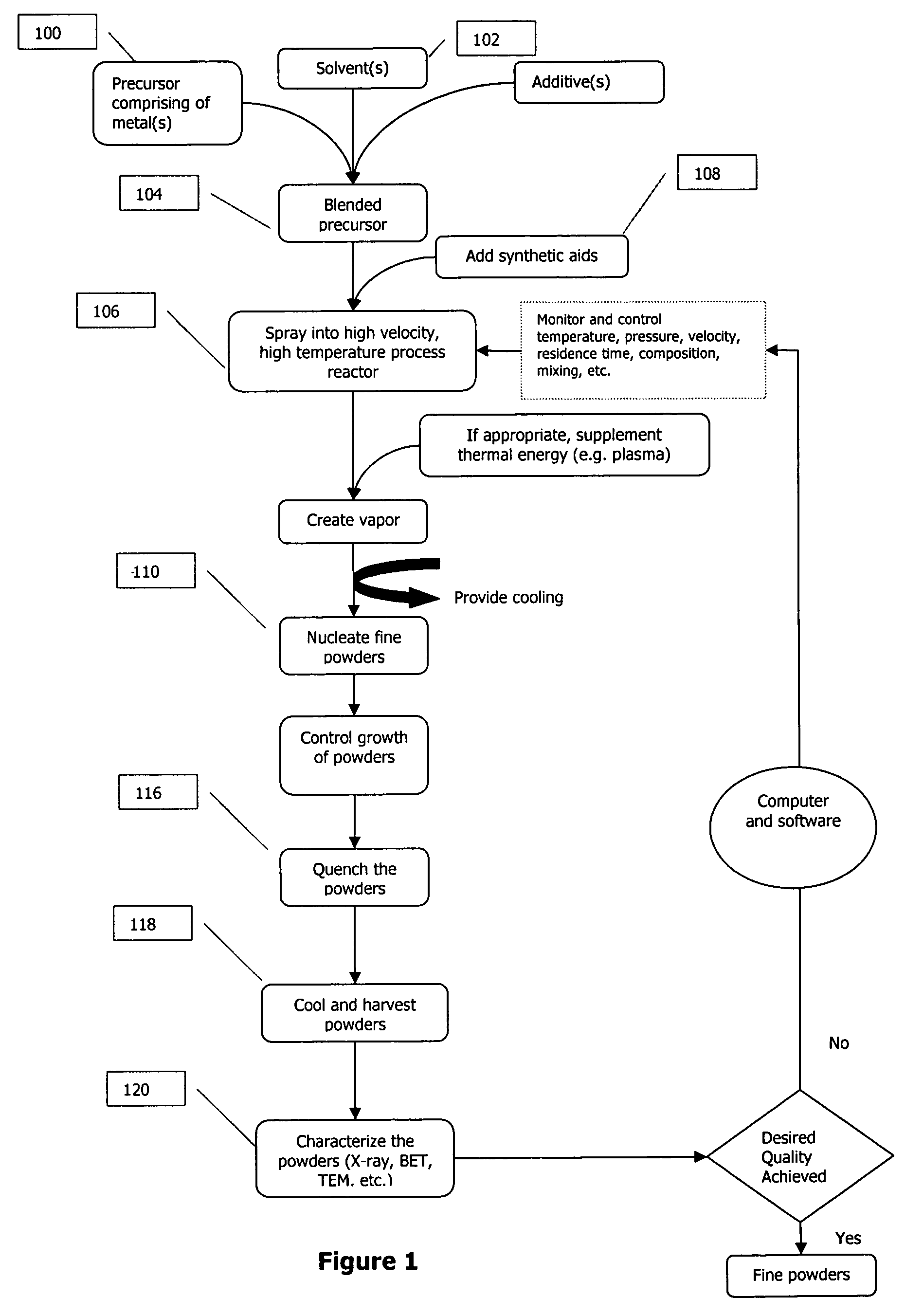

Methods for producing composite nanoparticles

InactiveUS6855426B2Improve performanceMaterial nanotechnologyLiquid surface applicatorsAlloyComposite nanoparticles

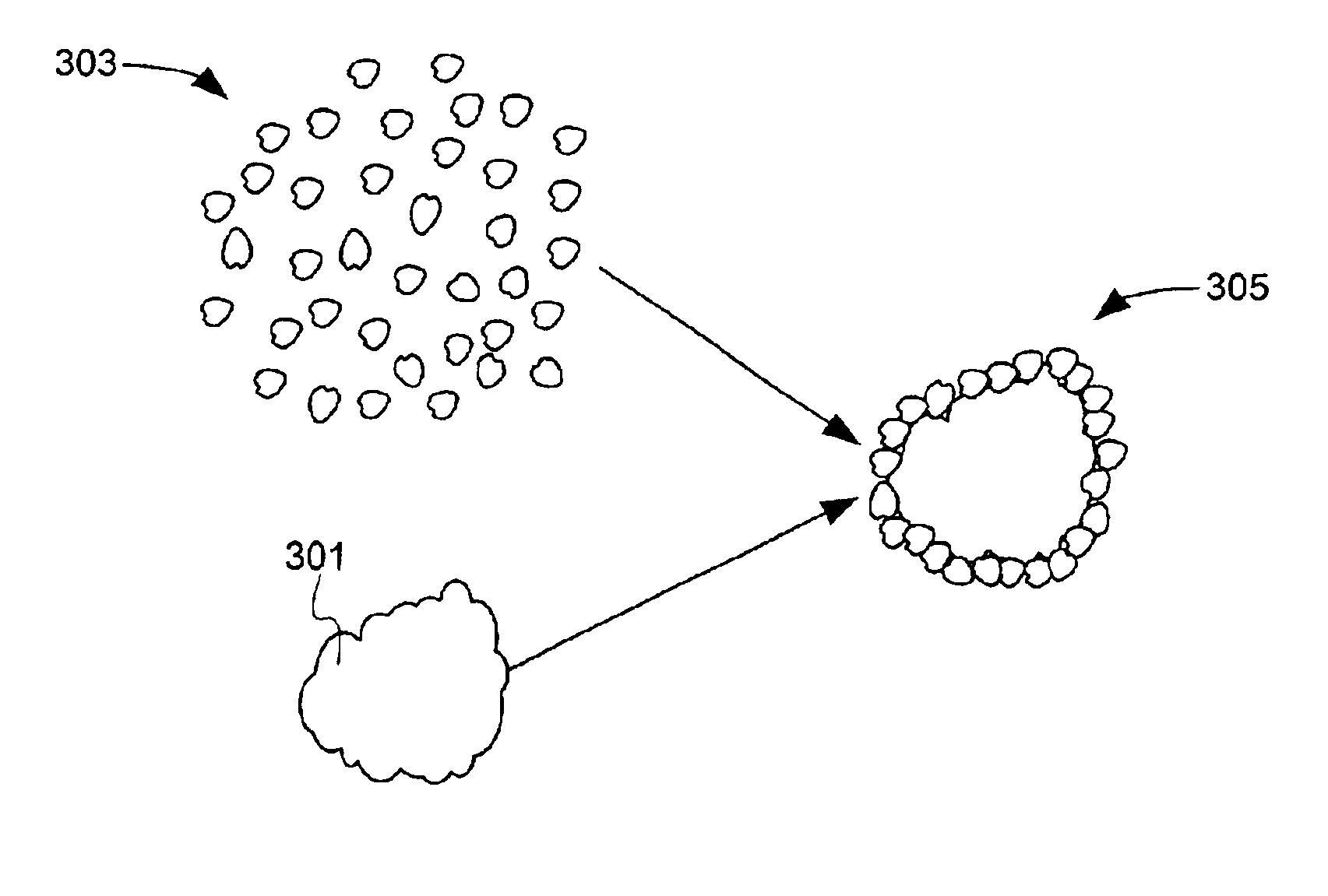

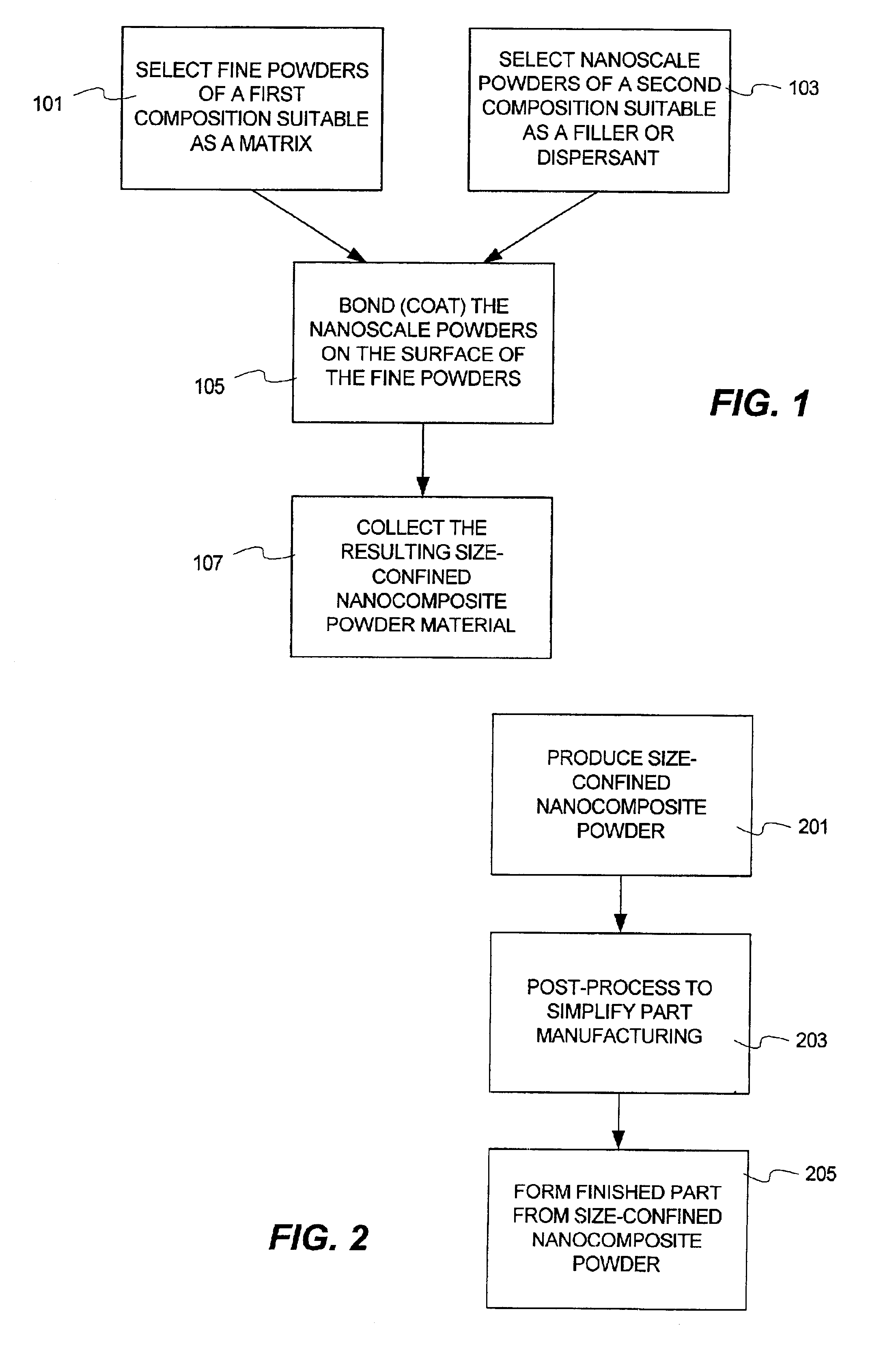

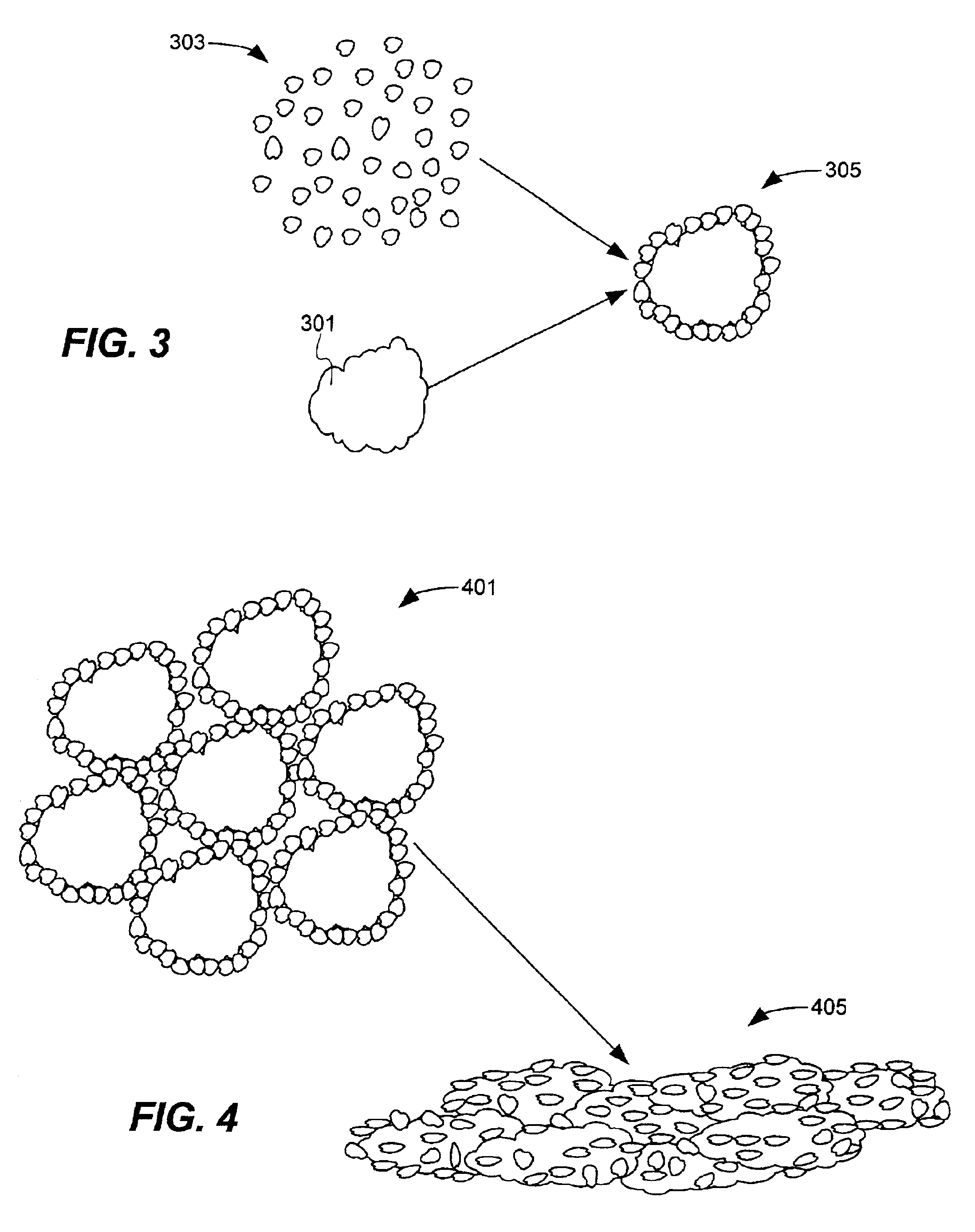

Size-confined nanocomposite powders and methods for their manufacture are provided by coating fine powders with a nanoscale powder of a different composition. The nanocomposite plastics disclosed offer performance characteristics approaching those of metals and alloys. The nanocomposite powders are alternatively used for dispersion strengthening of metals, alloys, and ceramics. Novel materials based nanotechnology for energy devices and programmable drug delivery are disclosed.

Owner:PPG IND OHIO INC

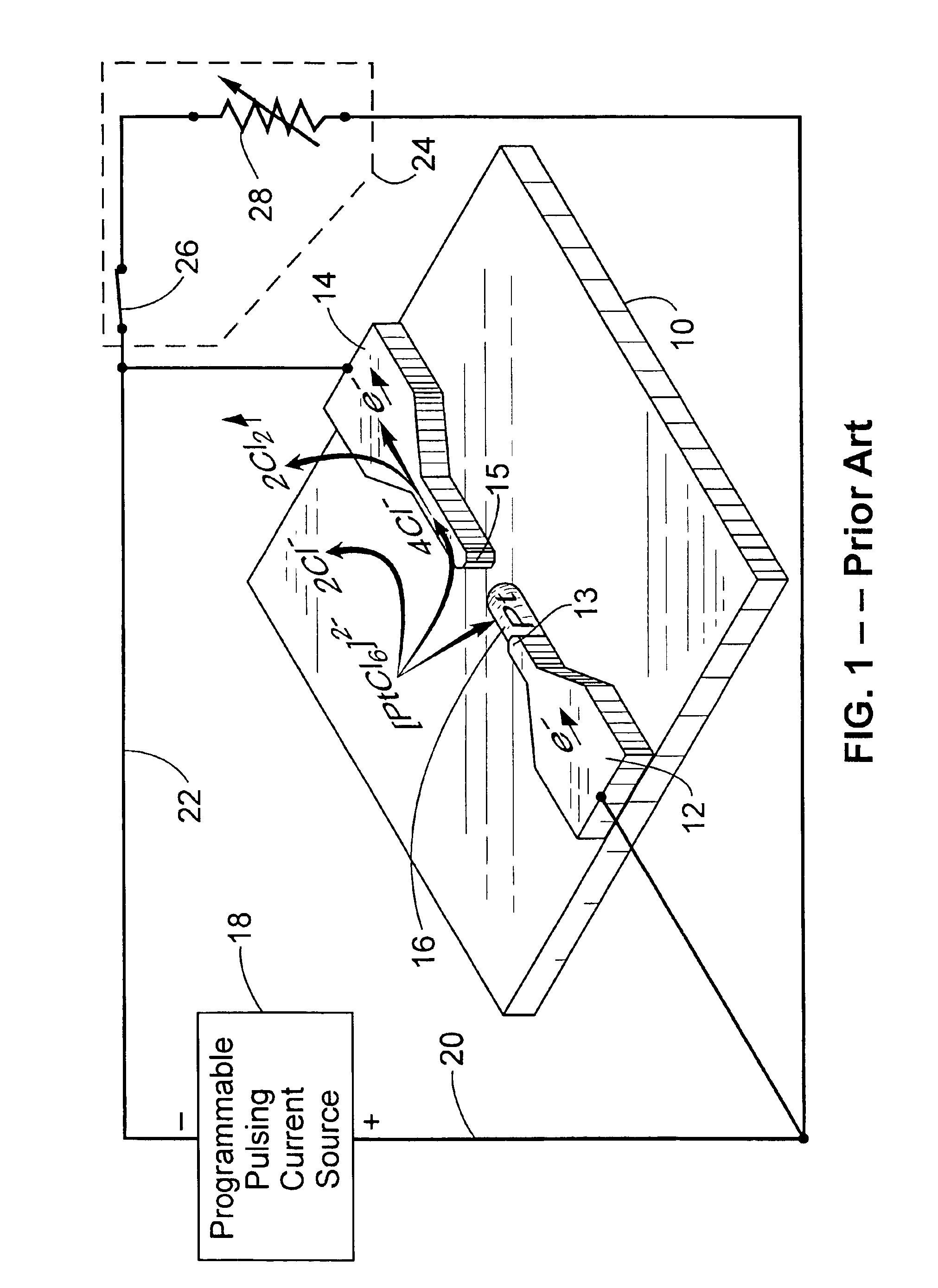

DNA and RNA sequencing by nanoscale reading through programmable electrophoresis and nanoelectrode-gated tunneling and dielectric detection

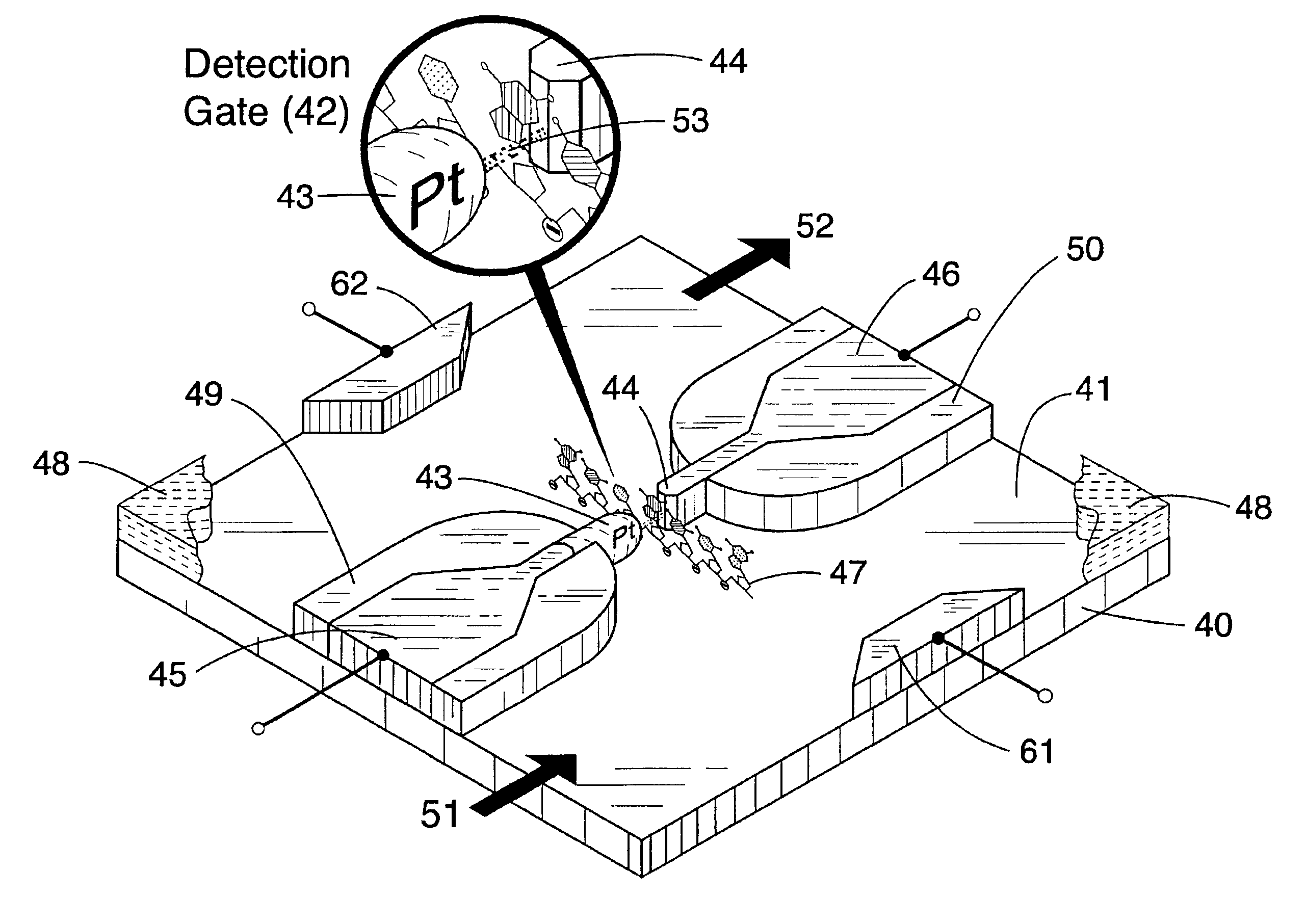

An apparatus and method for performing nucleic acid (DNA and / or RNA) sequencing on a single molecule. The genetic sequence information is obtained by probing through a DNA or RNA molecule base by base at nanometer scale as though looking through a strip of movie film. This DNA sequencing nanotechnology has the theoretical capability of performing DNA sequencing at a maximal rate of about 1,000,000 bases per second. This enhanced performance is made possible by a series of innovations including: novel applications of a fine-tuned nanometer gap for passage of a single DNA or RNA molecule; thin layer microfluidics for sample loading and delivery; and programmable electric fields for precise control of DNA or RNA movement. Detection methods include nanoelectrode-gated tunneling current measurements, dielectric molecular characterization, and atomic force microscopy / electrostatic force microscopy (AFM / EFM) probing for nanoscale reading of the nucleic acid sequences.

