Method for preparing magnetic magnesium oxide surface molecular imprinting solid phase extractant

A technology of surface molecular imprinting and solid phase extraction agent, which is applied in the direction of chemical instruments and methods, and other chemical processes, to achieve the effect of improving binding efficiency, enhancing adsorption performance, and good specific adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

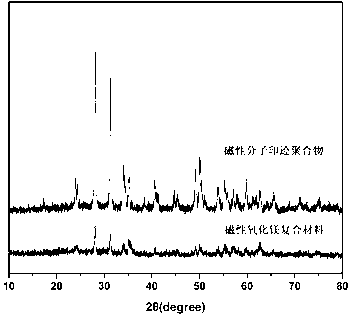

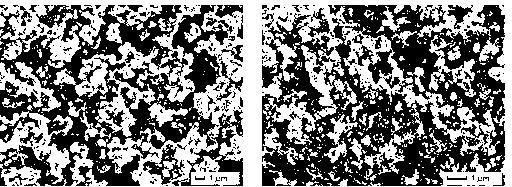

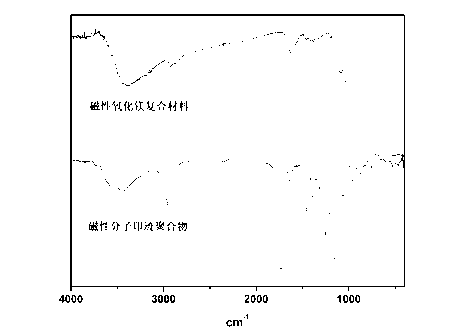

Image

Examples

Embodiment 1

[0022] Example 1: (1) Preparation of magnetic magnesium oxide: Add 2.36 g of ferric chloride, 1.0 g of magnesium oxide and 50 mL of distilled water into a 250 mL flask, then ultrasonicate for 30 minutes, and stir at room temperature for 3 hours to obtain a stable suspension liquid; then add 0.86g of ferrous chloride to deoxygenate with nitrogen gas and continue to stir for 30 minutes at a speed of 800rmp, and heat up to 80 o After C, add 5.0mL 25% ammonia water dropwise, and continue to react for 1 hour to obtain a black product; o C vacuum dried.

[0023] (2) Preparation of cyclodextrin-modified magnetic magnesium oxide: Dissolve 1.19g cyclodextrin in 50mL N,N-dimethylformamide and then add 0.25g NaH, and stir the mixture at room temperature at 300rpm until no Gas generation; after filtering to remove excess sodium hydride, transfer the filtrate to a 250mL flask, add 1.0g KH-560, pass nitrogen to remove oxygen for 10min, and heat up to 90 o C for 5 hours; then add 1.25g of ...

Embodiment 2

[0025] Example 2: (1) Preparation of magnetic magnesium oxide: Add 4.72 g of ferric chloride, 2.0 g of magnesium oxide and 180 mL of distilled water into a 250 mL flask, then ultrasonicate for 30 minutes, and stir at room temperature for 3 hours to obtain a stable suspension liquid; then add 1.72g of ferrous chloride and continue to stir for 30 minutes at a speed of 800rmp after adding 1.72g of ferrous chloride to deoxygenate with nitrogen, and then heat up to 80 o Add 10mL 25% ammoniacal liquor dropwise after C, obtain black product after continuing to react for 1 hour; Product is washed with distilled water to neutral back 60 o C vacuum dried.

[0026] (2) Preparation of cyclodextrin-modified magnetic magnesium oxide: Dissolve 2.29g cyclodextrin in 100mL N,N-dimethylformamide and then add 0.5g NaH, and stir the mixture at room temperature at 300rpm until no Gas generation; filter to remove excess sodium hydride, transfer the filtrate to a 250mL flask, add 2.0g KH-560, pass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com