Automatic-assembling method for preparing molecular imprint polyaniline nanocomposite

A technology of nanocomposites and imprinted polymers, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of destroying the preferential hydrogen bonding between template molecules and functional monomers, and limited research, so as to broaden the preparation and application environment , high selectivity, fast adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

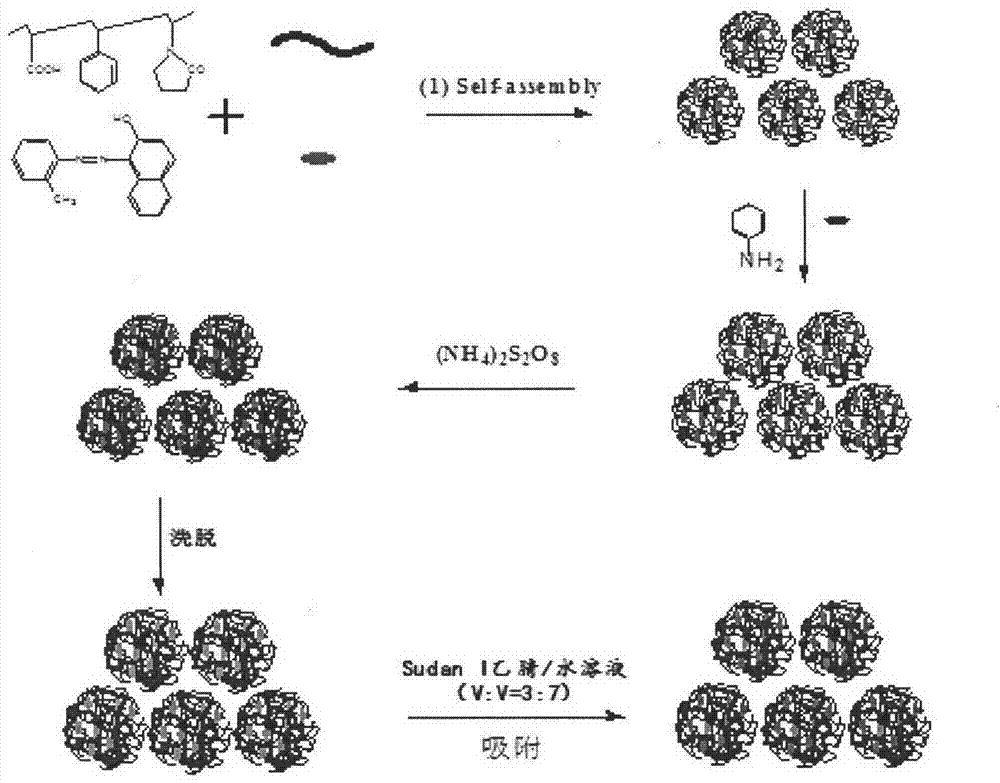

Method used

Image

Examples

Embodiment 1

[0017] Weigh 0.72g of acrylic acid (AA), 1.12g of N-vinylpyrrolidone (VP), 2.08g of styrene (St), 0.0392g of azobisisobutyronitrile (AIBN) in a 50mL round bottom flask, Add 30 mL of dioxane, react in an 80°C oil bath for 24h, precipitate with petroleum ether, and dry in an oven at 40°C. Weigh 0.2g of polymer P(AA-co-VP-co-St) and dissolve it in 10mL of N,N-dimethylformamide, and add template molecules, the amount of template molecules added is the mass of random polymer Stir to fully dissolve the template molecules and complex with the random polymer; slowly add ultra-pure water, a poor solvent for the amphiphilic polymer, under stirring until the volume of the solution is approximately 1.5 times the initial volume, so that the random polymer Micro-phase separation, self-assembly and coating template molecules to form imprinted polymer micelles solution, continue to stir at a constant speed for 3 hours, so that the non-returning polymers are completely assembled; add the impri...

Embodiment 2

[0019] Weigh 0.1.44g of acrylic acid (AA), 1.12g of N-vinylpyrrolidone (VP), 2.08g of styrene (St), 0.0462g of azobisisobutyronitrile (AIBN) in a 50mL round bottom flask , add 30mL of dioxane, react in an 80°C oil bath for 24h, precipitate with petroleum ether, and dry in an oven at 40°C. Weigh 0.2g of polymer P(AA-co-VP-co-St) and dissolve it in 10mL of N,N-dimethylformamide, and add template molecules, the amount of template molecules added is the mass of random polymer Stir to fully dissolve the template molecules and complex with the random polymer; slowly add ultra-pure water, a poor solvent for the amphiphilic polymer, under stirring until the volume of the solution is roughly twice the initial volume, so that the random polymer Micro-phase separation, self-assembly and coating template molecules to form imprinted polymer micelles solution, continue to stir at a constant speed for 3 hours, so that the non-returning polymers are completely assembled; add the imprinted pol...

Embodiment 3

[0021] Weigh 2.16g of acrylic acid (AA), 1.12g of N-vinylpyrrolidone (VP), 2.08g of styrene (St), 0.0536g of azobisisobutyronitrile (AIBN) in a 50mL round bottom flask, Add 30 mL of dioxane, react in an 80°C oil bath for 24h, precipitate with petroleum ether, and dry in an oven at 40°C. Weigh 0.2g of polymer P(AA-co-VP-co-St) and dissolve it in 10mL of N,N-dimethylformamide, and add template molecules, the amount of template molecules added is the mass of random polymer Stir to fully dissolve the template molecules and complex with the random polymer; slowly add ultra-pure water, a poor solvent for the amphiphilic polymer, under stirring until the volume of the solution is approximately 3 times the initial volume, so that the random polymer Micro-phase separation, self-assembly and coating template molecules to form imprinted polymer micelles solution, continue to stir at a constant speed for 3 hours, so that the non-returning polymers are completely assembled; add the imprint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com