Owner:UT BATTELLE LLC

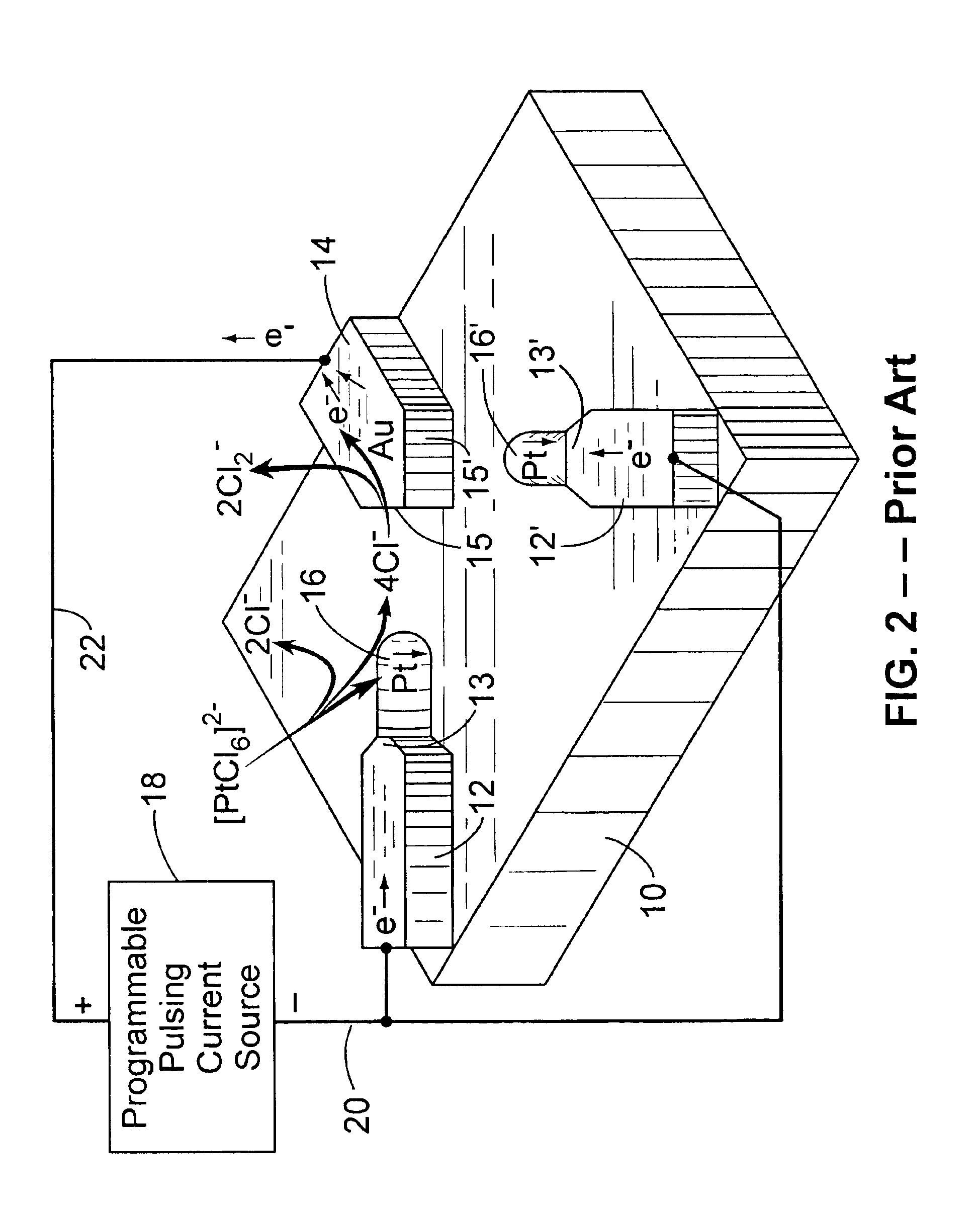

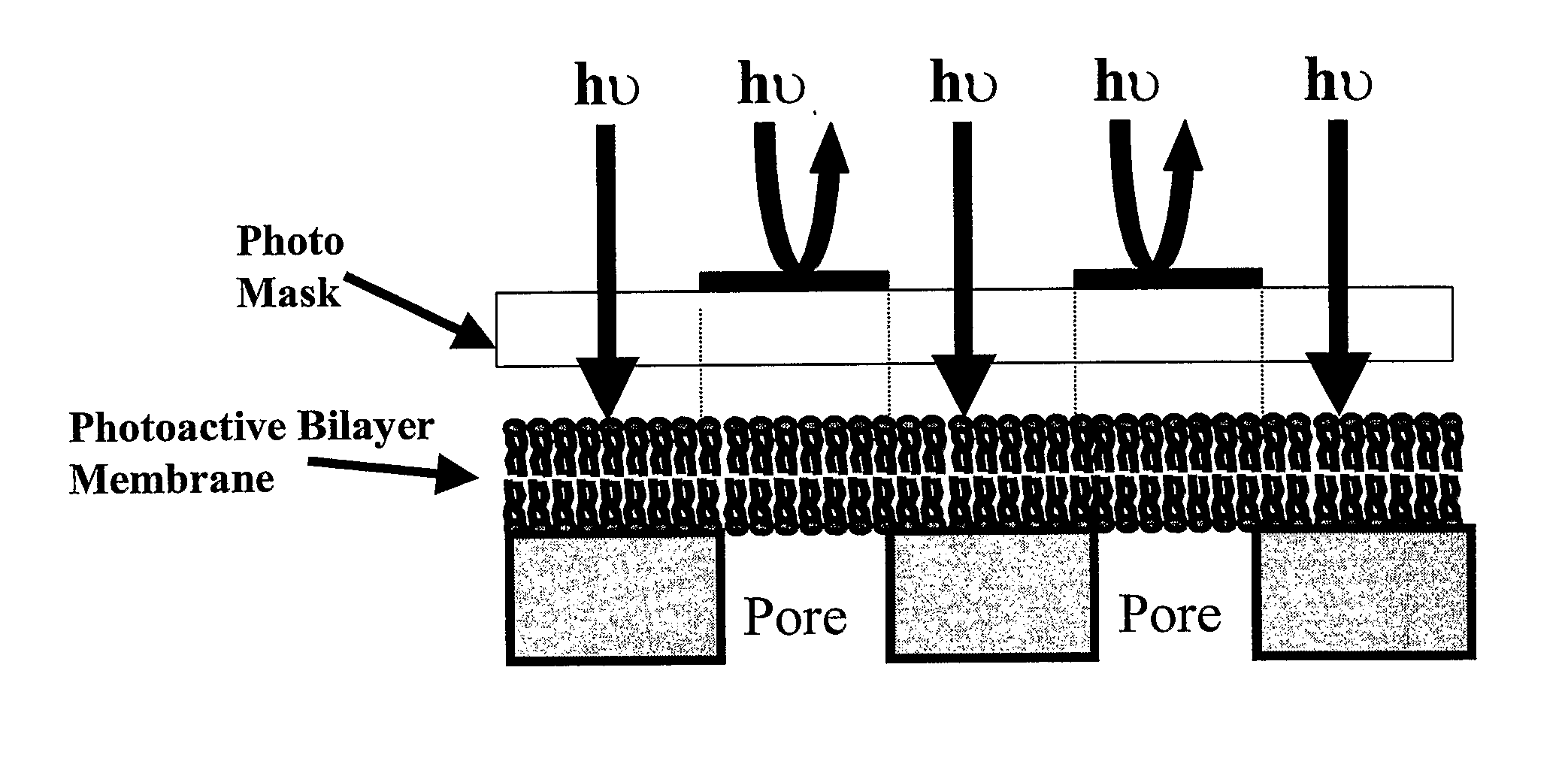

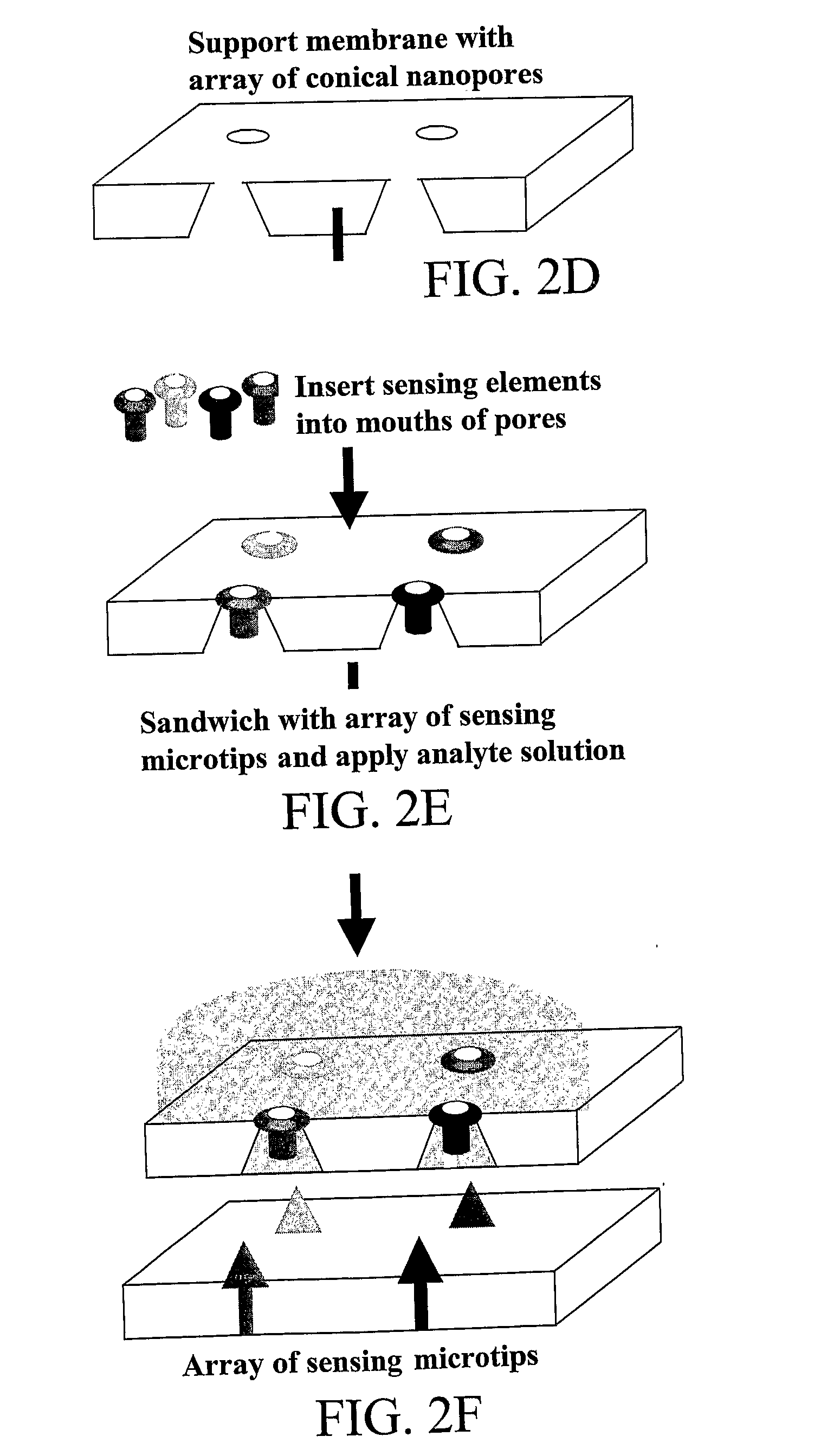

Chemical, Particle, and Biosensing with Nanotechnology

InactiveUS20080025875A1Reduce manufacturing costEase and flexibility of preparationBioreactor/fermenter combinationsBiological substance pretreatmentsBiological macromoleculeMolecular recognition

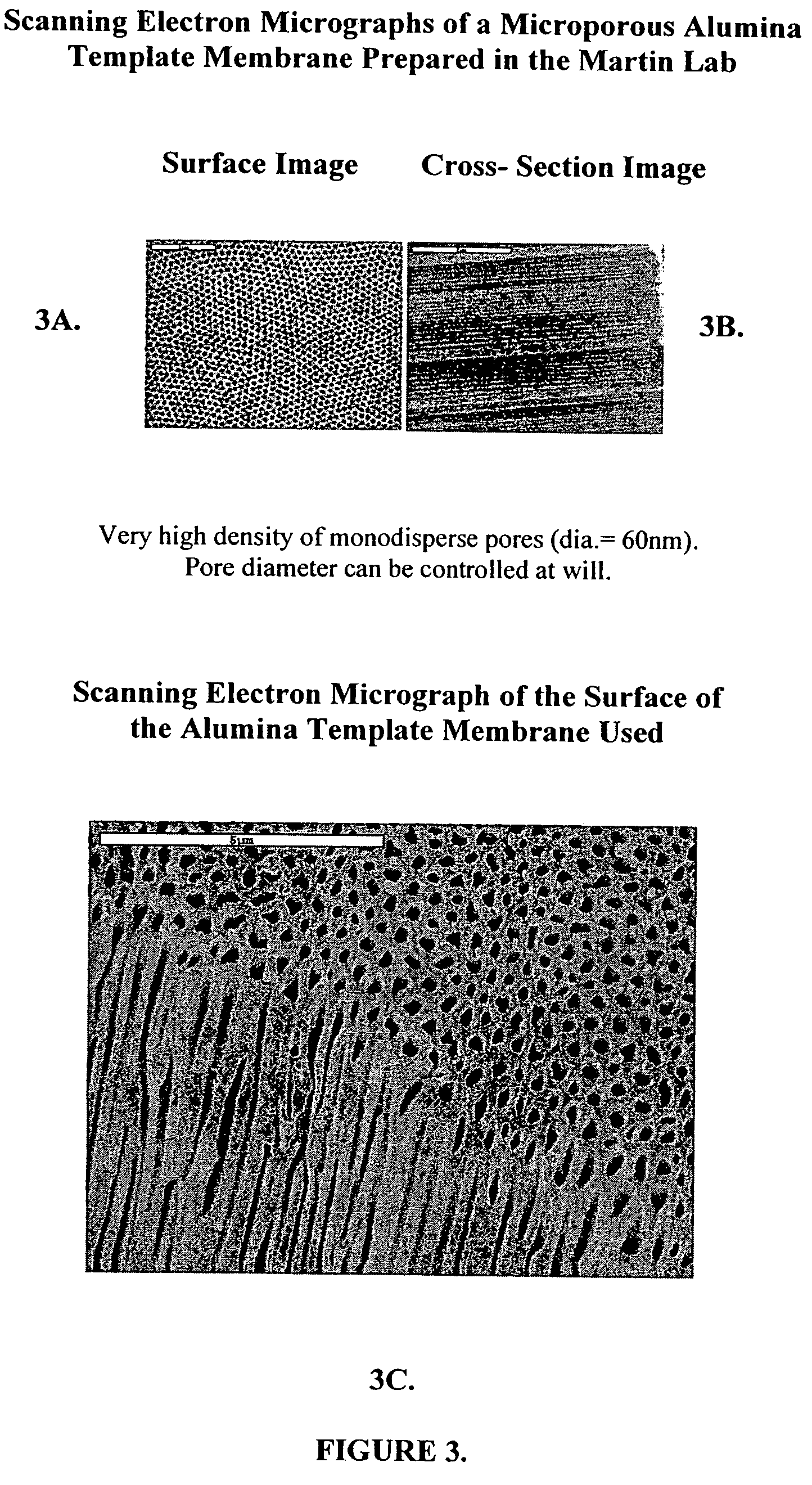

The subject invention provides novel and efficacious systems and methods for particle, chemical, and / or biocompound sensing. In one embodiment, the system of the invention comprises a sensing device that includes a membrane containing at least one nanochannel that spans all or substantially all of the thickness of the membrane. The nanochannel(s) of the invention can be functionalized to enhance target analyte detection and quantification. In one embodiment, the nanochannel is conically shaped and includes a molecular recognition agent for a target analyte. In certain operations, the sensing systems of the invention quantitatively and qualitatively detect biochemical / biomedical species and biomacromolecules, such as proteins, DNA, cells, spores and viruses, with a high degree of sensitivity and specificity.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

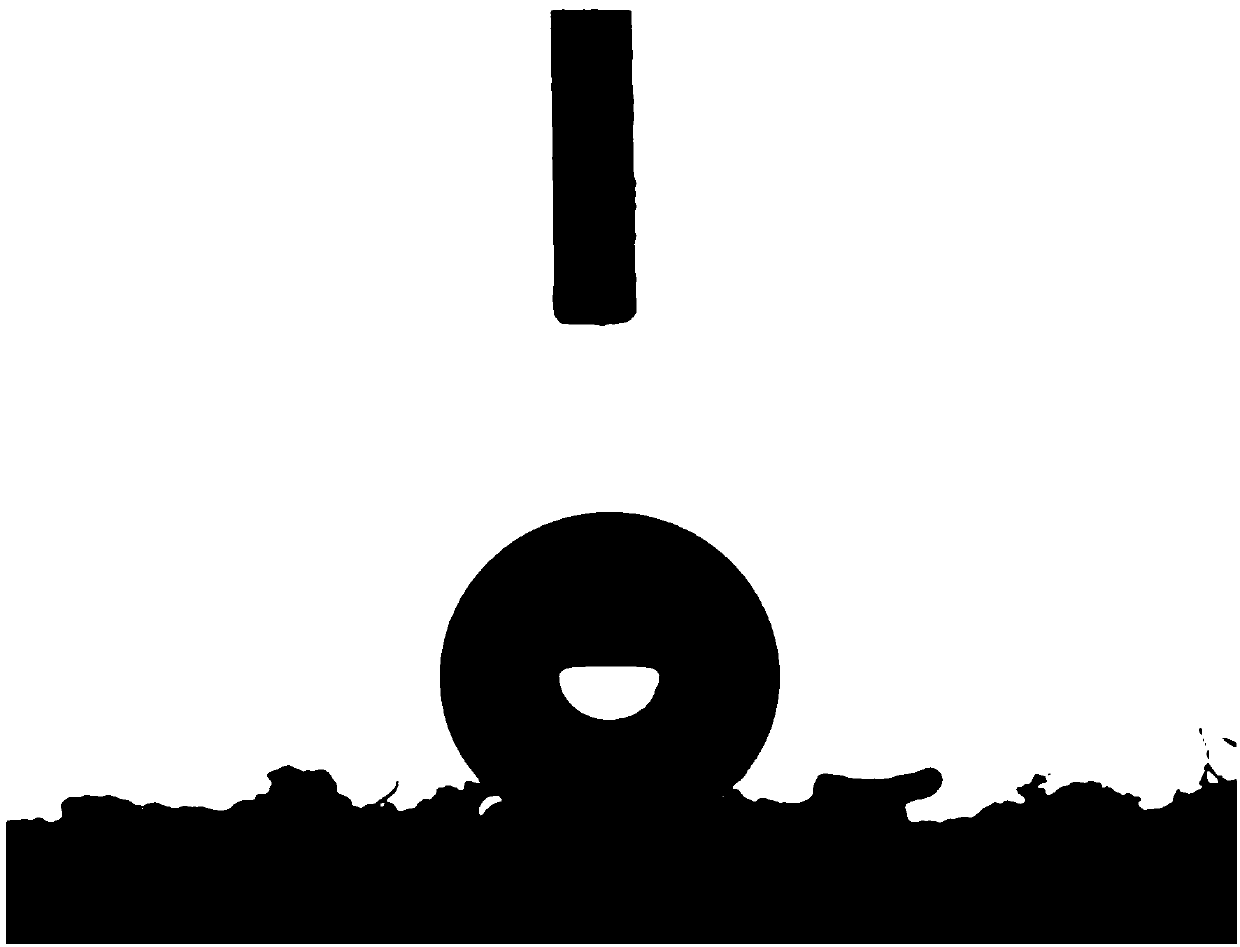

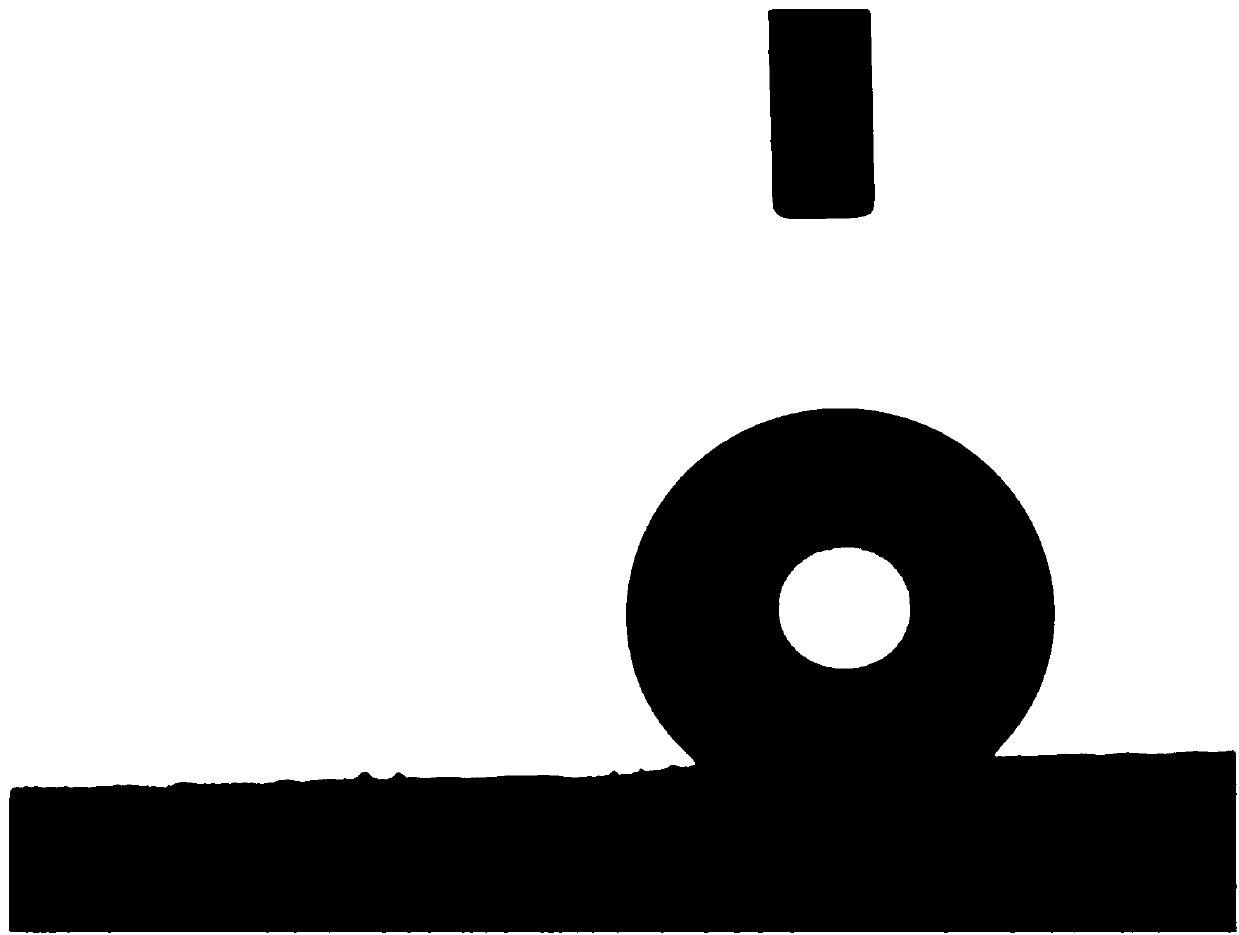

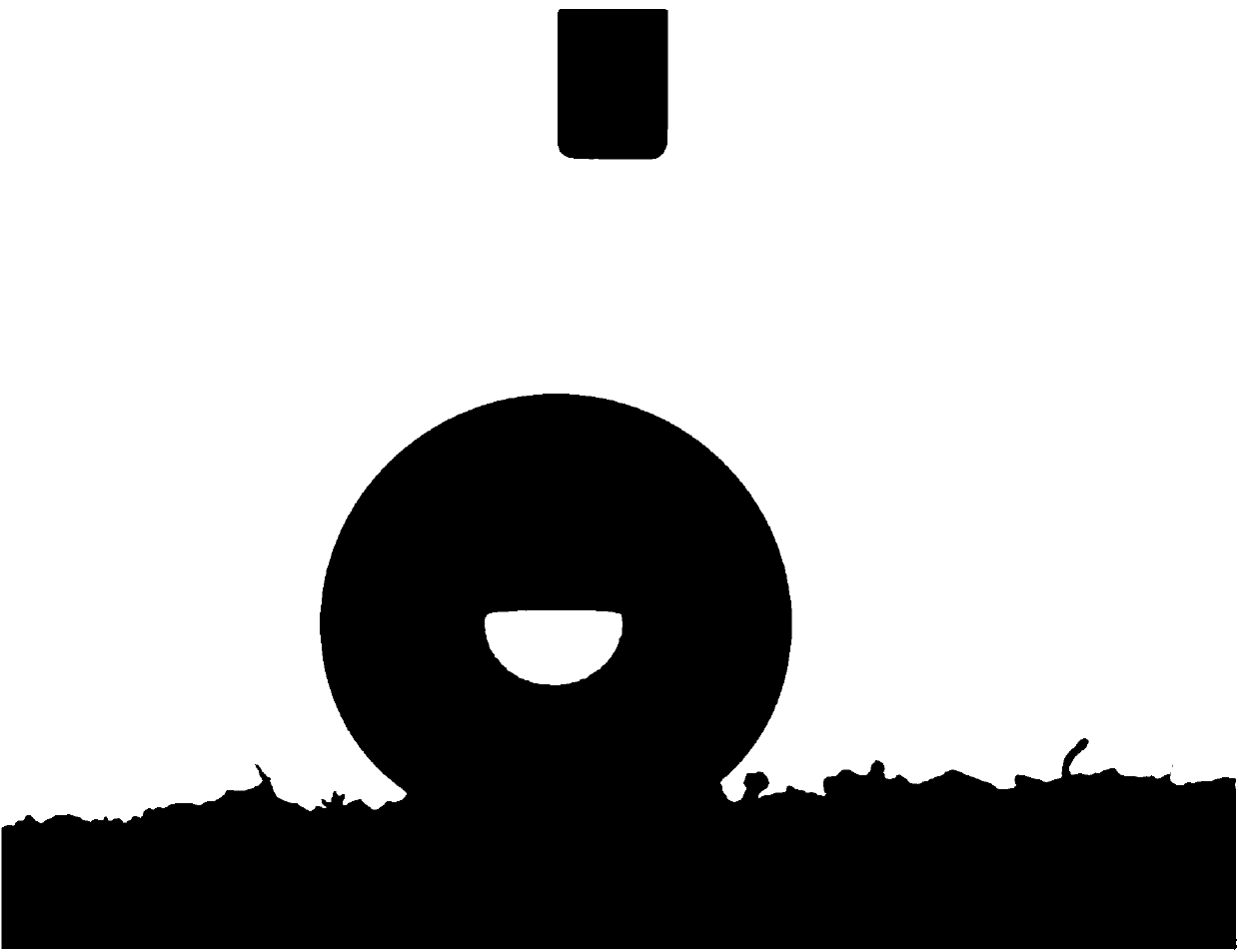

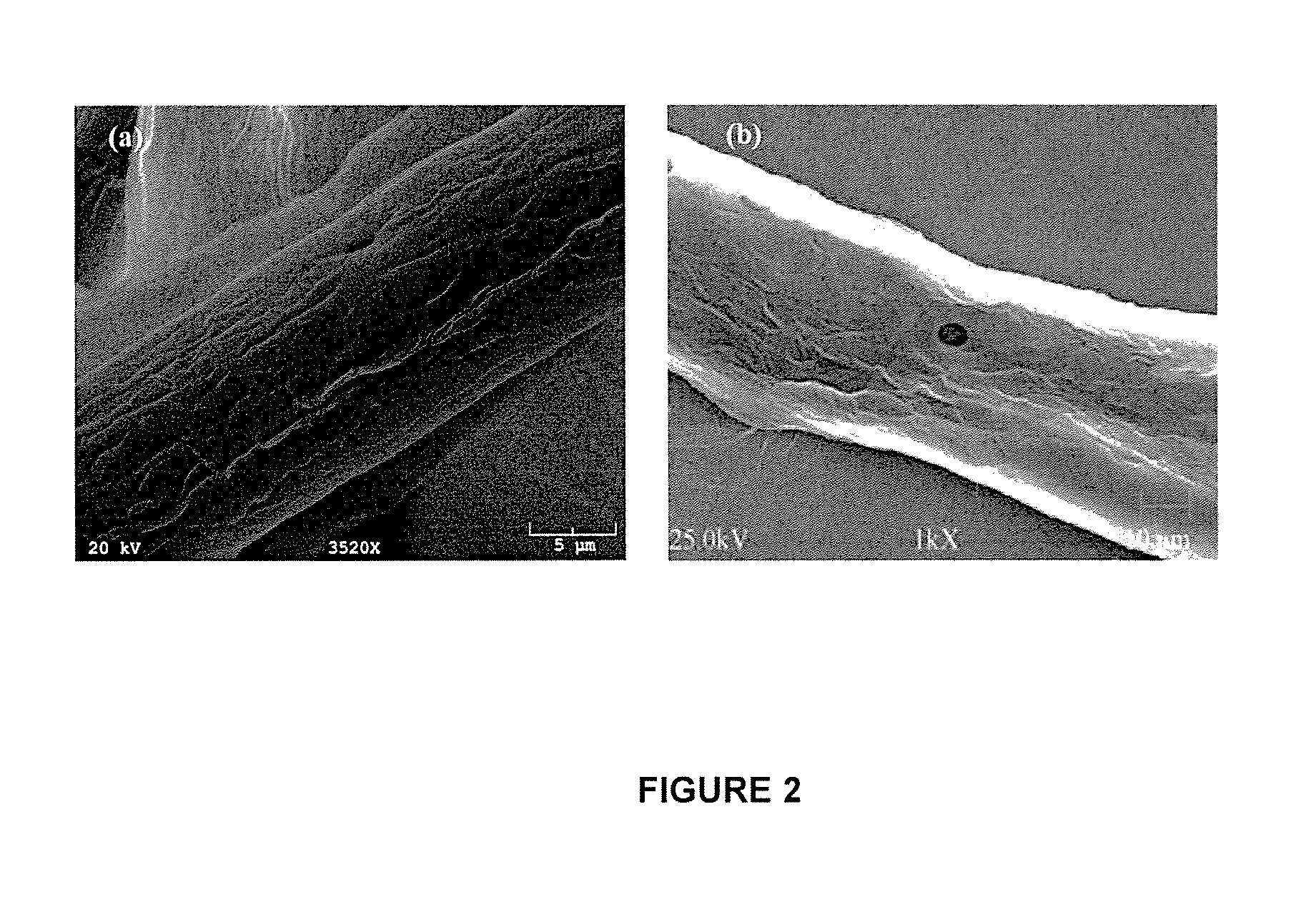

Preparation method for super-hydrophobic material

The invention provides a preparation method for a super-hydrophobic material. The method comprises the following steps: (1) modifying the integral three-dimensional structure of a substrate material by using a nanomaterial with a nanotechnology, so that the roughness of the integral three-dimensional structure of the material is increased; (2) coating the material with a low-surface-energy substance through a surface modifying technology to obtain the super-hydrophobic material. The static contact angle between the super-hydrophobic material and water is 152-158 degrees. The prepared super-hydrophobic material has superior hydrophobicity, the preparation process is simple, the reaction conditions are mild, and special machining equipment is not needed.

Owner:SICHUAN UNIV

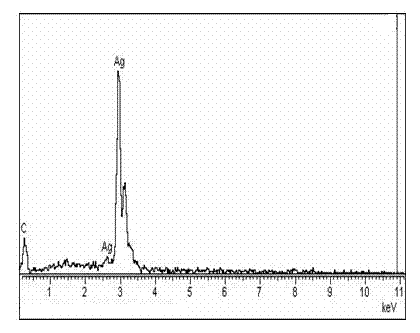

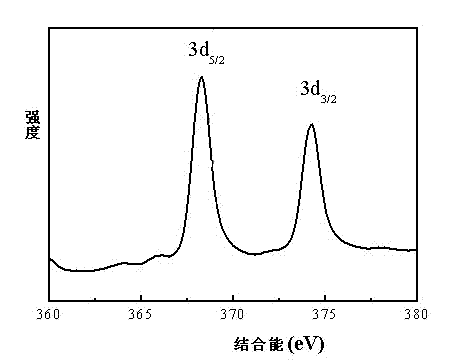

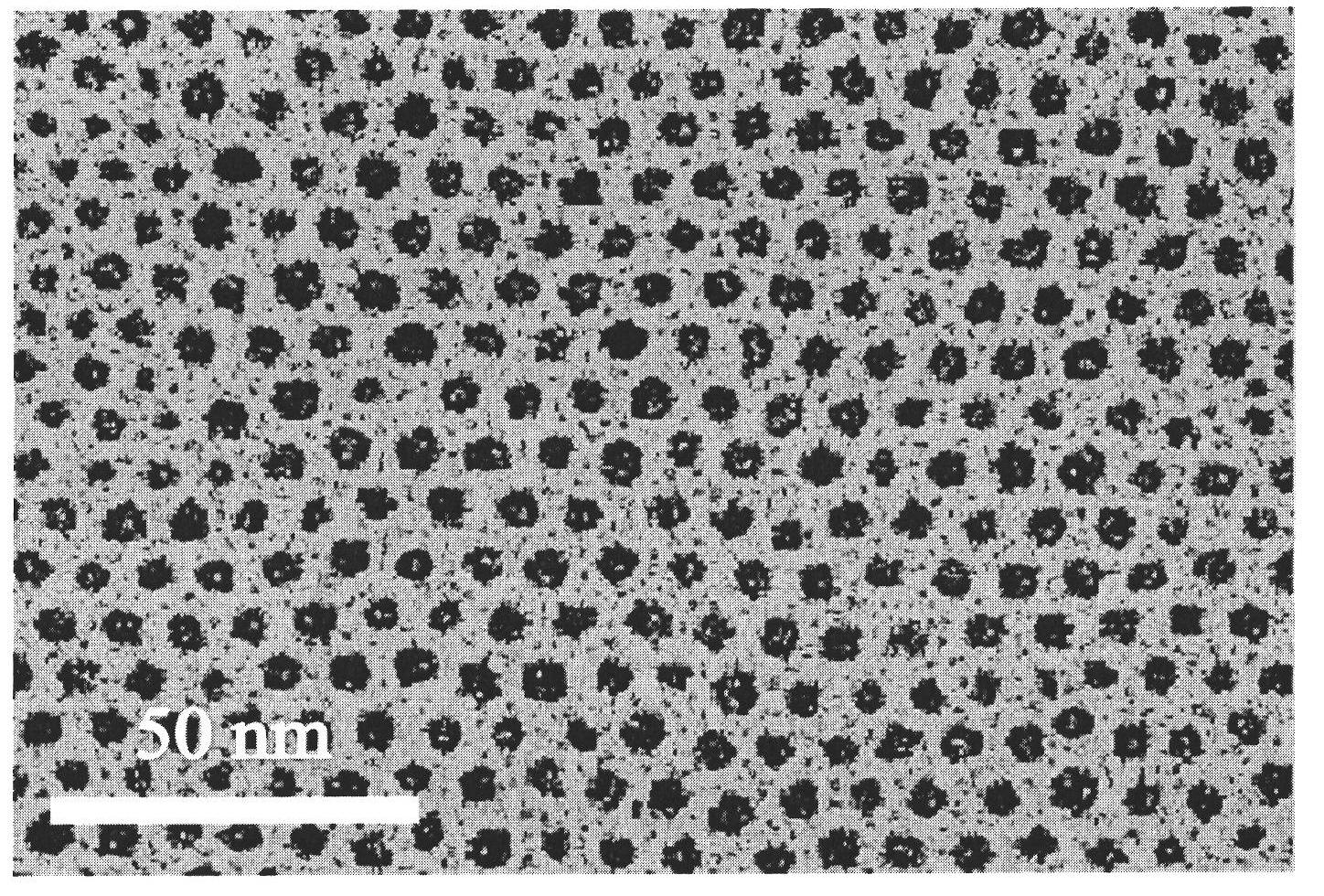

Method for preparing spherical nano-silver particles

The invention provides a method for preparing spherical nano-silver particles and belongs to the field of nanotechnology. The method comprises the following steps: (1) mixing sodium salt, macromolecular protective agent and polyhydric alcohol uniformly to obtain a mixed solution A; (2) mixing silver nitrate and polyhydric alcohol uniformly to obtain a mixed solution B; (3) dropwise adding the mixed solution A into the mixed solution B, and mixing the solutions A and B uniformly to obtain a colloidal solution; (4) heating and reacting the colloidal solution obtained in step (3) for 1-5 min under the radiation of microwave of 300-550 W, and cooling the reaction product to the room temperature to obtain the spherical nano-silver particles, wherein the macromolecular protective agent is polyvinylpyrrolidone or citric acid. The spherical nano-silver particles prepared by the method have the advantages of uniform particle size, dispersibility, short reaction time, high production efficiency and high yield.

Owner:TAIYUAN UNIV OF TECH

Tungsten comprising nanomaterials and related nanotechnology

InactiveUS7708974B2Increase volumeLow cost productionNanostructure manufactureCell electrodesPhotonicsNanotechnology Techniques

Nanoparticles comprising tungsten, methods of manufacturing nanoparticles comprising tungsten, and applications of nanoparticles comprising tungsten, such as electronics, optical devices, photonics, reagents for fine chemical synthesis, pigments, and catalysts are provided.

