Nano vanadium oxide and method for making same

A vanadium oxide and nanotechnology, which is applied in the field of nanomaterials and nanotechnology, can solve the problems of high production cost and high price, and achieve the effects of low price, simple preparation method, and easy large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: the preparation of nanorod VO-N

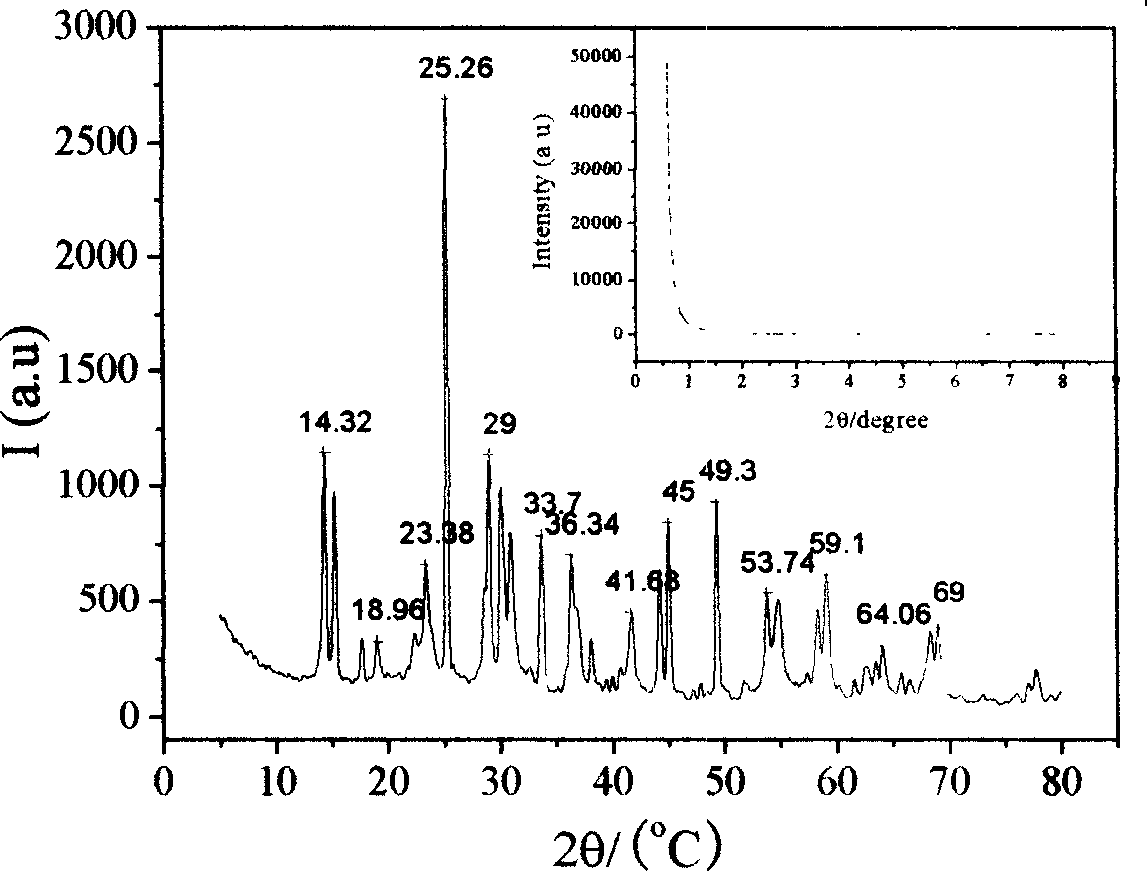

[0041] 20mmolV 2 o 5 Add 20mmol of aniline into 10ml of deionized water and stir vigorously for 1h to make it a viscous liquid, then add 30ml of deionized water and stir vigorously for 1h to fully hydrolyze it and adjust it into a rheological state in which solid particles and liquid substances are evenly distributed, and then It was moved into a stainless steel reactor with a polytetrafluoroethylene substrate, pretreated at 140°C for 1 day, and then heated to 180°C for 3 days of crystallization. The product was washed and filtered with water, and the filter cake was transferred to 50ml of ethanol and stirred at room temperature for 1d to completely remove organic matter, then filtered, and dried at 70°C to obtain nanorod VO-N. Its TEM, SEM and XRD spectra are respectively figure 1 , 2 and 3.

Embodiment 2

[0042] Embodiment 2: the preparation of nanorod VO-N-H

[0043] Under exactly the same conditions as in Example 1, before moving into the reactor, the pH value of the medium was adjusted to 1-2 with acetic acid. Obtain nanorod VO-N-H, its TEM, SEM and XRD spectra are respectively Figure 4 , 5 and 6.

Embodiment 3

[0044] Embodiment 3: the preparation of nanorod VO-2N-H

[0045] Under exactly the same conditions as in Example 2, the template agent aniline was replaced by p-phenylenediamine to obtain nanorod VO-2N-H, and its transmission electron microscope, scanning electron microscope and XRD spectra were 7, 8 and 9, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com