Method for preparing small-diameter artificial blood vessels on basis of nanotechnologies

A technology of artificial blood vessels and nanotechnology, applied in medical science, fiber processing, textiles and papermaking, etc., can solve the problems of poor shape retention, low strength, slow degradation rate, etc., and achieve improved mechanical stability, high porosity, high The effect of histocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]Example 1 Making silk fibroin / PCL small-diameter nanofiber blood vessels with nanostructures

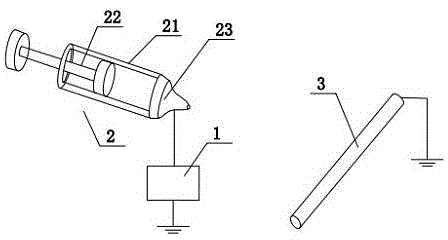

[0045] 1) Polycaprolactone and silk fibroin are dissolved in hexafluoroisopropanol (HFIP) to make a spinning solution for electrospun nanofiber blood vessels. The quality of polycaprolactone and silk fibroin in the spinning solution The percentage concentrations are 5% and 8%, respectively. The electrospinning equipment includes a DC high voltage generator, a microinjector, a cylindrical rod-shaped receiving screen and a power device, wherein the power device drives the cylindrical rod-shaped receiving screen to rotate, and the needle of the micro-injector Connect to the positive power supply of the DC high-voltage generator, the ground wire of the cylindrical rod-shaped receiving screen, and the ground wire of the cylindrical rod-shaped receiving screen. The diameter of the cylindrical rod-shaped receiving screen is 1-1.2mm. Put the spinning solution into the micro-injector, s...

Embodiment 2

[0048] Example 2 Heparinized treatment of nanofibrous vessels

[0049] By covalently combining heparin with polyethylene glycol diamine, the heparin is combined on the nanofibrils of the nanofibrous blood vessel to realize the heparinization treatment of the nanofibrous blood vessel.

[0050] The specific operation steps are as follows:

[0051] 1) Place the nanofiber blood vessel in a centrifuge tube, add 2ml of 70% deionized water and alcohol, and shake it on the machine at room temperature for 5 minutes;

[0052] 2) Discard the previous solution, add 2ml of deionized water to the centrifuge tube, and shake for 5 minutes x 4 times;

[0053] 3) Discard the former solution, add 2ml of sodium hydroxide (NaOH) with an equivalent concentration of 0.01N into the centrifuge tube, and shake it for 10 minutes to increase the amount of carboxyl groups on the surface of the nanofiber vascular material;

[0054] 4) Discard the previous solution, add 2ml of phosphate buffer solution in...

Embodiment 3

[0063] Example 3 Preparation of heparinized nanofibrous vessels compounded with mechanical growth factors

[0064] The aforementioned preliminarily heparinized nanofibrous blood vessels are covalently bound to the mechanical growth factor and heparin through a surface covalent binding method.

[0065] The specific operation steps are as follows:

[0066] 1) Place nanofibrous blood vessels in a centrifuge tube, add mechanical growth factor-phosphate buffer solution mixed solution with a concentration of mechanical growth factor of 20ng / ml, and shake the mixture at 4°C for 24 hours.

[0067] 2) Discard the previous solution, add 2ml of phosphate buffer solution into the centrifuge tube, and shake for 5 minutes x 3 times. Phosphate buffer was kept at 4°C until the mechanical growth factorization was completed at this step.

[0068] In this example, the preparation process of EDH-suflo-N-hydroxysuccinimide solution is as follows:

[0069] Use 0.5mmol / L 2-(N-morpholine)ethanesul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com