Owner:PPG IND OHIO INC

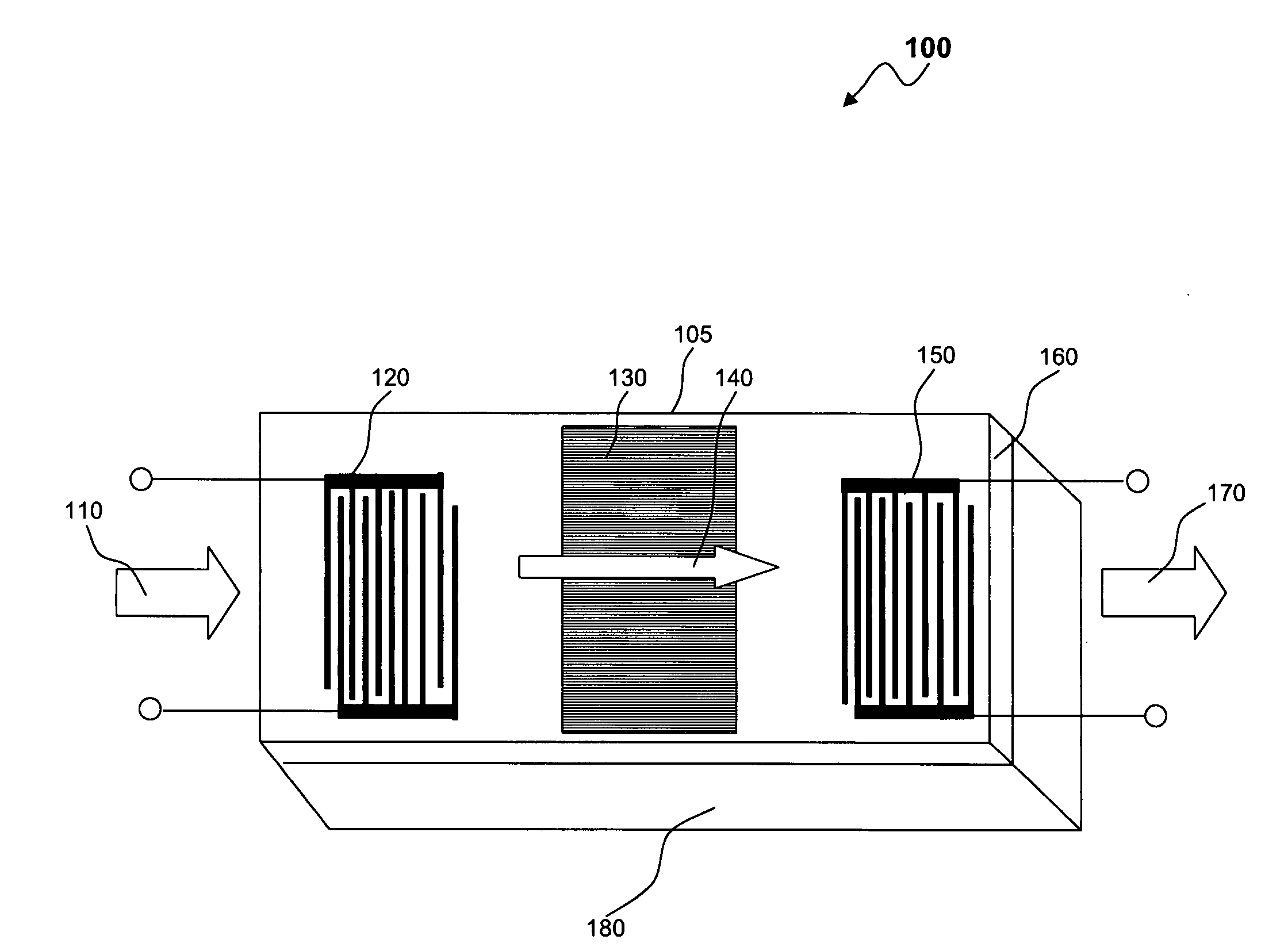

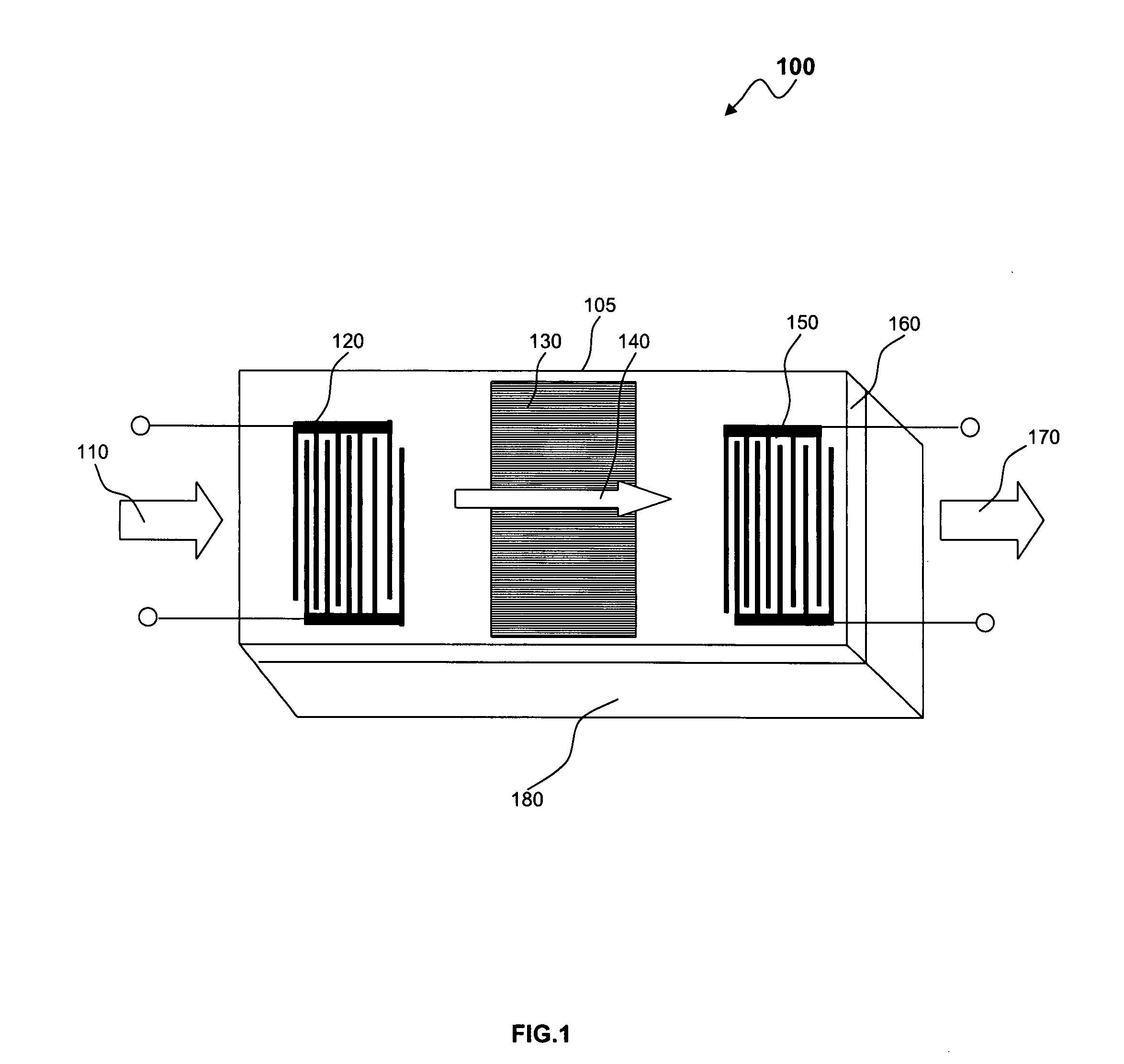

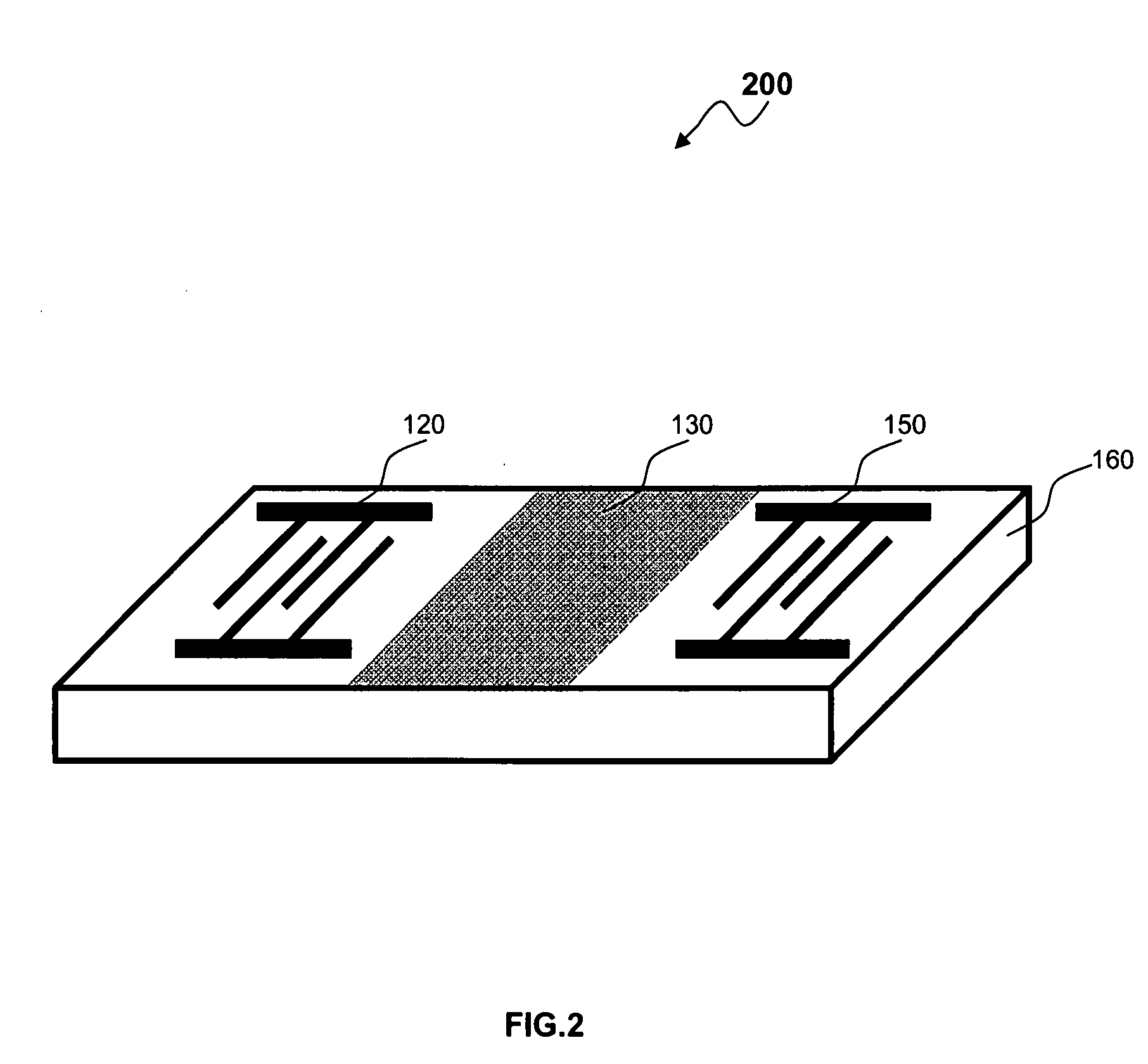

Saw based CO2 sensors using carbon nanotubes as the sensitive layer

InactiveUS20080216558A1Easy to understandAnalysing fluids using sonic/ultrasonic/infrasonic wavesGas analyser construction detailsRoom temperatureNanotechnology Techniques

A surface acoustic wave based CO2 sensor using carbon nanotubes as the sensitive layer fabricated by combining surface acoustic wave (SAW) devices and nanotechnology. The device structure consists of the gas sensitive material between the input and output interdigital transducers (IDTs) of a SAW device. The CO2 gas gets adsorbed on nanotubes when the carbon nanotube based SAW sensor is exposed to CO2 at room temperature and / or at elevated temperature, which in turn changes conductivity of the carbon nanotube. This conductivity change will affect the velocity of the SAW traveling across the nanotubes and will give a frequency change which corresponds to the percentage of the CO2 molecules adsorbed by the nanotubes.

Owner:HONEYWELL INT INC

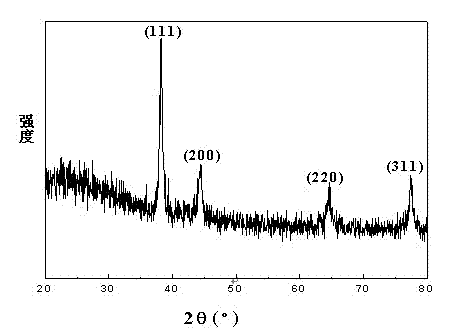

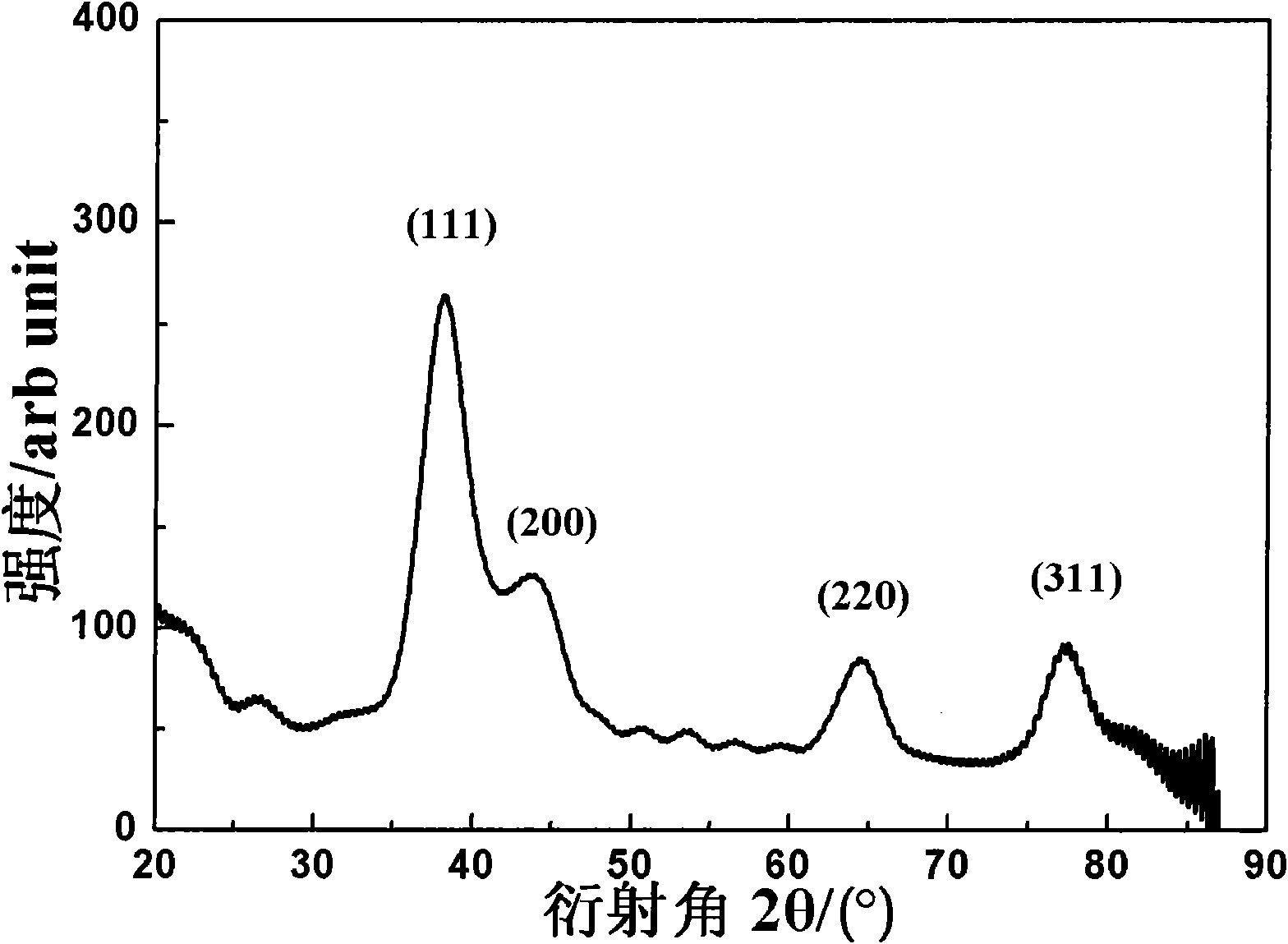

Organic-inorganic hybrid silicates and metal-silicates having an ordered structure

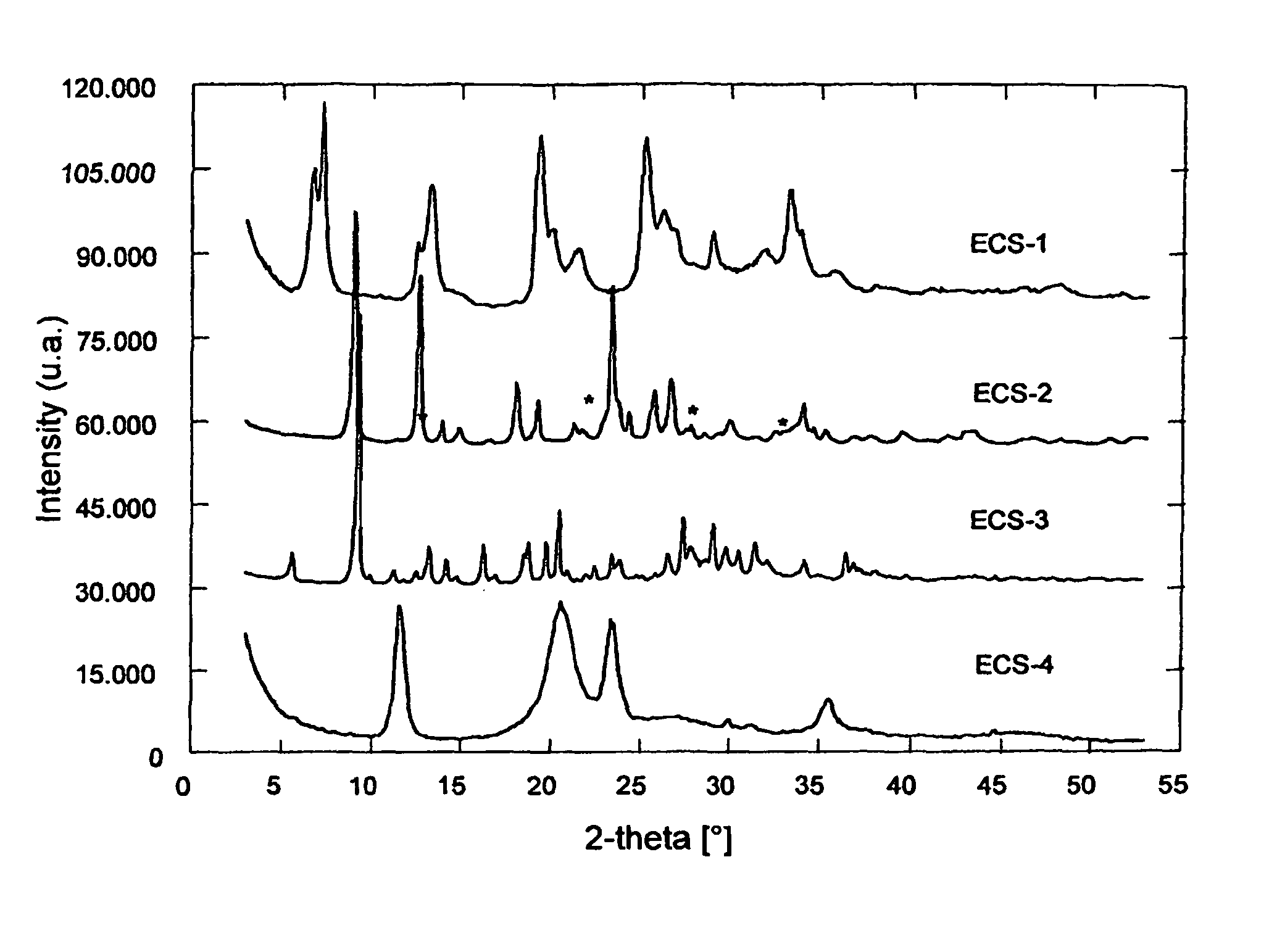

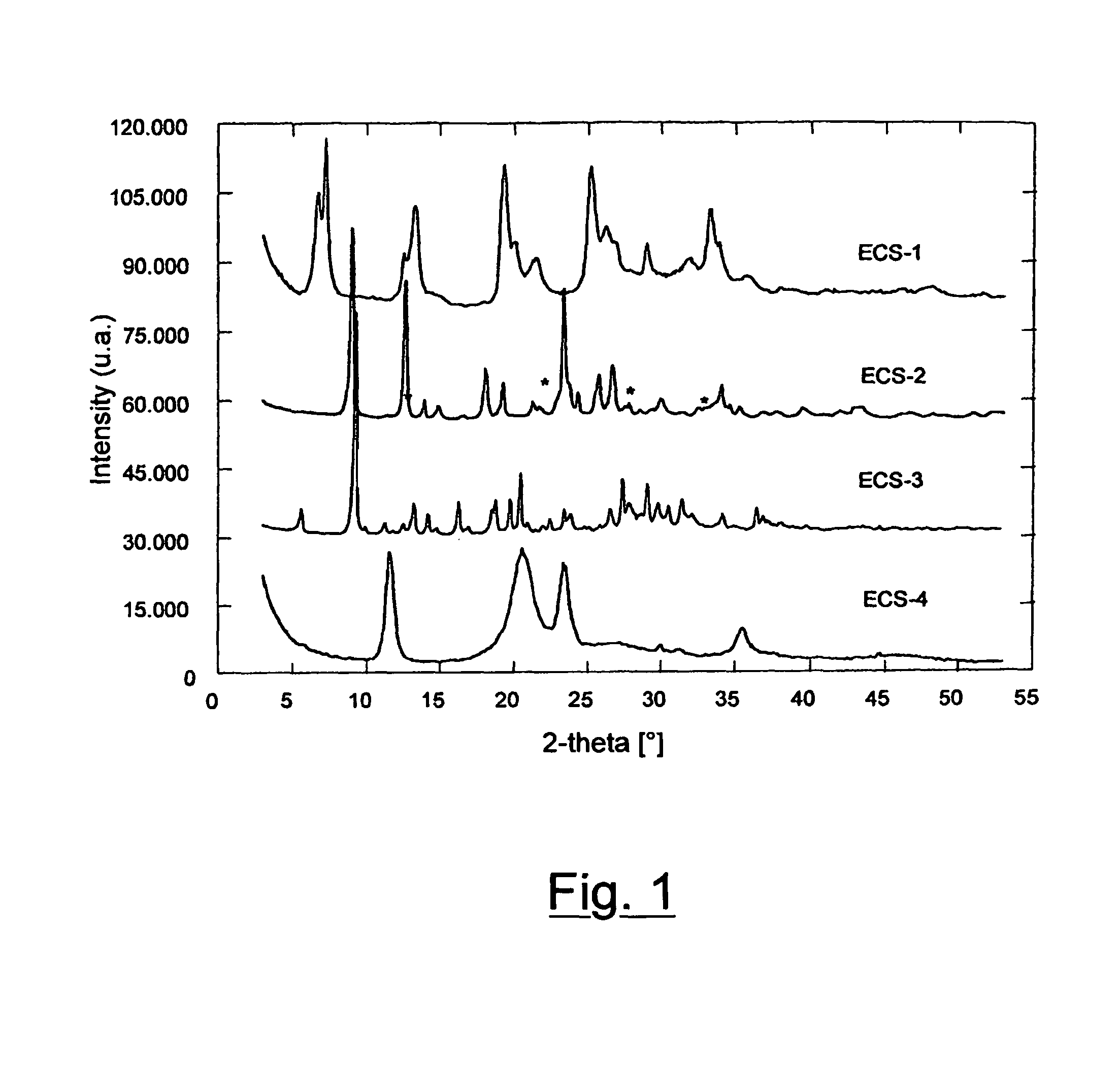

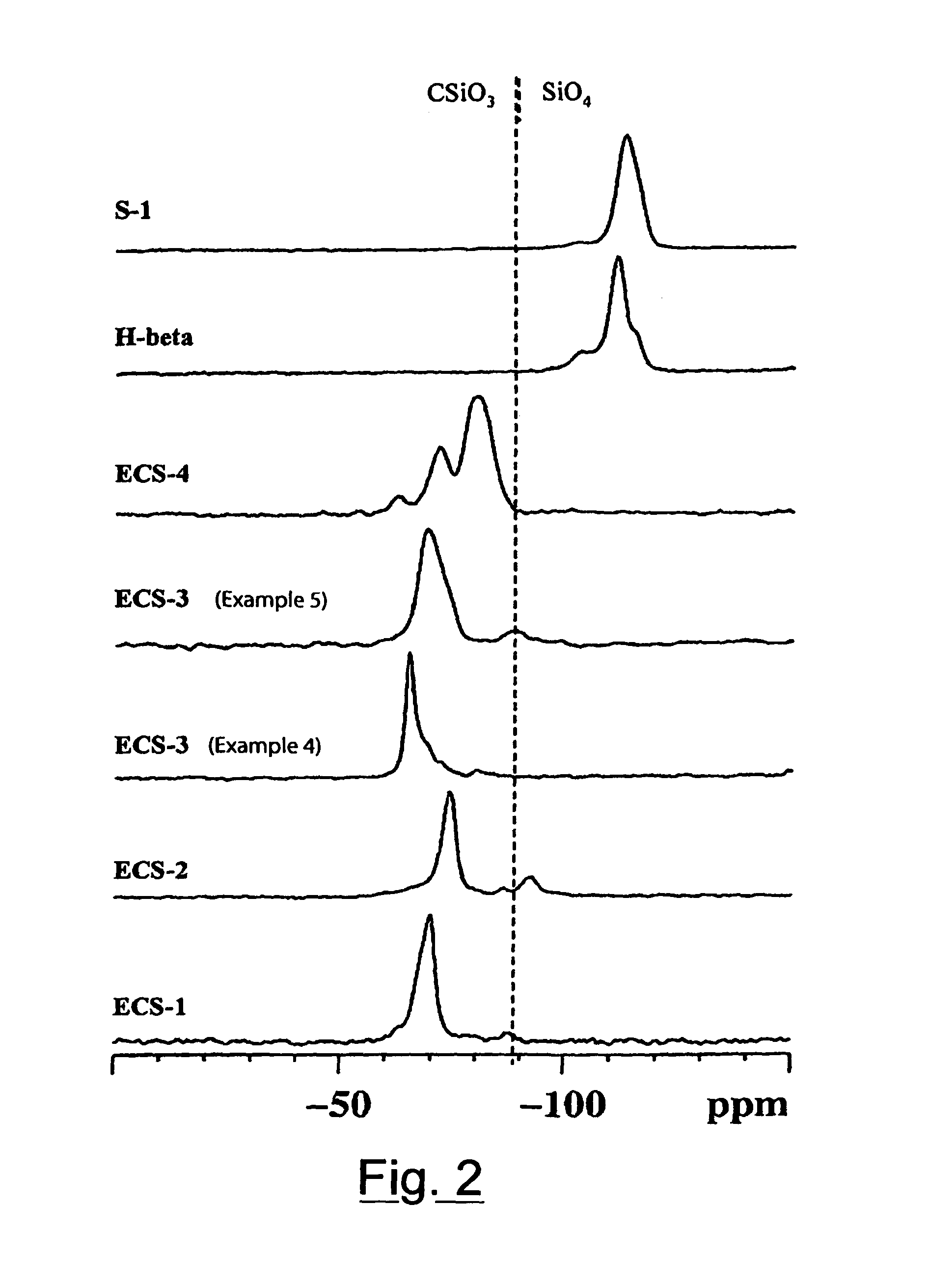

The present invention relates to new organic-inorganic hybrid silicates and metal-silicates called ECS, characterized by an X-ray powder diffraction pattern with reflections exclusively at angular values higher than 4.0° of 2θ, preferably at angular values higher than 4.7°, and an ordered structure containing structural units having formula (a) wherein R is an organic group: Formula (a) and possibly containing one or more elements T selected from groups III B, IV B, V B and transition metals, with a Si / (Si +T) molar ratio in said structure higher than 0.3 and lower than or equal to 1, wherein Si is the silicon contained in the structural unit (a). A process is also described, starting from disilanes, for the preparation of these materials, which does not include the use of templates or surfactants. These materials can be used as molecular sieves, adsorbents, in the field of catalysis, in the field of electronics, in the field of sensors, in the field of nanotechnologies.

Owner:ENI SPA

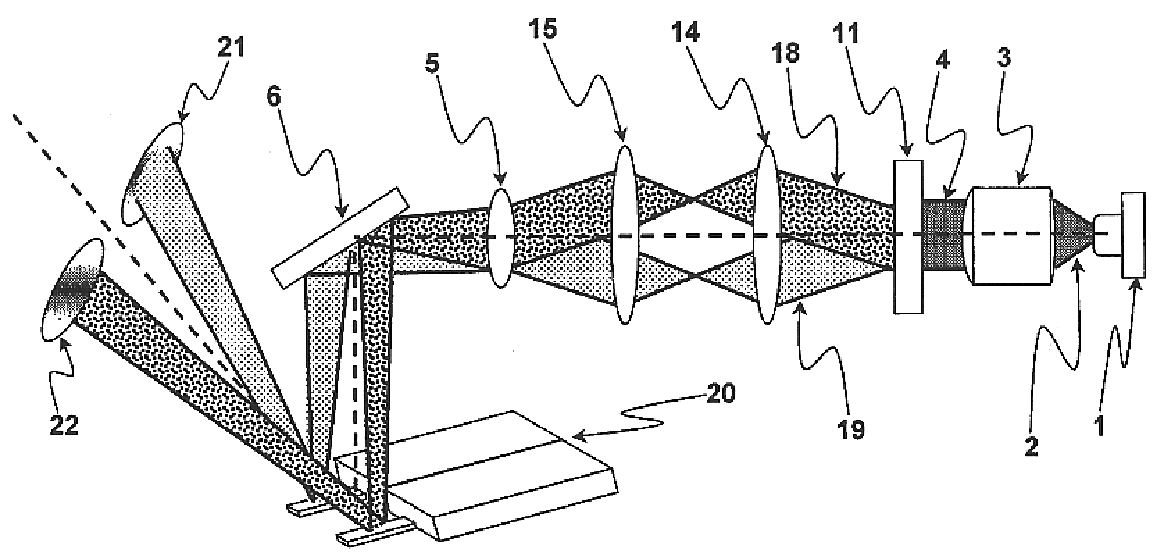

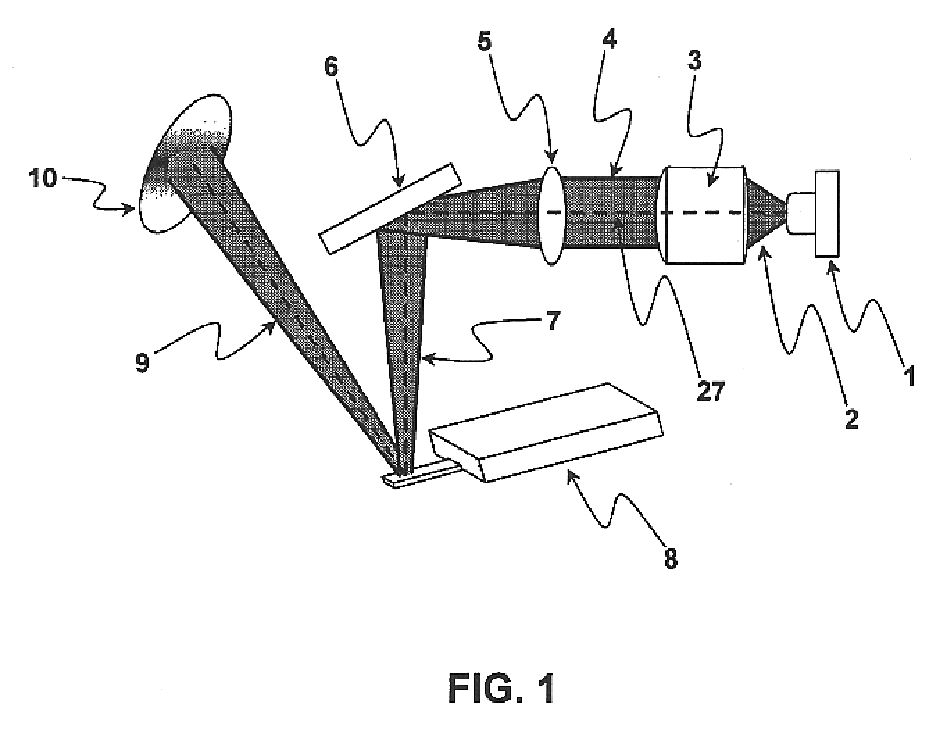

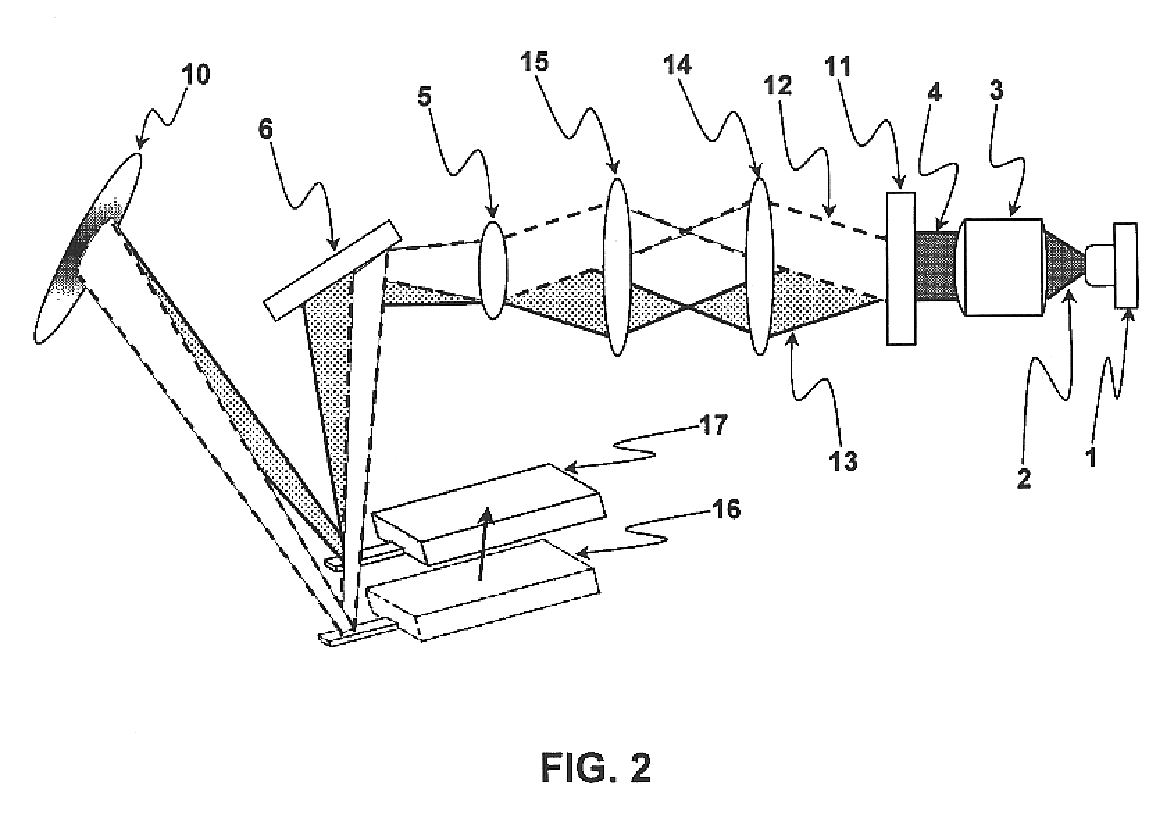

Diffractive optical position detector

InactiveUS6884981B2Limited spaceOptimizing optical lever sensitivityMaterial analysis using wave/particle radiationBeam/ray focussing/reflecting arrangementsAtomic force microscopyOptical measurements

An apparatus and method for measuring optically the position or angle of a variety of objects or arrays of objects, including cantilevers in scanning probe microscopy, micromechanical biological and chemical sensors and the sample or a probe in surface profilometry. The invention involves the use of one or more diffractive optical elements, including diffraction gratings and holograms, combined with conventional optical elements, to form a plurality of light beams, each with a selectable shape and intensity, from a single light source, reflect the beams off mechanical objects and process the reflected beams, all to the end of measuring the position of such objects with a high degree of precision. The invention may also be used to effect mechanical changes in such objects. Devices with these improvements have numerous applications, including molecular force measurements, atomic force microscopy and manipulation technology, lithographic manufacturing, nanometer scale surface profiling and other aspects of nanotechnology.

Owner:OXFORD INSTRUMENTS +1

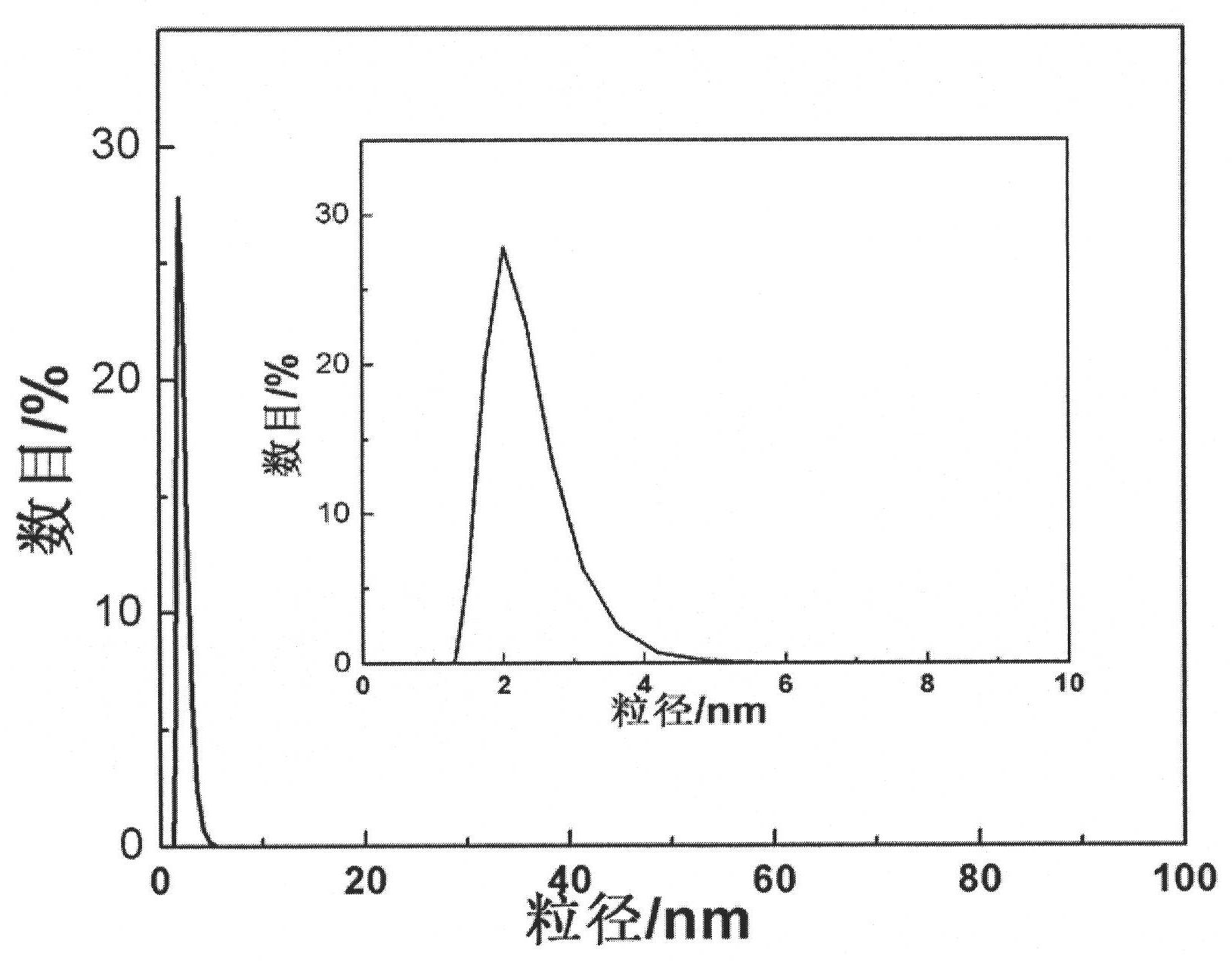

Method for preparing nano silver conductive ink

InactiveCN101870832ASimple processMild reaction conditionsInksMetallic pattern materialsSilver inkElectrolysis

The invention belongs to the field of nano technology and particularly relates to a method for preparing nano silver conductive ink. The method comprises the following steps: dissolving a silver salt and an organic protective agent in a solvent, adjusting the pH value of the solution to 9 to 10 with an alkaline complexing agent, and raising the temperature gradually to 30 to 100 DEG C till the reaction system is a transparent solution; and cooling the reaction system obtained by the previous step to room temperature, adding a reducer into the reaction system, and continuously stirring the reaction system for 20 to 30 minutes to obtain the nano silver conductive ink. The molar ratio of the organic protective agent to the silver salt is 0.01-3:1; each 0.01 mol of silver salt is dissolved in 5 to 50 milliliters of solvent; and the molar ratio of the reducer to the silver salt is 1-3:1. The nano silver prepared by the method has the advantages that: the particle size is less than 10 nanometers; the process is simple, the reaction conditions are mild and the reaction time is short; the raw materials are simple and the dose of the dispersant is small; the purity and concentration are high; and the conductive property is good. In addition, the preparation cost of the nano silver ink is low; no harmful waste is produced, so the requirements for 'green production' are met; and the nano silver ink can be widely used in fields of touch screens, electronic tags, thin film switches, flexible circuit boards, medical products, sensors, printing contact, radio frequency interference screening, electrolysis, multilayer circuit board hole filling and the like.

Owner:FUDAN UNIV

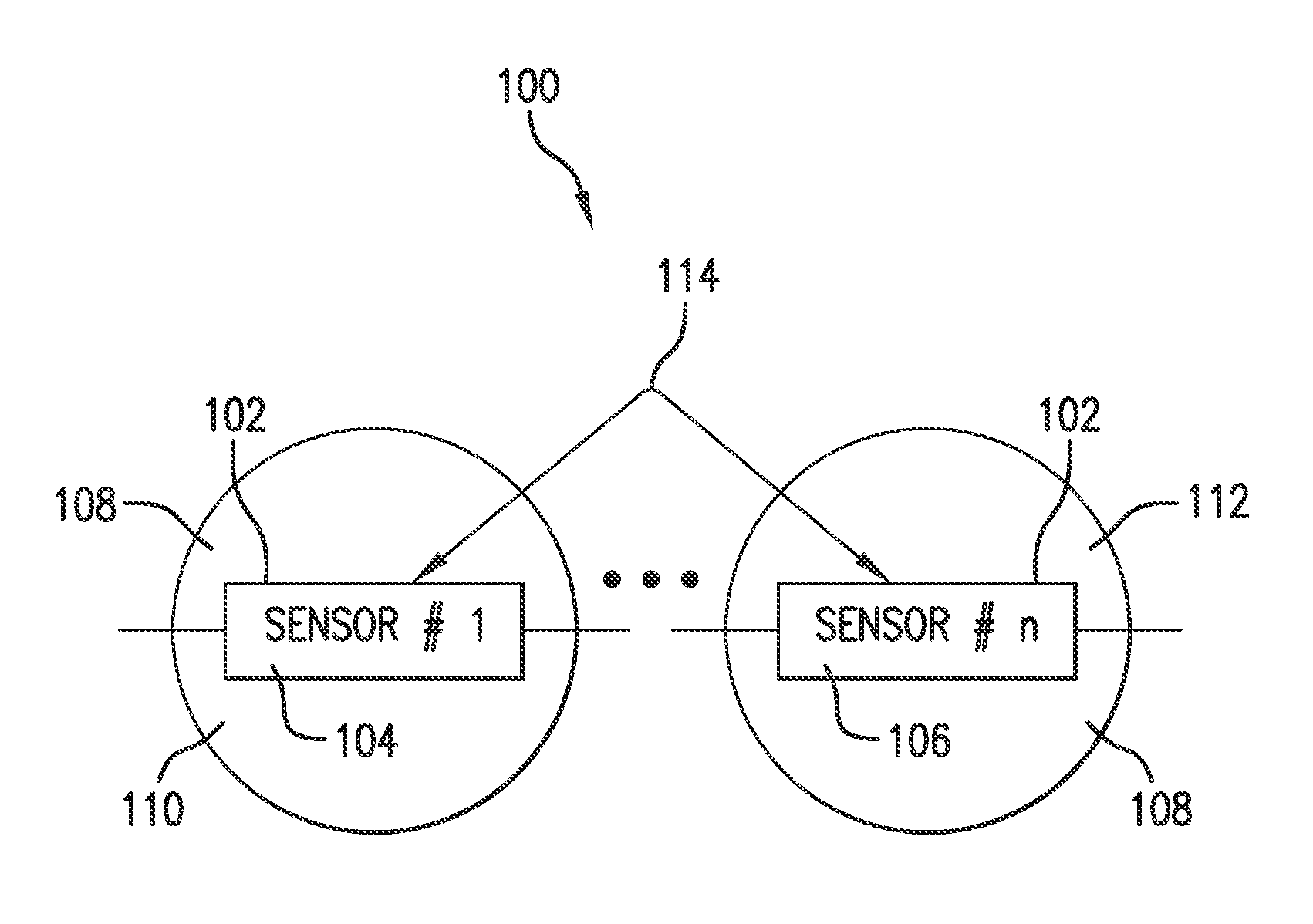

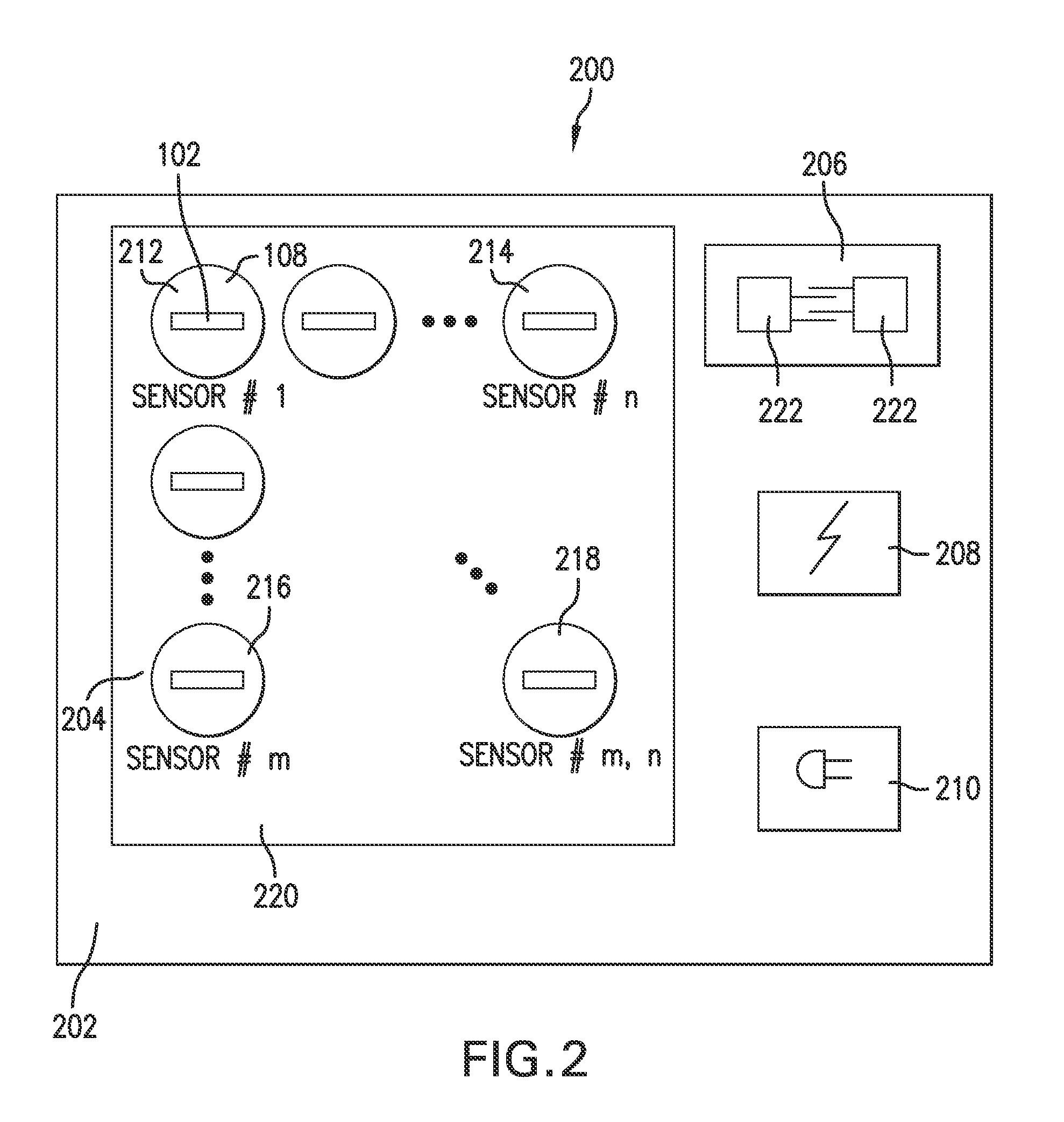

Wireless, motion and position-sensing, integrating radiation occupational and environmental dosimetry

ActiveUS8822924B2Measurement with semiconductor devicesNuclear energy generationAccelerometerFiltration

Described is a radiation dosimeter including multiple sensor devices (including one or more passive integrating electronic radiation sensor, a MEMS accelerometers, a wireless transmitters and, optionally, a GPS, a thermistor, or other chemical, biological or EMF sensors) and a computer program for the simultaneous detection and wireless transmission of ionizing radiation, motion and global position for use in occupational and environmental dosimetry. The described dosimeter utilizes new processes and algorithms to create a self-contained, passive, integrating dosimeter. Furthermore, disclosed embodiments provide the use of MEMS and nanotechnology manufacturing techniques to encapsulate individual ionizing radiation sensor elements within a radiation attenuating material that provides a “filtration bubble” around the sensor element, the use of multiple attenuating materials (filters) around multiple sensor elements, and the use of a software algorithm to discriminate between different types of ionizing radiation and different radiation energy.

Owner:LANDAUER INC

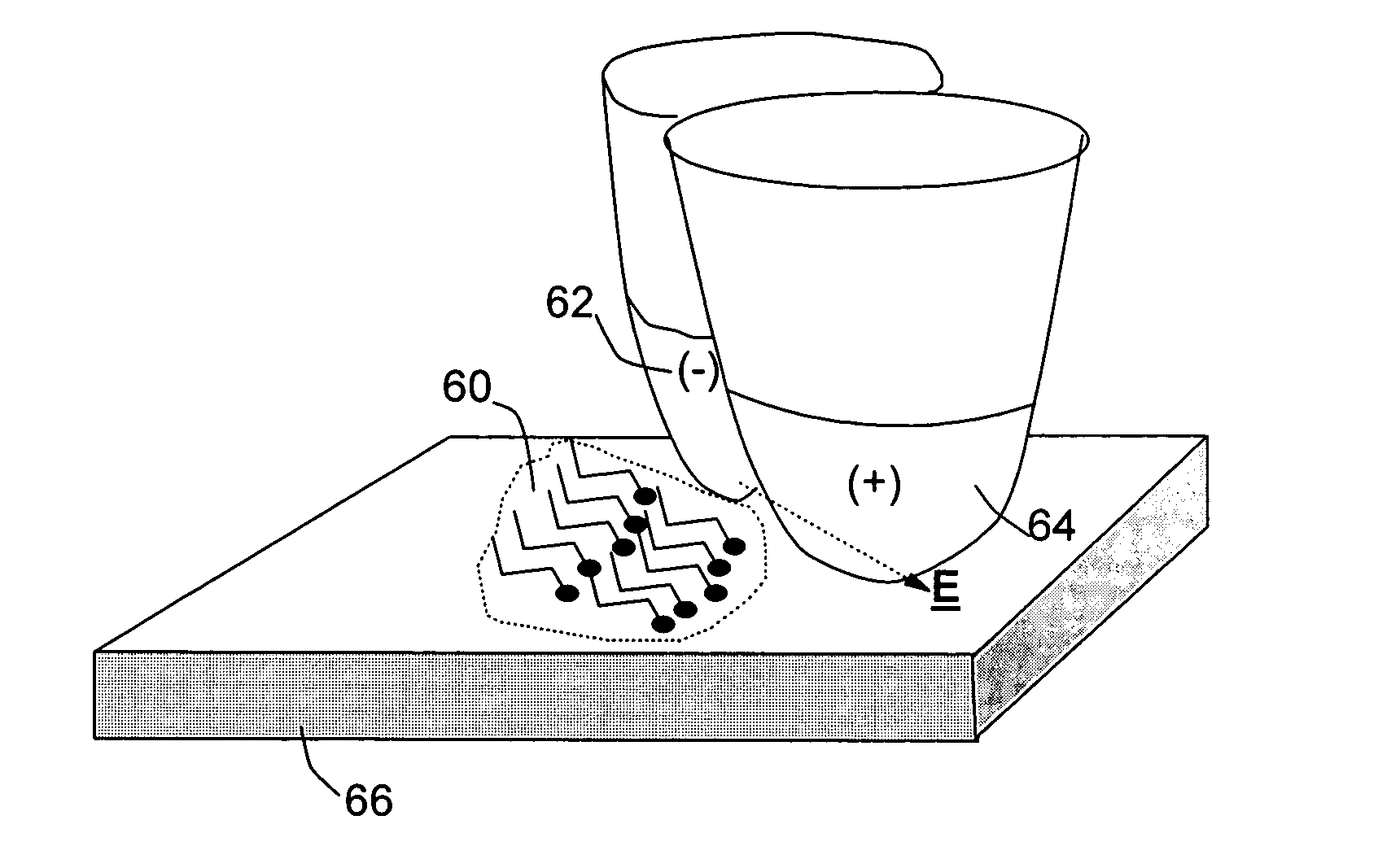

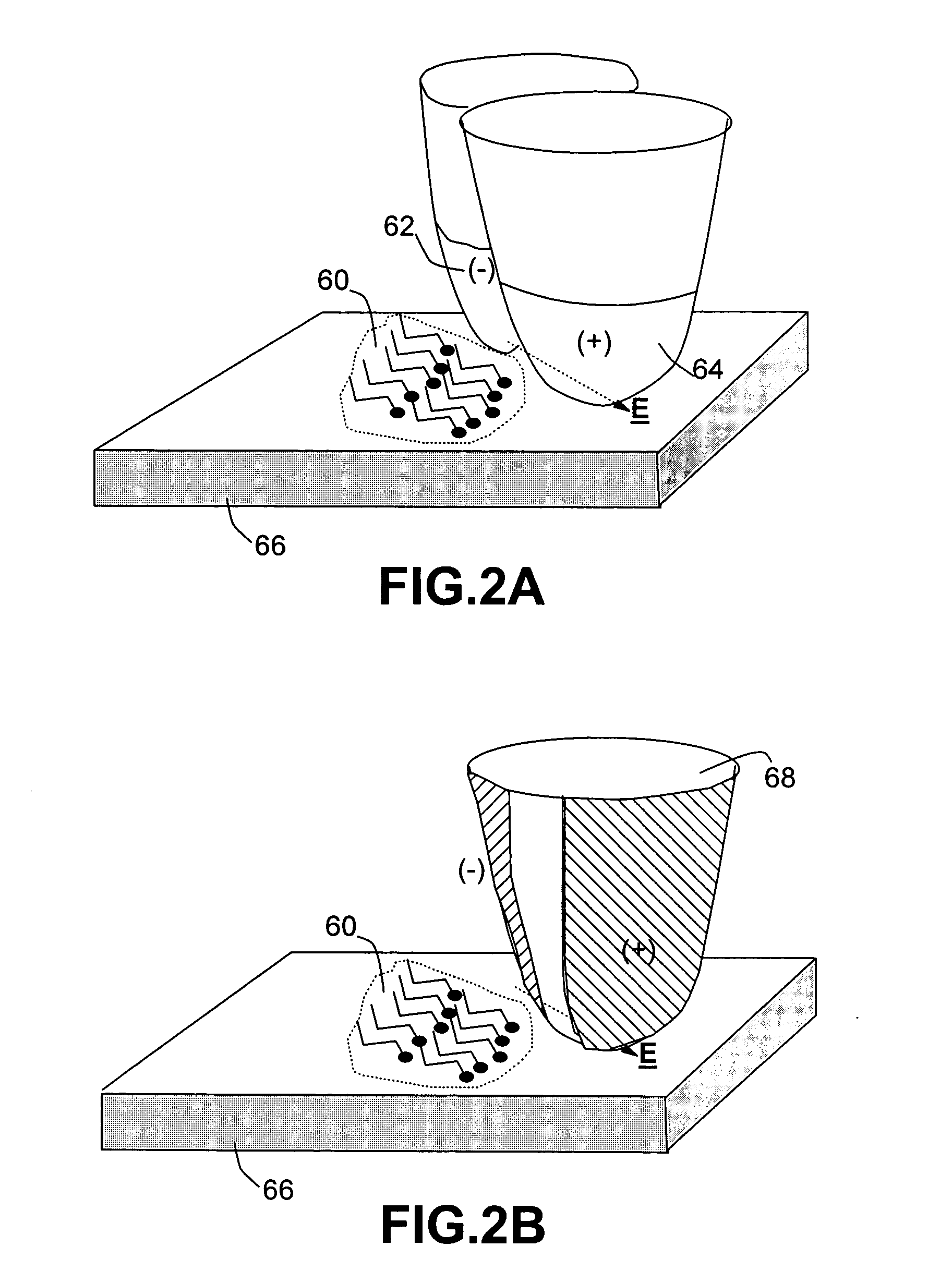

Field-assisted micro- and nano-fabrication method

InactiveUS20050112505A1NanoinformaticsSemiconductor/solid-state device manufacturingNanolithographyMolecular electronics

A direct-write micro- or nano-lithography method for depositing a functional material with a preferred orientation onto a target surface. The method includes the steps of (1) forming a precursor fluid to the functional material; (2) operating a sub-micrometer tip to discharge, on contact, the precursor fluid onto the target surface so as to produce a desired pattern of deposited functional material in sub-micrometer dimensions; and (3) during the pattern-producing step, subjecting the deposited material to a highly localized electric or magnetic field for attaining a preferred orientation in at least a portion of the functional material. The method is particularly useful for microfabrication, nanotechnology, and molecular electronics.

Owner:HUANG WEN C +1

Techniques for use of nanotechnology in photovoltaics

Owner:GLOBALFOUNDRIES INC

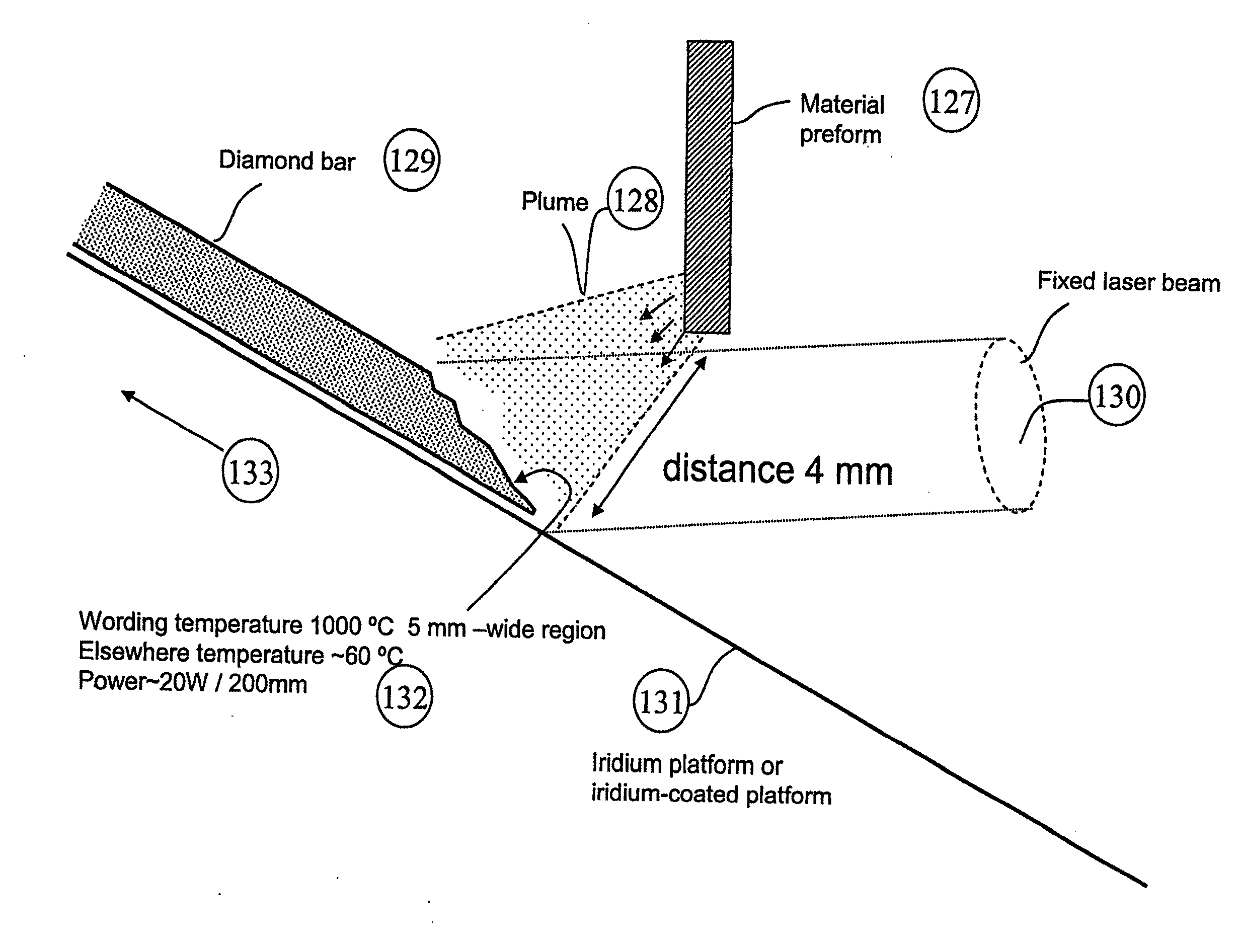

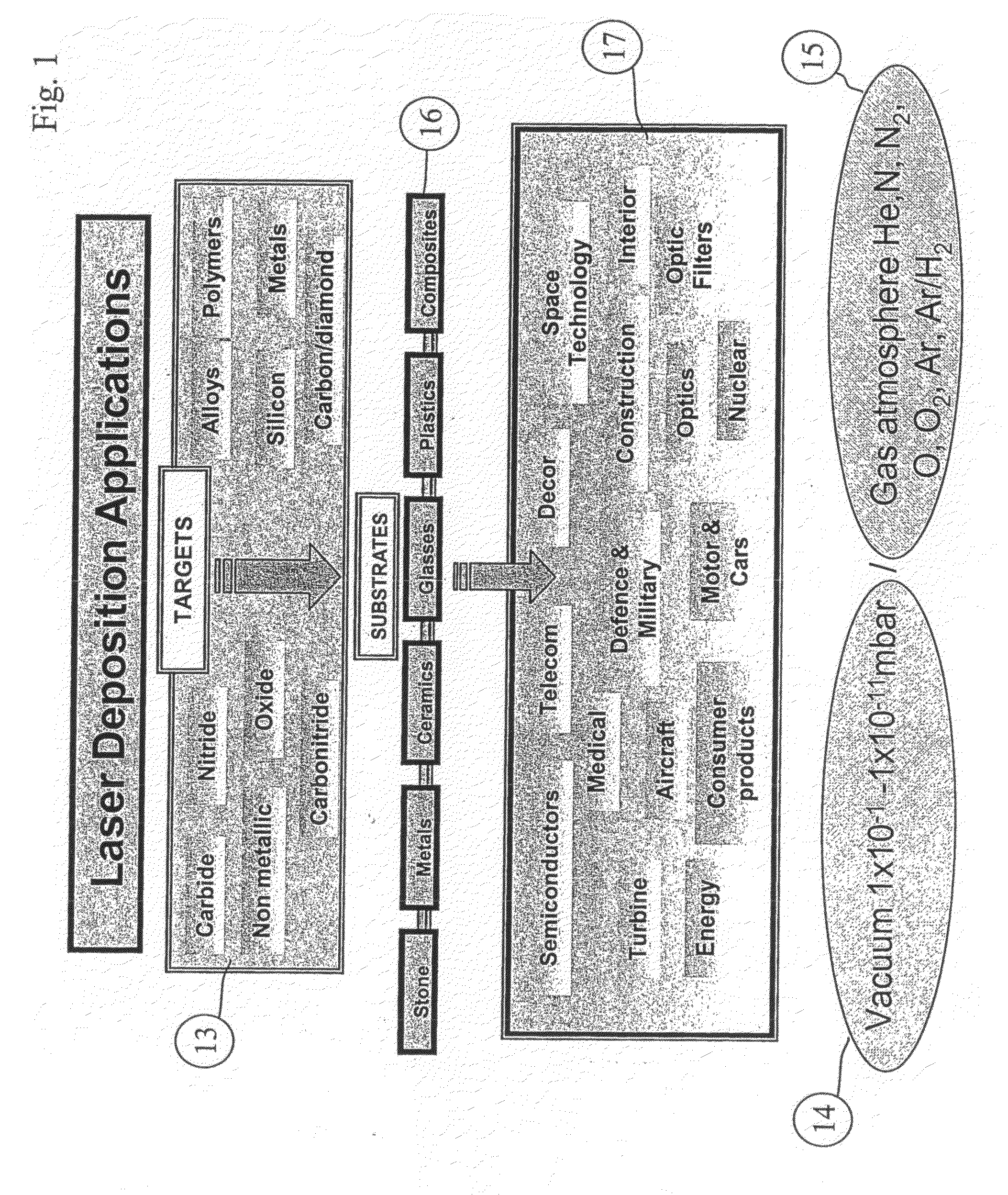

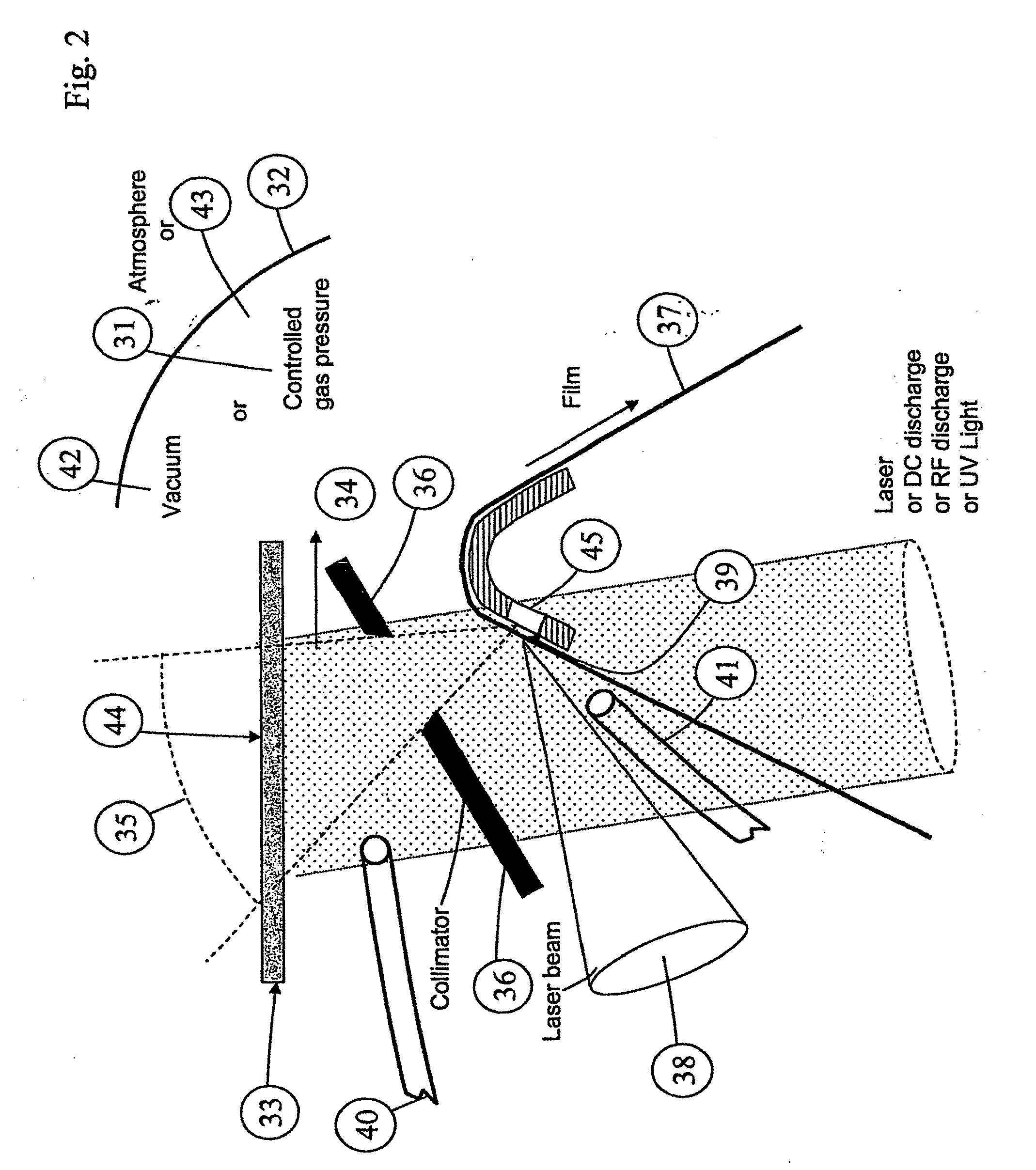

Method for Producing High-Quality Surfaces and a Product Having a High-Quality Surface

InactiveUS20090169871A1Fine and uniformSmall sizeElectric discharge heatingVacuum evaporation coatingEngineeringPhoto ablation

The invention relates to a laser ablation method for coating an object with one or more surfaces, so that the object to be coated, i.e. the substrate, is coated by ablating the target, so that the uniformity of the surface deposited on the object to be coated is ±100 nm. The surface of the coated object is advantageously free of micron size particles, and it is typically a nano technological surface where the size of separate particles is ±25 nm at most. The object also relates to products made by said method.

Owner:PICODEON OY

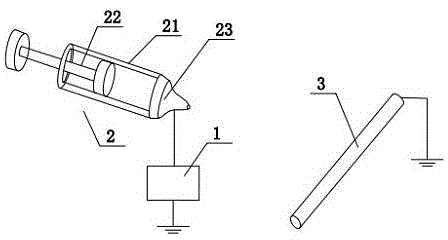

Method for preparing small-diameter artificial blood vessels on basis of nanotechnologies

InactiveCN105079874AGood tissue compatibilityHigh porosityFilament/thread formingProsthesisFiberPorosity

The invention belongs to the field of medicine and high-polymer materials, and discloses a method for preparing small-diameter artificial blood vessels on the basis of nanotechnologies. The method includes steps of dissolving, by weight, 8% of fibroin and 5% of polycaprolactone in hexafluoroisopropanol to obtain spinning liquor; manufacturing the nano-fiber blood vessels with the wall thicknesses of 130-170 micrometers on cylindrical rod-shaped receiving screens with the diameters of 1-1.2mm by means of electrospinning by the aid of electrospinning technologies. Compared with the prior art, the method has the advantages that requirements of tissue engineering on high tissue compatibility, high porosity, plasticity and degradability can be met owing to the electrospinning technologies, vascular stents can be modified by cell activity factors (mechanical growth factors) and medicine (heparin) with anticoagulant activity, and accordingly shortcomings of technological complexity and poor tissue compatibility of existing cell-modified vascular stents can be overcome by the aid of the method.

Owner:AFFILIATED HUSN HOSPITAL OF FUDAN UNIV

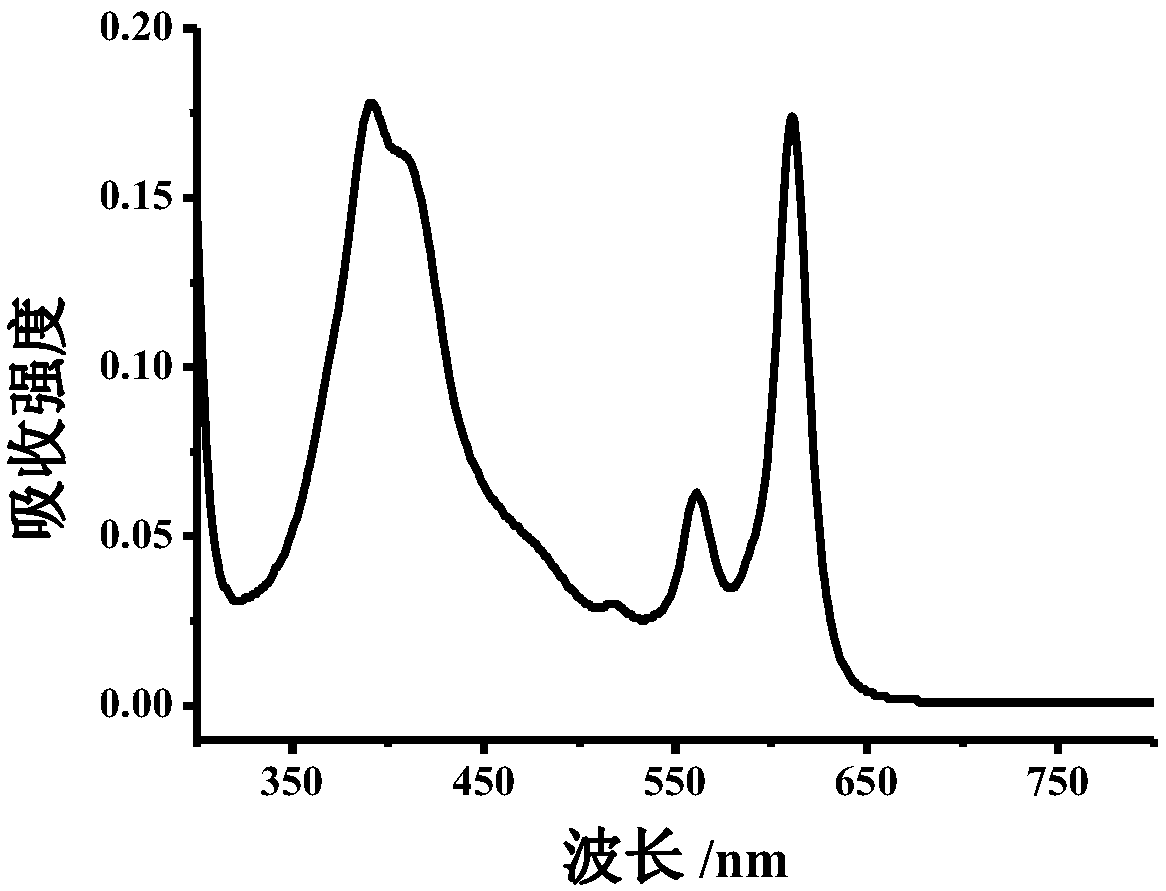

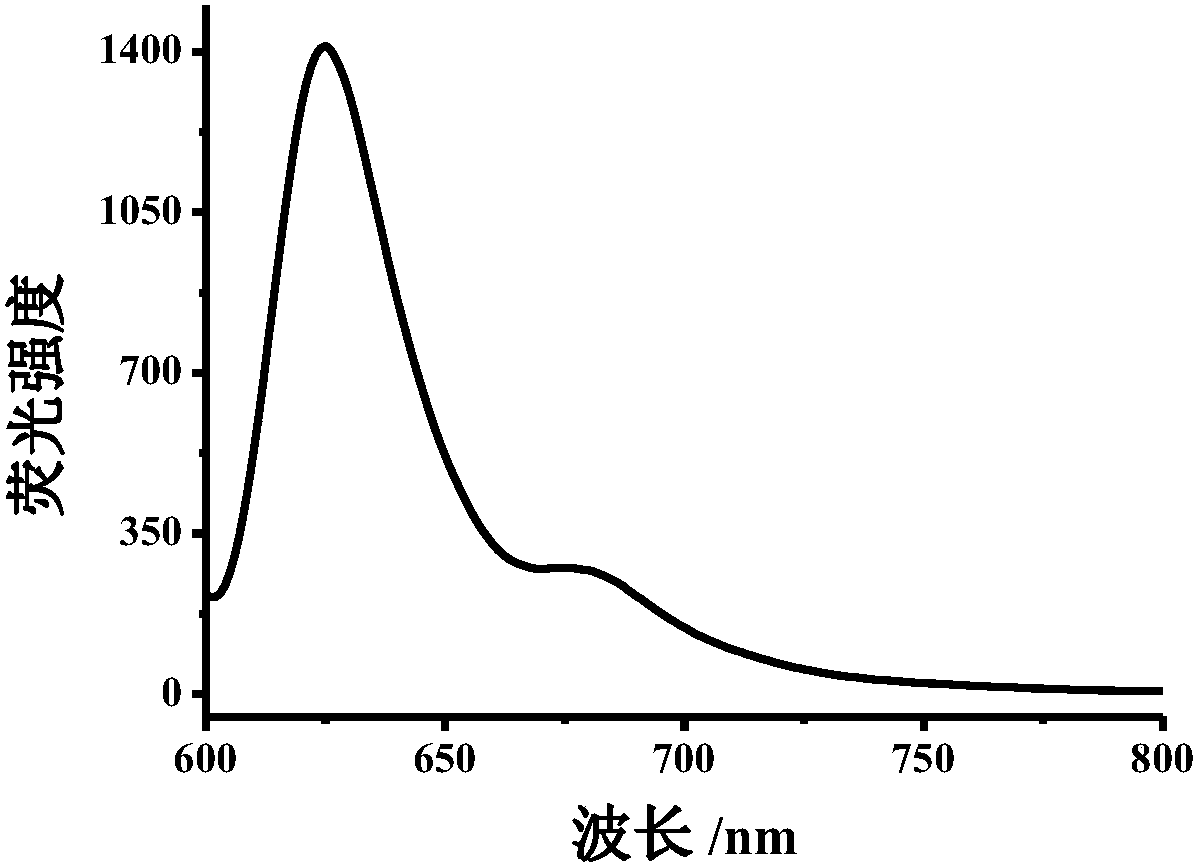

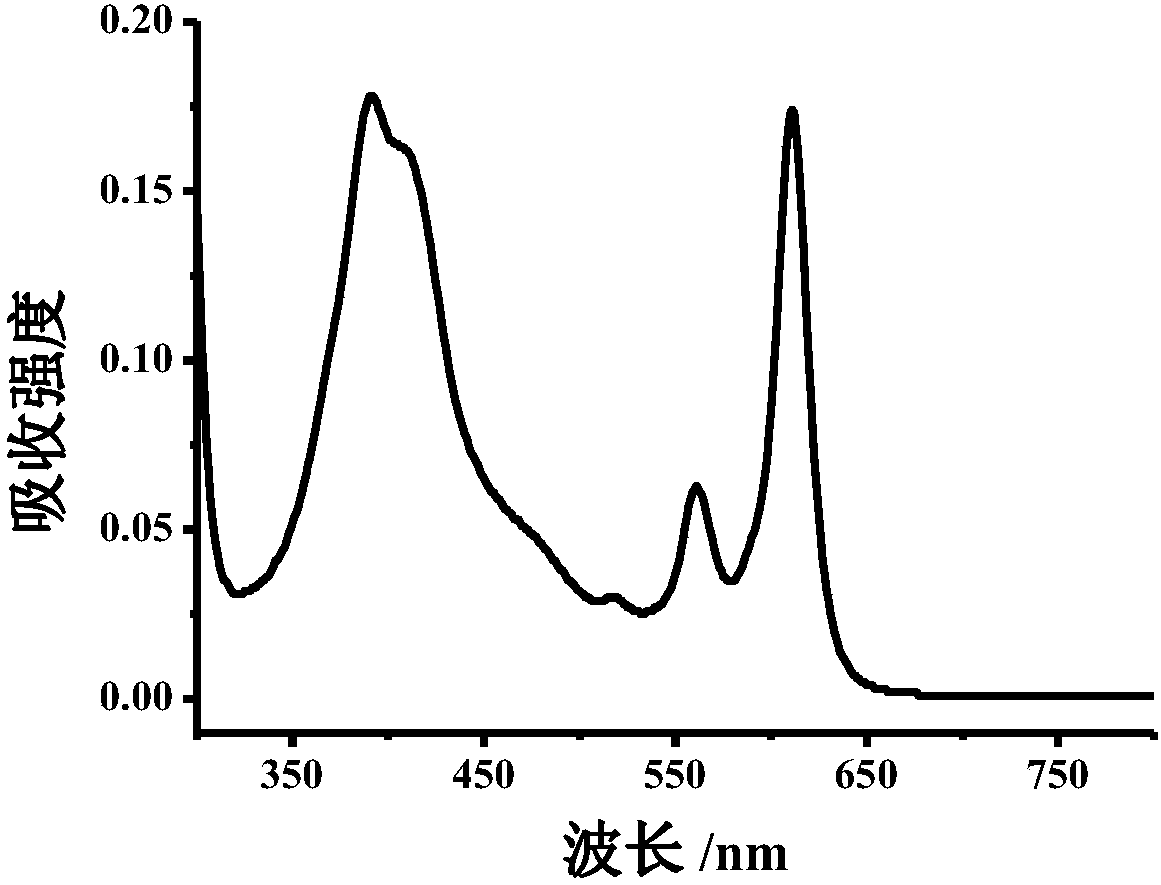

Method for detecting nitrite ions on basis of polymer carbon dot fluorescence colorimetry

ActiveCN108593618AEasy to synthesizeHighly sensitive and selective detectionFluorescence/phosphorescenceNitrite ionHigh selectivity

The invention belongs to the technical field of nanometer, and discloses preparation of polymer carbon dots and a detection method thereof applied to nitrite ion colorimetry fluorescence. When different concentrations of nitrite ions exist in a buffer system containing a certain amount of polymer carbo dots, for an absorption spectrum, the absorption peak in a 610nm position is obviously reduced;the absorption peak in a 380 nm position is gradually increased; the intensity of the fluorescence emission peak in a 625 nm position of the fluorescence spectrum is gradually reduced along with the increasing of the nitrite ion; Therefore according to the change of polymer carbon dot fluorescence spectrum and absorption spectrum in a system, through fluorescence colorimetry multi-output signal analysis, the high-sensitivity and high-selectivity detection on the nitrite ions can be realized; the detection on the nitrite ions in a complicated system such as urine can be further realized. A polymer carbon dot-based fluorescent colorimetric probe is a novel expansion on the original analysis method, and is hopeful to be used for the analysis and detection of nitrite ions in the complicated systems such as food, environment and the like.

Owner:NANJING UNIV OF TECH

Customizable high-gain ZnO nanowire array UV detector and preparation method thereof

ActiveCN106409975AImprove uniformitySolve the problem of controllability of growth directionFinal product manufactureSemiconductor devicesUv detectionUv detector

A customizable high-gain ZnO nanowire array UV detector and a preparation method thereof relate to the fields of microelectronic technologies, nanometer technologies and UV detection. On the basis of a synergic theory, nanowires compete for a reaction solute when fluctuation is instable, an in such a competition mechanism, the thinner a seed layer is, the fewer solute resources are needed, and growth time is decided by the growth speed. Based on such a growing principle, the thickness of the seed layer, the solution concentration and growth time are adjusted to obtain nanowires of higher quality, and UV detection devices of different gains are obtained. The method is simple and effective, and the customized devices of different gains can be suitable for UV detection in different environments.

Owner:BEIJING UNIV OF TECH

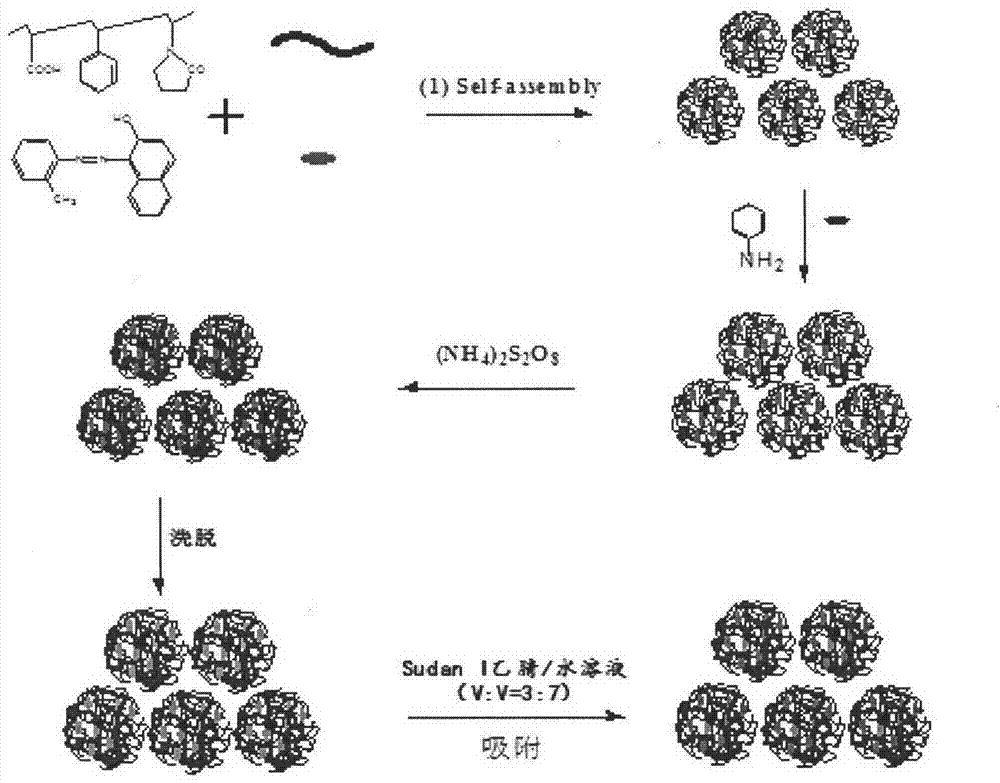

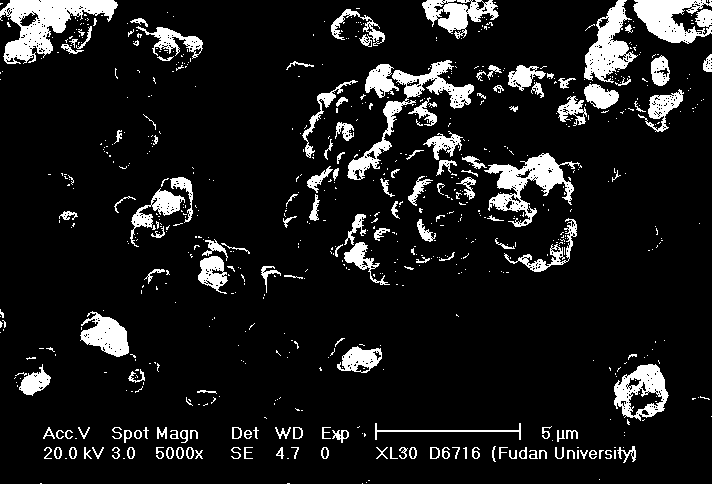

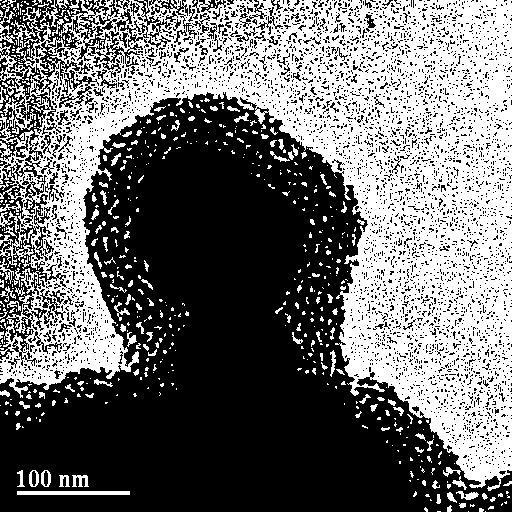

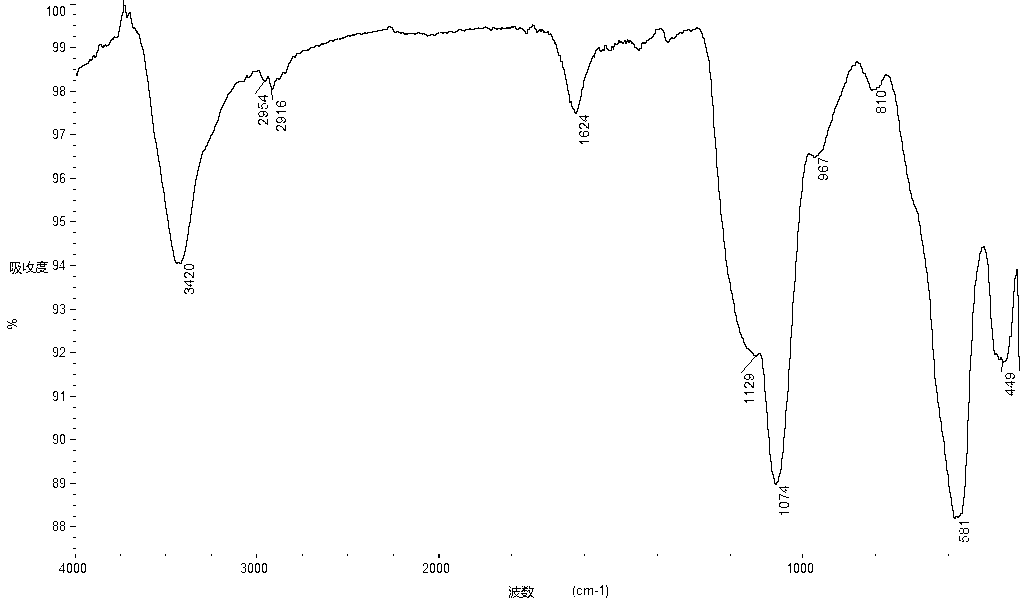

Automatic-assembling method for preparing molecular imprint polyaniline nanocomposite

InactiveCN103613758AGood specific adsorptionImprove adsorption capacityOther chemical processesIn situ polymerizationSorbent

The invention provides an automatic-assembling method for preparing a molecular imprint polyaniline nanocomposite, and relates to the technical field of high molecular material science. The preparation method comprises the followings steps: firstly, synthesizing a random amphiphilic copolymer through free radical polymerization; preparing micelle of polymer by adopting an automatic-assembling method; synthesizing the molecular imprint polyaniline nanocomposite through in-situ polymerization by taking a safety hazard factor in food as a template molecule, wherein the molecular imprint polyaniline nanocomposite is applied to food as an absorbent for the safety hazard factor. According to the invention, electric conductive polyaniline, the nano technique and the molecular imprint technique are combined, and the preparation method is simple, is controllable in condition, and is low in cost; the prepared molecular imprint polyaniline nanocomposite has the advantages of specific recognition capability on the template molecule, high selectivity, high adsorption speed, capability of being used repeatedly, environment friendliness and the like.

Owner:JIANGNAN UNIV

A synthesis method for a dopamine-modified magnetic mesoporous silica material and applications thereof

InactiveCN103232991AEasy to separateGood environmental stabilityPreparing sample for investigationOn/in inorganic carrierMicrospherePhosphate

The invention belongs to the field of nanotechnology, and in particular to a synthesis method for a dopamine-modified magnetic mesoporous silica material and applications thereof. The synthesis method comprises: first, dispersing a magnetic mesoporous silica material in a dopamine solution uniformly; adding a sodium monohydrogen phosphate - disodium hydrogen phosphate buffer solution with a concentration of 0.2M, adding glutaraldehyde, and shaking the obtained solution for reaction at a room temperature for 0.5-1 hours; washing completely; dispersing the obtained product in above step in a sodium monohydrogen phosphate - disodium hydrogen phosphate buffer solution with a concentration of 0.2M, and shaking the obtained solution for reaction at the room temperature for 2-4 hours; washing completely; dispersing the obtained product in above step in a 2mg / mL trypsin-containing ammonium bicarbonate buffer solution with a concentration of 25mM, and shaking for reaction at the room temperature for 2 hours; and washing completely to remove surface impurities the product to give the desired material. According to the material, magnetic microspheres are employed as skeletons to provide magnetism to benefit subsequent separation and analysis, the pore size distribution and biocompatibility are good, the synthesis method is simple and low in cost, and size-exclusion selective enzymolysis can be performed by fixing enzyme inside the pore.

Owner:FUDAN UNIV

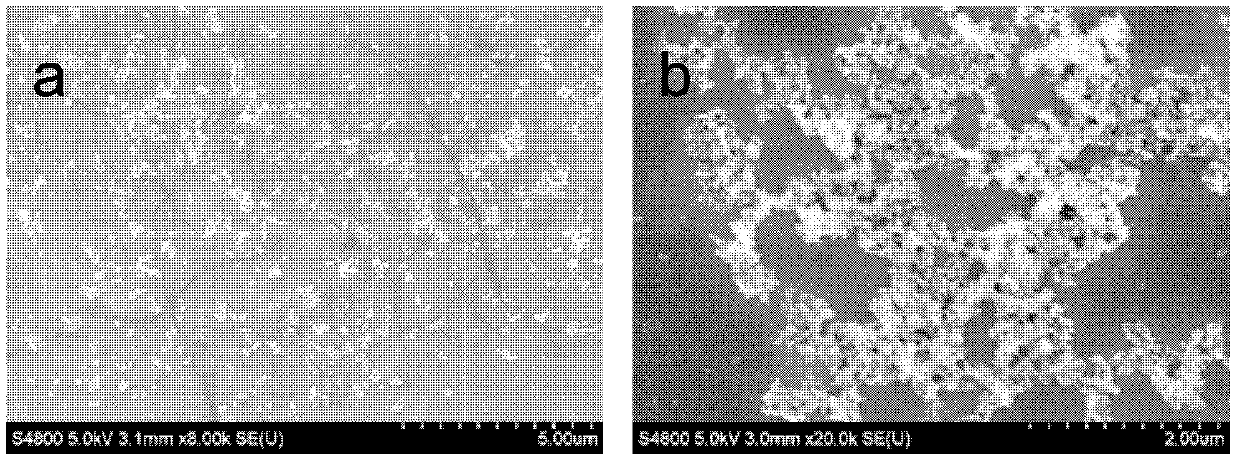

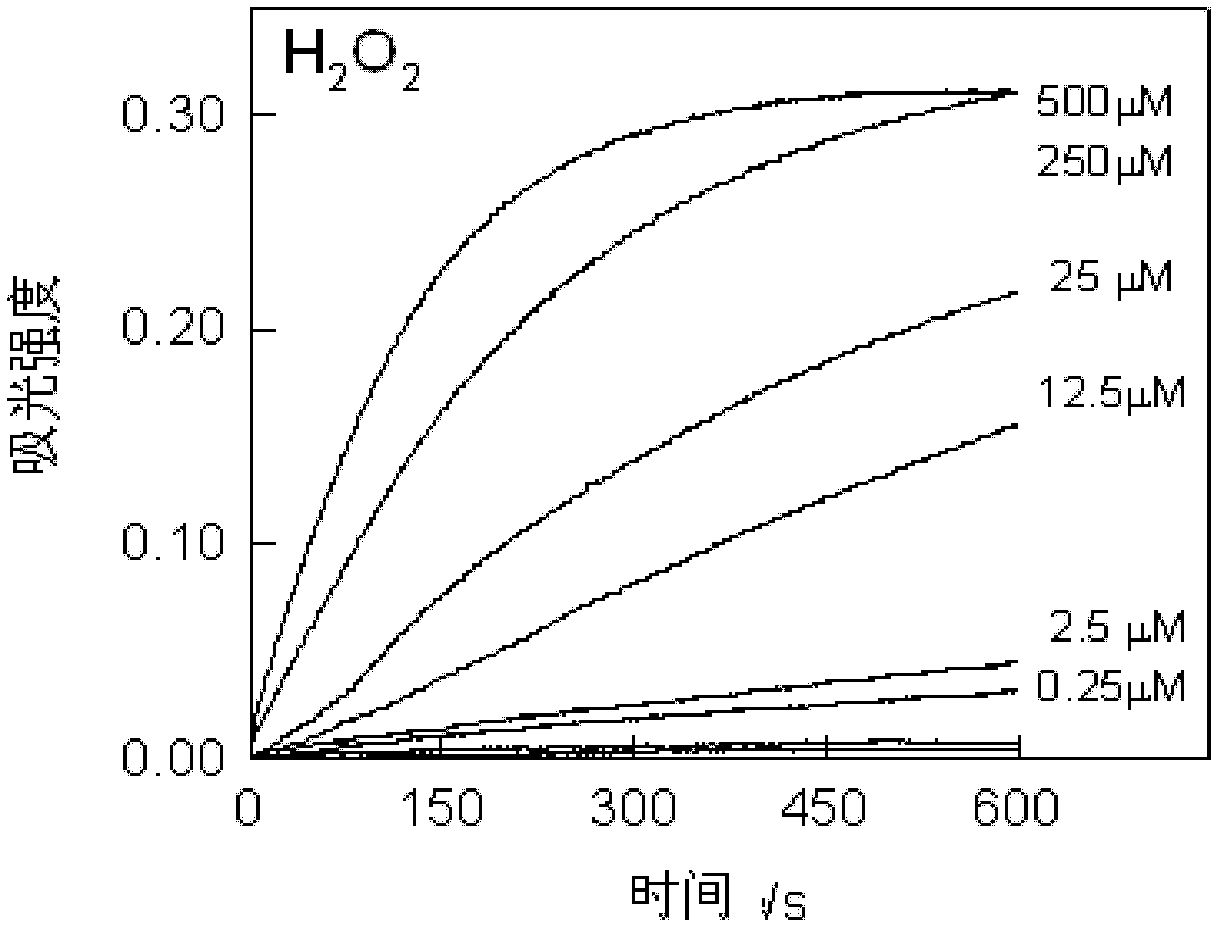

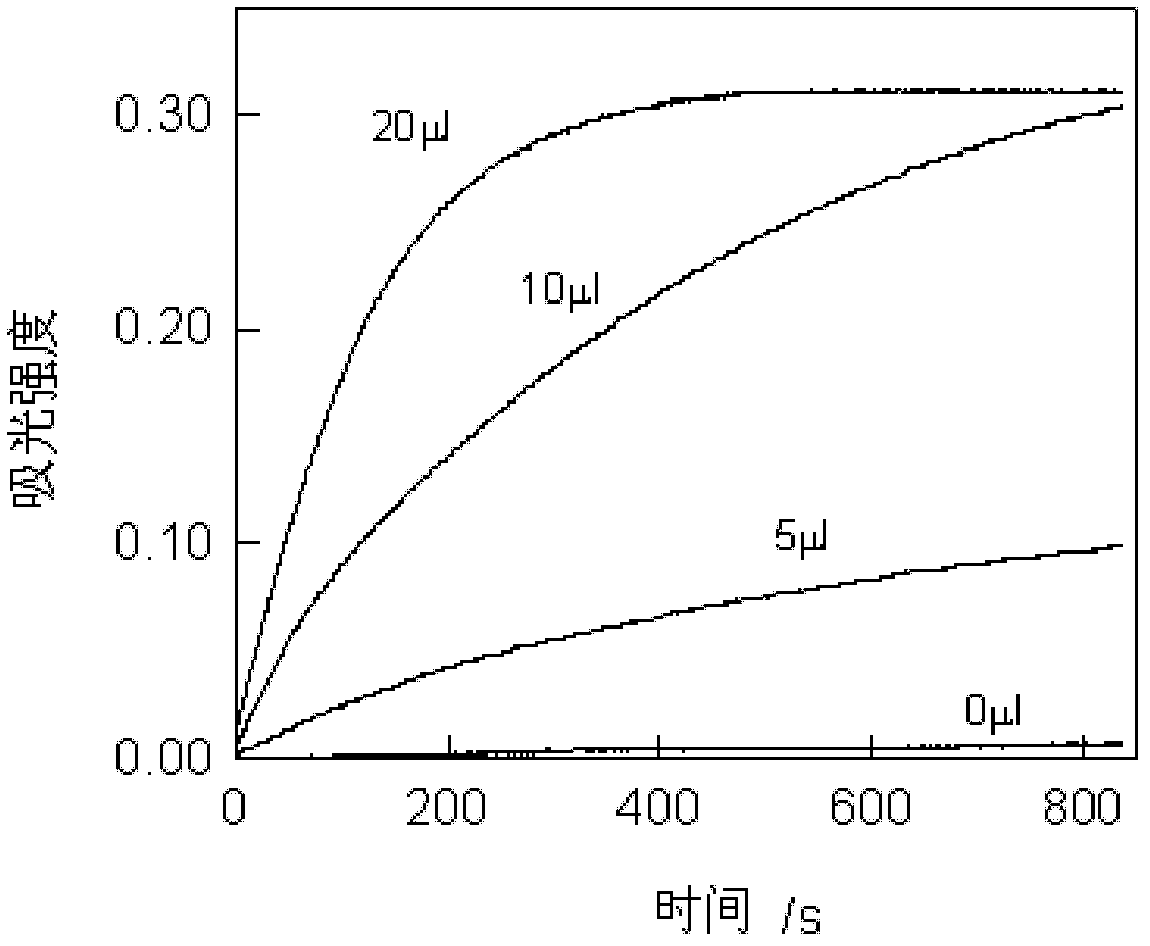

Method for efficiently catalyzing TMB (Tetramethylbenzidine) color development reaction by using carbon nanoparticles

InactiveCN102519889ASave materialShort color development timePhysical/chemical process catalystsColor/spectral properties measurementsModified carbonCarbon nanotube

The invention belongs to the field of nanometer technologies and particularly relates to a method for efficiently catalyzing a TMB (Tetramethylbenzidine) color development reaction by using carbon nanoparticles. The method comprises the steps of: adding 250 mu M of TMB solution and 0.25-500 mu M of H2O2 into 400 mu L of water, then adding 5-40 mu L of surfactant-modified carbon nanoparticles, shaking to reach a uniform state, and measuring time-varying absorption values under the wavelength of 652nm, wherein the surfactant is anyone of SDS (Sodium Dodecyl Sulfate), DNA (Deoxyribose Nucleic Acid), DTAB (Dodecyl Trimethyl Ammonium Bromide) and Tuwen20, and the dimension of the carbon nanoparticles is 20-70nm. By utilization of the carbon nanoparticles as a catalyst, the favorable characteristics of cheap materials, short color development time, high catalysis efficiency and the like are achieved, and the catalytic effect of the carbon nanoparticles is far better than that of graphene and single-walled carbon nanotubes.

Owner:HUNAN UNIV

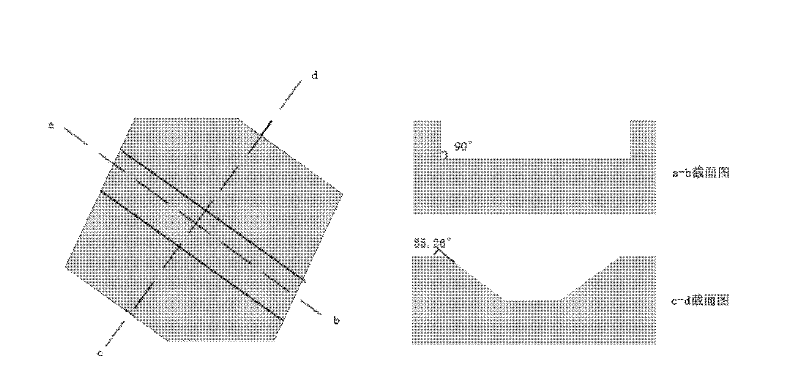

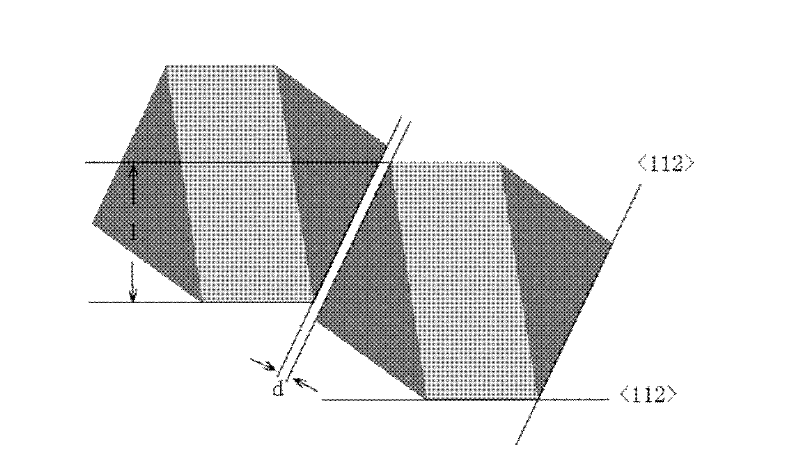

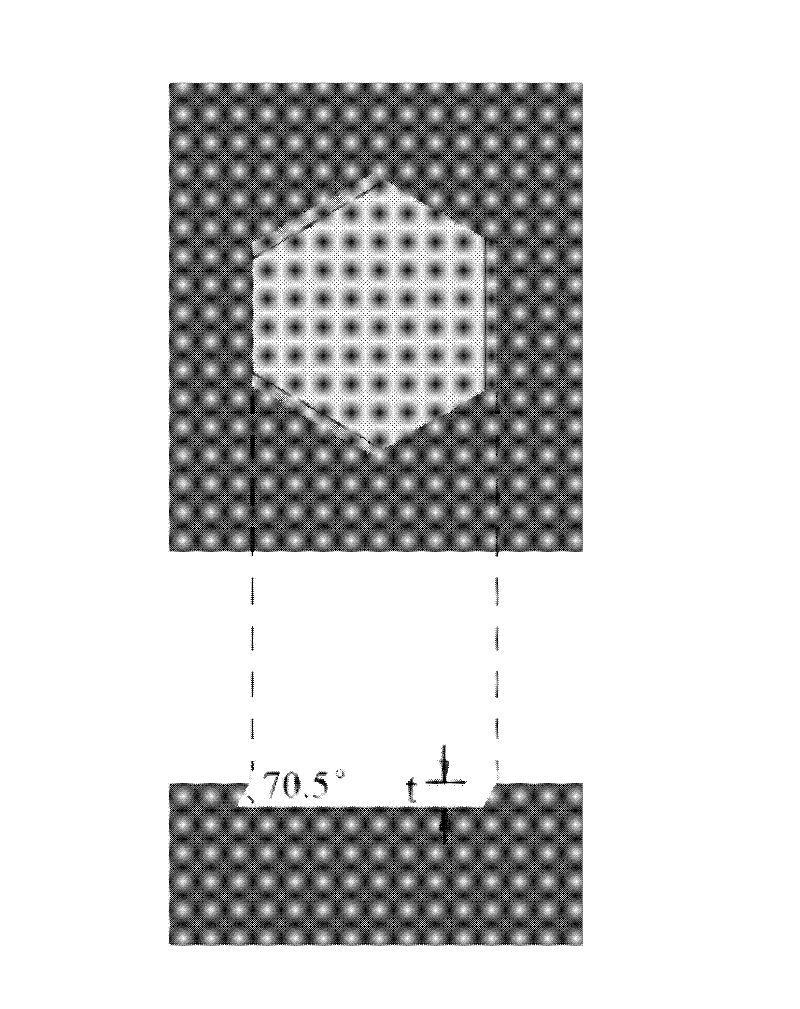

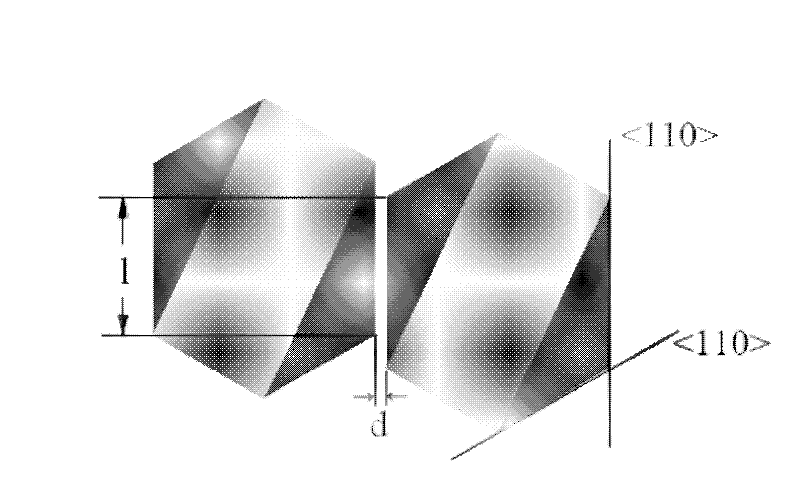

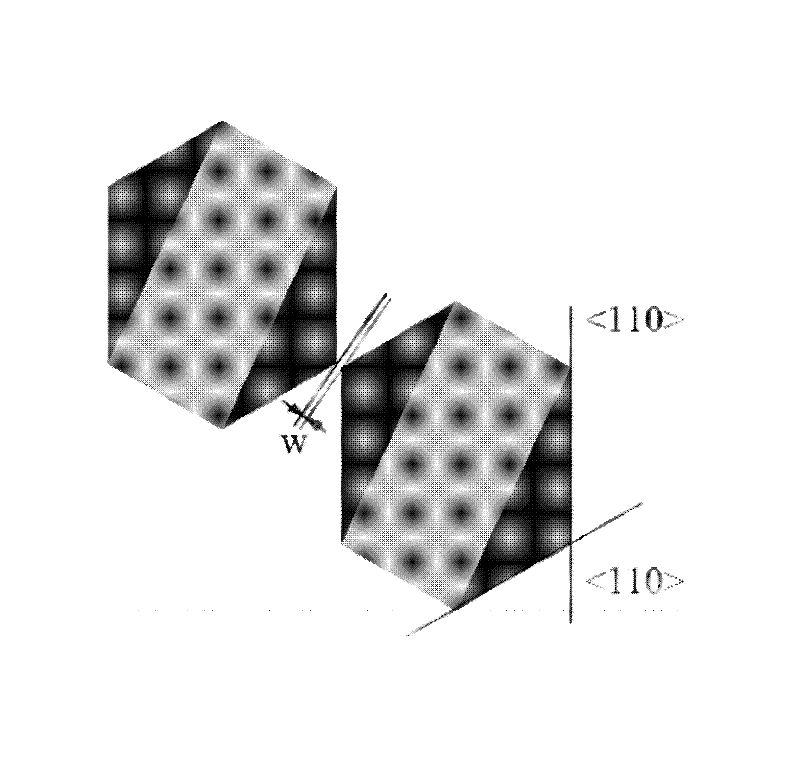

Method for preparing nanometer structures from top to bottom on surfaces of (110) type silicon chips

InactiveCN102398893AOvercome the disadvantage of being expensiveSimple processNanostructure manufactureNanowireNanotechnology Techniques

The invention relates to a method for preparing nanometer structures from top to bottom on the surfaces of (110) type silicon chips, which belongs to the technical field of nanometer and is characterized in that the anisotropy wet process corrosion characteristics of silicon materials are used for preparing monocrystalline silicon nanometer wall structures or nanometer corner structures with the characteristic dimension being nanometer level on the surfaces of the (110) silicon chips, or a self limitation oxidation process is combined for further preparing the monocrystalline silicon nanometer line structure with the cross section in a reverse triangular shape. The method has the advantages that the process is simple, only the conventional photoetching and the anisotropy wet process corrosion masking manufacture, corrosion and etching processes are adopted, the large-scale manufacture can be realized, and the method belongs to a convenient micro nanometer integrating process technology. The nanometer structure manufactured in the invention can be used for studying the structure properties of the low-dimension monocrystalline silicon materials, including the study of the mechanical property, the thermal property, the electric property and the like, can also be used as sensor function structure components and has the application prospects.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

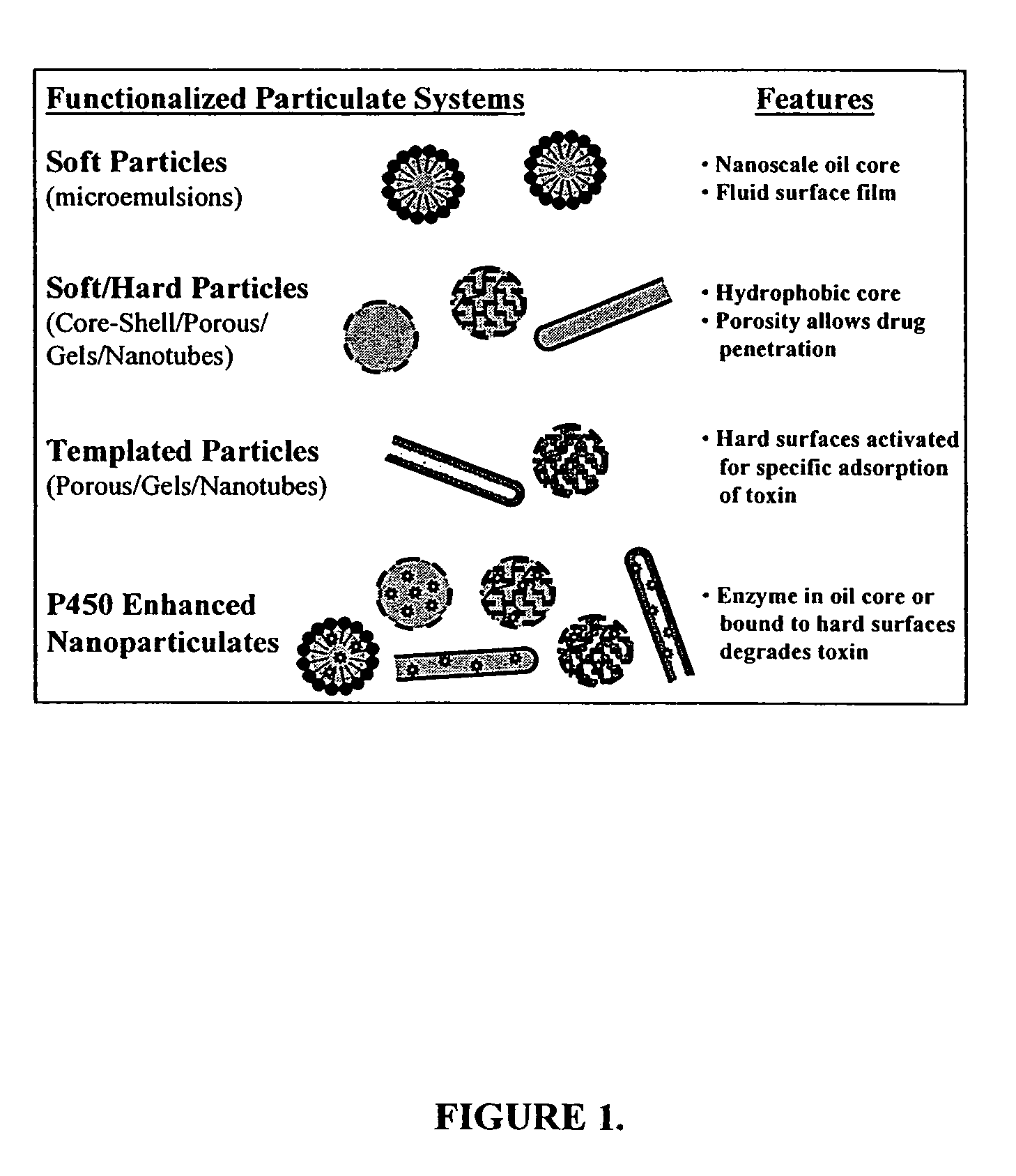

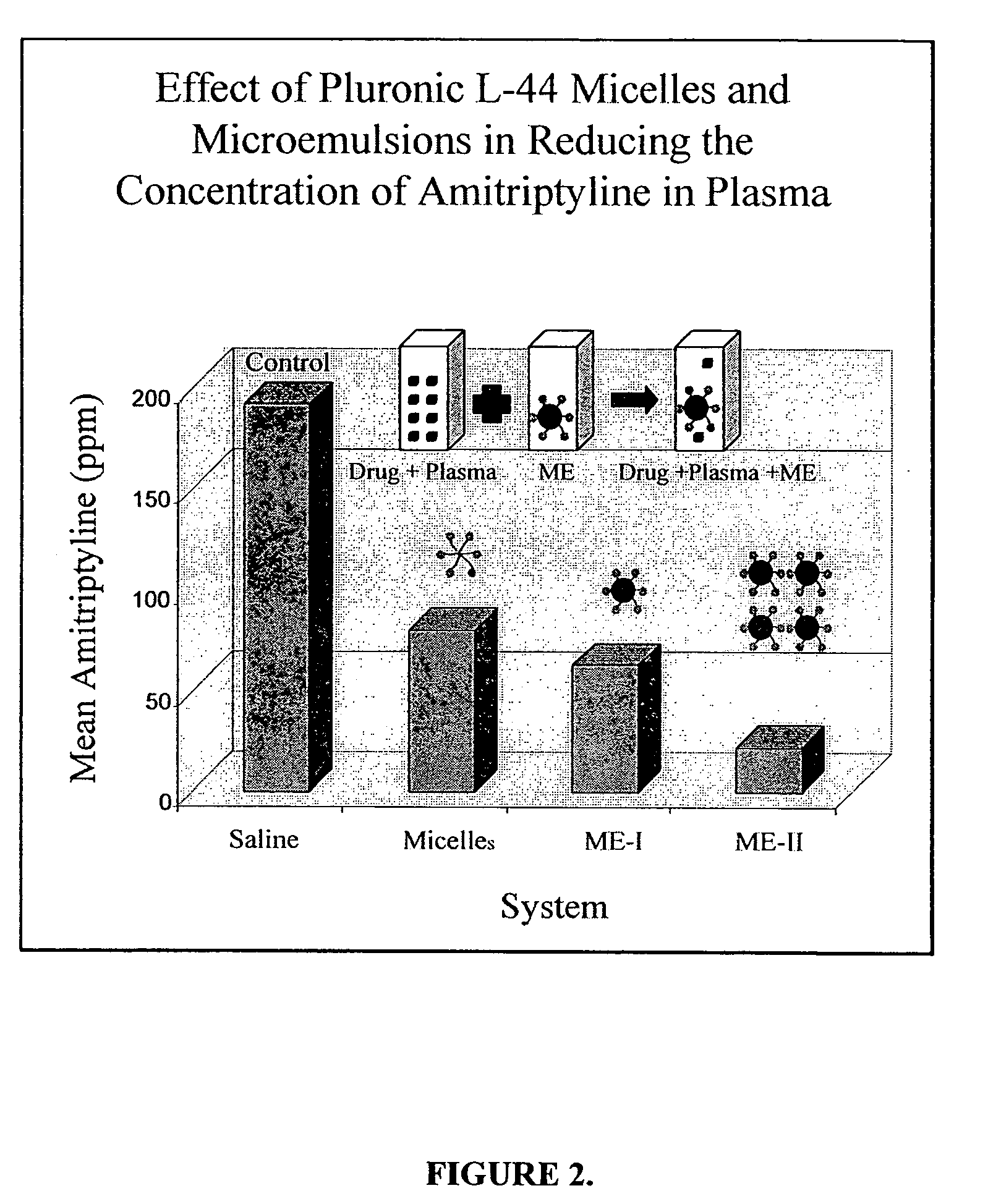

Detoxification and decontamination using nanotechnology therapy

A particle with two regions, the first region contains a detoxifying enzyme and a second region that partitions toxic compounds. The particle may be a nanoparticle.

Owner:UNIV OF FLORIDA +1

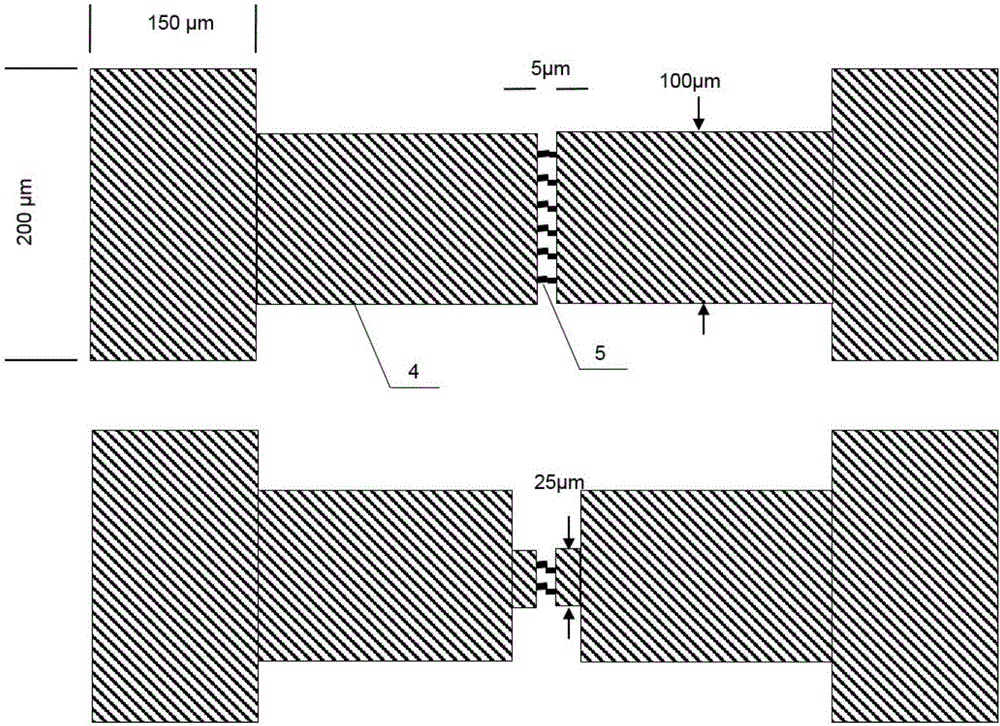

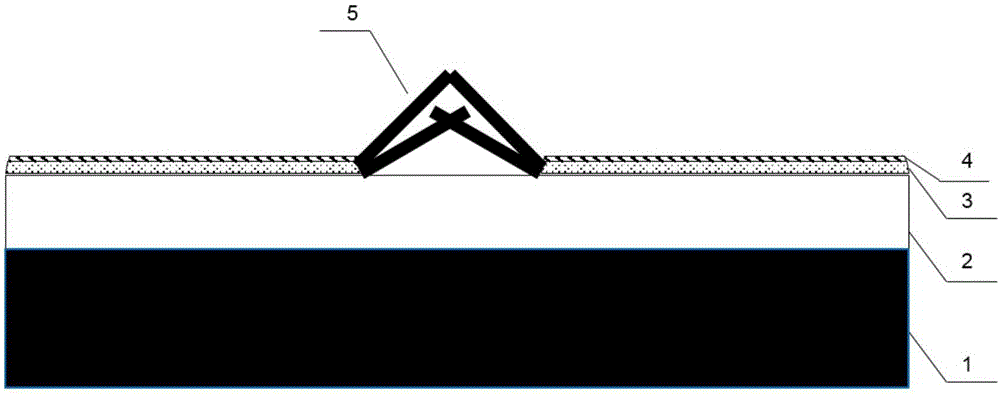

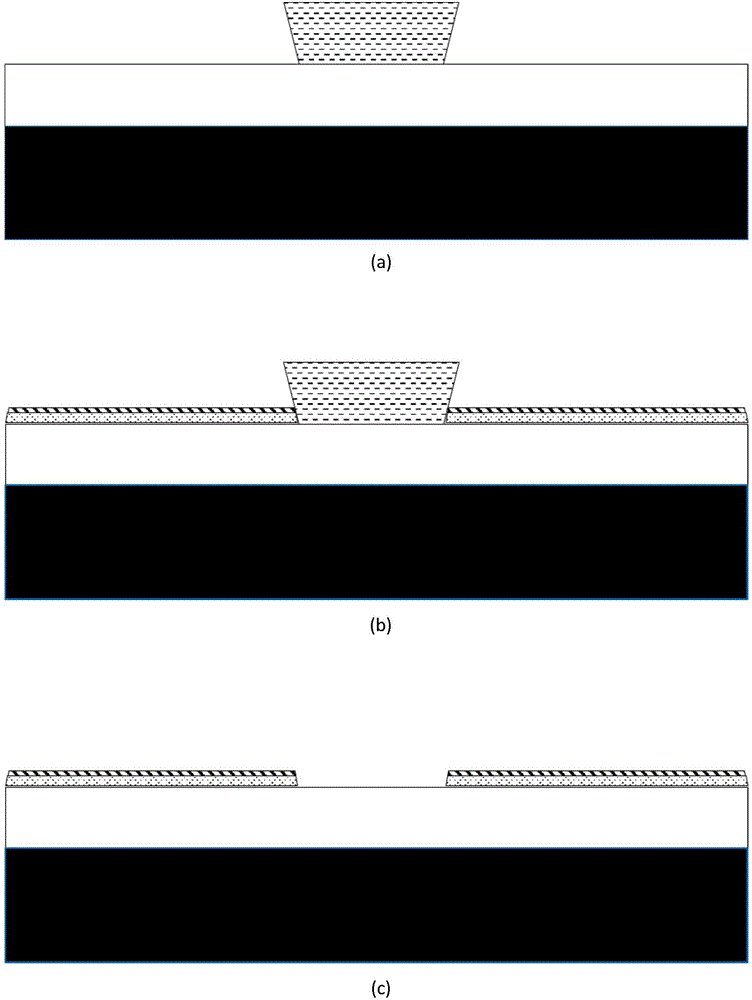

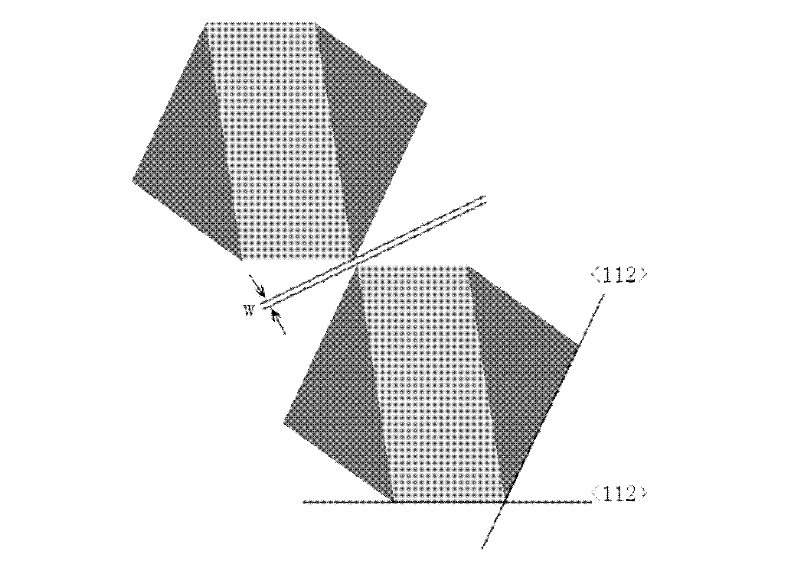

Method for preparing nano structure on surface of (111) silicon wafer

InactiveCN102437017AOvercome the disadvantage of being expensiveSimple processAfter-treatment detailsSemiconductor/solid-state device manufacturingNanowireNano structuring

The invention relates to a method for preparing a nano structure on a surface of a (111) silicon wafer, belonging to the technical field of nano. The invention is characterized in that a monocrystalline silicon nano wall structure or nano horn structure of which the characteristic dimension is on a nano level is prepared on the surface of a (111) silicon wafer by utilizing the anisotropic wet-process corrosive characteristic of the silicon material, or a self-restricting oxidation technique is combined to further prepare a monocrystalline silicon nanowire structure of which the cross section is in an inverted triangle shape. The invention has the advantage of simple technique, only relates to conventional photoetching, anisotropic wet-process etching mask manufacturing, corroding and etching techniques, can implement large-scale manufacture, and is a convenient micro / nano integration technology. The nano structure manufactured by the method provided by the invention can be used for researching properties (including mechanical, thermal, electric and other properties) of a low-dimension monocrystalline silicon material structure, can be used as a functional structure component of a sensor, and has application prospects.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

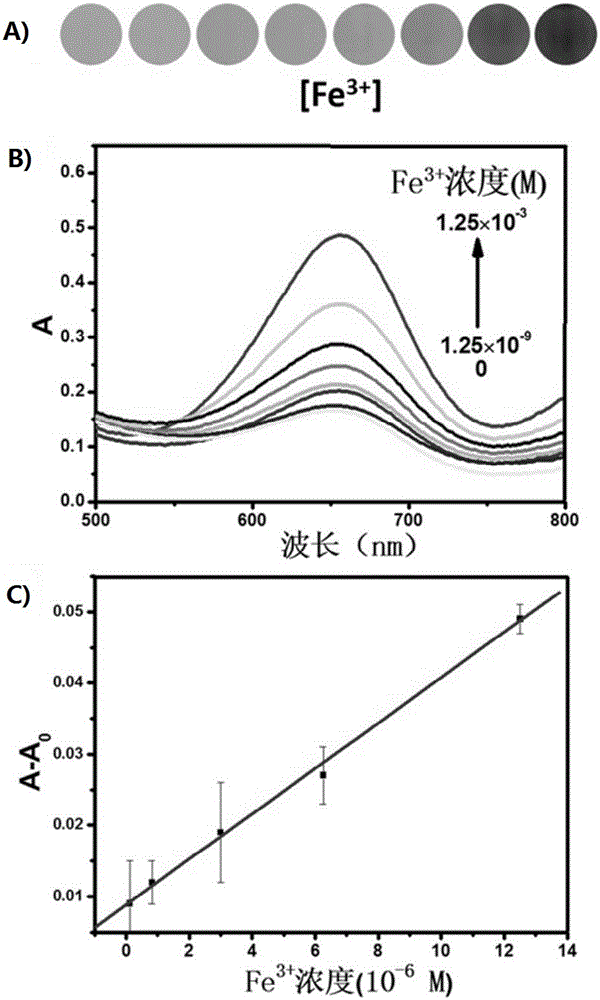

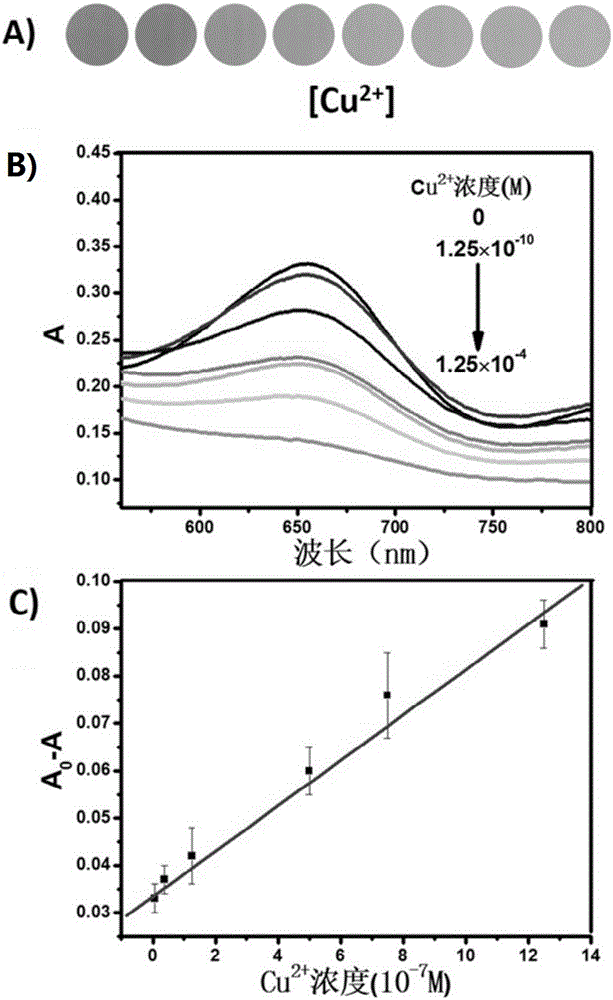

Nanometer sensing method for separately or simultaneously detecting iron ions and copper ions, and applications

InactiveCN106442373AExcellent optical propertiesImprove stabilityMaterial nanotechnologyNanosensorsSolution systemNanoclusters

Owner:TIANJIN UNIV

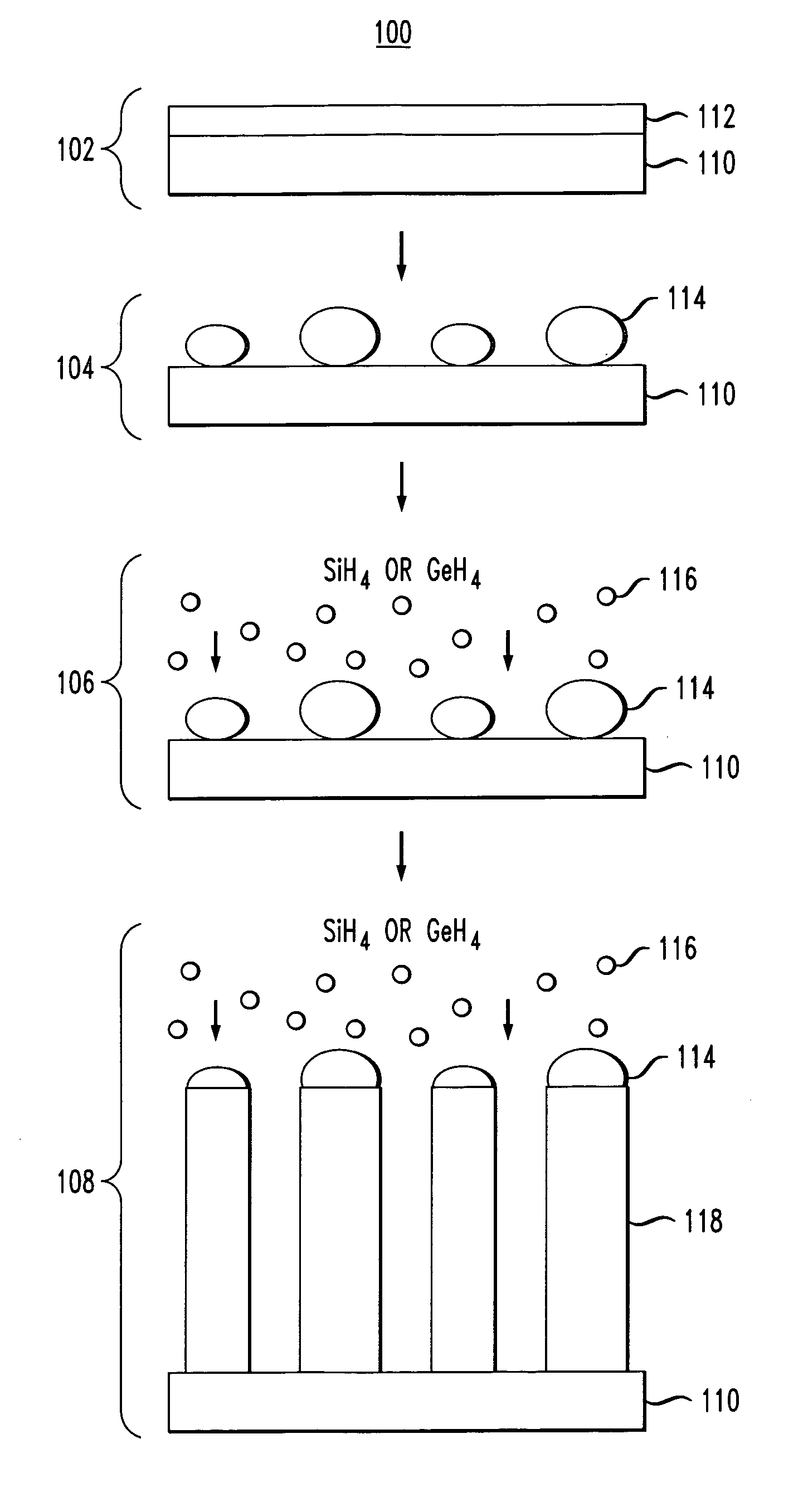

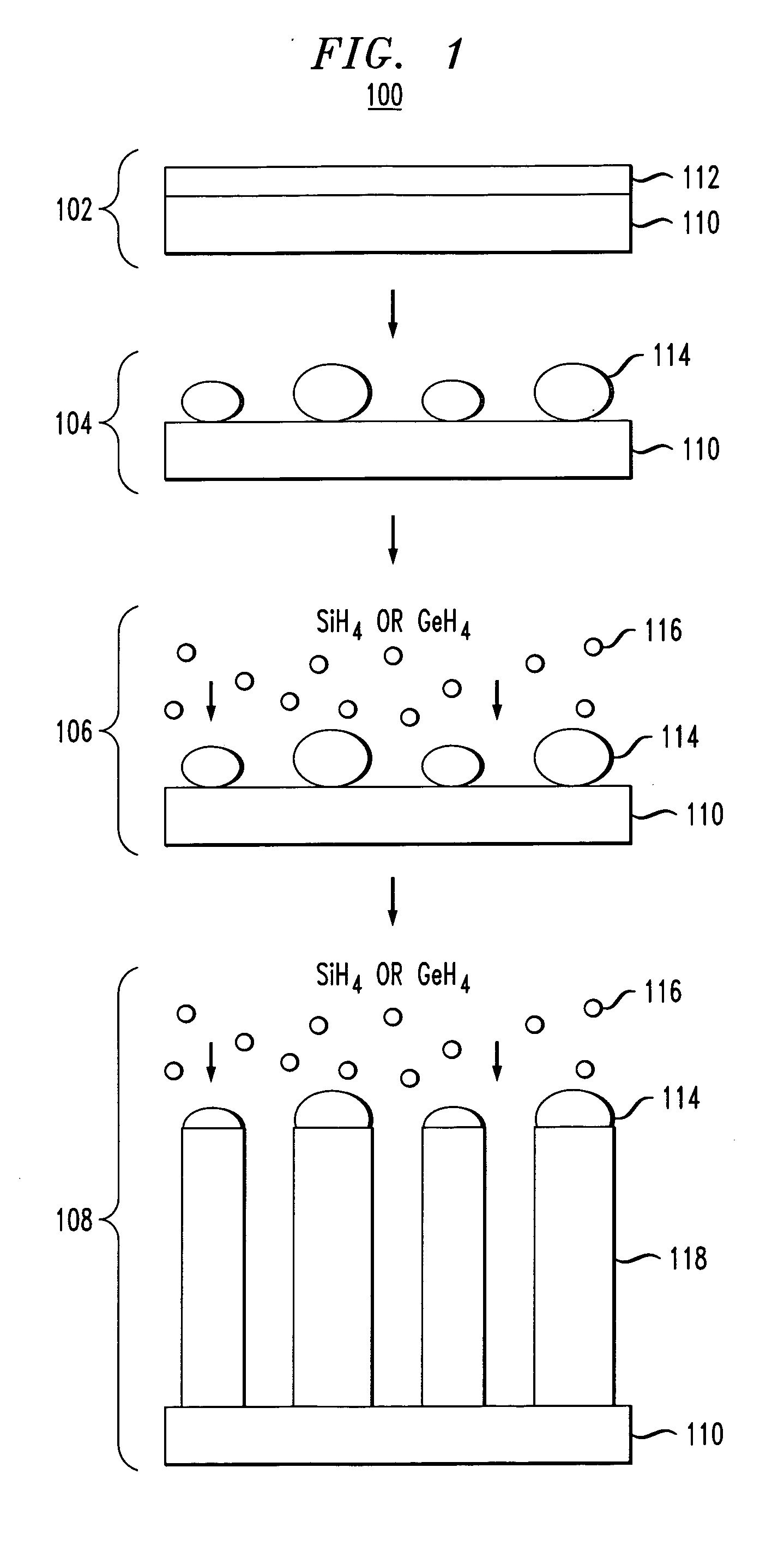

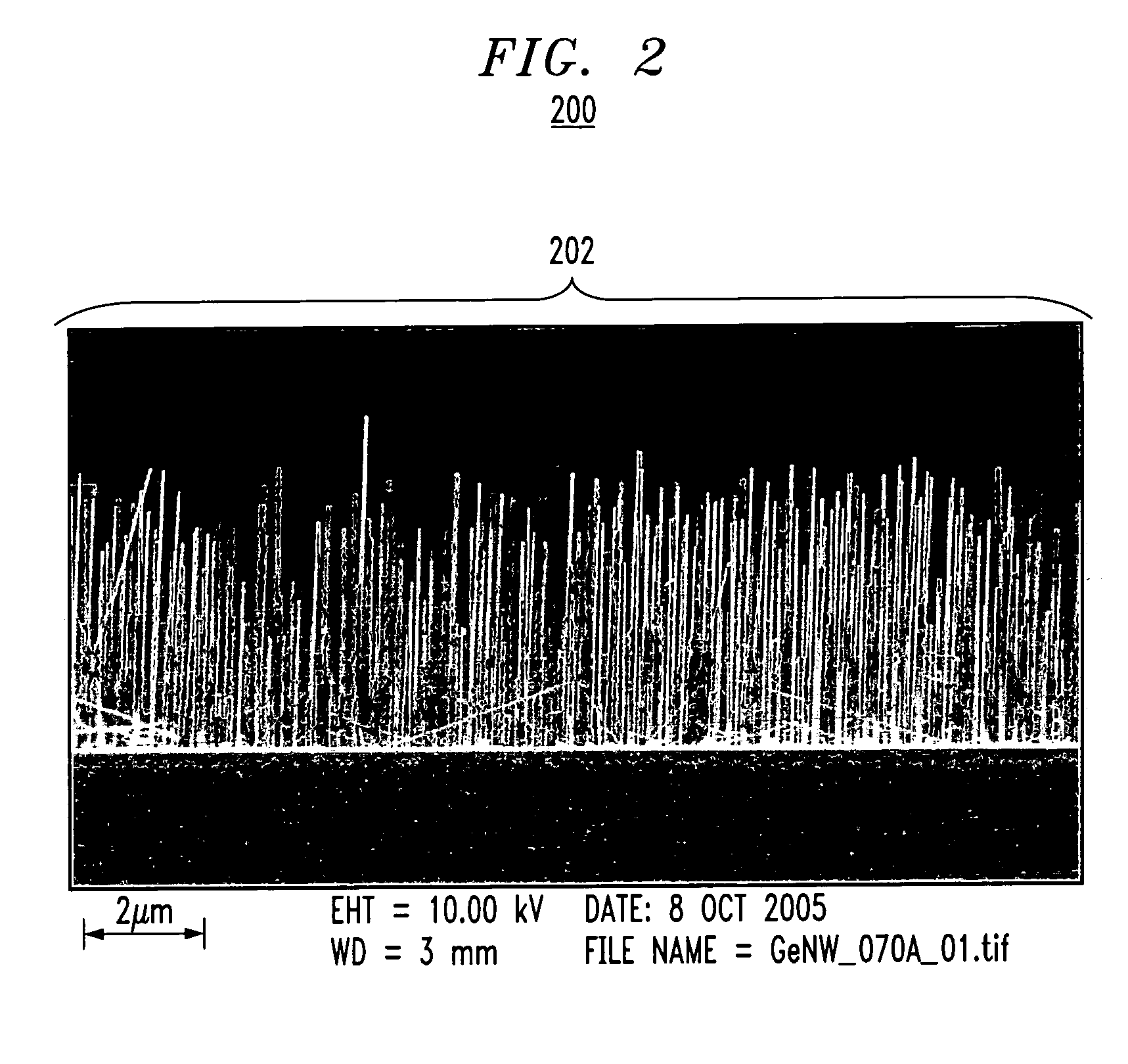

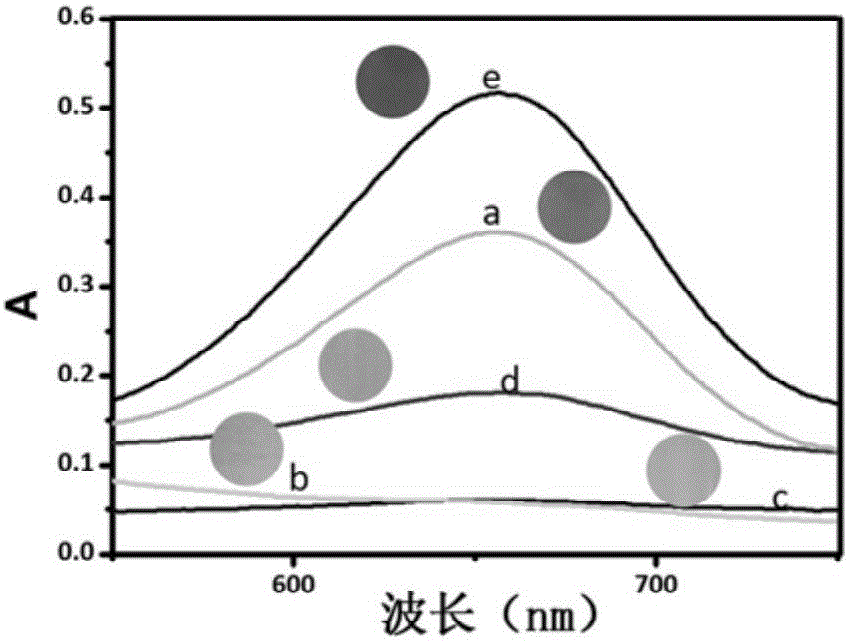

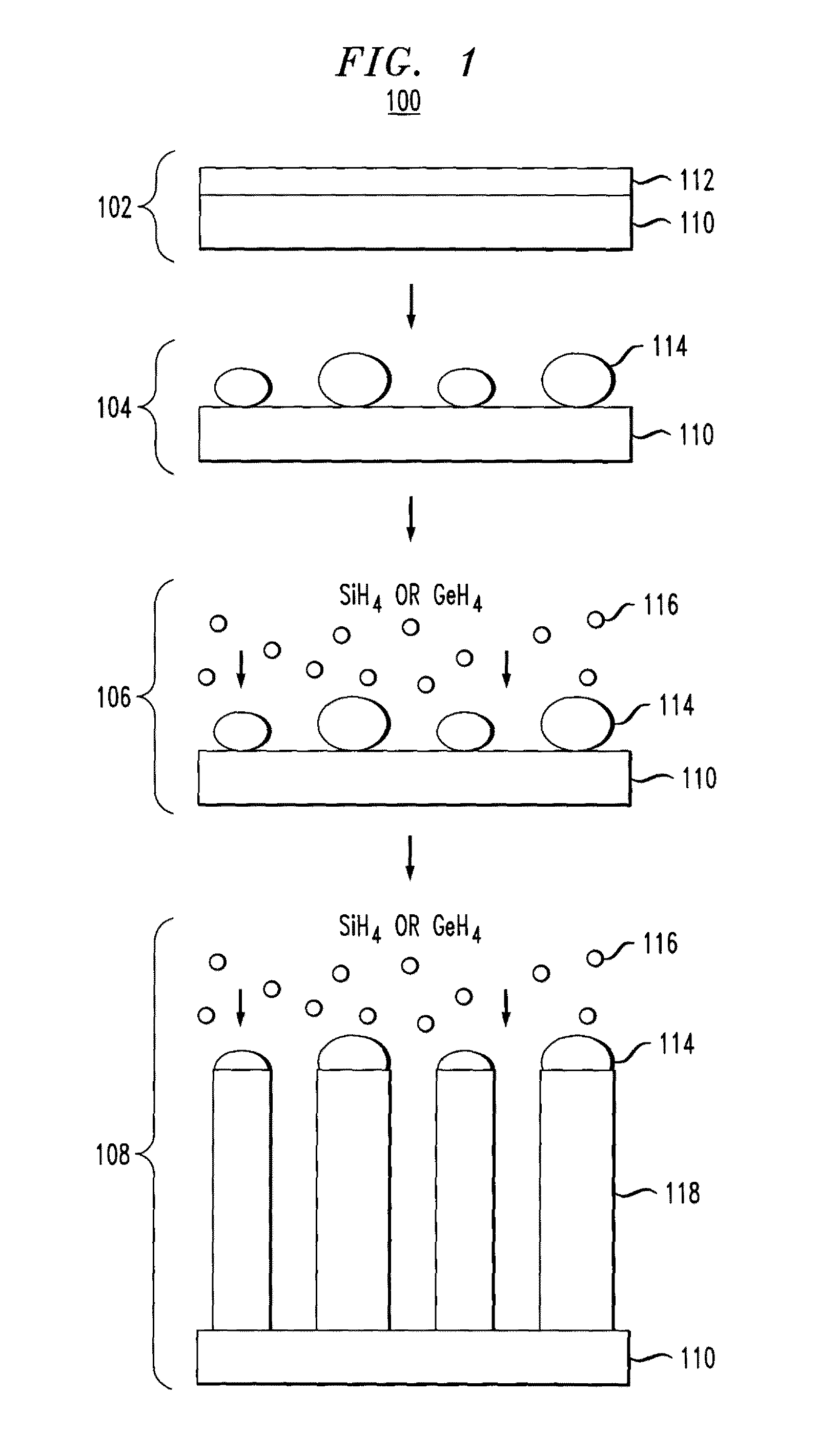

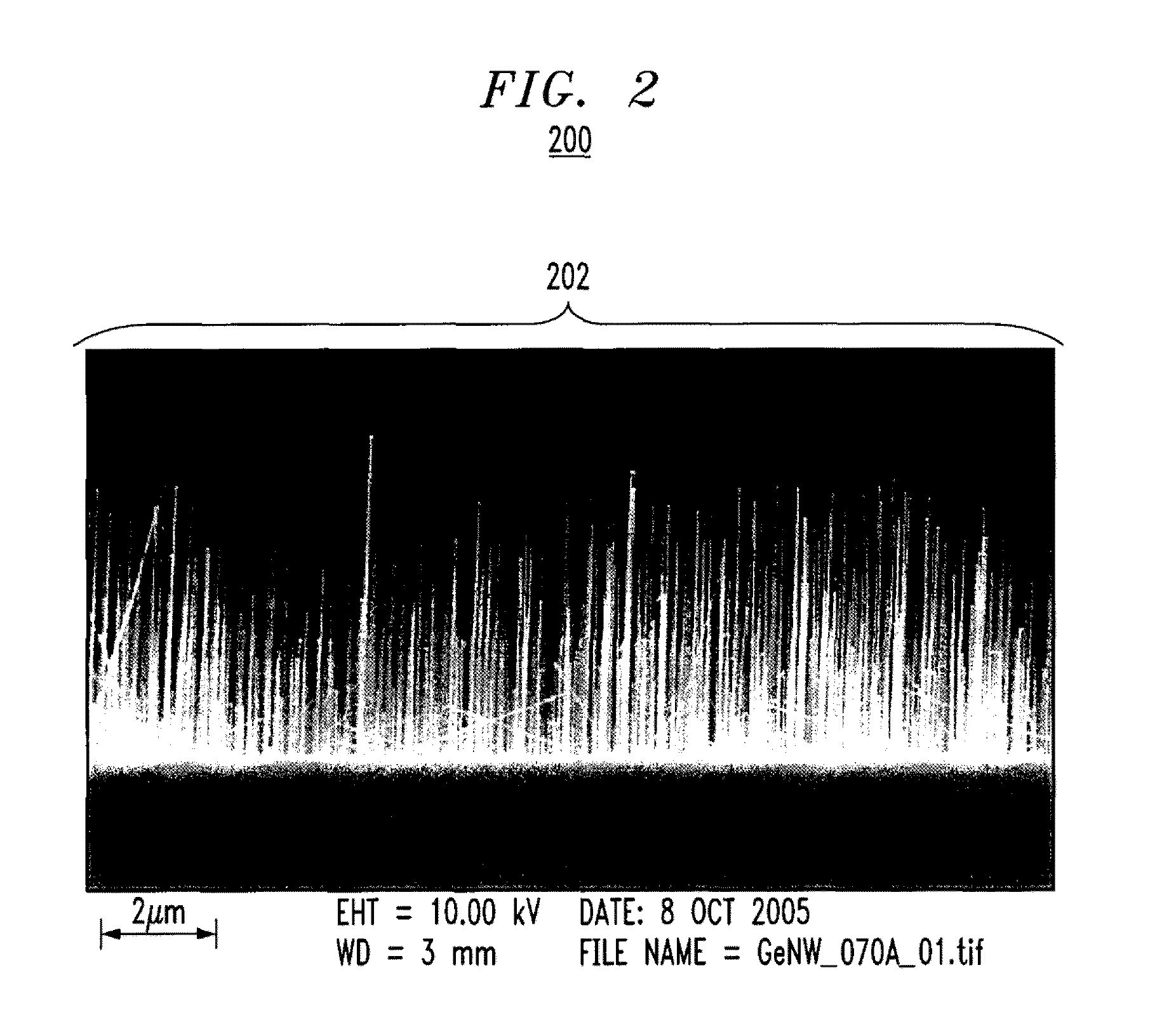

Techniques for Use of Nanotechnology in Photovoltaics

Techniques for combining nanotechnology with photovoltaics are provided. In one aspect, a method of forming a photovoltaic device is provided comprising the following steps. A plurality of nanowires are formed on a substrate, wherein the plurality of nanowires attached to the substrate comprises a nanowire forest. In the presence of a first doping agent and a first volatile precursor, a first doped semiconductor layer is conformally deposited over the nanowire forest. In the presence of a second doping agent and a second volatile precursor, a second doped semiconductor layer is conformally deposited over the first doped layer. The first doping agent comprises one of an n-type doping agent and a p-type doping agent and the second doping agent comprises a different one of the n-type doping agent and the p-type doping agent from the first doping agent. A transparent electrode layer is deposited over the second doped semiconductor layer.

Owner:GLOBALFOUNDRIES INC

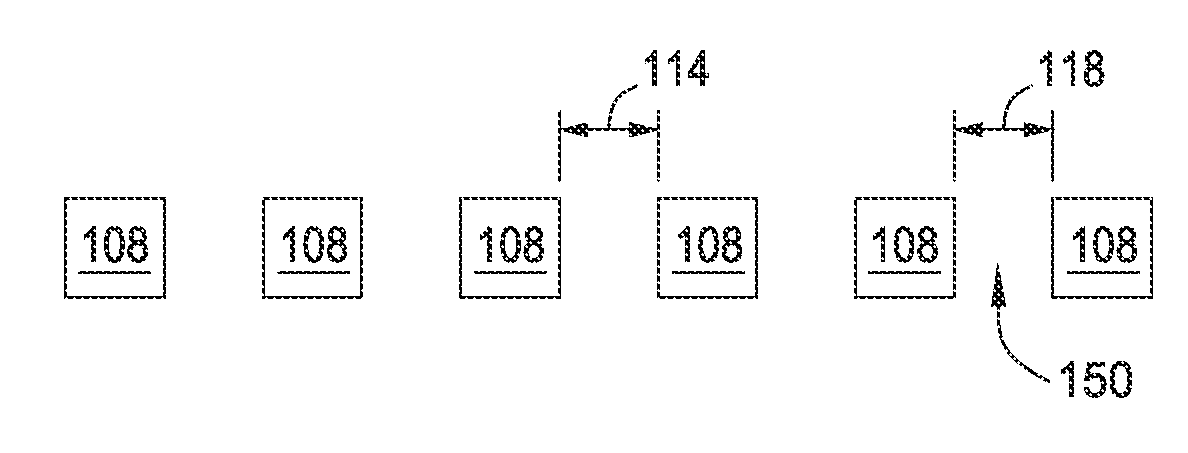

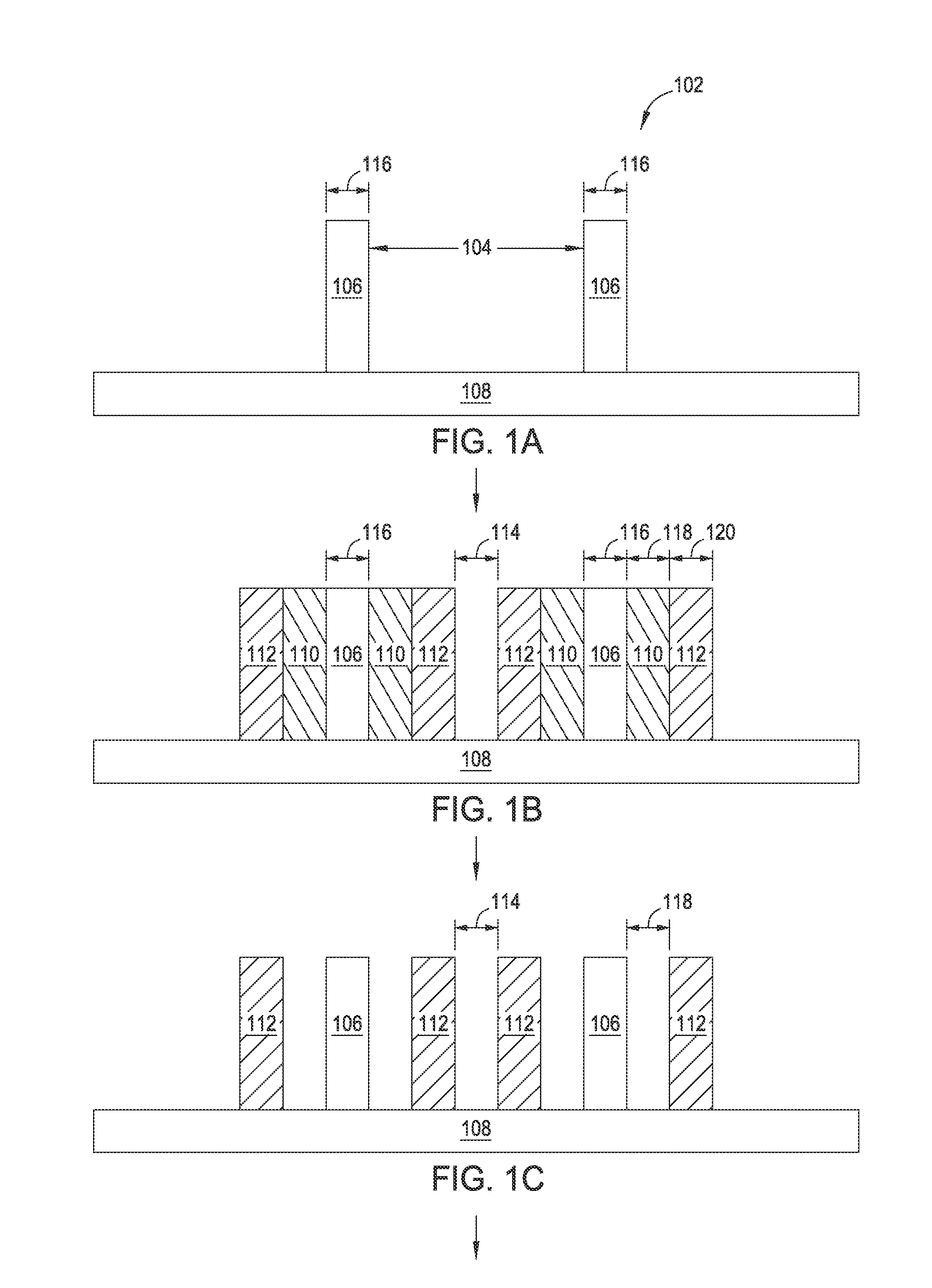

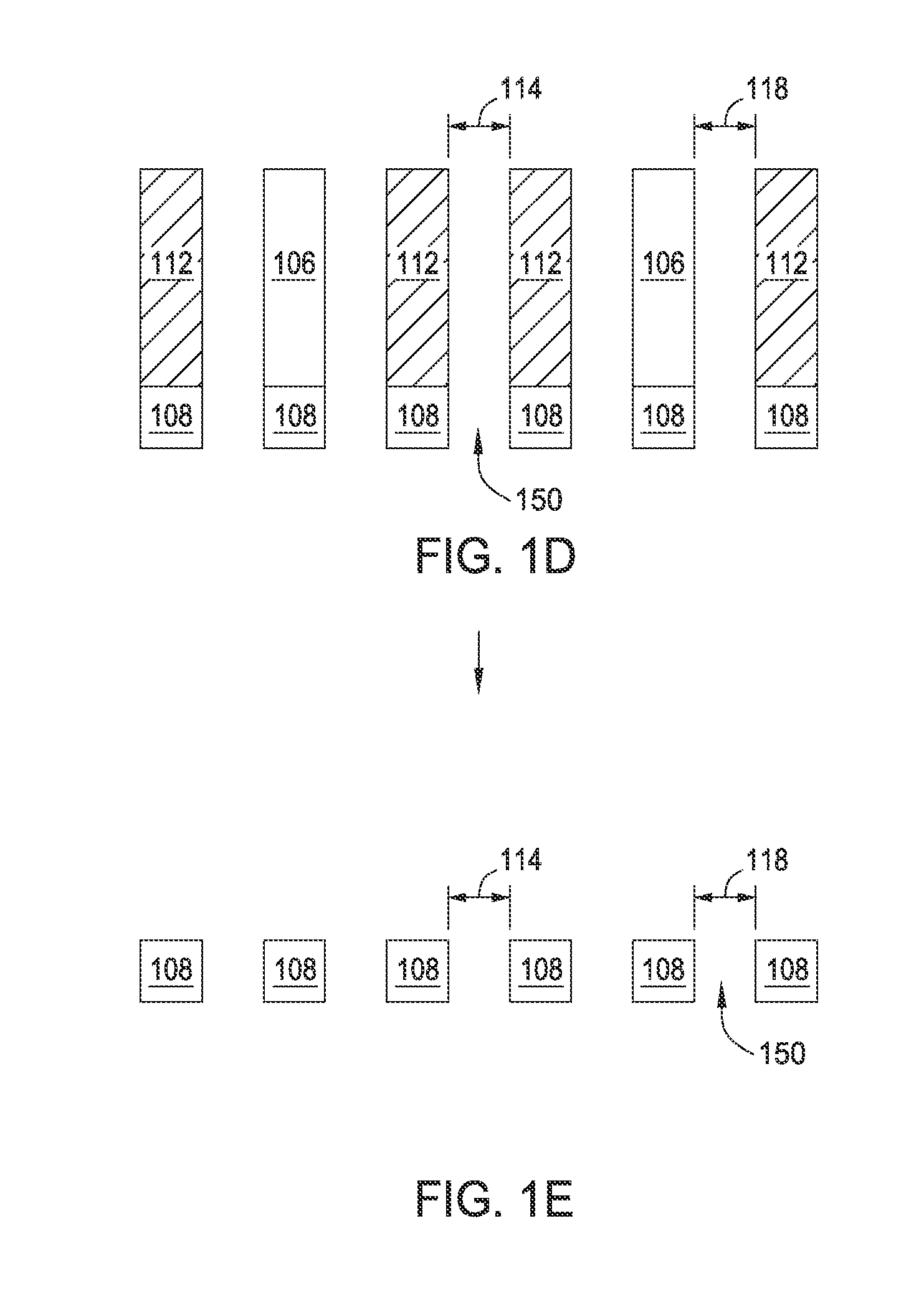

Self-aligned multiple spacer patterning schemes for advanced nanometer technology

ActiveUS20150371852A1Precise size controlMinimum errorSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyNanotechnology Techniques

The present disclosure provides forming nanostructures with precision dimension control and minimum lithographic related errors for features with dimension under 14 nanometers and beyond. A self-aligned multiple spacer patterning (SAMSP) process is provided herein and the process utilizes minimum lithographic exposure process, but rather multiple deposition / etching process to incrementally reduce feature sizes formed in the mask along the manufacturing process, until a desired extreme small dimension nanostructures are formed in a mask layer.

Owner:APPLIED MATERIALS INC

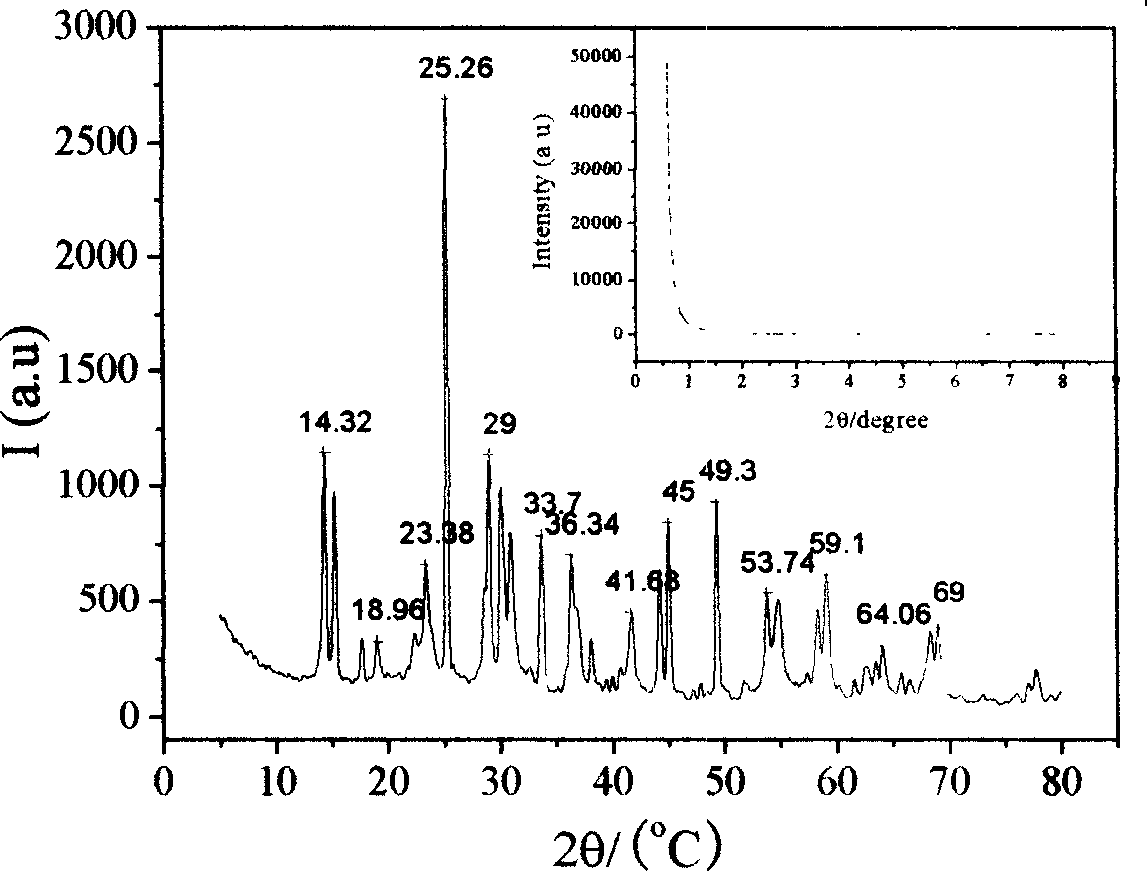

Nano vanadium oxide and method for making same

The invention relates to a nanometer vanadium oxide and the preparing method thereof, which belongs to the fields of nanometer material and nanometer technology.Under the effects of different templates, through hydrothermal synthesis or renewed arrangement process of fine articles , different vanadium sources generate nanometer vanadium oxides with the shapes of rod-like and irregular flakes or regular round flakes.The length of nanometer rod is 1 to 5Mum and the diameter is 20 to 150nm.The length of the vanadium oxide with the shape of round flake is 0.5-2 Mum and the thickness is 20 to 150nm.The preparing method is characterized by the low material cost, simple process, as well as controllable shape and appearance of the nanometer material, etc., and the same time has important exploitation value and application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

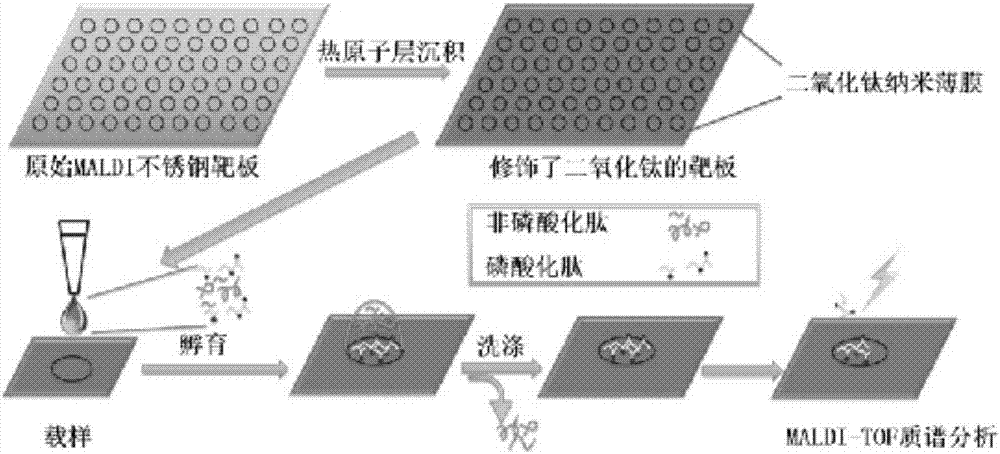

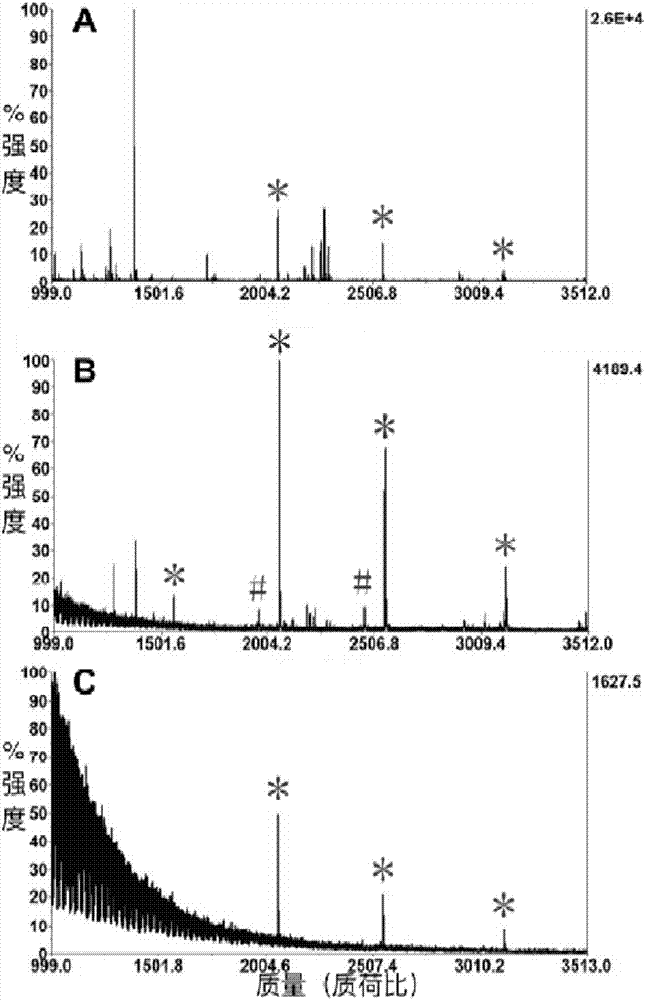

Method for modifying titanium dioxide nanofilm on target plate and application thereof

InactiveCN106884156AImprove bindingNot easy to fall offChemical vapor deposition coatingTitanium dioxideGut duplication

The invention belongs to the field of advanced nanomaterials and nanotechnology, and specifically provides a preparing method for modifying a titanium dioxide nanofilm on a target and application thereof. The method applies an atomic layer deposition technology, a layer of titanium dioxide nanofilm is modified on a stainless steel MALDI target plate, and the layer of film and the target plate are combined very firmly. Afterwards, the modified target plate is applied to purification and MALDI analysis of phosphorylated peptides on a target. The target plate in the invention displays excellent purification performance, has well repeatability and has broad application prospect in the field of purification of the phosphorylated peptides.

Owner:FUDAN UNIV

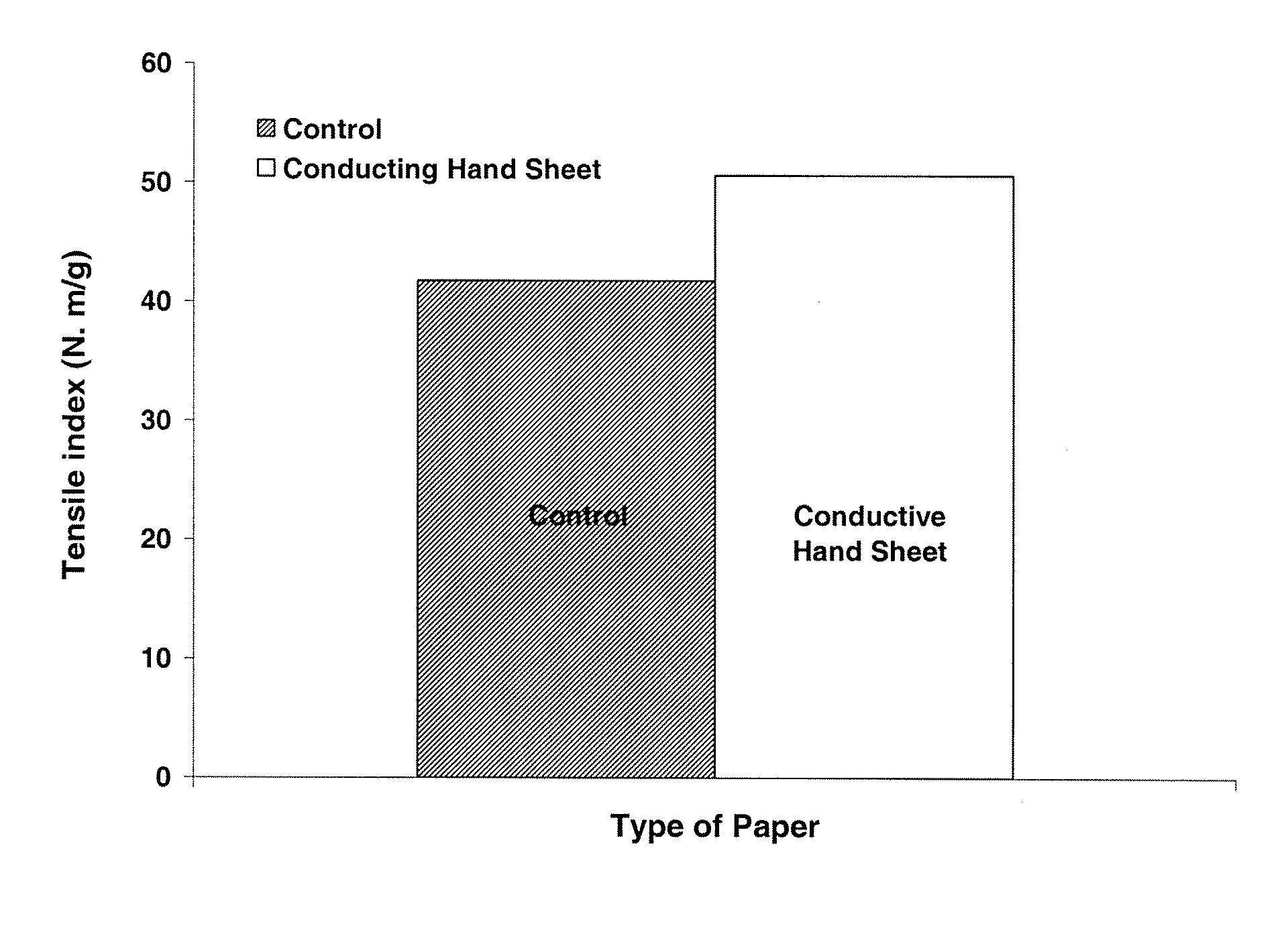

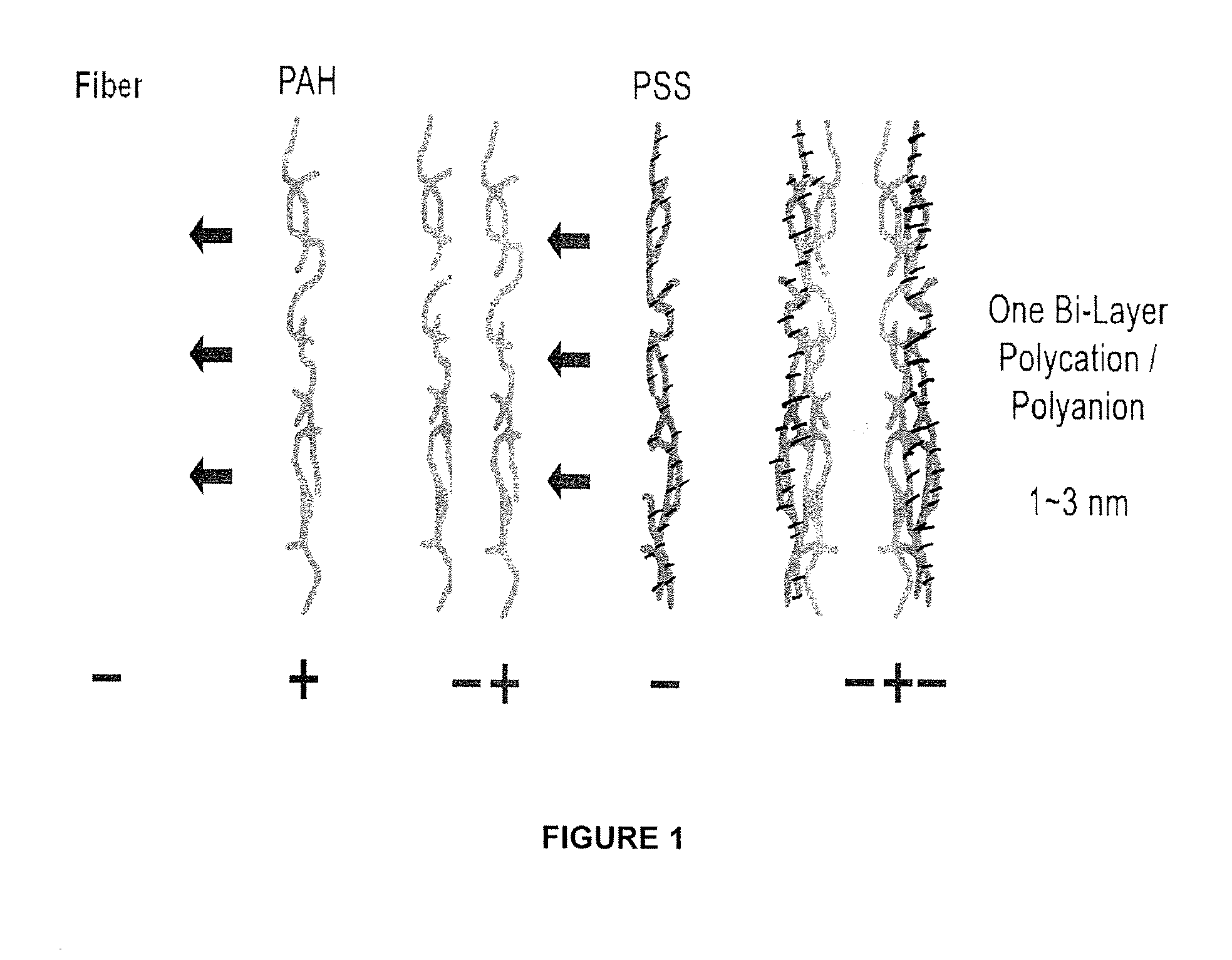

Method for the manufacture of smart paper and smart wood microfibers

InactiveUS8349131B1Improve performanceImprove conductivityNon-fibrous pulp additionNatural cellulose pulp/paperActive polymerPolyelectrolyte

A method is provided for making “smart” paper and “smart” microfibers by means of nanotechnology layer-by-layer techniques. The method comprises forming an aqueous pulp of lignocellulose fibers and nanocoating it by alternatively adsorbing onto the fibers multiple consecutively-applied layers of organized ultra thin and oppositely-charged polyelectrolytes, at least one of which is an electrically conductive polymer or nanoparticle (or a magnetically active polymer or nanoparticle, or an optically active polymer or nanoparticle), and another one of which has a charge opposite of said electrically conductive polymer or nanoparticle (or magnetically active polymer or nanoparticle, or optically active polymer or nanoparticle), thereby making a modified aqueous pulp of electrically conductive (or magnetically active, or optically active) multi-layer nanocoated lignocellulose fibers; then draining the water out of the modified aqueous pulp to form sheets of smart microfibers. A finished paper is manufactured by drying the sheets of the nanocoated multi-layer fibers and processing the dried sheets to make a smart paper having enhanced electrical conductivity, magnetic and / or optical properties.

Owner:LOUISIANA TECH RES CORP

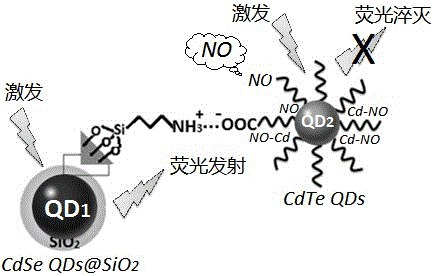

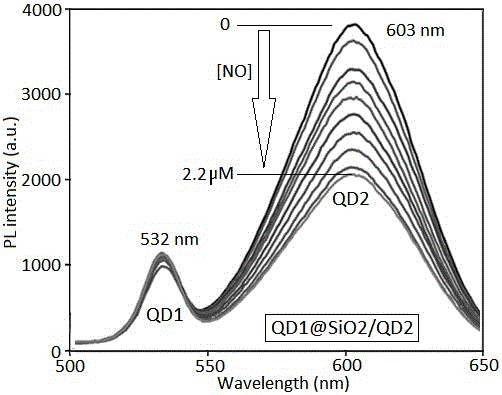

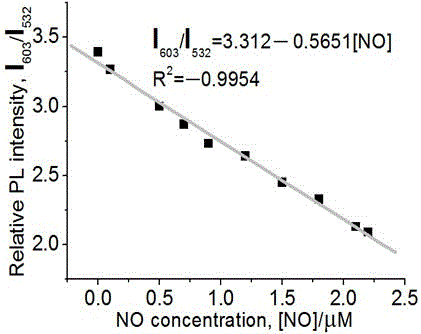

Double-quantum-dot nano complex nitrogen monoxide ratiometric fluorescent probe and preparation method thereof

InactiveCN105885849ASimple methodLow costNanoopticsFluorescence/phosphorescenceSilanesLinear relationship

The invention discloses a double-quantum-dot nano complex nitrogen monoxide ratiometric fluorescent probe and a preparation method thereof, belonging to the fields of nano technology and chemical analysis. The preparation method of the probe comprises the following steps: (1) carrying out reaction on mercaptopropionic-acid-stable CdSe quantum dots and a silane agent to obtain an amino-surface-functionalized CdSe@SiO2 core-shell complex; (2) dropwisely adding the mercaptopropionic-acid-stable CdSe quantum dot dispersion solution into the core-shell complex system to prepare a CdSe@SiO2-CdTe nano complex; and (3) introducing NO into the nano complex system, determining the fluorescence emission spectrum of the system, fitting the linear relationship between the CdTe / CdSe quantum dot ratiometric fluorescence intensity and NO concentration, and establishing the NO ratiometric fluorescent probe based on the CdSe@SiO2-CdTe nano complex. Compared with the prior art, the ratiometric fluorescence intensity introduced into the fluorescent probe can obviously enhance the NO detection accuracy and feasibility, and has important application value.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com